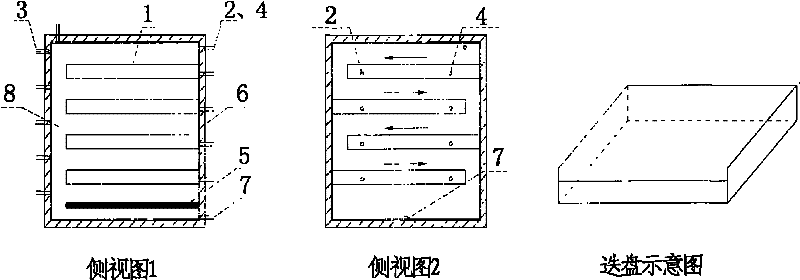

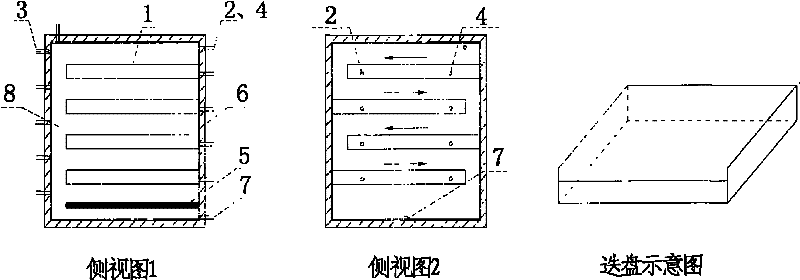

Baffled multistage disc distiller enhanced by externally adding negative pressure

A still and baffled technology, applied in the field of brackish water distillation and desalination, can solve the problems of difficult utilization of condensation heat, low mass transfer and heat transfer efficiency, large energy loss, etc., so as to reduce water production cost and energy consumption. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0012] Example 1: Water production test of the two-stage stacked disc system at different temperatures.

[0013] Only the bottom stack of distillation trays is assembled to form a two-stage distillation, and the water temperature of the chassis is heated to 45°C, 50°C, 55°C, 60°C, and 65°C (salt content is 10g / L) in order to test the dynamic water production rate. The experimental suction pressure is 0.06Mpa. It is measured that the water production rate can reach 352L / d, and the average conductivity of the effluent water is 73μs / cm.

example 2

[0014] Example 2: Water production test of three-stage stacked disc system at different temperatures.

[0015] A two-layer stacked tray is installed at the bottom, and the water temperature of the chassis is heated to 45°C, 50°C, 55°C, 60°C, and 65°C (salt content is 10g / L) in sequence in the form of three-stage distillation to test the dynamic water production rate. The pumping pressure in the experiment is 0.06Mpa. It is measured above 60°C and runs for 20 hours a day. The water production rate can reach 476L / d, and the conductivity of the effluent water is 79μs / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com