Patents

Literature

108results about How to "Controllable particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

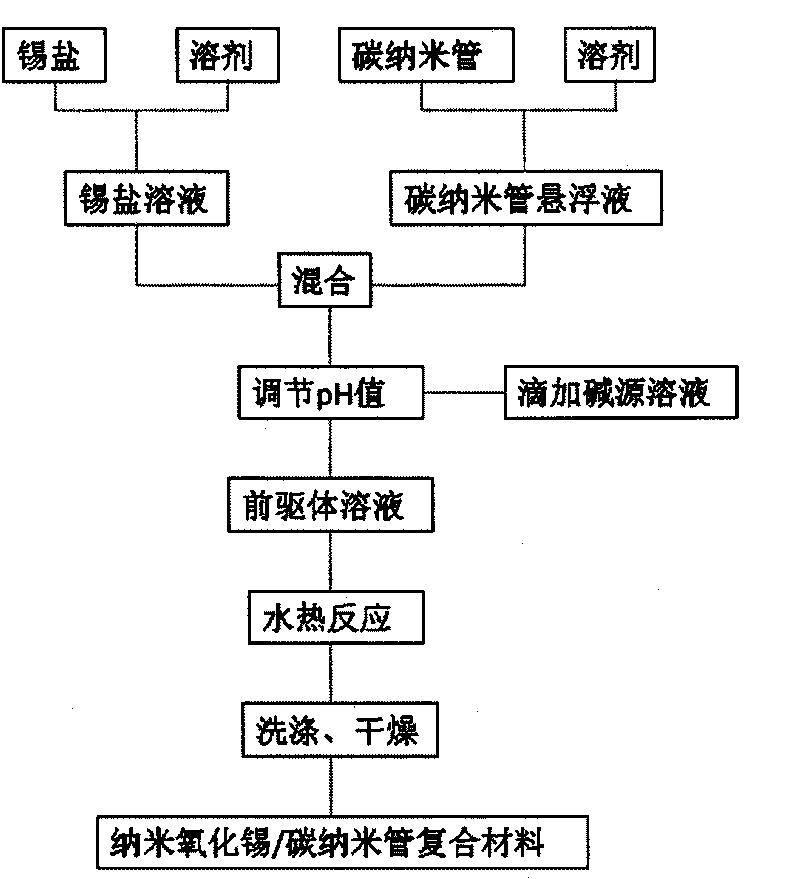

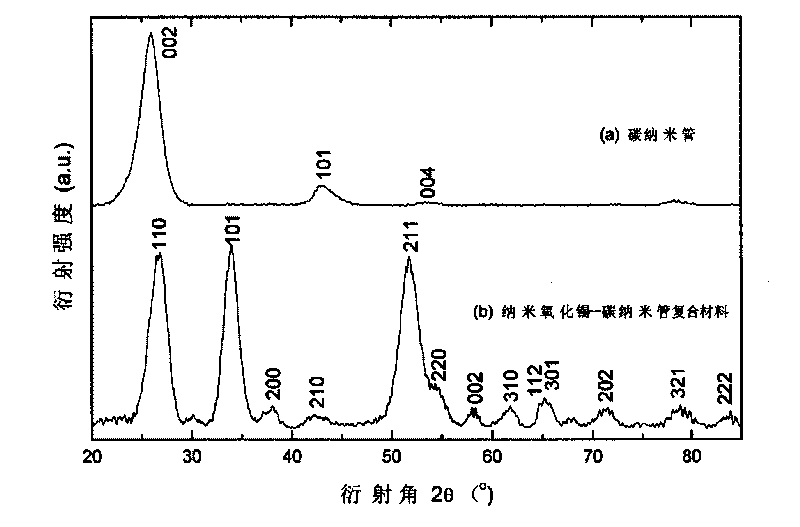

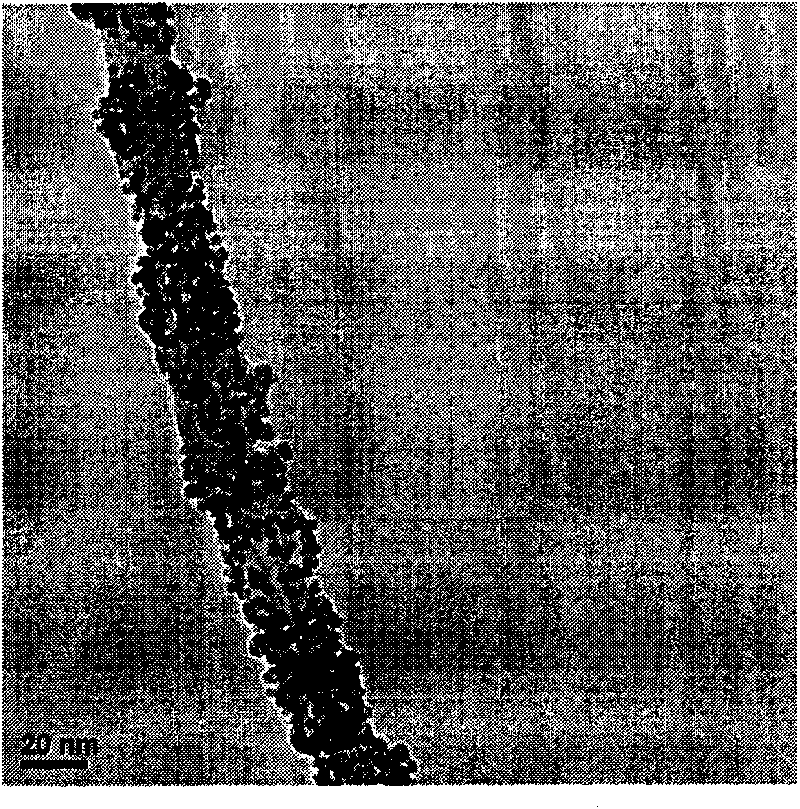

In-situ synthesis method for nano tin dioxide/carbon nano tube composite material

InactiveCN101704504AControllable particle sizeShape is easy to controlNanostructure manufactureTin dioxideSynthesis methods

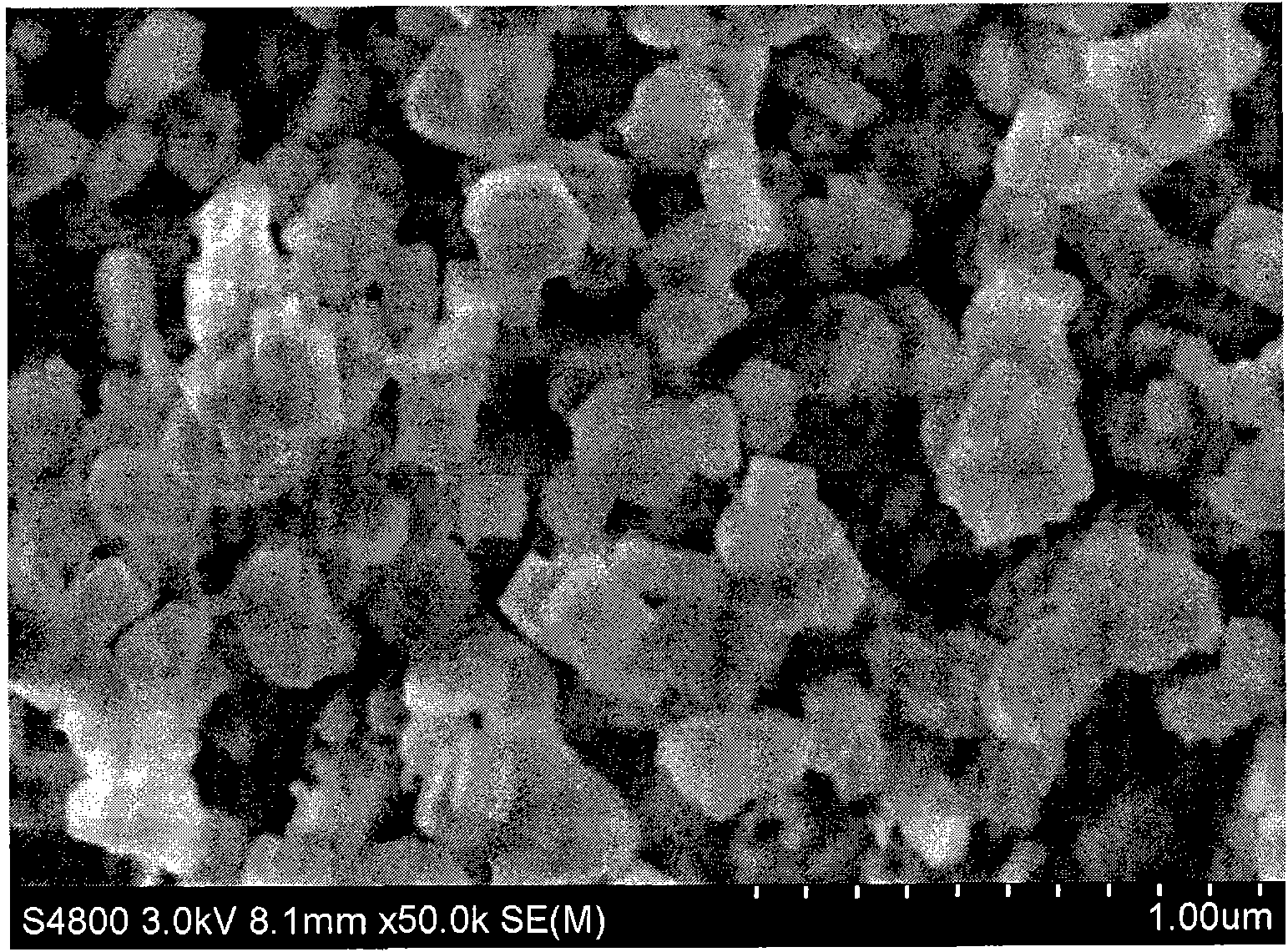

The invention discloses an in-situ synthesis method for a nano tin dioxide / carbon nano tube composite material, which mainly uses an inorganic tin salt, a carbon nano tube and an alkali source as raw materials. The experimental process mainly comprises the steps of precursor preparation, hydrothermal reaction, precipitate washing and drying and the like. The in-situ synthesis method for the nano tin dioxide / carbon nano tube composite material has the advantages that: a hydrothermal method is adopted to realize the in-situ deposition and the growth of the nano tin dioxide on the surface of the carbon nano tube; the obtained SnO2 nano particles have small and uniform particle size (less than 10nm), are well-crystallized, are uniformly coated on the surface of the carbon nano tube, and are tightly combined with the carbon nano tube; the composite material has potential application prospect in the aspects of a gas sensor material, an anode material of a lithium ion battery and the like. The method has no addition of any surface active agent, has simple and easily-obtained materials, simple process without pollution, short preparation period, mild reaction condition and low cost, and is suitable for large-scale production, so the method is an environment-friendly synthesis method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

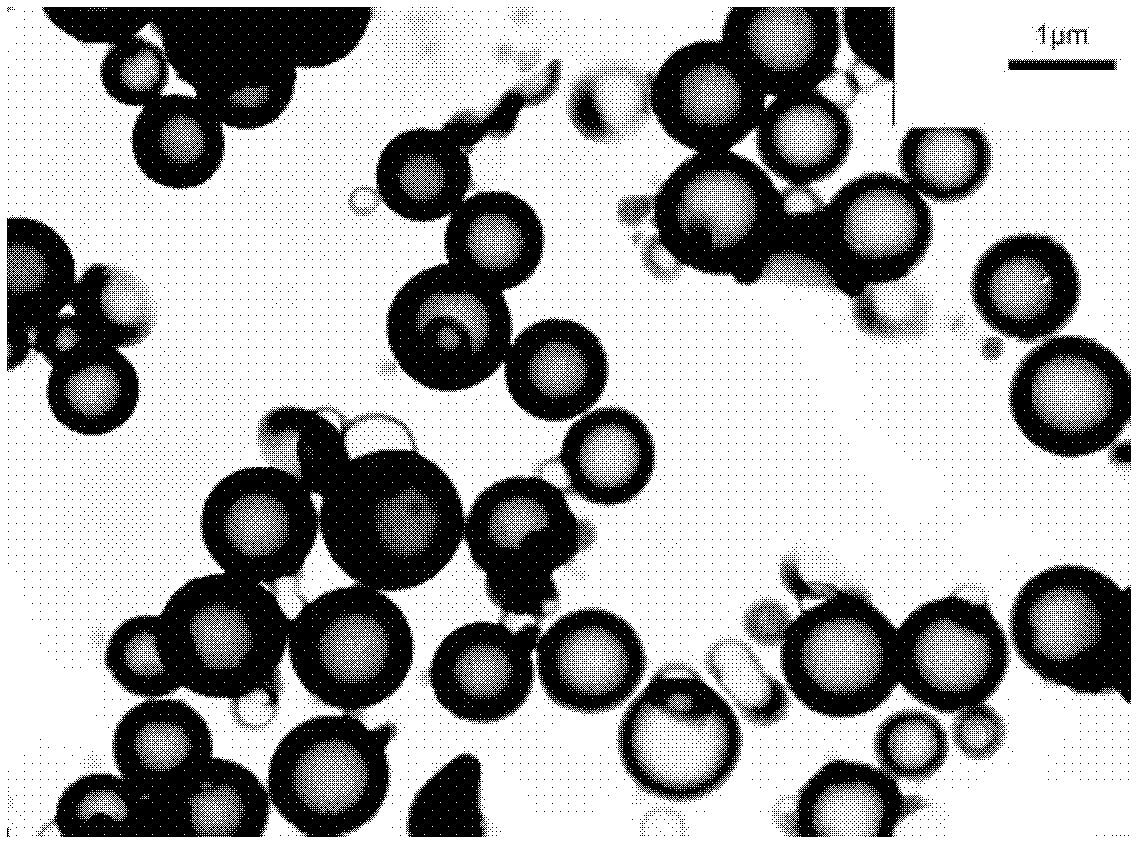

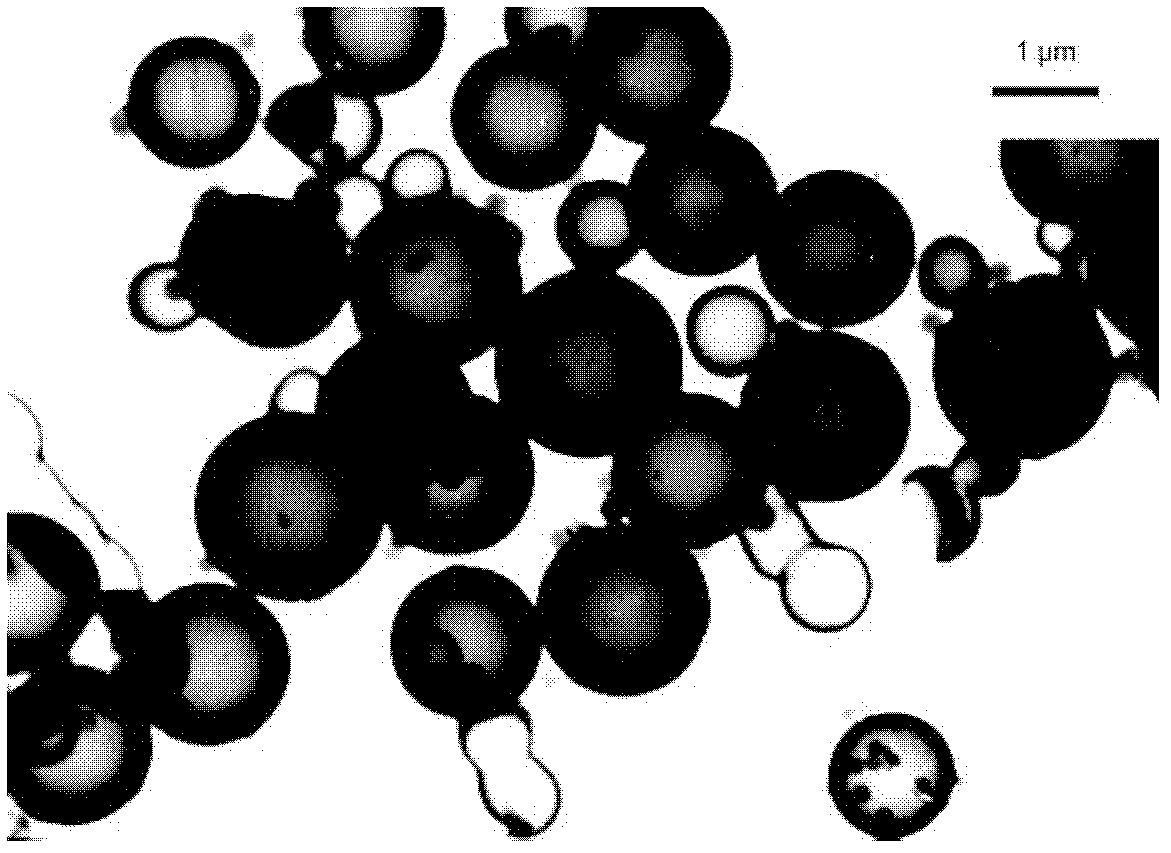

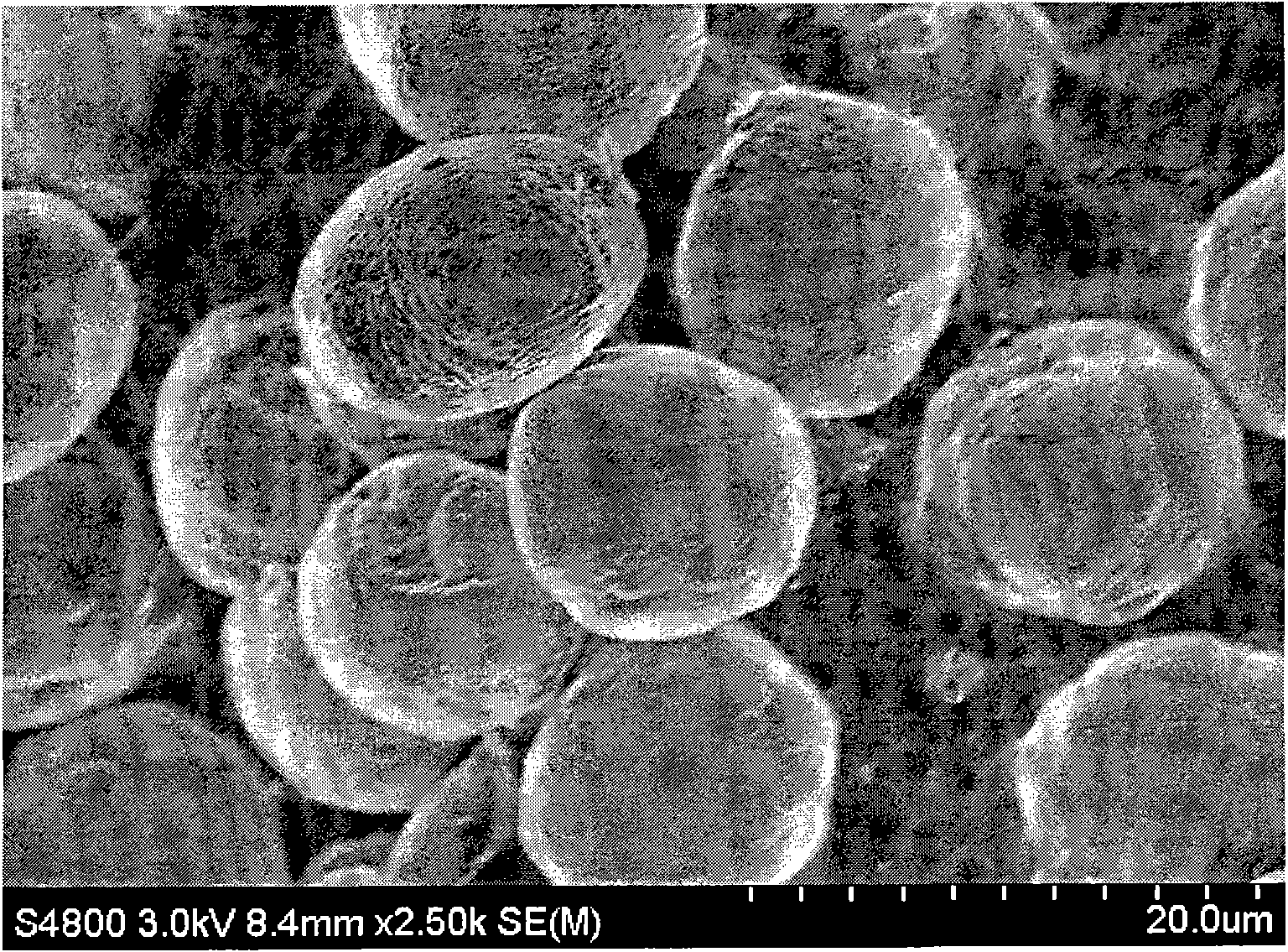

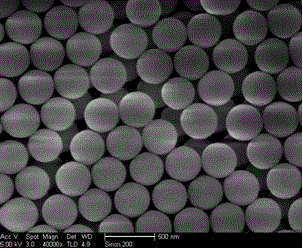

Preparation method of polysilsesquioxane hollow microspheres

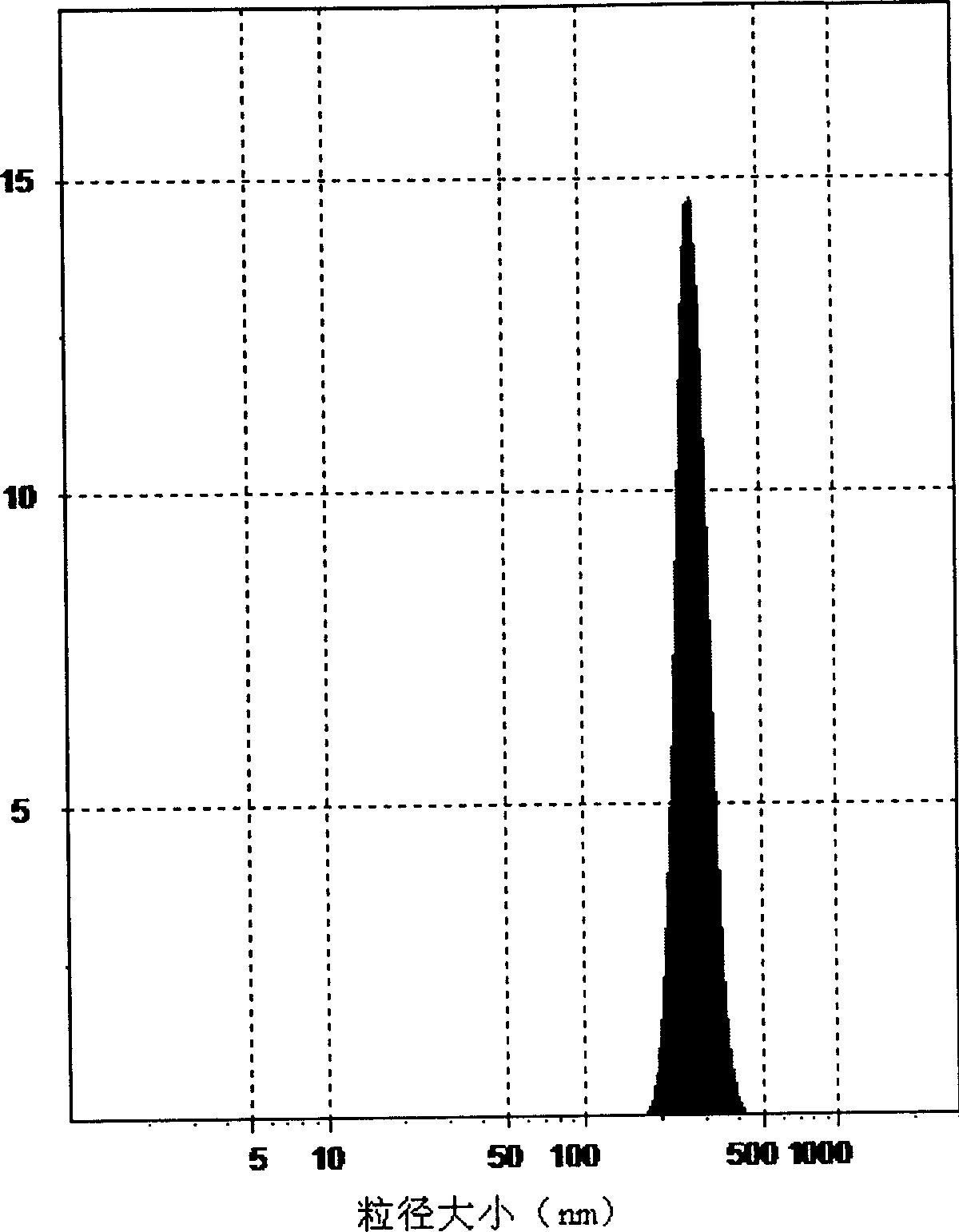

The invention relates to a preparation method of polysilsesquioxane hollow microspheres. In the method, a trifunctional silane monomer is used as a raw material, an organic solvent is used as a template and the polysilsesquioxane hollow microspheres are prepared by utilizing the oil-in-water (O / W) suspension polymerization. According to the invention, the raw material is easy to obtain, the reaction condition is mild, the method is simple and convenient to operate, the step of removing a template core does not need to be carried out, and the cost is low. The hollow microspheres prepared by the method disclosed by the invention are white powder particles, have a polysilsesquioxane organic-inorganic hybrid material as a component, have low density and good mechanical strength, do not contain a surfactant, have physiological inert and can be loaded with object molecules. The particle sizes of the polysilsesquioxane hollow microspheres can be controlled in the range of 200nm to 5.0mum. The polysilsesquioxane hollow microspheres can be used as high-end packing, light scattering particles, a medicament and catalyst carrier, a microreactor and the like and are widely used for the fields of chemical industry, cosmetics, catalysis, separation, medicinal preparation, environmental protection and the like.

Owner:SHANDONG UNIV

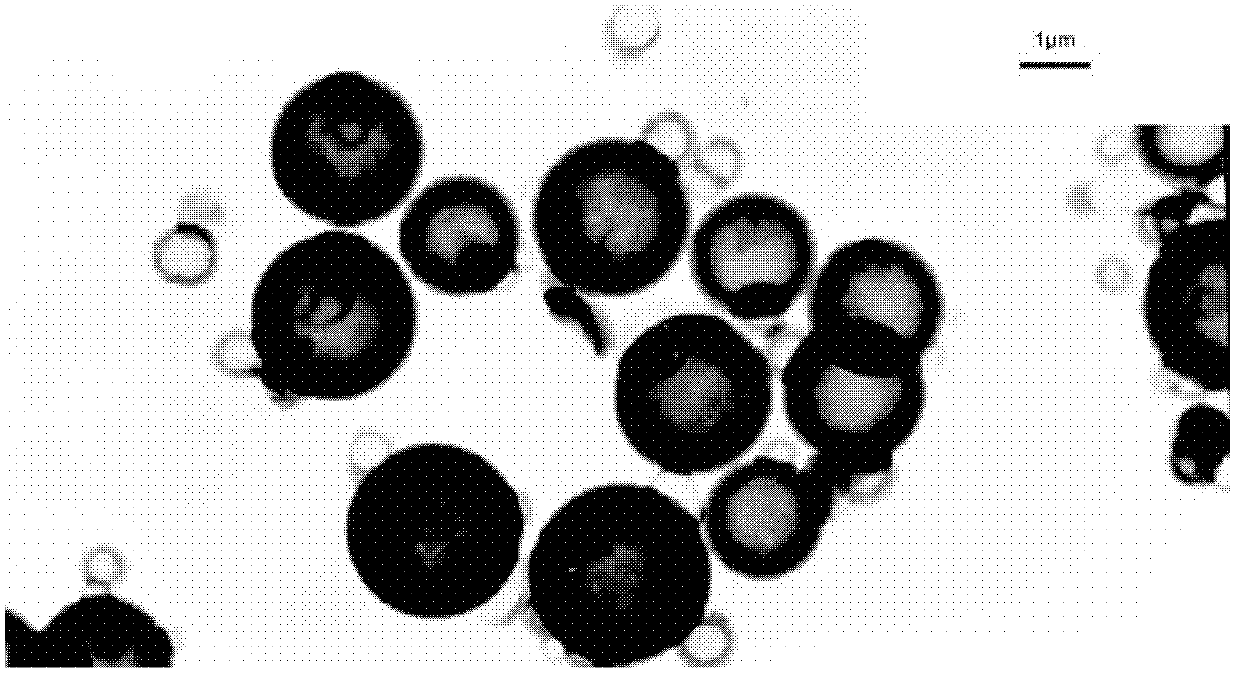

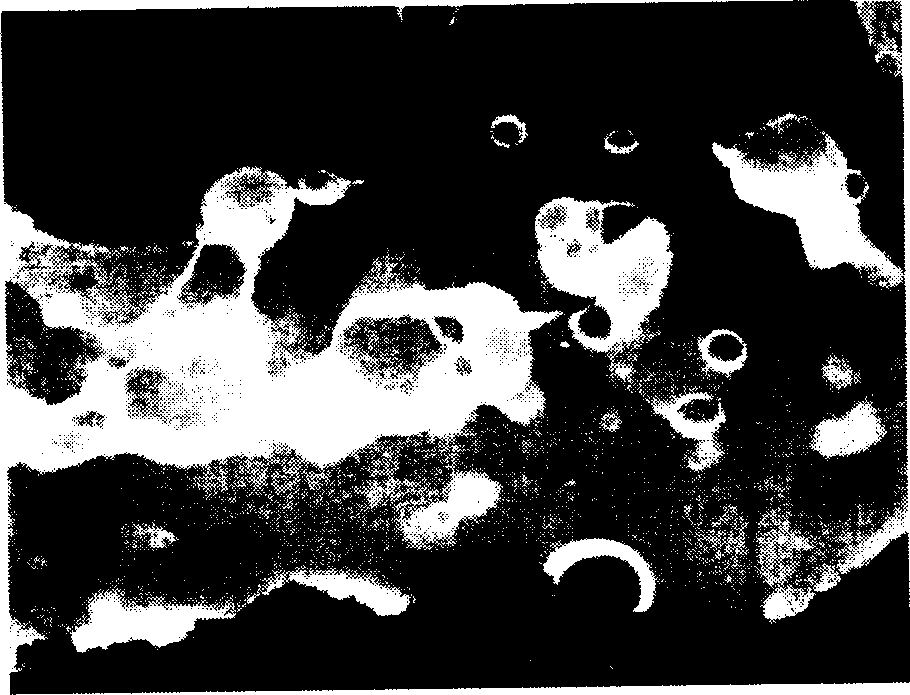

Preparation method of silica-coated iron oxide nano-core-shell structural material

ActiveCN102602883AControllable particle sizeShape is easy to controlNanostructure manufactureSilicaSilicon dioxideHeating temperature

A preparation method of silica-coated iron oxide nano-core-shell structural material includes: dissolving molysite, acetic acid and polyvinylpyrrolidone in ethanol, and mixing well; moving the solution into a polytetrafluoroethylene reactor, allowing the solution to react at the heating temperature of 160-220 DEG C for 3-48 hours and under the mixing speed of 10-100rpm, and obtaining 0.1-8g / L iron oxide nanoparticle suspension; and adding the ethanol and deionized water into the suspension, allowing the volume ratio of the ethanol to water in the suspension system to be 0.5-10 / 1, adjusting pH value to be 7-12, allowing the mass ratio of tetraethoxysilane to iron oxide nanoparticles to be 1:1-40, slowly adding the tetraethoxysilane under mixing, allowing the mixture to react for 12-70 hours, performing filtering and drying, and calcining at 400-600 DEG C to obtain the silica-coated iron oxide nano-core-shell structural material, wherein the molar concentration of the molysite in solution is 0.01-0.1mol / L, the volume ratio of the acetic acid to the ethanol is 0.002-1:1, and the mass concentration of the polyvinylpyrrolidone in the solution is 1.5-20g / L. The preparation method has the advantages that synthetic process is simple, cost is low, operation is simple, and amplification and synthesis are easy.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

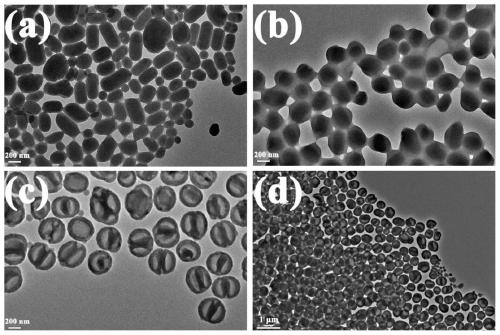

Prussian blue-based intelligent pH-triggered MRI drug release-monitoring synergetic nanometer diagnosis and treatment agent and preparation method thereof

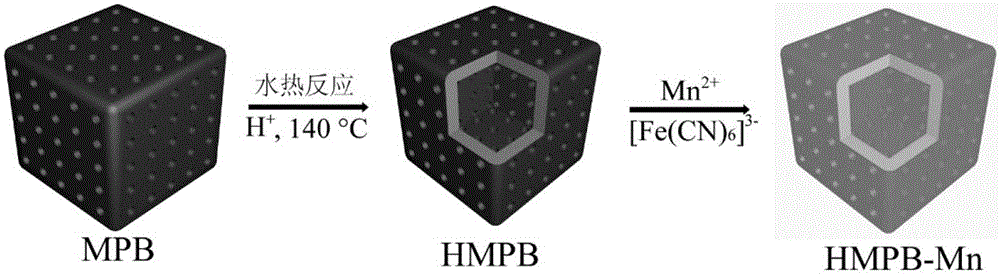

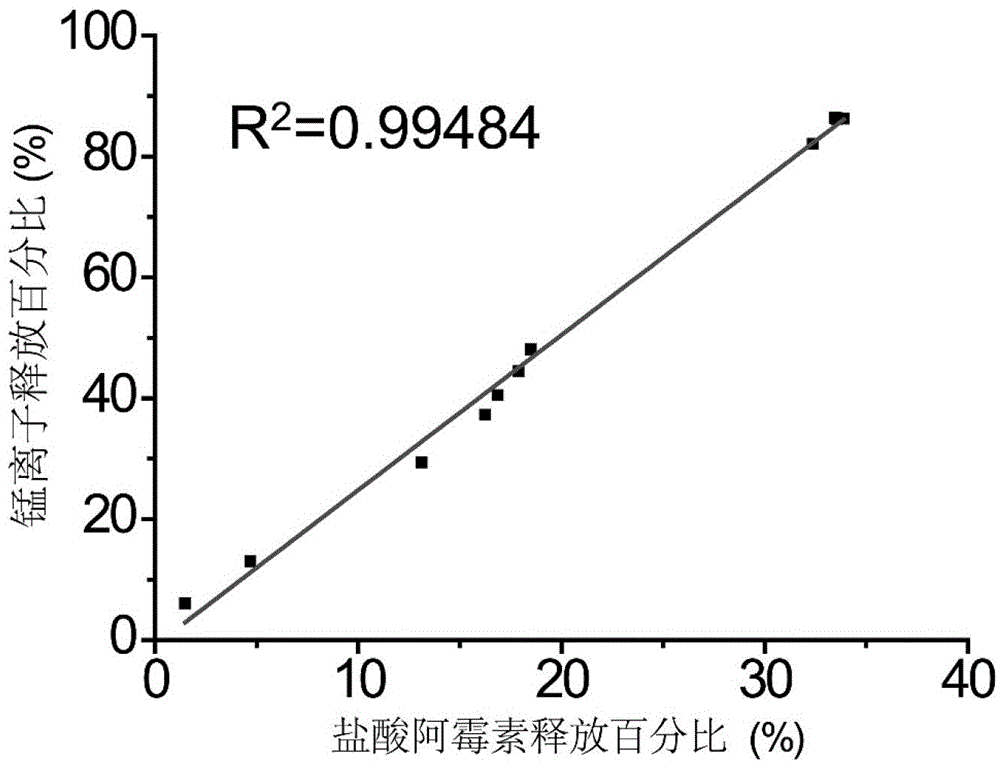

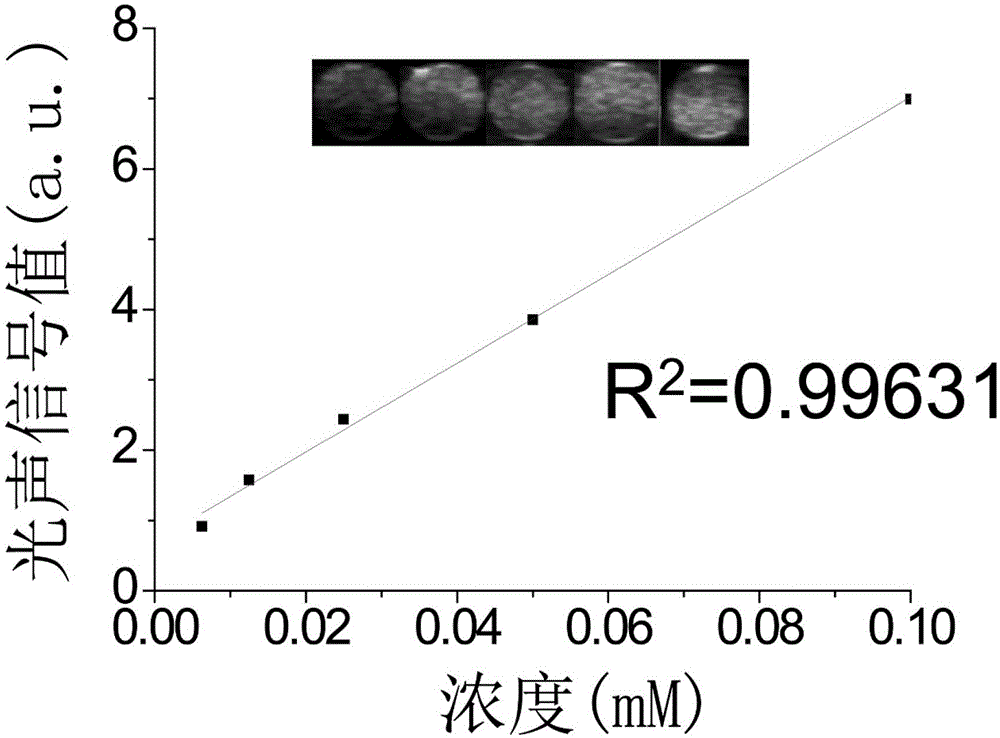

ActiveCN105031671AReduce releaseFacilitated releaseOrganic active ingredientsEnergy modified materialsMri guidedPrussian blue

The invention relates to a Prussian blue-based intelligent pH-triggered MRI drug release-monitoring synergetic nanometer diagnosis and treatment agent and a preparation method thereof. The nanometer diagnosis and treatment agent comprises hollow Prussian blue nanometer particles with mesopores. The surfaces of the hollow Prussian blue nanometer particles with mesopores are coated with KxMny[Fe(CN)6]z, wherein x is greater than or equal to 0.05 and less than or equal to 0.3, y is greater than or equal to 0.5 and less than or equal to 0.98 and z is equal to 1. The nanometer diagnosis and treatment agent comprises hollow mesoporous nanometer particles with core-shell structures. The HMPB-Mn nanometer diagnosis and treatment agent is used for tumor part pH-sensitive MRI and pH-sensitive drug release control in chemotherapy. Through combination with thermotherapy, MRI-guided thermotherapy-chemotherapy combined treatment on tumors is realized.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

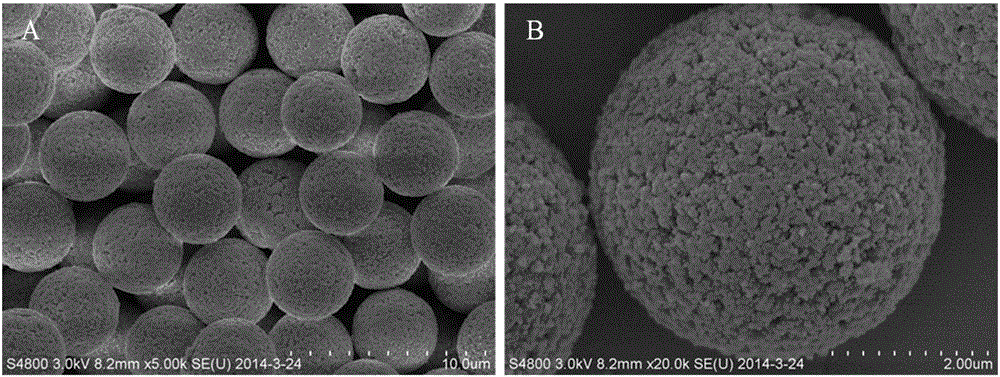

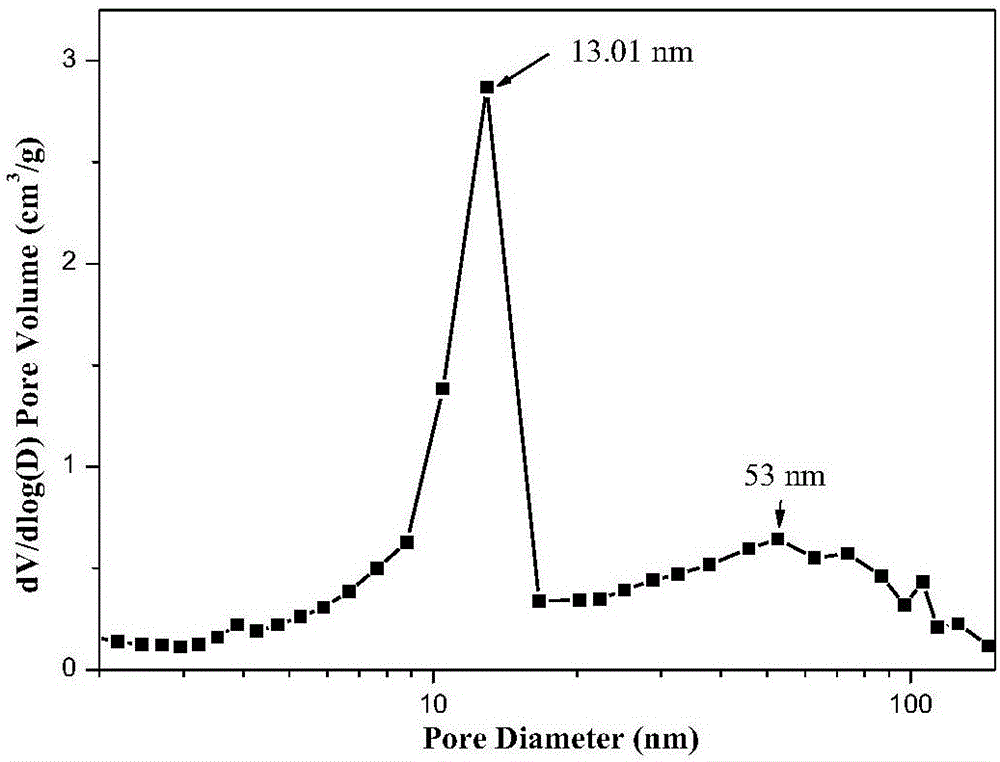

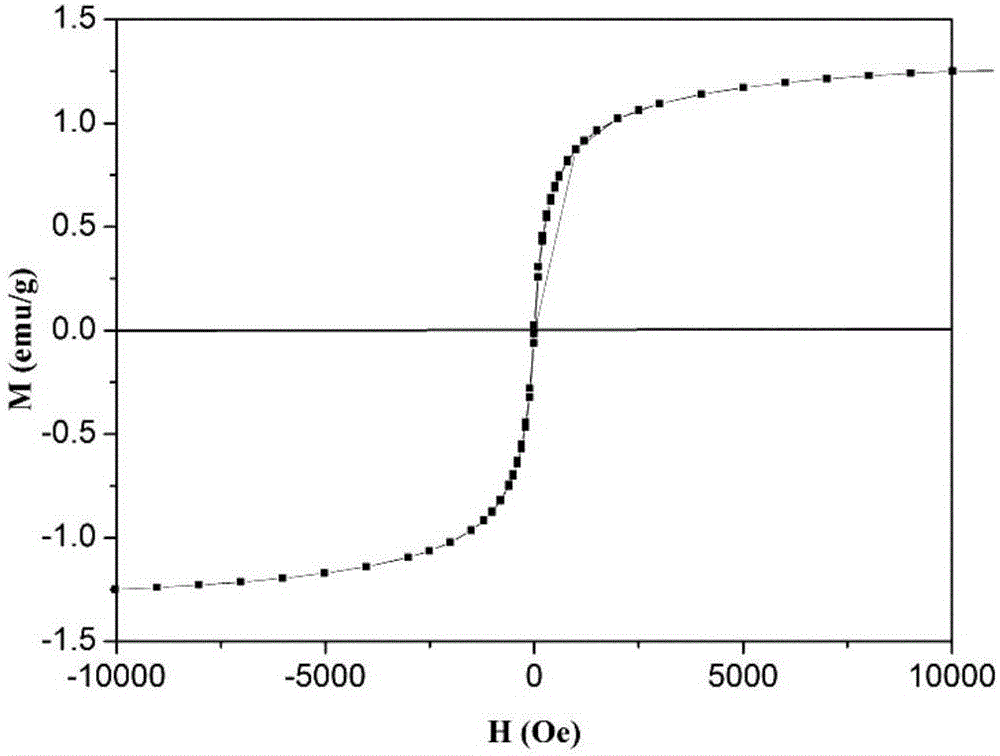

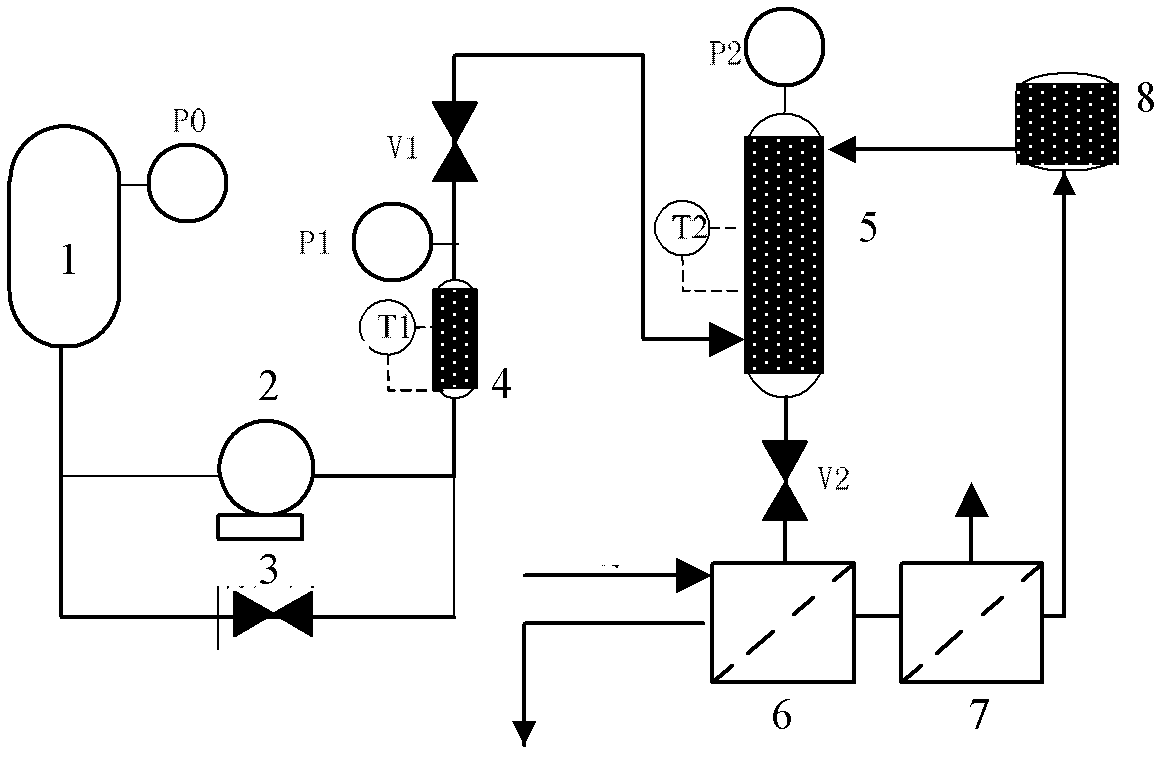

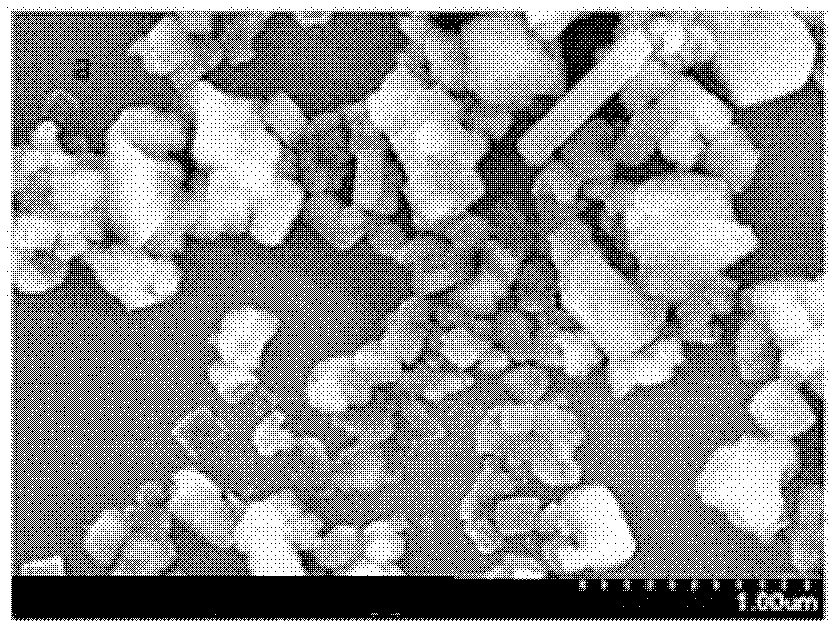

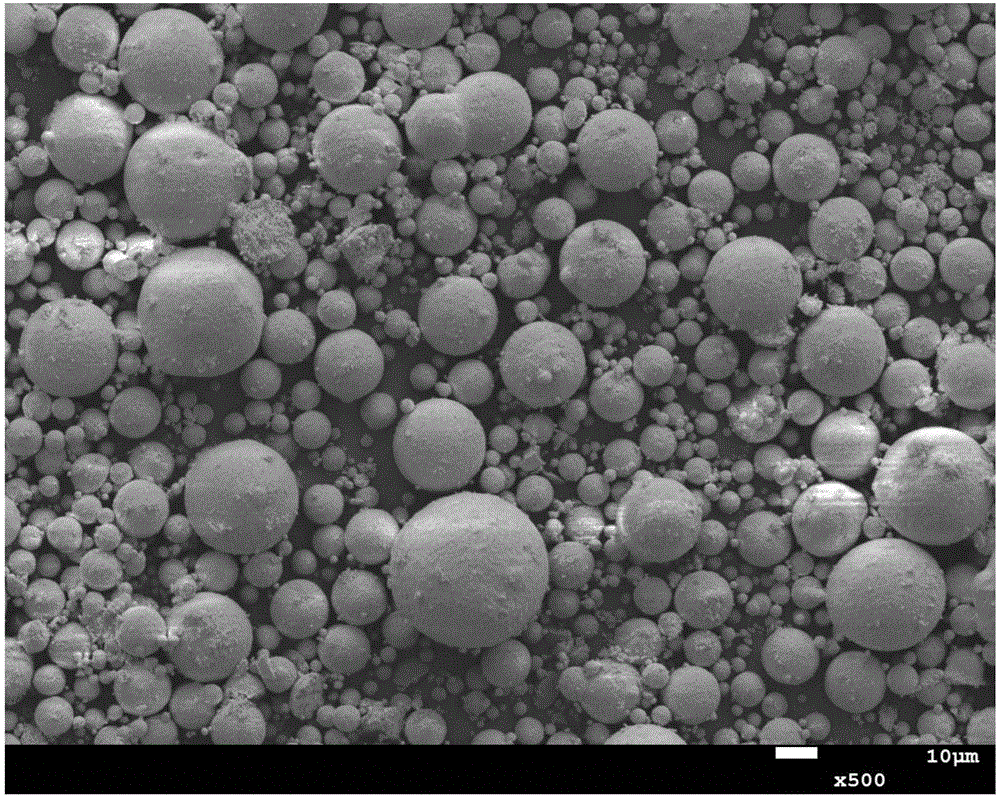

Monodisperse magnetic porous silicon dioxide pellet and preparing method thereof

InactiveCN106710773AMagnetically stableControllable particle sizeSilicaInorganic material magnetismMicrosphereMagnetite Nanoparticles

The invention discloses a monodisperse magnetic porous silicon dioxide pellet and a preparing method thereof. The preparing method of the monodisperse porous silicon dioxide pellet comprises the steps of utilizing a monodisperse magnetic porous macromolecule pellet as a template, generating in situ a magnetic Fe3O4 particle and sol-gelation of a silicon source and using a Fe3O4 particle to oxidize gamma-Fe2O3, forming a magnetic macromolecule-silicon dioxide composite pellet, and then removing the macromolecule template after calcination to obtain the monodisperse magnetic porous silicon dioxide pellet. The preparing method of the monodisperse magnetic porous silicon dioxide pellet is simple in process and easy to operate, and the prepared monodisperse magnetic porous silicon dioxide pellet has the advantages of being homogenous in particle size, controllable in particle diameter and pore diameter, connective in pore, simple in method of introducing magnetic nanoparticles, stable in magnetism and the like.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Solvent-out crystallization method of erythritol

InactiveCN102992957AShorten the production cycleReduce manufacturing costHydroxy compound separation/purificationPhysical chemistrySlurry

The invention relates to a solvent-out crystallization method of erythritol. The technical solution is as follows: firstly, a clear supersaturated crystallization solution is prepared by feeding a solvent-out agent in an erythritol crystallization mother solurion; then, a suspension crystal fluid is prepared by adding seed crystals to the supersaturated crystallization solution for controlling nucleation; a suspension slurry is prepared by adding the solvent-out agent at different speed continuously in three stages; and finally, an erythritol crystal product is obtained by growing the crystal with the suspension slurry via a programmed temperature control method, filtering, washing and drying. Crystals with the diameter of 30-60 meshes or 40-80 meshes in the erythritol crystal product accounts for more than 90%; the erythritol crystal product has smooth and clean crystal surface, high purity and good flowability; and single-process crystallization yield is higher than 80%. Average particle size and particle size distribution of the erythritol crystal product can be regulated in the crystallization process by changing the particle size of the seed crystals and the addition amount. The solvent-out crystallization method has the advantages of low production cost, short production period, controllable average particle size, concentrated particle size distribution, high single-process crystallization yield and high product quality.

Owner:WUHAN UNIV OF SCI & TECH

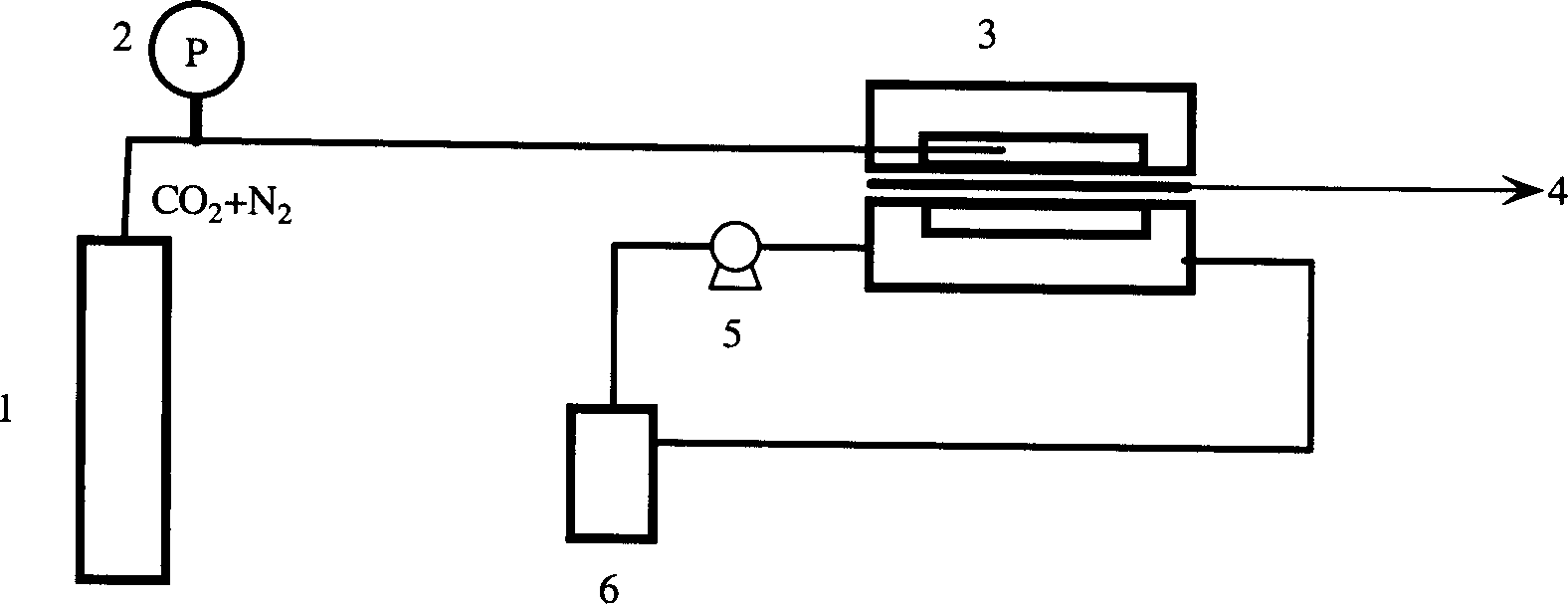

Method for preparing nanometer calcium carbonate

InactiveCN102491396AIncrease reaction rateControllable particle sizeCalcium/strontium/barium carbonatesNanotechnologyCarbonizationHigh pressure

The invention relates to a method for preparing nanometer calcium carbonate and provides a method for preparing the nanometer calcium carbonate, which is capable of performing carbonization reaction with the participation of high-pressure carbon dioxide and ionic liquid under an anhydrous condition. Ca(OH)2, the ionic liquid and the carbon dioxide are added into a high-pressure autoclave to perform the carbonization reaction. A reaction product is separated to obtain a nanometer calcium carbonate product, and the ionic liquid is recovered. The carbonization reaction which the carbon dioxide, especially a supercritical carbon dioxide participates in is performed with the assistance of the ionic liquid, and is characterized in that no water participates in the carbonization reaction. By means of the participation of the ionic liquid, reaction speed can be greatly improved and particle size of the product can be controlled. The ionic liquid can facilitate achievement of cyclic utilization so that the method is a green chemistry chemical production technology. The ionic liquid can be room-temperature ionic liquid or non-room-temperature ionic liquid, thereby facilitating selection of industrialization application.

Owner:XIAMEN UNIV

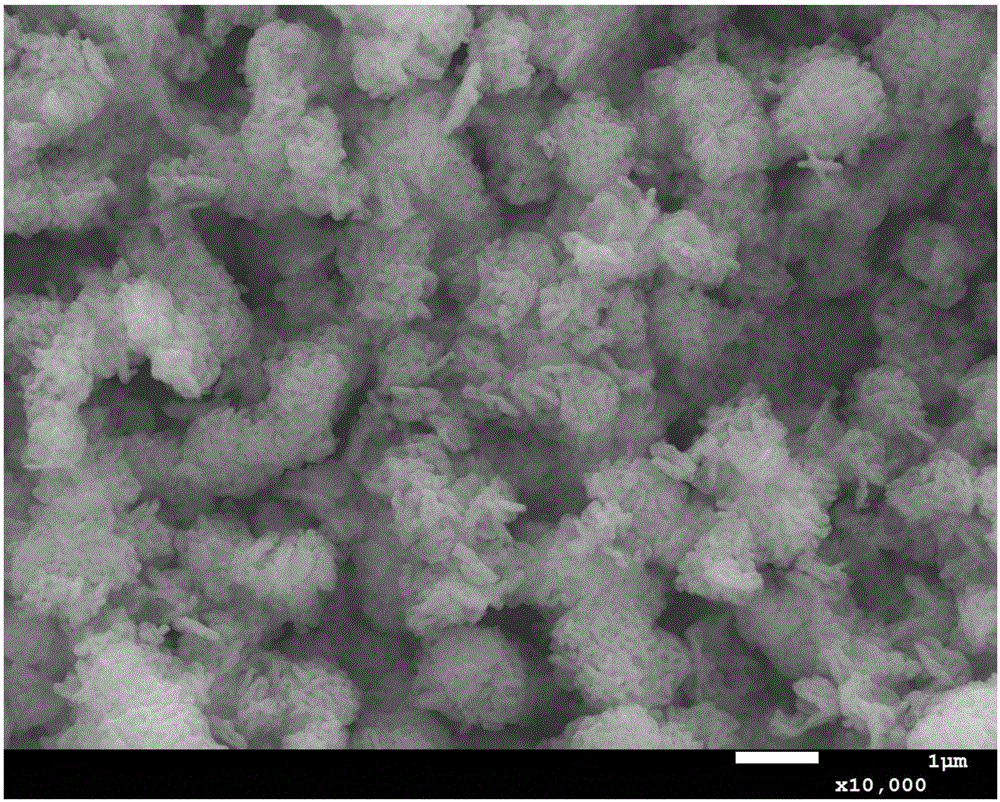

Preparation method of nano spherical ferric phosphate as well as nano ferric phosphate prepared by the method, lithium ferric phosphate and lithium battery

ActiveCN107522188AControllable particle sizeUniform particle size distributionCell electrodesNanotechnologyPhosphate productLithium-ion battery

The invention discloses a preparation method of nano spherical ferric phosphate as well as nano ferric phosphate prepared by the method, lithium ferric phosphate and a lithium battery. The method comprises the following steps: mixing: dropwise adding a mixed solution consisting of a phosphorus source compound solution and an oxidant solution into a soluble ferrous compound solution, adding a nano spherical control agent, and stirring and mixing; reacting: stirring at 50 to 100 DEG C under a refluxing condition, and reacting for 5 to 10 h; filtering: magnetically filtering the mixed solution after the reaction by adopting a high magnetic filter, press filtering the filtered solution, and obtaining a ferric phosphate crude product; and calcining: calcining for 24h at 650 to 850 DEG C under the protection of inert gas, and cooling to obtain a final ferric phosphate product. By adopting the method, the morphology of the ferric phosphate product can be controlled, and the performance of the lithium ferric phosphate can be improved.

Owner:YOSHIHIRO COMM EQUIP GRP CO LTD

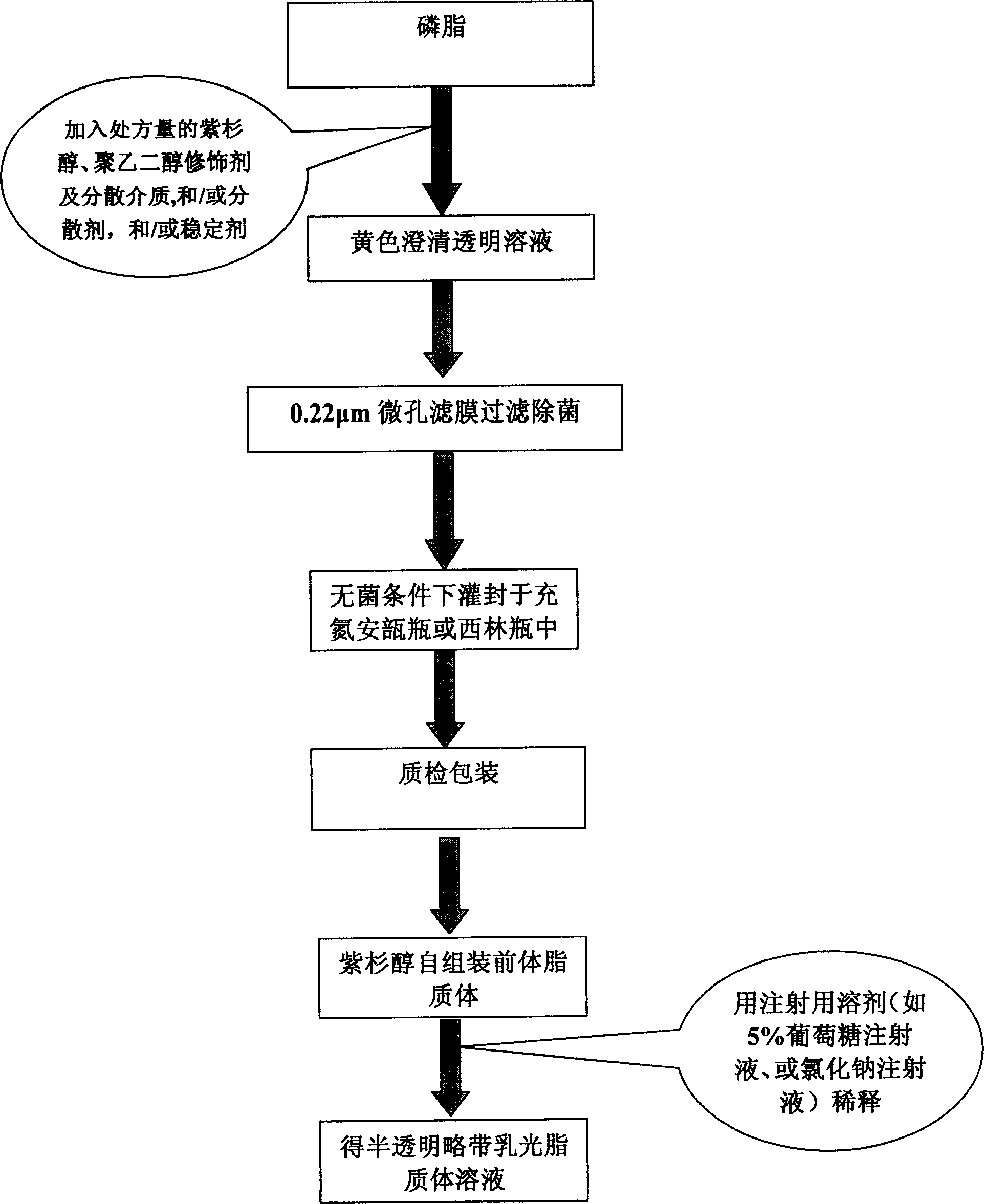

Poly olefinic taxadol self assembled precusor liposome and its preparation method

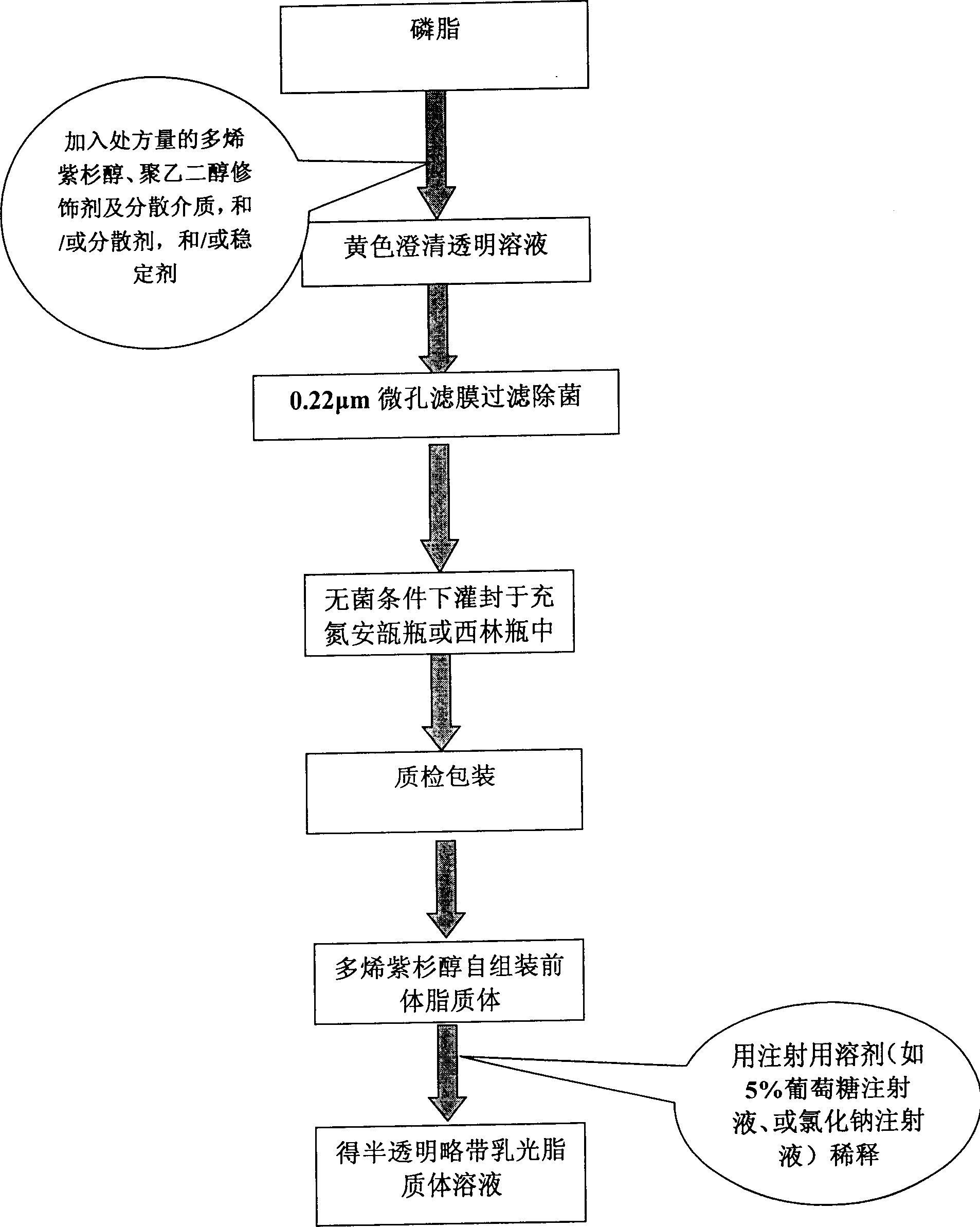

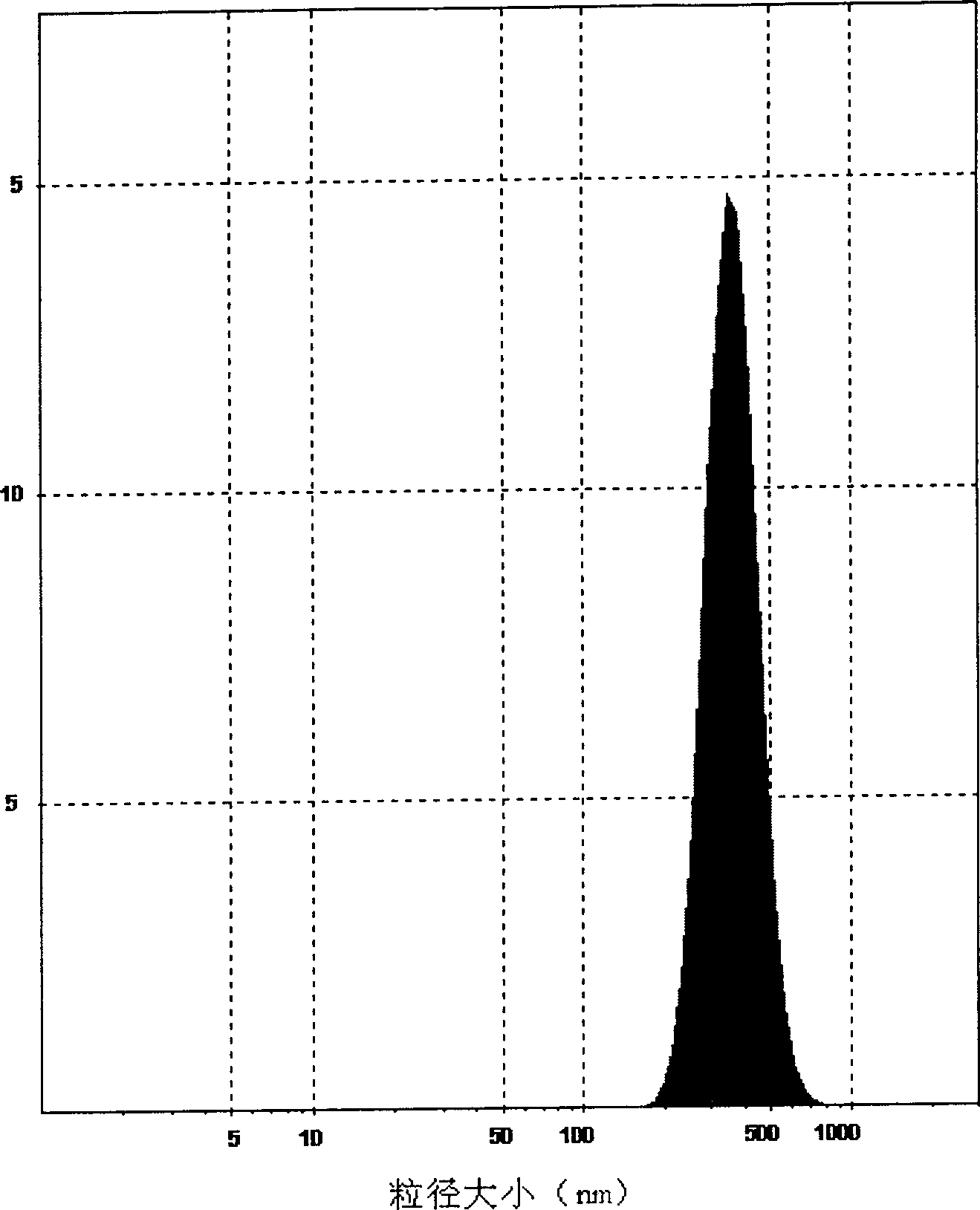

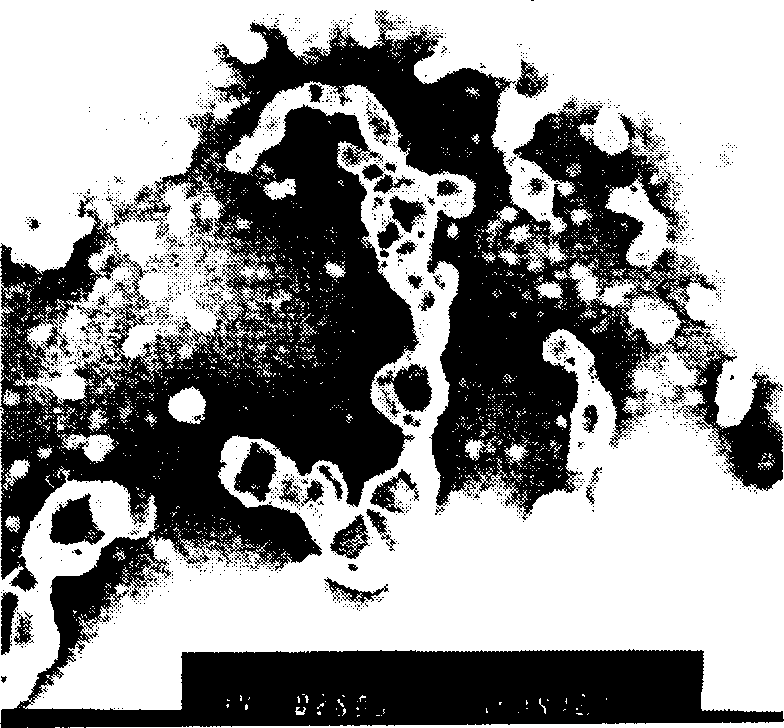

ActiveCN1823732AImprove product qualityHigh encapsulation efficiencyOrganic active ingredientsPharmaceutical non-active ingredientsPhospholipinPolymer science

A self-assembled precursor liposome of polyenic taxusol is proportionally prepared from polyenic taxusol, phosphatide, polyethylene glycol and dispersing medium through mixing, dispersing, press-filtering by millipore film, and pouring it in a container full of N2.

Owner:CHINA PHARM UNIV +1

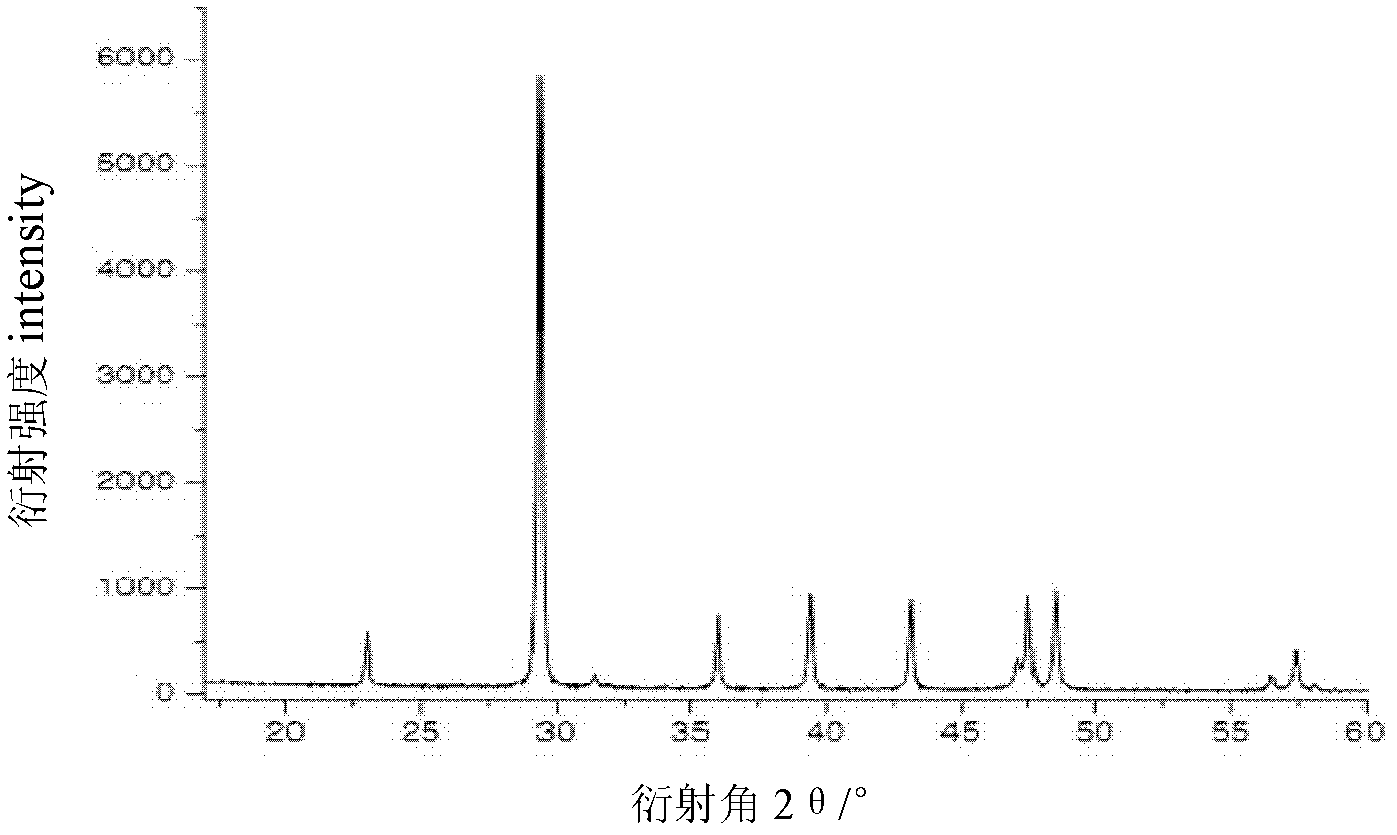

Synthetic method of high silica ZSM-5 zeolite

InactiveCN101898767AReduce dosageShape is easy to controlPentasil aluminosilicate zeoliteTetramethylammonium bromideAdhesive

The invention discloses a synthetic method of high-silica ZSM-5 zeolite, the method comprises the steps of adopting water glass as a silica source, adopting aluminum salts of aluminum sulfate, aluminum nitrate, aluminum chloride and the like, as well as organic aluminum compounds of sodium metaaluminate, isopropanol and the like as aluminum sources, using sulfuric acid or hydrochloric acid to regulate alkalinity, adding an organic template, simultaneously adding a guide adhesive, carrying out high-temperature crystallization at 120-200 DEG C, and then synthesizing the high-silica ZSM-5 zeolite with the SiO2 / Al2O3 ratio which is greater than 100; and the molar ratio of raw materials is as follows: SiO2 / Al2O3 is equal to 100-infinity, Na2O / SiO2 is equal to 0.05-0.20, and H2O / SiO2 is equal to 10-100. The organic template comprises tetrapropylammonium bromide, tetrapropylammonium hydroxide, tetraethylammonium bromide, tetraethylammonium hydroxide, n-butylamine, ethylamine, hexamethylene diamine and any other organic matters which can synthesize the ZSM-5 zeolite or the mixture thereof, wherein the using amount of the organic template is that R / SiO2 is equal to 0.005-0.50; and the amount of silicon dioxide in the guide adhesive is 0-5% of the total weight of the silicon dioxide in a synthetic system. The synthetic method can synthesize the high-silica ZSM-5 zeolite with the SiO2 / Al2O3 ratio which is greater than 100 and has the advantages of cheap raw materials, a small using amount of the organic template, and capability of realizing the control of product appearance and particle size by changing the relative using amount of the template and the guide adhesive.

Owner:EAST CHINA NORMAL UNIV

Method for preparing nanometer calcium carbonate granule

ActiveCN1769180ASmall stagnationFast and uniform mixingCalcium/strontium/barium carbonatesNanoparticlePH decrease

The invention relates to a method for preparation of nano calcium carbonate particles by highly effective mixture, belonging to the art of preparation of nano particles. Preparing Ca(OH)2 suspension in a container; fixing dispersion medium in the container and venting reacting gas in; pumping the prepared Ca(OH)2 suspension into reactor by a pump to react, and dropping until PH decreases to 7, the reaction finishes and the nano calcium carbonate particles are prepared; the gas-liquid mixture prepared after the reaction returns to the container to be used cyclically. The merit of the invention is characterized in that the mixture speed is rapid and uniform, the grain size and shape are controllable, the usage ratio of CO2 is high and can reach more than 50%, the operation energy-consumption is low, and the stability is high; the grain size of prepared nano calcium carbonate is about 20nm, the shape is cube-type. And it has good prospect in preparation of nano calcium carbonate.

Owner:山东海泽纳米材料有限公司 +1

Polyvinylidene fluoride anti-pollution membrane and preparation method thereof

ActiveCN107149882AEasy to makeLow preparation equipment requirementsMembranesSemi-permeable membranesPhase conversionUltraviolet

The invention discloses a polyvinylidene fluoride anti-pollution membrane and a preparation method thereof, and belongs to the field of environmental functional membrane materials. The preparation method comprises: (1) self-polymerizing dopamine on the surface of polyvinylidene fluoride powder, and adhering the generated poly dopamine functional layer onto the surface of the polyvinylidene fluoride powder; (2) preparing a poly dopamine modified polyvinylidene fluoride membrane by using a phase conversion method; and (3) depositing a nano-TiO2 functional layer on the membrane prepared in the step (2) through a liquid phase deposition method to prepare the polyvinylidene fluoride anti-pollution membrane. According to the present invention, by combining the strong adhesion and the polyfunctional group of poly dopamine, the ultraviolet resistance and stable chemical performance of polyvinylidene fluoride, and the advantages of hydrophilicity, high photocatalytic activity and the like of nano-TiO2, the polyvinylidene fluoride anti-pollution membrane is developed; and the prepared polyvinylidene fluoride anti-pollution membrane has excellent pollution resistance, and can be used in various membrane separation fields.

Owner:天津鼎芯膜科技有限公司

Method of preparing anode catalyst for direct methyl alcohol fuel cell

InactiveCN1601788AGood dispersionEvenly dispersedCell electrodesMetal/metal-oxides/metal-hydroxide catalystsAlcohol fuelPt element

Method of spraying pyrolysis and carrier gas deoxidation is adopted to make particles of platinum and ruthenium deoxidized from chloro-platinic acid and ruthenium trichloride distribute in pores of active carbon and surface evenly. Moreover, particle diameter of platinum is in 3+ / - 0.5 Nano evenly. Features of the method are simple operation, producing Nano platinum and ruthenium / carbon electrocatalyst continuously without need of procedures of filtering, washing and drying. Performance of the electrocatalyst for oxidation catalysis of methanol is better than relevant product of platinum and ruthenium / carbon electrocatalyst produced from E-TEK Company.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

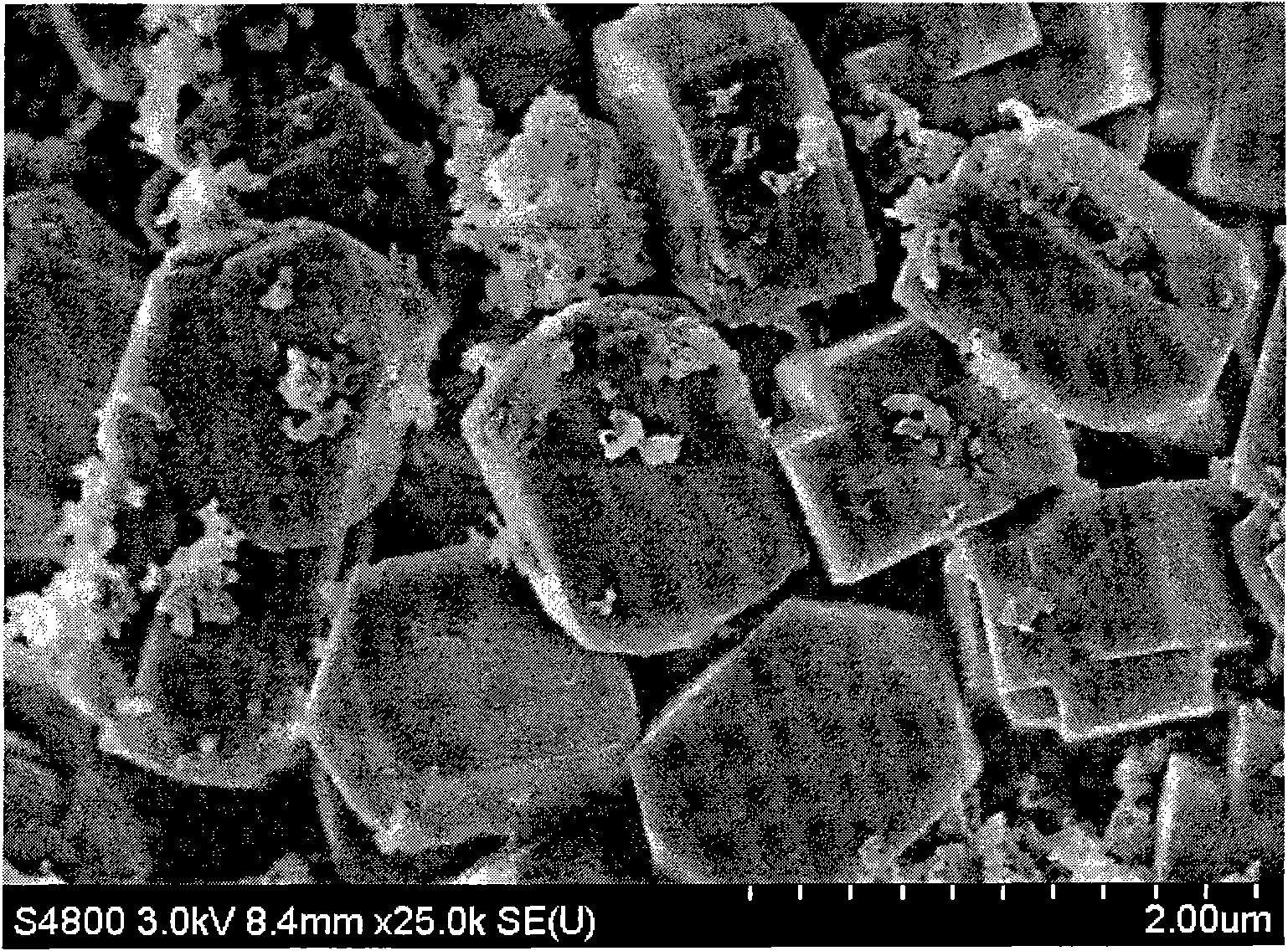

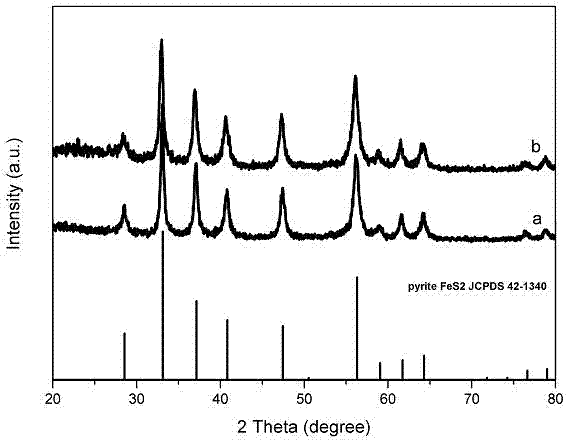

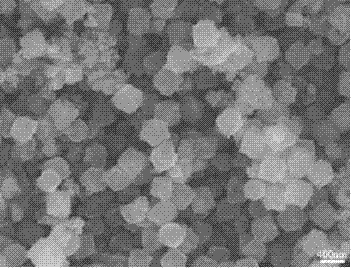

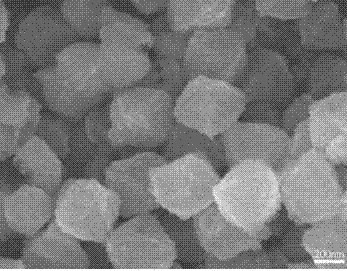

Preparation method of pyrite-type ferrous disulfide micron/nano crystalline material with controllable morphology

InactiveCN102786098AEffective particle size controlEffective control of morphologyMaterial nanotechnologyIron sulfidesThio-Active agent

The invention relates to a preparation method of a pyrite-type ferrous disulfide micron / nano crystalline material with a controllable morphology. The method comprises the following steps of: (1) respectively adding solvent dimethyl sulfoxide into compounding agent thioglycolic acid and surfactant polyvinylpyrrolidone under the condition of agitating and leading in nitrogen or argon, and obtaining a solution A by mixing and agitating; (2) orderly adding an iron source and a sodium thiosulfate water solution into the solution A, leading in the nitrogen or argon and vigorously stirring to obtain a solution B; (3) transferring the solution B into a reaction kettle and reacting for 4-12 hours at 120-180 DEG C after uniformly agitating, to obtain pyrite-type ferrous disulfide suspension liquid; (4) centrifugally separating, washing for a plurality of times and drying the pyrite-type ferrous disulfide suspension liquid in vacuum to constant weight to obtain the pyrite-type ferrous disulfide micron / nano crystalline material. The product obtained by the method has controllable particle size and morphology, good process repeatability and stable quality, and is expected to be applied to the fields such as photovoltaic conversion and lithium ion battery materials.

Owner:LANZHOU UNIVERSITY

Superfine copper powder and preparation method thereof

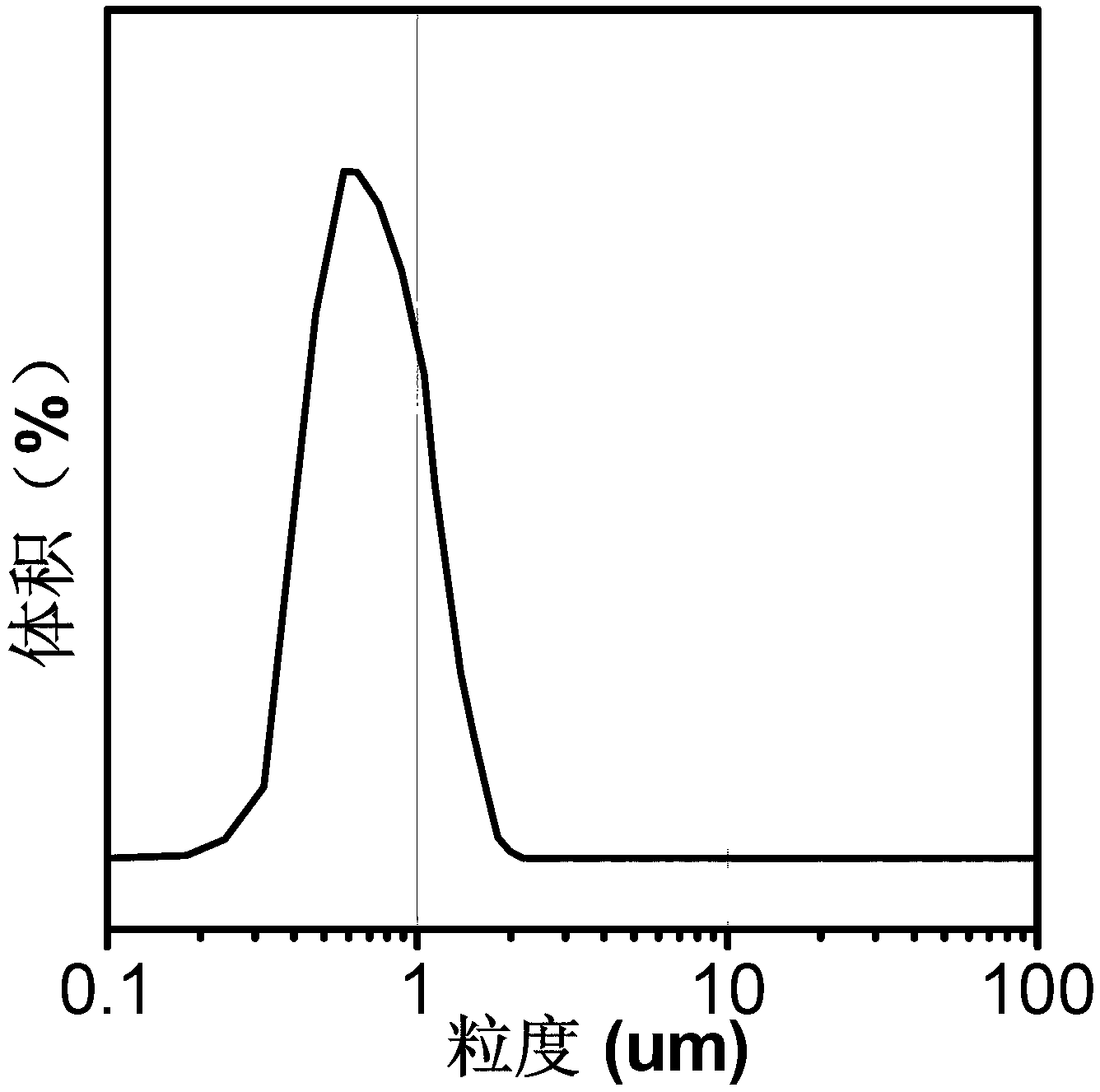

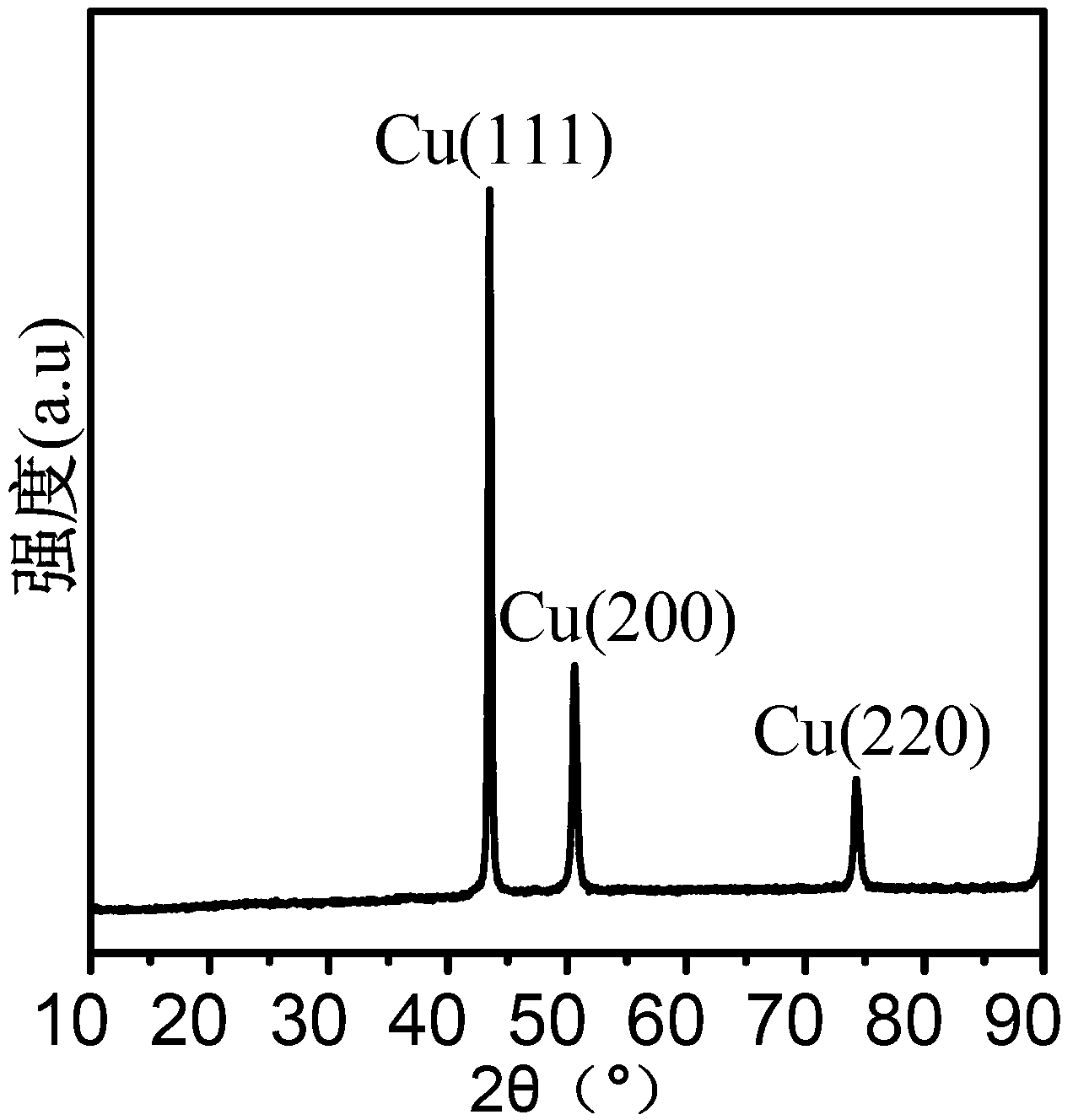

The invention belongs to the technical field of powder material and particularly relates to superfine copper powder prepared through a liquid-phase ball mill reduction method and a preparation method of the superfine copper powder. The preparation method comprises the following steps: reductant is added in slurry of copper oxide powder, and grinding dispersion or ultrasonic dispersion is performed while liquid-phase reduction reaction is performed to obtain superfine copper powder; and the obtained product is filtered and dried to obtain superfine copper powder with the particle size of about 0.1 to 2 um. The preparation method provided by the invention has the advantages that raw materials are cheap, the technical process is simple, the reaction is moderate, the operation is simple and convenient, and large-scale production can be realized easily; and meanwhile, the prepared copper powder is very small in particle size and is easy to control and good in dispersity.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

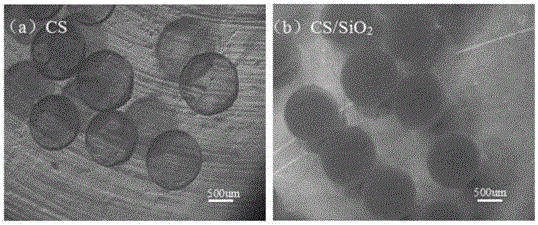

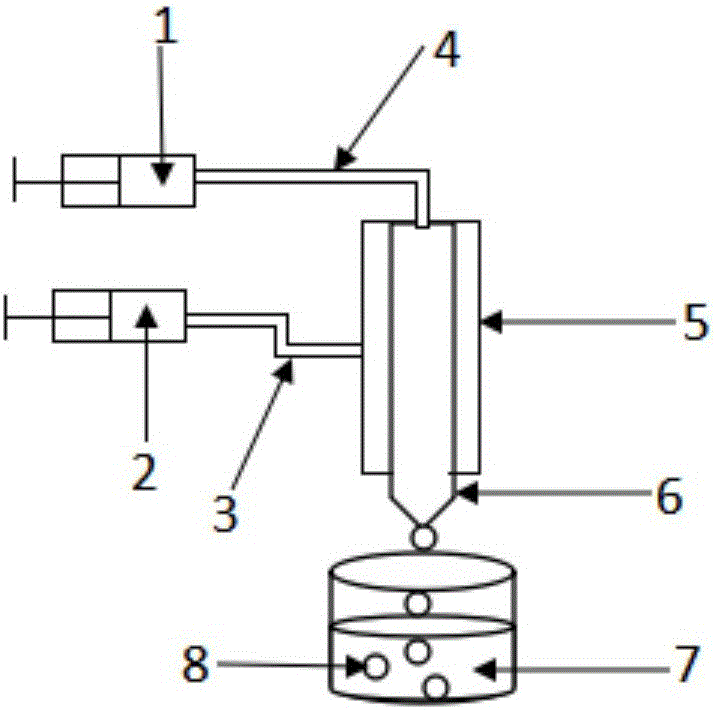

Preparation method for SiO2 nanoparticle reinforced chitosan composite microcapsule

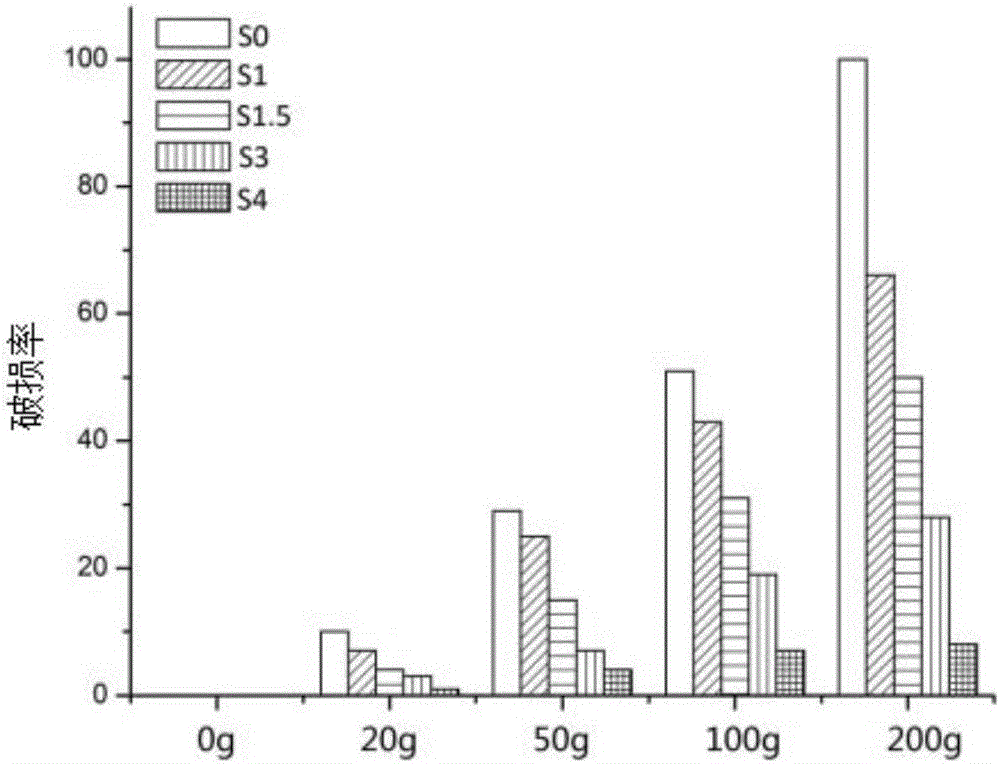

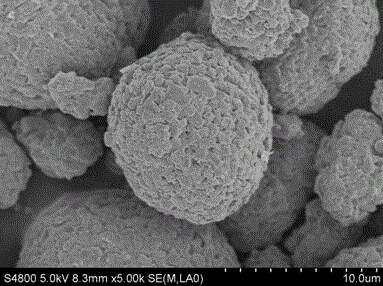

InactiveCN106040120AReduce breakage rateGood dispersionMicroballoon preparationMicrocapsule preparationSolubilitySio2 nanoparticle

The invention discloses a preparation method for a SiO2 nanoparticle reinforced chitosan composite microcapsule. The preparation method is as follows: by utilizing a gas-liquid microfluidic device, and through mixing of an acidic silica sol with a liquid-phase solution, SiO2 nanoparticles are dispersed in a chitosan solution; by utilizing hydrogen-bond interaction generated by active groups in chitosan molecules and the SiO2 nanoparticles, the nanoparticles are introduced into the capsule wall of the chitosan microcapsule; meanwhile, the chitosan used as a cationic electrolyte forms cationic and anionic complex compounds with a sodium dodecyl sulfate anionic electrolyte by mutual attraction through charges, so solubility of the chitosan in a solution is reduced; and the chitosan coats a capsule core substance to form a composite microcapsule, so a chitosan / nanometer SiO2 composite microcapsule is obtained. The prepared composite microcapsule provided by the invention has the following advantages: the nanoparticles are introduced onto the capsule wall of the microcapsule, so compactness of the capsule wall of the microcapsule is increased; the mechanical performance of the microcapsule is reinforced; the capsule wall of the chitosan composite microcapsule is insusceptible to cracking under stress; and application range and fields of the chitosan microcapsule are expanded.

Owner:WUHAN UNIV OF TECH

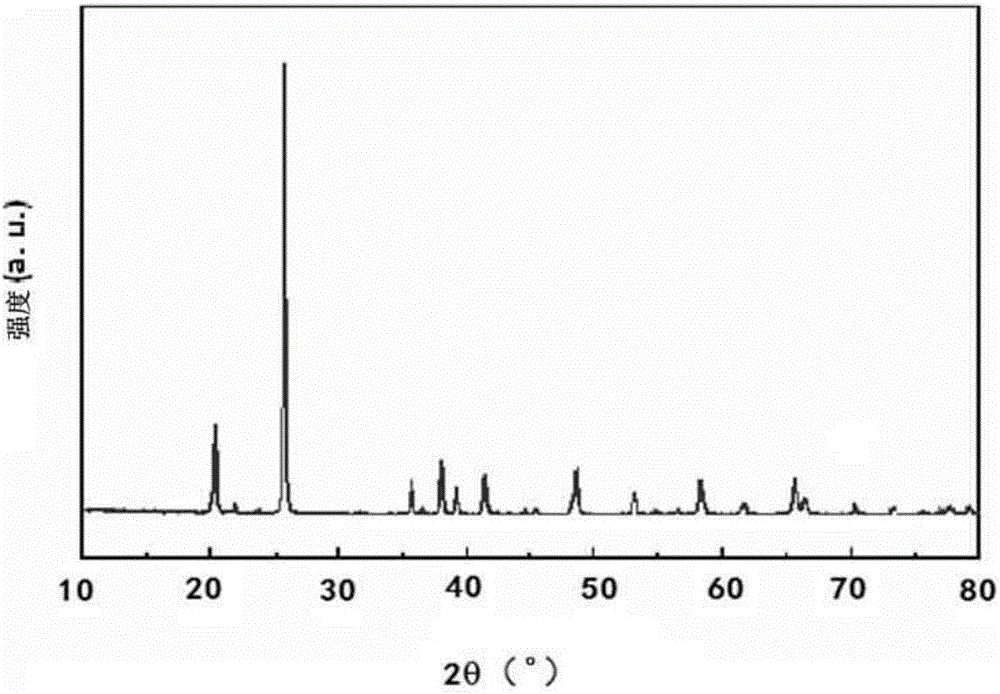

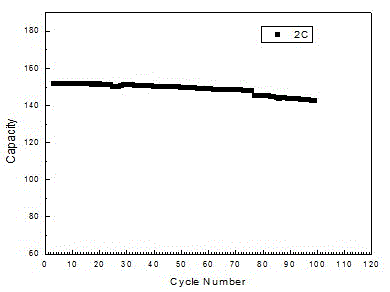

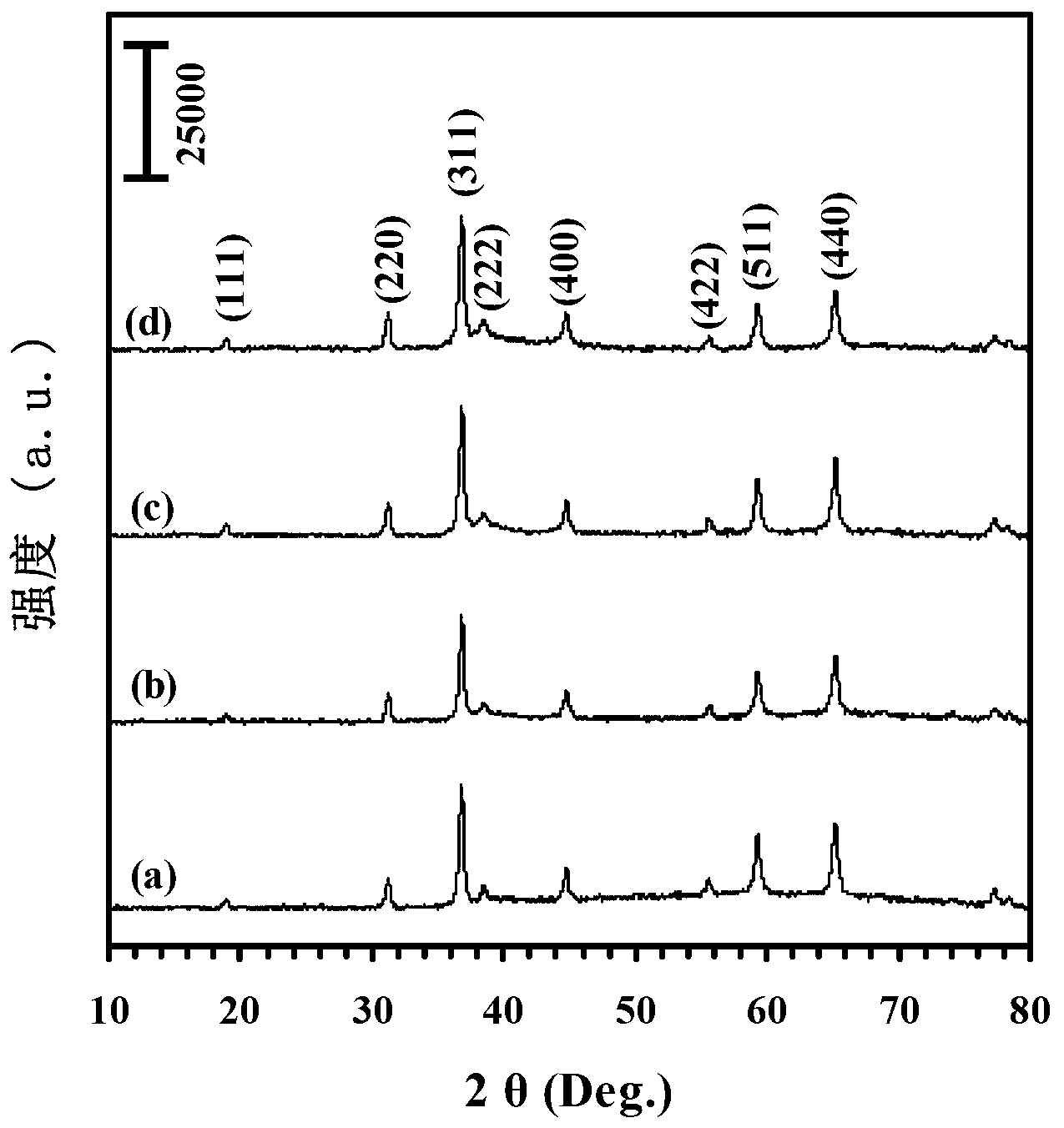

Lithium ion battery LiNixCoyMn1-x-yO2 anode material reverse microemulsion assisted preparation method

ActiveCN104993123AUniform compositionShape is easy to controlCell electrodesSecondary cellsNew energyLithium-ion battery

Belonging to the technical field of new energy materials, the invention relates to a lithium ion battery LiNixCoyMn1-x-yO2 anode material reverse microemulsion assisted preparation method. The method includes: preparing a metal ion solution and a precipitant solution, then preparing an oil phase, a surfactant and a co-surfactant into two mixed solutions, and adding the metal ion solution and the precipitant solution into the two mixed solutions respectively to obtain two reverse microemulsions, and finally preparing a precursor and an anode material. The preparation process provided by the invention is simple and easy to operate, and the prepared material has the advantages of uniform composition, controllable shape and particle size, large compaction density, stable structure, high electrical conductivity, good reversibility of lithium intercalation and deintercalation, and excellent electrochemical performance.

Owner:中国东方电气集团有限公司

Method for synthesizing tantalum carbide superfine powder through molten salt assisted magnesiothermic reduction

The invention discloses a method for synthesizing tantalum carbide superfine powder through molten salt assisted magnesiothermic reduction. The method includes: using tantalum oxide and carbon black as raw materials, NaCl, KCl and KF as molten salts and magnesium powder as a reductant; weighing the raw materials proportionally; mixing the raw materials well, and filling a graphite crucible with a mixture of the raw materials; performing low-temperature carbothermic reduction in a flowing argon atmosphere to prepare the tantalum carbide superfine powder. The method is simple in process, easy in preparation condition control and low in cost. The tantalum carbide superfine powder prepared by the method can be applied to producing modifiers of ultrahigh-temperature tantalum carbide ceramic and hard alloys.

Owner:ZHENGZHOU UNIV

Paclitaxel liposome and preparation method therefor

InactiveCN101015525ASmall side effectsProlong the action timeOrganic active ingredientsAntineoplastic agentsPaclitaxel LiposomeFreeze dry

The invention provides a Paclitaxel liposome and process for preparation, wherein the components include Paclitaxel 1-30%, phosphatides 1-95%, cholesterin 0-30%, thermo-sensible auxiliary material D 0-50%, auxiliary material G 0-50%, freeze-drying protecting agent 0-80%, octadecyl amine 0-10%, anti-oxidant 0.001-50% and right amount of buffer salt.

Owner:SHENYANG PHARMA UNIVERSITY

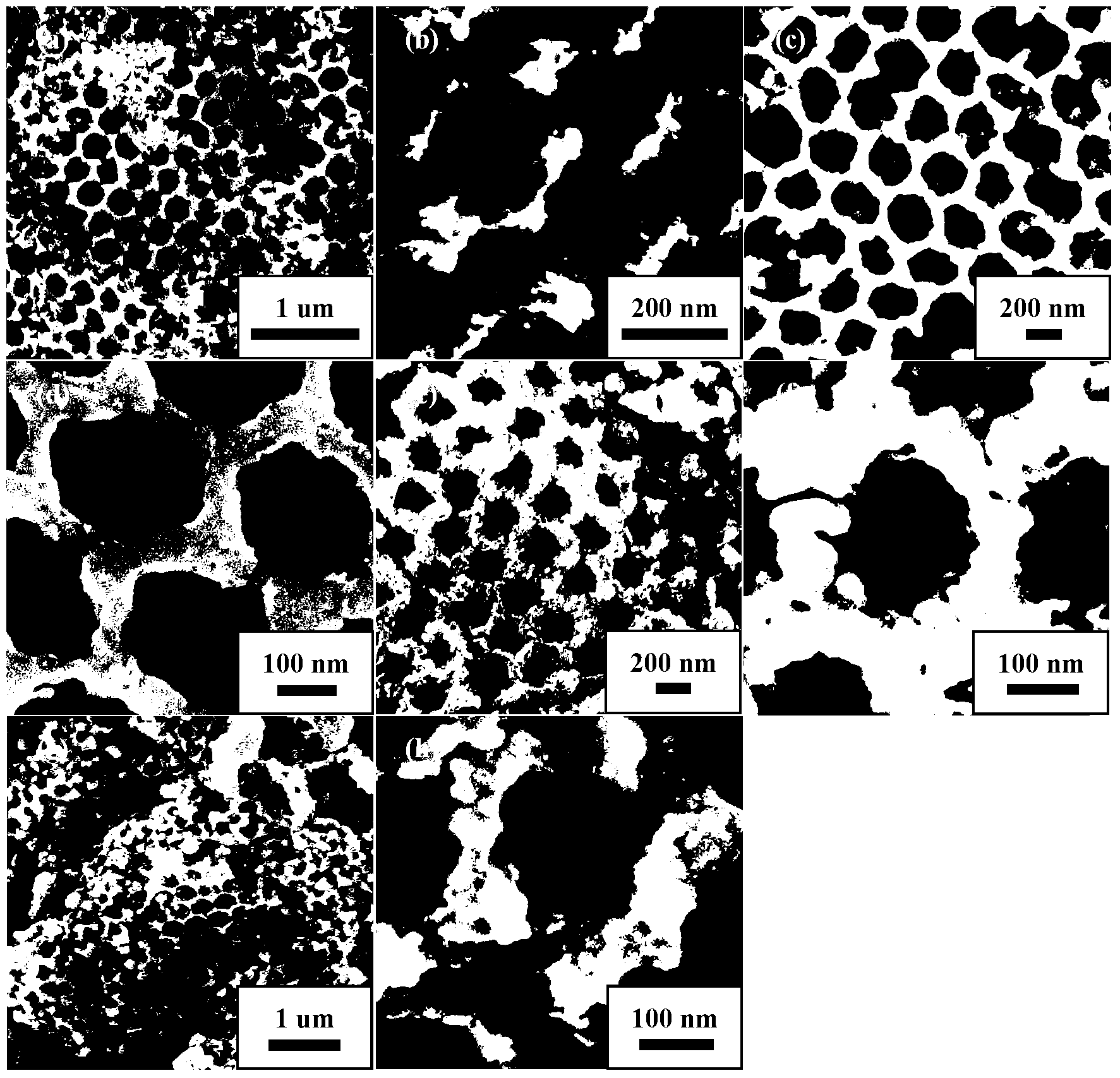

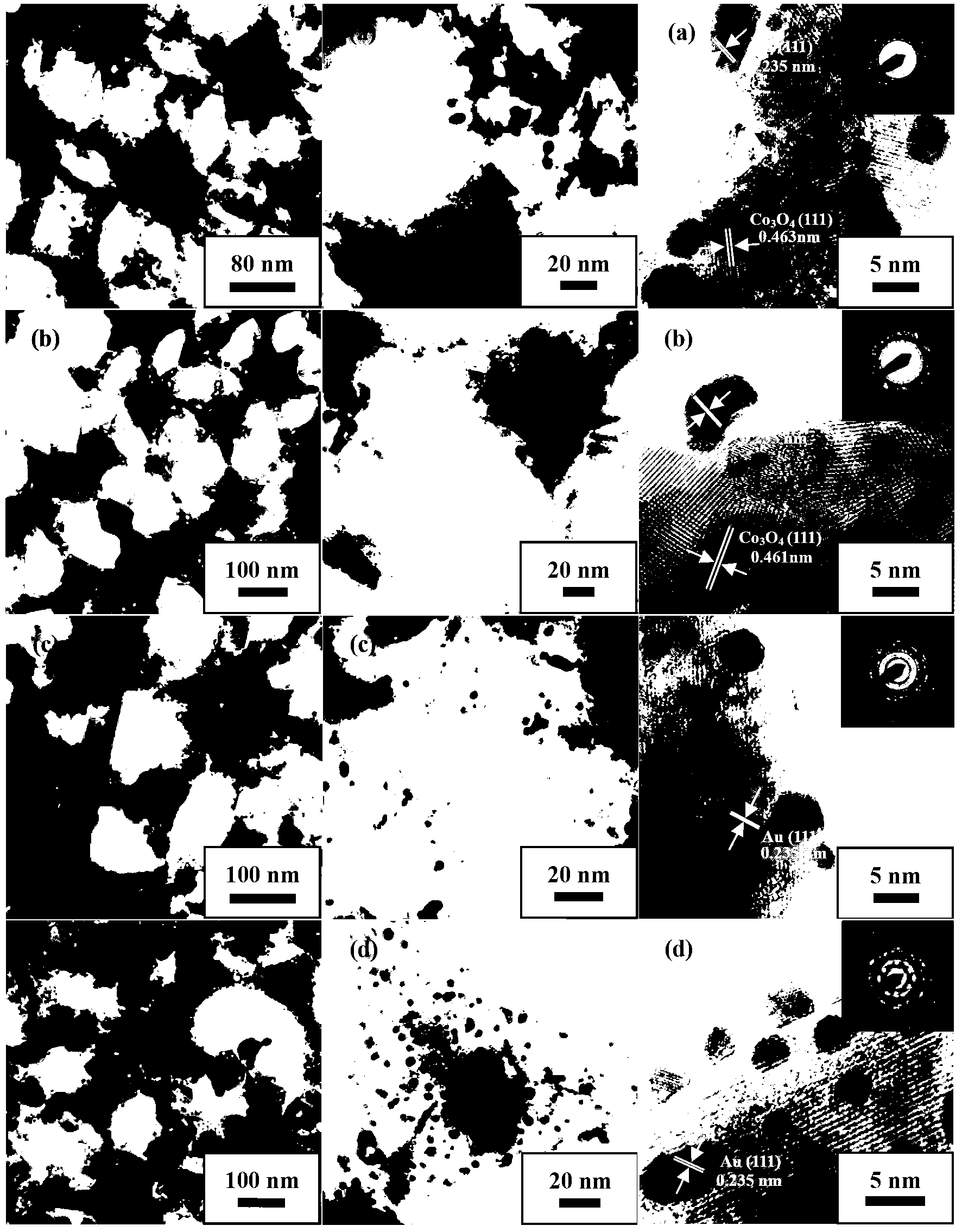

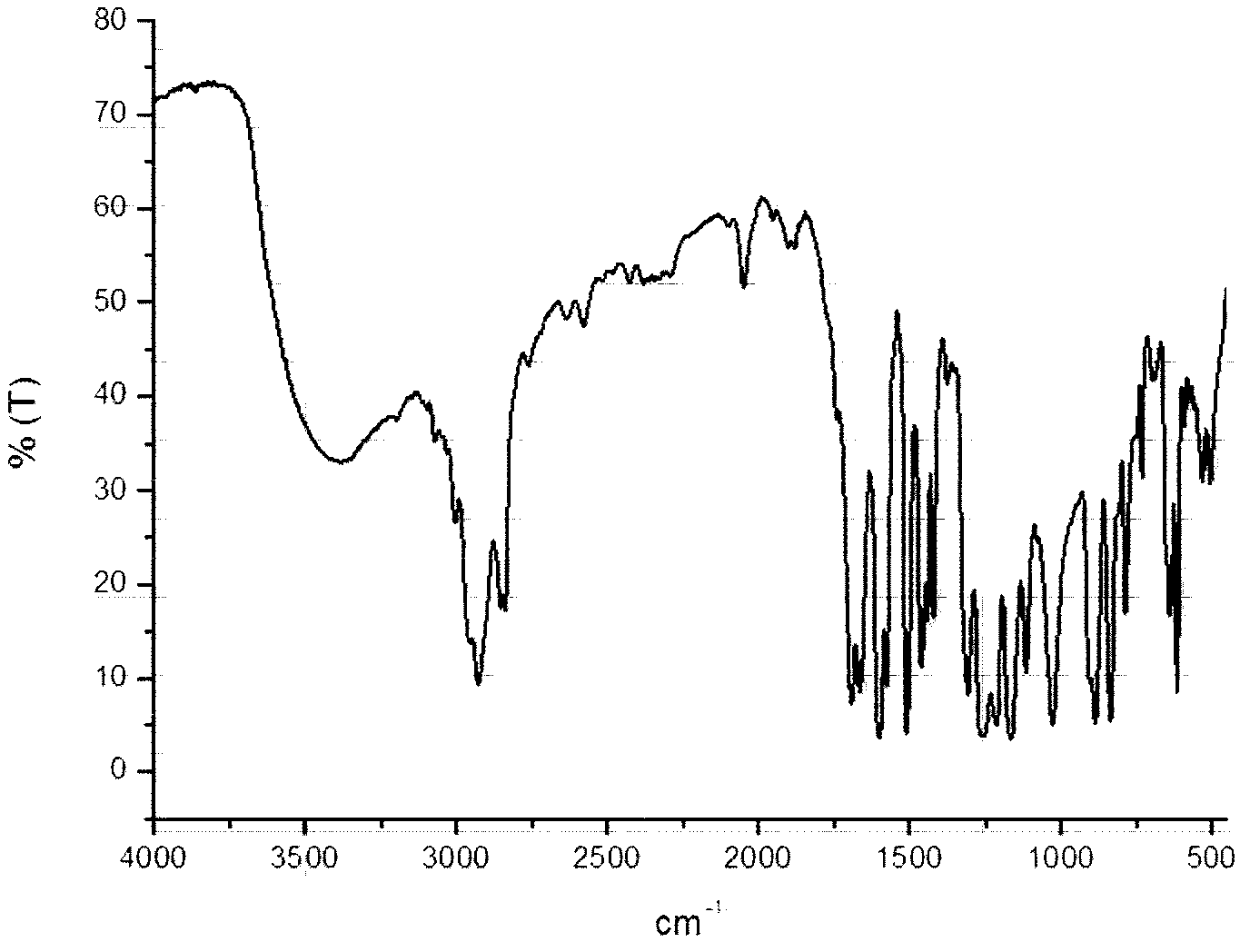

Three-dimensional sequential macroporous Co3O4 loaded nanometer Au catalyst as well as preparation method and application thereof

InactiveCN103301850AShape is easy to controlControllable particle sizeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChemistryOxide

The invention relates to a three-dimensional sequential macroporous Co3O4 loaded nanometer Au catalyst as well as a preparation method and an application thereof, and belongs to a transition metal oxide loaded nanometer noble metal catalyst. The pore wall of Co3O4 with a 3DOM structure is supported with cubic phase Au nanometer particles. According to the preparation method, 3DOM Co3O4 is prepared by a polyethyleneglycol 400 assisted PMMA (polymethyl methacrylate) colloidal crystal template method, and then a gold nanometer adhesive is loaded on 3DOM Co3O4 by using a polyvinyl alcohol protection bubble reduction method, so that Au / 3DOM Co3O4 is obtained. The raw materials of the three-dimensional sequential macroporous Co3O4 loaded nanometer Au catalyst is cheap in price and can be easily obtained, the preparation process is simple, and the product obtained by the preparation method is controllable in shape, size and pore diameter.

Owner:BEIJING UNIV OF TECH

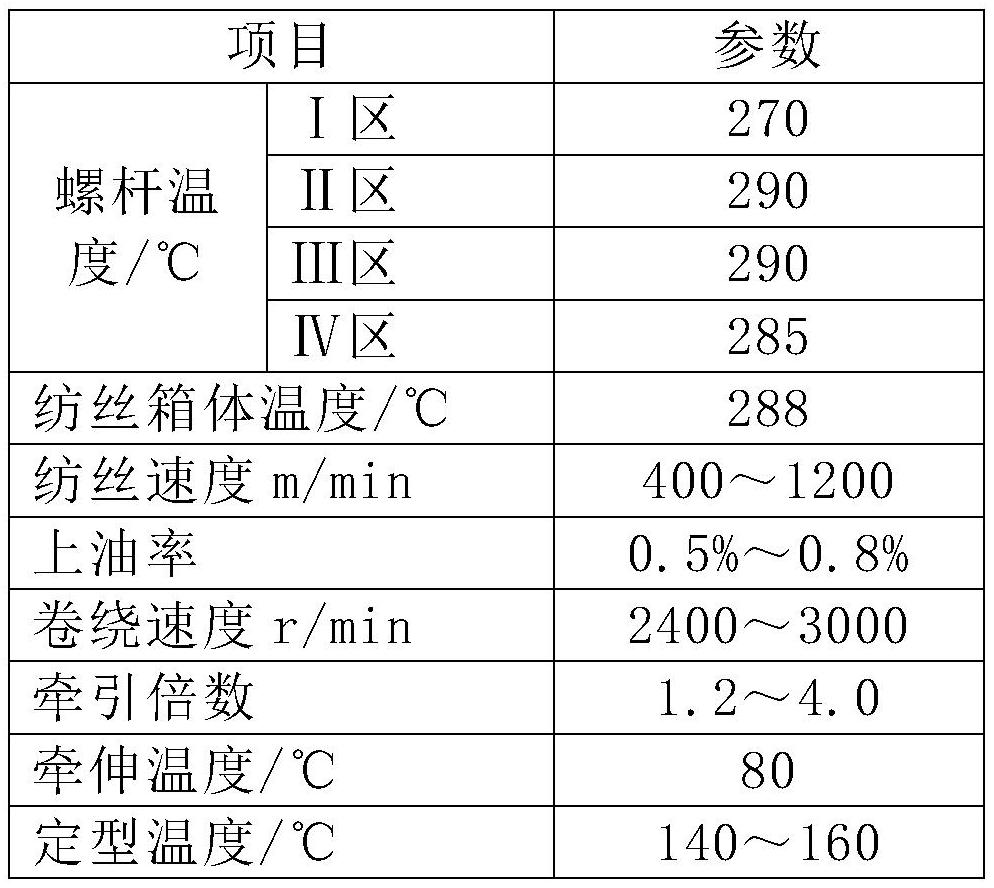

Preparation method of aerogel-containing polyester fibers

PendingCN112410922AControllable particle sizeControllable shapeMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterPolymer science

The invention provides a preparation method of aerogel-containing polyester fibers. The preparation method comprises the following steps of 1, uniformly mixing aerogel microspheres with polyester powder to obtain mixed powder; step 2, fully mixing the mixed powder with a second polyester chip, extruding and dicing to obtain polyester fiber master batch containing aerogel; and step 3, uniformly mixing the polyester fiber master batch containing the aerogel with a third polyester chip, and then carrying out melt spinning in a spinning machine. The preparation method has the beneficial effects that (1) the aerogel microspheres are selected as the modified filler, the particle size and shape of the aerogel microspheres are controllable, and spinning is facilitated; (2) polyester and aerogel microspheres are subjected to multistage mixing, so that the problem of poor spinnability caused by non-uniform mixing of aerogel-containing polyester fibers is solved, and the spinning quality stability is facilitated; and (3) the prepared aerogel fibers can be used in multiple fields such as textile fabrics, fillers and the like, so that the thermal insulation performance is improved, and the large-range application of the aerogel in the textile field is widened.

Owner:素湃科技(上海)有限公司

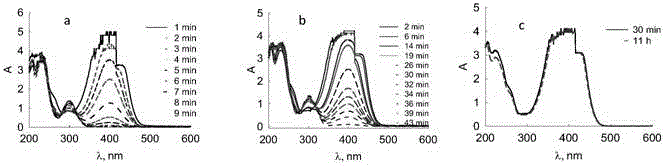

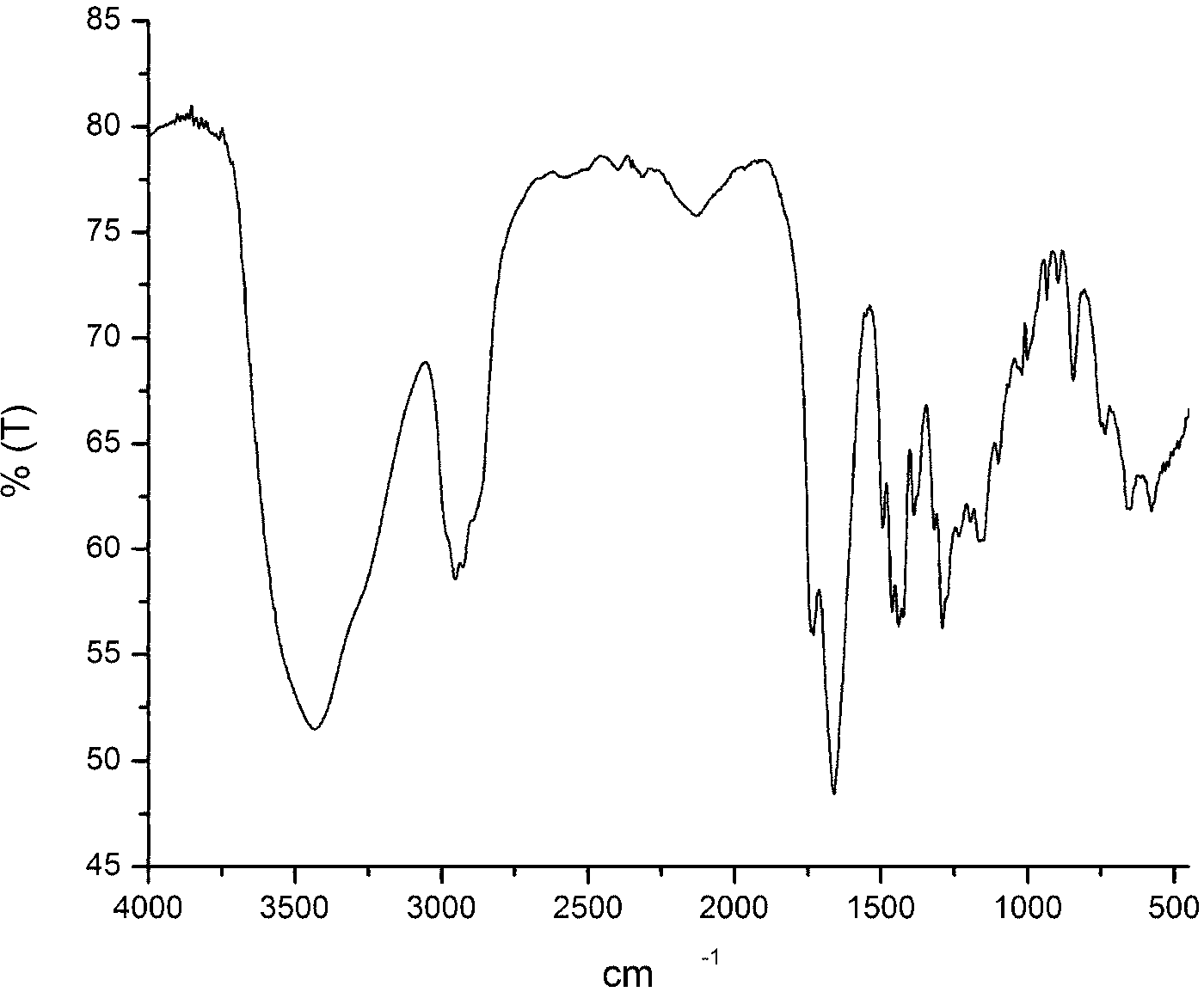

Gold nano catalyst with stable yeast cells and preparation method and application thereof

ActiveCN105413682AImprove adsorption performanceFast responseOrganic compound preparationWater contaminantsNano catalystChemistry

The invention provides a gold nano catalyst with stable yeast cells and a preparation method and application thereof, and relates to yeast cell culture and treatment and the preparation method and application of the gold nano catalyst. Yeast cells or chemically-treated modified yeast cells which are subjected to shake-flask culture on the appropriate condition are used as a carrier, a stabilizing agent and a reducing agent, chloroauric acid is reduced on the mild reaction condition, and therefore the gold nano catalyst with the stable yeast cells is prepared, wherein the gold nano catalyst is good in dispersity and stability, uniform in particle size distribution and good in catalytic activity for reduction of nitryl in nitro-compounds, hydrodechlorination of chlorinated organic compounds and degradation of dye and other organic pollutants. Particularly, according to the method, the particle size of gold nano particles can be effectively adjusted and controlled by controlling the reaction condition. The preparation technology is simple, the process is environmentally friendly, and the gold nano catalyst is widely used for reduction of the nitryl in the nitro-compounds, hydrodechlorination of the chlorinated organic compounds and degradation of the dye and other organic pollutants.

Owner:HUNAN AGRICULTURAL UNIV

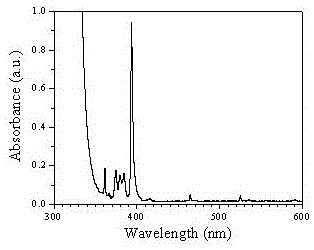

Method for preparing Eu3+ labelled molecule imprinted sensor used for pesticide residue detection

ActiveCN105136758ARealize detectionReliable methodFluorescence/phosphorescencePesticide residueNanoparticle

The invention relates to a method for preparing a Eu3+ labelled molecule imprinted sensor used for pesticide residue detection and belongs to the technical field of environment functional material preparation. The method comprises the steps that Eu3+ and amino groups and pesticide residue molecules in APTS are pre-organized and then subjected to hydrolytic crosslinking condensation with TEOS so that the Eu3+ labelled pesticide residue molecule imprinted silicon dioxide nanoparticle sensor can be obtained, pesticide residue molecule selective recognition site holes are obtained after pesticide residue molecules are eluted, chelation between pesticide residue molecules and Eu3+ on a recognition site is conducted after the pesticide residue molecules enter the recognition site of the sensor again, the fluorescence intensity of the pesticide residue molecules is improved after being chelated with Eu3+, and then high-selectivity, high-binding-capacity and high-sensitivity detection of the trace pesticide residue molecules is achieved by means of the change of the fluorescence intensity. The obtained Eu3+ labelled molecule imprinted sensor has the advantages that the rigidity of the recognition site is high, Eu3+ is not prone to elution, repeated utilization can be achieved, solvent inertness, light stability and single dispersity are high, and size is uniform.

Owner:HEFEI UNIV

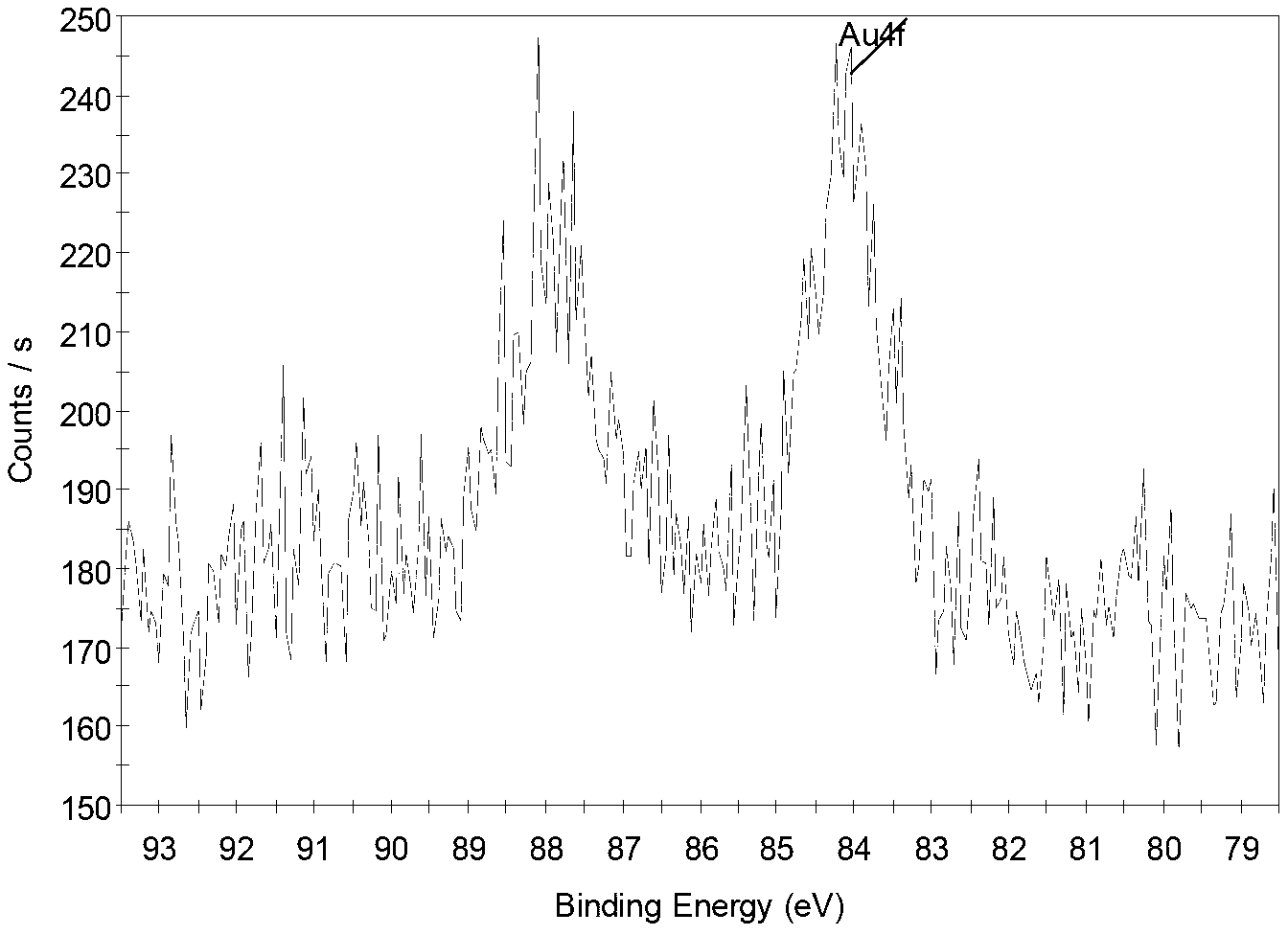

Preparation methods of cyclodextrin-based star-block polymer and cyclodextrin-based star-block polymer/gold nano-rod composite material

The invention discloses a preparation method of a cyclodextrin-based star-block polymer. The method comprises the steps that: (1) beta-cyclodextrin, P2S5, and p-methoxybenzoic acid are subjected to a sufficient reflux reaction under an alkaline and anaerobic condition in an organic solvent; the obtained product is purified, such that a RAFT polymerization chain-transfer agent is obtained; (2) the prepared RAFT polymerization chain-transfer agent, methyl methacrylate, and a functional monomer are mixed; the mixture is subjected to a polymerization reaction under the existence of a free radical initiator and an anaerobic condition in a solvent; polymerization is stopped, and the obtained product is purified and separated; and (3) the obtained product is adopted as a macromolecular chain-transfer agent; a hydrophilic monomer and the macromolecular chain-transfer agent are subjected to a polymerization reaction in a solvent under the existence of a free radical initiator and an anaerobic condition; polymerization is stopped by ice-water bath cooling; the obtained product is purified and separated; and the product is reduced by using a reducing agent. The synthesis route provided by the invention is simple. The star-block polymer has a clear structure. The particle size and morphology of the nano-gold are controllable.

Owner:ANKANGDEMEI ZHONGSHAN NANO TECH CO LTD

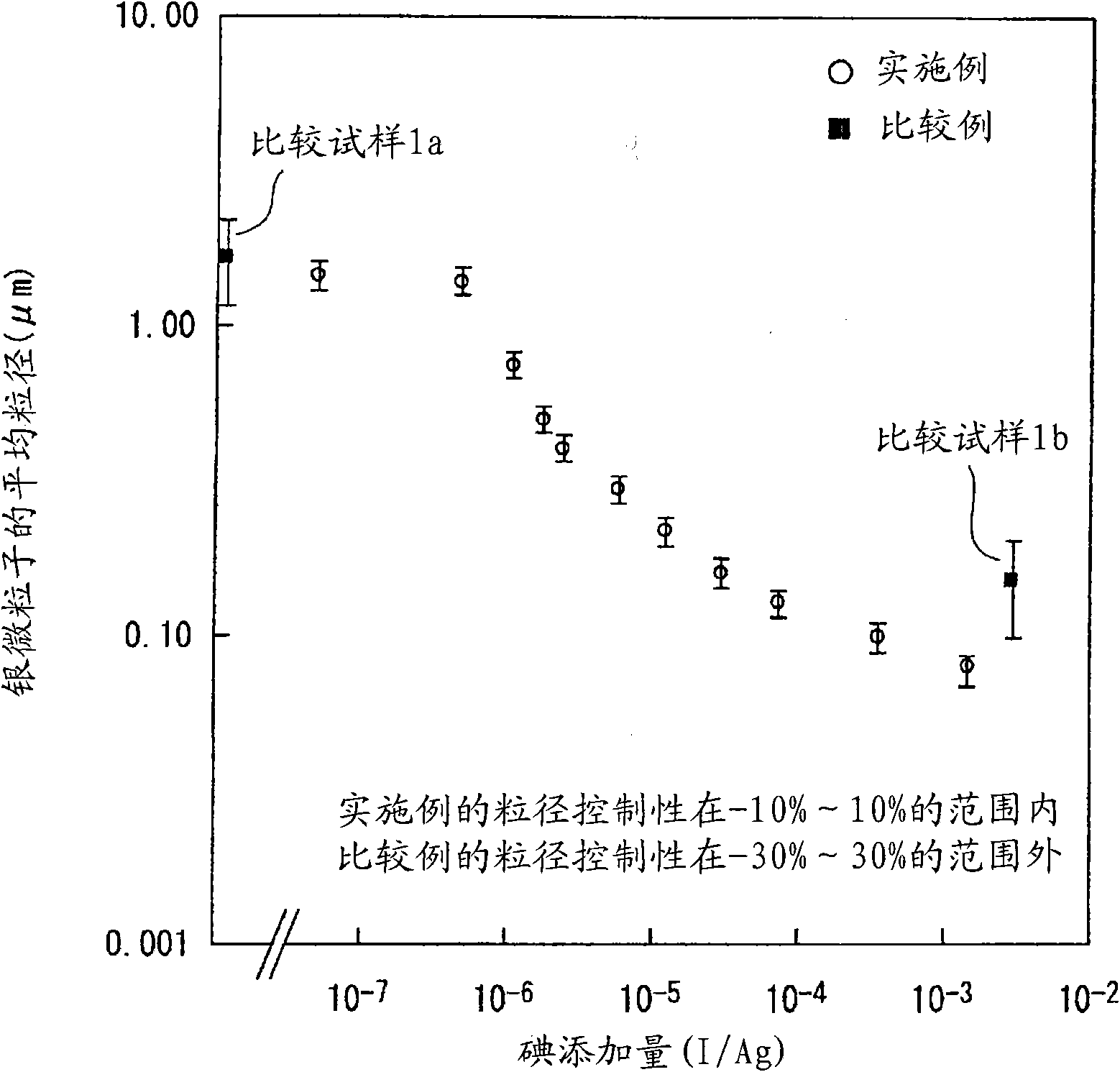

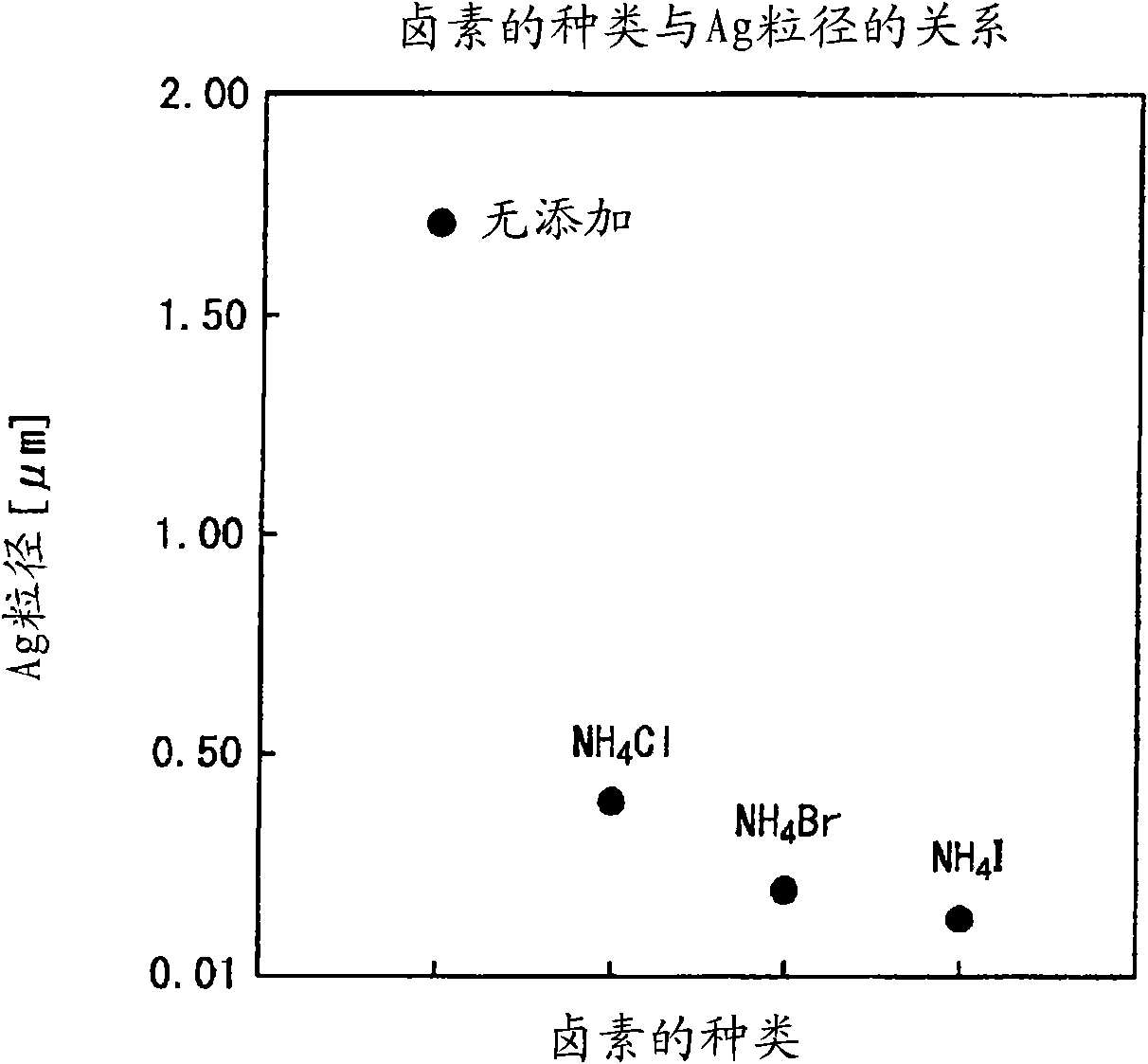

Fine silver particle, process for producing fine silver particle, and apparatus for producing fine silver particle

Fine silver particles which contain a halogen in an amount of 5.0OE0<-8> to 1.5OE0<-3> mol per mol of the silver. Also provided is a process for producing the fine silver particles which includes a step in which a reducing agent is added to a silver ion solution to reduce the silver ions and thereby precipitate fine silver particles, the silver ion reduction being conducted in the presence of a nucleating substance which constitutes nuclei for the fine silver particles. Furthermore provided is an apparatus for producing the fine silver particles which comprises a silver ion solution tank, a first pipeline connected to the silver ion solution tank, an aqueous-ammonia-solution tank, a second pipeline connected to the aqueous-ammonia-solution tank, a reducing-liquid tank, a third pipeline connected to the reducing-liquid tank, and a fourth pipeline extending from a part where the first and second pipelines cross each other. The apparatus has a constitution in which a reducing liquid supplied through the third pipeline is mixed with a liquid mixture of a silver ion solution and an ammonia solution, the liquid mixture being supplied through the fourth pipeline.

Owner:MITSUBISHI MATERIALS CORP

Taxdol self assembled precusor liposome and its preparation method

ActiveCN1823734ASolve the "bottleneck" problem that is difficult for efficient industrial productionImprove product qualityOrganic active ingredientsOil/fats/waxes non-active ingredientsDispersed mediaPolyethylene glycol

A self-assembled precursor liposome of taxusol is proportionally prepared from tausol, phosphatide, polyethylene glycol and dispersing medium through mixing, dispersing, press-filtering by millipore film, and pouring it in a container full of N2.

Owner:CHINA PHARM UNIV +1

Method for producing industrial grade superior ammonium sulfate through coked coarse ammonium sulfate dilution crystallization

InactiveCN103496715AImprove color levelReduced growth rateAmmonium sulfatesActivated carbonCrystal habit

The invention particularly relates to a method for producing industrial grade superior ammonium sulfate through coked coarse ammonium sulfate dilution crystallization. According to the technical scheme, the method comprises the steps that the pH value of a coked coarse ammonium sulfate aqueous solution is adjusted through NaOH, activated carbon is further added, and the aqueous solution is filtered, so that a coked coarse ammonium sulfate crystallization mother solution is obtained; an acidity adjusting agent, a crystal habit modification agent and seed crystals are added to the mother solution, crystal is cultivated, and therefore suspended turbid crystal mush is prepared; finally, eluent is added to suspended turbid crystal mush flow, dilution crystallization is conducted, ammonium sulfate crystals are prepared through filtration and drying, the particle size distribution of a crystal product is concentrated, the surface is smooth, the purity is high, the liquidity is good, and the standard of an industrial grade superior product can be met. The particle size and the addition quantity of the seed crystals are changed so that the average particle size and the particle size distribution of the ammonium sulfate crystal product can be adjusted and controlled in the process of crystallization. The method for producing the industrial grade superior ammonium sulfate through coked coarse ammonium sulfate dilution crystallization has the advantages that the production cost is low, the production cycle is short, the average particle size is controllable, the particle size distribution is concentrated, one-way crystallization yield is high (no less than 95%), and the quality of the product is high.

Owner:WUHAN UNIV OF SCI & TECH

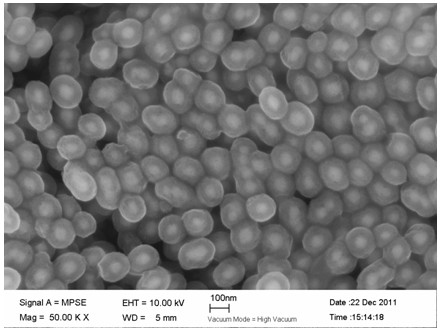

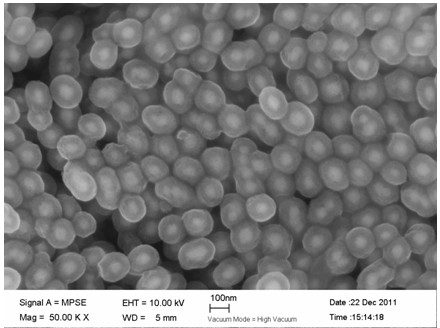

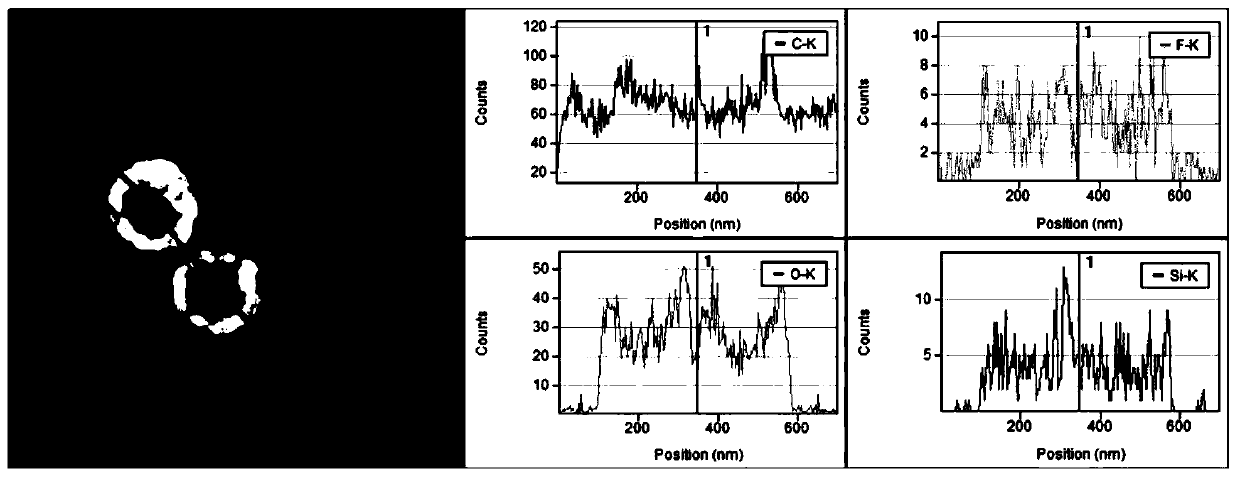

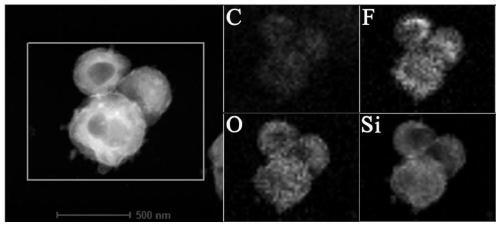

Polytetrafluoroethylene-based core-shell nano composite material as well as preparation method and application thereof

The invention provides a polytetrafluoroethylene-based core-shell nano composite material as well as a preparation method and application thereof, and belongs to the technical field of polymer composite materials. According to the polytetrafluoroethylene-based core-shell nano composite material provided by the invention, polytetrafluoroethylene latex particles are used as a core, a polymer layer obtained by polymerization reaction of a first monomer, a second monomer, a first initiator, a second initiator and water is used as a first shell layer, and a silicon dioxide layer obtained by hydrolysis condensation reaction of the polymer layer, ethanol, water, ammonia water and a silicon source reagent is used as a second shell layer. The polytetrafluoroethylene-based core-shell nano compositematerial provided by the invention has excellent self-lubricating property, high chemical activity and high wear resistance under the condition that a C-F molecular chain skeleton is not damaged.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

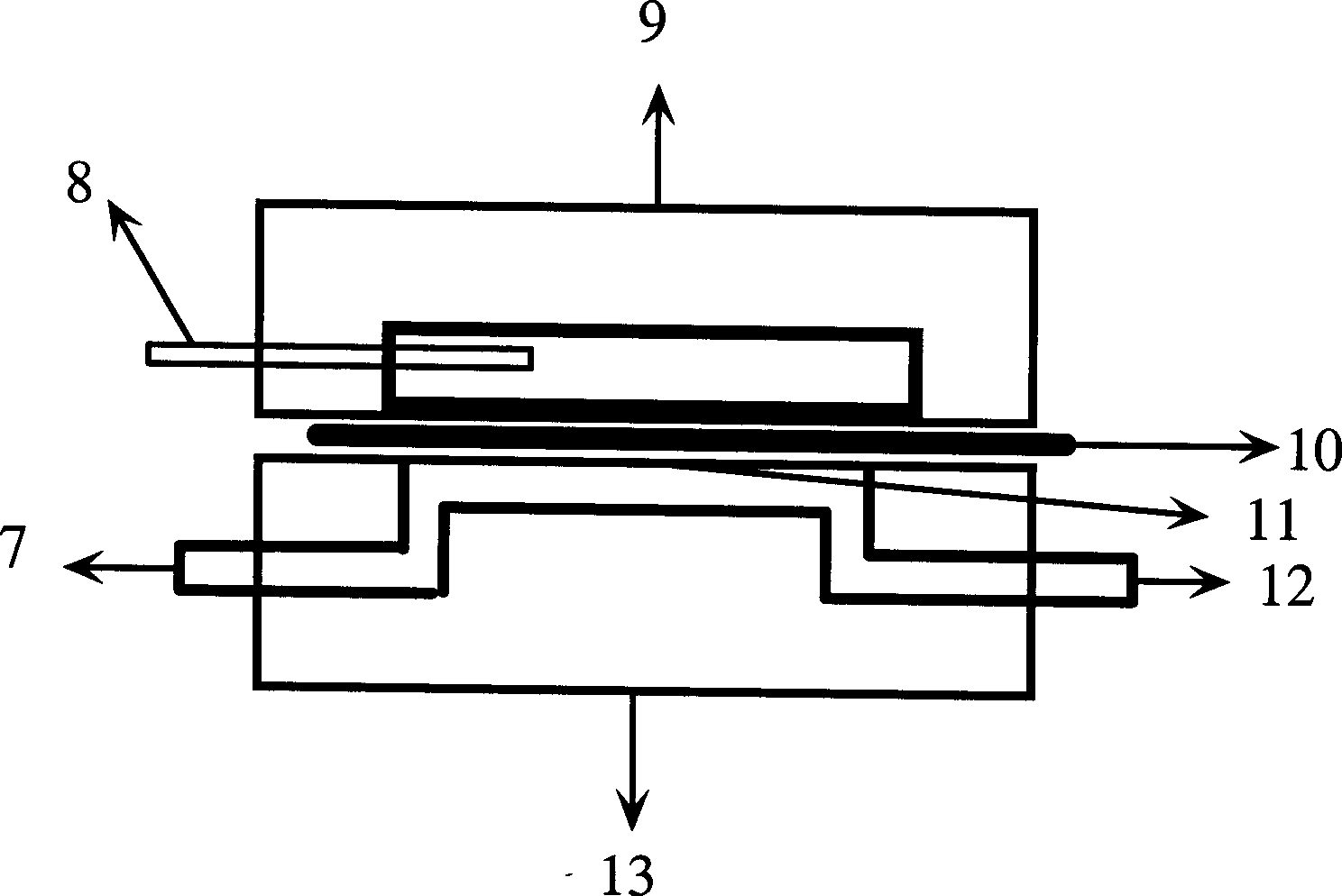

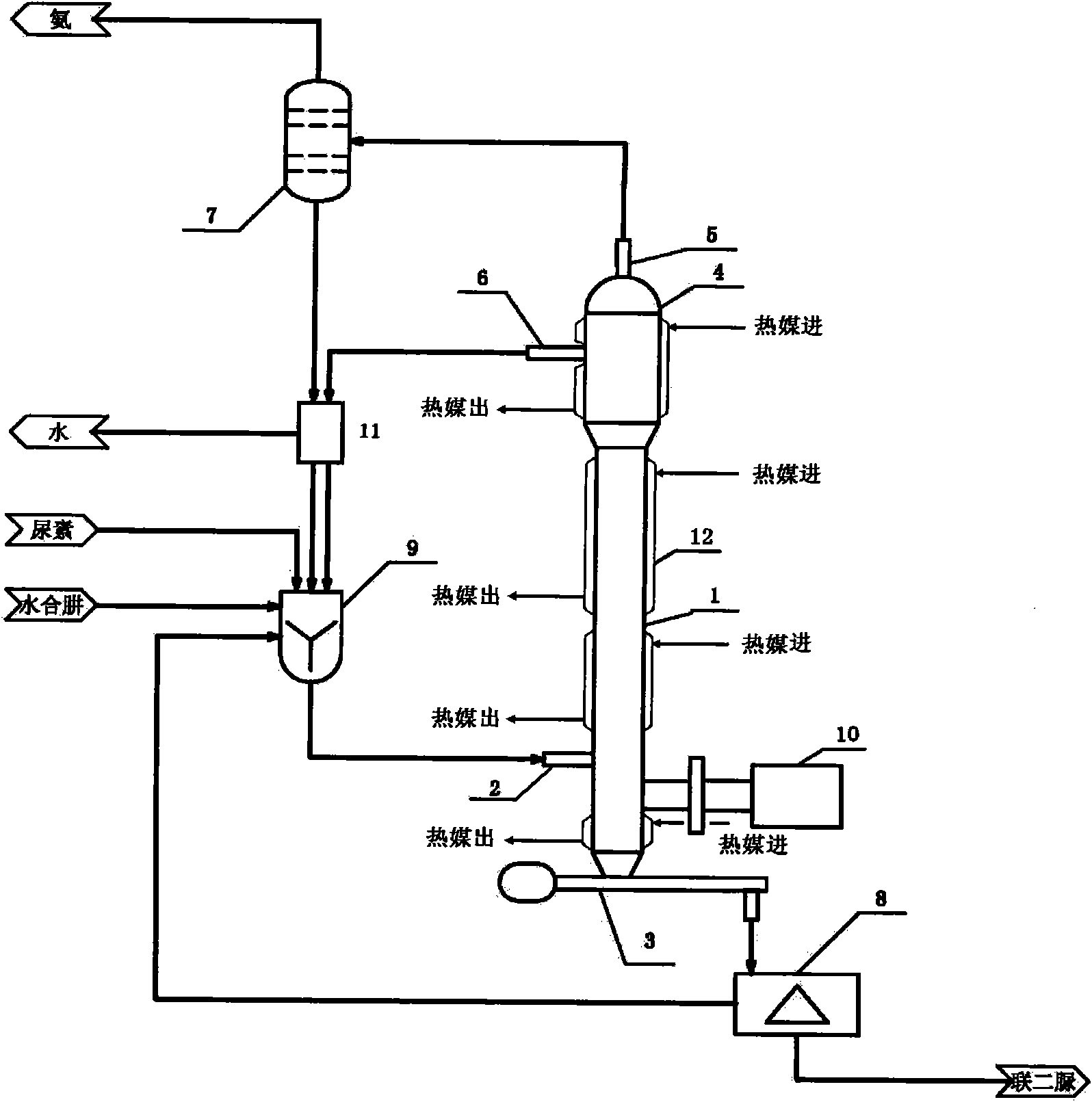

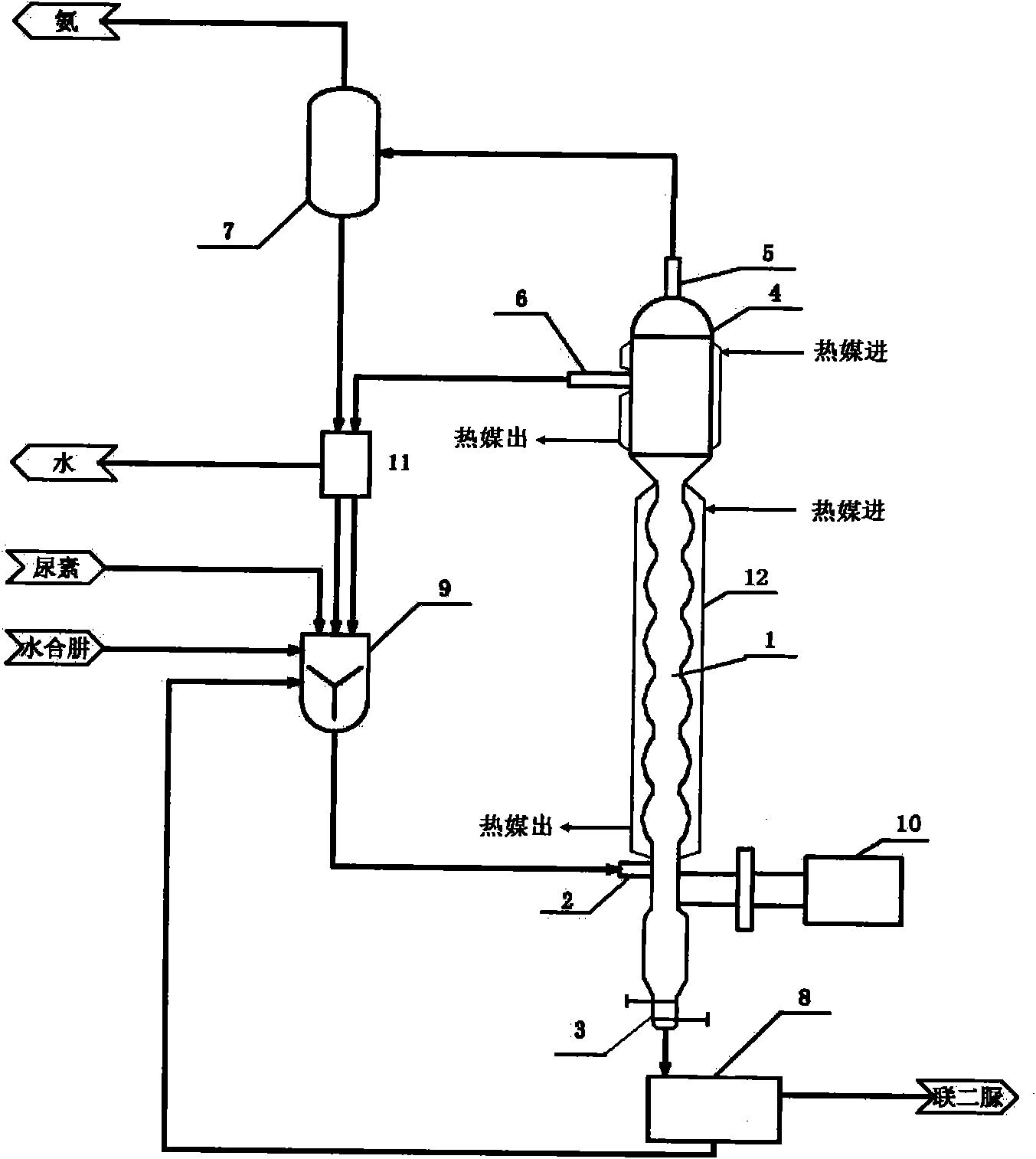

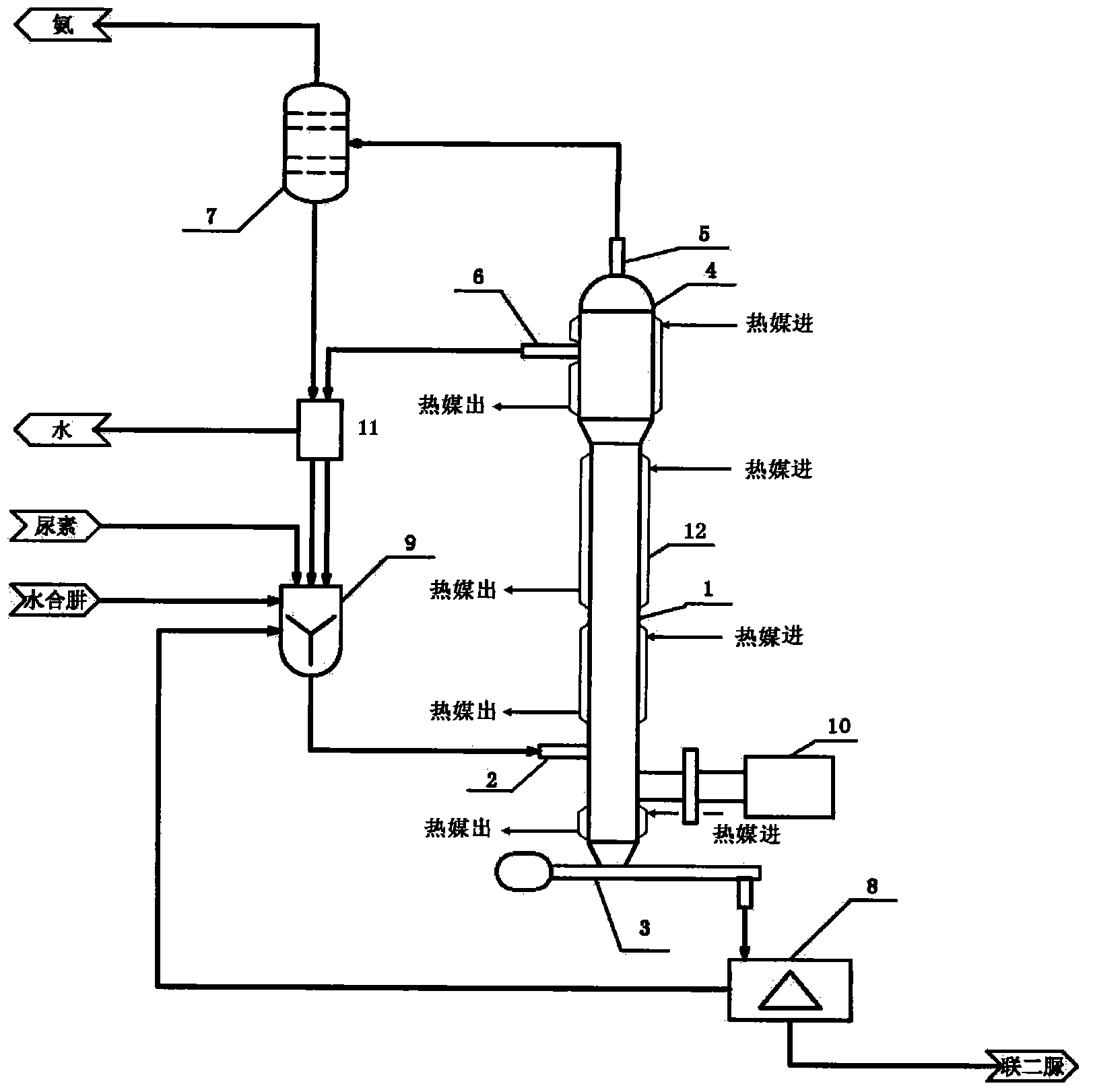

Continuous production method and continuous production device for synthesizing biruea

ActiveCN101967114ANarrow residence time distributionWith selective suspensionUrea derivatives preparationOrganic compound preparationReaction rateOscillating flow

The invention discloses a continuous production method for synthesizing biruea, comprising the following steps of: (1) continuously adding hydrazine hydrate and a urea solution into the middle lower part of an oscillating flow tubular reaction crystallizer to react and generate biruea grains; (2) along with the processes of reaction and crystallization, gradually increasing the grain diameter of the biruea grains, settling the biruea grains at the bottom of the reaction crystallizer, continuously discharging the biruea grains settled at the bottom of the reaction crystallizer, separating solids and liquid and cleaning to obtain the biruea; and (3) continuously discharging mother liquid with unconverted reactants from the upper part of the reaction crystallizer and continuously dischargingammonia as a by-product from the top of the reaction crystallizer. The invention also discloses the oscillating flow tubular reaction crystallizer which is used for implementing the production method. The continuous production method is suitable for alkaline condensation technology, increases an average reaction rate, has high production capacity of unit reactor volume and can control the grain diameter of the biruea to separate subsequently and reduce purification cost.

Owner:ZHEJIANG ENG DESIGN +2

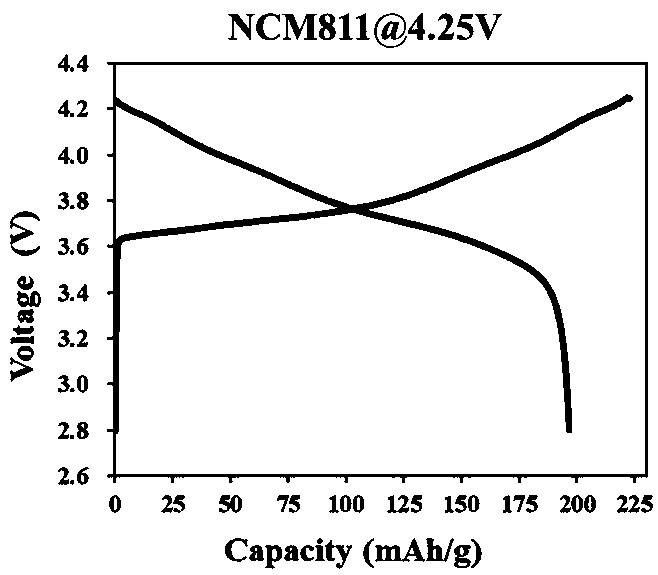

Preparation method of ternary positive electrode material of lithium-rich manganese-based coating layer

PendingCN110668507AImprove performanceImprove electrochemical stabilityCell electrodesNickel compoundsElectrolytic agentPhysical chemistry

The invention discloses a preparation method of a ternary positive electrode material of a lithium-rich manganese-based coating layer. The preparation method comprises the following steps: synthesizing a nickel-rich ternary positive electrode material on the basis of a conventional coprecipitation method, and coating a lithium-rich manganese-based layer on the nickel-rich ternary positive electrode material by a solvothermal method. According to a microscopic core-shell structure, the high-capacity characteristic of the lithium-rich manganese-base layer and the structural stability of the ternary positive electrode material are perfectly combined, so that the material optimal performance is achieved. And finally, the material is coated with an AlF3 coating for protecting the material fromreacting with electrolyte, so that the performance of the material is more stably. The morphology and particle size of the material can be controlled, and the method is simple, controllable and suitable for industrial production.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com