Patents

Literature

154results about How to "High mass and heat transfer efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

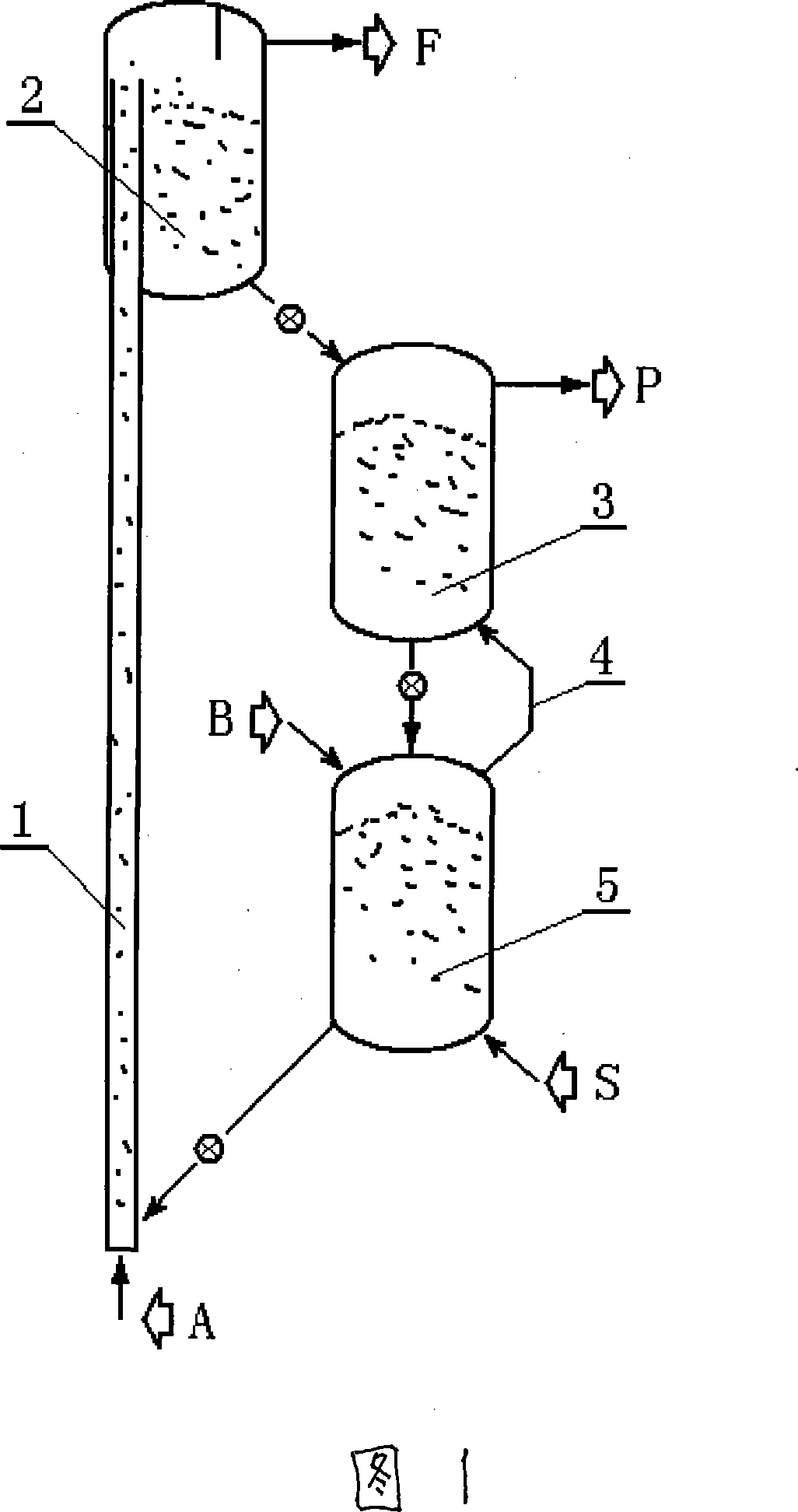

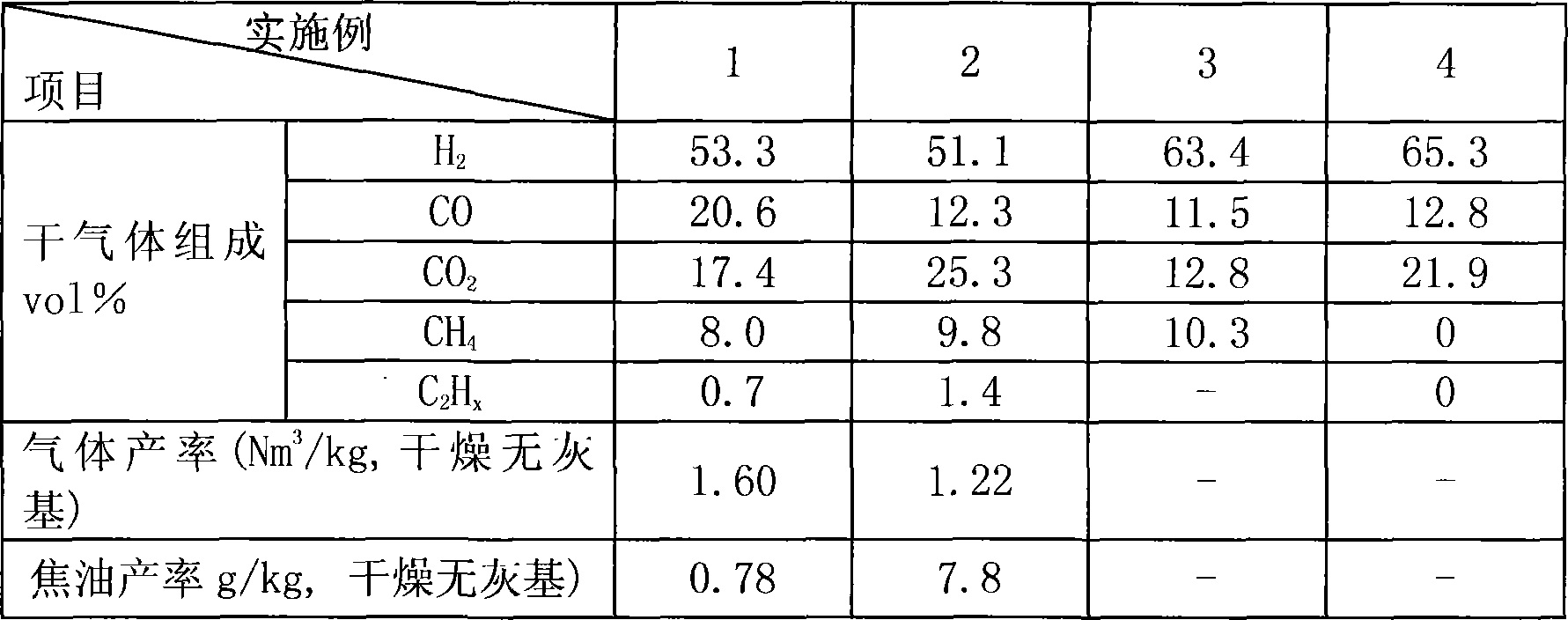

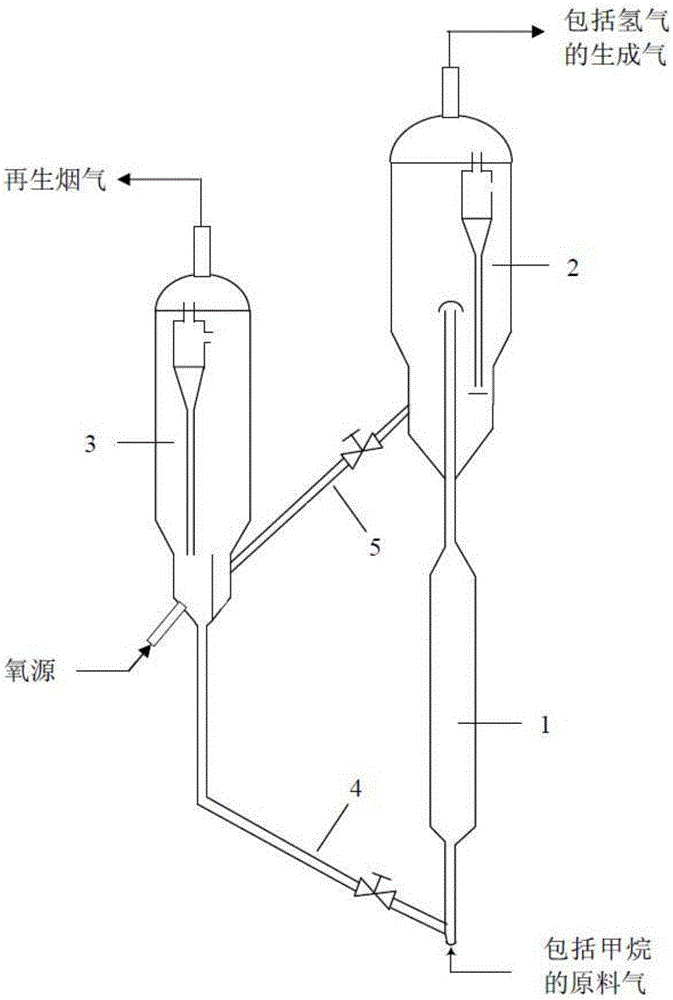

Method for preparing hydrogen-riched gas by solid fuel catalytic gasification

InactiveCN101045524AReasonable temperature distributionReduce the temperatureDirect heating destructive distillationHydrogen productionCatalytic reformingHeat carrier

A process for preparing the H2-enriched gas by catalytic gasification of solid fuel features that the solid catalyst used also as the heat carrier is circulating through riser combustion reactor, solid catalyst storage tank, catalytic reforming reactor and pyrolyzing reactor. In said pyrolyzing reactor, the biomass or coal and the solid heat carrier (catalyst) take part in fast pyrolytic reaction. Its resultant and the water steam take part in catalytic decomposing and reforming reaction to generate H2-enriched gas or synthetic gas.

Owner:DALIAN UNIV OF TECH

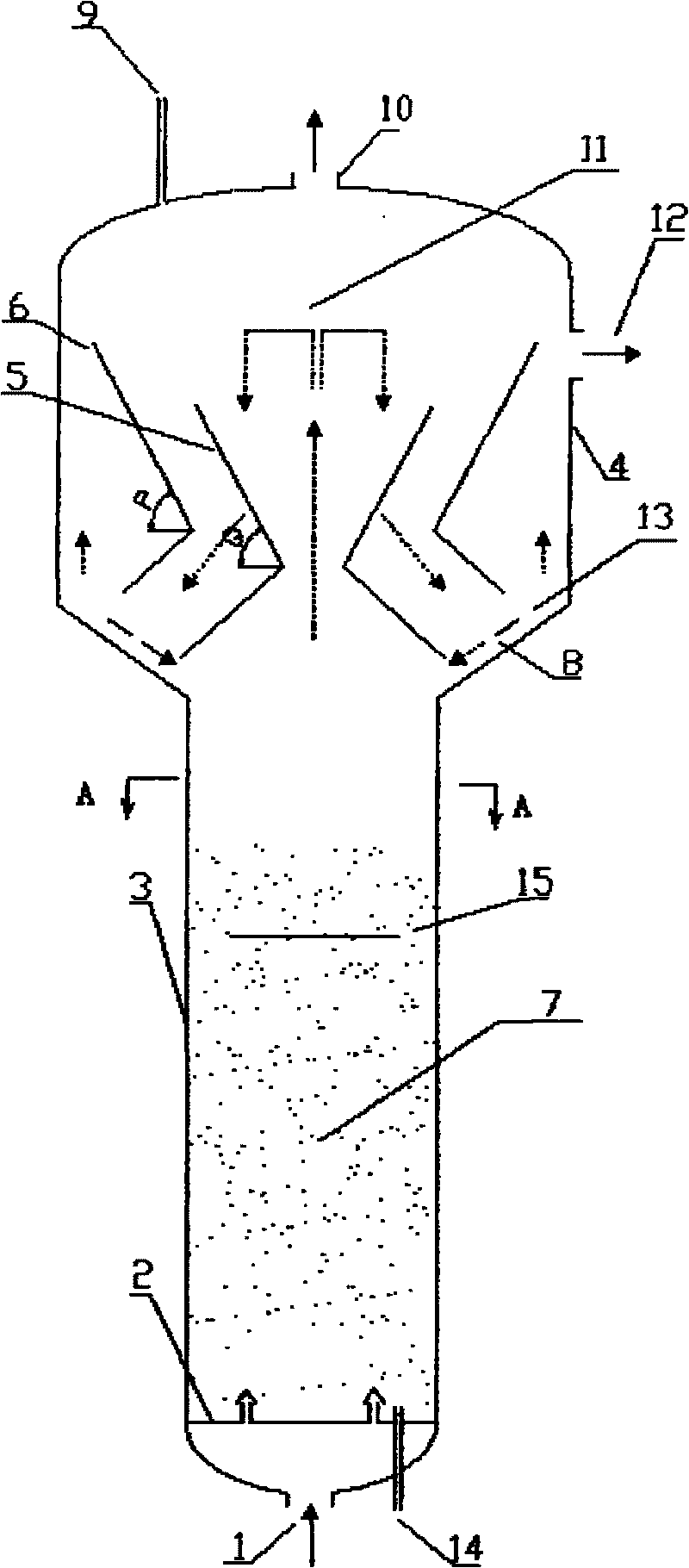

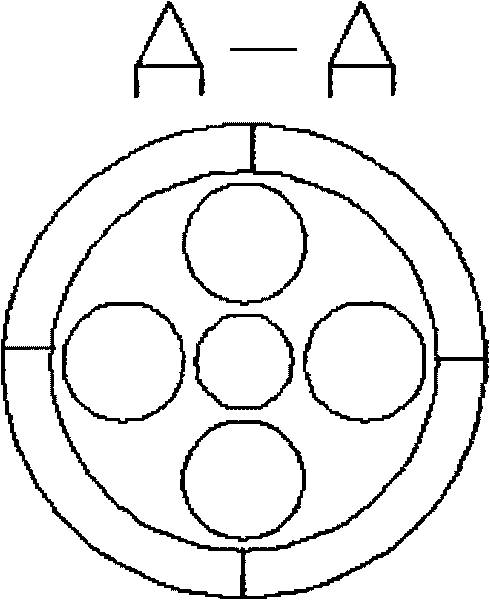

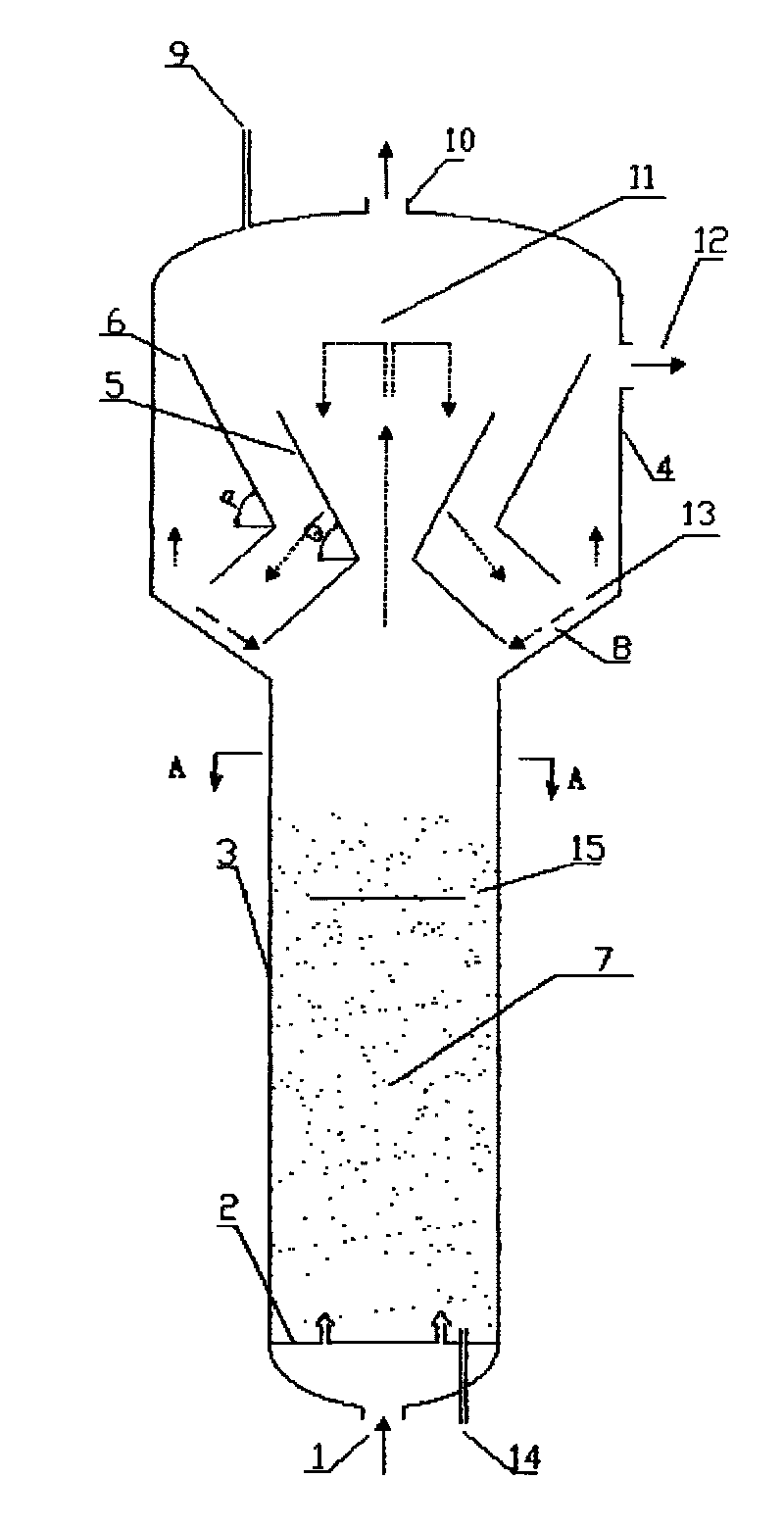

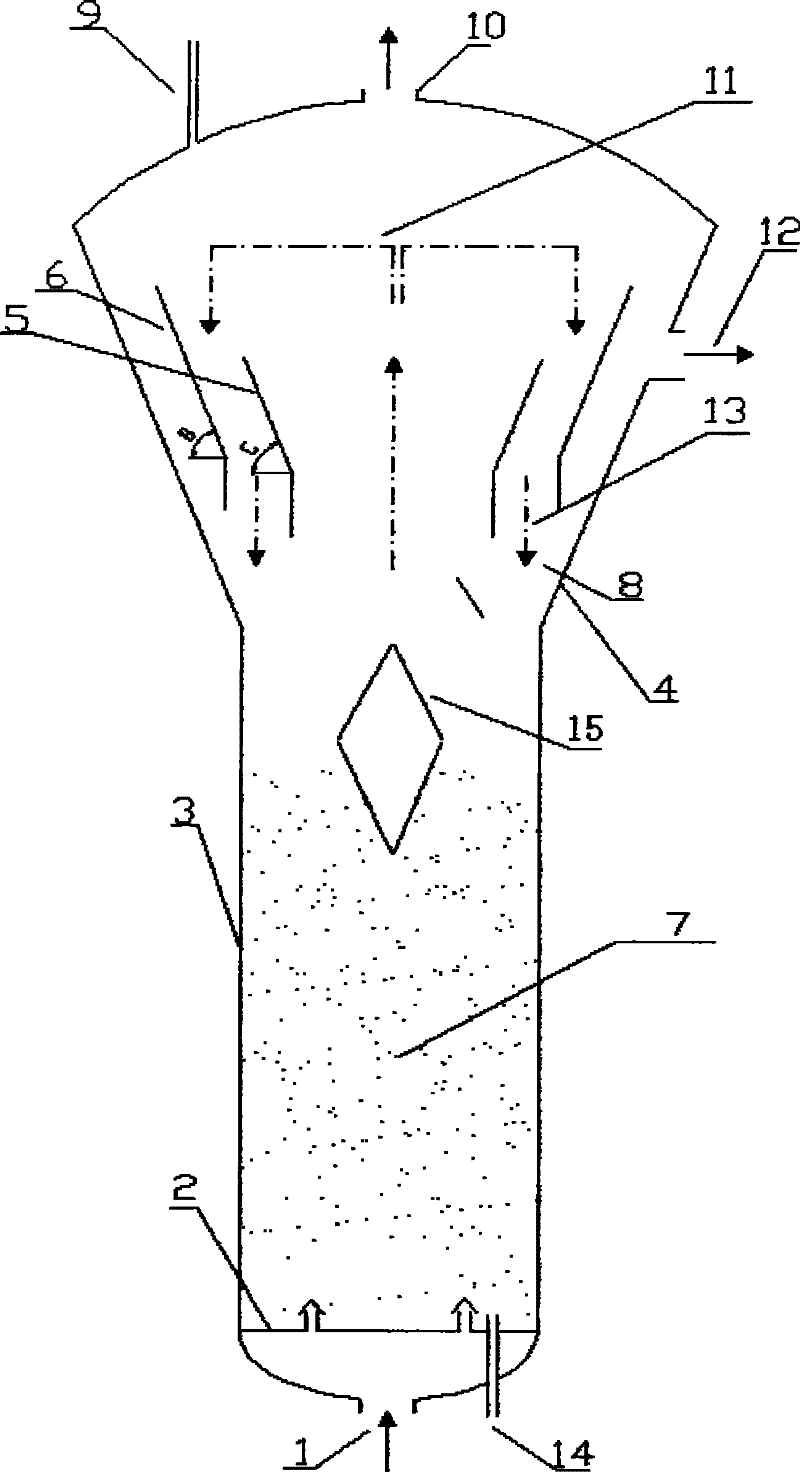

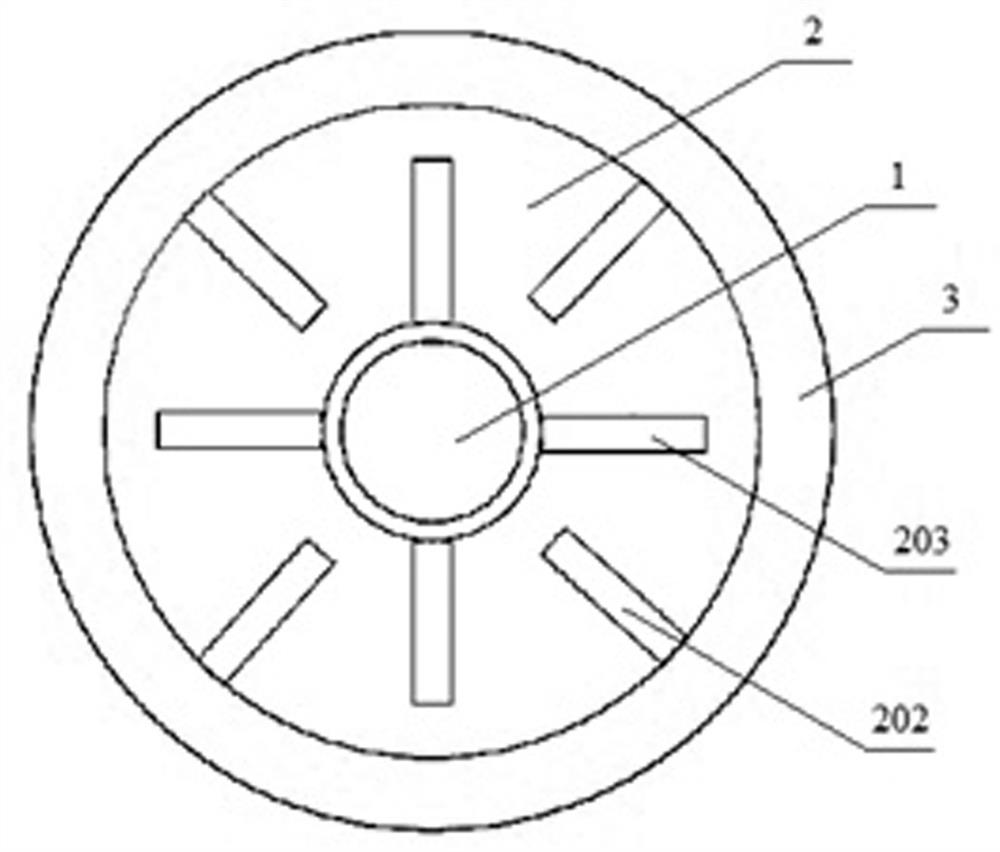

Fluidized bed reactor

ActiveCN101721960AGreat operating flexibilityEfficient separationChemical/physical processesChemical reactionFluidized bed

The invention discloses a fluidized bed reactor which comprises a reactor shell and a three-phase separator, the three-phase separator is arranged at the upper part inside the reactor shell and is of a sleeve structure comprising an inner sleeve and an outer sleeve, the upper ends and lower ends of the inner sleeve and the outer sleeve are both of opening structures, the inner sleeve and the outer sleeve are respectively composed of an upper section and a lower section, the upper sections of the inner sleeve and the outer sleeve are in reverse frustum structures, and the lower sections of the inner sleeve and the outer sleeve are in frustum structures. By designing a novel three-phase separating structure, the invention can further improve separating effect, reduce catalyst carrying-out amount, and enhance the operation elasticity of the three-phase separator. The reactor is mainly applicable to chemical reactions between liquid and gas substances of different types and solid particles under contact condition, and has the advantages of large catalyst inventory, high reactor use ratio, simple structure, easy operation and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

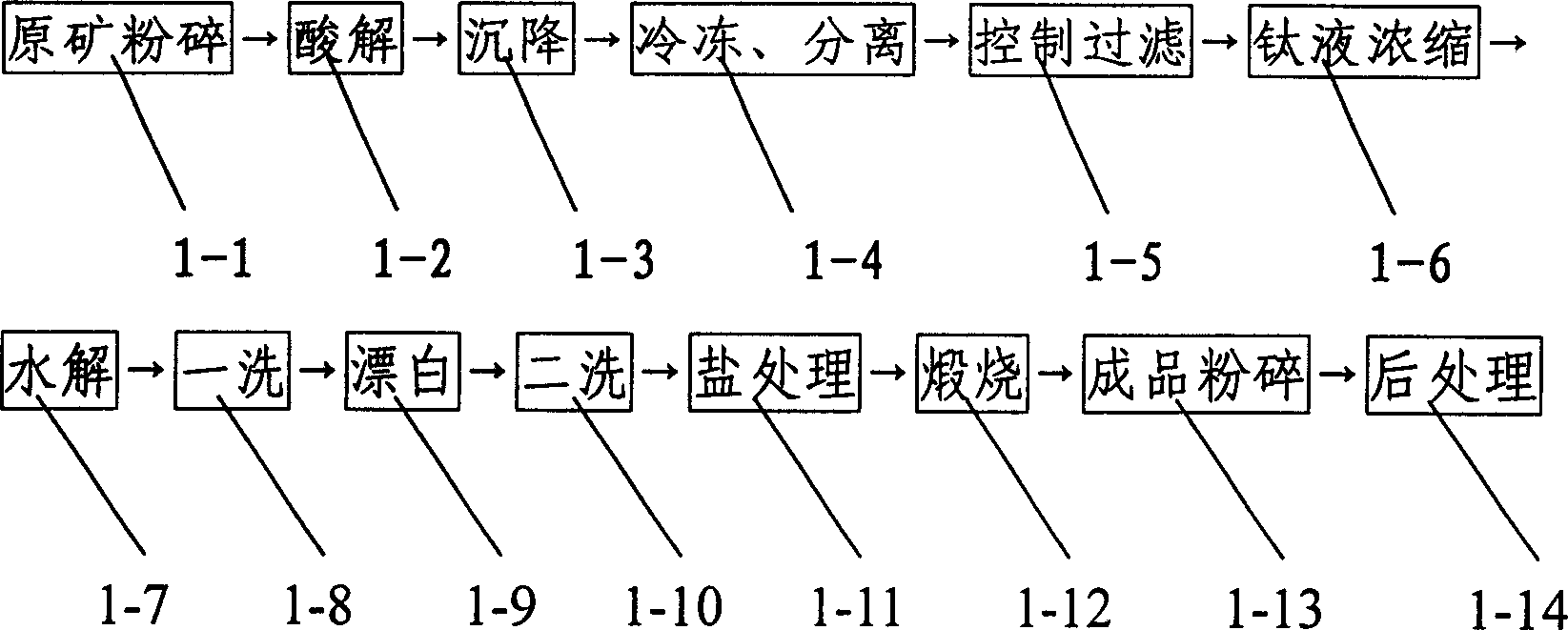

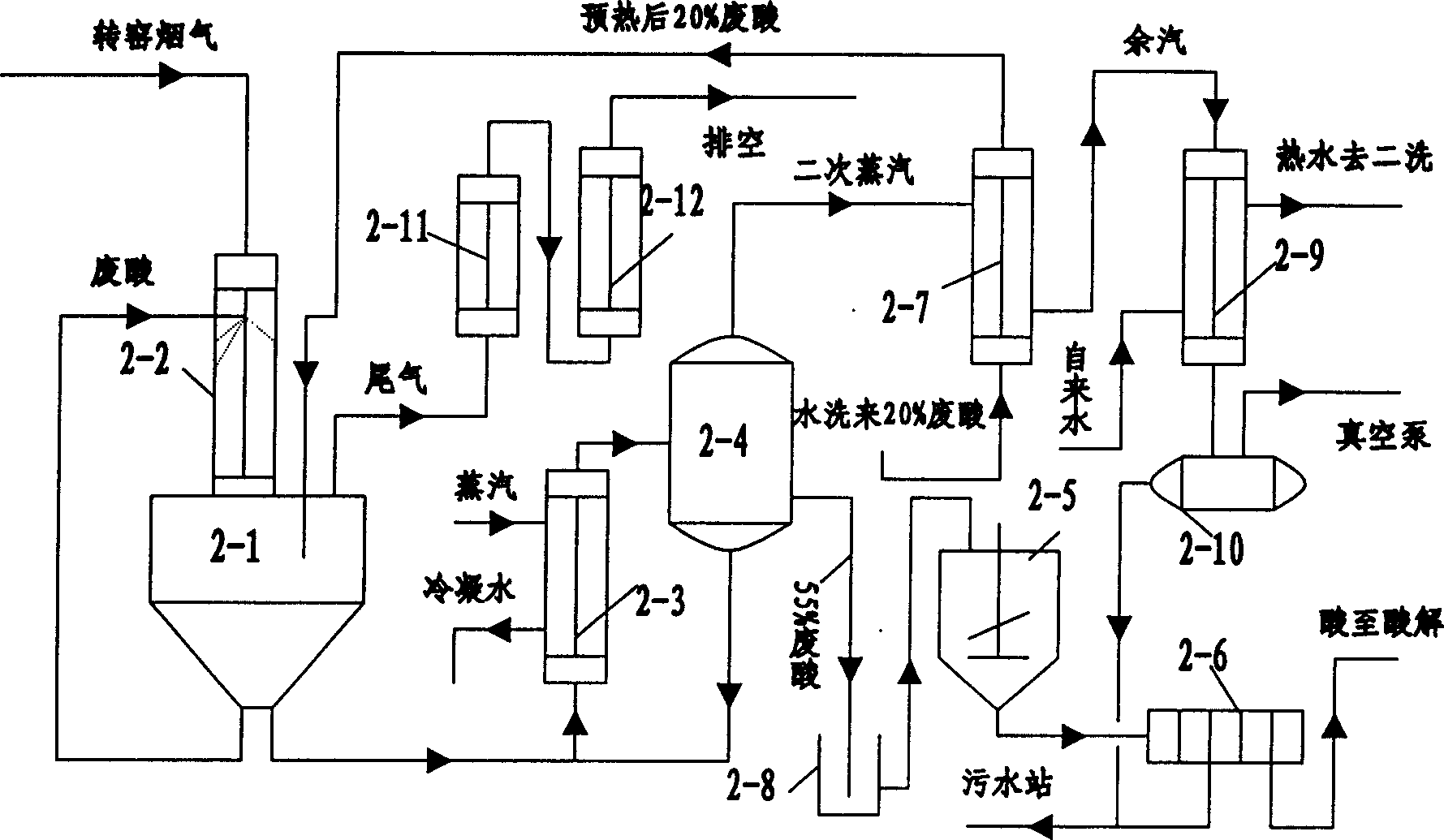

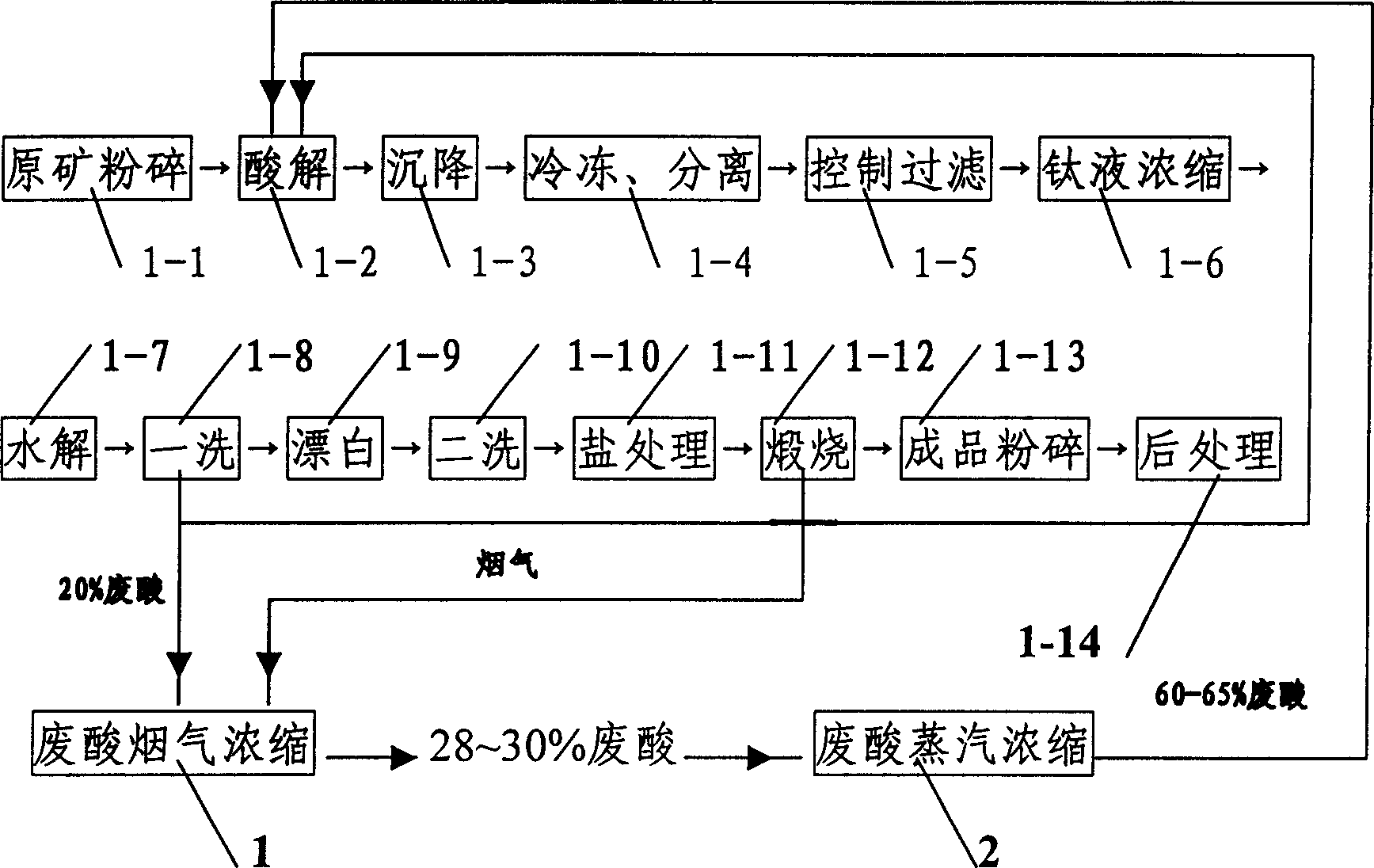

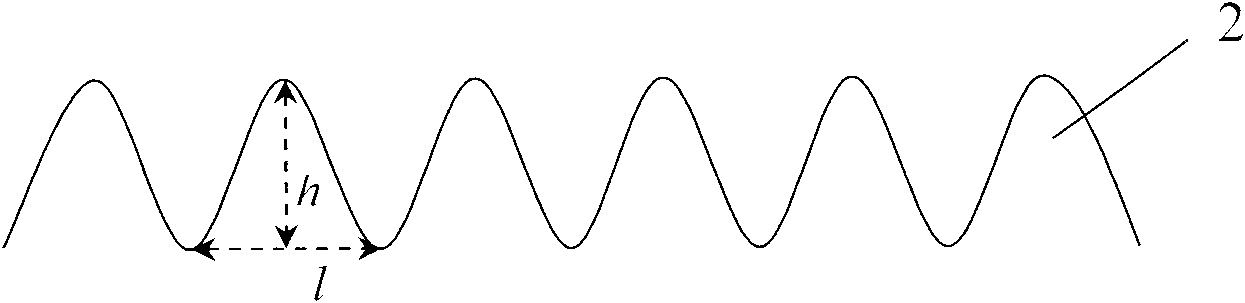

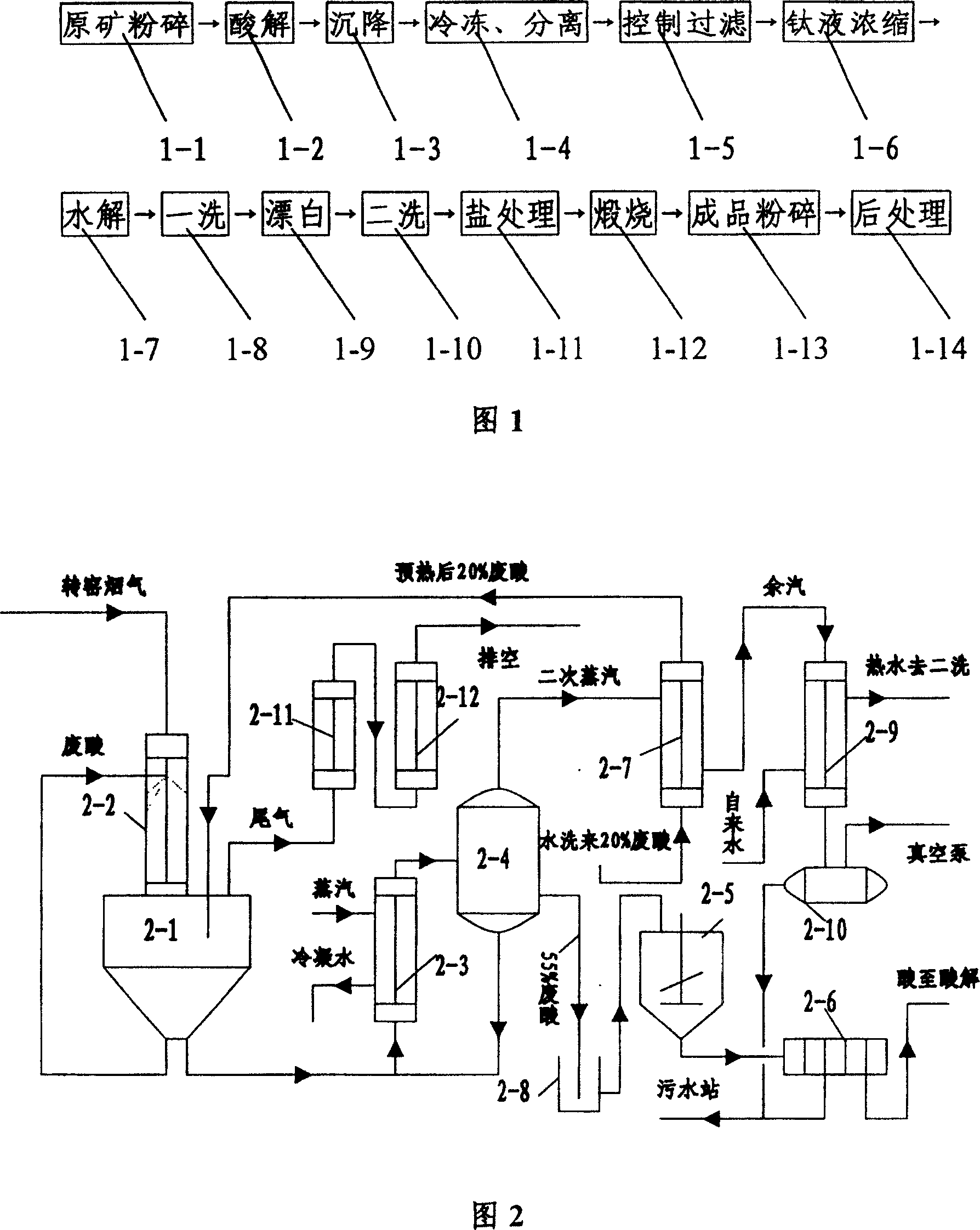

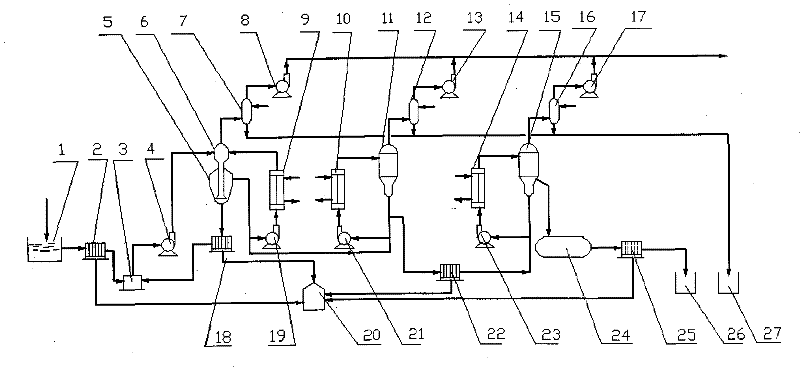

Process of industrialize for waste acid concentrition recovering used in titanium white production by sulfuric acid method

ActiveCN1724339AReduce energy consumptionReduce dosageSulfur-trioxide/sulfuric-acidTitanium dioxideWhite powderTitanium

An industrial process for reclaiming the waste acid in the production of titanium white powder by sulfuric acid method features that the waste acid is concentrated by fume and then by steam. Its advantages are high efficiency, low cost, and no environmental pollution.

Owner:潜江方圆钛白有限公司

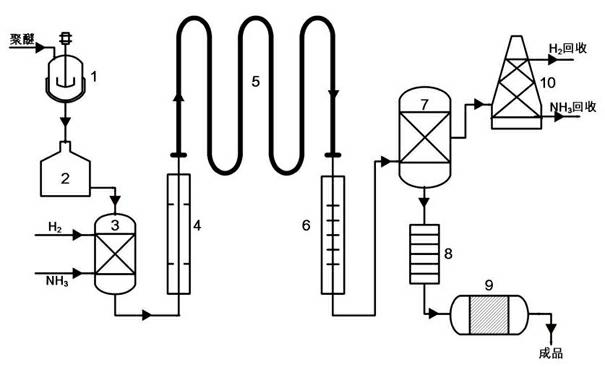

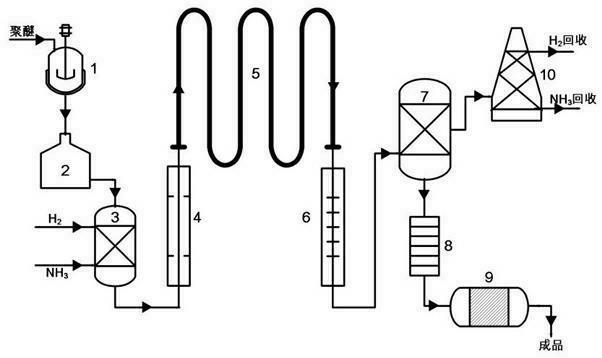

Continuous production method for amino end-capped polyether

ActiveCN102585211ARealize continuous productionHigh catalytic efficiencyOrganic compound preparationAmino-hyroxy compound preparationLiquid productReaction temperature

The invention relates to a continuous production method for amino end-capped polyether. The method comprises the following three continuous phases of: (1) a pre-treatment phase: dehydrating and drying a polyether raw material, proportionally mixing with hydrogen and liquid ammonia to form a mixed material, and heating to a reaction temperature; (2) a reaction phase: putting the mixed material into a tubular reactor, contacting with a porous nickel-based catalyst filled into the tubular reactor, and undergoing a hydro-ammoniation reaction under the action of the catalyst; and (3) a post-treatment phase: cooling a product generated in the reaction phase, introducing into a gas-liquid separating device, separating ammonia gas and hydrogen gas from a liquid product, filtering the separated liquid, and drying to obtain a finished product. The continuous production method has the advantages of realization of continuous production of aminopolyether, high mass transfer and heat transfer efficiencies, high reaction speed, mild reaction condition, reduction in side reactions, safety and reliability. The catalyzing efficiency of the catalyst is high, and the production efficiency and the conversion rate of the product are effectively increased.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

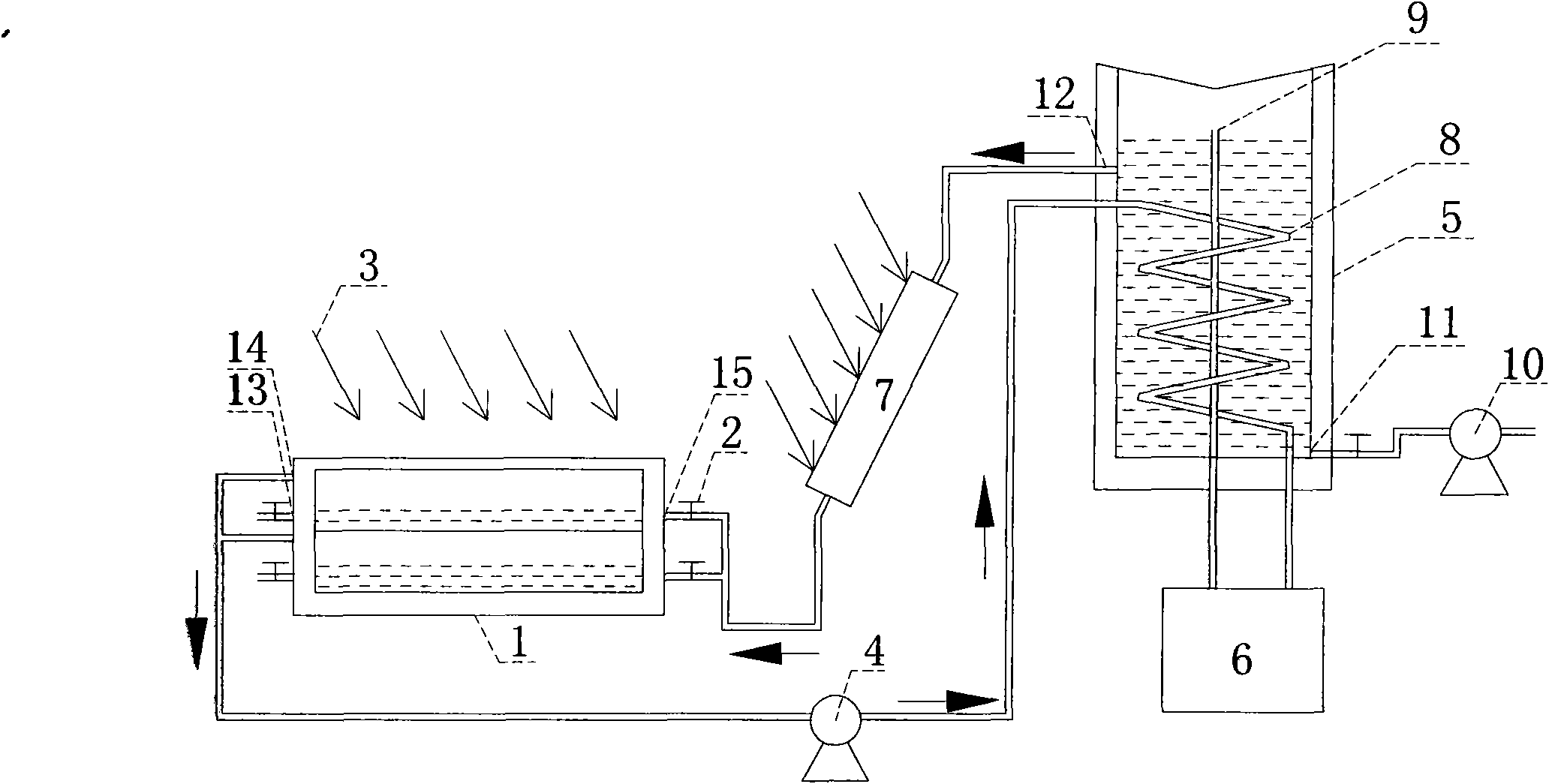

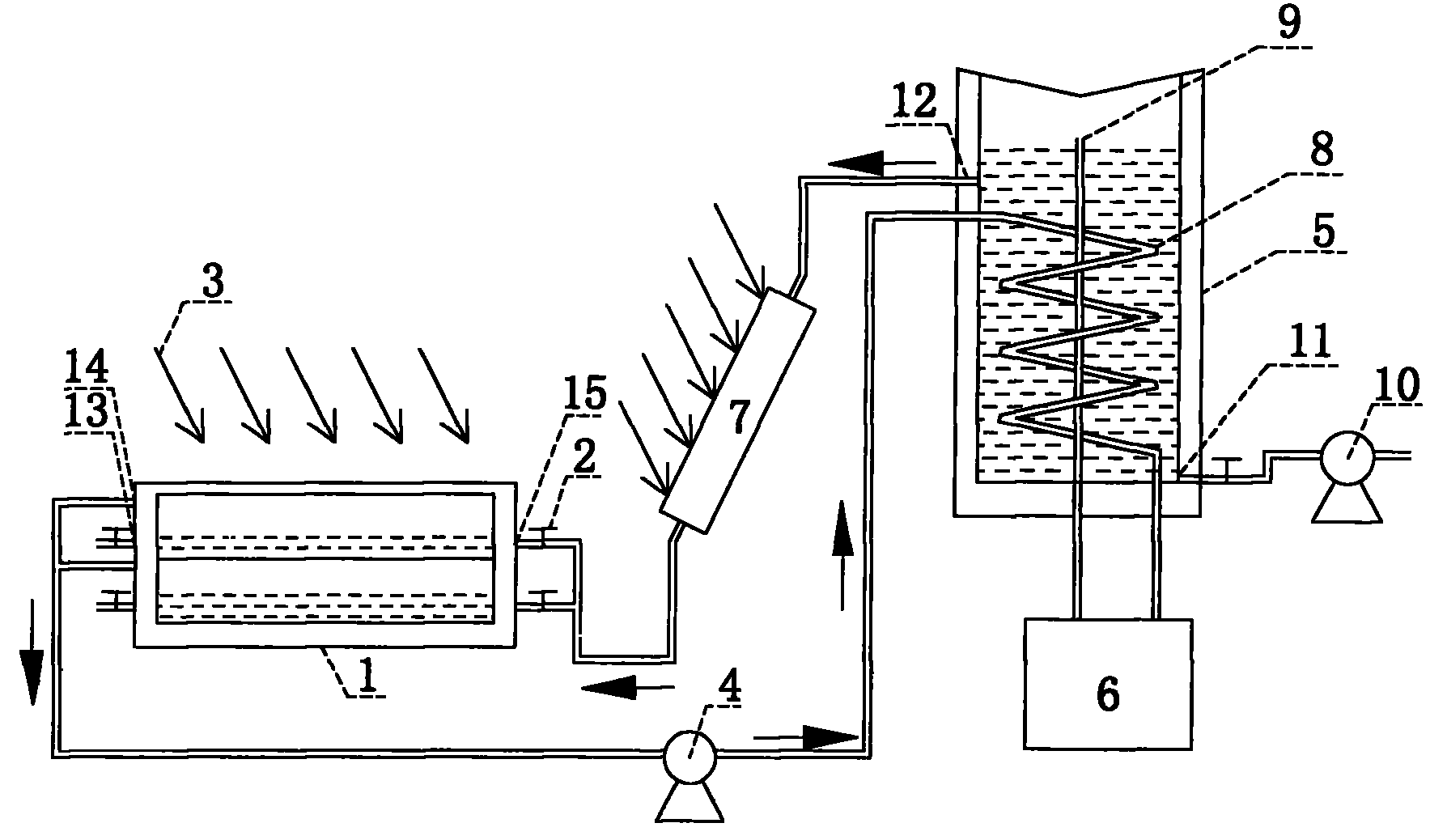

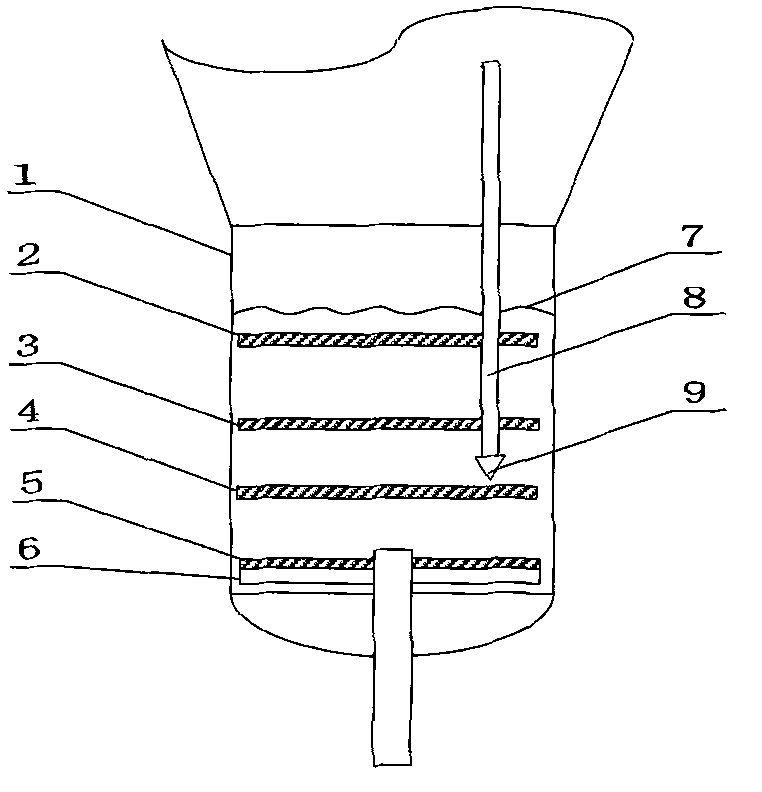

Negative pressure strengthened multi-stage laminated disc type solar energy distillation system for desalination

InactiveCN101880069AReduce energy consumptionLow costGeneral water supply conservationWater/sewage treatmentDistillationEvaporation

The invention provides a negative pressure strengthened multi-stage laminated disc type solar energy distillation system for desalination, which takes solar energy as a heat source to heat brackish water in laminated discs, and under the negative pressure chimney effect of a vacuum pump, the multi-stage cyclic utilization of condensation heat and evaporation heat between the multi-stage laminated discs is realized, the heat transfer efficiency is increased, and pure distilled water can be obtained with less energy consumption. The system has the advantages of compact structure, small floor area, and low cost for water preparation, and is suitable for desalinating brackish water in western villages and small towns.

Owner:王鹤立

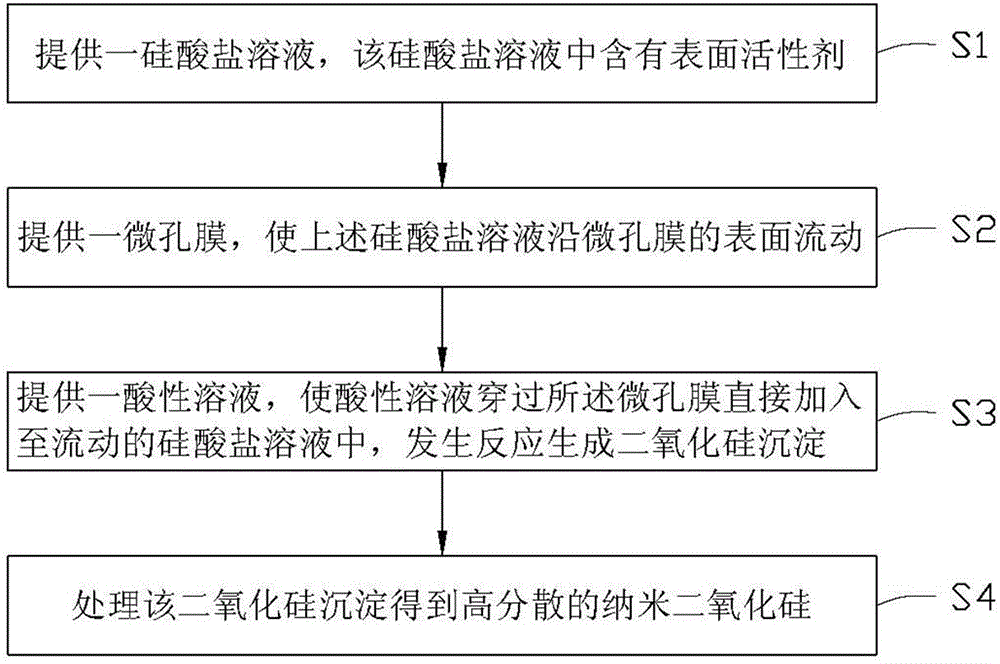

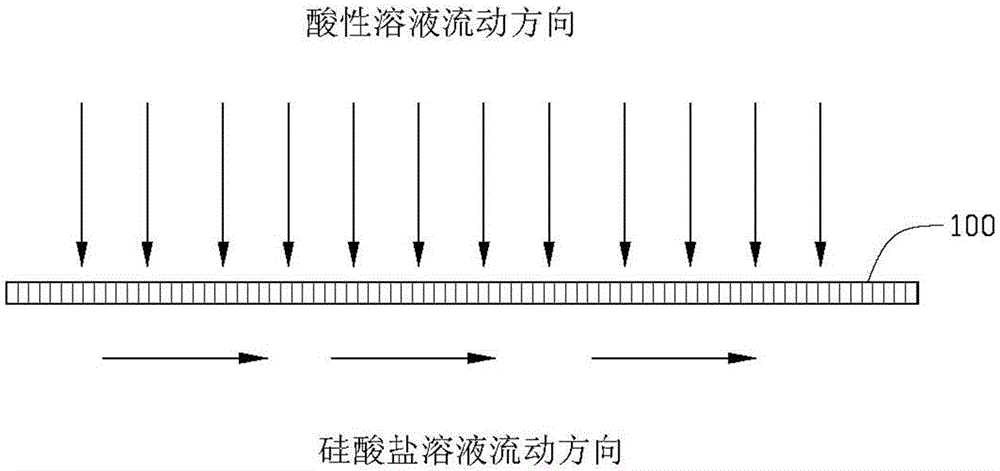

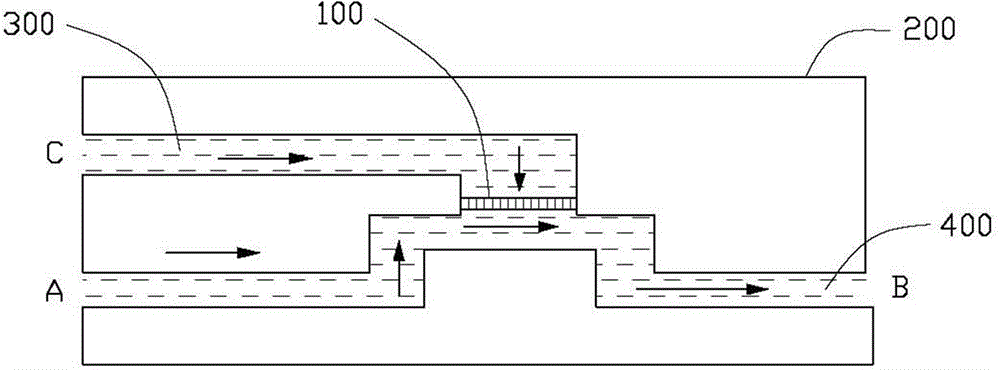

Preparation method for high-dispersion nano silicon dioxide

InactiveCN104058415AGood dispersionHigh mass and heat transfer efficiencyMaterial nanotechnologySilicaSilica particleSilicon dioxide

The invention provides a preparation method for high-dispersion nano silicon dioxide. The method comprises the following steps of: providing acidy liquor and a microporous membrane; preparing a certain amount of silicate liquor, wherein the silicate liquor contains a surfactant, so that the silicate liquor flows along the surface of the microporous membrane; vertically adding the acidy liquor into flowing silicate liquor through the microporous membrane; enabling the acidy liquor and the silicate liquor to generate reaction at a certain temperature to generate silicon dioxide precipitates; and treating the silicon dioxide precipitates to obtain the high-dispersion nano silicon dioxide. The method for preparing the silicon dioxide is low in cost, controllable in process and simple; and the prepared silicon dioxide particle is moderate in specific surface area, uniform in particle diameter distribution and good in dispersion.

Owner:TSINGHUA UNIV

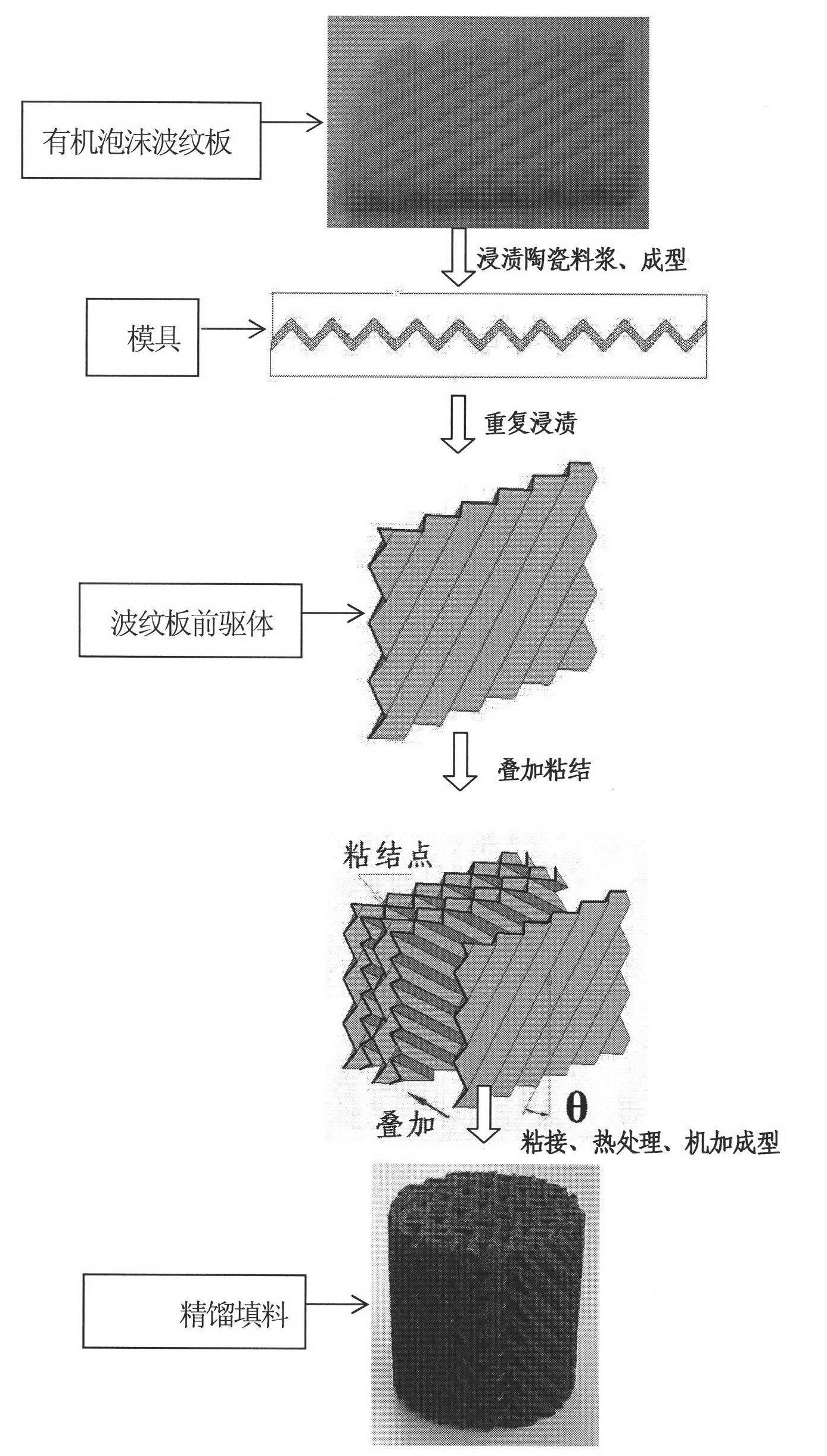

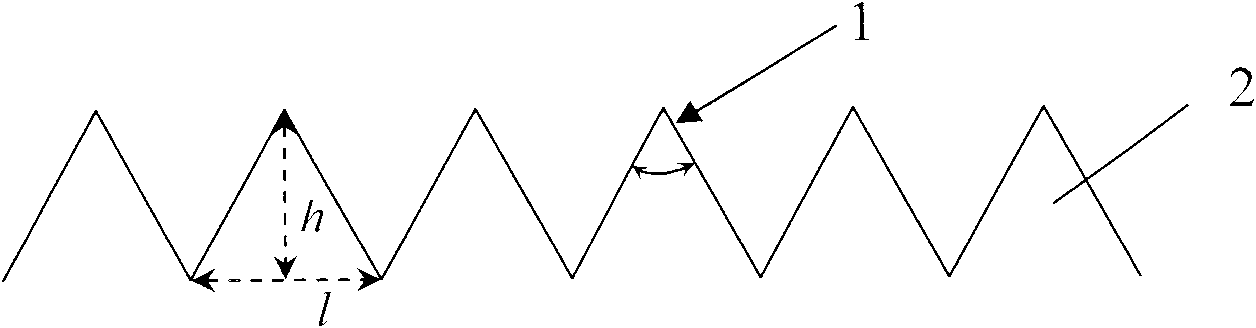

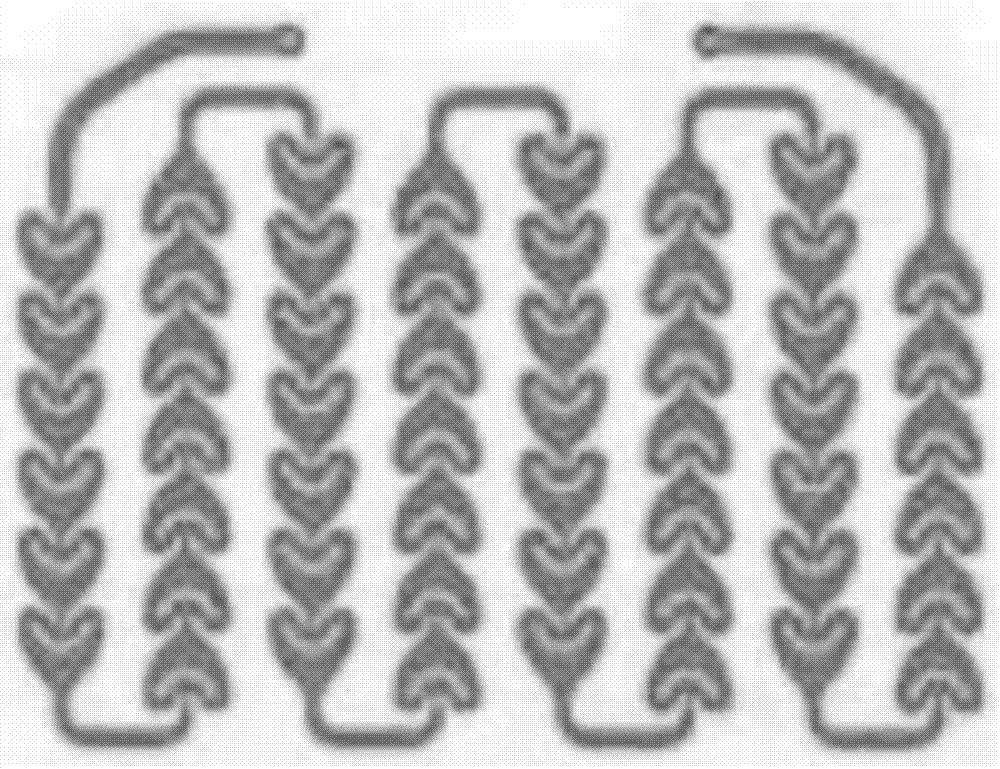

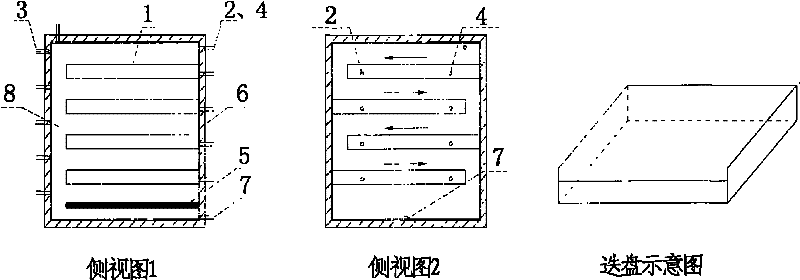

Cheap and high efficiency rectification filler and preparation method thereof

ActiveCN102247795ALarge specific surface areaFully contactedChemical/physical/physico-chemical processesNetwork structureEngineering

The invention which relates to the field of structured fillers concretely relates to a cheap and high efficiency rectification filler and a preparation method thereof. The filler which is suitable for a rectification operation under a temperature of less than 300 DEG C is formed by stacking filler unit plates with corrugated shapes, the filler unit plates are foamed resin-based filler unit plateswith three-dimensional connected network structures, the foam pore sizes are between 10PPi and 80PPi, and the volume fraction is controlled between 10% and 80%. A plurality of the filler unit plates are stacked, the filler unit plates of the odd-numbered layers have a consistent channel direction, and the filler unit plates of the even-numbered layers have a consistent channel direction, and an angle between the channel direction of the filler unit plates of the odd-numbered layers and the channel direction of the filler unit plates of the even-numbered layers is 30-170 DEG; a corrugation angle between a corrugation parallel direction and a vertical direction of a filler disc is 15-85 DEG, corrugations of adjacent filler unit plates have a same angle and opposite directions; and the filler unit plates are bonded after being stacked, and are subjected to a heat treatment to obtain the filler. The foamed resin-based structured filler unit plates of the invention allows the three-dimensional network connectivity characteristic of a polyurethane foamed plastic template to be kept, and has the characteristics of large specific surface area, thin wall, cheapness, high chemical stabilityand the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Process of industrialize for waste acid concentrition recovering used in titanium white production by sulfuric acid method

ActiveCN1330562CReduce energy consumptionReduce dosageSulfur-trioxide/sulfuric-acidTitanium dioxideWhite powderTitanium

An industrial process for reclaiming the waste acid in the production of titanium white powder by sulfuric acid method features that the waste acid is concentrated by fume and then by steam. Its advantages are high efficiency, low cost, and no environmental pollution.

Owner:潜江方圆钛白有限公司

Nickel-based catalyst, preparation method thereof and method for catalyzing methane cracking to produce hydrogen

ActiveCN104998654AAchieving self-heating operationSlow ascent rateHydrogenChemical recyclingCarbon depositCracking reaction

The invention provides a nickel-based catalyst, a preparation method thereof and a method for catalyzing methane cracking to produce hydrogen. The catalyst includes a nickel-based composite metal oxide with a general formula shown as xX.yA.zB.(100-x-y-z)M, wherein X is Ni and / or its oxide, A is an auxiliary metal component, B is an assistant metal component, and M is a carrier. The method for catalyzing methane cracking to produce hydrogen includes: contacting methane-containing feed gas with the catalyst in a high density circulating fluidized bed reactor, and carrying out catalytic cracking reaction to obtain hydrogen containing product-gas and a deactivated catalyst, performing separation in a settler, letting the catalyst carry carbon deposit to enter a regenerator for regeneration, thus obtaining regenerated flue gas containing CO or synthetic gas, and letting the regenerated catalyst enter the reactor again. The heat generated by regeneration supplies the energy need of the whole system to realize self-heating operation. The method provided by the invention can realize large-scale continuous production of hydrogen at low price, and can effectively reduce energy consumption and save the production cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for synthesizing lenalidomide

InactiveCN107033126AImprove recycling ratesQuick responseOrganic chemistryChemical recyclingNitro compoundActivated carbon

The invention provides a method for synthesizing lenalidomide, belongs to the field of anti-tumor and anti-leukemia medicines in organic synthesis, and particularly relates to the method for synthesizing lenalidomide. To solve the problems of low yield, low purity, environmental pollution caused by massive harmful waste, excessive cost for environment-friendly treatment, easily occurred risk of violent explosive, degradation caused by long reacting time at high temperature and low catalyst recycling frequency in a traditional lenalidomide synthesis reaction, the method comprises the following steps: 1, adding a lenalidomide precursor nitro compound into an organic solvent, adding an activated carbon catalyst having a Pd loading capacity of 10 percent, then leading the mixture serving as a material I into a pre-heating module of a microchannel reactor; and 2, respectively pumping preheated material I and a material II hydrogen into a reaction module of the microchannel reactor into a reactor, collecting outflowing reaction liquid, and treating to obtain the lenalidomide. The method is environment-friendly, and has the advantages of high reaction yield, high purity and good economical efficiency.

Owner:HEILONGJIANG XINCHUANG BIOLOGICAL TECH DEV CO LTD

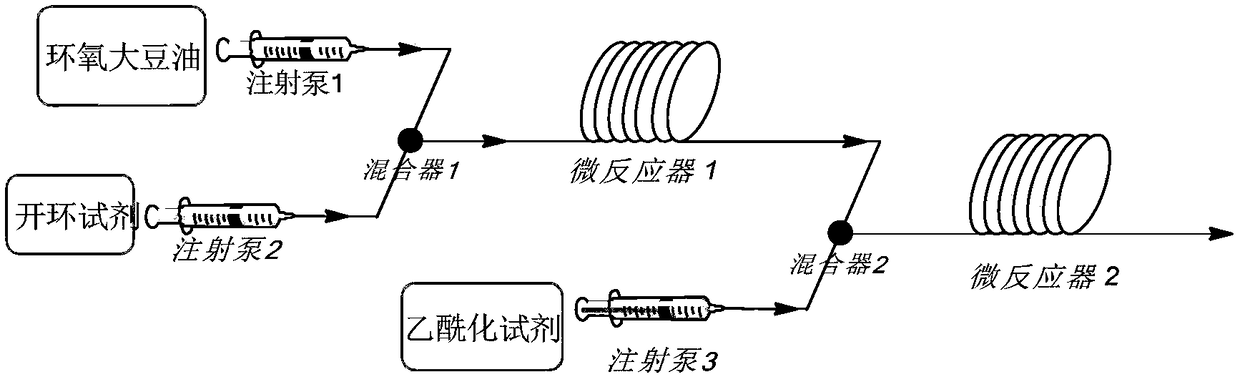

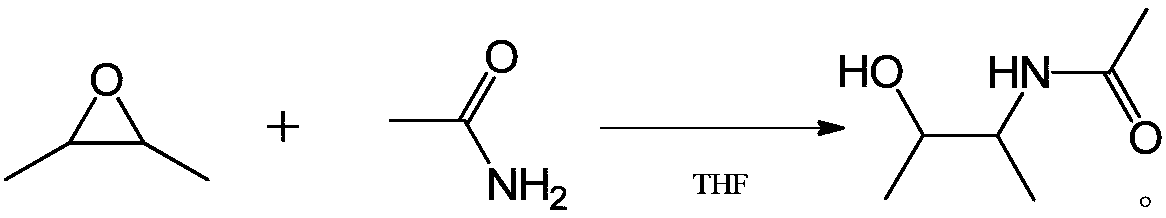

Method for preparing vegetable oil-based plasticizer by micro-reaction continuous flow by using amido

ActiveCN109265361AImprove performanceImprove migration resistanceOrganic compound preparationCarboxylic acid amides preparationEpoxyVegetable oil

The invention discloses a method for preparing a vegetable oil-based plasticizer by micro-reaction continuous flow by using amido, which comprises the steps of dissolving epoxy soybean oil in an organic solvent to obtain a solution A, dissolving an amide ring-opening reagent and a ring-opening reaction catalyst in an organic solvent to obtain a solution B, pumping the solution A and the solution Bsimultaneously into a first mixer of a microreactor to mix, enabling the mixture to enter a first microreactor of the microreaction device and react to obtain an epoxy soybean oil ring-opening product, dissolving an acetylation reagent and an acetylation reaction catalyst in an organic solution to obtain a solution C, simultaneously pumping with the epoxy soybean oil ring-opening product into a second mixer of the microreaction device to mix, enabling the mixture to enter a second microreactor of the microreaction device to react, and performing rotary evaporation a reaction product to obtainthe vegetable oil-based plasticizer. Compared with a conventional preparation process, the method has the advantages that the specificity of an amide group is utilized and combined with the micro-reaction continuous flow device, and the new plasticizer with superior performance is prepared by the ring-opening reaction and the acetylation reaction in sequence,.

Owner:CHINA PETROLEUM & CHEM CORP

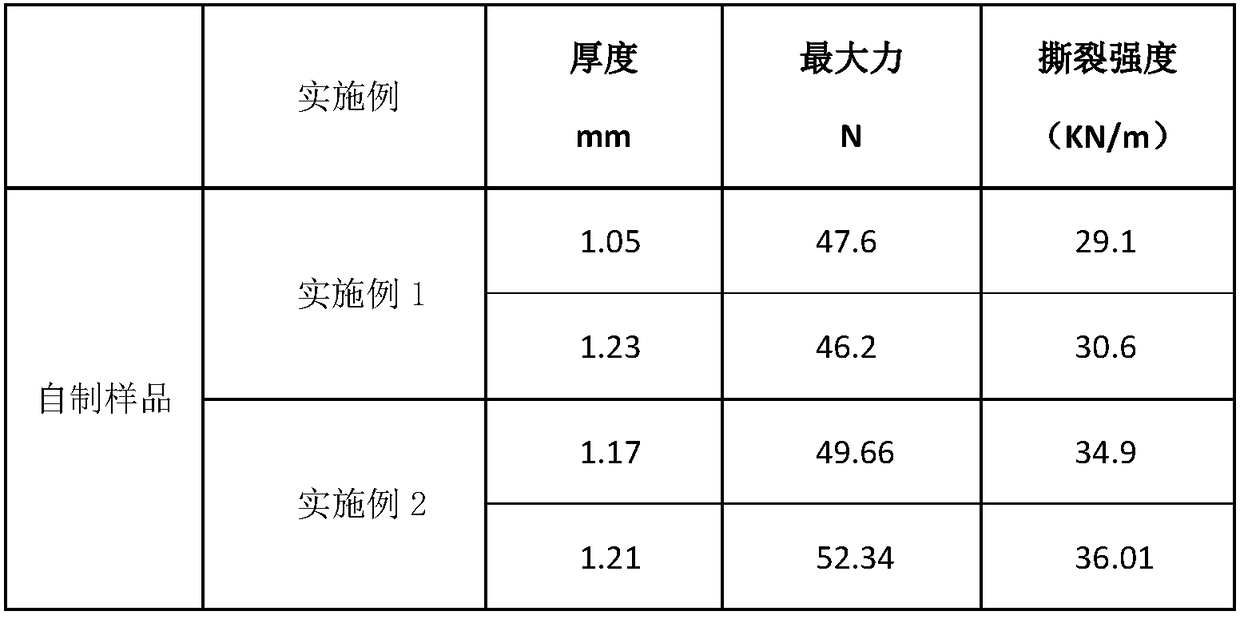

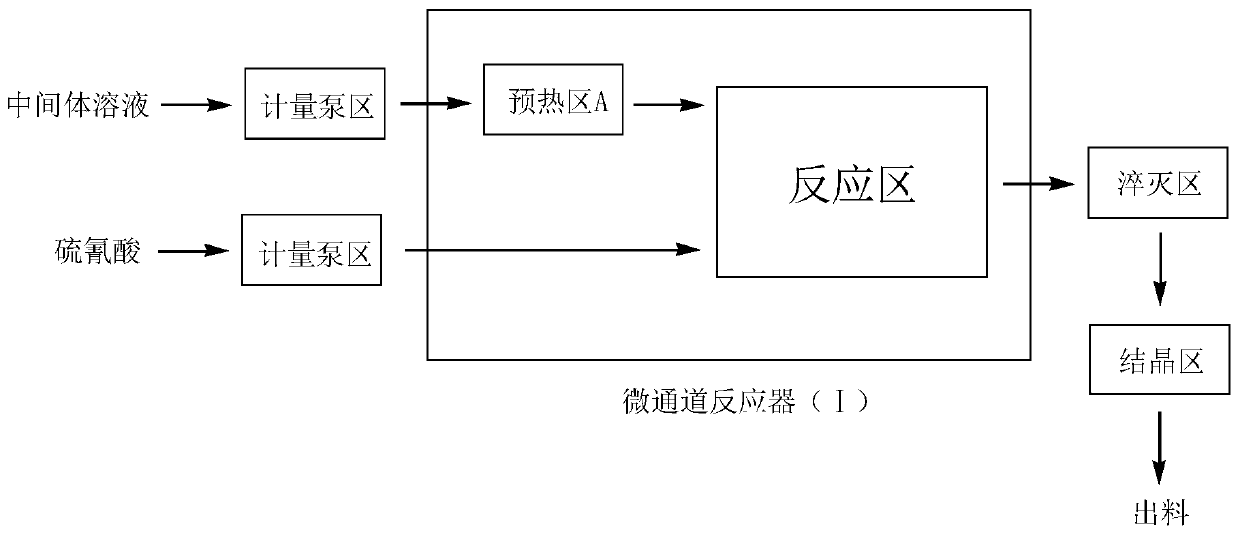

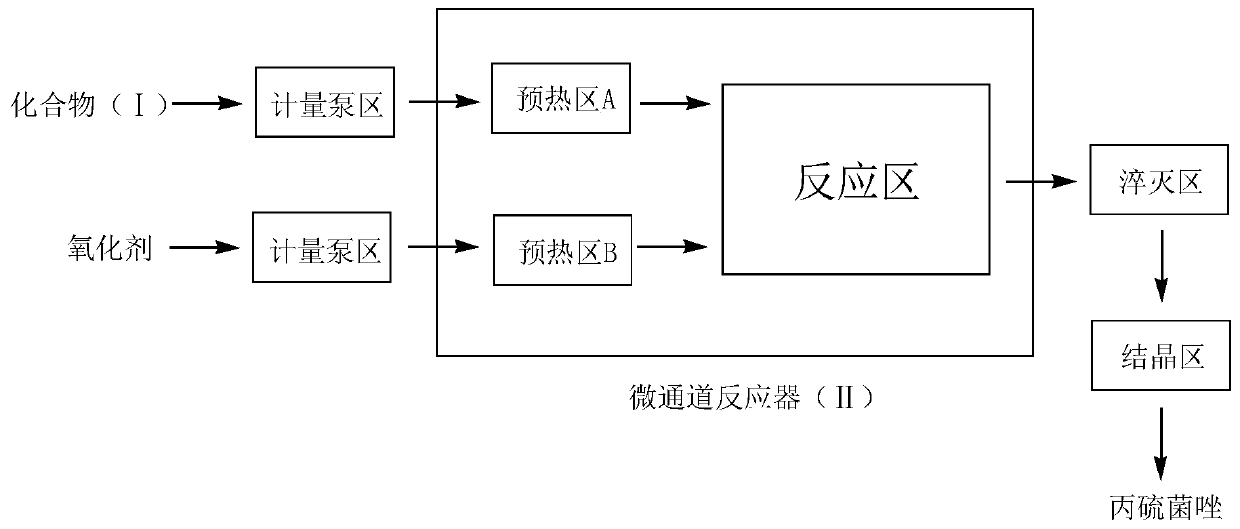

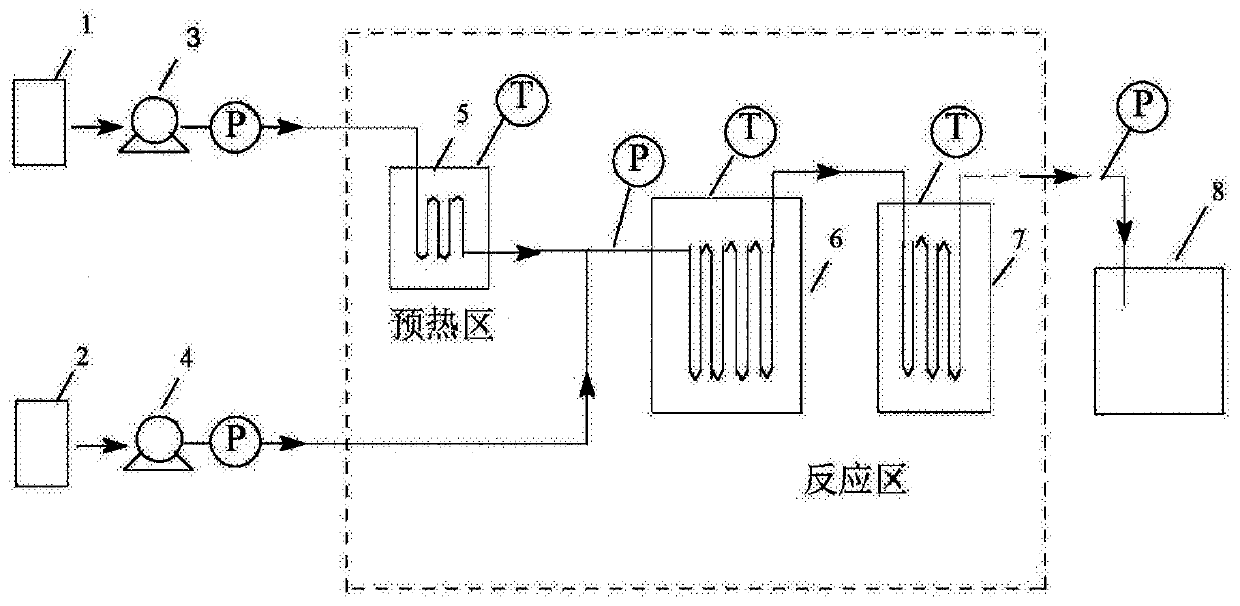

Method for continuously producing prothioconazole by utilizing micro-channel reactor and micro-channel system

ActiveCN110218197APrevent self-aggregationReduce generationOrganic chemistryChemical/physical/physico-chemical microreactorsOrganic synthesisReaction temperature

The invention relates to a method for continuously producing prothioconazole by utilizing a micro-channel reactor and a micro-channel system and belongs to the technical field of organic synthesis processes. The method comprises the following steps: taking 2-(1-chloro-cyclopropyl)-1-(2-chlorphenyl)-3-hydrazino-propyl-2-ol as a raw material, carrying out a cyclization and oxidization two-step reaction in the micro-channel reactor so as to continuously complete a preparation process of prothioconazole, introducing the material into the micro-channel reactor by a metering pump, performing preheating, mixed reaction and quenching crystallization separation so as to obtain the product prothioconazole. According to the method, mass transfer and heat transfer in the reaction process can be enhanced, the reaction temperature and reaction time are accurately controlled, side reactions and a reactant auto-polymerization phenomenon caused by material enrichment in the cyclization process are avoided, and conditions that the side reactions are increased due to 'temperature runaway' and reactive oxygen species overflow in the oxidization process and the like are also avoided. The reaction timeis finally reduced, the atom utilization ratio is improved, the reaction conversion rate is greatly improved, and production of solid wastes and side reactions is reduced.

Owner:RUICHENG COUNTY SIPULUNDI BIOLOGICAL ENG CO LTD

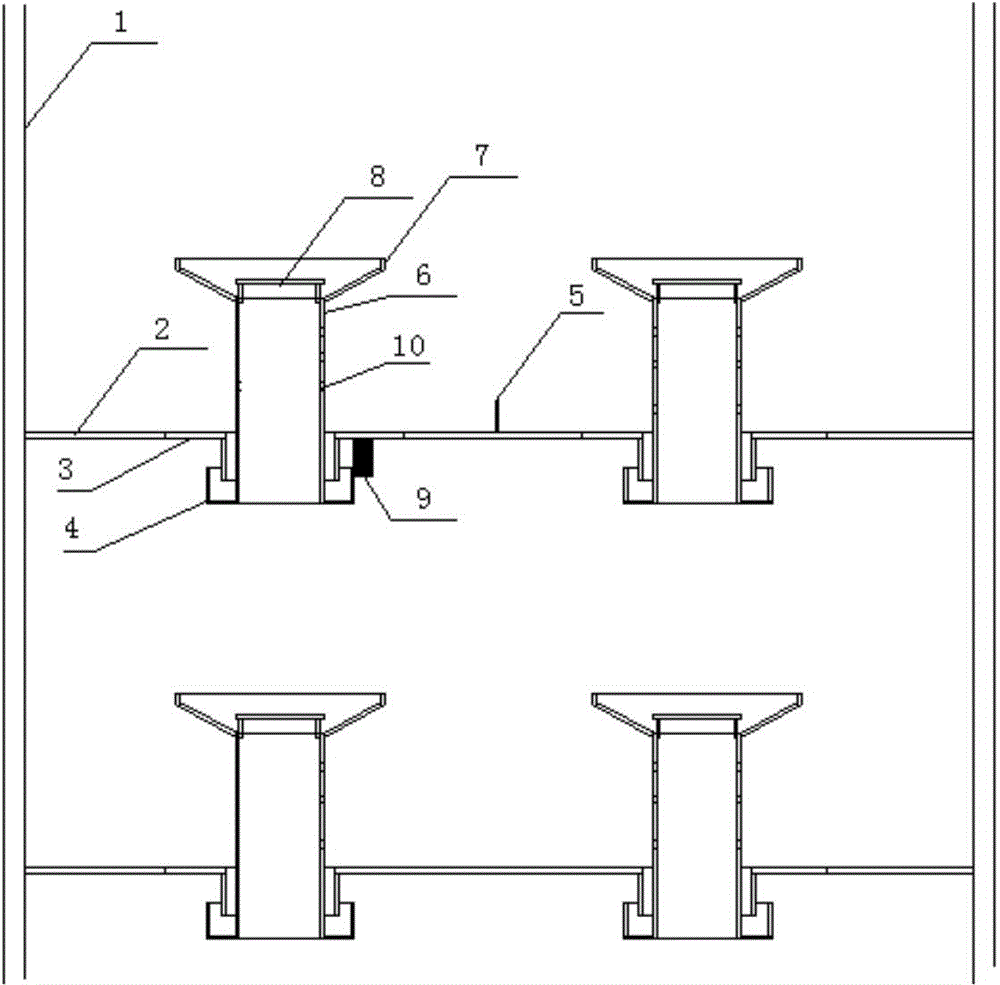

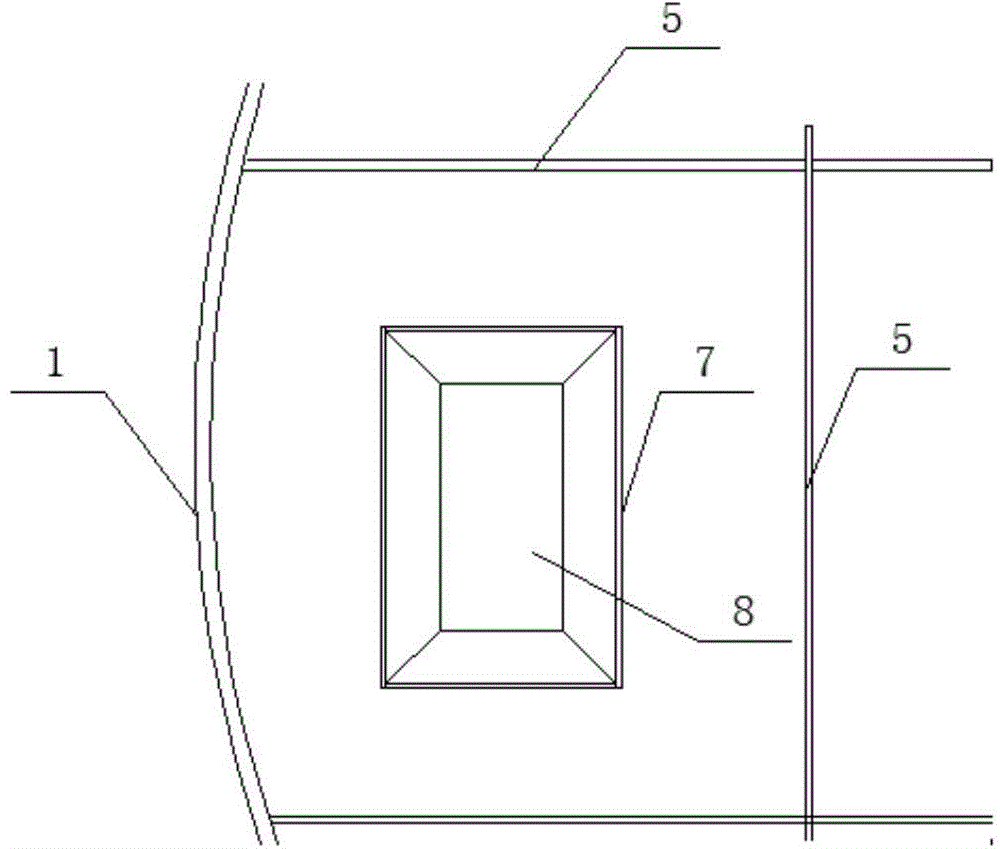

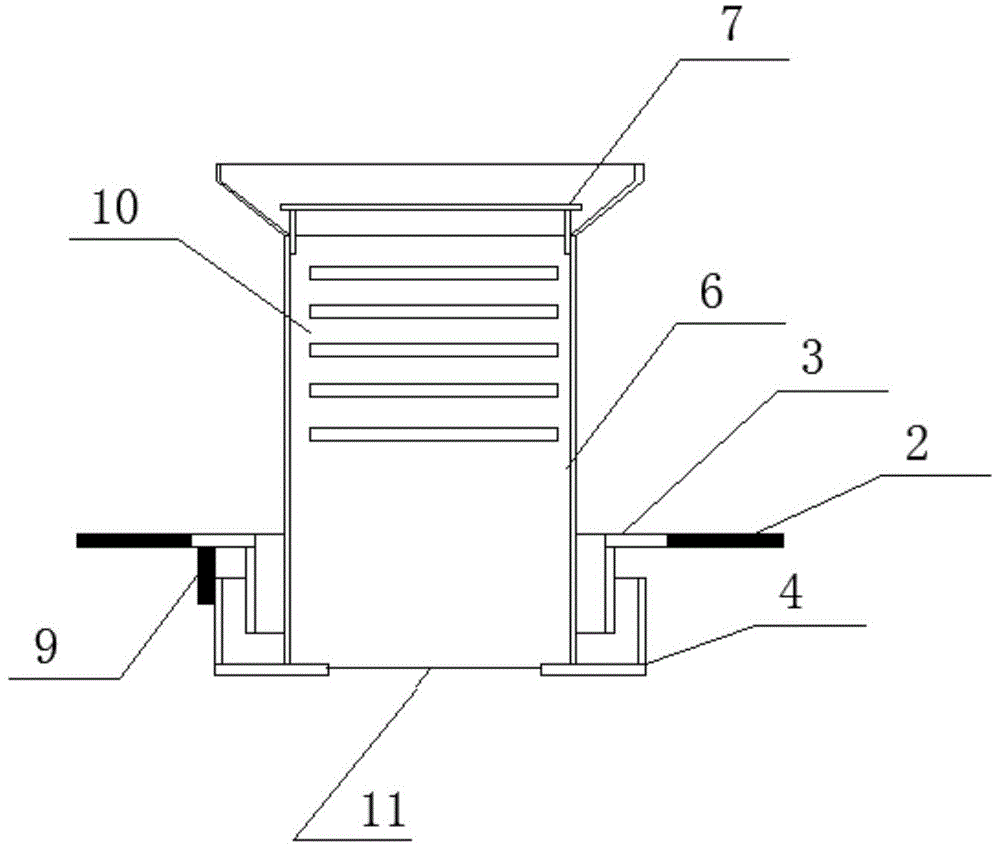

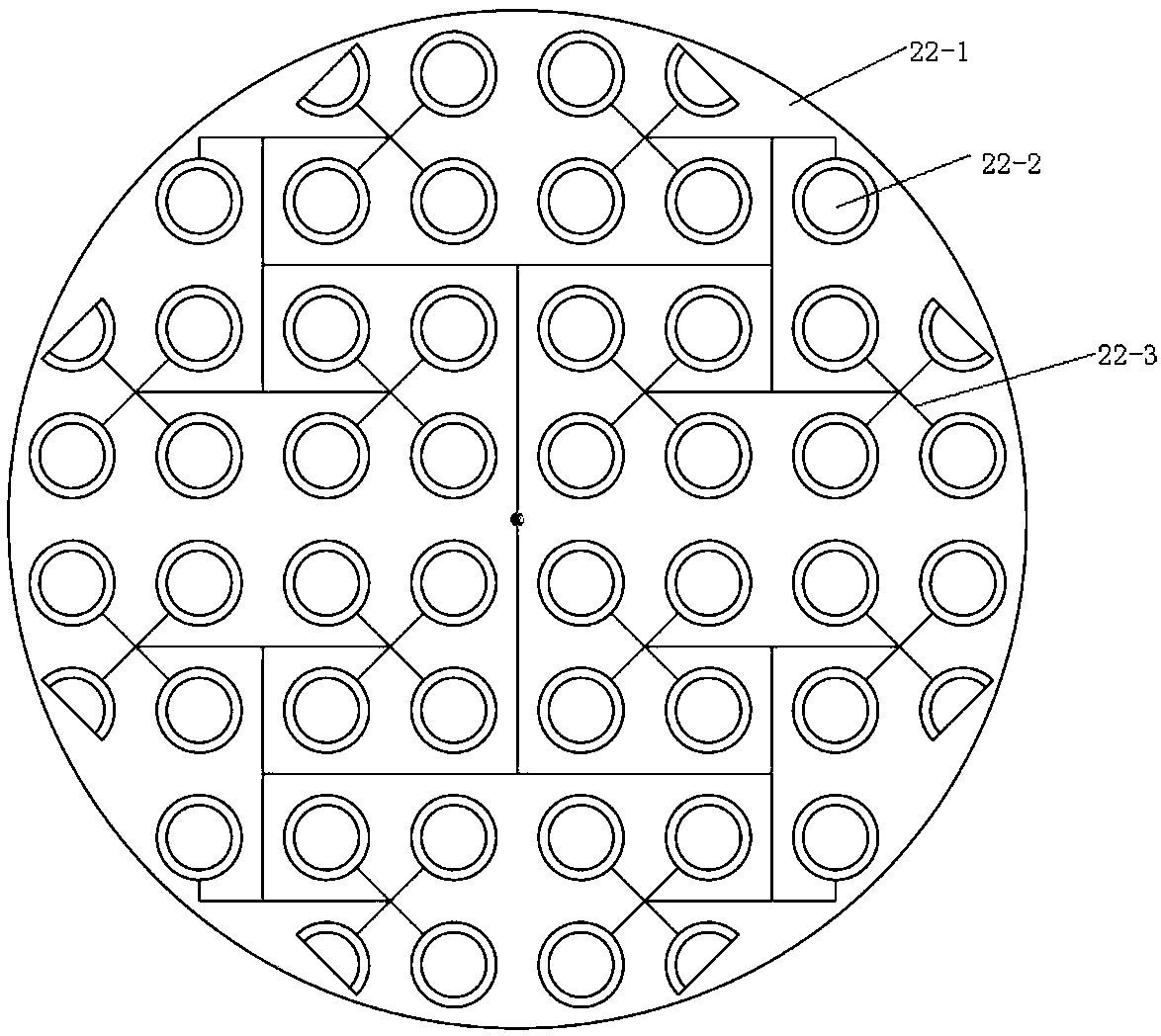

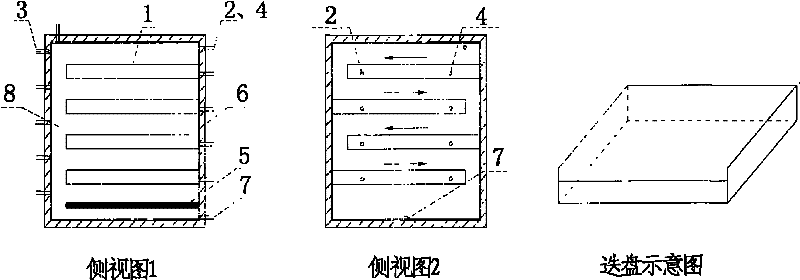

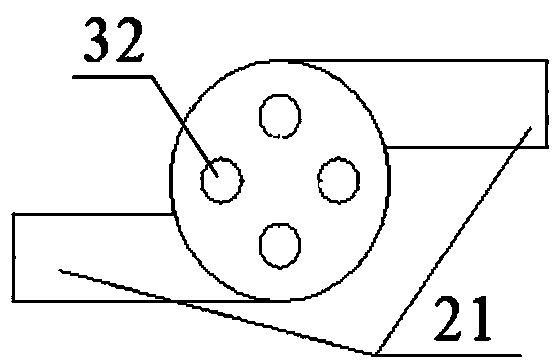

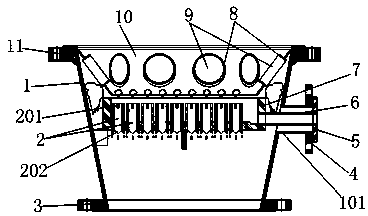

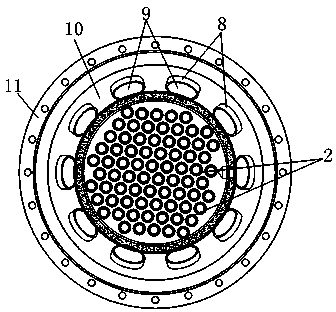

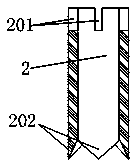

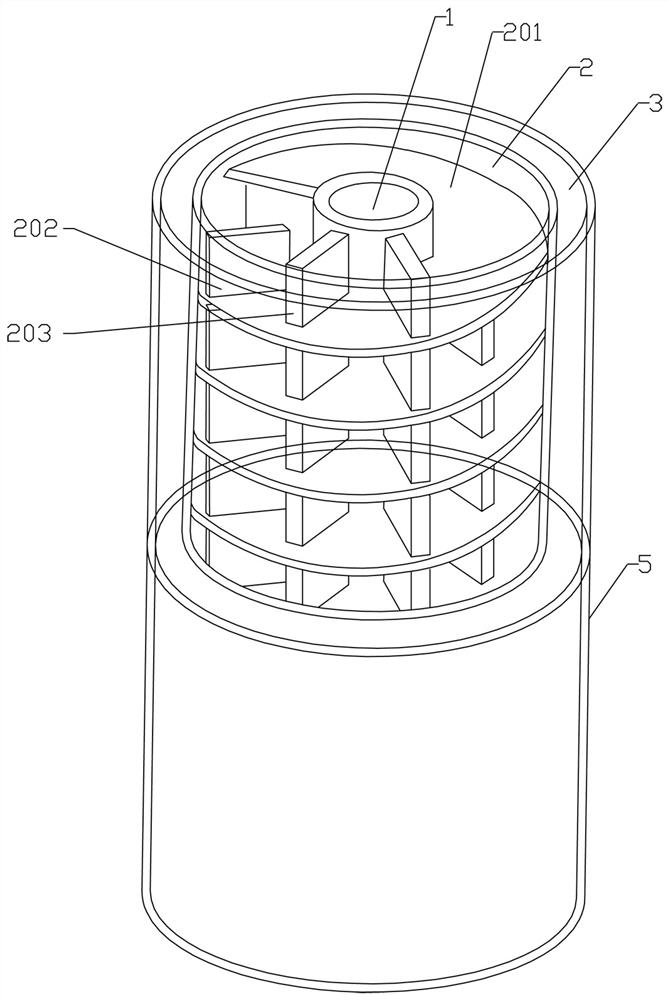

Three-dimensional film spraying and perforating tray

ActiveCN104083891AExtended flow timeReduce leakageFractional distillationContact timeCompound (substance)

The invention provides a three-dimensional film spraying and perforating tray belonging to the field of mass transfer and heat transfer equipment in chemical engineering. The three-dimensional film spraying and perforating tray comprises a tower body and a tower plate arranged inside the tower body, and spraying covers arranged on the tower plate. The three-dimensional film spraying and perforating tray is characterized in that a plurality of fixing holes are formed in the tower plate, a guide cylinder is fixed in each fixing hole, a liquid seal trough is arranged at the outer ring of the side wall of each guide cylinder, a gas raising hole is formed at the bottom of each liquid seal trough and is concentric with each fixing hole, the spraying cover is arranged at the inner ring of the side wall of each guide cylinder, the lower end face of the side wall of each spraying cover is welded with the bottom of each liquid seal trough, a plurality of spraying holes are formed in the side wall of each spraying cover, a top cover is arranged at the top of each spraying cover, a liquid receiving trough is arranged at the upper end of each spraying cover, the side wall of each guide cylinder is coaxially connected with the outer wall of each spraying cover and the side wall of each liquid seal trough, gaps are reserved between the side wall of each guide cylinder and the outer wall of each spraying cover and between the outer wall of each spraying cover and the side wall of each liquid seal trough, and a gap is reserved between each top cover and each spraying cover. According to the three-dimensional film spraying and perforating tray, by adopting a perforating technology, on the one hand, the problem caused by liquid streaming and mixing is solved, and on the other hand, the gas-liquid contact time is increased and through perforation, and thus the mass transfer efficiency is increased.

Owner:衡水酷祥生物科技有限公司

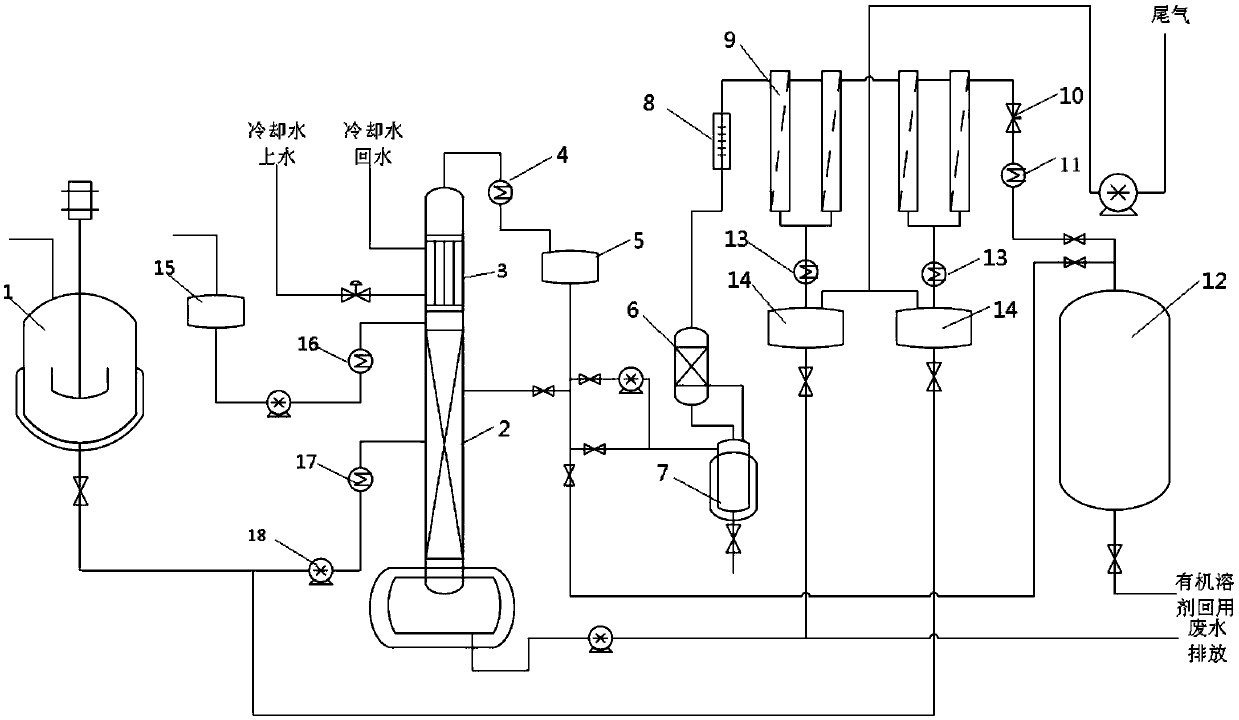

Separation and recycle system for water-containing organic waste liquid and organic solvents as well as recycle method

PendingCN109663376AAvoid accumulationEasy to separateLiquid distribution in distillationDistillationLiquid wasteRecovery method

The invention provides a separation and recycle system for water-containing organic waste liquid and organic solvents as well as a recycle method, wherein the separation and recycle system consists ofa distillation system and a pervaporation membrane separation system through process pipeline connection. A packed tower is adopted as a rectifying tower, and the material inlet of the packed tower is arranged in the center of a packed tower liquid distributor. A damping structure is arranged in the pervaporation membrane unit of the pervaporation membrane separation system. The separation and recycle system provided by the invention is suitable for online dehydration and recycle of multiple kinds of water-containing and two or more than two azeotropic or non-azeotropic organic solvents as well as for separation and reuse of the organic solvents.

Owner:CHENGDU GELAI HIGH TECH CO LTD

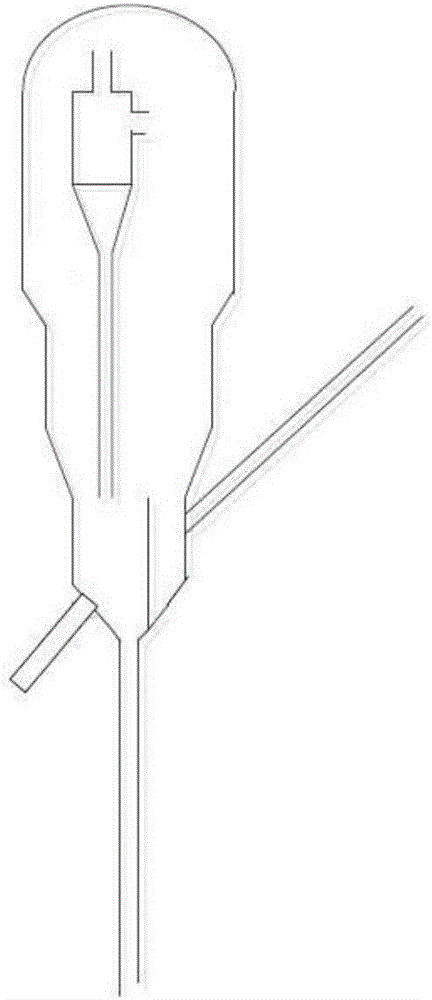

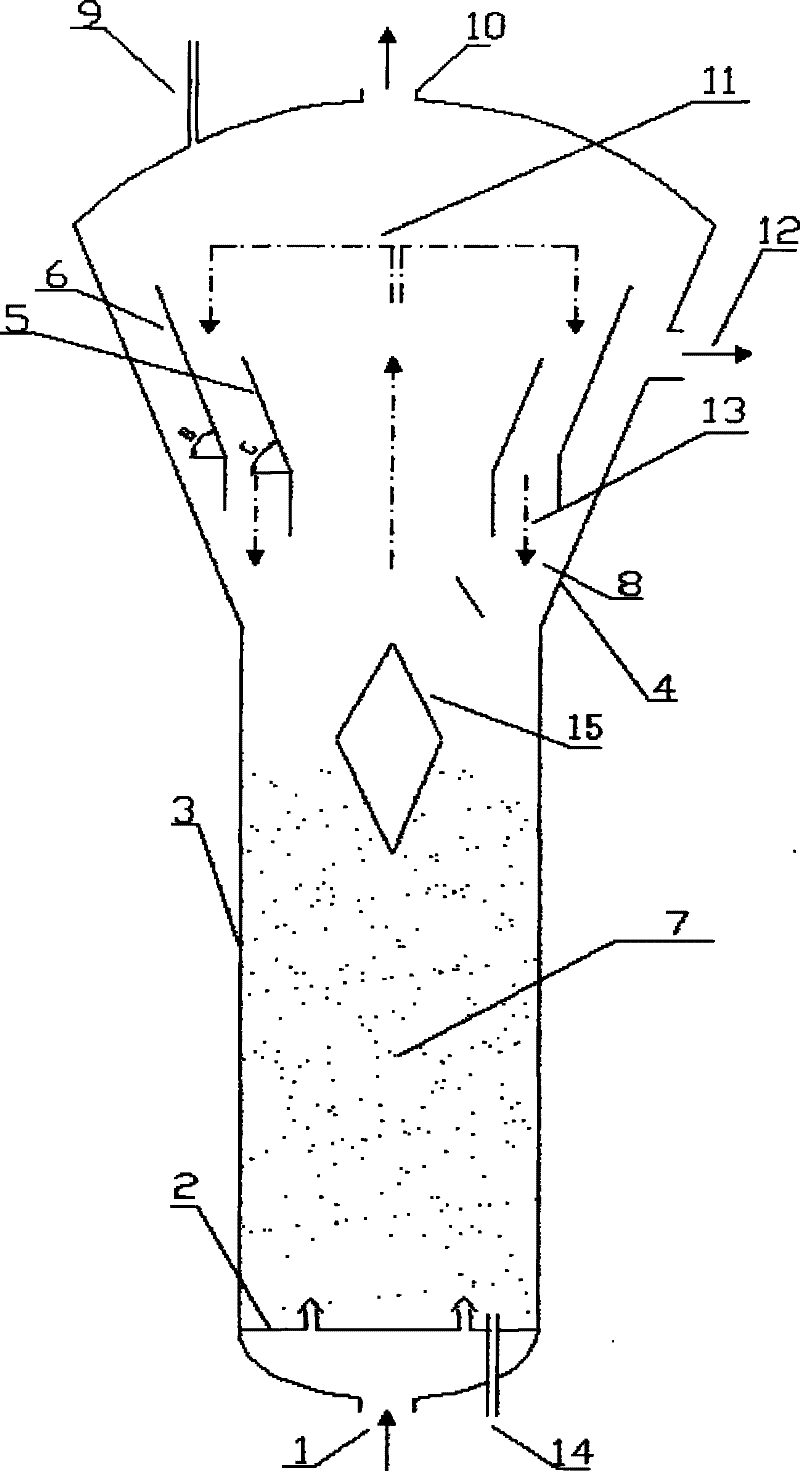

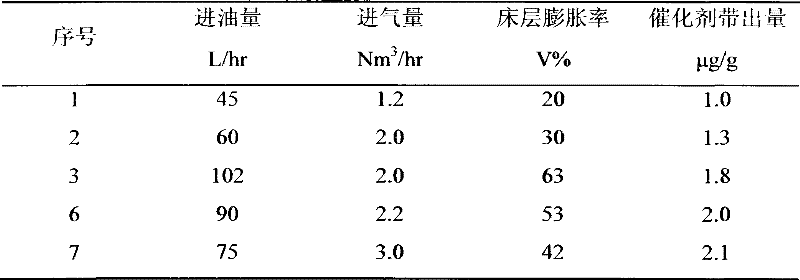

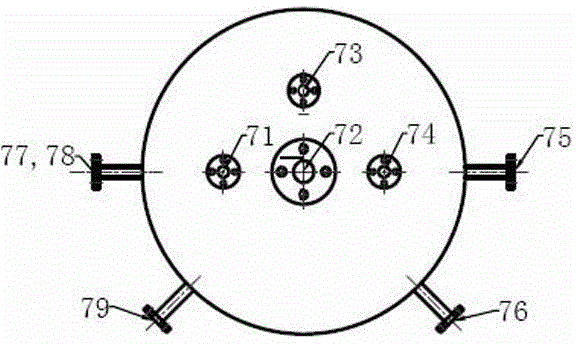

Improved method and improved equipment for dense phase fluidized bed and equipment

InactiveCN104275129ASmall diameterIncrease profitCatalytic crackingChemical/physical processesPtru catalystPetrochemical

The invention relates to an improved method for a dense phase fluidized bed, belonging to the technical field of fluidization and petrochemical engineering and used for solving the problems of non-uniform gas distribution of the dense phase fluidized bed, relatively large fluctuation of the fluidized bed due to bubbles, low mass and heat transfer efficiency and relatively high catalyst loss. The improved method comprises the fluidized bed, gas distribution and powder catalyst recycling. The improved method is characterized in that gratings are respectively arranged above a distributor, below and above a wing valve or back taper, and below a charge level, thus the beneficial effects of guiding and re-distributing gas, crushing bubbles to reduce diameter, improving the work environment of the wing valve or back taper, improving the mass and heat transfer efficiency of the fluidized bed, reducing the elutriation of the fluidized bed, improving the gas utilization rate, improving the elasticity of a device, improving the efficiency of the fluidized bed, and reducing the catalyst are achieved. The invention further provides gas re-distributing grating and bubble crushing grating equipment for realizing the improved method disclosed by the invention. The gas re-distributing grating and bubble crushing grating equipment is used in a regenerator and a reactor of devices for catalytic cracking, methanol-to-olefin production and inferior residue oil treatment.

Owner:刘英聚

Baffled multistage disc distiller enhanced by externally adding negative pressure

InactiveCN102211793AReduce energy consumptionLow costGeneral water supply conservationSeawater treatmentBoiling pointSalt water

The invention provides a baffled multistage disc distiller enhanced by externally adding a negative pressure. Bitter in a disc is heated by utilizing a heating pipe at the bottom; one side of the distiller is provided with a steam lifting flow channel, and a large amount of steam is evaporated below a boiling point through negative pressure suction of a vacuum pump; after pumping, condensation is carried out so as to obtain fresh water, thereby achieving the effect of salt-water separation. The distiller can also be externally connected with a solar heat collector for heat supply, thereby greatly saving energy consumption.

Owner:刘若鹏

Fluidized bed reactor

ActiveCN101721961BGreat operating flexibilityEfficient separationChemical/physical processesChemical reactionFluidized bed

Owner:CHINA PETROLEUM & CHEM CORP +1

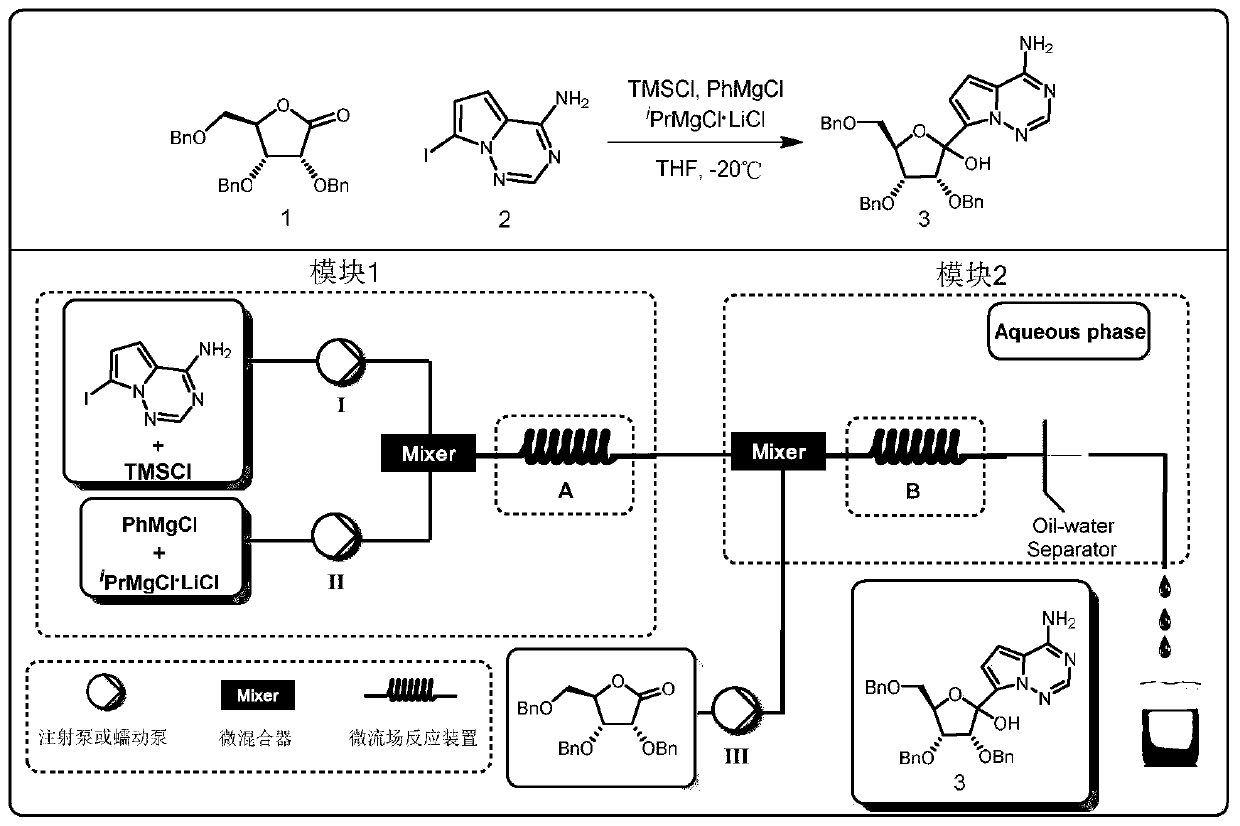

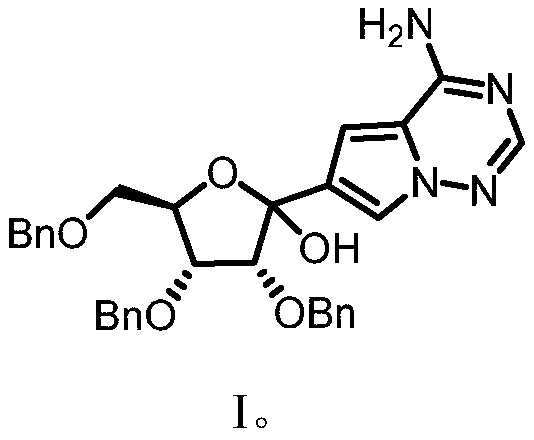

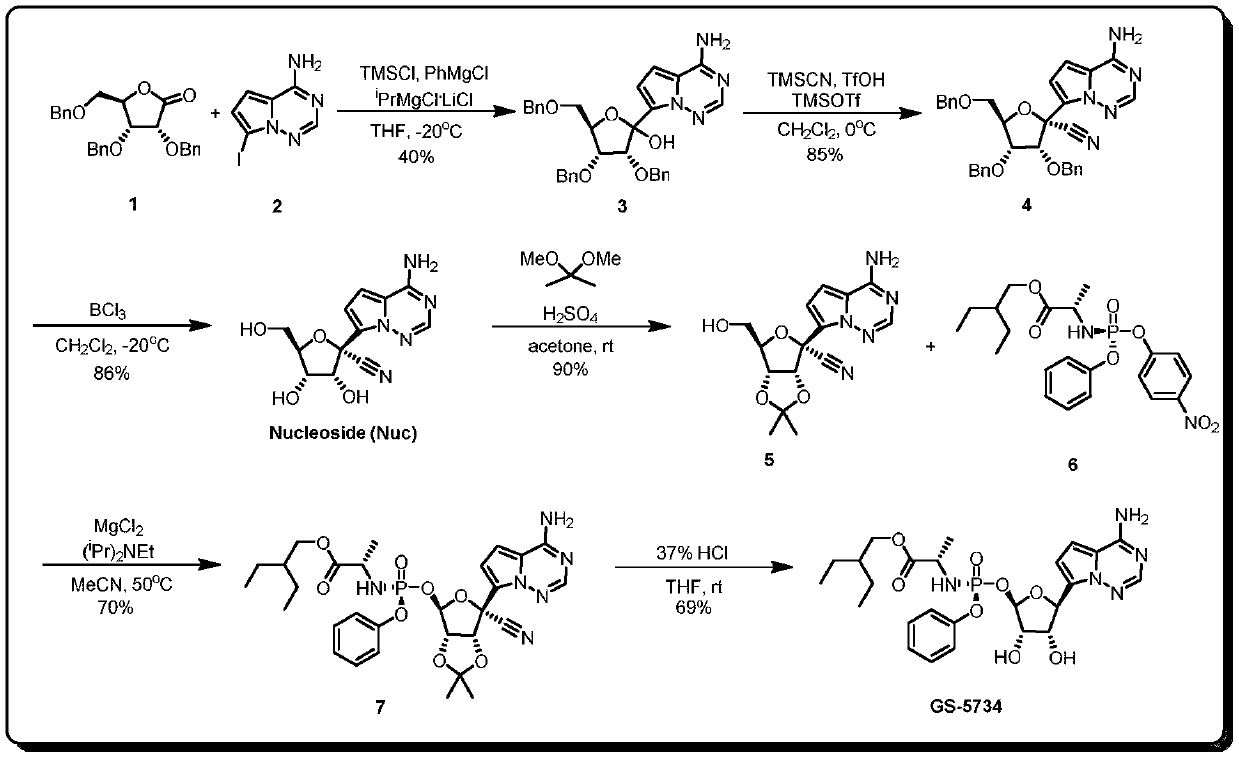

Method for preparing key intermediate of Remdesivir by using micro-channel reaction device

ActiveCN111484537AAvoid Yield DropsLarge specific surface areaSugar derivativesChemical/physical/physico-chemical microreactorsOrganosolvPhenyl group

The invention discloses a method for preparing a Remdesivir key intermediate by using a micro-channel reaction device, comprising the following steps of: (1) adding 7-iodopyrrolo [2, 1-f] [1, 2, 4] triazine-4-amine into an organic solvent, and adding trimethylchlorosilane to obtain a mixed solution as a first material; taking an organic mixed solution of phenyl magnesium chloride and isopropyl magnesium chloride. magnesium chloride as a second material; adding 2, 3, 5-tri-O-benzyl-D-ribose-1, 4-lactone into an organic solvent to be used as a third material; (2) respectively pumping the first material and the second material into a first micro-mixer of a micro-channel reaction device at the same time, mixing, and introducing into the first micro-reactor for reaction; and (3) pumping an effluent of the first micro-reactor and the third material into a second micro-mixer of the micro-channel reaction device at the same time, mixing, introducing into the second micro-reactor for reaction,and collecting an effluent, thereby obtaining the product.

Owner:NANJING UNIV OF TECH

Process for recovering sulfuric acid and sulfate from waste acid generated in preparation of titanium dioxide by using sulfuric acid method

InactiveCN102079512BImprove recycling ratesIncrease concentrationSulfur-trioxide/sulfuric-acidIron sulfatesHigh concentrationWater vapor

The invention relates to a process for recovering sulfuric acid and sulfate from waste acid generated in the preparation of titanium dioxide by using a sulfuric acid method, belonging to the technical field of waste acid treatment in the industrial production. The invention recovers sulfuric acid and sulfate products from waste acid generated in the production process for preparing the titanium dioxide by using the sulfuric acid method through the sedimentation pretreatment and the simple process including the first segment of flash evaporation-crystallization, concentration and separation, the second segment of vacuum evaporation, concentration and separation and the third segment of vacuum evaporation, concentration and separation. The invention has simple process, convenience of operation, simple equipment, high performance price ratio and high yield, high concentration and less impurities of the product acid, can recycle resources without waste liquid or waste residue emission andcan be favorable to environmental protection and energy saving, and emitted exhaust mainly contains air and less vapor, is non-toxic to the environment and can effectively overcome the difficulties of fouling and clogging of the equipment. The invention can be widely applied to the recovery of waste acid in the industrial production and be particularly suitable for recovering the waste acid generated in the preparation of titanium dioxide by using the sulfuric acid method.

Owner:CHONGQING UNIV

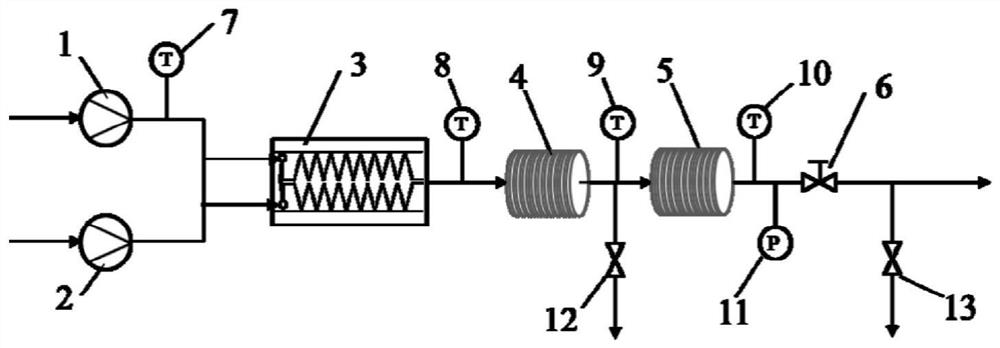

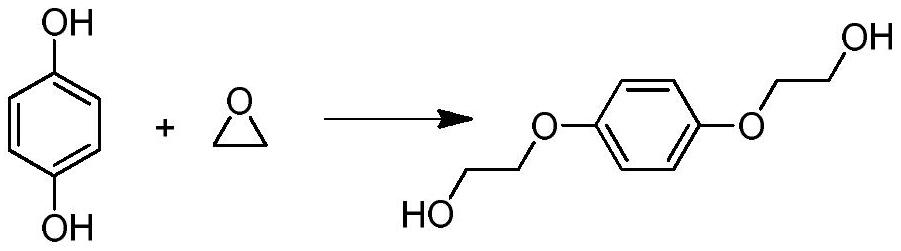

Method for continuously synthesizing hydroquinone dihydroxyethyl ether

InactiveCN112679323AAvoid flammable and explosive risksHeating up fastEther preparation from oxiranesPtru catalystEthylene oxide

The invention relates to the field of organic synthesis, in particular to a method for continuously synthesizing hydroquinone dihydroxyethyl ether by a micro-channel reactor. Hydroquinone and ethylene oxide are used as raw materials, a catalyst is added into a hydroquinone diluent, the two raw materials are controlled by a metering advection pump to be synchronously input into a micro-channel reaction system, the volume flow of hydroquinone and ethylene oxide is regulated and controlled, reaction liquid reacts in a reaction unit of a micro-channel, and hydroquinone dihydroxyethyl ether is obtained. According to the method, the hydroquinone dihydroxyethyl ether is synthesized by adopting a micro-channel continuous process, so that rapid heating can be realized, the liquid holdup is small, the safety is high, and the flammable and combustible risk of ethylene oxide with relatively high initial concentration in the rapid heating process in an intermittent process can be avoided.

Owner:SHENYANG RES INST OF CHEM IND

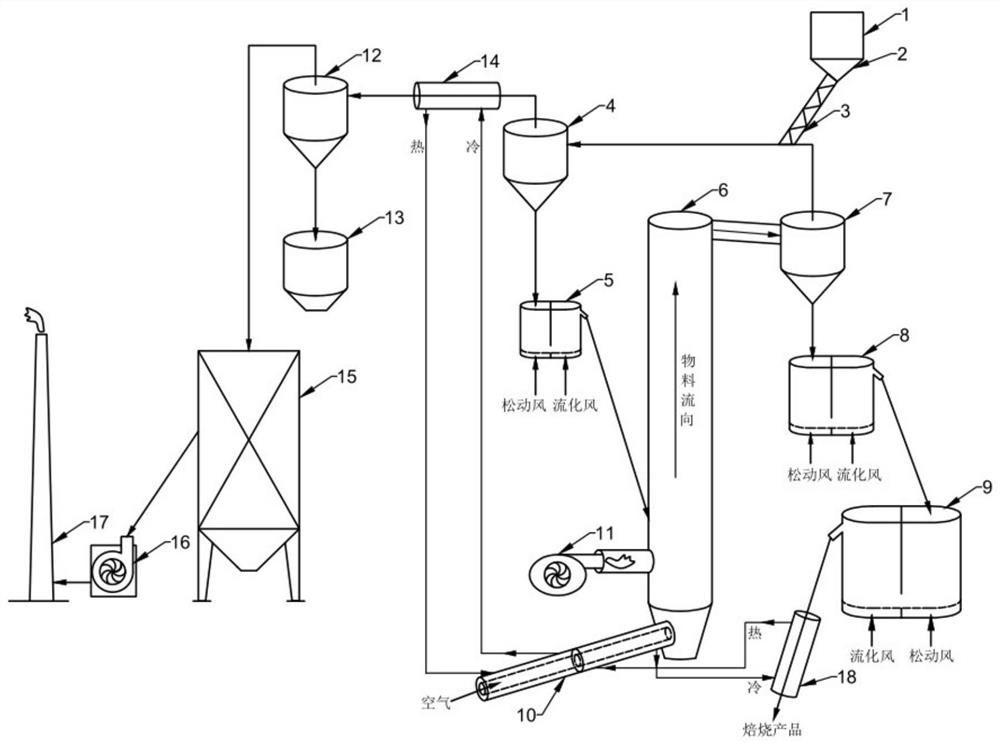

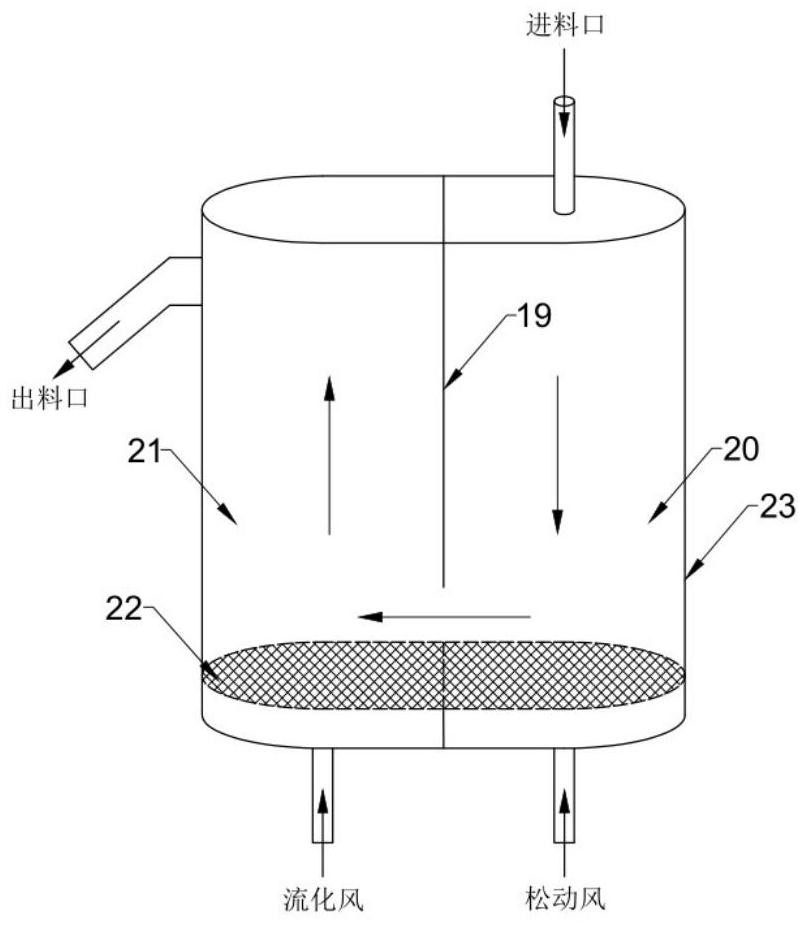

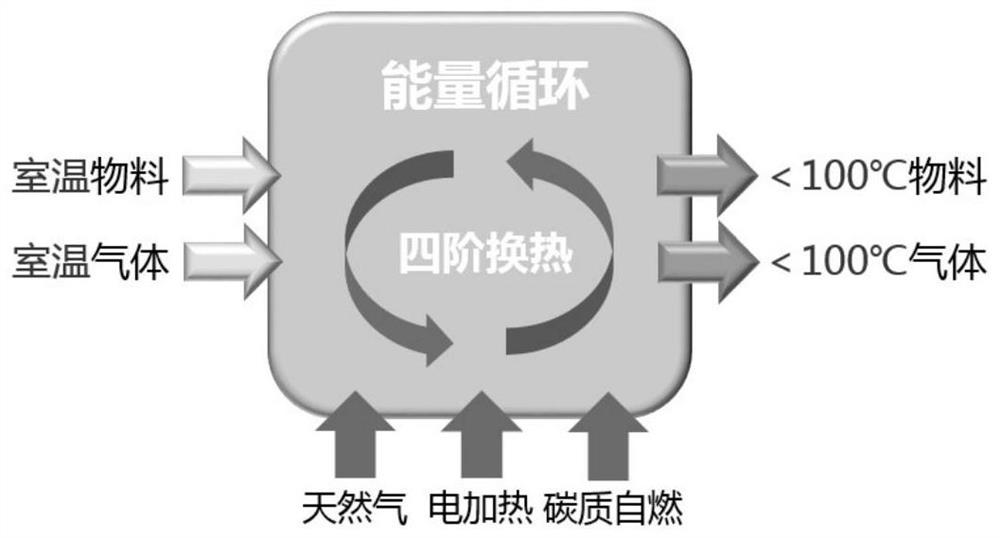

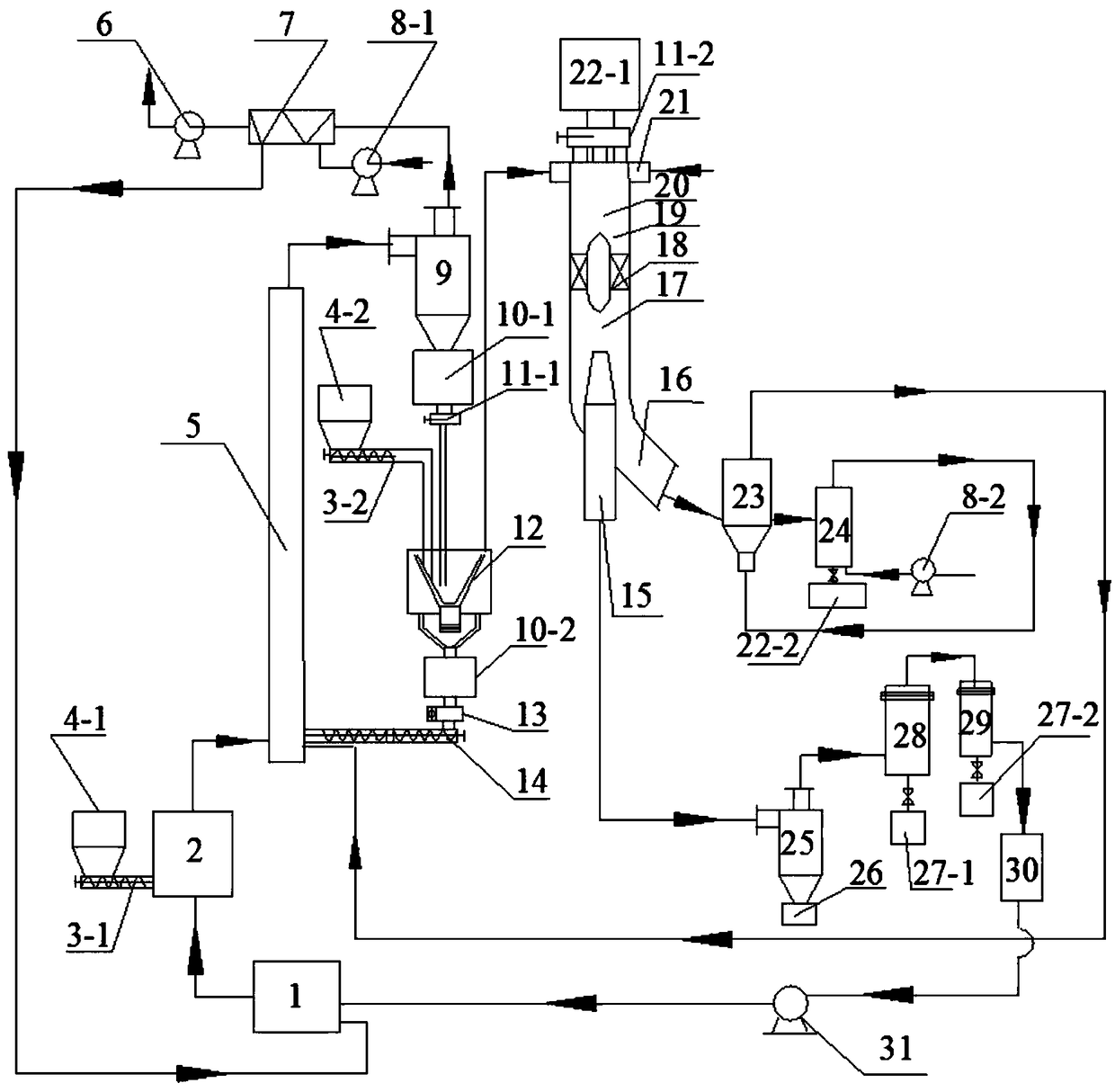

Stone coal vanadium ore cascade oxidizing roasting vanadium extraction system and oxidizing roasting method

PendingCN114111359APrevent sinteringImprove energy utilizationControl devices for furnacesWaste heat treatmentHeat transfer efficiencyDecarburization

The invention provides a stone coal vanadium ore cascade oxidizing roasting vanadium extraction system and an oxidizing roasting method. The system comprises a feeding system, a discharging system and a vanadium extraction system, wherein the feeding system is composed of a stock bin, a weightlessness scale and a spiral feeding pipe; the material circulating heat storage system consists of a primary cyclone separator, a flow sealing valve, a main furnace and a secondary cyclone separator; the stepped oxidizing roasting system consists of a decarburization roasting reactor, a crystal breaking roasting reactor and an ore discharge heat exchange pipe; the negative pressure dust removal system consists of a three-stage cyclone separator, a dust hopper, a bag-type dust remover, a Roots blower and a chimney; the decarburization roasting reactor and the crystal breaking roasting reactor are connected in series, so that the purpose of segmented suspension roasting of materials can be achieved; in addition, the system comprises a four-stage heat exchange process and a first-stage self-heating utilization process, and the overall energy utilization rate is extremely high, so that the stepped oxidation roasting system has the advantages of independent and controllable two-stage roasting, full gas-solid contact, high energy utilization rate, high mass and heat transfer efficiency, low operation cost, high efficiency, environmental protection and the like.

Owner:上海逢石科技有限公司

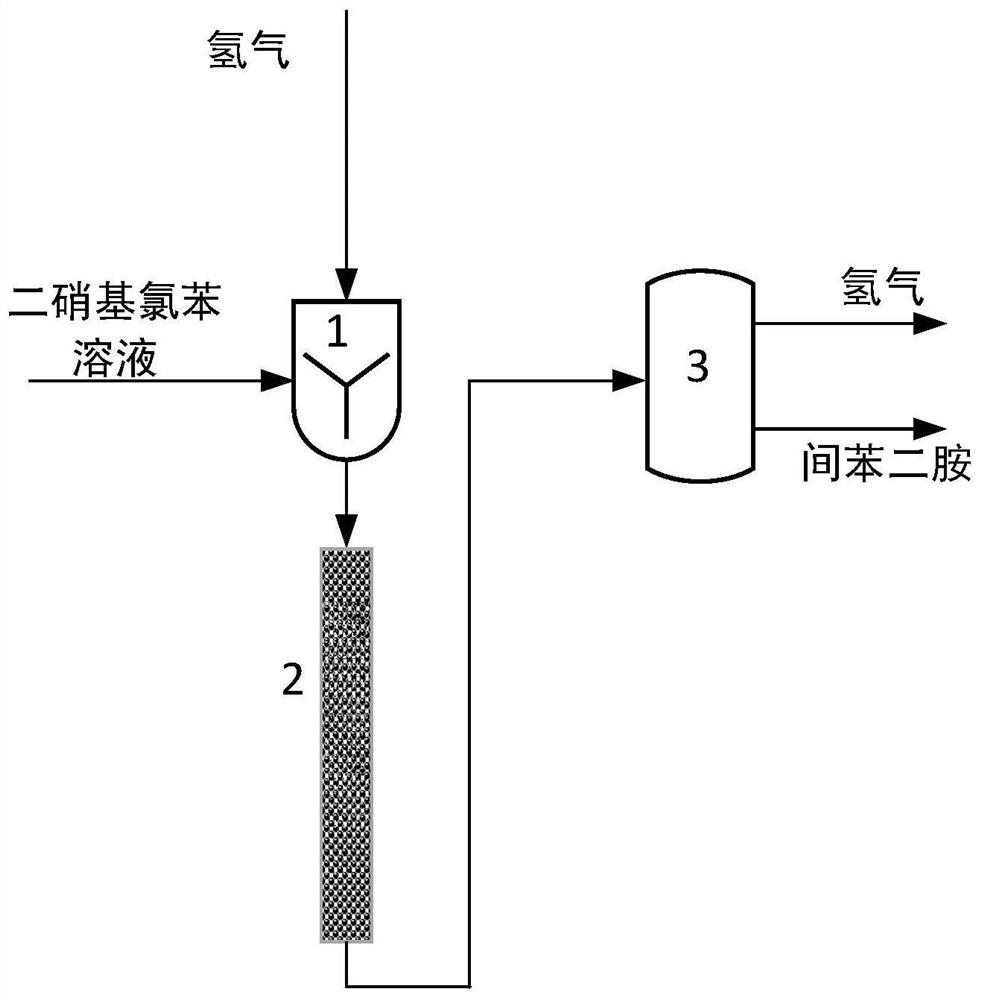

Method for preparing m-phenylenediamine based on continuous catalytic hydrogenation of fixed bed microreactor

ActiveCN113429295AReduce generationHigh yieldAmino compound purification/separationOrganic compound preparationLiquid productMicroreactor

The invention discloses a method for preparing m-phenylenediamine based on continuous catalytic hydrogenation of a fixed bed microreactor, which comprises the following steps: (1) taking dinitrochlorobenzene as a raw material, and dissolving the dinitrochlorobenzene in a solvent to serve as a to-be-hydrogenated substrate solution, wherein the dinitrochlorobenzene is at least one of 2, 4-dinitrochlorobenzene, 2, 6-dinitrochlorobenzene and 3, 5-dinitrochlorobenzene; (2) mixing a to-be-hydrogenated substrate solution and hydrogen in a micro-mixer to form a gas-liquid mixture with a good gas-liquid micro-dispersion state, and then enabling the gas-liquid mixture to enter a micro-packed bed reactor filled with a solid particle catalyst to react, wherein the reaction temperature is 40-160 DEG C, and the pressure is 1-5 MPa, and the retention time of the gas-liquid mixture in the micro-packed bed reactor is 10-120 s; and (3) carrying out gas-liquid separation on a gas-liquid mixture obtained after the reaction is finished, and feeding a liquid product into a subsequent separation and purification system.

Owner:ZHEJIANG DIBANG CHEM +1

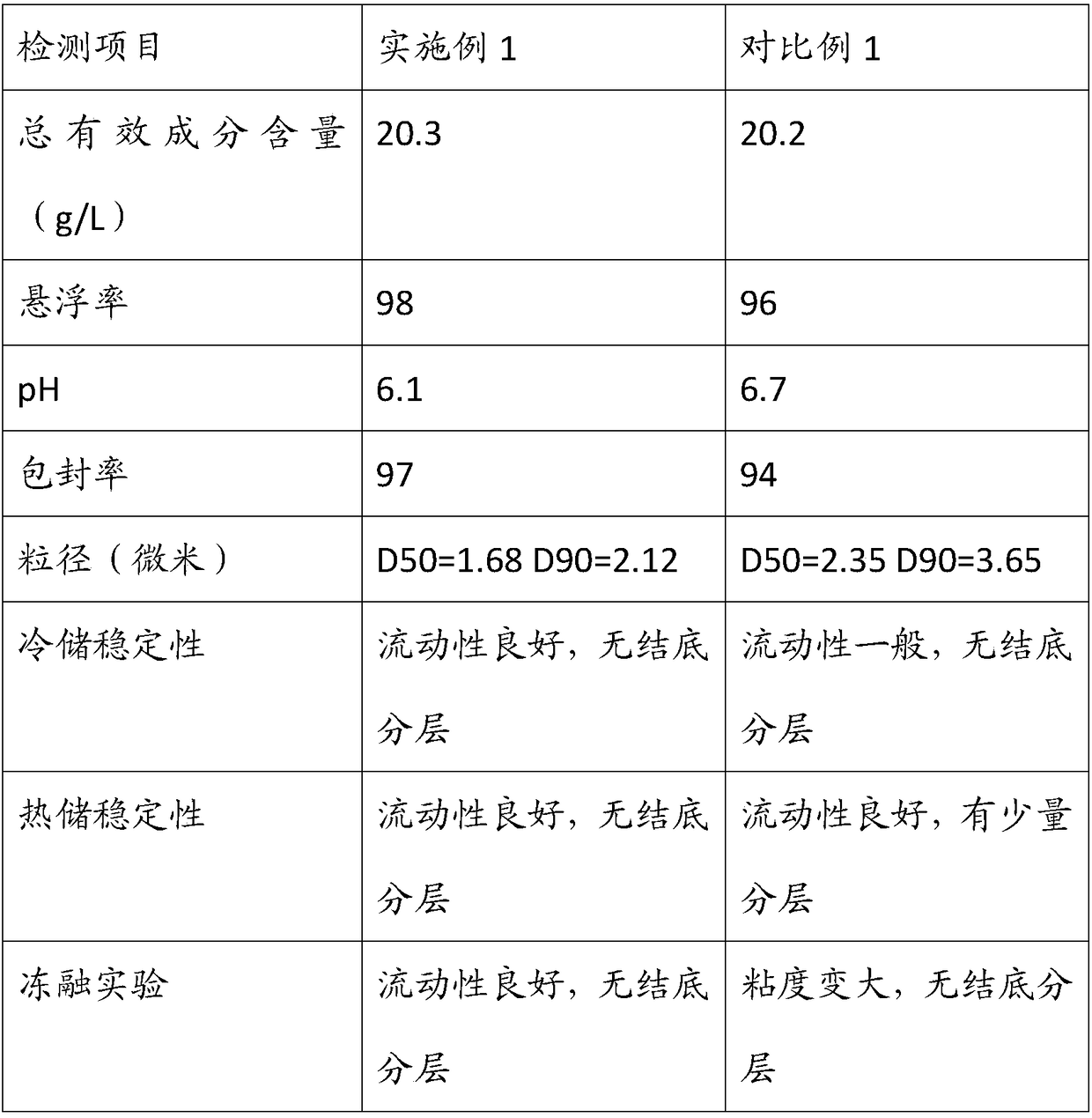

Pesticide micro-capsule suspending agent and preparation method thereof

ActiveCN108353897AParticle size controllableSimple processBiocideAnimal repellantsMicroreactorSuspending Agents

The invention discloses a pesticide micro-capsule suspending agent and a preparation method thereof. The particle size of the pesticide micro-capsule suspending agent is 0.1 to 20 mu m, the capsule wall adopts a material of polyurethane or polyurea, and a capsule core can be a pyrethroid pesticide, an organophosphorus pesticide or an aniline pesticide. The pesticide micro-capsule suspending agentis prepared through liquid / liquid interface polymerization of a microreactor, the technology is simple, prepared microcapsules are controllable in particle size and are uniform in distribution, a preparation technology of the pesticide micro-capsule suspending agent is simplified, a production amplification effect is reduced, and important value in aspect of pesticide microencapsulation is obtained.

Owner:SHIJIAZHUANG SENTAY CHEM CO LTD

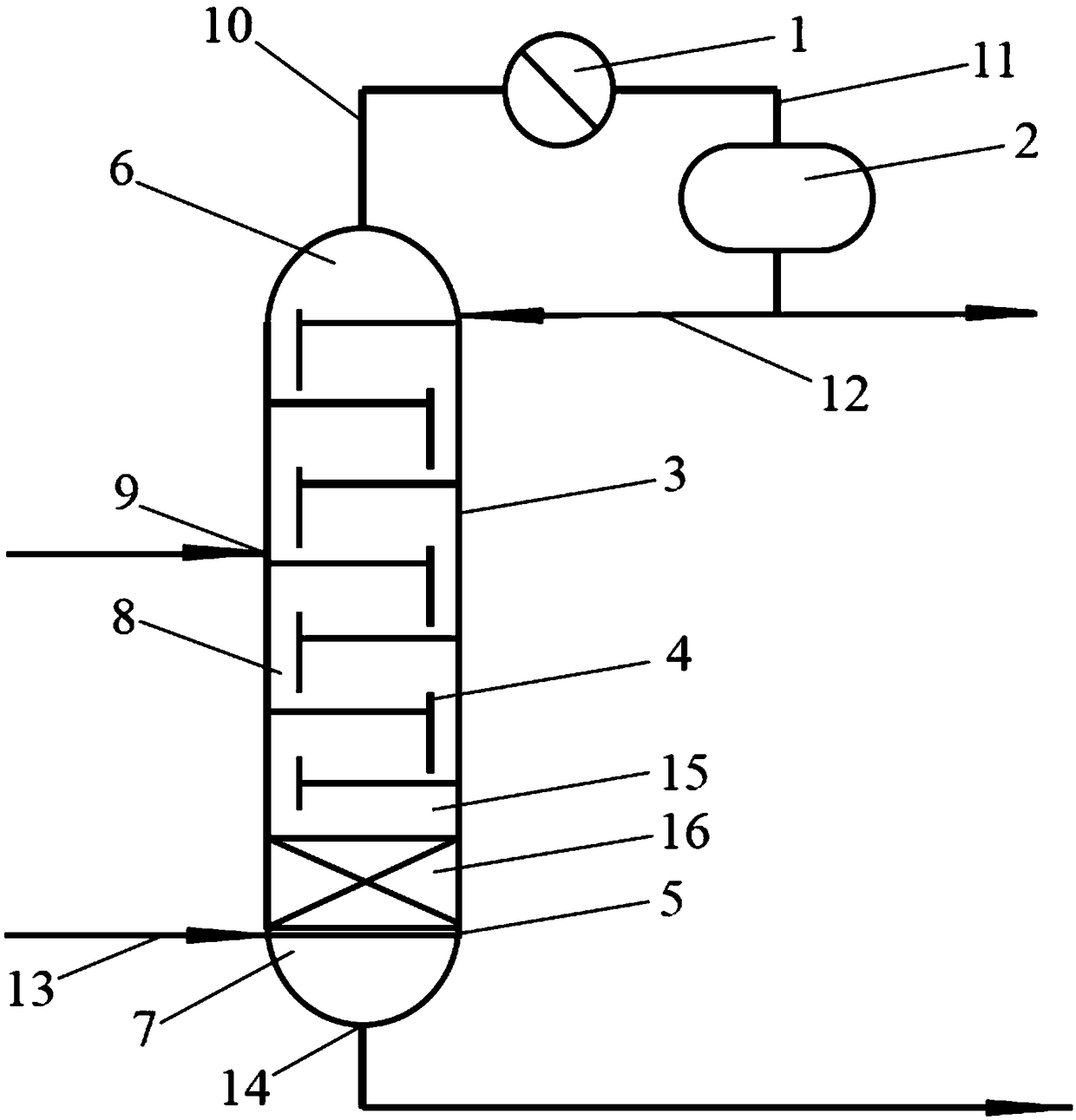

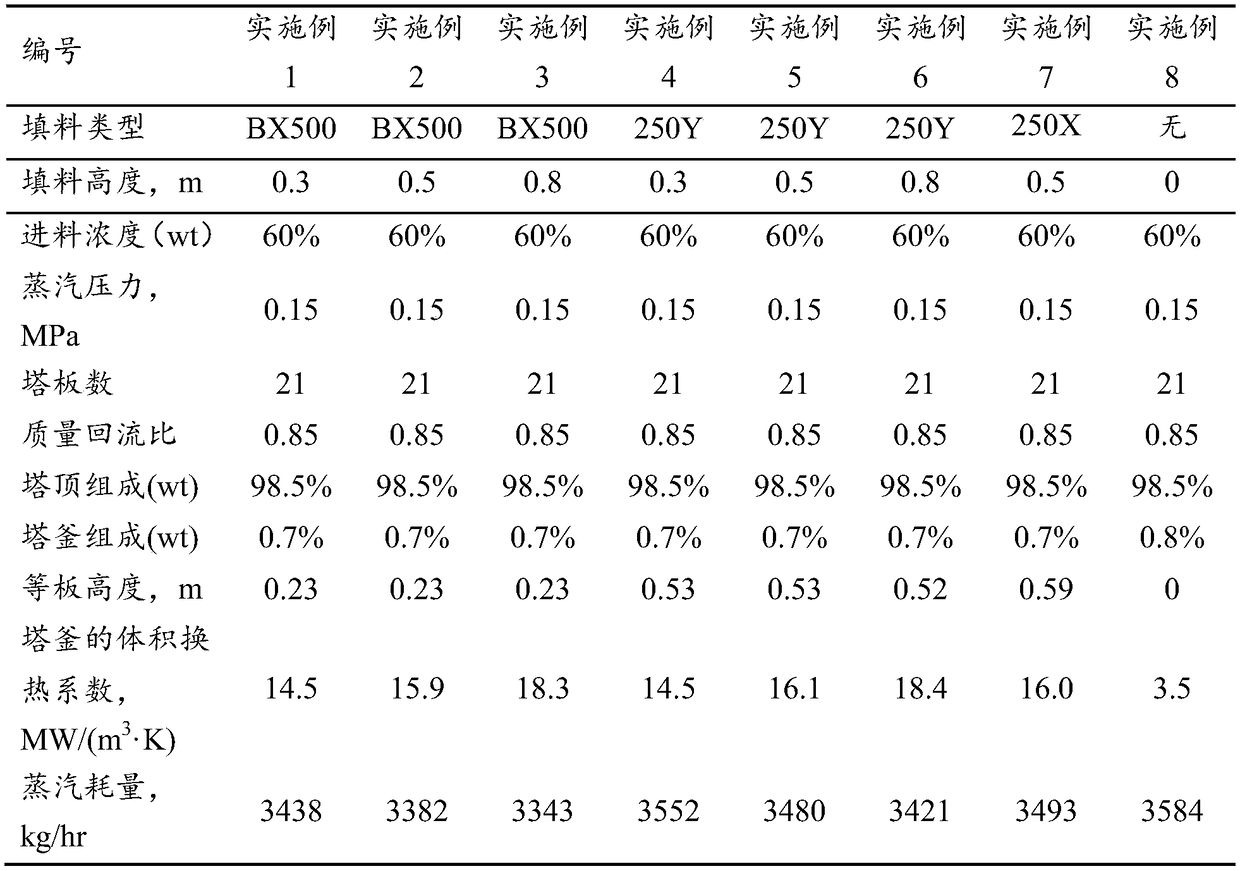

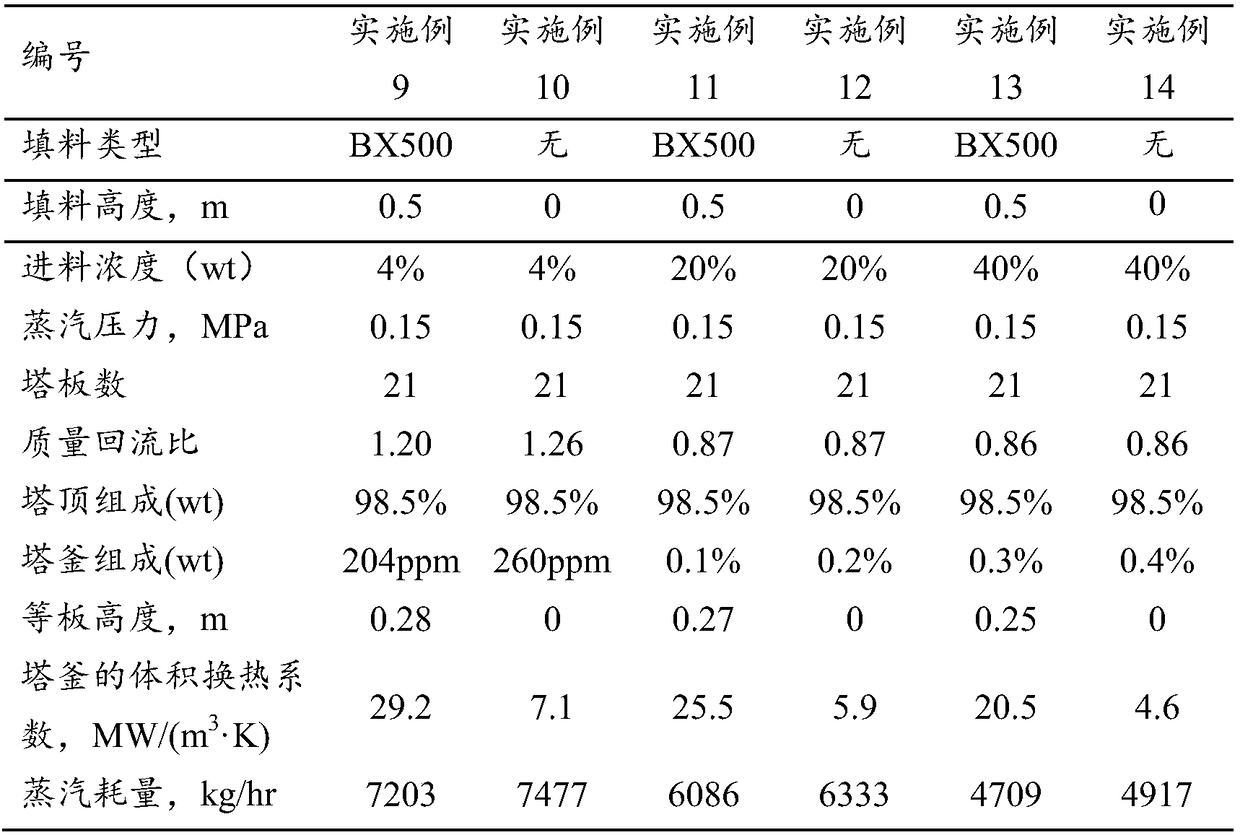

Rectifying and recovering device and method for rectifying and recovering acetone in acetone water solution

PendingCN109289222AImprove gas-liquid contactLarge specific surface areaCarbonyl compound separation/purificationFractional distillationRefluxAqueous acetone

The invention relates to the field of chemical separation and recovery, in particular to a rectifying and recovering device and a method for rectifying and recovering acetone in acetone water solutionby the device. A reserved cavity with the height of 1m-2m is formed between the upper portion of a gas distributor and a bottommost tower plate in a tower kettle of the device, and a filler layer with the height of 0.3m-0.8m is arranged in the reserved cavity and made of metal regular fillers. According to the rectifying method, the acetone water solution with acetone mass concentration of 4%-60%is rectified, and the mass reflux ratio of a rectified object is 0.85-1.2. According to the device, the filler layer is reasonably arranged by the aid of limited reserved space between the gas distributor and the bottommost tower plate, the shortcoming of mass and heat transfer of the gas distributor can be overcome, gas-liquid contact conditions of the tower kettle are improved, and the dosage of heating steam can be decreased.

Owner:ZHUHAI CELLULOSE FIBERS CO LTD

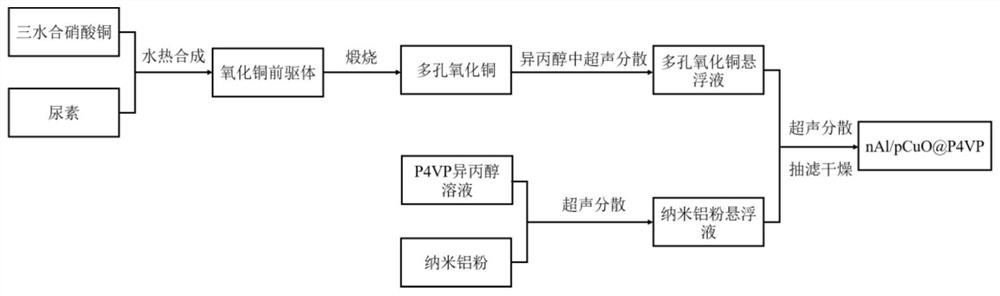

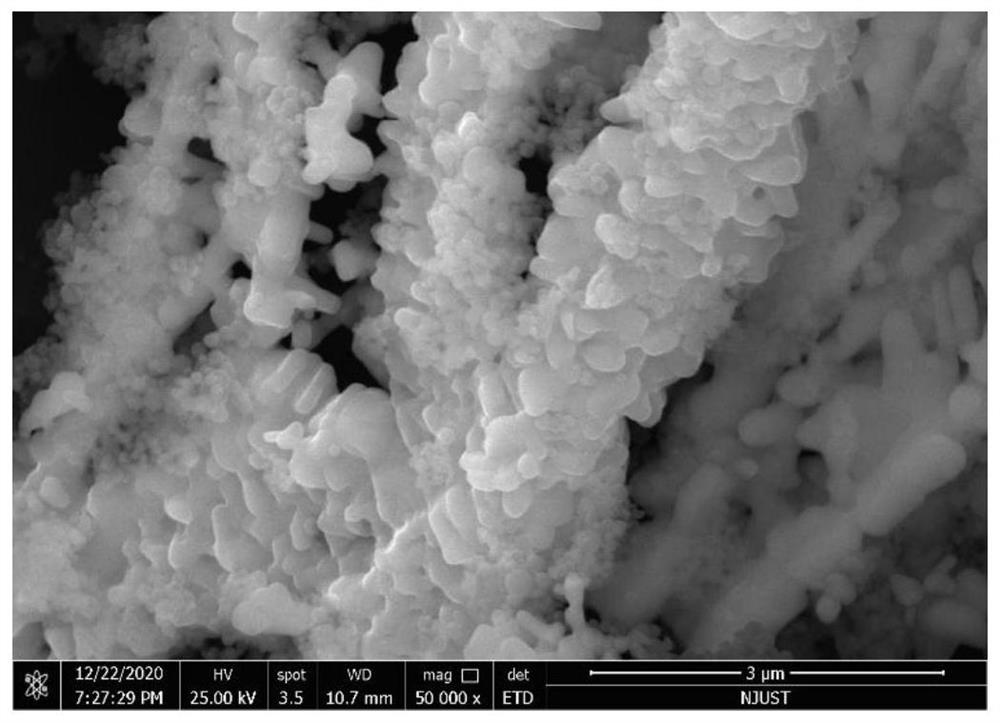

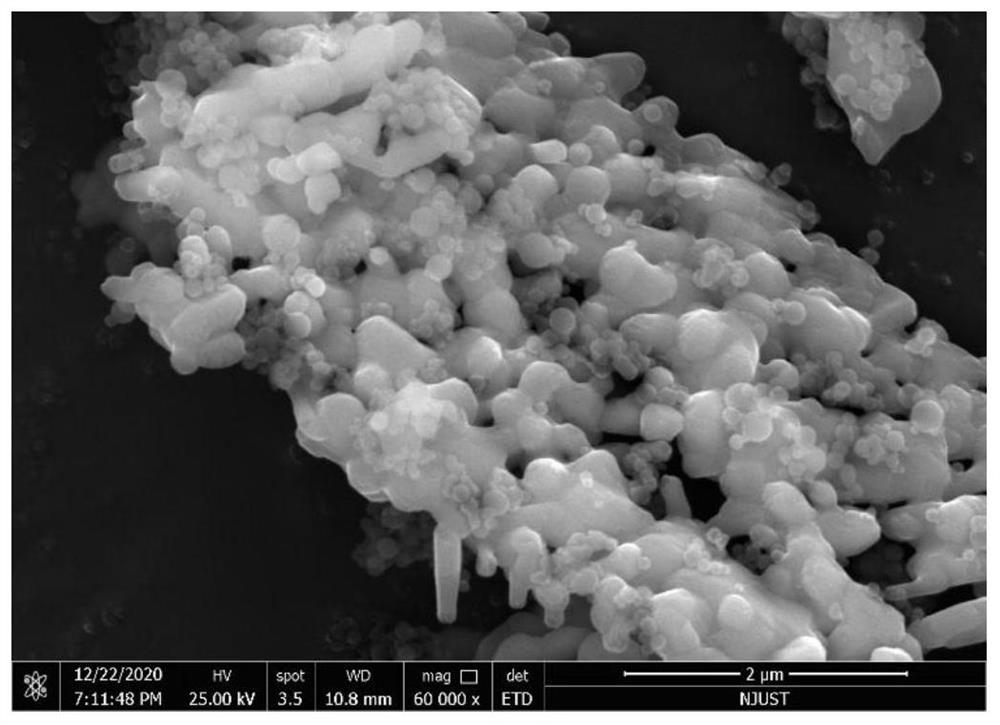

Method for preparing nano aluminum/porous copper oxide nano thermite through P4VP self-assembly

InactiveCN112920001AIncrease contact areaFacilitated releaseCopper oxides/halidesNon-explosive/non-thermic compositionsAl powderPhysical chemistry

Owner:NANJING UNIV OF SCI & TECH

Ex-situ catalytic pyrolysis liquefaction system for biomass

ActiveCN108728143AEasy to operate and controlReduce coke inactivationBiofuelsLiquid hydrocarbon mixture productionCycloneCatalytic pyrolysis

The invention relates to the technical field of conversion and utilization of biomass energy, in particular to an ex-situ catalytic pyrolysis liquefaction system for biomass. The ex-situ catalytic pyrolysis liquefaction system comprises a gasifier, a riser heater, a rotating cone reactor, a flow-guide cyclone reactor, a catalyst regeneration system, a gas-solid separator and a condensation system,wherein the bottom of the gasifier is connected with a first biomass feeder, and the upper part of the gasifier is connected with the lower part of the riser heater; a quartz sand feeder is connectedwith the lower part of the riser heater; the upper part of the riser heater is connected with an inlet of a quartz sand separator; the lower part of the quartz sand separator is connected with a heated sand box which is connected with an inlet of the rotating cone reactor; an outlet of the rotating cone reactor is connected with a gas inlet of the flow-guide cyclone reactor through a gas pipe; the flow-guide cyclone reactor is connected with a catalyst box at the upper part through catalyst inlets. An ex-situ catalytic pyrolysis process is performed on biomass with the system, operation is convenient and controllable, and working condition parameters in a pyrolysis process and a catalytic cracking process can be adjusted and controlled respectively.

Owner:SHANDONG UNIV OF TECH

Graphite distribution collector

ActiveCN103768820ACompact structureReduce manufacturing costFractional distillationHeat transfer efficiencyEngineering

The invention relates to a graphite distribution collector. The graphite distribution collector is characterized by comprising a shell, wherein a collecting tray is fixedly arranged in the shell; a plurality of distribution pipes which vertically penetrate through the bottom surface of the collecting tray are uniformly arranged on the bottom surface of the collecting tray in an array form and are circular pipes; at least two overflow notches which are symmetrical to each other are formed in the upper end of each circular pipe; saw-toothed distribution teeth are arranged at the lower end of each distribution pipe; the number of the saw-toothed distribution teeth is equal to that of the overflow notches; the tooth tip of each distribution tooth and the corresponding overflow notch are positioned in the same vertical line. The graphite distribution collector is simple and compact in structure, low in manufacturing cost and maintenance cost, and convenient and quick to assemble and disassemble; a plurality of pairs of overflow notches and distribution points in the same vertical line are arranged on each distribution pipe; the number of the distribution points is increased, the distribution points are uniform, materials are uniformly distributed, coefficients of a tower plate are improved, the mass and heat transfer efficiency is improved, the rectification efficiency is improved, the production cycle is shortened, and the production efficiency is improved; the distribution pipes and the collecting tray are made of graphite and are corrosion-resistant, and the service life is prolonged.

Owner:WUXI YANGSHI CHEM

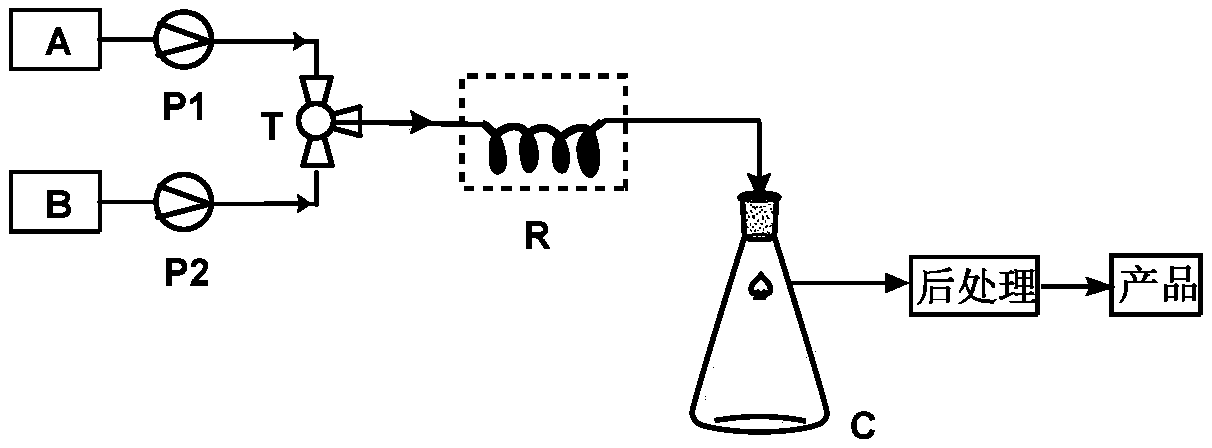

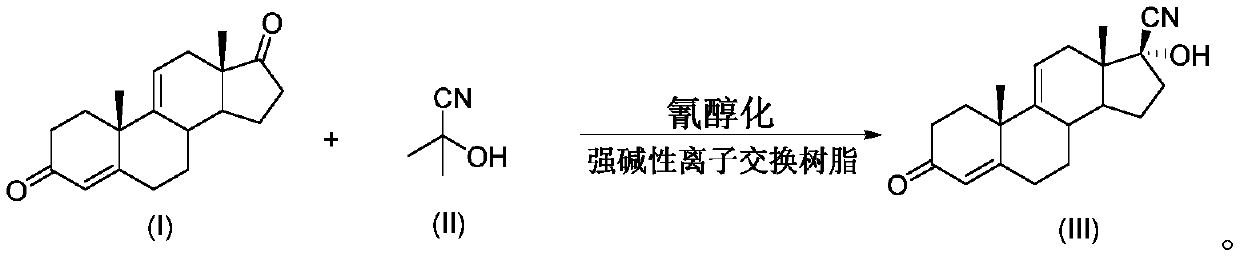

Method for preparing 17beta-cyano-17alpha-hydroxy-9-dehydroandrostenedione

InactiveCN111320665ASmall amount of online responseReduce backmixingSteroidsChemical/physical processesOrganic solventIon exchange

The invention discloses a method for preparing 17 beta-cyano-17 alpha-hydroxy-9-dehydroandrostenedione. The method comprises the following steps: (1) dispersing 9-dehydroandrostenedione (I) and acetone cyanohydrin (II) into an organic solvent; (2) carrying out a cyanohydrination reaction on the obtained mixed raw material liquid in a tubular reactor filled with strongly basic ion exchange resin, and (3) carrying out post-treatment on the material liquid after the cyanohydrination reaction to obtain 17beta-cyano-17alpha-hydroxy-9-dehydroandrostenedione (III), the reaction formula of which is shown in the specification.

Owner:台州仙琚药业有限公司

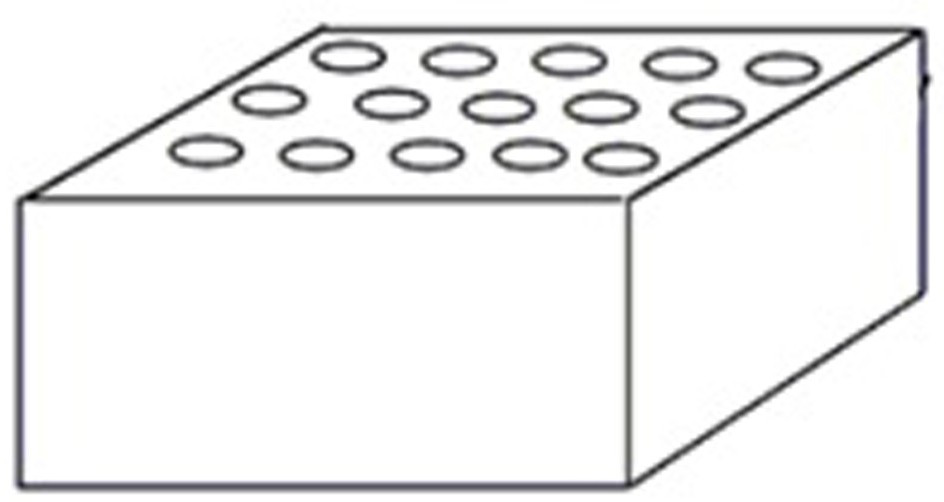

Micro-channel reactor manufactured based on 3D printer technology

PendingCN113499744AMix well and evenlyHigh mass and heat transfer efficiencyChemical/physical/physico-chemical microreactorsMicroreactorThermodynamics

The invention relates to the technical field of chemical engineering devices, in particular to a micro-channel reactor manufactured based on a 3D printer technology. According to the technical scheme, the micro-channel reactor comprises at least one micro-reaction channel module unit printed through the 3D technology, the micro-reactor module unit is a square body, a plurality of regularly-arranged micro-channel reaction tubes are embedded in the micro-reactor module unit, the micro-channel reaction tube is simultaneously provided with an inner-layer heat exchange medium cavity, a material reaction cavity and a surrounding heat exchange medium cavity; and the inner-layer heat exchange medium cavity is located in the center of the micro-channel reaction tube, the surrounding heat exchange medium cavity is surrounded by the material reaction cavity, and the surrounding heat exchange medium cavity surrounds the material reaction cavity. The reaction cavity in the micro-channel increases the reaction contact area and time length through the action of a spiral flow guide partition plate structure and a baffle plate, so that reaction materials can be mixed more fully and uniformly, the reaction is promoted to be carried out quickly and stably, and the reaction rate and the product quality are improved.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

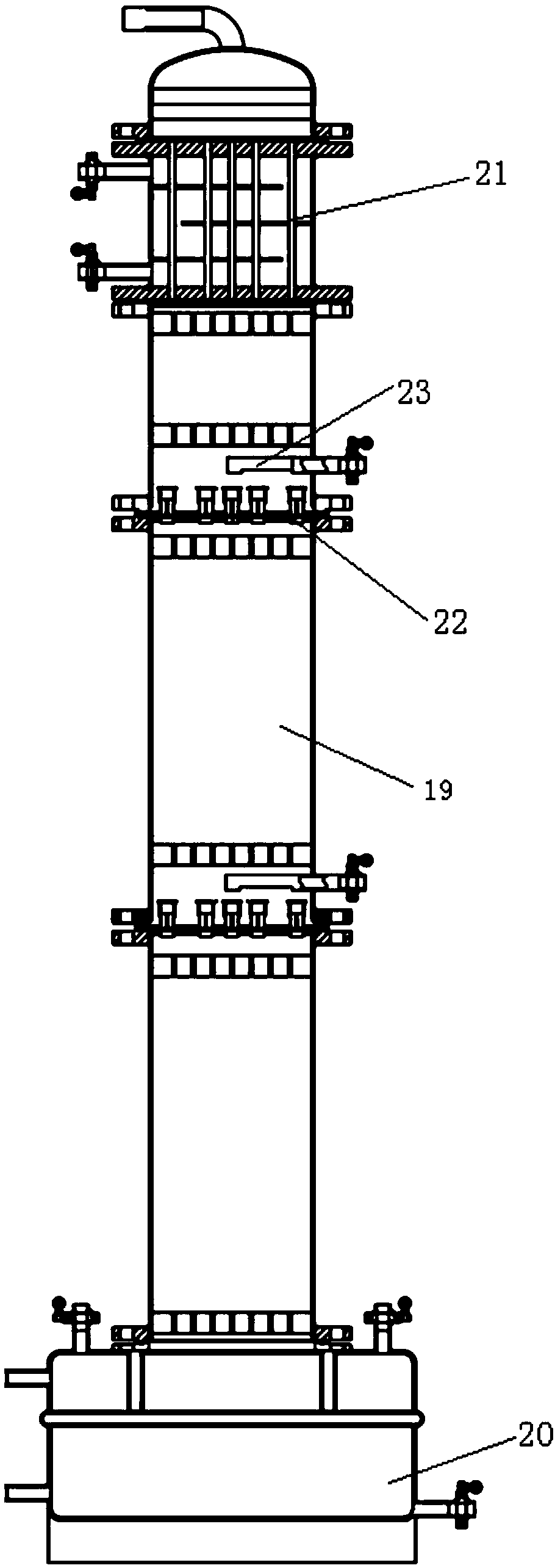

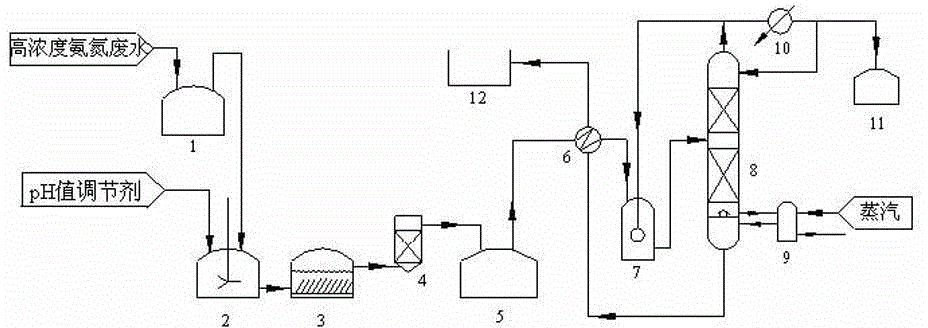

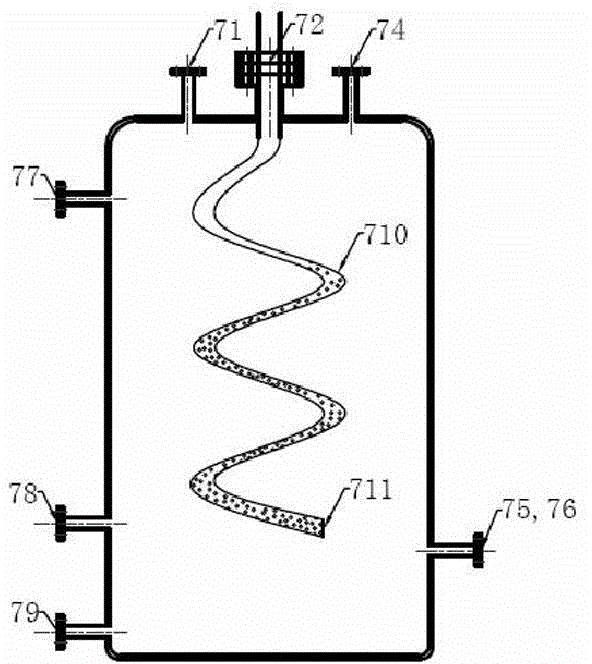

Treatment system for high-concentration ammonia-nitrogen wastewater

ActiveCN104891726AEasy to operateIncrease temperatureMultistage water/sewage treatmentAmmoniacal nitrogenNitrogen removal

The invention discloses a treatment system for high-concentration ammonia-nitrogen wastewater. The treatment system comprises a pretreatment system, a concentration-increasing and energy-saving device, a stripping tower, a condenser and an ammonia water storage tank which are connected sequentially. The treatment system has the advantages that the treatment system is simple to operate, equipment investment is low, ammonia-nitrogen removal efficiency is high, steam unit consumption in ammonia-nitrogen wastewater treatment is low, up-to-standard discharge can be achieved through one-step treatment, and finished ammonia water with high economic value can be recycled.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com