Synthetic method of high silica ZSM-5 zeolite

A technology of ZSM-5 and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of high production cost, reduce the amount of template agent, and high price, and achieve The effect of cheap raw materials and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

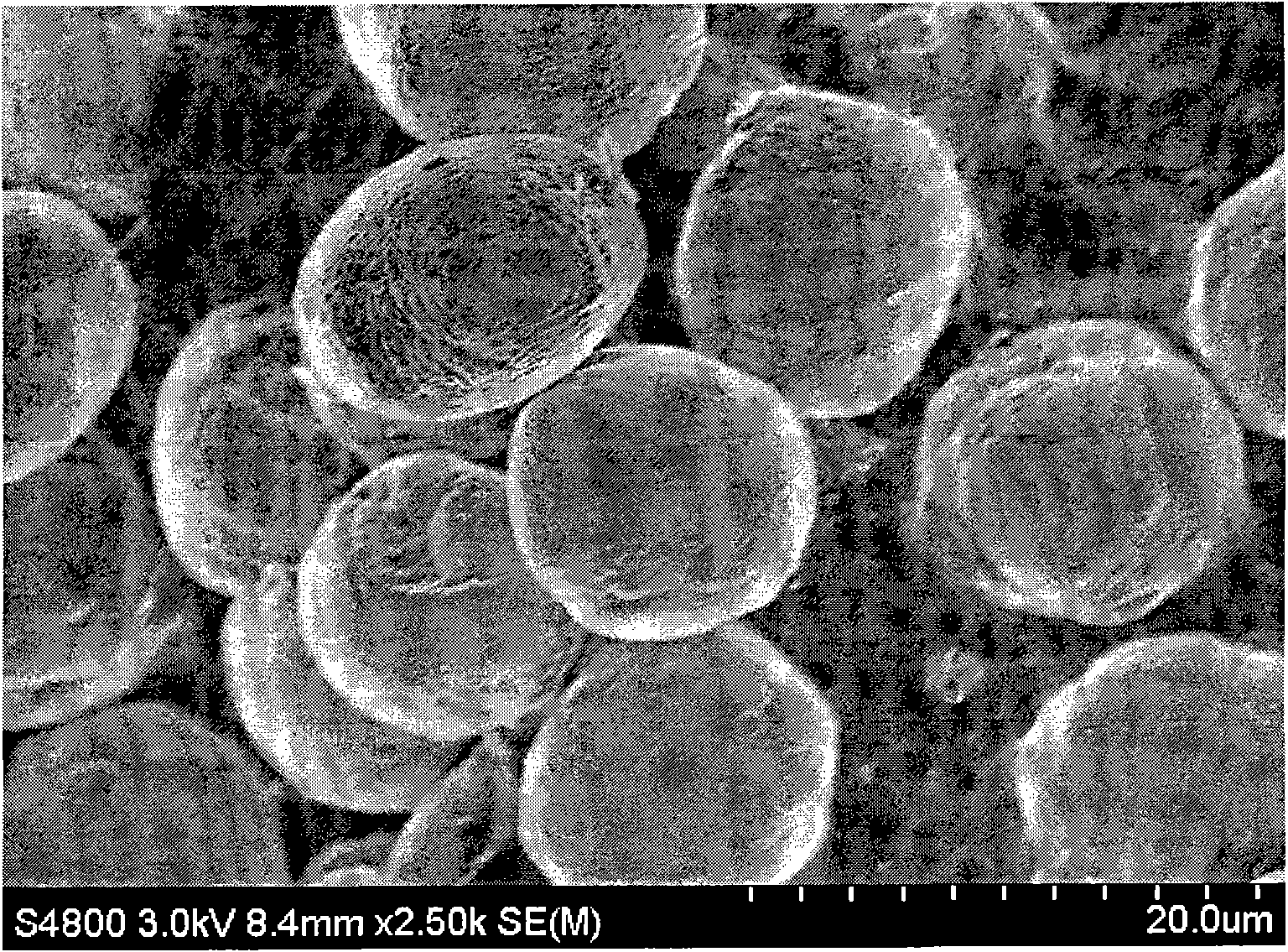

[0021] The guide glue used is the same as in Comparative Example 2; 0.76 grams of aluminum sulfate octadecahydrate and 13 milliliters of 4.0mol L -1 Sulfuric acid was dissolved in 47 grams of water, and the solution was slowly added dropwise to 58.8 grams of water glass (silicon dioxide, 20.4%; sodium oxide, 6.9%), and 0.029 grams of guiding glue and 0.93 grams of organic template tetrapropylammonium bromide were added. g (SiO 2 / Al 2 o 3 =150,Na 2 O / SiO 2 =0.05,H 2 O / SiO 2 =30,TPA + / SiO 2 =0.0175), after being mixed uniformly, it was crystallized at 175° C. for 24 hours, and its relative crystallinity (relative to comparative example 1) was measured to be 98%, and its morphology and particle size were as follows: image 3 As shown, it is dispersed ZSM-5 zeolite particles with a size of 1-1.5 microns, and its SiO is determined by inductively coupled plasma atomic emission spectrometry 2 / Al 2 o3 The ratio is 123.

Embodiment 2

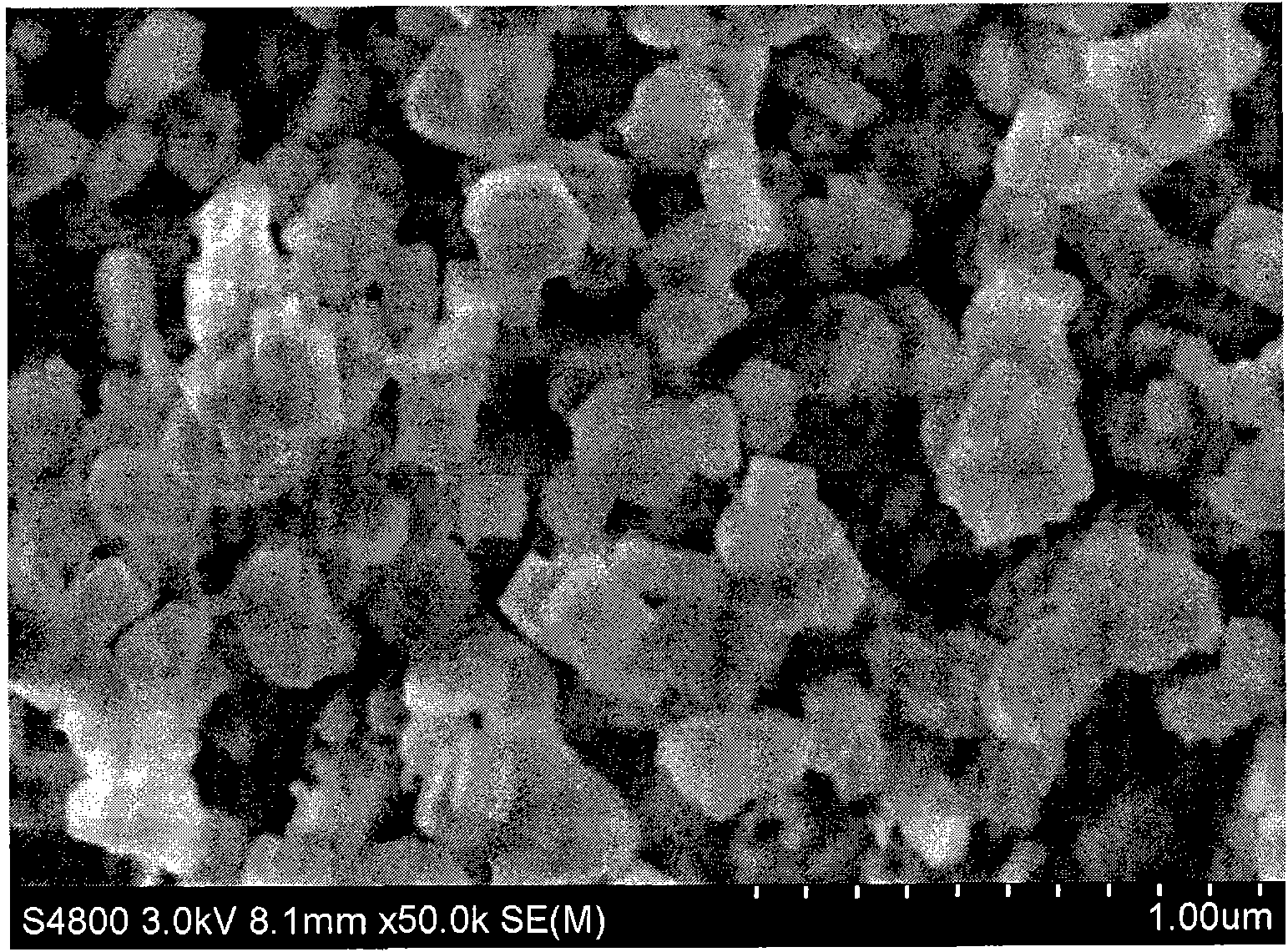

[0023] Use the same guide glue as in Comparative Example 2; mix 0.76 grams of aluminum sulfate octadecahydrate and 13 milliliters of 4.0mol L -1 Sulfuric acid was dissolved in 47 grams of water, and the solution was slowly added dropwise to 58.8 grams of water glass (silicon dioxide, 20.4%; sodium oxide, 6.9%), and 0.264 grams of guiding glue and 0.93 grams of organic template tetrapropylammonium bromide were added. g (SiO 2 / Al 2 o 3 =150,Na 2 O / SiO 2 =0.05,H 2 O / SiO 2 =30,TPA + / SiO 2 =0.0182), after being mixed uniformly, it was crystallized at 175° C. for 24 hours, and its relative crystallinity (relative to Comparative Example 1) was measured to be 102%, and the particle size of dispersed ZSM-5 was 0.5 to 0.6 microns.

Embodiment 3

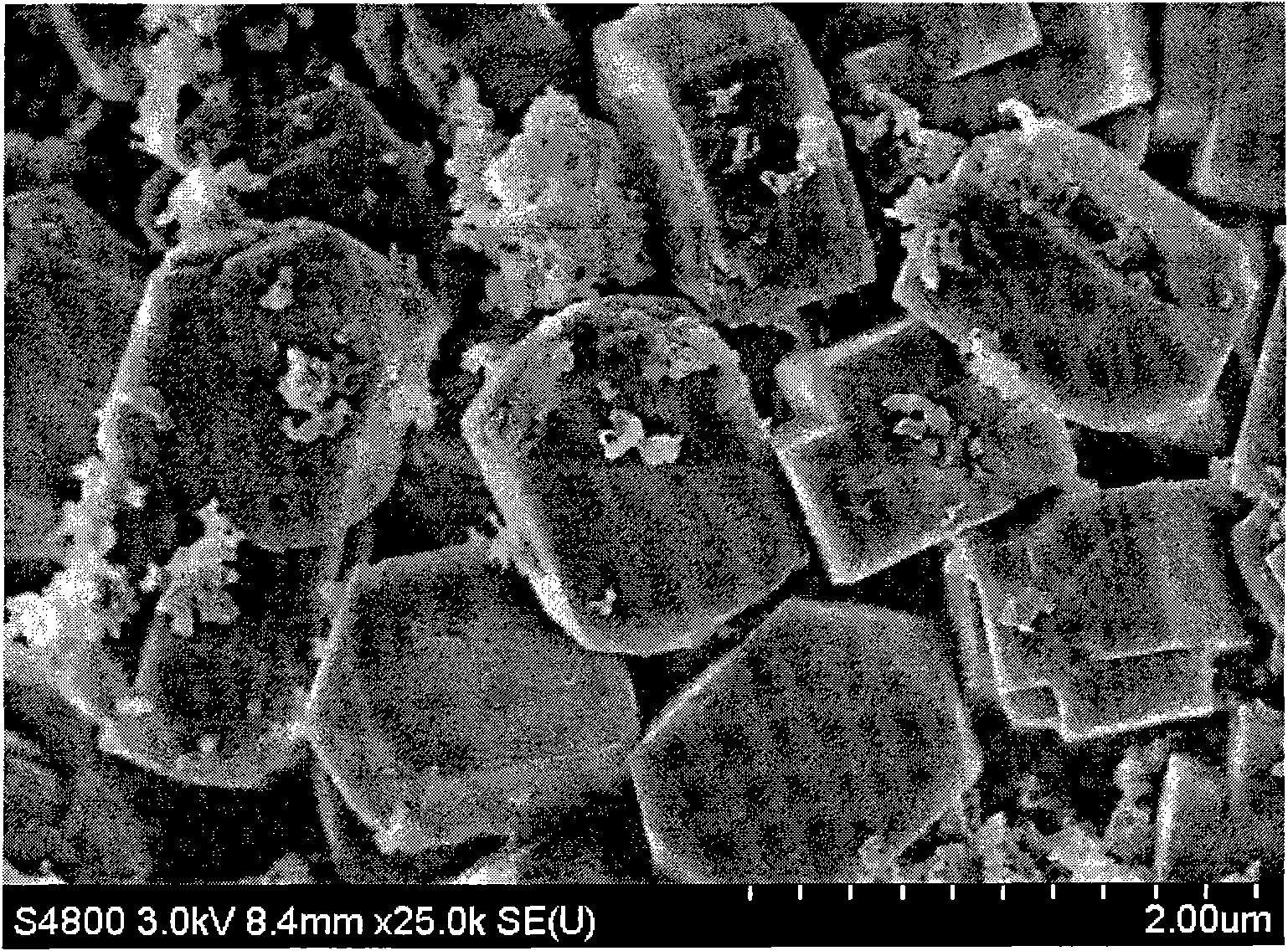

[0025] Preparation of guide gel B: 30.0 g of silica sol (30.0%) and 42.7 g of tetrapropylammonium hydroxide (25.0% aqueous solution) were evenly mixed, and then aged at 80° C. for 3 days to obtain the desired guide gel B. The molar ratio of the directing agent is SiO 2 :0.35TPAOH:20H 2 O.

[0026] 0.47 g of aluminum isopropoxide and 13.8 ml of 4.0mol L -1 Sulfuric acid was dissolved in 47 grams of water, and the solution was slowly added dropwise to 58.8 grams of water glass (silicon dioxide, 20.4%; sodium oxide, 6.9%), adding 0.193 grams of the above guide glue and organic template agent tetrapropylammonium bromide 0.93 g (SiO 2 / Al 2 o 3 =175,Na 2 O / SiO 2 =0.05,H 2 O / SiO 2 =30,TPA + / SiO 2 =0.0182), after being mixed uniformly, crystallize at 175 DEG C for 24 hours to obtain the product ZSM-5 zeolite, and measure its relative crystallinity (comparative example 1) to be 102%, and the sample is dispersed ZSM-5 zeolite particles with a size of 2.5 ~ 3.0 microns, ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com