Patents

Literature

387 results about "N-Butylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

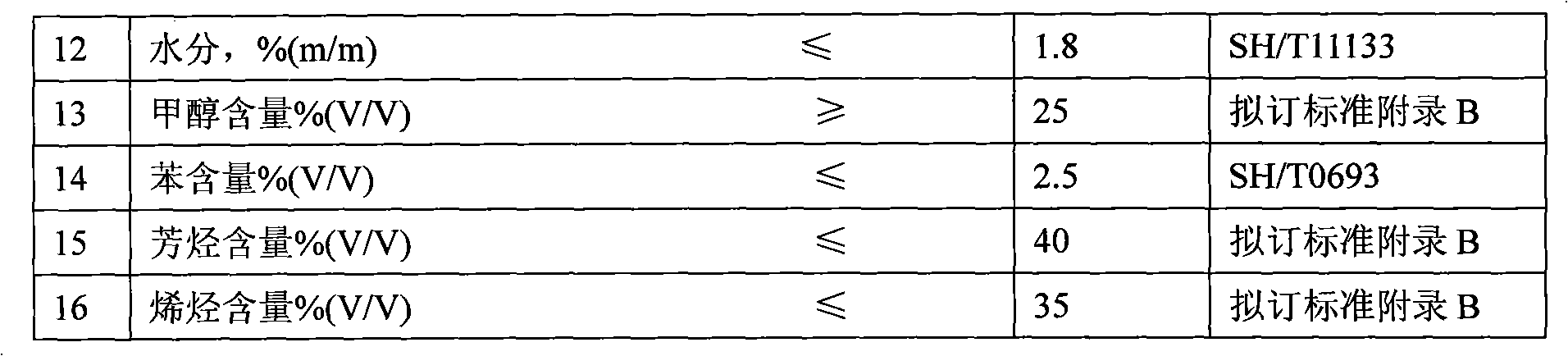

Patent Status

Application Year

Inventor

N-Butylamine is an organic compound (specifically, an amine) with the formula CH₃(CH₂)₃NH₂. This colourless liquid is one of the four isomeric amines of butane, the others being sec-butylamine, tert-butylamine, and isobutylamine. It is a liquid having the fishy, ammonia-like odor common to amines. The liquid acquires a yellow color upon storage in air. It is soluble in all organic solvents.

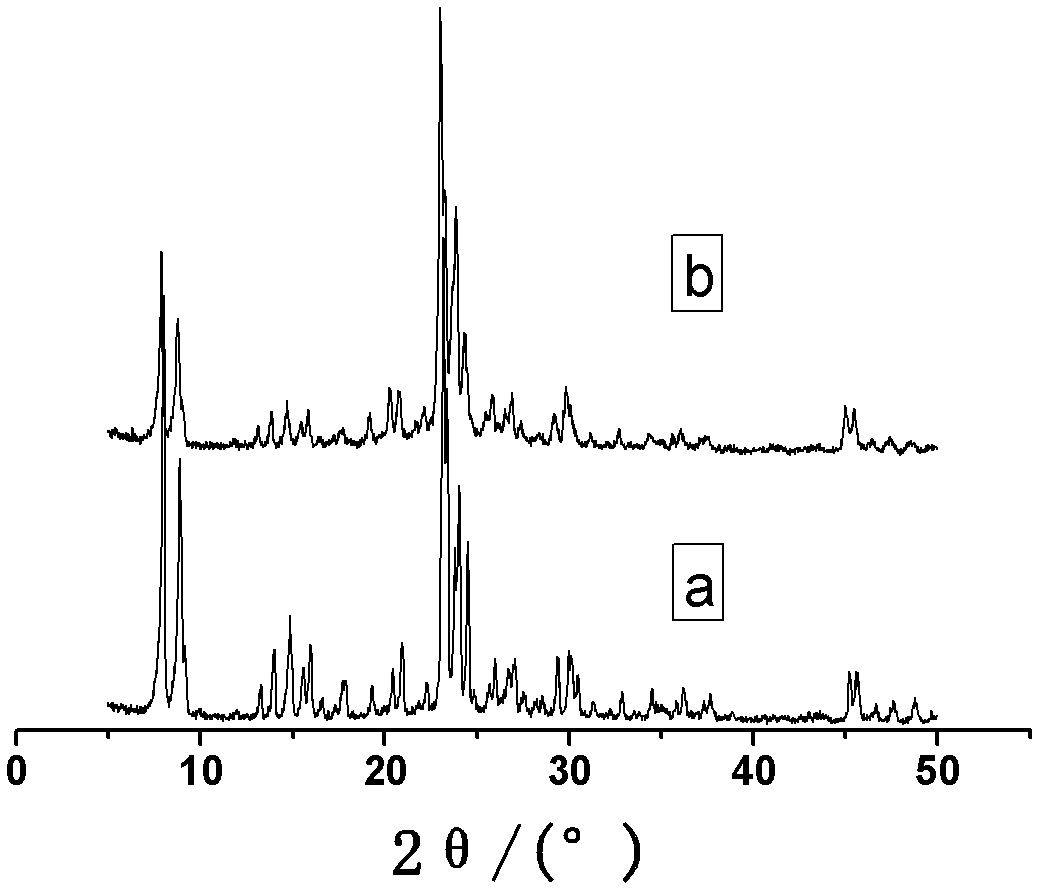

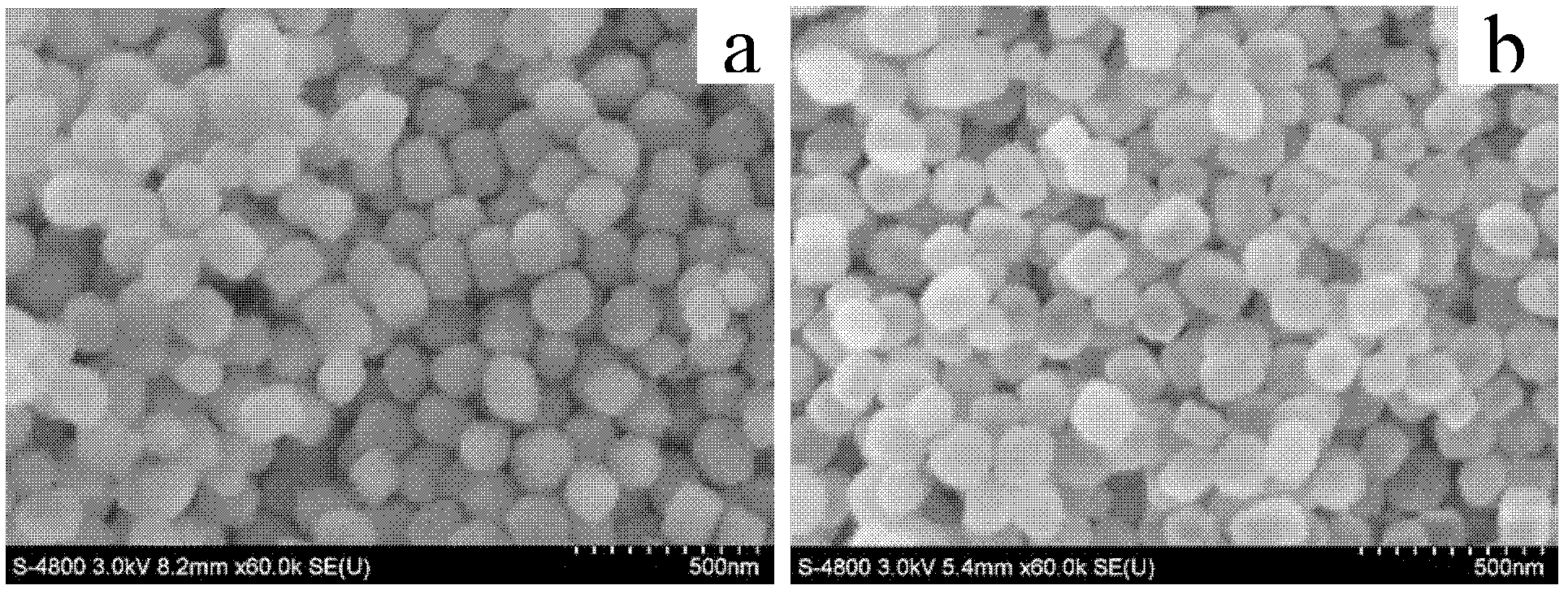

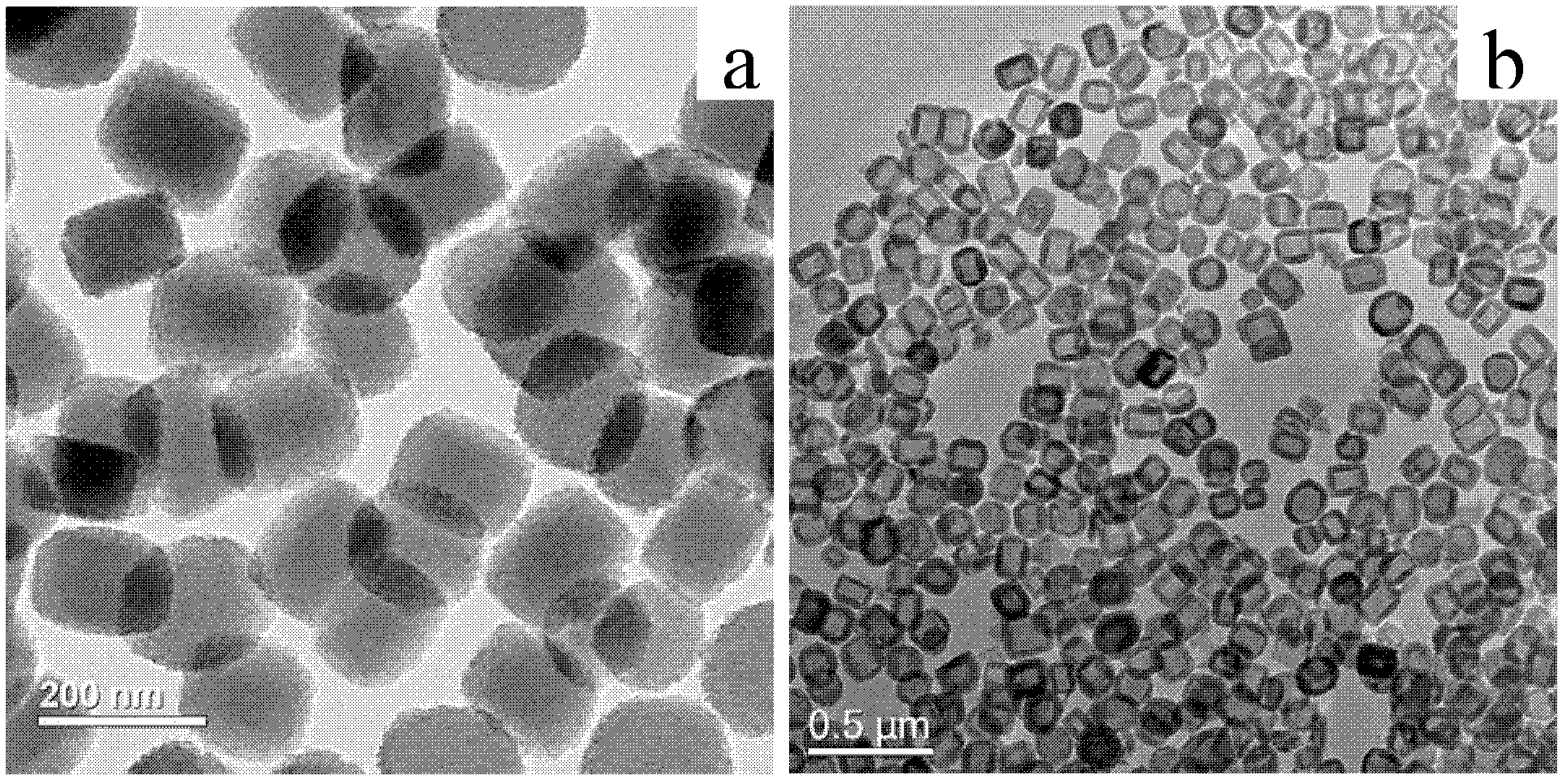

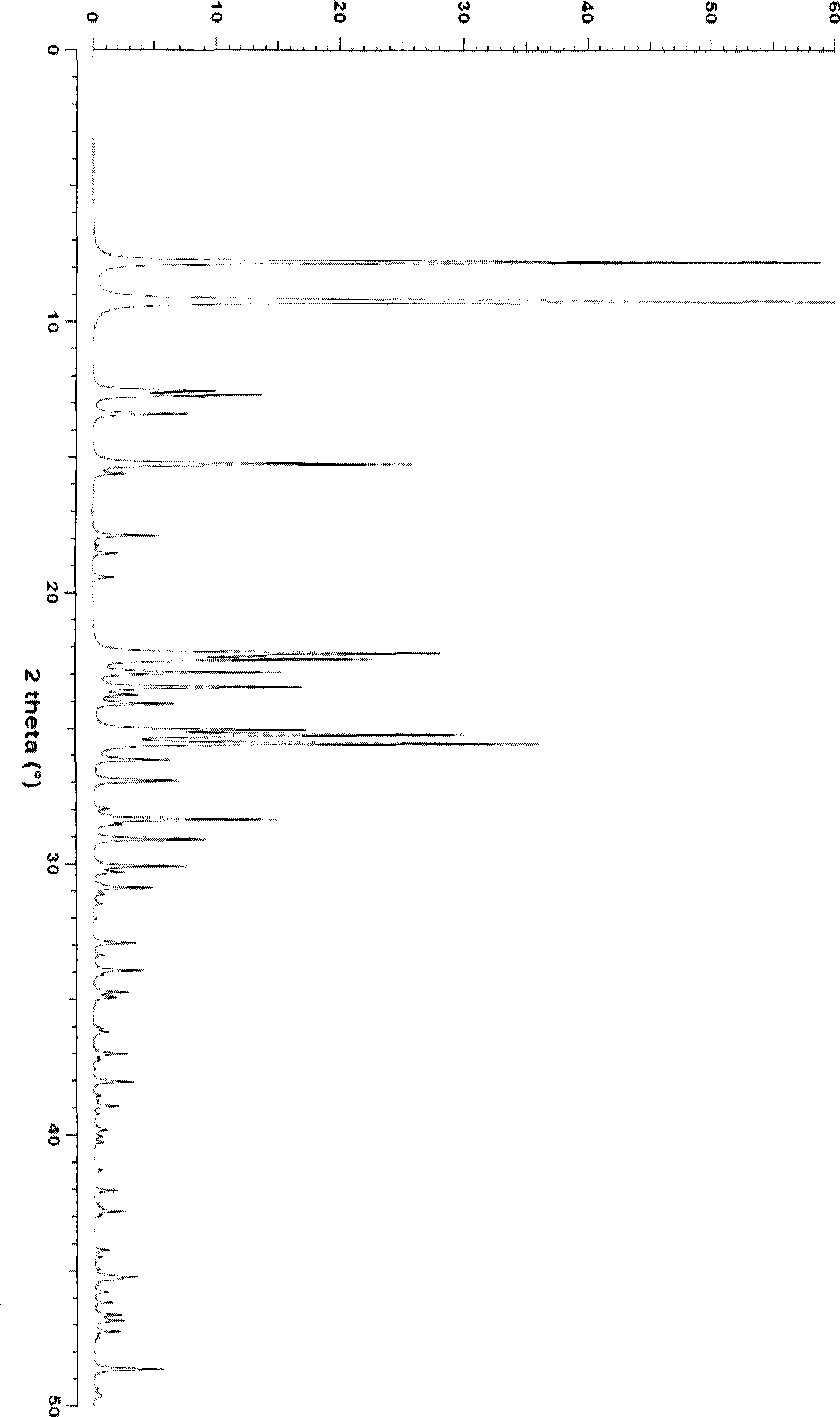

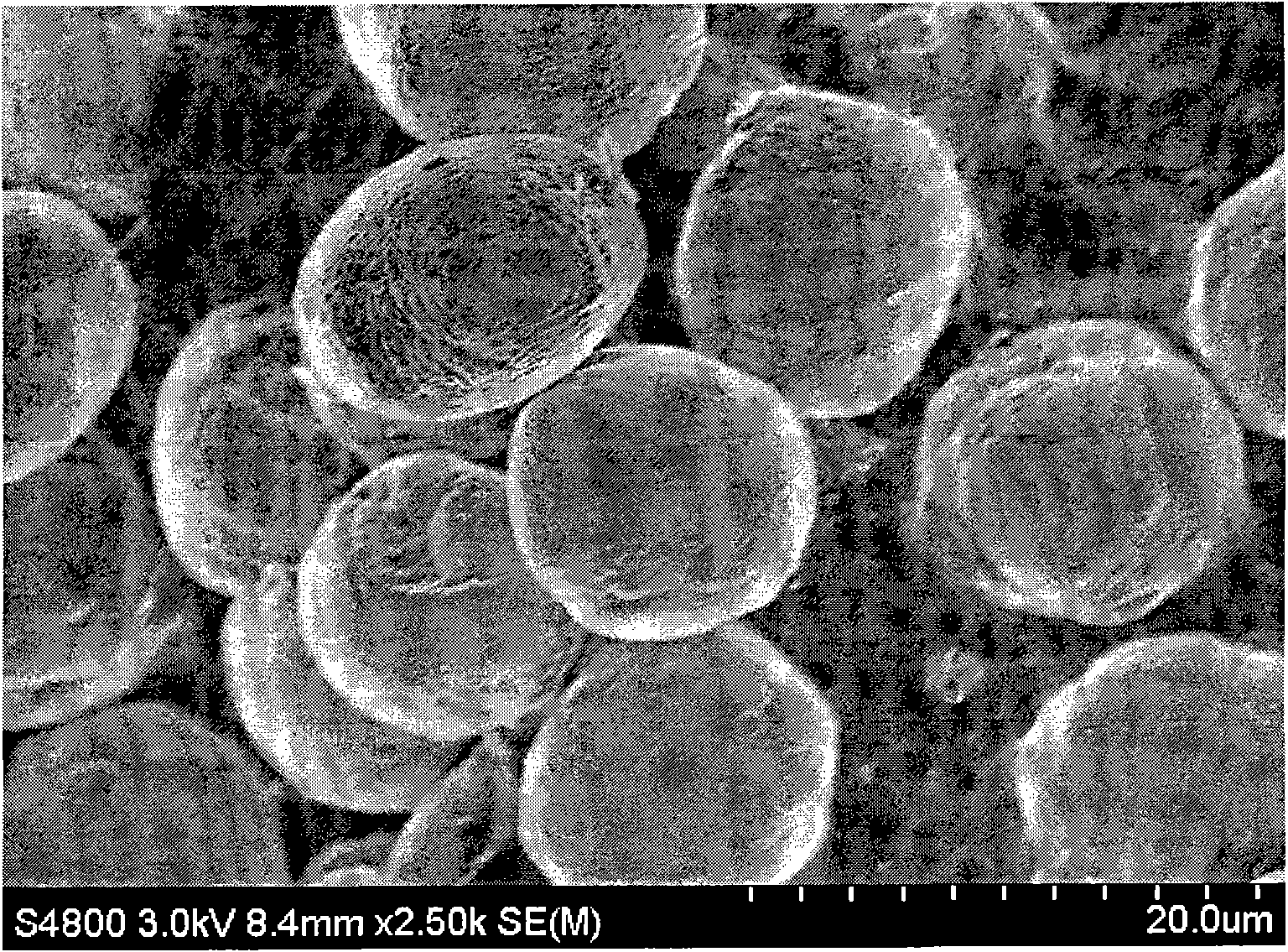

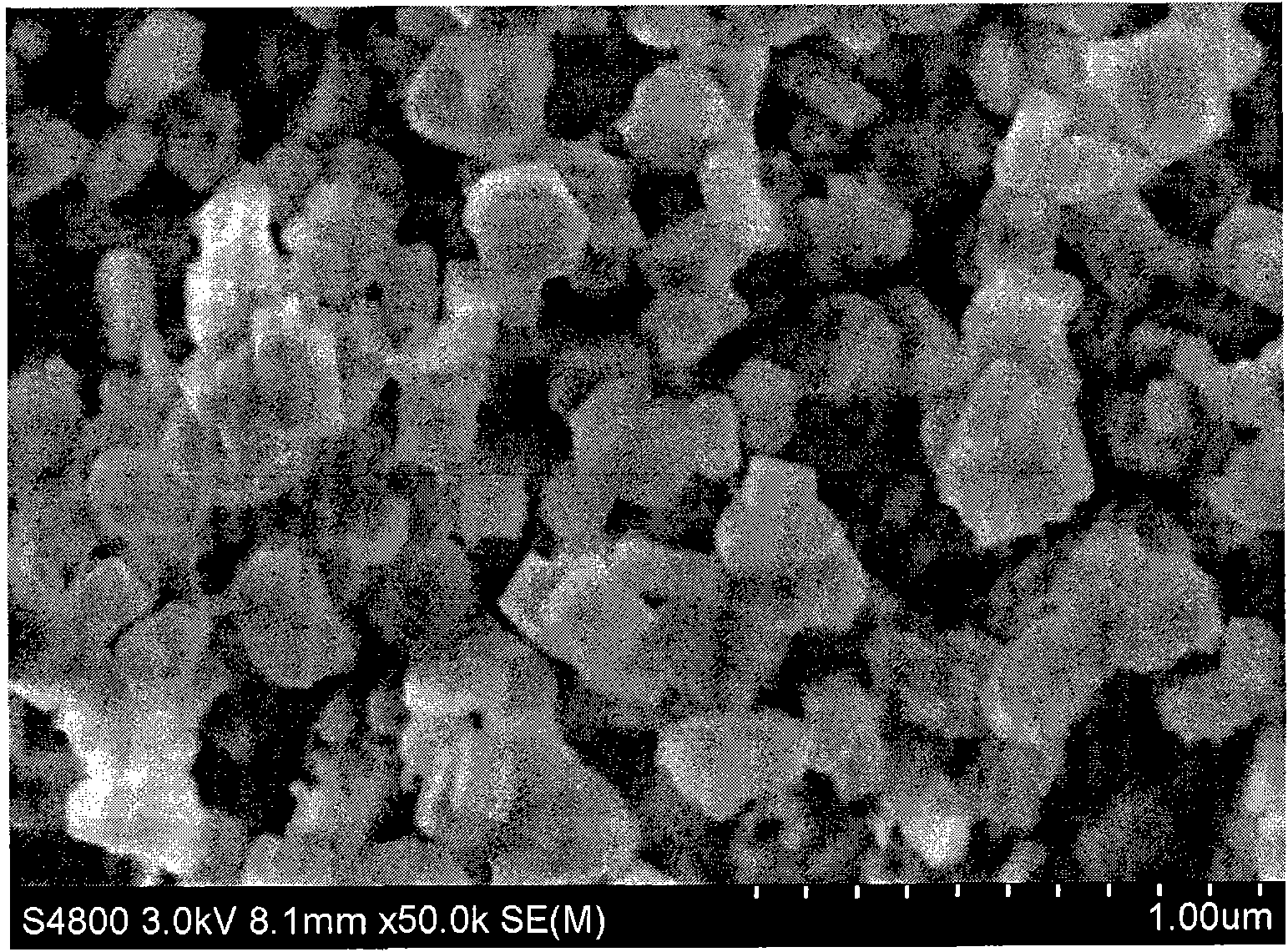

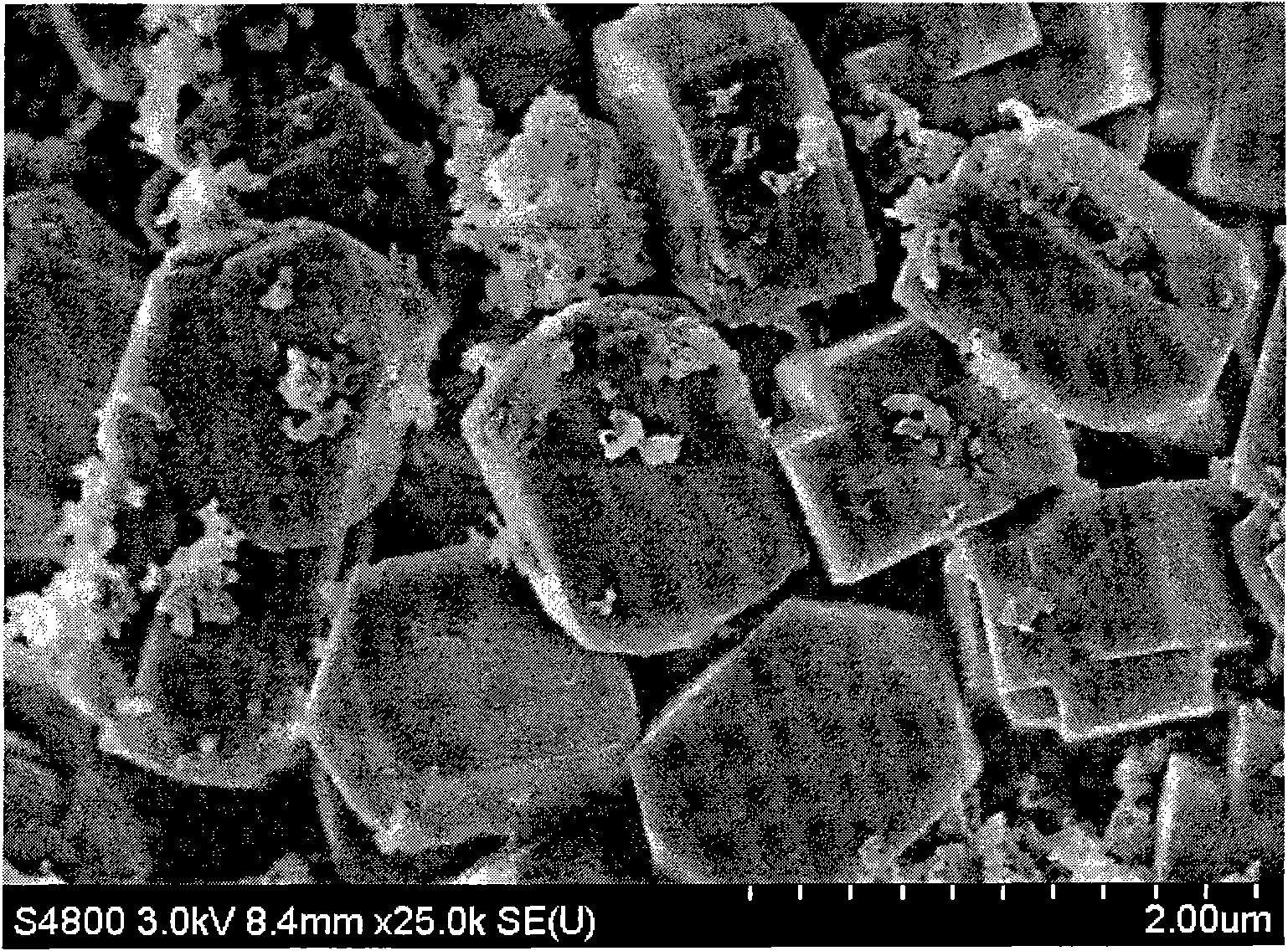

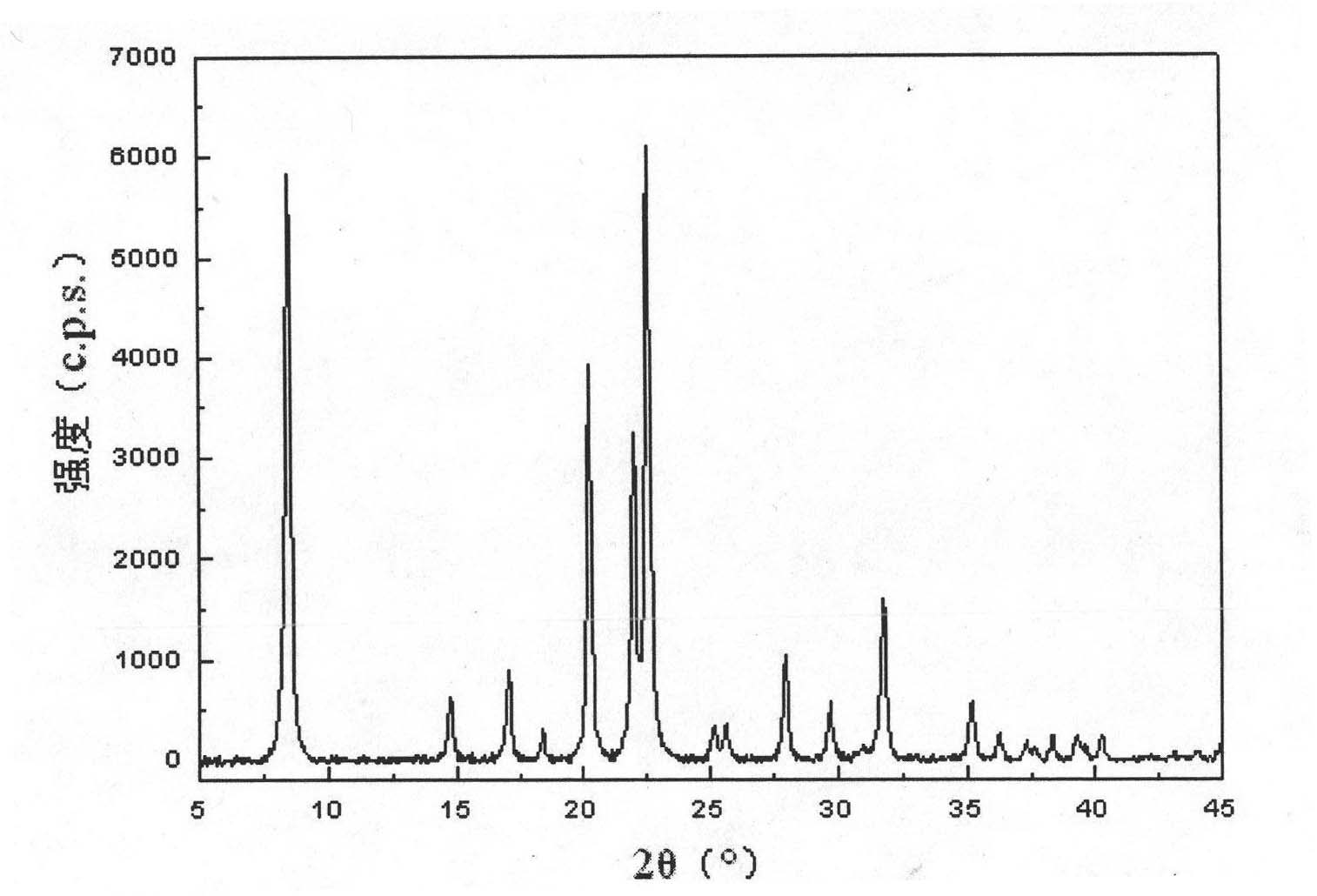

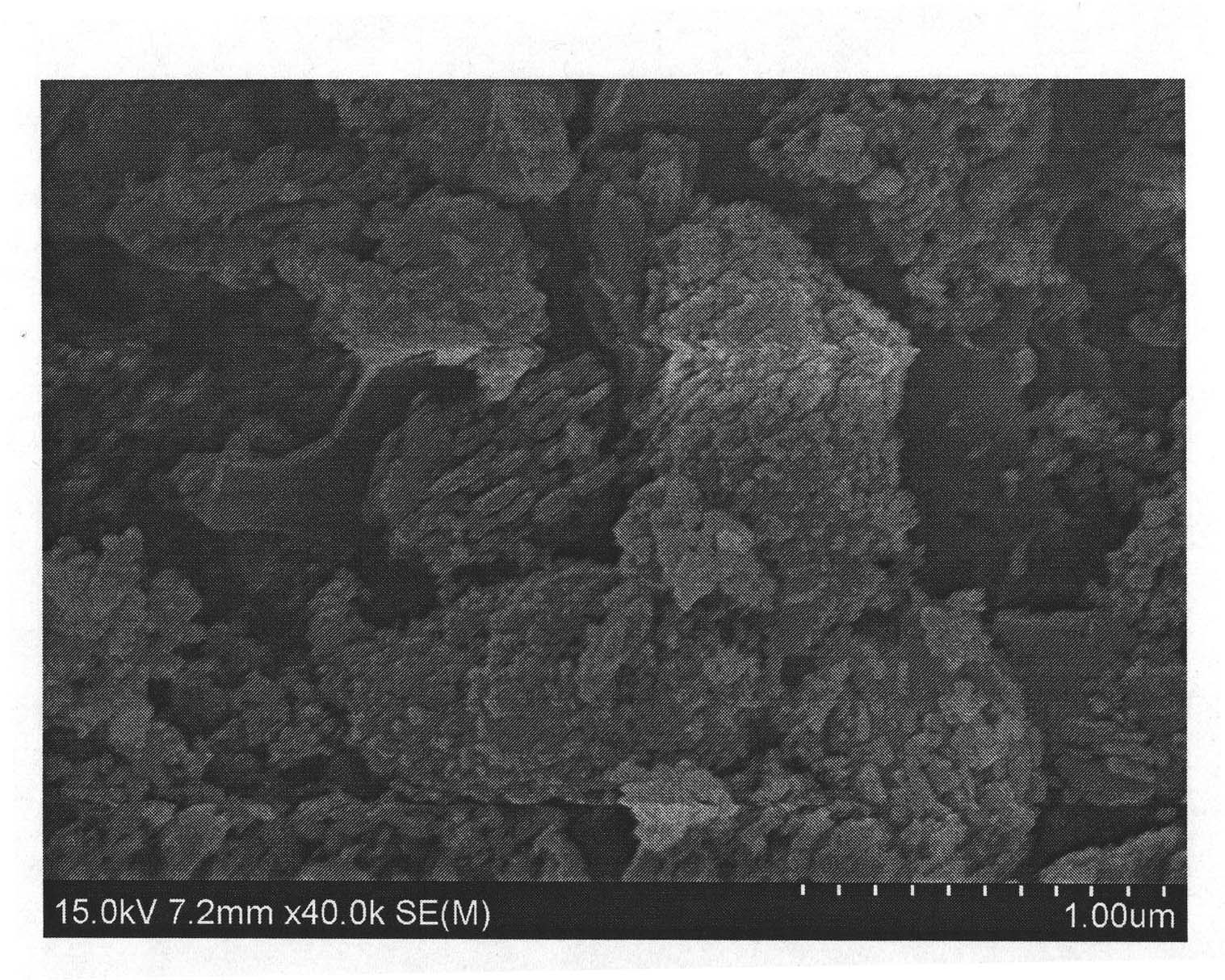

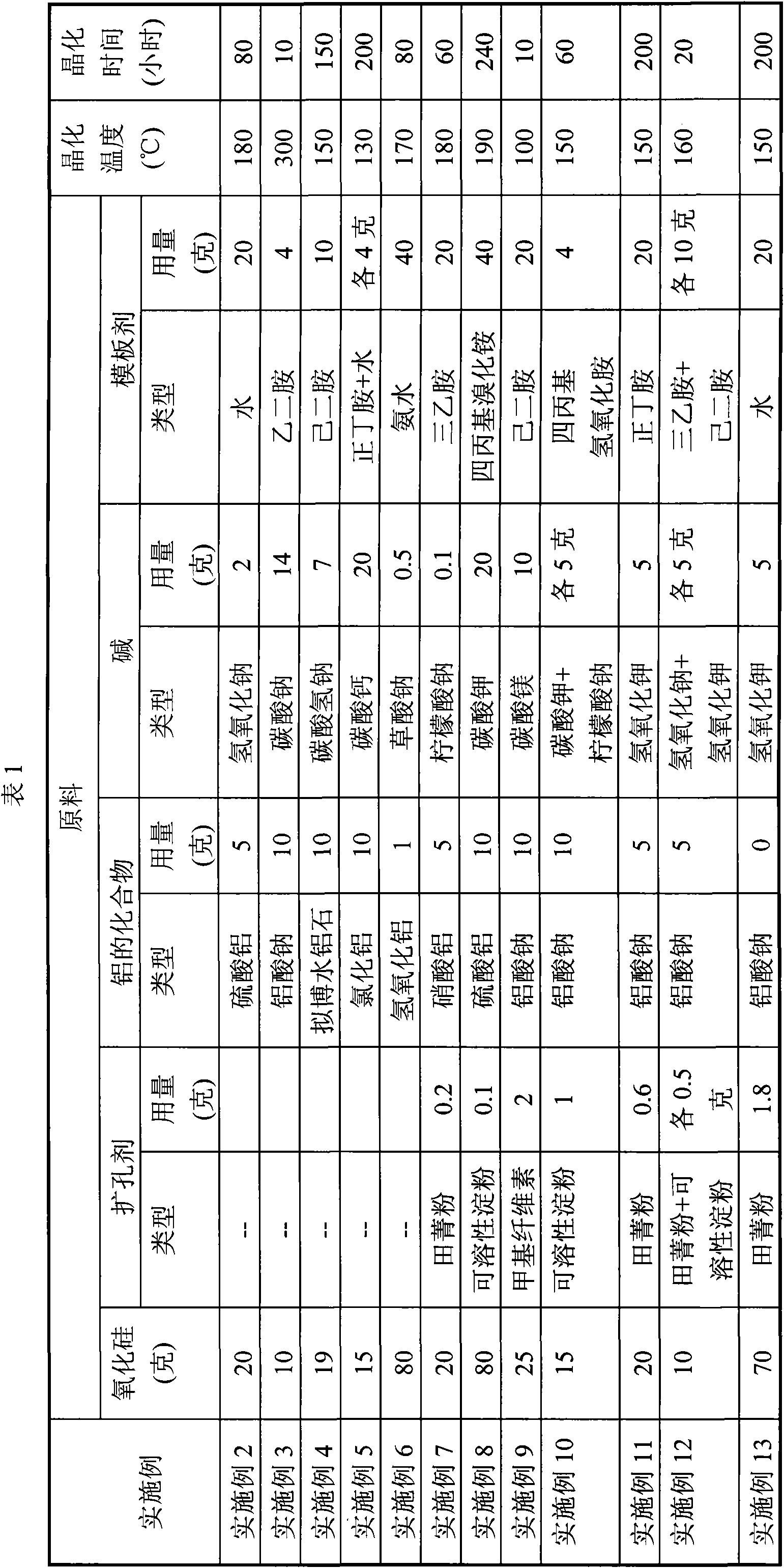

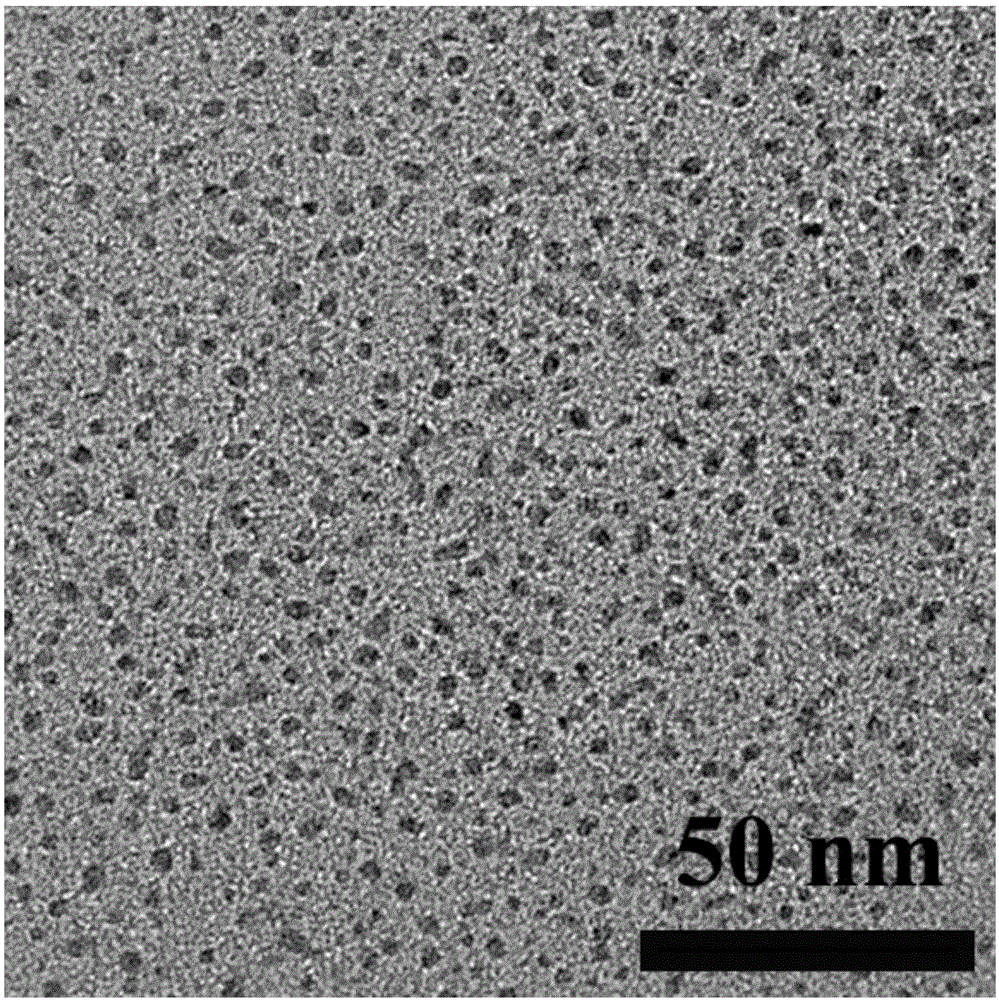

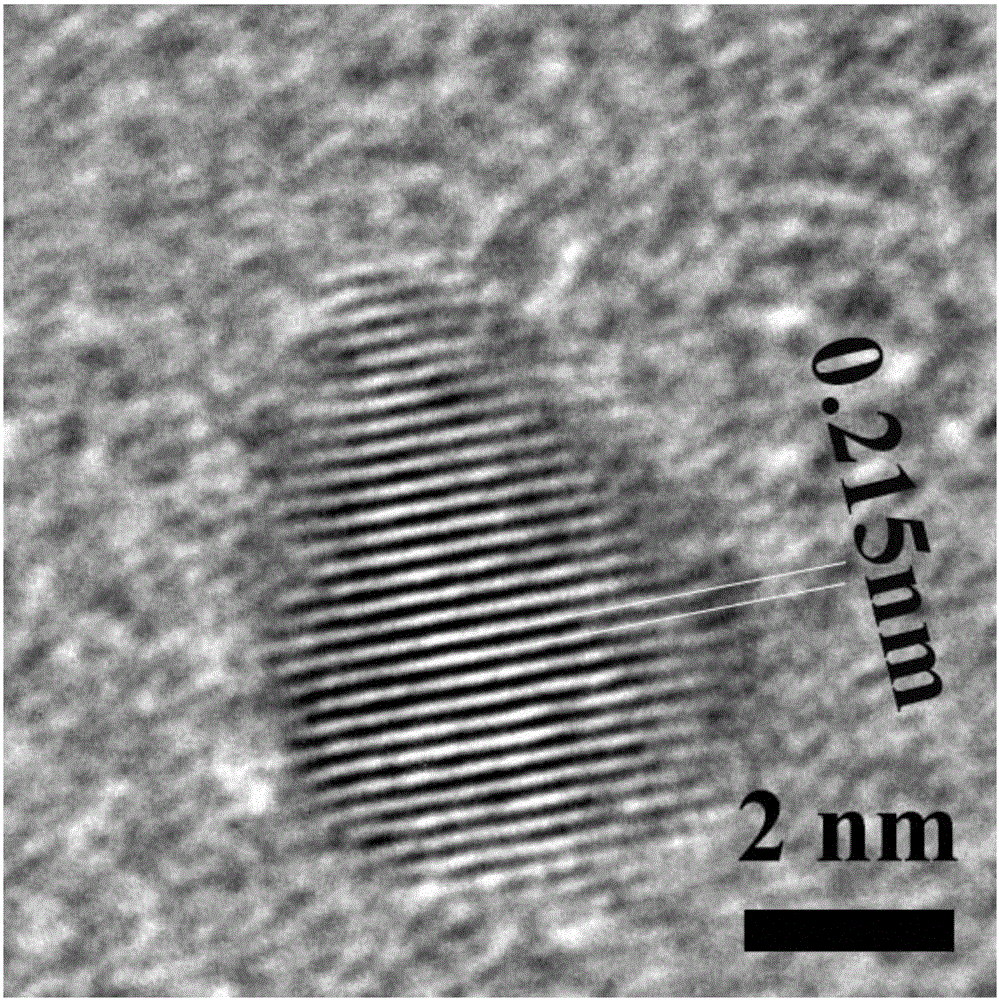

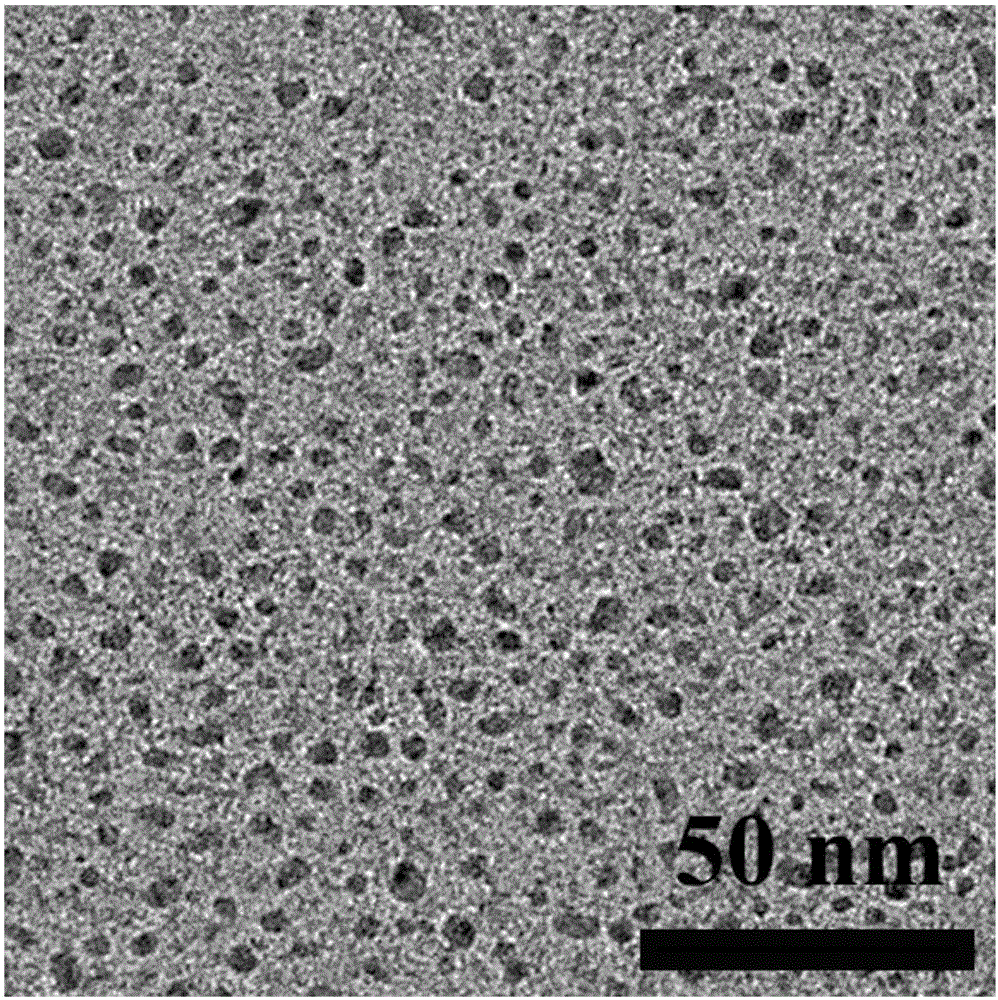

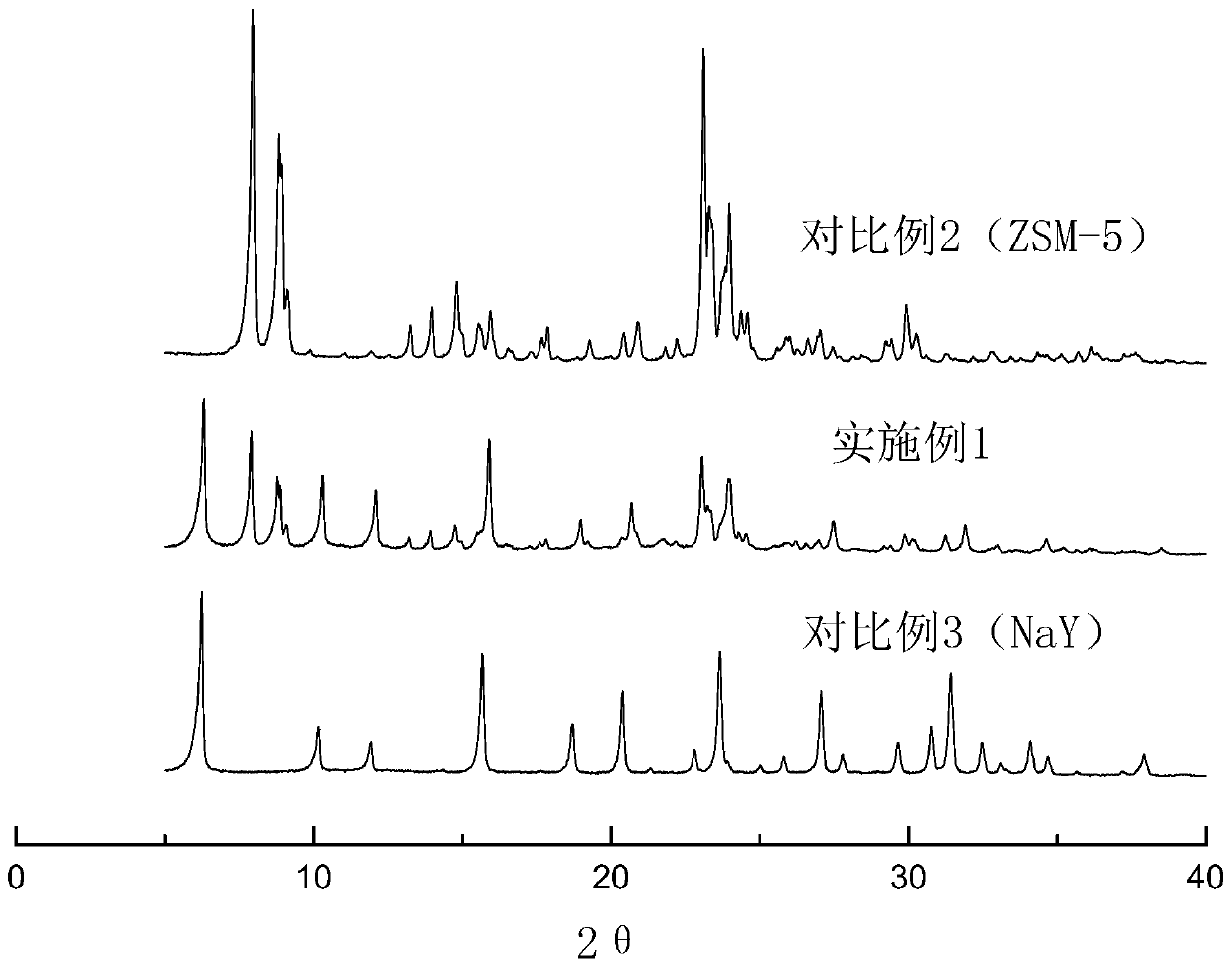

Method for preparing hollow zeolite socony mobil-5 (ZSM-5) nanometer zeolite

ActiveCN102491366AEasy to passHigh crystallinityNanotechnologyPentasil aluminosilicate zeoliteHigh volume manufacturingPotassium hydroxide

The invention relates to a method for preparing hollow zeolite socony mobil-5 (ZSM-5) nanometer zeolite. The method is characterized by comprising the following steps of: mixing single-dispersion ZSM-5 nanometer zeolite of which the silicon-aluminum molar ratio of SiO2 / Al2O3 is over 20 and the partical size ranges from 100 to 400 nanometers with 0.05 to 0.5 mol / L of an aqueous solution of alkaline substances, wherein the alkaline substances are selected from a mixture in which a molar ratio of quaternary ammonium salt to sodium hydroxide is 1:1, a mixture in which a molar ratio of the quaternary ammonium salt to potassium hydroxide is 1:1, n-butylamine and quaternary ammonium base; and stirring at the temperature of between 80 and 200 DEG C for 10 to 200 hours, and separating. By the method, a regular cavity structure is formed, so that reactants and products are easy to transfer, and the crystallinity is high; and the method is simple, low in cost and high in yield, and can be used for mass production. The hollow ZSM-5 nanometer zeolite with different silicon-aluminum ratios can be obtained by using different matrixes or under different treatment conditions, and the sizes of cavities of hollow ZSM-5 nanometer zeolite can be regulated by changing the treatment condition.

Owner:DALIAN UNIV OF TECH

Friction modifier additives for fuel compositions and methods of use thereof

InactiveUS6866690B2Improve fuel economyFriction lossLiquid carbonaceous fuelsAdditivesCombustionFriction loss

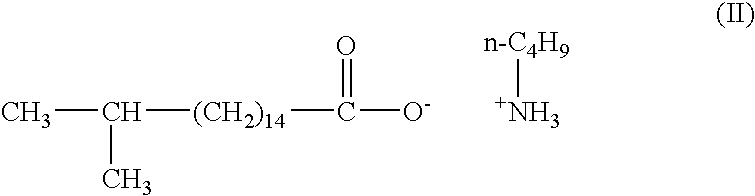

A friction modifier for combustible fuels is provided that is prepared by combining a saturated carboxylic acid and an alkylated amine. Furthermore, there also is an additive concentrate for use in fuels, especially in gasoline for internal combustion engines, comprising (a) a friction modifier comprising of a branched saturated carboxylic acid salt of an alkylated amine, such as n-butylamine isostearate; (b) a detergent package, as well as the combustible fuels containing this additive concentrate. The particular selection of friction modifier (a) enables a stable additive concentrate to be formulated providing a significant benefit in friction loss when incorporated in gasoline used to fuel an internal combustion engine, and hence an improvement in fuel economy. Moreover, the use of the friction modifier (a) in combination with a detergent package permits increased fuel efficiency to be obtained without increasing the incidence of IVD deposits in combustion engines running on a fuel modified with the additive concentrate.

Owner:AFTON CHEM INTANGIBLES

Quantum dot sensitized solar cell

InactiveUS20120103404A1Electrolytic capacitorsPhotovoltaic energy generationElectron injectionSolar cell

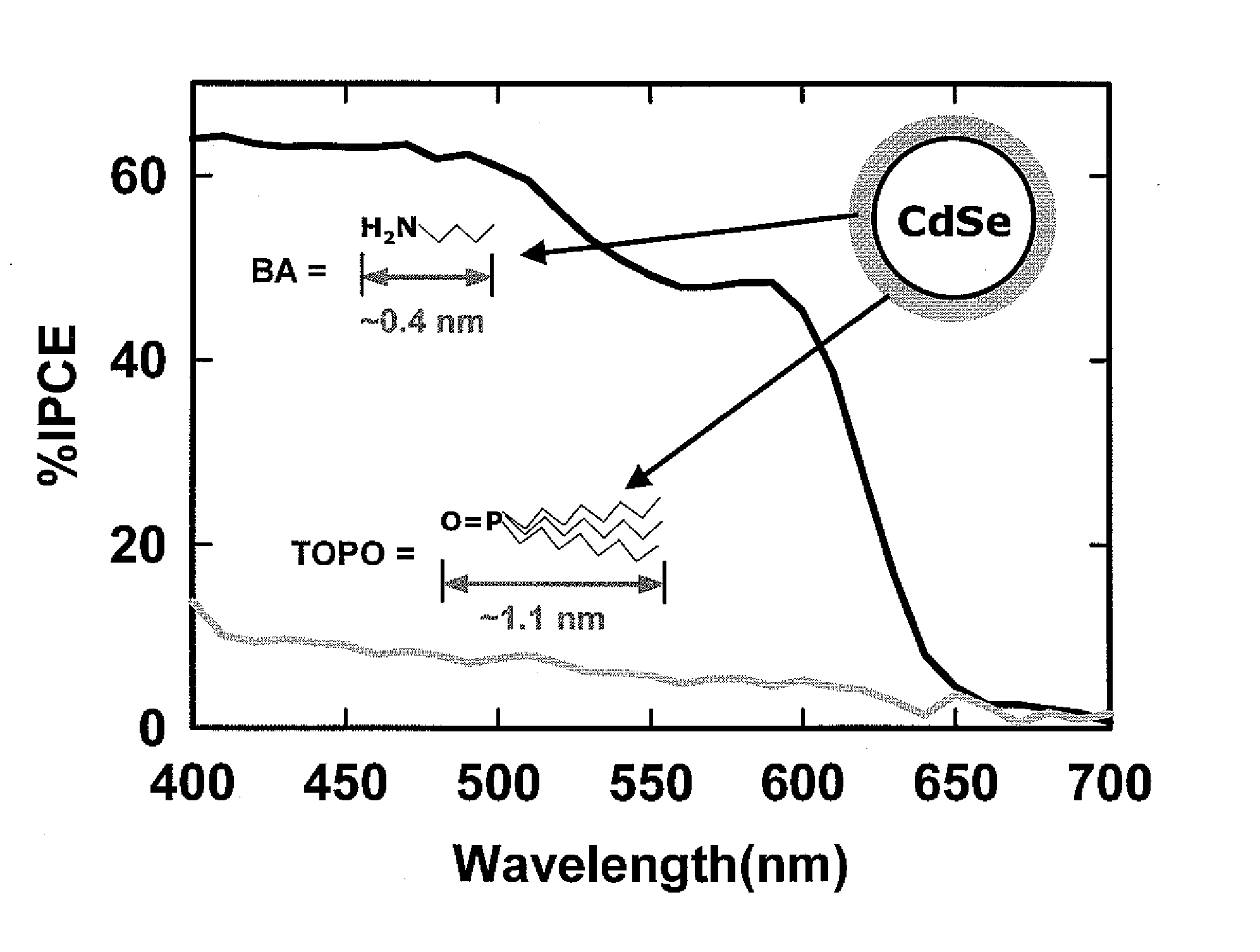

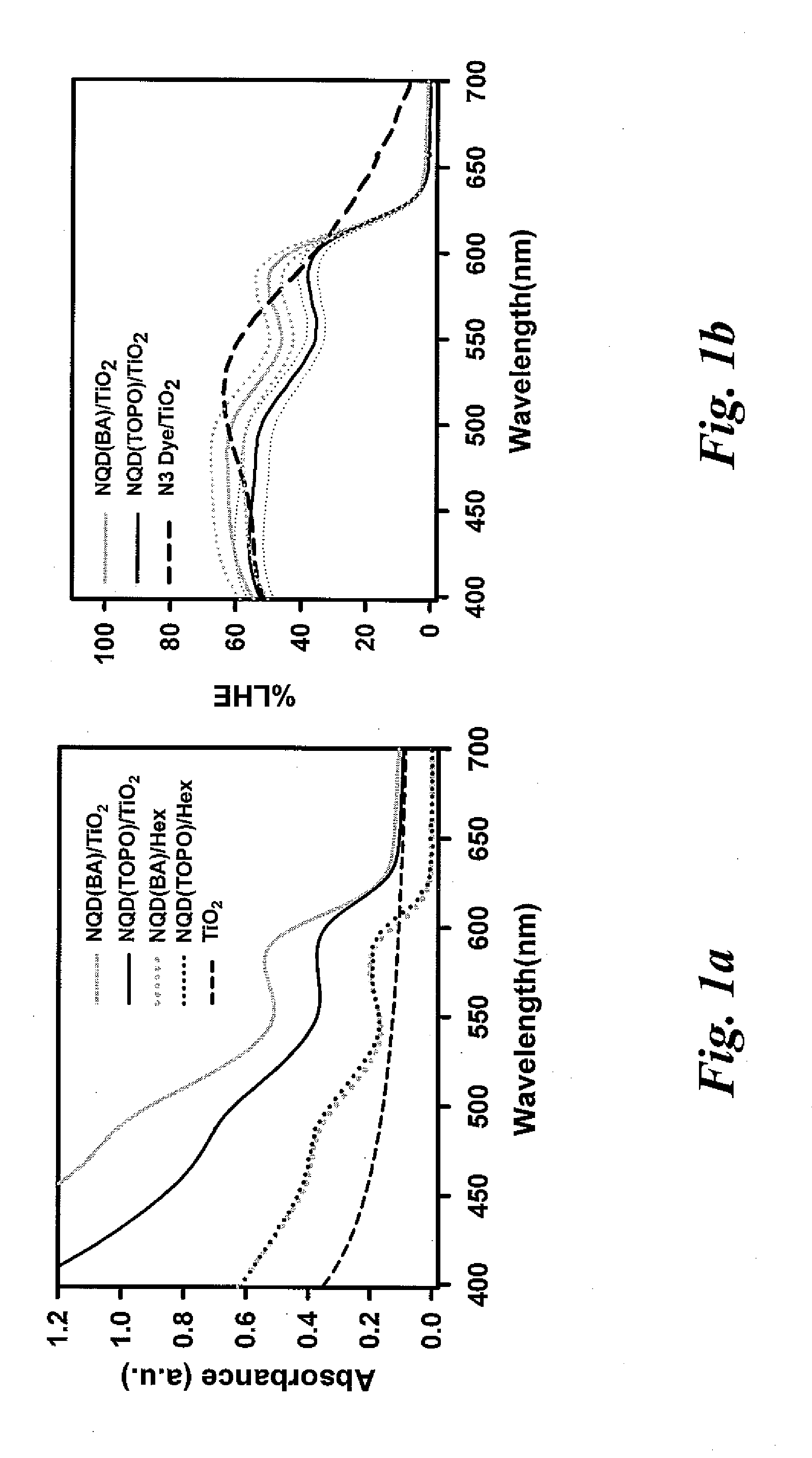

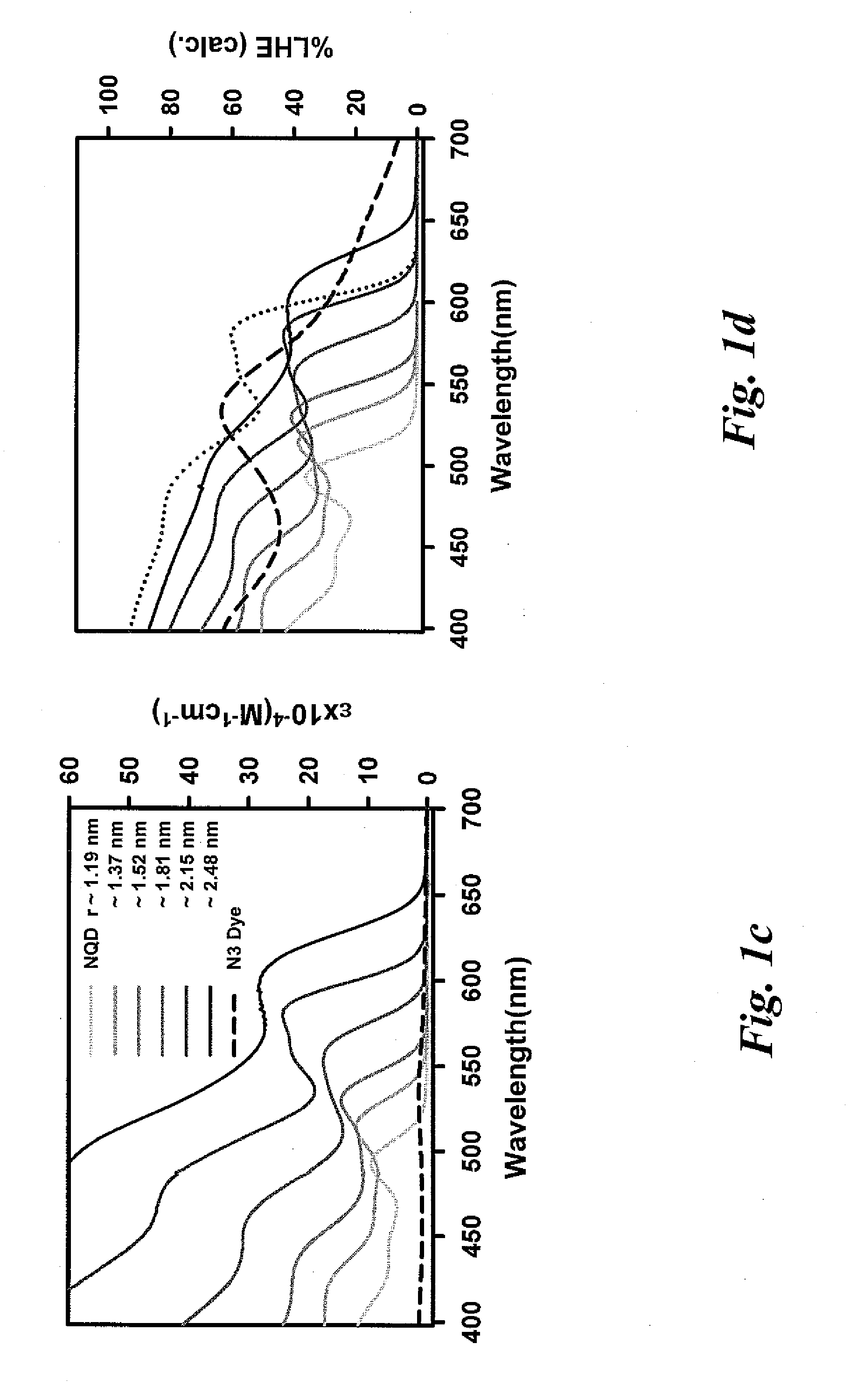

Photoelectrochemical solar cells (PECs) consisting of a photoanode were prepared by direct deposition of independently synthesized CdSe nanocrystal quantum dots (NQDs) onto a nanocrystalline TiO2 film (NQD / TiO2), aqueous Na2S or Li2S electrolyte and a Pt counter electrode. The light harvesting efficiency (LHE) of the NQD / TiO2 photoanode is significantly enhanced when the NQD surface passivation is changed from tri-n-octylphosphine oxide (TOPO) to a smaller ligand (e.g. n-butylamine (BA)). Using NQDs with a shorter passivating ligand, BA, leads to a significant enhancement in both the electron injection efficiency at the NQD / TiO2 interface and charge collection efficiency at the NQD / electrolyte interface, with the latter attributed mostly to a more efficient diffusion of the electrolyte through the pores of the photoanode. By utilizing BA capped NQDs and aqueous Li2S as an electrolyte, it is possible to achieve about 100% internal quantum efficiency of photon-to-electron conversion, matching the performance of dye sensitized solar cells.

Owner:LOS ALAMOS NATIONAL SECURITY +1

Heavy grease stain environment-friendly type water base cleaning compound

InactiveCN103834487AGood decontamination effectGood compatibilityOrganic detergent compounding agentsSurface-active detergent compositionsWater basedTriclosan

The invention discloses a heavy grease stain environment-friendly type water base cleaning compound comprising 10-15% of surfactant, 1-3% of additive, 1-5% of antiseptic, 3-5% of organic amine and remaining tap water; the ingredient of the surfactant comprises 4-5% of aliphatic acid methyl esters ethoxylate, 2-3.5% of APG, 1-3% of fatty alcohol polyoxyethylene ether sodium sulfate (AES), 0.5-1% of straight chain sodium alkyl benzene sulfonate (LAS) and 0.5-2% of aliphatic acid methyl esters ethoxylate; the additive is one or more from a group formed by sodium citrate, citric acid, lactic acid and DL-malic acid; the organic amine is one or more from a group formed by triethanolamine, n-butylamine, diethanolamine and N-methyl diethanolamine; the antiseptic at least is triclosan or tetrachloro isophthalonitrile; through the said method, the heavy grease stain environment-friendly type water base cleaning compound has anti bacterium, heavy grease stain cleaning and environmental protection performances.

Owner:SUZHOU LOTTE CHEM TECH

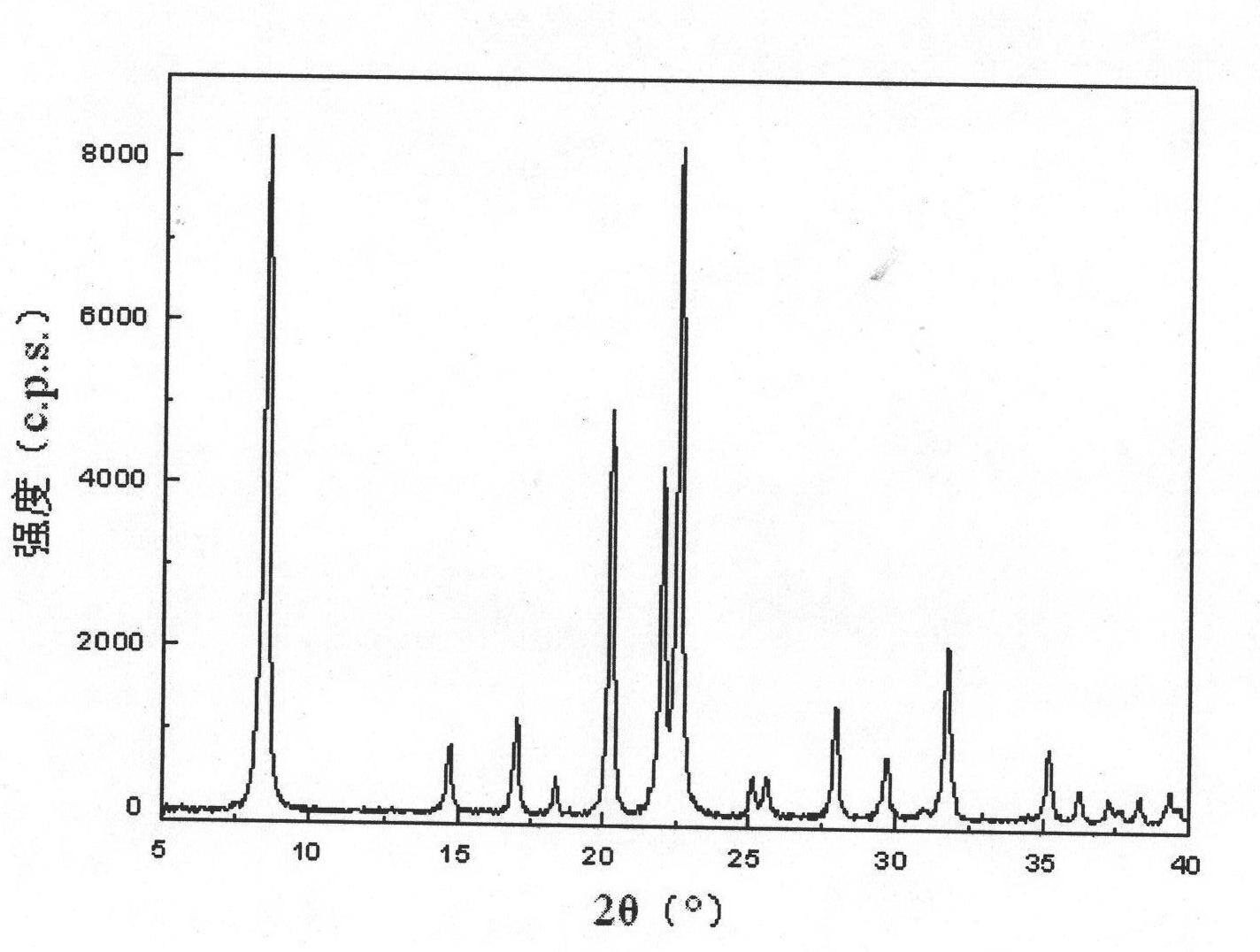

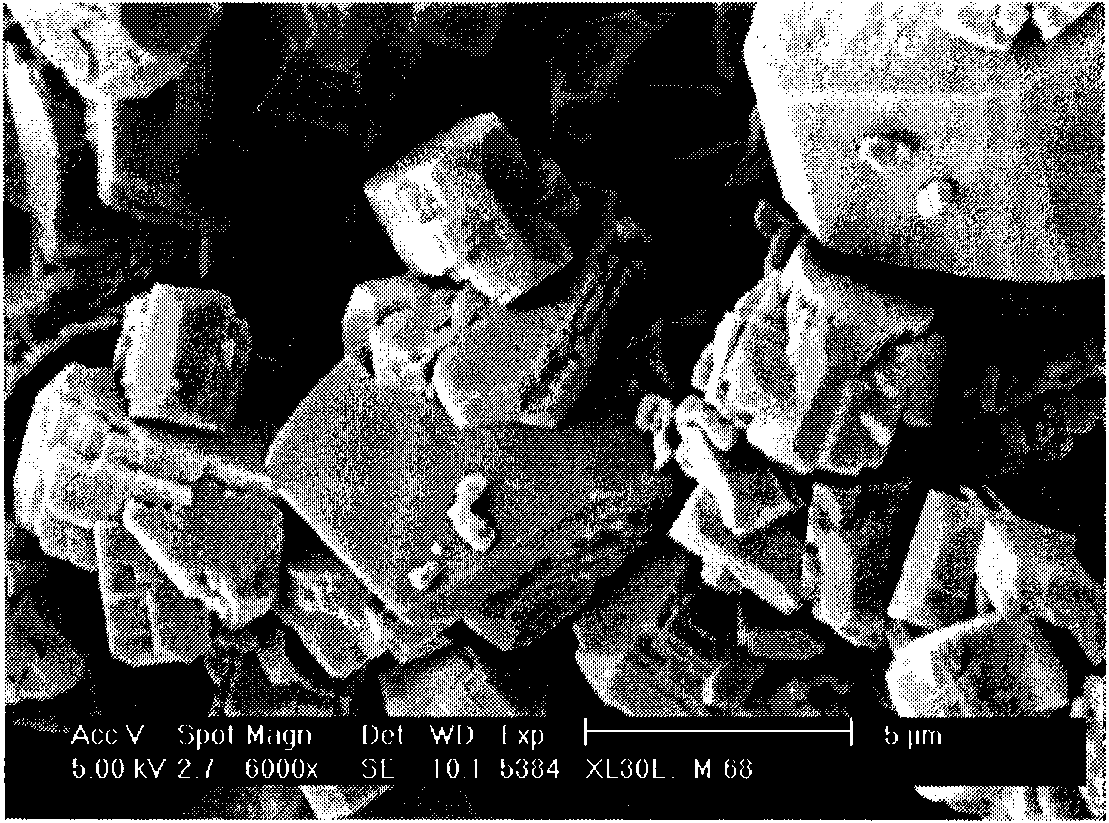

Method for synthesizing ZSM-35 molecular sieve

ActiveCN101468809AThe method is simpleGood repeatabilityFerrierite aluminosilicate zeoliteMolecular sieve catalystsMolecular sieveN-Butylamine

The invention discloses a method for synthesizing a ZSM-35 molecular sieve, which is characterized by recovering and obtaining the ZSM-35 molecular sieve by taking n-butylamine as a template agent and kaolin as a whole aluminum source and a whole or a part of silicon source and subjecting a reaction mixture to hydrothermal crystallization at 140 to 190 DEG C, wherein in the reaction mixture, the SiO2 to Al2O3 molar ratio is between 12 and 100, the n-butylamine to SiO2 molar ratio is between 0.1 and 0.5, the Na2O to SiO2 is between 0.07 and 0.2 and the H2O to SiO2 molar ratio is between 12 and 30. The method uses cheap raw materials and can reduce production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

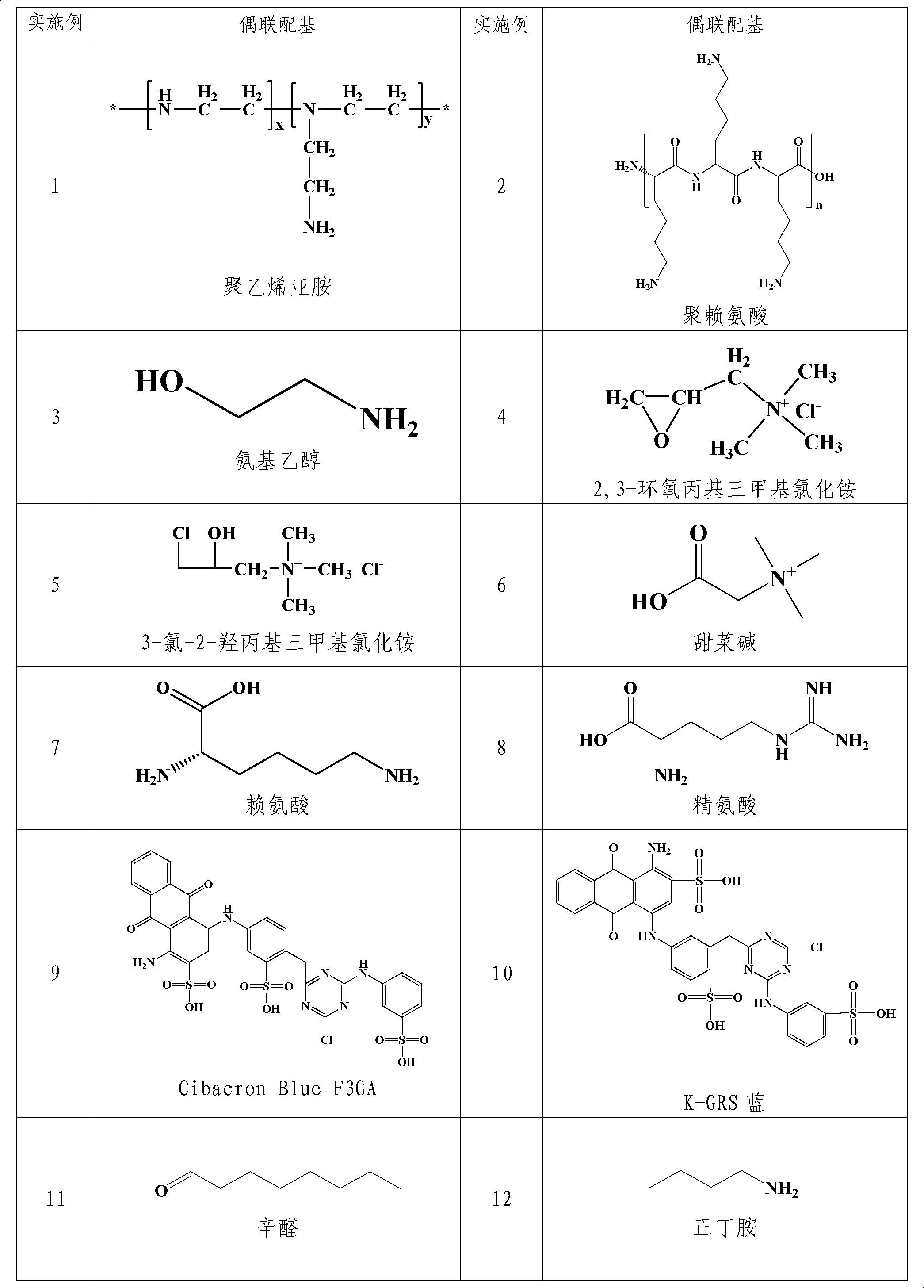

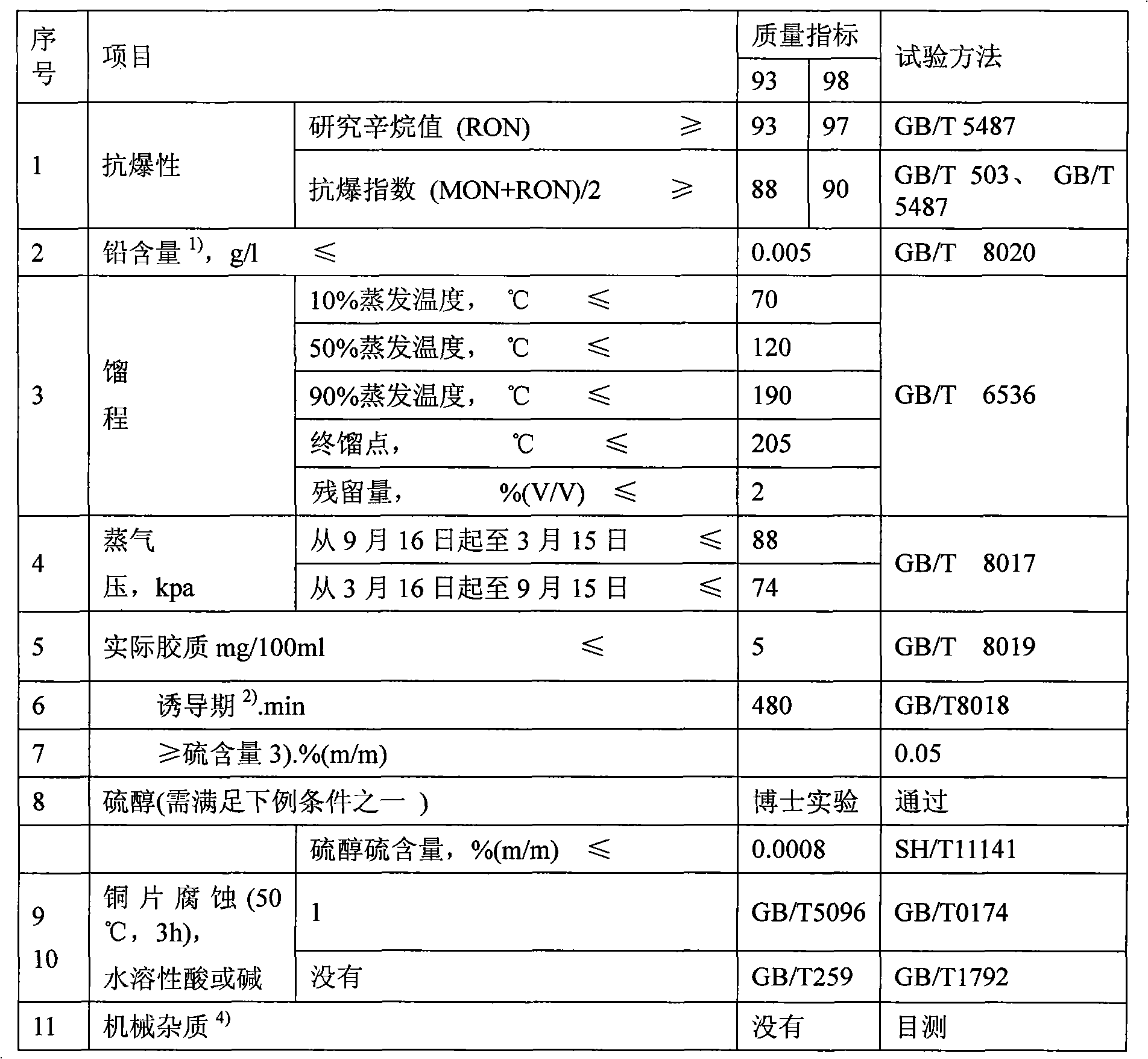

Absorption film for eliminating bilirubin and preparation method thereof

InactiveCN101862610AEasy to operateMild conditionsSemi-permeable membranesHaemofiltrationFiberCibacron Blue F3GA

The invention discloses an absorption film for eliminating bilirubin in blood and a preparation method thereof, and belongs to the technical field of biomedical materials. The method is characterized in that: a modifying method that chitosan is deposited on a hollow fiber film support layer and an outer surface of a hemodialyzer, and the chitosan is coupled with aglucon which can be interacted with the bilirubin is adopted; the coupled aglucon comprises polymine, polylysine, aminoethanol, 2,3-epoxypropyltrimethylammonium chloride, 3-chloro-2-hydroxypropltrimethyl ammonium chloride, betaine, lysine, arginine, dye Cibacron Blue F3GA, K-GRS blue, caprylaldehyde, n-butylamine, aniline, beta-cyclodextrin, bovine serum albumin and human sreum albumin. The method has the advantages of simple operation, mild condition, no damage to the structure of the film per se, capability of being coupled with various aglucons according to requirement and strong expansibility. When the absorption film is used for eliminating bilirubin, the bilirubin can be removed by the conventional dialysis with a simple system and low operation pressure.

Owner:DALIAN UNIV OF TECH

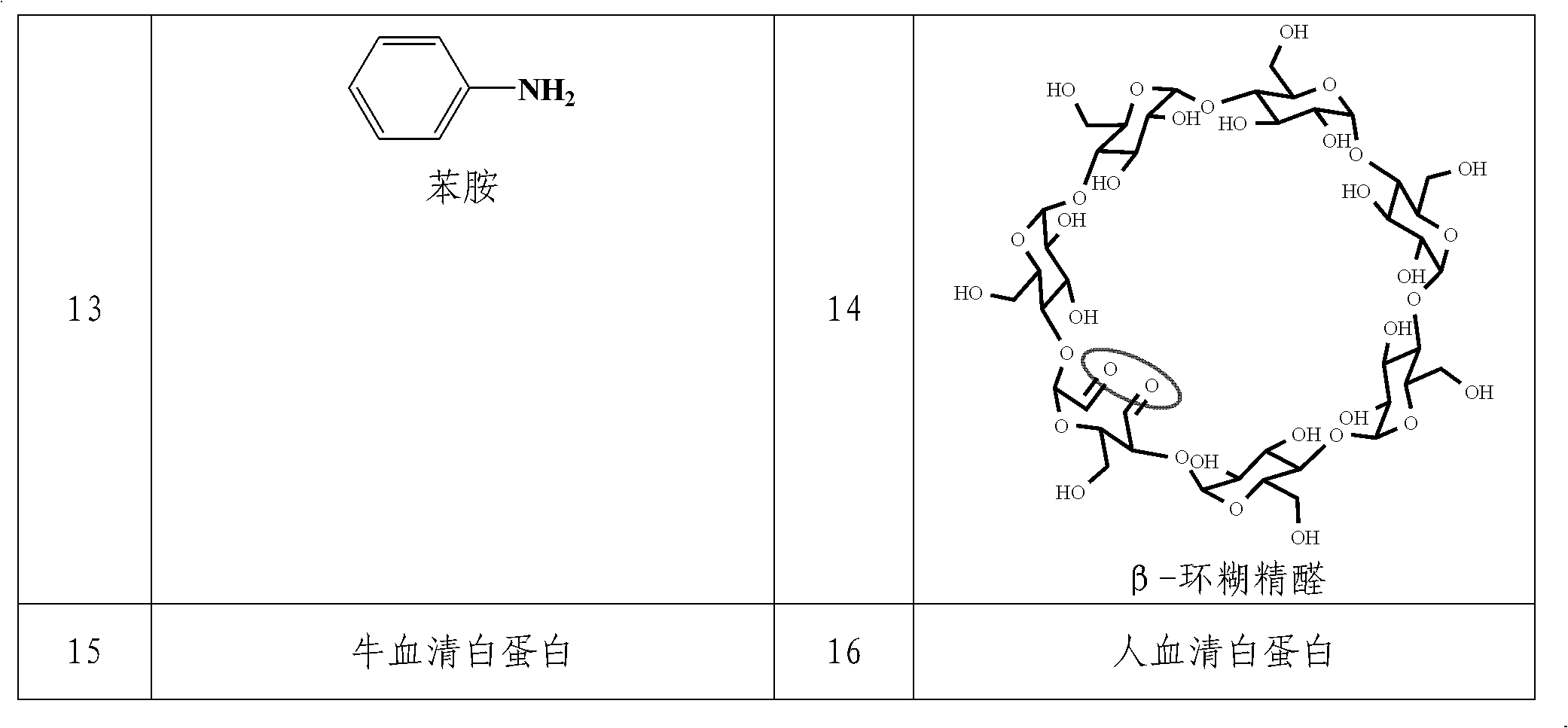

Methanol diesel fuel complex additive and preparation method thereof

ActiveCN101709234AGood compatibility stabilityStable in natureLiquid carbonaceous fuelsCyclohexanoneN-Butylamine

The invention discloses a methanol diesel fuel complex additive and a preparation method thereof. The complex additive is prepared from the following raw materials in parts by volume: 1-4 parts of diethyl phthalate, 1-8 parts of n-butylamine, 1-9 parts of isooctanol, 1-6 parts of cyclohexanone, 13-42 parts of lauryl methacrylate, 7-30 parts of mixed fatty glyceride, 1-5 parts of phenyl propargyl ether, 1-8 parts of dihexadecyl dimethyl ammonium chloride, 2-12 parts of ethyl formate, 2-14 parts of isooctyl nitrate and 1-6 parts of polyoxyethylene hexadeeylalkyl ether selies. The methanol diesel fuel complex additive can enable methanol diesel fuel to be evenly mixed and to be stably stored for more than 6 months, which effectively improves the fire behaviour of the methanol diesel fuel and inhibits the volatilization when the methanol content is higher; moreover, the production process is simple and the use is convenient, thereby being beneficial to the popularization and application of the methanol diesel fuel.

Owner:临沂星火知识产权服务有限公司

Rosin-disproportionating high activity Pd/C catalyst preparing process

InactiveCN1672787AHydrocarbon by hydrogenationCatalyst activation/preparationActive componentGranularity

The rosin-disproportionating high-activity Pd / C catalyst is prepared through simple and fast wet reduction process with palladium acetate as the precursor compound of active component palladium, active carbon as carrier and n-butylamine as solvent. The prepared catalyst has granularity of 300-350 mesh, and Pd content of 1.5-10 wt%. The catalyst may be used in the rosin disproportionating reaction to produce high quality disproportionated rosin.

Owner:SINO PLATINUM METALS CO LTD

Alcohol ether gasoline used in new energy vehicles

InactiveCN101538491AReduce consumptionReduce pollutionLiquid carbonaceous fuelsNew energyLiquid fuel

The invention relates to a liquid fuel, and particularly a liquid carbonaceous fuel of the mixture of hydrocarbons and alcohol ether. The alcohol ether gasoline used in new energy vehicles comprises 25 to 85 percent of gasoline constituents and 15 to 75 percent of alcohol ether-major other chemical raw materials by weight percentage, wherein the components of the alcohol ether-major other chemical raw materials and the weight proportions thereof in the alcohol ether gasoline used in new energy vehicles are as follows: industrial methanol: 10 to 60 percent, n-hexane: 0 to 3 percent, isopropyl chloride: 0 to 1 percent, trichloroethylene: 0 to 1 percent, epichlorohydrin: 0.2 to 3 percent, bromoethanol: 0.2 to 2 percent, isodibutyl ether: 0.5 to 2 percent, ethylene glycol monobutyl ether: 0 to 1 percent, lauric acid : 0.4 to 2 percent, methyl chloroacetate: 0 to 4 percent, isopropyl nitrate: 0.2 to 4 percent, trimethyl phosphate: 0 to 3 percent, nitromethane: 0.1 to 1 percent, nitroethane: 0 to 1 percent, nitroguanidine: 0 to 3 percent, cyclopentadiene: 0 to 4 percent, and n-butylamine: 0 to 1 percent.

Owner:陈斌

Synthetic method of high silica ZSM-5 zeolite

InactiveCN101898767AReduce dosageShape is easy to controlPentasil aluminosilicate zeoliteTetramethylammonium bromideAdhesive

The invention discloses a synthetic method of high-silica ZSM-5 zeolite, the method comprises the steps of adopting water glass as a silica source, adopting aluminum salts of aluminum sulfate, aluminum nitrate, aluminum chloride and the like, as well as organic aluminum compounds of sodium metaaluminate, isopropanol and the like as aluminum sources, using sulfuric acid or hydrochloric acid to regulate alkalinity, adding an organic template, simultaneously adding a guide adhesive, carrying out high-temperature crystallization at 120-200 DEG C, and then synthesizing the high-silica ZSM-5 zeolite with the SiO2 / Al2O3 ratio which is greater than 100; and the molar ratio of raw materials is as follows: SiO2 / Al2O3 is equal to 100-infinity, Na2O / SiO2 is equal to 0.05-0.20, and H2O / SiO2 is equal to 10-100. The organic template comprises tetrapropylammonium bromide, tetrapropylammonium hydroxide, tetraethylammonium bromide, tetraethylammonium hydroxide, n-butylamine, ethylamine, hexamethylene diamine and any other organic matters which can synthesize the ZSM-5 zeolite or the mixture thereof, wherein the using amount of the organic template is that R / SiO2 is equal to 0.005-0.50; and the amount of silicon dioxide in the guide adhesive is 0-5% of the total weight of the silicon dioxide in a synthetic system. The synthetic method can synthesize the high-silica ZSM-5 zeolite with the SiO2 / Al2O3 ratio which is greater than 100 and has the advantages of cheap raw materials, a small using amount of the organic template, and capability of realizing the control of product appearance and particle size by changing the relative using amount of the template and the guide adhesive.

Owner:EAST CHINA NORMAL UNIV

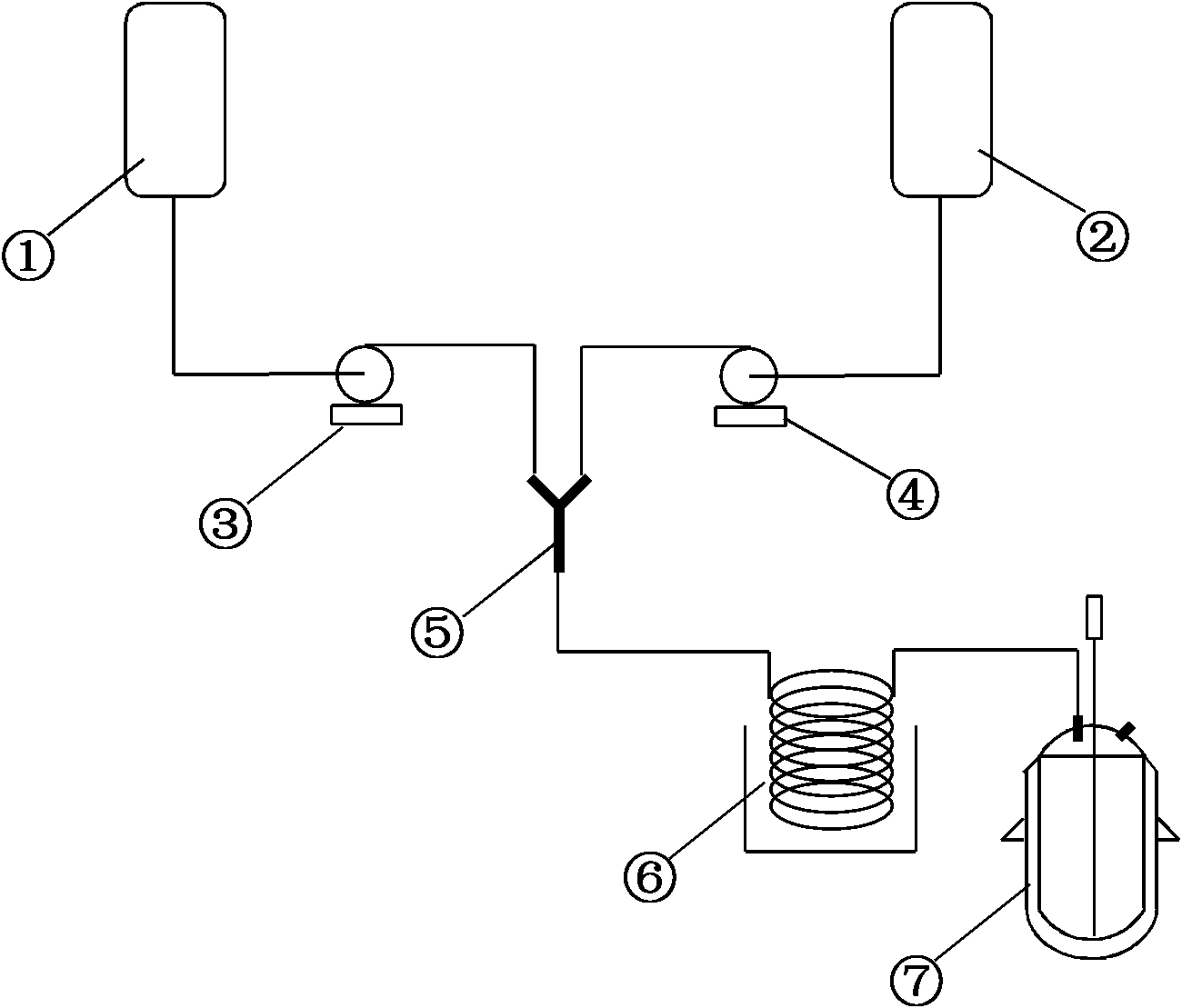

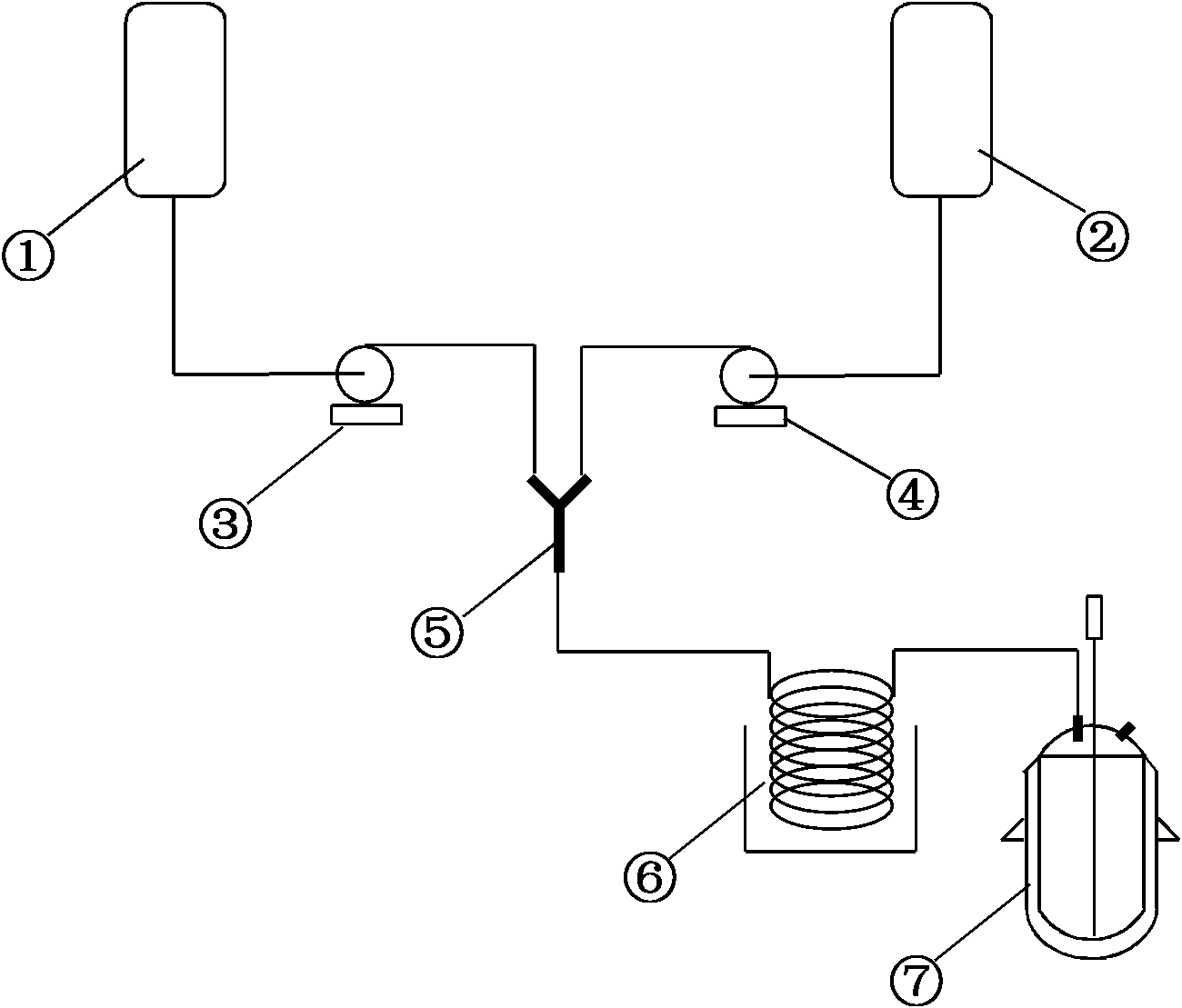

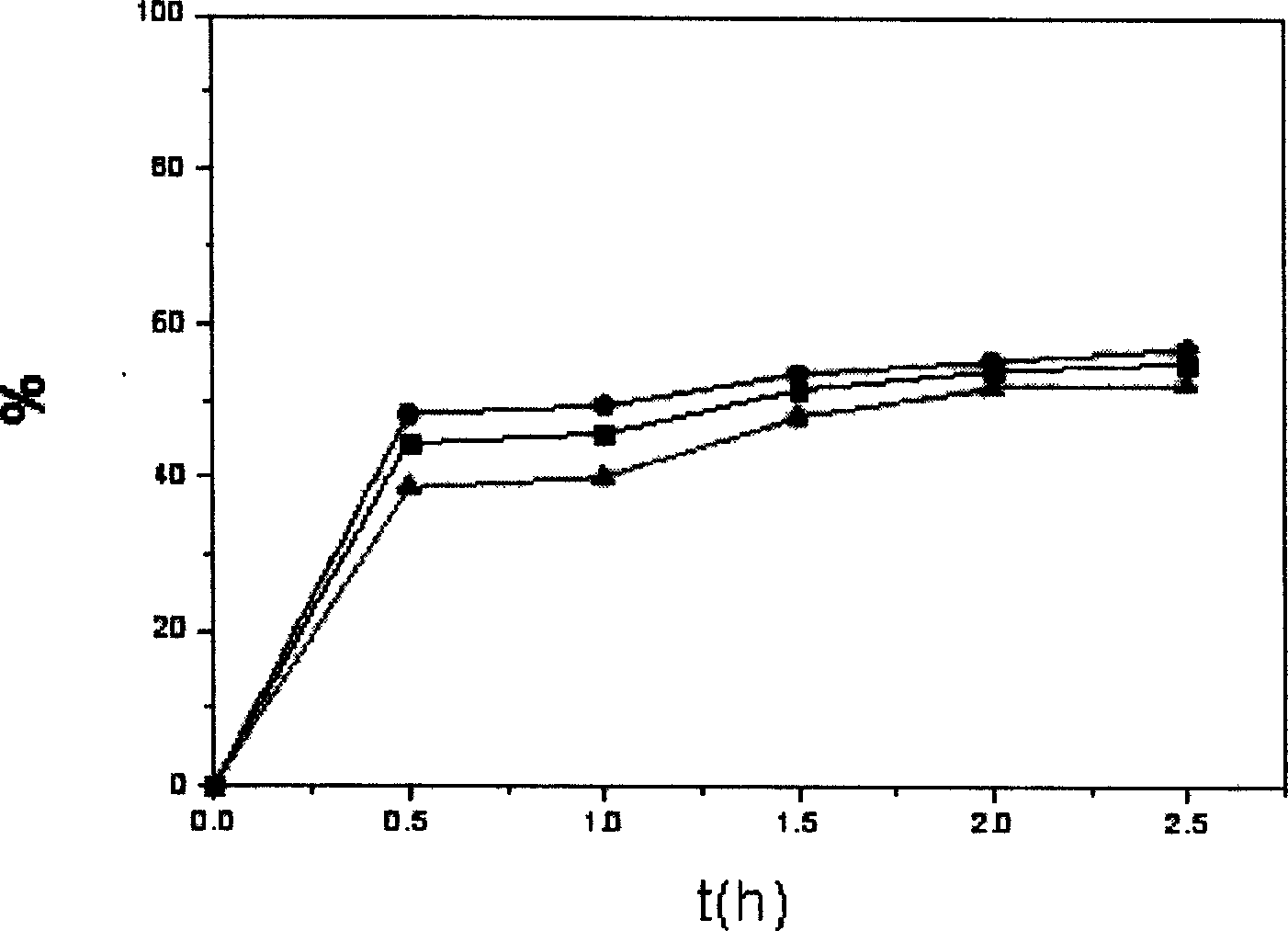

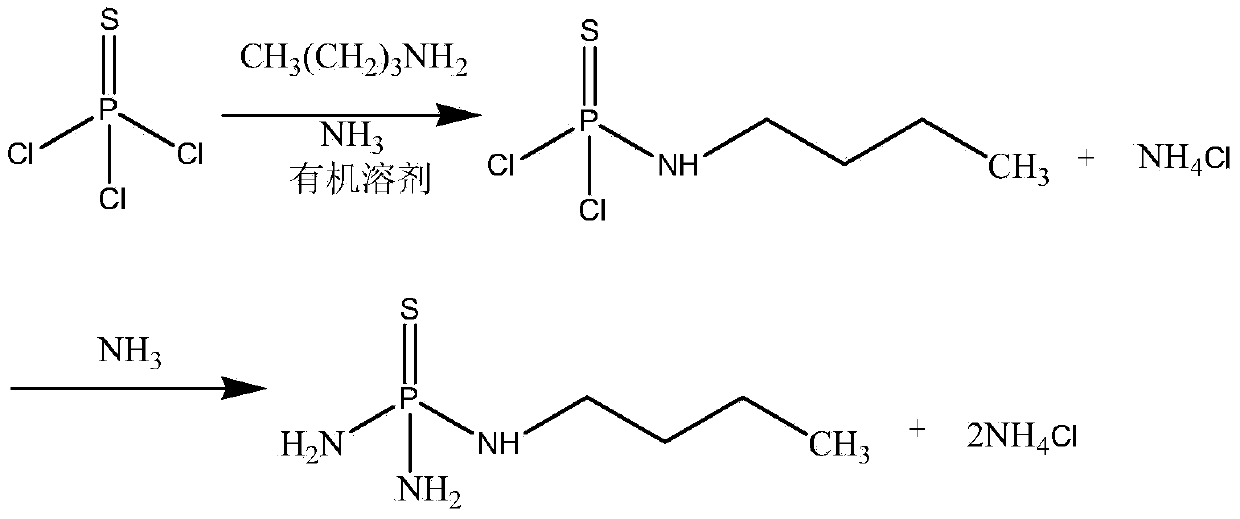

Method for producing N-(N-butyl)thiophosphoric triamide in channelization manner and special equipment

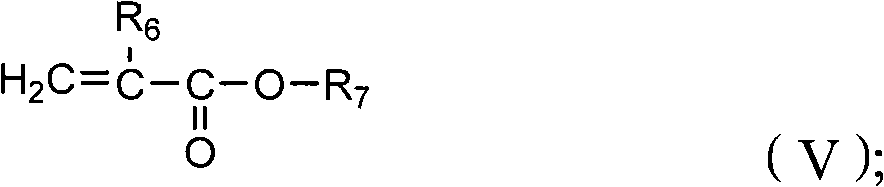

ActiveCN102030775ASimple processSimple and fast operationGroup 5/15 element organic compoundsLiquid-gas reaction processesOrganic solventReaction temperature

The invention discloses a method for producing N-(N-butyl)thiophosphoric triamide in a channelization manner and special equipment. The method comprises the steps of: respectively inputting phosphorus thiochloride and n-butylamine into a Y-shaped jet mixer for rapidly uniformly mixing, then putting the mixture into a tubular reactor, controlling the reaction temperature in the tubular reactor at 10-35 DEG C and the reaction time for 5-90s; and enabling reaction liquid to enter an amination reactor added with an organic solvent in advance from the outlet of the tubular reactor, continuously introducing ammonia at a temperature of 20-25 DEG C and the normal pressure for reacting for 2.5-3h, and separating and purifying after the reaction is completed to obtain the N-(N-butyl)thiophosphoric triamide. The special equipment is shown in the specification. The method has the advantages of reasonable process, low production cost and high yield, and is suitable for industrialized production.

Owner:ZHEJIANG UNIV OF TECH +1

Method for producing N-butyl-phosphorothioic triamide n-(n-butyl)thiophosphoric triamide

ActiveCN101503424AEasy to operateLow costGroup 5/15 element organic compoundsFertilizer mixturesReaction temperatureSolvent

The invention relates to a production method of N-normal-butyl thiophosphoryl triamine, comprising the following steps: dehydrating raw materials to control the water content to be within a required range, mixing phosphorus thiochloride with tetrahydrofuran, stirring the mixture, lowering the temperature, adding a mixture of n-butylamine, triethylamine and tetrahydrofuran in the mixture of the phosphorus thiochloride and the tetrahydrofuran by means of slow dripping, keeping a certain reaction temperature for 1-8h to obtain a white turbid liquid; leading ammonia gas into the a reaction system under the normal atmosphere, controlling the lead-in speed of ammonia gas, and keeping the temperature of the reaction system for 1-5h; centrifugating the reaction liquid to separate solid generated in the reaction system, distilling an obtained organic liquid in a decompression mode to remove most of the solvent and obtain a crude product, recrystallizing and refining the crude product to obtain a refined product with the purity higher than 99 percent. The invention has the advantages of wide raw material source, short process, simple operation, low cost, no three waste discharge, high economical benefit, applicability for industrial production, and the like.

Owner:NORTH HUAJIN CHEM IND GRP

Bilirubin adsorption material for treating hyperbilirubinemia

InactiveCN1876226AImprove securityGood blood compatibilityOther blood circulation devicesOther chemical processesBILIRUBINAEMIAArginine

The related bilirubin adsorption material selects agarose gel as carrier activated by N, N'-carbonyldiimidazole, the dual-amido agent and dual-aldehydo agent as separation arm, and couples all of lycine, aethanolamina, arginine and n-butylamine on back end, wherein in 324mg / L blood, the adsorption capacity for former material with different coupled is: 0.71~1.21g / Lgel, 0.78~1.29g / Lgel, 0.91~1.44g / Lgel and 1.20~1.81g / Lgel, and the removal rate to bilirubin by material coupled n-butylamine is up to 50.0%. this invention has well adsorption rate with low cost.

Owner:DALIAN UNIV OF TECH

Preparation method for high-stability quantum dot composite

InactiveCN104650848AReduced fluorescence efficiencyGood fluorescence efficiencyLuminescent compositionsOrganic solventFluorescence

The invention relates to a preparation method for high-stability quantum dot composite, and specifically provides a preparation method for the high-stability quantum dot composite, which belongs to the nano scientific field. The preparation method comprises the following steps: dissolving a quantum dot with an organic solvent to obtain a quantum dot solution; and uniformly mixing the quantum dot solution, n-butylamine, ethyl silicate, 3-sulfydryl propyl triethoxy silicane, methane and water in proportion. According to the preparation method disclosed by the invention, short-chain organic amine is used to replace strong alkali catalysts of long-chain organic amine, ammonia water and the like in the prior art, so that damages to the quantum dot in the preparation process are reduced, and the stability and the fluorescence efficiency of the quantum dot composite are improved.

Owner:陈续晋

Continuous production method for N-NBPT

InactiveCN103755739AHigh yieldHigh purityGroup 5/15 element organic compoundsN-ButylamineRaw material

The invention relates to a production method for chemical fertilizer urease inhibitors, in particular to a continuous production method for N-NBPT. The continuous production method comprises the following steps: mixing thiophosphoryl chloride and dichloromethane for stirring; cooling; then dropwise adding a mixed solution of n-butylamine and dichloromethane, and acid bounded reaction agents simultaneously; preserving heat for 0.5-6 hours after dropwise adding to obtain a reaction solution, wherein the acid bounded reaction agents are ammonium hydroxides or ammonia gases; filtering and layering the obtained reaction solution; introducing the ammonia gases into the underlayer reaction solution for an ammonolysis reaction; centrifuging, filtering and concentrating the reaction solution obtained after the ammonolysis reaction; recrystallizing to obtain the product. According to the invention, other auxiliary raw materials are not needed except for raw materials used for producing the product; the continuous production method needs no purification in the tremendously optimized reaction process, has a mild reaction condition and no other by-products, and has the advantages of high production efficiency, mild reaction condition, high yield, good quality, less three wastes, fully utilized resources and the like.

Owner:CANGZHOU JINCANG FINE CHEM CO LTD

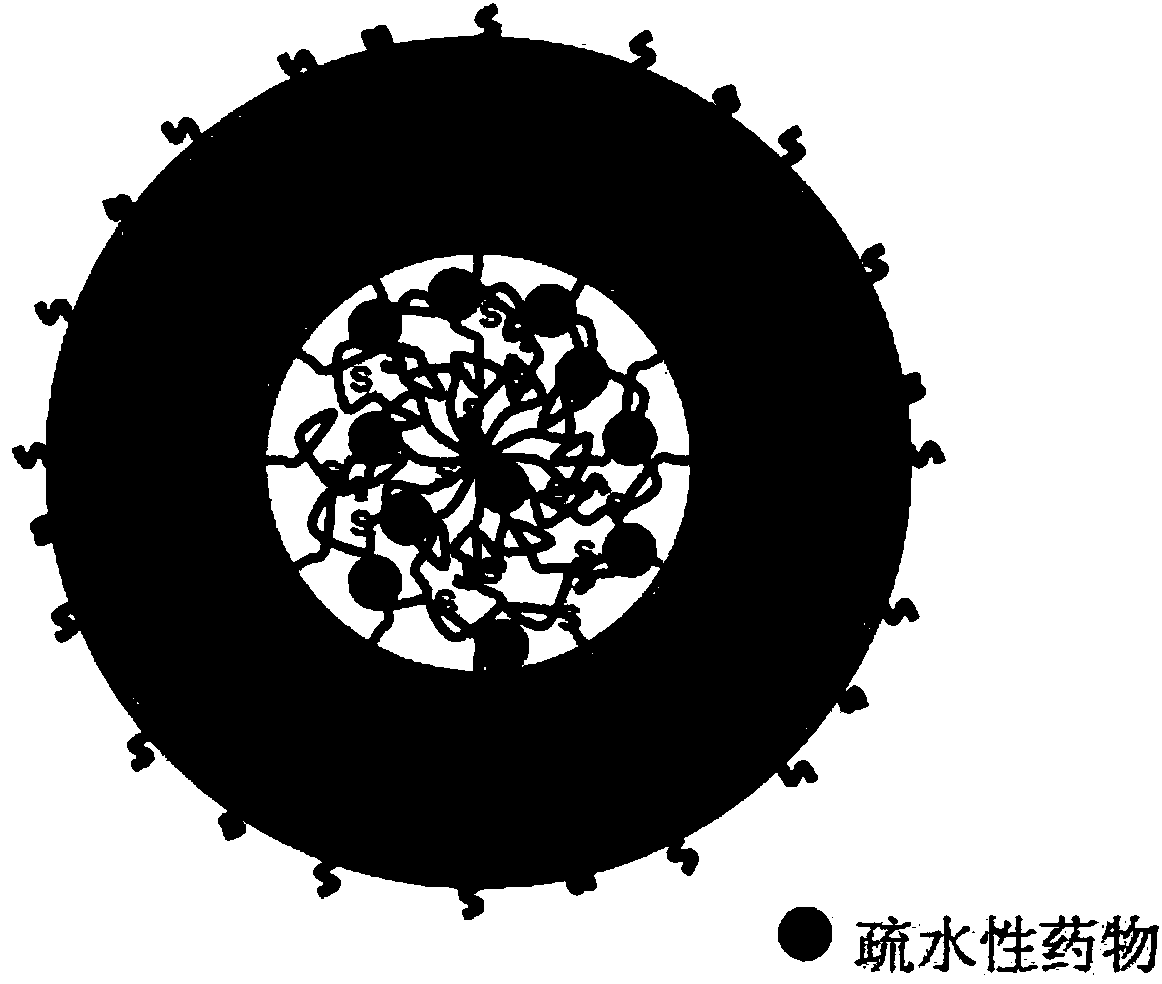

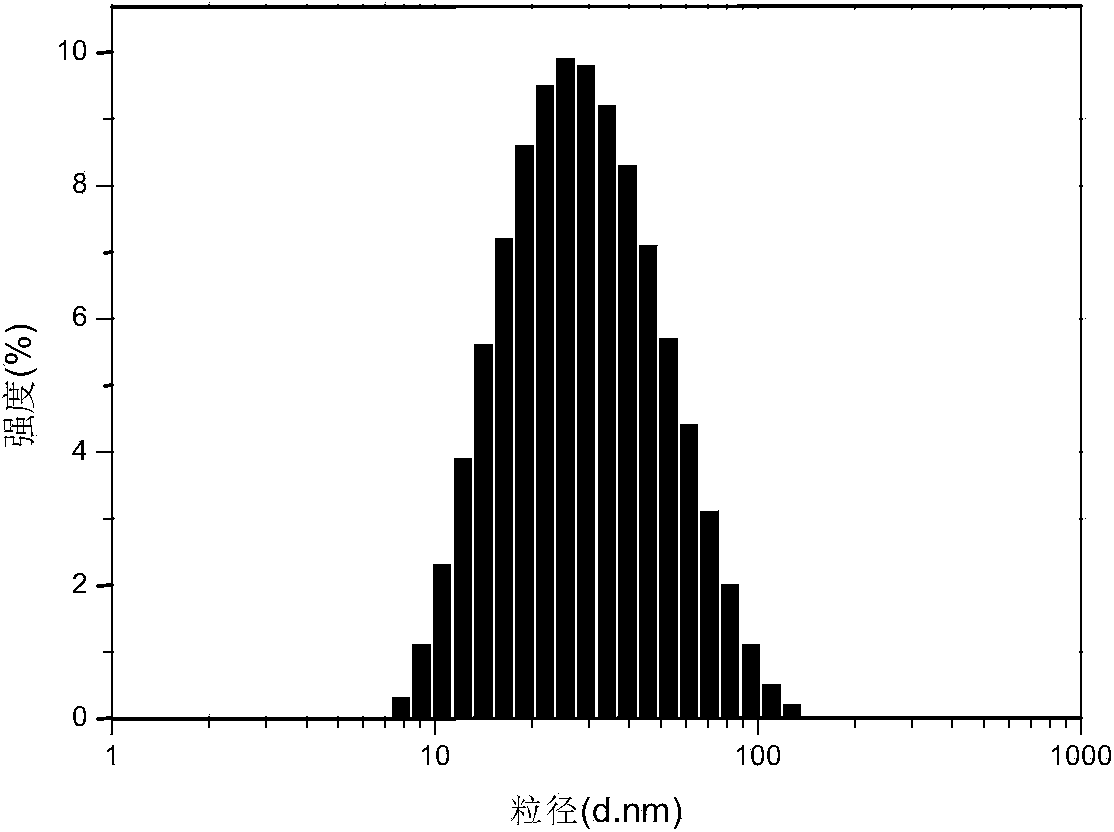

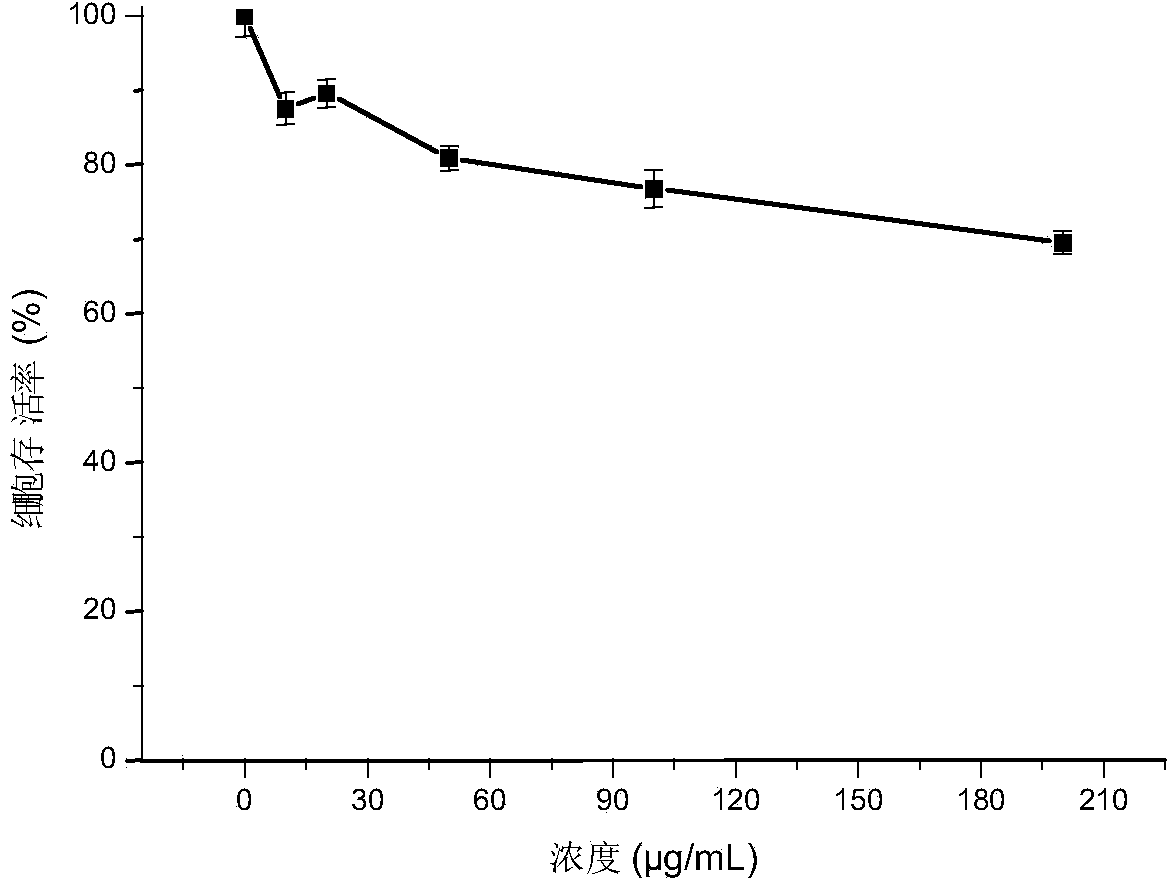

Dual-sensing response type polymer nano-micelle as well as preparation method and application thereof

ActiveCN103656652AImprove stabilityAvoid clearingOrganic active ingredientsPharmaceutical non-active ingredientsSide chainResponse type

The embodiment of the invention provides a dual-sensing response type polymer nano-micelle. The component of the nano-micelle is n-butylamine-polylysine (folic acid / 2,3-dimethylmaleic anhydride)-b-polycysteine, wherein n-butylamine is connected with one end of a polylysine chain segment through an amido bond, and the other end of the polylysine chain segment is connected with a polycysteine chain segment; folic acid is connected with the amidogen of the side chain part of the polylysine chain segment through the amido bond; 2,3-dimethylmaleic anhydride is connected with the rest amidogen of the side chain of the polylysine chain segment in an amido bond manner. The dual-sensing response type polymer nano-micelle can be used as a carrier of a hydrophobic drug, is biodegradable and stable in property, has a function of positive target transfer, and can realize charge reversal and reducing response. The embodiment of the invention also provides a preparation method and application of the dual-sensing response type polymer nano-micelle.

Owner:SHENZHEN INST OF ADVANCED TECH

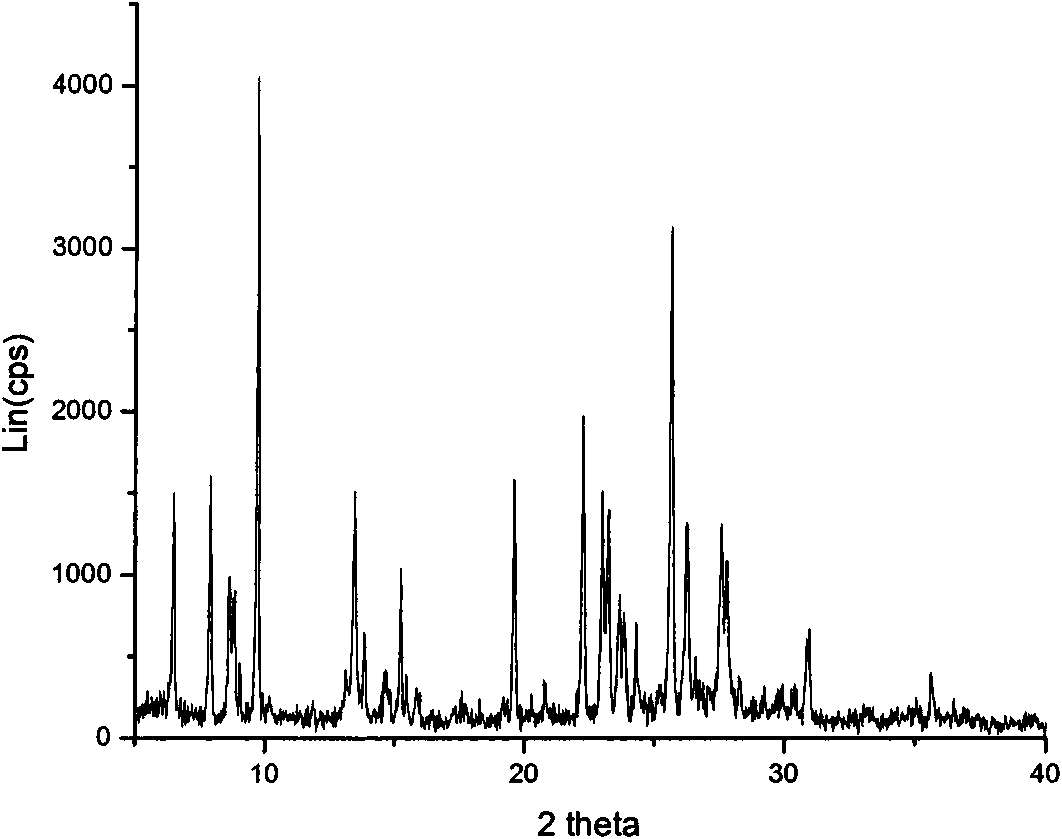

Method for synthesizing SAPO-31 molecular sieves through microwave heating

ActiveCN101786640AAcidity is highly adjustableShorten crystallization timeMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesPhosphorous acidPhosphoric acid

The invention provides a method for synthesizing an SAPO-31 molecular sieve through microwave heating, which relates to a preparation method of an SAPO-31 molecular sieve. The invention solves the problems that the crystallization time of the existing preparation method of the SAPO-31 molecular sieve is long, stray crystals exist in products, and the price of template agents is high. The method of the invention comprises the following steps: firstly, preparing phosphorous acid, water, di-n-butylamine, aluminium isopropoxide and silicon aerosol into gel; then, placing the gel into a reaction kettle to be heated by microwaves; carrying out crystallization at 130 DEG C to 190 DEG C; and then, obtaining the SAPO-31 molecular sieve through centrifugal filtration, washing, drying and roasting. The invention has the advantages of short crystallization time, no stray crystal and low price of the template agents. The SAPO-31 molecular sieve of the invention is applied to the fields of petrochemical industry and fine chemistry industry as a catalyst.

Owner:HEILONGJIANG UNIV

Preparation method of binder-free mordenite catalyst

ActiveCN102039152AHigh activityHigh strengthCatalytic crackingMolecular sieve catalystsCatalytic pyrolysisWater vapor

The invention relates to a preparation method of a binder-free mordenite catalyst, mainly aiming at solving the problems that the existing preparation method of the mordenite is complex in preparation process and higher in cost by using a seed crystal or a guiding agent. By adopting the technical scheme, the preparation method comprises the steps of mixing 0.01-20wt% of alkaline substance, 0.5-40wt% of aluminum compound and 40-80wt% of silicon oxide, shaping the mixture, drying the mixture, putting the mixture into water vapor containing at least one of template agents of water, ammonia water, quadrol, triethylamine, n-butylamine, hexamethylene diamine, tetra-propyl ammonium bromide or tetra-propyl ammonium hydroxide, and crystallizing the mixture for 10-200 hours at 120-200 DEG C to obtain the binder-free mordenite catalyst, thereby preferably solving the problems, and leading the prepared binder-free mordenite catalyst to be applied to the reaction for preparing propylene from naphtha by catalytic pyrolysis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing quantum dot of transitional metal chalcogenide compound

ActiveCN105129748AEasy to manufactureWide versatilityMaterial nanotechnologyBinary selenium/tellurium compoundsMetal chalcogenidesReaction temperature

The invention discloses a method for preparing a quantum dot of a transitional metal chalcogenide compound and belongs to the field of preparing functional nanomaterials by colloidal chemical methods. The method disclosed by the invention comprises the following steps: mixing a metal carbonyl compound and trioctylphosphine oxide, heating and dissolving the mixture as a metal source precusor, by taking octadecene as a reaction solvent, heating the mixture under inert gas protection to reaction temperature, and preparing a metal source reaction system; by taking organic phosphorus as a coorinating solvent, preparing non-metal source sulfur powder, selenium powder or tellurium powder into a precusor solution; injecting the non-metal source solution into the metal source reaction system under inert gas protection and maintaining the reaction temperature and carrying out a heating reaction; and carrying out high speed centrifugal separation, and adding a mixed solution of n-butylamine / n-hexane into the obtained solid product to obtain a quantum dot material of the transitional metal chalcogenide compound in a collide dispersing state. The preparation method for the quantum dot material of the transitional metal chalcogenide compound disclosed by the invention is good in universality, fast in reaction speed, high in reaction yield, simple to operate, mild in reaction condition and easy for large-scaled production.

Owner:NANJING UNIV OF POSTS & TELECOMM

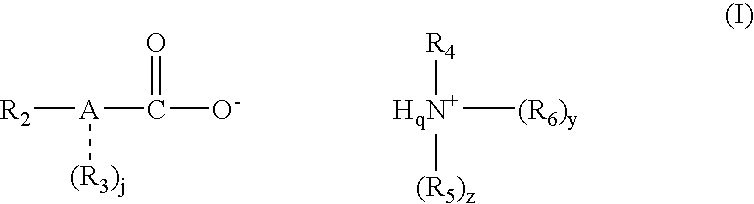

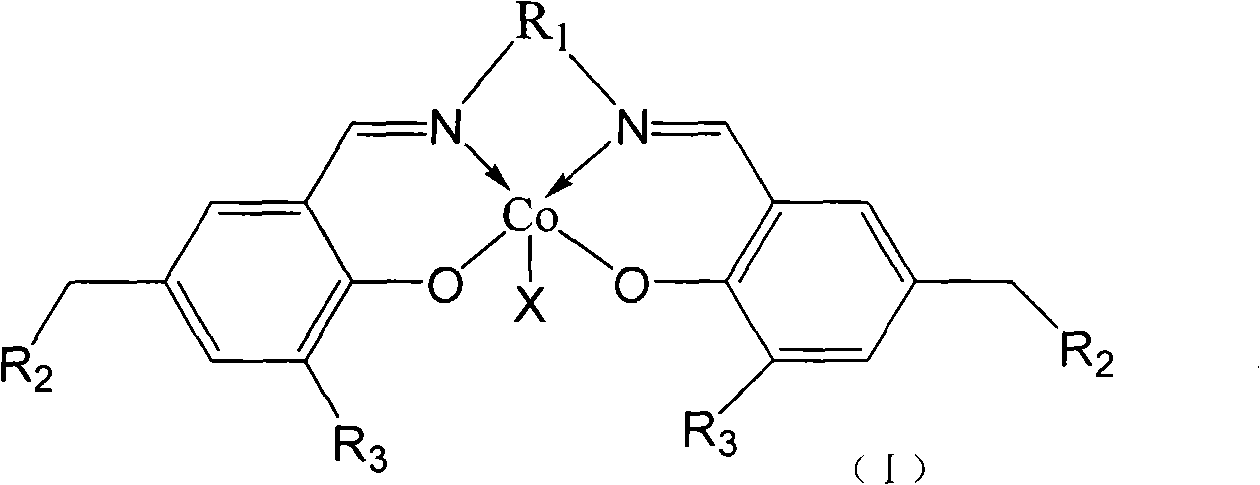

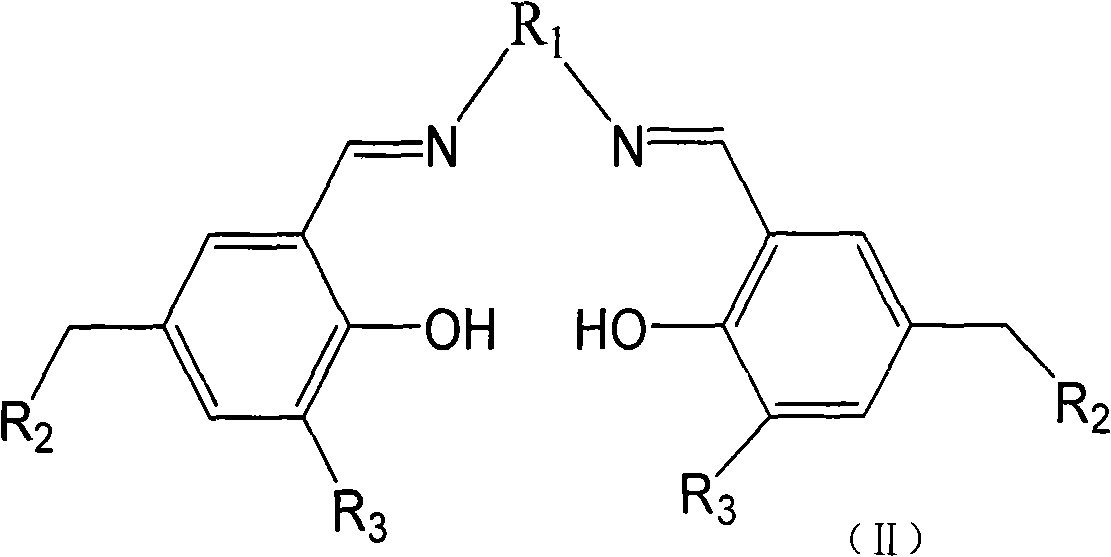

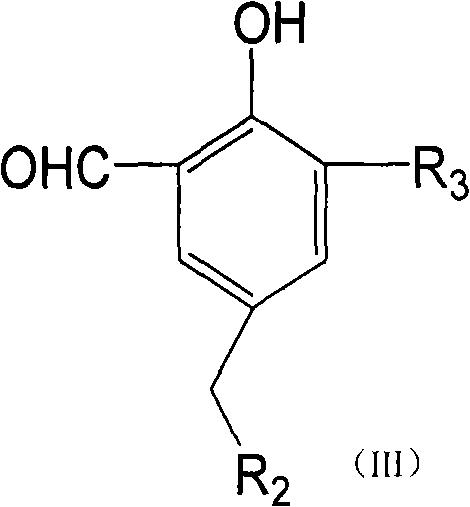

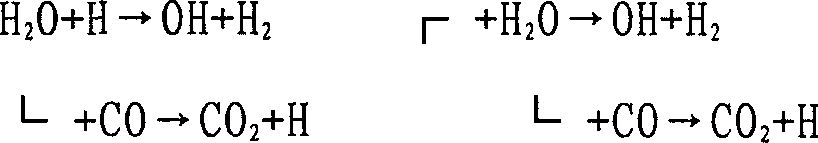

Catalyst for copolymerization of carbon dioxide and epoxy compounds, preparation method and applications thereof

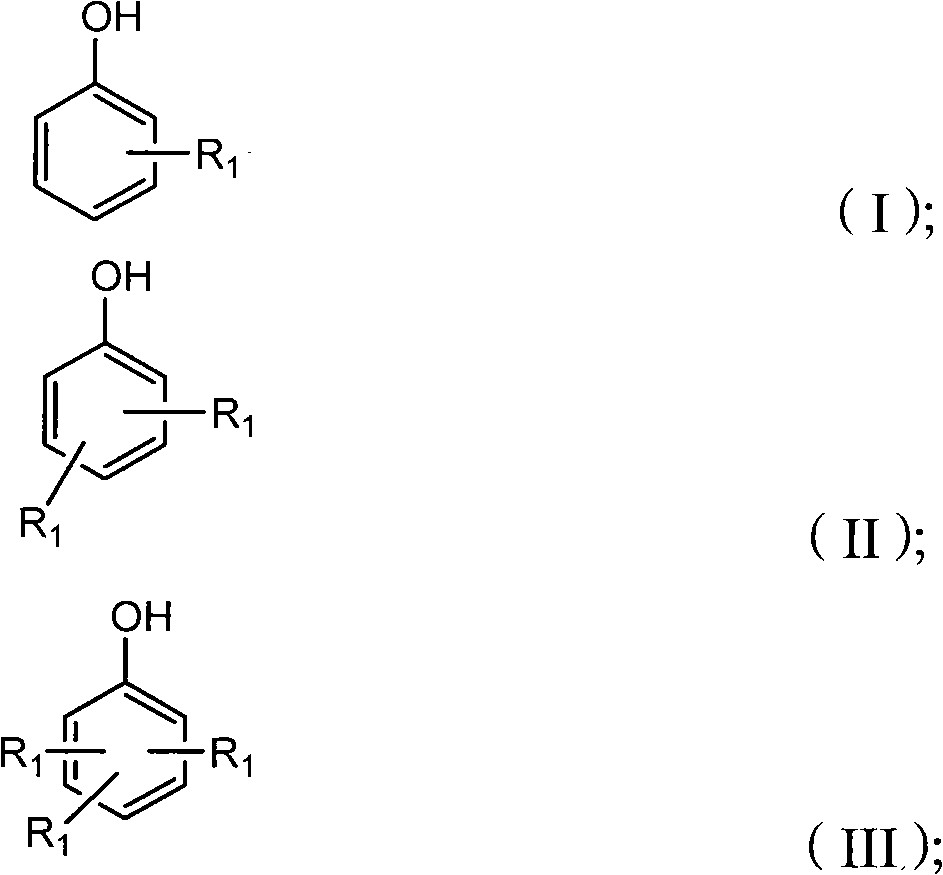

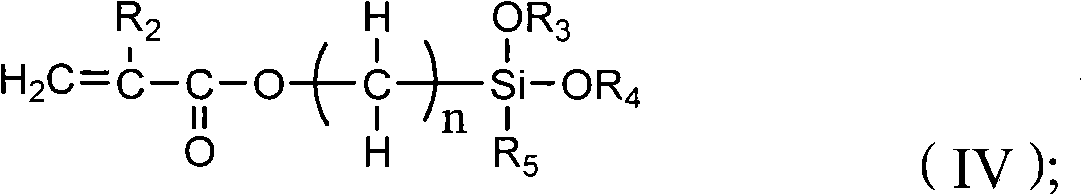

InactiveCN101565502ASimple preparation stepsLow costCobalt organic compoundsEpoxyBulk polymerization

The invention relates to a catalyst for copolymerization of carbon dioxide and epoxy compounds, a preparation method and applications thereof. The structural formula of the catalyst is compound (I) at the right side, wherein X refers to halogen, nitrate radical, azide group or trifluoroacetic acid group; R1 is 1, 2-site disubstituted cyclohexyl or 1, 2-site disubstituted 1, 2-diphenyl-ethyl; R2 is N substituted pyrrolidine, piperidyl, morpholinyl, dibutylamine or 4- methylamino-pyridyl; R3 is tert-butyl group. The preparation method of the catalyst for the copolymerization of carbon dioxide and epoxy compounds comprises the two preparation steps of a ligand and the catalyst. The catalyst preparation method has simple preparation steps, low cost and good catalysis efficiency and product selectivity. Under the noumenon polymenrism or the solution polymenrism, the carbon dioxide and epoxy compounds are polymerized under the lower polymenrism of carbon dioxide (optimal pressure is 30 atm) and simultaneously the copolymer with the content of the polycarbonate unit of more than 98% and the catalyst with the catalytic efficiency of 60-214g polymer / g are obtained.

Owner:HEBEI UNIV OF TECH

Environmental protective diesel oil, and preparation method

This invention relates to environmentally friendly diesel oil, which is composed of: diesel oil 13-20 parts, water 15-30 parts, plant oil 20-25 parts, methanol 8-11 parts, kerosene 10-30 parts, and composite additive 5-8 parts. The composite additive is composed of: triton X-100 2.0-2.65 parts, ethanolamine 1.5-3 parts, NaOH 14-16 parts, 99.5% ammonia solution 50-55 parts, n-butylamine 5.0-6..0 parts, isopropane 18-21 parts, water 2.0-2.3 parts, and cetane 0.2-1.0 parts. The environmentally friendly diesel oil is prepared in a raw material tank, an aid tank, a product tank, a sealing device, a high-energy static magnetic device and pipelines. This invention solves the problems of low stability, easy separation of oil and water, large amount of emulsifier, high price and difficult transportation faced by present W / O emulsified diesel oil, and has such advantages as abundant raw materials and wide applications.

Owner:陈志红

Ultraviolet thick-film photoresist and film-forming resin thereof

The invention discloses an ultraviolet thick-film photoresist. The photoresist is mainly prepared by the following steps of: mixing 10 to 35 parts of phenolic resin, 1 to 10 parts of silicon-containing copolymer film-forming resin, 5 to 20 parts of diazo naphthoquinone light-sensitive compound, 30 to 85 parts of solvent and a small number of other additives such as n-butylamine and a surfactant serving as raw materials; and filtering the mixture by using 5-micron, 1-micron and 0.2-micron filters. In a thick-film ultraviolet exposure positive photoresist which is applied to the embossing process of advanced packaging and the manufacturing of micro electro mechanical systems (MEMS) and is prepared by the invention, a one-step film thickness uniform adhesive spinning piece is up to 1 to 20 microns and a multi-step film thickness uniform adhesive spinning piece is up to 50 to 100 microns as required.

Owner:SUZHOU RUIHONG ELECTRONIC CHEM CO LTD

Continuous production process of N-normal-butyl thiophosphoryl triamide

ActiveCN103524551AEasy accessReduce lossesGroup 5/15 element organic compoundsAmmonium halidesThio-Reaction temperature

The invention discloses a continuous production process of N-normal-butyl thiophosphoryl triamide. Mixture of thiophosphoryl chloride and organic solvent and mixture of n-butyl amine, tertiary amine acid-binding agent and organic solvent are respectively input in a Y-type jet flow mixing device to be rapidly mixed, then the mixture enters a first tubular reactor and an amination reaction is conducted, an obtained reaction solution is pre-heated, and enters a second tubular reactor, ammonia gas is added, the amination reaction is conducted, and finally the N-normal-butyl thiophosphoryl triamide is obtained through separation and purification. According to the continuous production process of the N-normal-butyl thiophosphoryl triamide, proper solvent and acid-binding agent are selected, proper reaction temperature is selected, and therefore the purpose that the amination reaction is continuously conducted in a pipeline without added pressure is achieved. The continuous production process of the N-normal-butyl thiophosphoryl triamide has the advantages that production efficiency is high, reaction condition can be controlled easily, yield is high, quality is high, discharge amount of the three wastes is small, resources are sufficiently used, and the continuous production process of the N-normal-butyl thiophosphoryl triamide is suitable for large-scale industrialized production.

Owner:江西吉翔医药化工有限公司

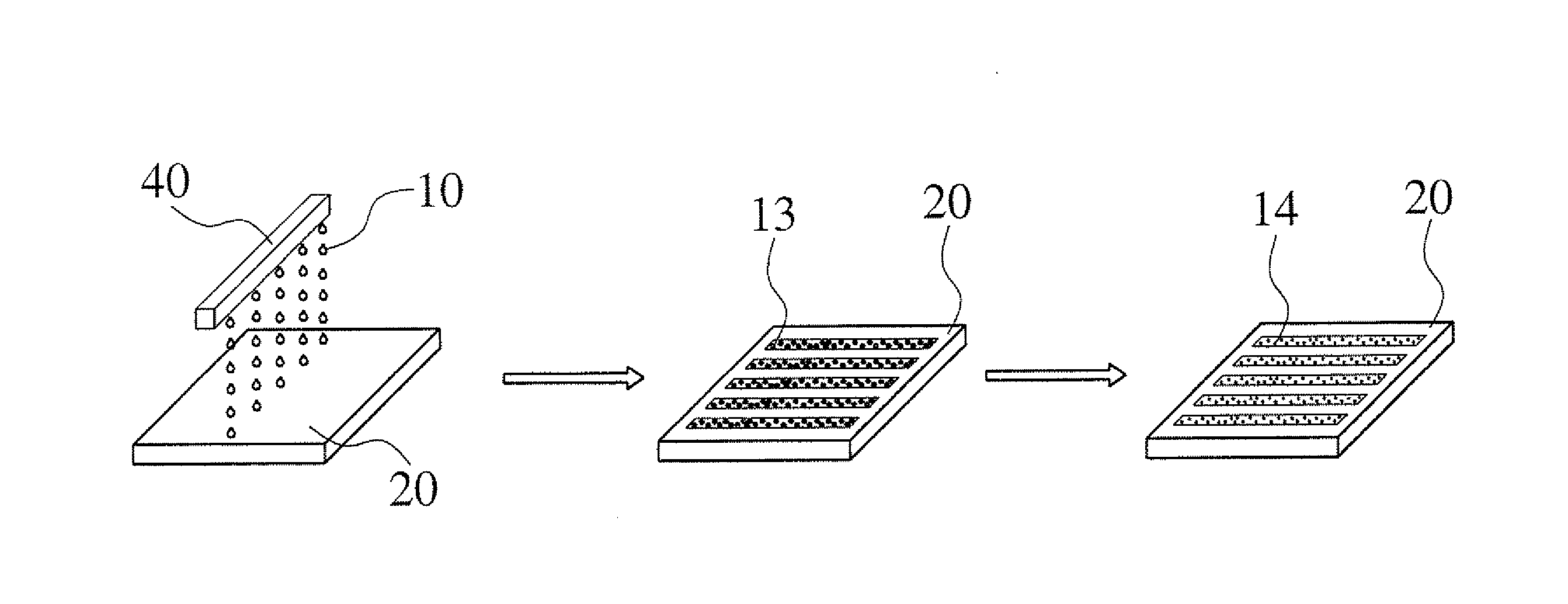

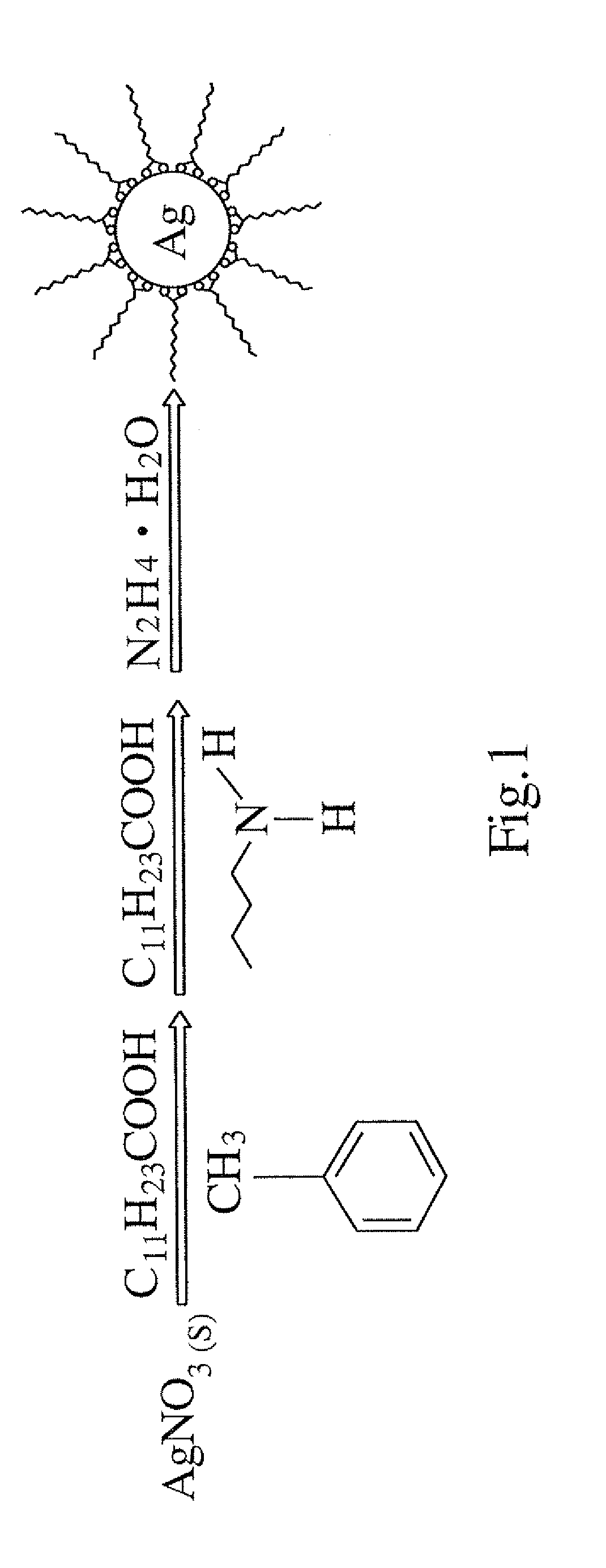

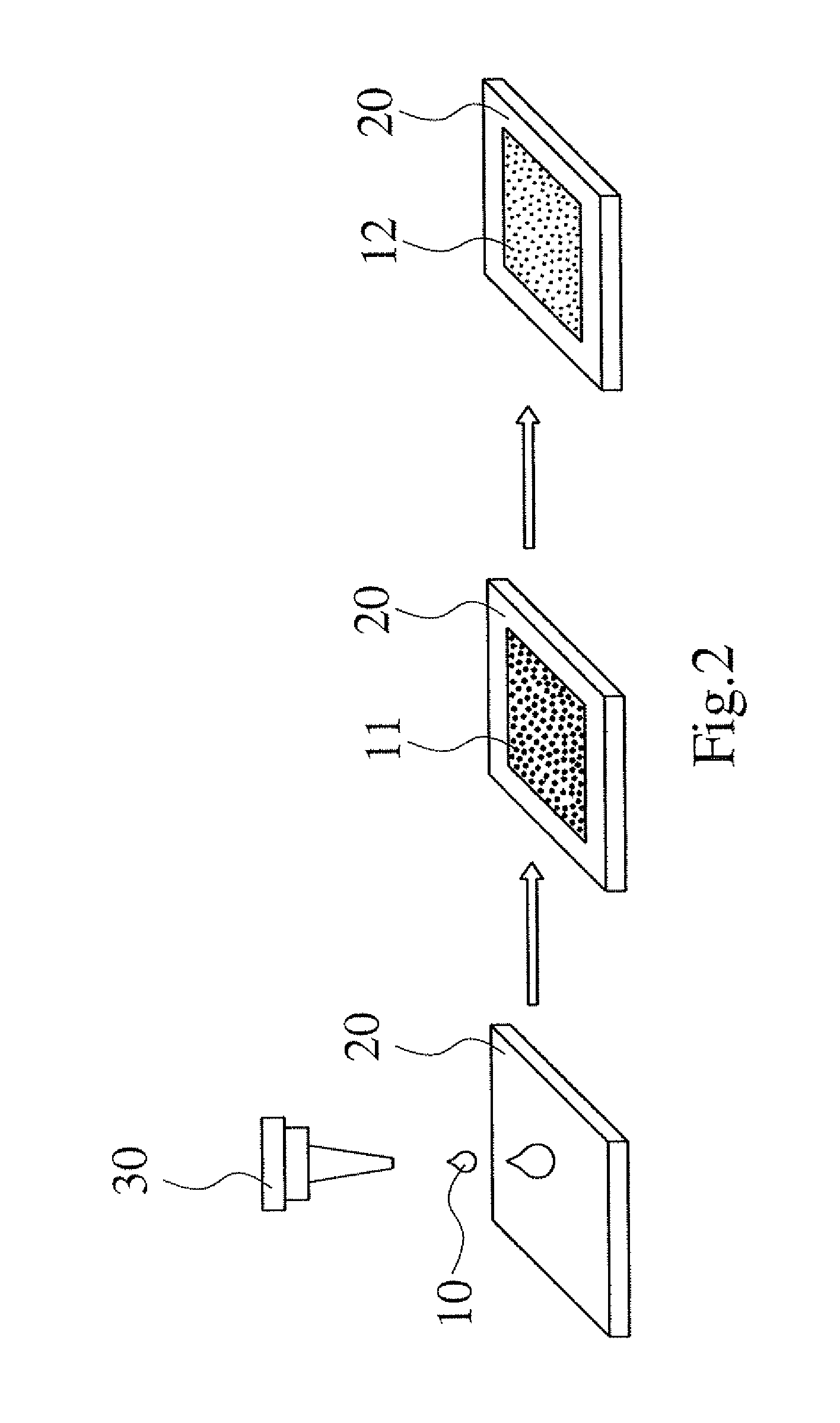

Method for forming conductive film at room temperature

InactiveUS20140161972A1Conveniently and rapidly printHigh application potentialSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingSolventN-Butylamine

A method for forming a conductive film at room temperature is provided and includes steps of: adding AgNO3 into a first solution of dodecanoic acid; dropping n-butylamine and a diluted aqueous solution of a reducing agent into the first solution in turn, so as to initially obtain the dodecanoate-protected silver nanoparticles as a capping ligand; then using cyclohexane as a solvent to apply the silver nanoparticles onto a surface of a substrate to form a patterned film of silver nanoparticles; and finally immersing the substrate into a high concentrated aqueous solution of a reducing agent to chemically reduce the patterned film of silver nanoparticles into a conductive silver film. Thus, a patterned film or circuit can be conveniently and rapidly formed, and the silver nanoparticles can be applied to flexible substrates with low material cost and temperature sensitivity.

Owner:NAT SUN YAT SEN UNIV

High-silicon composite molecular sieve adsorbent for removing VOCs and preparation method of high-silicon composite molecular sieve adsorbent

ActiveCN111408342AGood for desorption stabilityImprove adsorption capacityGas treatmentOther chemical processesMolecular sieveGlass fiber

The embodiment of the invention discloses a high-silicon composite molecular sieve adsorbent for removing VOCs and a preparation method thereof. The preparation method comprises the following steps: mixing an aluminum source I, an alkali source I and H2O, adding the mixture into a silicon source I, and carrying out ultrasonic aging treatment to obtain a Y-type molecular sieve guiding agent; mixingH2O, an alkali source II and an aluminum source II, adding n-butylamine and a silicon source II, carrying out a crystallization reaction under the microwave condition to obtain ZSM-5 crystallizationturbid liquid; adding a Y-type molecular sieve guiding agent, an aluminum source III and H2O into the ZSM-5 crystallization turbid liquid, adjusting the pH value to 12-12.5, performing hydrothermal crystallization treatment under a microwave condition, performing filtration and water washing after crystallization is completed to obtain a filter cake, and performing pulping treatment on the filtercake to obtain an emulsion; carrying out acid pickling on the emulsion, and then sequentially carrying out filtering, washing, drying and hydrothermal roasting treatment to obtain high-silicon composite molecular sieve powder; stirring the prepared powder with glass fibers, silica sol and H2O at a high speed to obtain mixed slurry, performing vacuum degassing, and performing spray molding to obtain the high-silicon composite molecular sieve adsorbent.

Owner:BEIJING LONGTAO ENVIRONMENTAL TECH CO LTD

Boron-nitride-type borate lubricating oil additive and preparation method thereof

InactiveCN104017009ASimple production processReduce manufacturing costGroup 3/13 element organic compoundsAdditivesOil additiveBoron nitride

The invention discloses a boron-nitride-type borate lubricating oil additive and a preparation method thereof. The preparation method comprises the following steps: putting tall oil and diethanolamine in a container, and reacting at 100-120 DEG C for 4-5 hours to obtain tall oil acetal amide; mixing salicylaldehyde and n-butylamine, adding ethanol, reacting at 50-60 DEG C in a reflux unit for 2-3 hours, adding the prepared tall oil acetal amide, adding boric acid, and uniformly mixing; reacting at 70-80 DEG C for 1-1.5 hours while keeping the pressure stable at 260-270 mmHg; depressurizing to the stable pressure of 60-70 mmHg, gradually heating to 90-100 DEG C, and reacting for 3-4 hours; and cooling, and filtering to obtain the light yellow liquid. The production method is simple, and has the advantages of low cost, high hydrolysis resistance of the product, high yield and environment friendliness.

Owner:TIANJIN SURENERGY CHEM

Synthesis method for 2-butyl-1, 2-benzisothiazolin-3-ketone

InactiveCN103664817AReduce process stepsReduce process generation costsOrganic chemistryBenzoic acidOrganic solvent

The invention belongs to the technical field of fine chemicals, and particularly relates to a synthesis method for 2-butyl-1, 2-benzisothiazolin-3-ketone. The specific steps are as follows: (1) o-(methylthio) benzoic acid reacts with acyl chloride agent, so that o-(methylthio) benzoyl chloride is obtained, wherein the molar ratio of the o-(methylthio) benzoic acid to the acyl chloride agent is 1:1.05 to 1:2, preferably 1:1.2 to 1:1.5; (2) the o-(methylthio) benzoyl chloride reacts with n-butylamine, so that corresponding amide compound is obtained, wherein the molar ratio of the o-(methylthio) benzoyl chloride to the n-butylamine is 1:1.1 to 1:2.5, preferably 1:1.2 to 1:1.8; (3) in organic solvent, the amide compound and halogenating agent conduct ring-closure reaction, so that the target product, 2-butyl-1, 2-benzisothiazolin-3-ketone, is obtained, wherein the synthesis method also includes the steps of washing, recovery and distillation after the reaction between the amide compound and the halogenating agent. Compared with the prior art, the synthesis method overcomes the defects of conventional processes, the process steps are greatly reduced, the process-produced cost is reduced, moreover, the quality of the product is good, the three wastes are little, and the synthesis method has certain industrial value and is worth popularizing and applying.

Owner:SHOUGUANG SYNTECH FINE CHEM

Golf ball

InactiveUS20070073031A1Improve wear resistancePolyurea/polyurethane coatingsGolf ballsPolyolChemical compound

In a golf ball composed of a core and one or more cover layers which enclose the core, at least one cover layer is made primarily of a thermoplastic polyurethane obtained by a polyurethane forming reaction of an organic polyisocyanate compound with a long-chain polyol and a chain extender, and satisfies conditions (1) to (3) below: (1) the long-chain polyol includes a copolymeric polycarbonate polyol having a number-average molecular weight of 400 to 4,000; (2) the thermoplastic polyurethane present in the cover material (after molding) has an inherent viscosity, as measured in DMF, of more than 1.5 dl / g; and (3) the thermoplastic polyurethane present in the cover material (after molding) has an inherent viscosity, as measured in a DMF solution containing 0.05 mol / L of n-butylamine, of at least 0.5 dl / g. The golf ball has an improved scuff resistance, particularly an improved low-temperature scuff resistance.

Owner:KURARAY CO LTD

Process for preparing butyl isocyanate

ActiveCN1844091AReduce side effectsImprove conversion rateIsocyanic acid derivatives preparationOrganic compound preparationCarbonyl chlorideDistillation

The invention discloses a Method for preparation of butylisocyanate, using n-butylamine as raw materal, dimethylbenzene as dissolvant, reacting with excess carbonyl chloride, getting the product which the purity is higher than 99% after two steps photo aerification reaction of low-temperature, high-temperature and distillation. Adopting two steps photo aerification reaction of low-temperature, high-temperature can reduce occurrence of secondary reaction effectly. In n-butylamine terms, the total yield of this invention is more than 95%.

Owner:JIANGSU ANPON ELECTROCHEM

Preparation method for bisphenol A hydrogenated catalyst

ActiveCN106563447AImprove performanceHigh activityPreparation by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsN-ButylamineChemistry

The invention relates to a preparation method for a bisphenol A hydrogenated catalyst. The preparation method comprises the steps that after a catalyst carrier is processed through a template agent, liquid RhCl3 is atomized and loaded onto the porous catalyst carrier, and after high-temperature reduction is conducted in the hydrogen atmosphere, the load type hydrogenated catalyst is obtained. The hydrogenated catalyst carrier is selected from one of Al2O3, TiO2 and SiO2. The template agent is selected from one of pyrrolidine, ethylenediamine and n-butylamine. According to the preparation method, the active component Rh is sprayed on the porous carrier in a vaporific mode, the obtained load type catalyst containing 1-10% of the Rh is suitable for hydrogenation of benzene rings and especially has good activity for preparing hydrogenated bisphenol A through bisphenol A hydrogenation; the aim product selectivity is good, and moreover, compared with a Ru system, the reaction load is improved by 30-50%; and the catalyst life still has the high activity after operation for 2000 hours.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com