Continuous production method for N-NBPT

A technology of n-butyl thiophosphoric triamide and production method, which is applied in the field of continuous production of N-n-butyl thiophosphoric triamide, can solve the problems of low recovery rate, high odor of triethylamine and high production efficiency Low and other problems, to achieve the effect of mild reaction conditions, easy industrial production, and slow reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

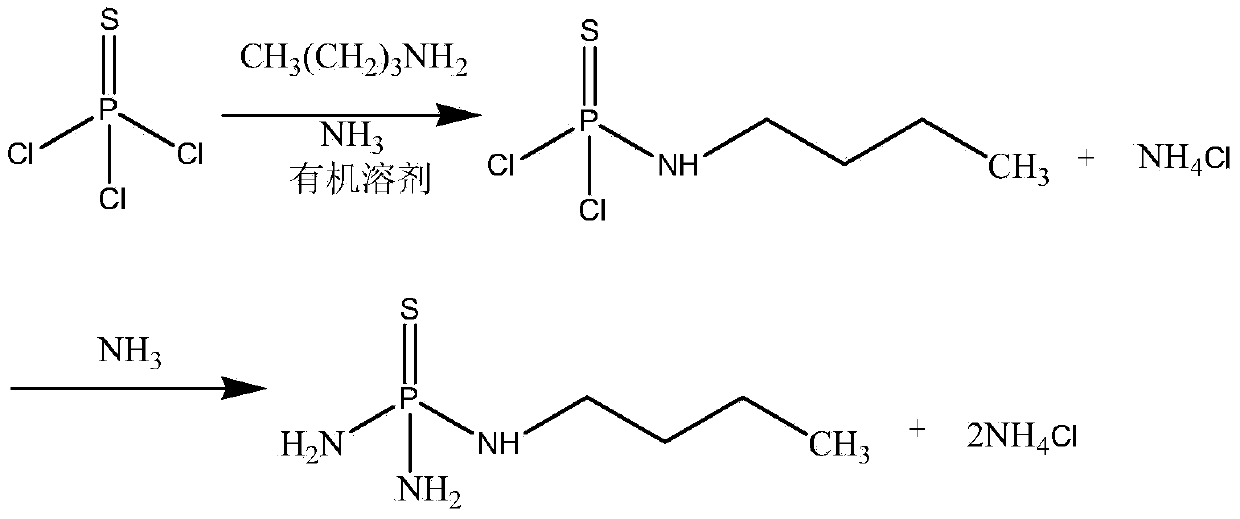

Method used

Image

Examples

Embodiment 1

[0031] (1) Add 225 grams (1.33 moles) of phosphorus trichloride and 1360 grams (16.0 moles) of dichloromethane into a four-necked flask, stir and cool to -5°C, add 100 grams (1.37 moles) of n-butylamine and 50 G (0.58 mol) of methylene chloride was mixed uniformly and alternately added dropwise with 100 g (1.32 mol) of concentrated ammonia water to the above solution, keeping at -5°C. After the addition is complete, keep it at -5°C for 2 hours and the reaction is over.

[0032] (2) The reaction solution obtained in step (1) is filtered and separated into layers, and the lower organic phase is reacted with 5.32 moles of ammonia gas at 10° C., the reaction is terminated when the pH is greater than 8.5, and centrifugal filtration is performed.

[0033] (3) Concentrate the obtained liquid phase to 40% for cooling and crystallization. The product after centrifugation is 152 grams, with a content of 97.2%. Then 152 grams of product was added to 300 grams of dichloromethane to dissolve a...

Embodiment 2

[0035] Add 450 grams (2.66 moles) of phosphorus trichloride and 1130 grams (13.3 moles) of dichloromethane to a four-necked flask, stir and cool to -10°C, mix 200 grams (2.74 moles) of n-butylamine and 1000 grams (11.7 moles) of n-butylamine. Mol) dichloromethane is mixed uniformly and added dropwise to the above solution with 210 grams (2.75 moles) of concentrated ammonia water at the same time, keeping it at 0°C, after the dropwise addition is complete, keep it at 5°C for 3 hours and the reaction is over.

[0036] (2) The reaction solution obtained in step (1) is filtered and separated into layers, and the lower organic phase is reacted with 10.2 moles of ammonia gas at 25°C, and the reaction is terminated when the pH is greater than 9, and centrifugal filtration is performed.

[0037] (3) Concentrate the obtained liquid phase to about 50% for cooling and crystallization. The product after centrifugation is 315 grams, with a content of 97.2%. Then add 315 grams of product to 600 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com