Mobile hot air distribution plate type fluidized bed dryer

A technology of fluidized bed drying and hot air distribution, which is applied in the direction of heating to dry solid materials, drying solid materials, drying, etc. Particles do not move, etc., to achieve uniform product moisture content, narrow distribution of material residence time, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

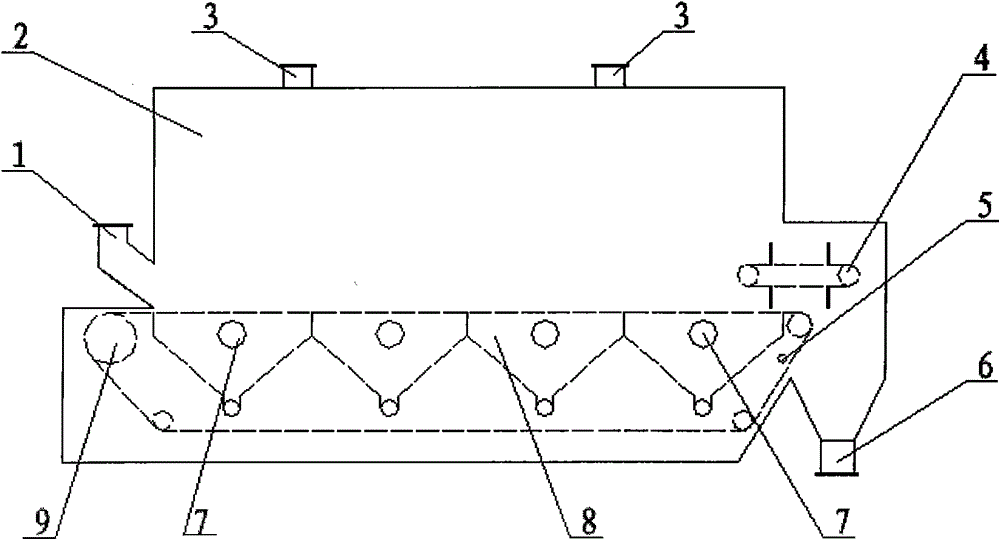

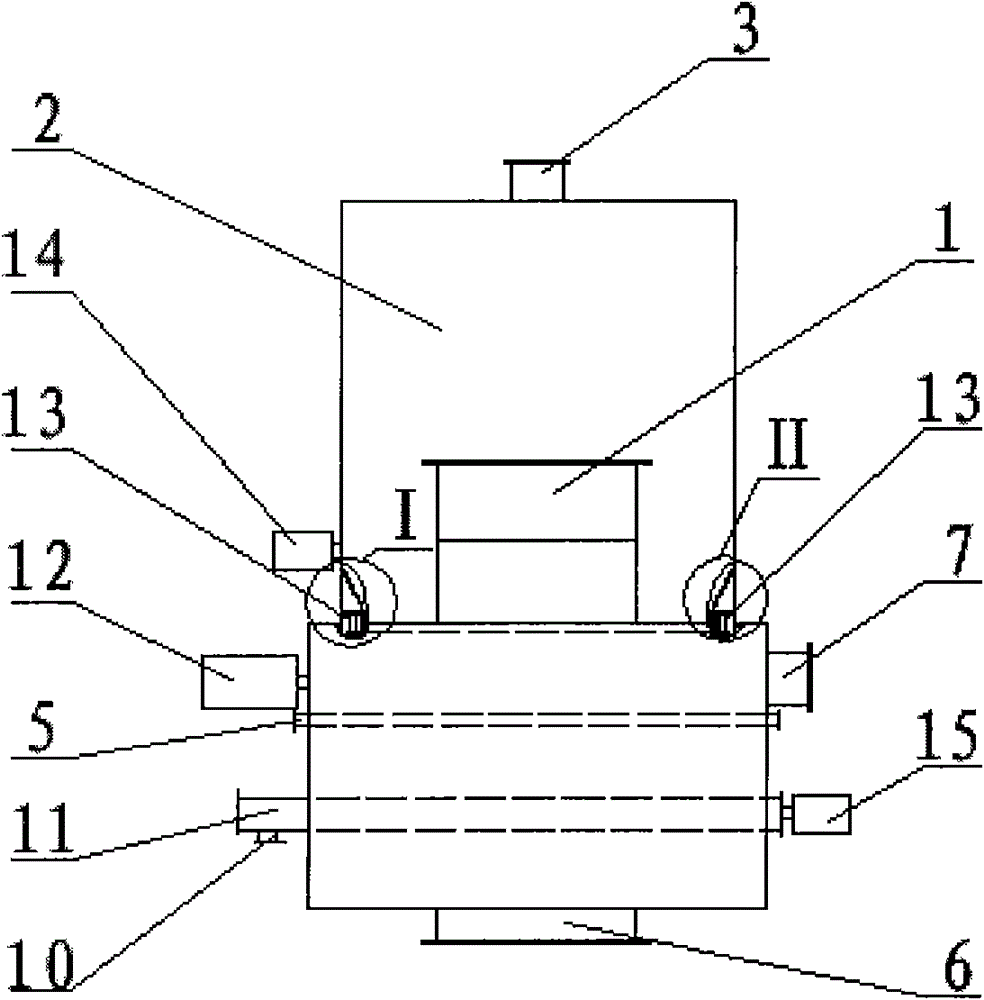

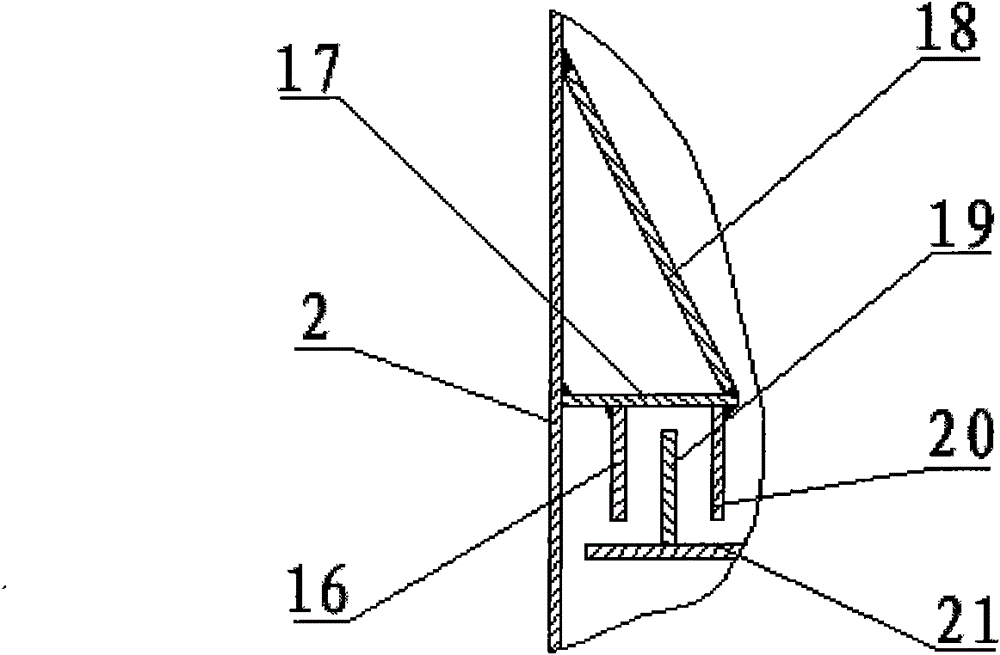

[0017] Such as Figure 1 to Figure 8 Shown, mobile hot blast distribution plate assembly 9 comprises hot blast distribution plate 21, driving wheel 22, driven wheel 25, tensioning pulley 23, roller chain 24 and mobile hot blast distribution plate driving device 12; Hot blast distribution plate 21 is made of many small The hot air distribution plate 28 is connected together, and the small hot air distribution plate 28 is provided with oblique circular channels, the diameter of which is 1 to 4 mm, the opening rate is 2% to 15%, and the angle between the oblique channels and the vertical direction is 0 to 10%. 65°, the small hot air distribution plate 28 and the roller chain 24 are fastened together with bolts; the horizontal movement speed of the moving hot air distribution plate is 20-300mm / s, and by adjusting the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com