Three-dimensional sequential macroporous Co3O4 loaded nanometer Au catalyst as well as preparation method and application thereof

A three-dimensional ordering and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effect of cheap raw materials, controllable pore size, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

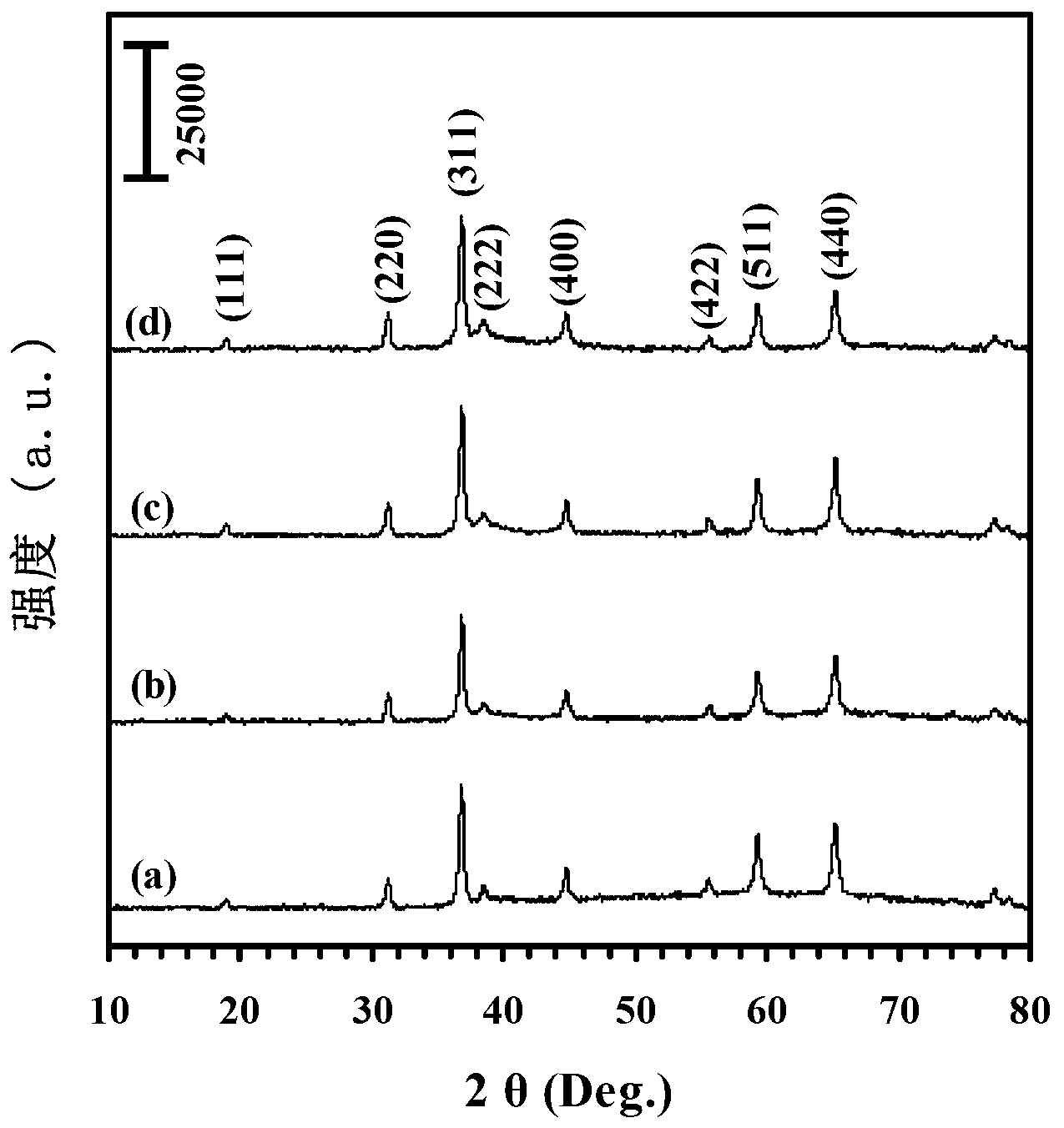

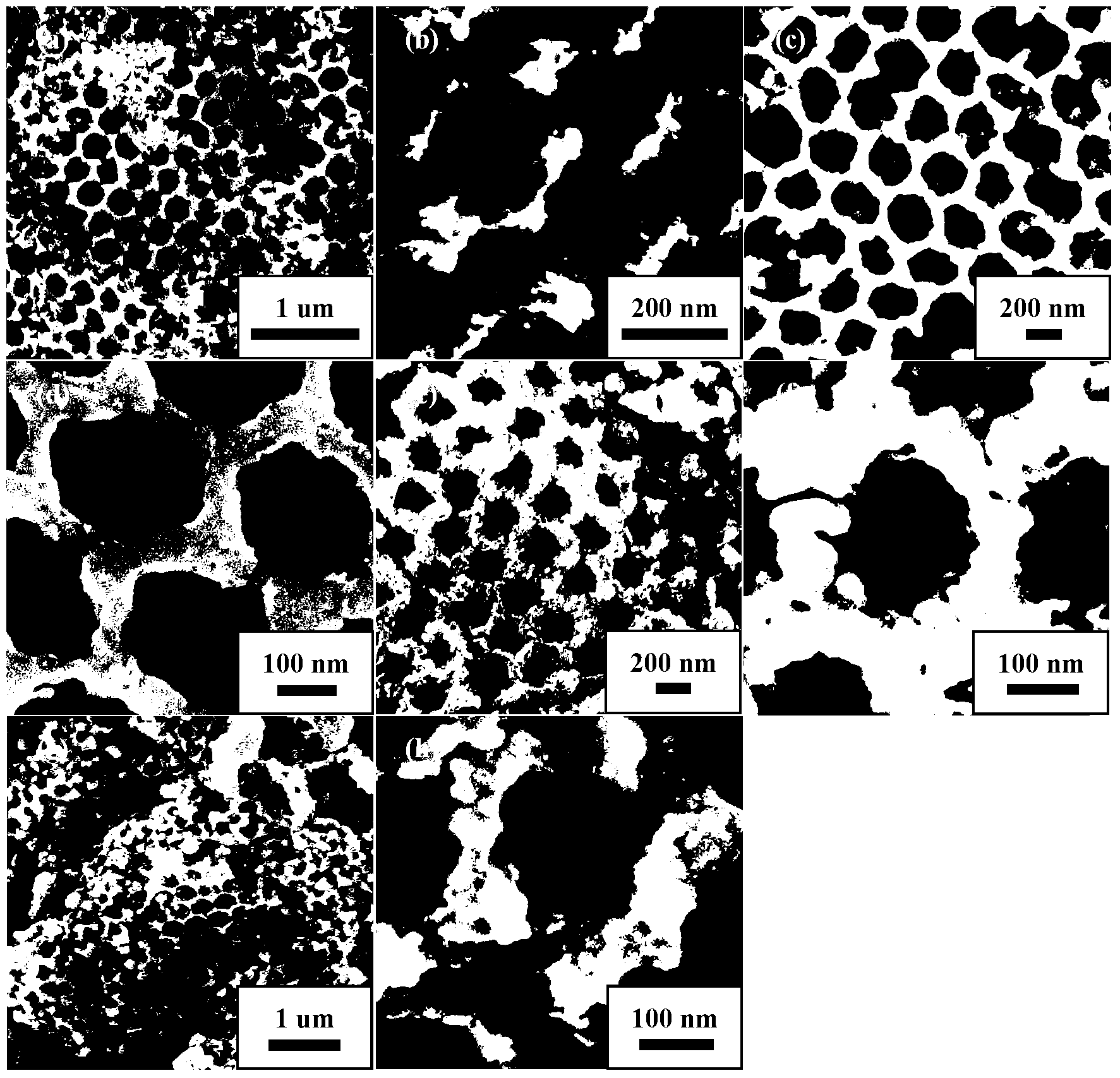

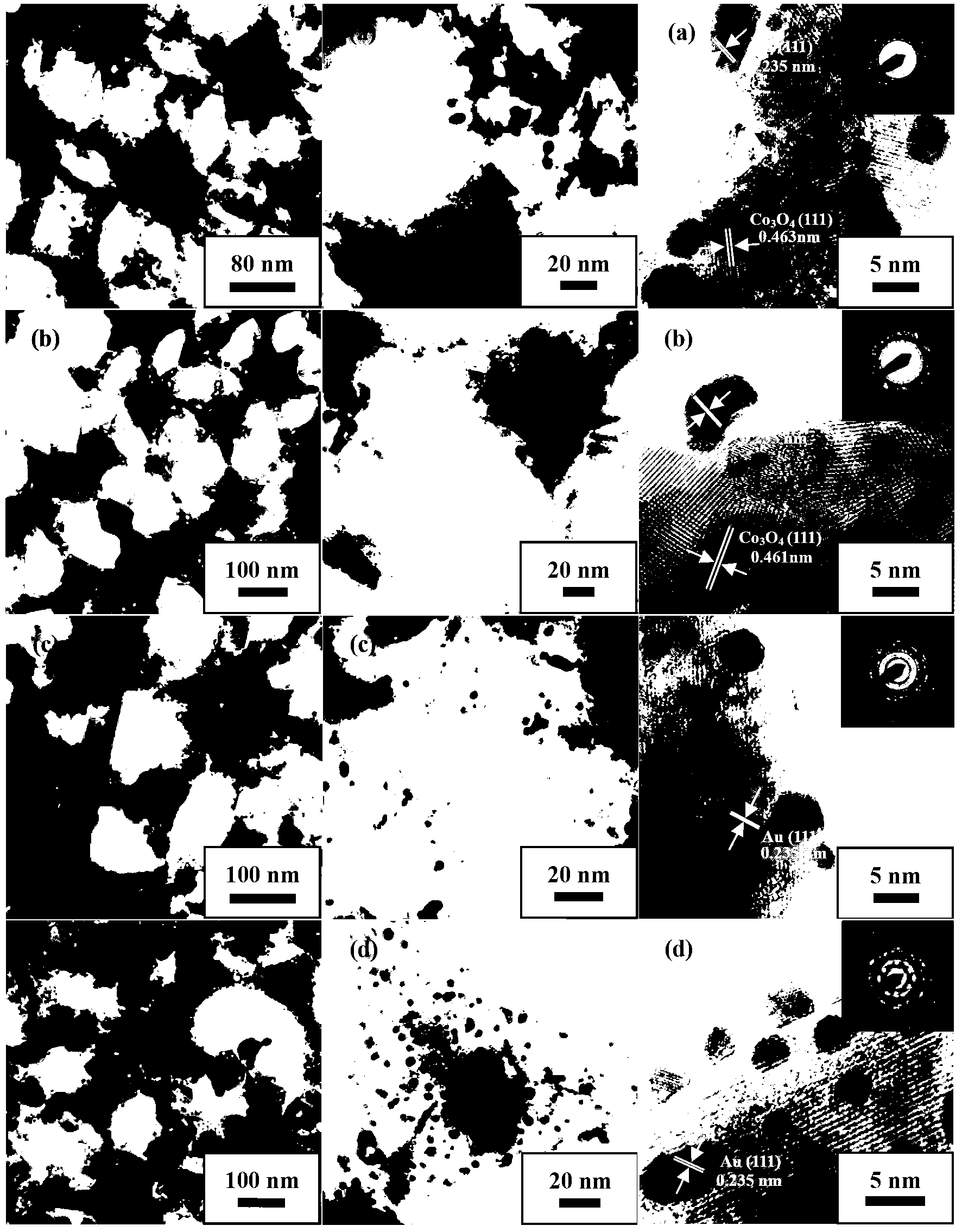

[0022] (1) Add 20mmol of cobalt nitrate hexahydrate to 9mL of anhydrous methanol and stir for 10min, add 1mL of polyethylene glycol 400 to the uniformly mixed precursor solution, stir at room temperature for 30min, then add an appropriate amount of PMMA hard template, and immerse at room temperature for 3h. Filter, dry at room temperature for 24 hours, and get 3DOM Co after roasting 3 o 4 carrier. The roasting conditions are: (1) in N 2 Under the atmosphere, the temperature was raised from room temperature to 300°C at a rate of 1°C / min, and kept for 3 hours, and then naturally lowered to room temperature; Raise to 450°C at a rate of 1°C / min, keep for 3 hours and then cool down to room temperature naturally.

[0023] (2) Ice-water bath and light-proof environment: Take 13.54mL chloroauric acid aqueous solution (1.5mmol / L) and add it to 1.33mL PVA aqueous solution (2.0mg / mL) (Au / PVA mass ratio = 1.5:1), and stir evenly 10min, followed by rapid addition of 1.92mL NaBH 4 Aque...

Embodiment 2

[0026] (1) Add 20mmol of cobalt nitrate hexahydrate to 9mL of anhydrous methanol and stir for 10min, add 1mL of polyethylene glycol 400 to the uniformly mixed precursor solution, stir at room temperature for 30min, then add an appropriate amount of PMMA hard template, and immerse at room temperature for 3h. Filter, dry at room temperature for 24 hours, and get 3DOM Co after roasting 3 o 4 carrier. The roasting conditions are: (1) in N 2 Under the atmosphere, the temperature was raised from room temperature to 300°C at a rate of 1°C / min, and kept for 3 hours, and then naturally lowered to room temperature; Raise to 450°C at a rate of 1°C / min, keep for 3 hours and then cool down to room temperature naturally.

[0027] (2) Ice-water bath and light-proof environment: Take 27.08mL chloroauric acid aqueous solution (1.5mmol / L) and add it to 2.67mL PVA aqueous solution (2.0mg / mL) (Au / PVA mass ratio = 1.5:1), and stir evenly 10min, followed by rapid addition of 3.84mL NaBH 4 Aque...

Embodiment 3

[0030] (1) Add 20mmol of cobalt nitrate hexahydrate to 9mL of anhydrous methanol and stir for 10min, add 1mL of polyethylene glycol 400 to the uniformly mixed precursor solution, stir at room temperature for 30min, then add an appropriate amount of PMMA hard template, and immerse at room temperature for 3h. Filter, dry at room temperature for 24 hours, and get 3DOM Co after roasting 3 o 4 carrier. The roasting conditions are: (1) in N 2 Under the atmosphere, the temperature was raised from room temperature to 300°C at a rate of 1°C / min, and kept for 3 hours, and then naturally lowered to room temperature; Raise to 450°C at a rate of 1°C / min, keep for 3 hours and then cool down to room temperature naturally.

[0031] (2) Ice-water bath and light-proof environment: Take 40.62mL chloroauric acid aqueous solution (1.5mmol / L) and add it to 4.00mL PVA aqueous solution (2.0mg / mL) (Au / PVA mass ratio = 1.5:1), and stir evenly 10min, followed by rapid addition of 5.76mL NaBH 4 Aque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com