Continuous production method and continuous production device for synthesizing biruea

A production method and biuret technology, applied in the field of environment-friendly chemical production, can solve the problems of movement and discharge, slow flow rate of reaction crystal tubes, unfavorable heat and mass transfer process, etc. The effect of narrow time distribution and reduced purification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

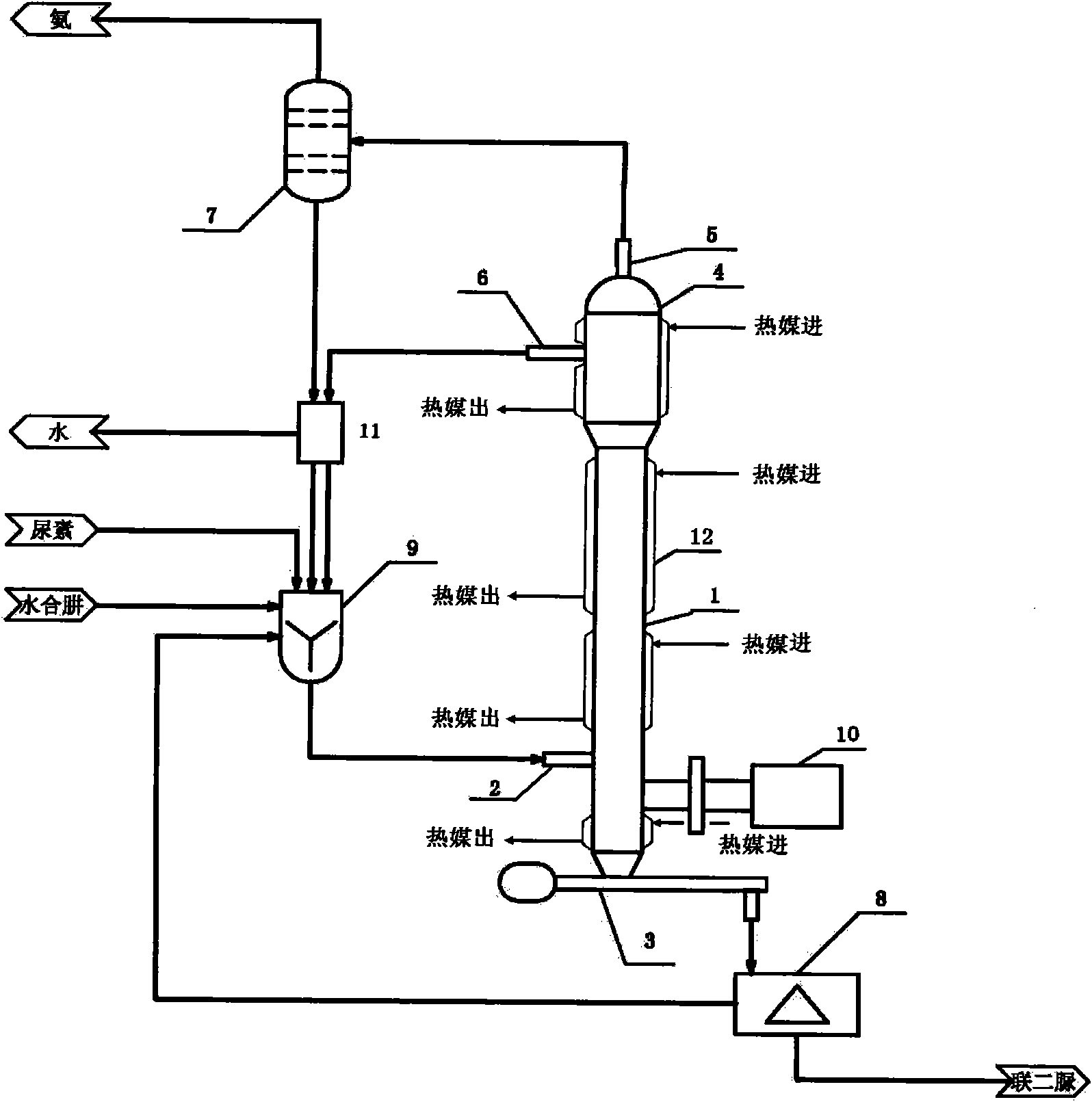

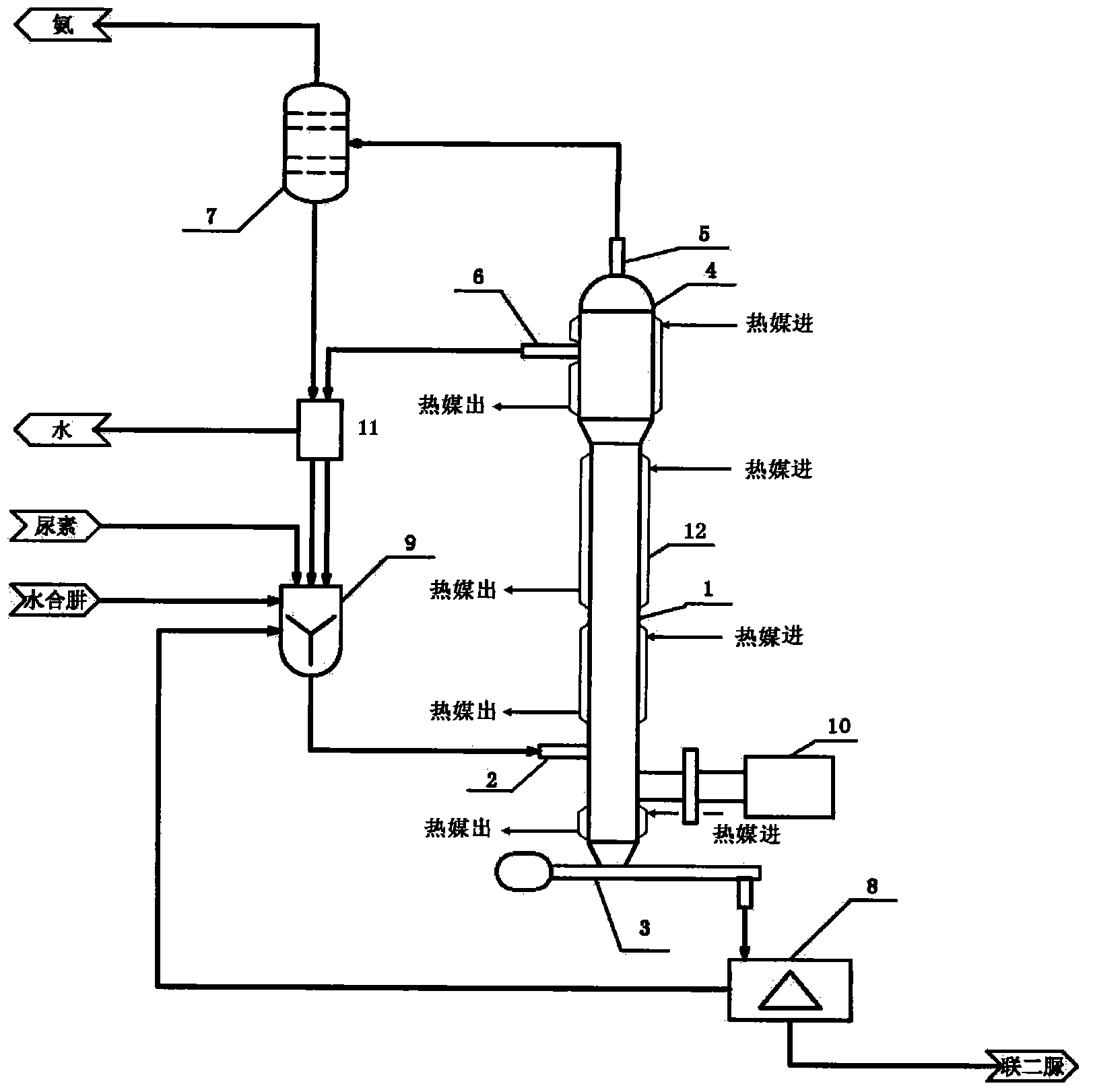

[0064] Such as figure 1In the oscillating flow tube reaction crystallizer shown, the inner diameter of the reaction crystallization tube is 150 mm, and the height is 12000 mm. The spoiler baffle adopts a conical ring baffle with an opening ratio of 25%. Four heat exchange jackets are set outside the reaction crystallization tube to adjust the The inlet temperature of the heat medium makes the temperature distribution in the reaction crystallization tube 50, 90, 105, and 110°C from bottom to top; the lower part of the reaction crystallization tube is equipped with a plunger-type hydraulic diaphragm oscillating flow generator, the oscillation frequency is 1-3Hz, and the amplitude 5~50mm; the inner diameter of the gas-liquid-solid separator is 600mm, a wire mesh demister is installed on the top, and a heat exchange jacket is installed outside, and the inlet temperature of the heat medium is adjusted so that the liquid phase temperature in the separator is 110~120°C; the solid phas...

Embodiment 2

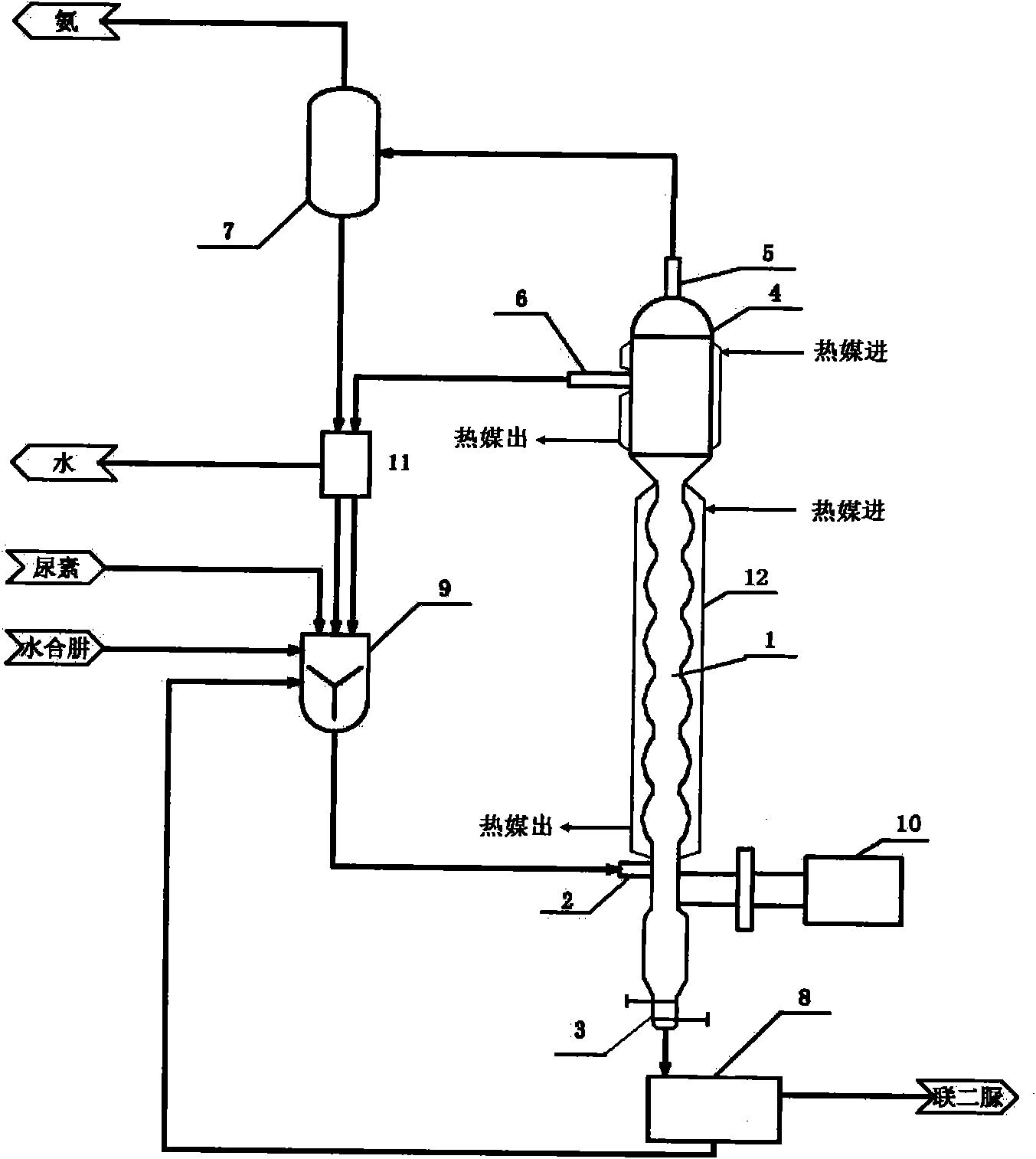

[0070] Such as figure 2 As shown, the reaction crystallization tube adopts a jacketed tube with a corrugated inner wall. The maximum inner diameter of the corrugated inner wall is 50 mm, the smallest inner diameter is 25 mm, the height is 2000 mm, and the inner diameter of the jacket is 80 mm. The lower part of the crystallization tube is equipped with a plunger-type diaphragm oscillating flow generator, the oscillation frequency is 1-3Hz, and the amplitude is 3-5mm; the inner diameter of the gas-liquid-solid separator is 100mm, and a heat exchange jacket is installed outside, and the inlet temperature of the heat medium is adjusted to make the separator The temperature of the liquid phase inside is 100-105°C; the solid phase discharge mechanism adopts a double-valve discharge device; the operating pressure of the reaction crystallizer is 0.15MPa.

[0071] The raw material preparation process uses a continuous stirring tank with an electric heating wall to realize the mixing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com