Patents

Literature

412results about How to "Lower water costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fully integrated NF-thermal seawater desalination process and equipment

InactiveUS20060157410A1High yieldEffectively and efficiently dealGeneral water supply conservationReverse osmosisDistillationEngineering

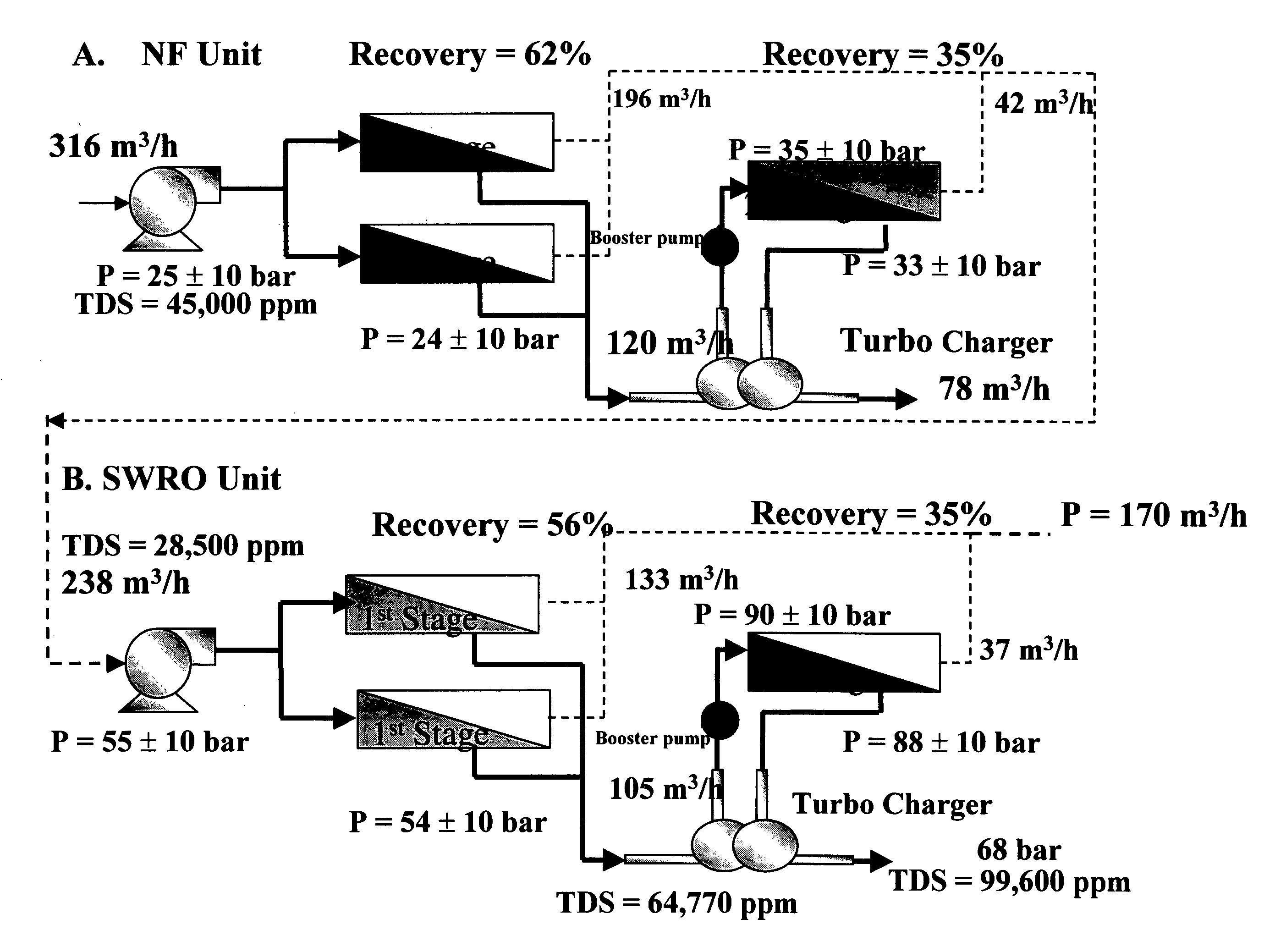

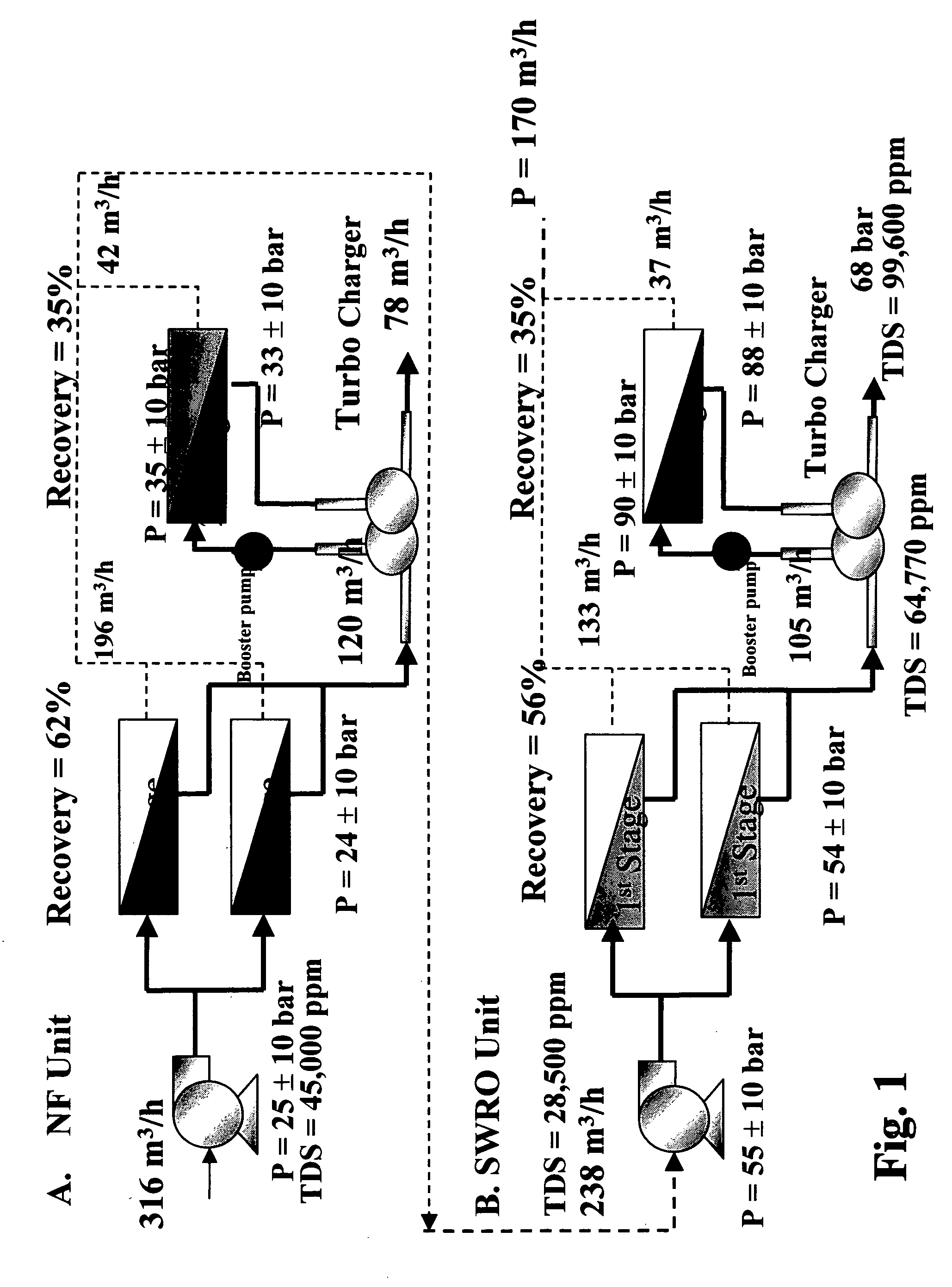

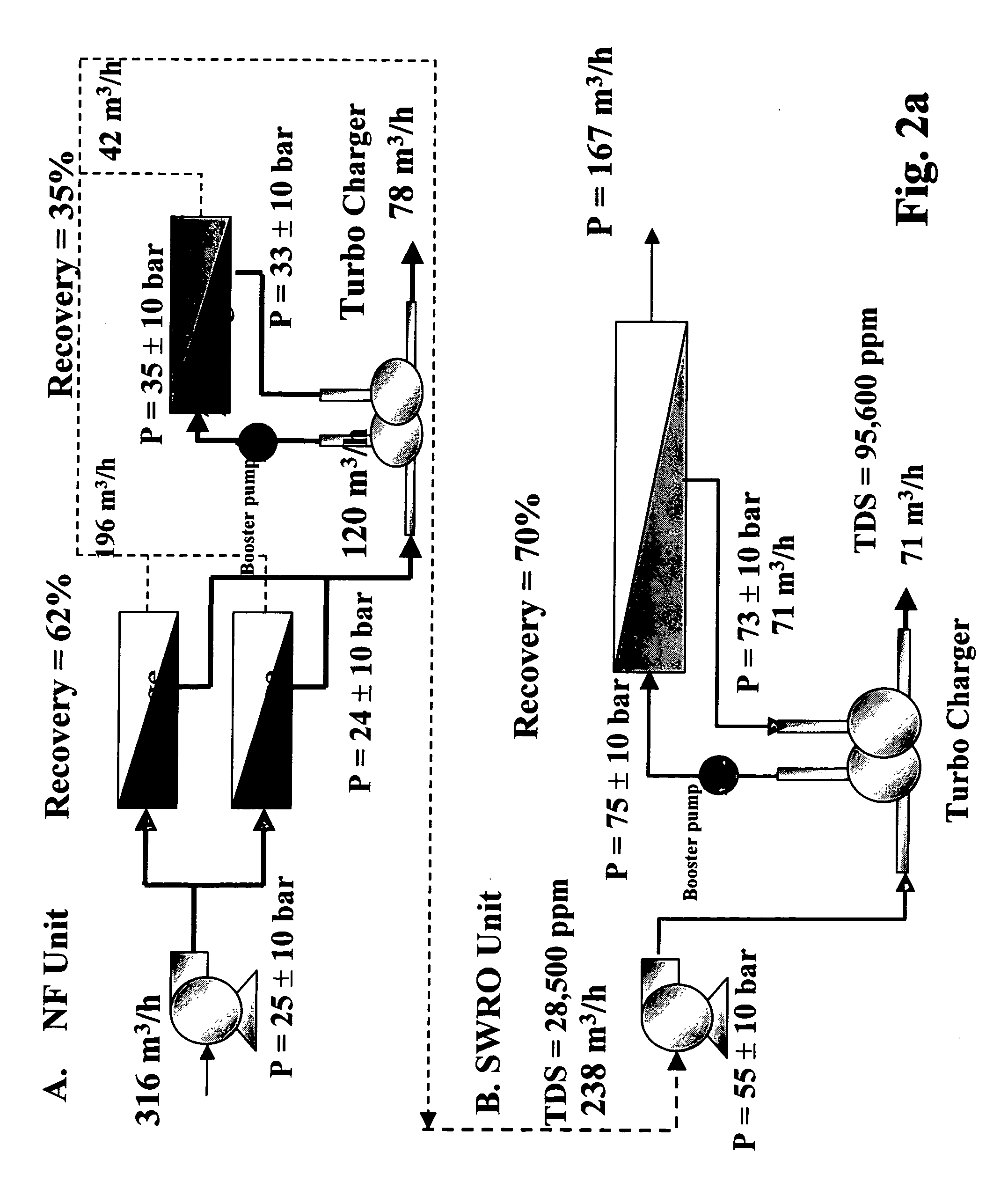

An optimal thermal seawater desalination process is disclosed, which combines two or more substantially different water pretreatment processes in a unique manner and in a special configuration, hereto unknown to prior desalination arts, to produce a high yield of high quality fresh water, including potable water. In this process a two stage NF membrane pretreatment unit (NF2) with an energy recovery turbo charger (TC) device in between the stages or equipped with an energy recovery pressure exchanger (PX) is synergistically combined with at least one thermal desalination unit to form a dual hybrid of NF2-Thermal (FIG. 4 ), or alternatively the two stage NF2 unit is synergistically combined with a two stage SWRO unit (SWRO2) with an energy recovery TC in between the stages or combined with one stage SWRO (SWRO1) equipped with an energy recovery TC or PX system and the reject from the SWRO2 or SWRO1 unit is made make-up to a thermal unit to form a tri-hybrid of NF2-SWRO2 reject-Thermal (FIG. 5 ). In both the cases of di- or trihybrids the thermal unit is equivalent to a multistage flash distillation (MSFD) or multieffect distillation (MED) or vapor compression distillation (VCD) or thermal reheat (RH) evaporator. Typically a process of this invention using the two stage NF2 initial pretreatment step will perform a semi-desalination step by reducing feed TDS by about 35 to 50%, but most important, especially to the thermal seawater desalination process, it removes the water recovery limiting, scale forming hardness ions of Ca++ and Mg++ by better than 80% and their covalent anions of sulfate to better than 95% and bicarbonate to about 65%. The removal of scale forming hardness ions, especially SO4=, and bicarbonates allowed for the operation of thermal unit in the above hybrids at top brine temperature (TBT) much greater than its present TBT limit by the singular conventional process of 120° C. for MSFD and operation of MED or VCD or RH unit at TBT much higher than their present TBT limit of 65-70° C., with many advantages gained by this process over prior art sweater desalination processes. The process of this invention exceeds all prior thermal seawater desalination arts in efficiency, including water yield, product water recovery ratio and unit water cost as well as in energy consumption per unit product which is equivalent or less than other efficient prior art seawater thermal desalination processes. By this process, an NF product recovery ratio of 75 and 80% or better is achieved from the high salinity Gulf sea (TDS≈45,000 ppm) and about an equal product recovery ratio is also obtained from the SWRO or thermal unit when it is operated on NF product for a total water recovery ratio in excess of 52% for seawater

Owner:SALINE WATER CONVERSION CORP SWCC

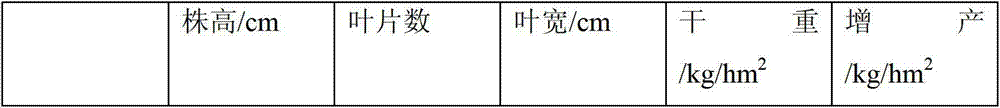

Liquid compound microbial fertilizer containing polyglutamic acid, and preparation method and application thereof

ActiveCN103172437AImprove fertilizer use efficiencyPromote high and stable productionFertilizer mixturesNutrientFertilizer

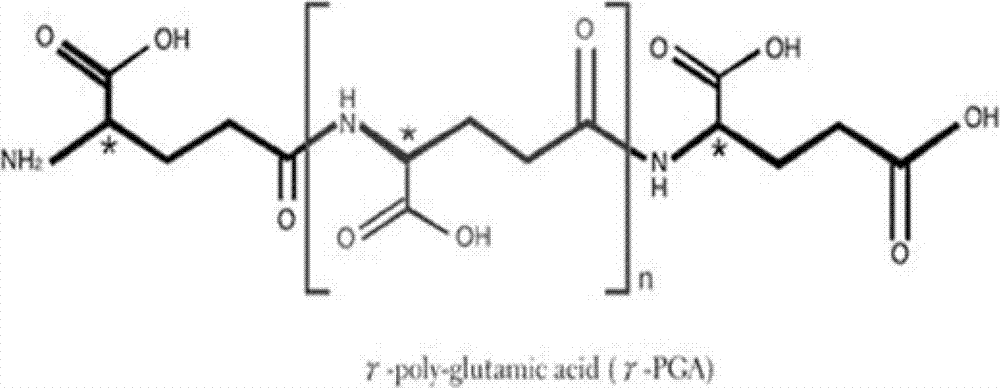

The invention discloses a liquid compound microbial fertilizer containing polyglutamic acid, and a preparation method and an application thereof, and belongs to the field of compound microbial fertilizers. Bacillus megaterium, bacillus thuringiensis and bacillus amyloliquefaciens are prepared into a bacteria liquid by liquid fermentation, and then the bacteria liquid is mixed with compound nutrients and a gamma-polyglutamic acid according to the mass ratio of 1:1:0.05-0.1 to be prepared into the efficient liquid compound microbial fertilizer. On the basis of good phosphorus dissolving capability of the bacillus megaterium, good insect resistance of the bacillus amyloliquefaciens and good organic matter degrading capability of the bacillus amyloliquefaciens, the purposes of more excellent fertilizer efficiency and lower water consumption are achieved under the characteristics of water retention, fertilizer preservation, and no environmental pollution of the gamma-polyglutamic acid, therefore, the scientific and reasonable matching of the compound fertilizers is formed.

Owner:山东省神农生态科技股份有限公司

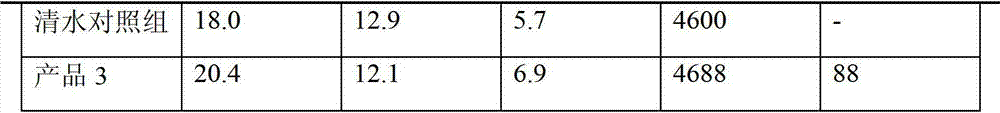

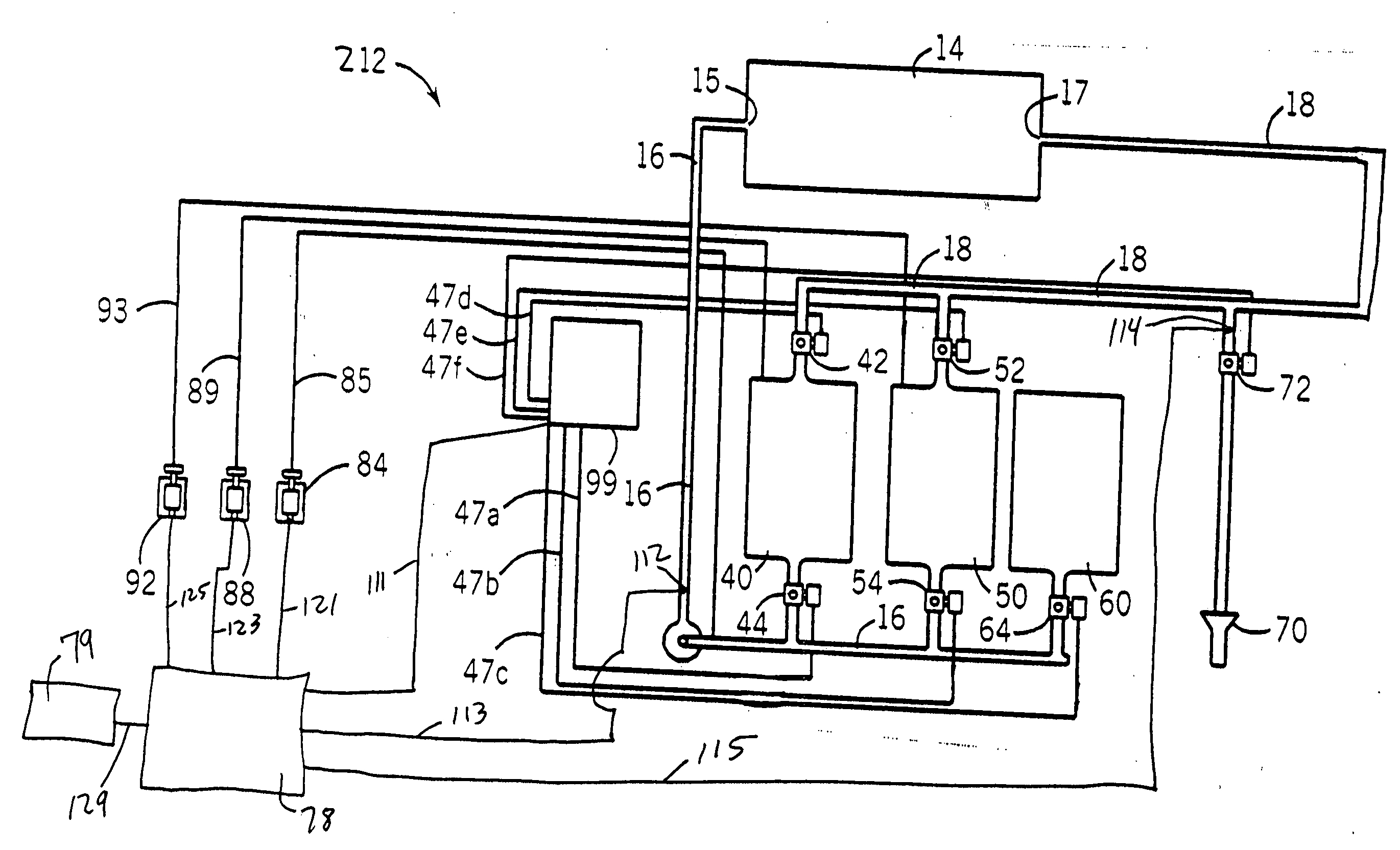

Chemical concentration controller and recorder

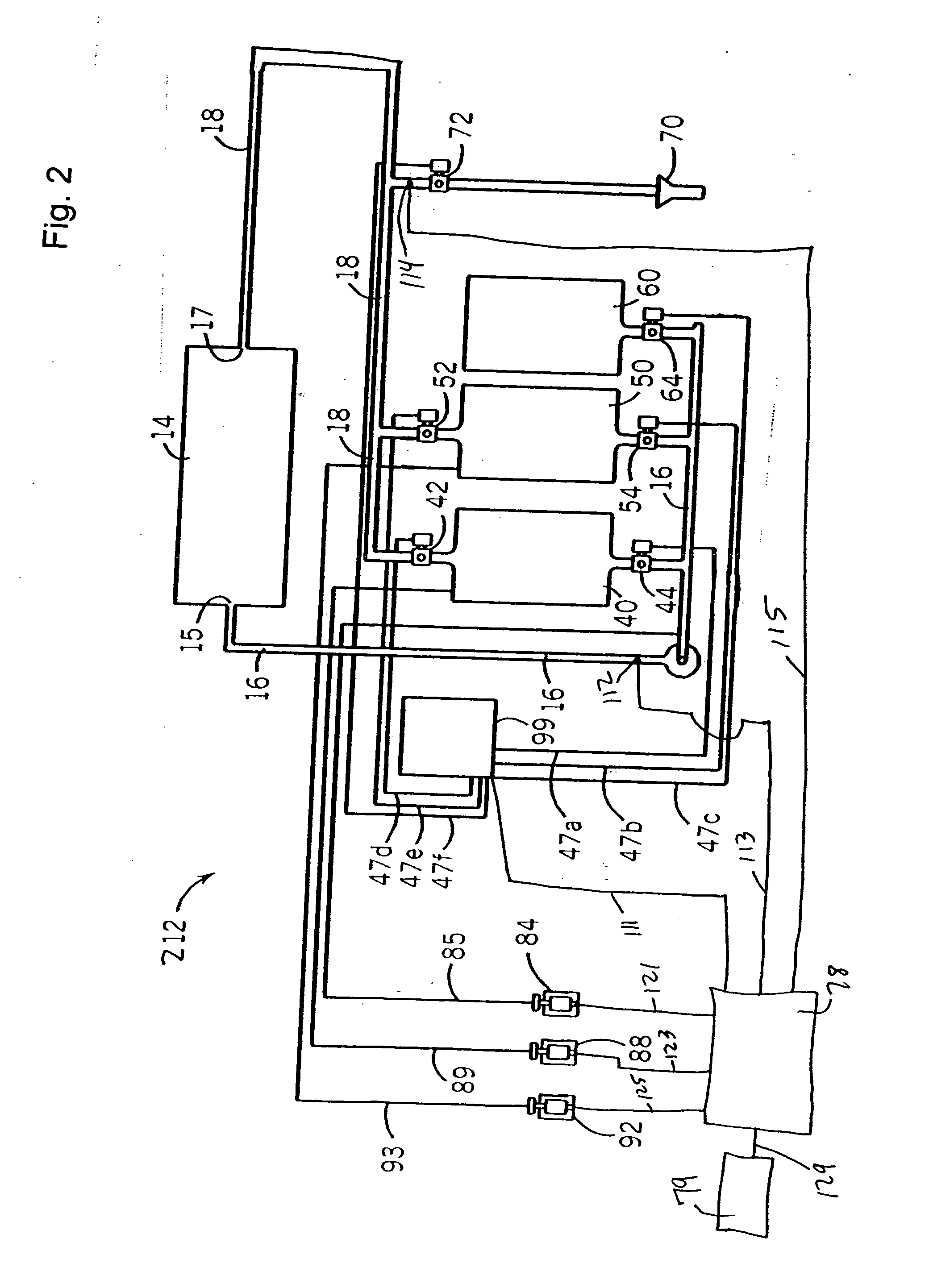

InactiveUS20060196529A1Lower water costsHollow article cleaningCleaning using liquidsCost ControlsEngineering

A chemical concentration controller and recorder is disclosed for controlling and recording chemical concentrations in a cleaning system. The invention allows a user to control the concentration of two or more chemicals in the cleaning system simultaneously using either concentration-based feed or timed feed. The invention records and archives chemical concentration data from sensors in the cleaning system tanks or the cleaning system fluid conduits during operation of the cleaning system. The data may then be downloaded by a user and analyzed for efficiency and cost control purposes. For example, the data may indicate the overfeeding of chemicals to the cleaning system or leaking valves in the cleaning system.

Owner:HYDRITE CHEM

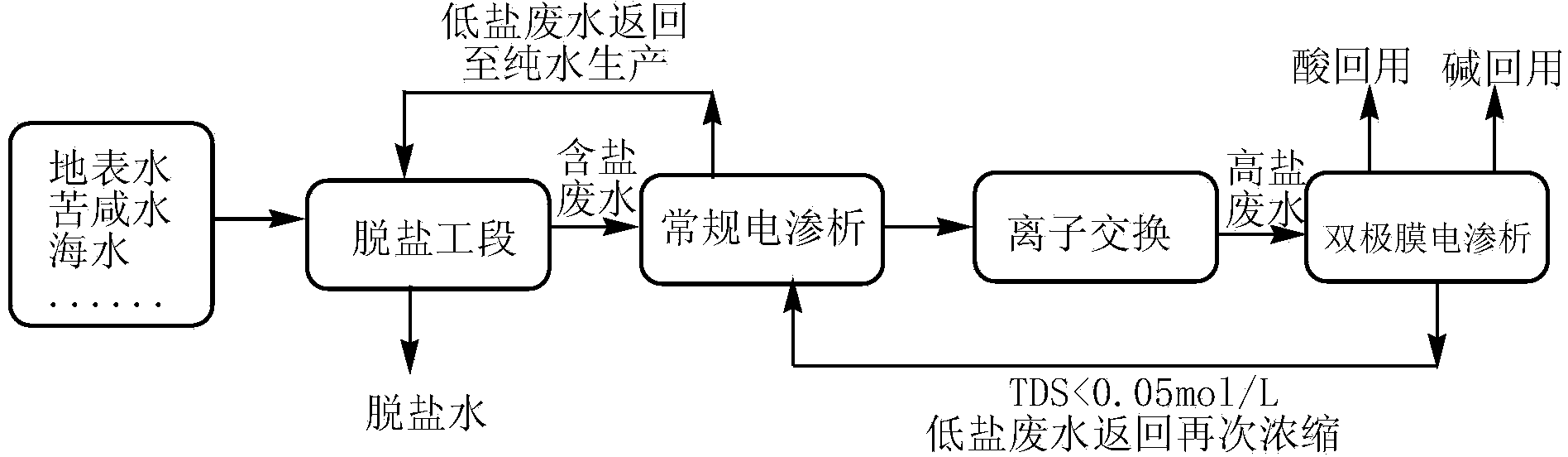

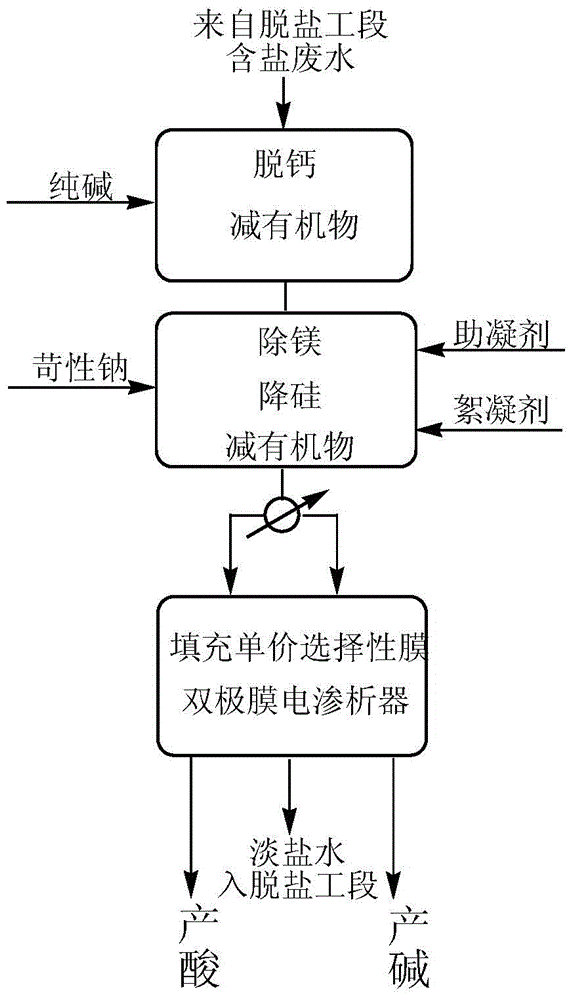

Recycling treatment method for salt-containing wastewater

ActiveCN103508521AHigh recovery rateSimple and efficient preprocessingGeneral water supply conservationDispersed particle separationSaline waterDesalination

The invention relates to a recycling treatment method for salt-containing wastewater. The recycling treatment method is characterized by comprising the following steps: (1) carrying out desalting, concentrating and initial hard water removal on the salt-containing wastewater through a general electrodialyzer at first, returning obtained low-salt wastewater to a desalting process for preparing pure water, and carrying out deep hard water removal on high-salt wastewater through ion exchange; (2) pumping the preprocessed high-salt wastewater into a bipolar membrane electrodialyzer for recycling treatment, dissociating sodium chloride and water for greatly reducing the content of salt in the wastewater, and obtaining hydrochloric acid and sodium hydroxide at the same time; returning the obtained low-salt wastewater to a water concentration chamber of the general electrodialyzer for concentrating again. According to the recycling treatment method, the environmental pollution caused by direct discharge of the high-salt wastewater is avoided, wastes (salt) are turned into wealth (acid and alkali), the water recovery rate of a salt water removal process is increased, the integral water preparation cost is remarkably reduced, and good economic and social benefits are achieved.

Owner:OCEAN UNIV OF CHINA +1

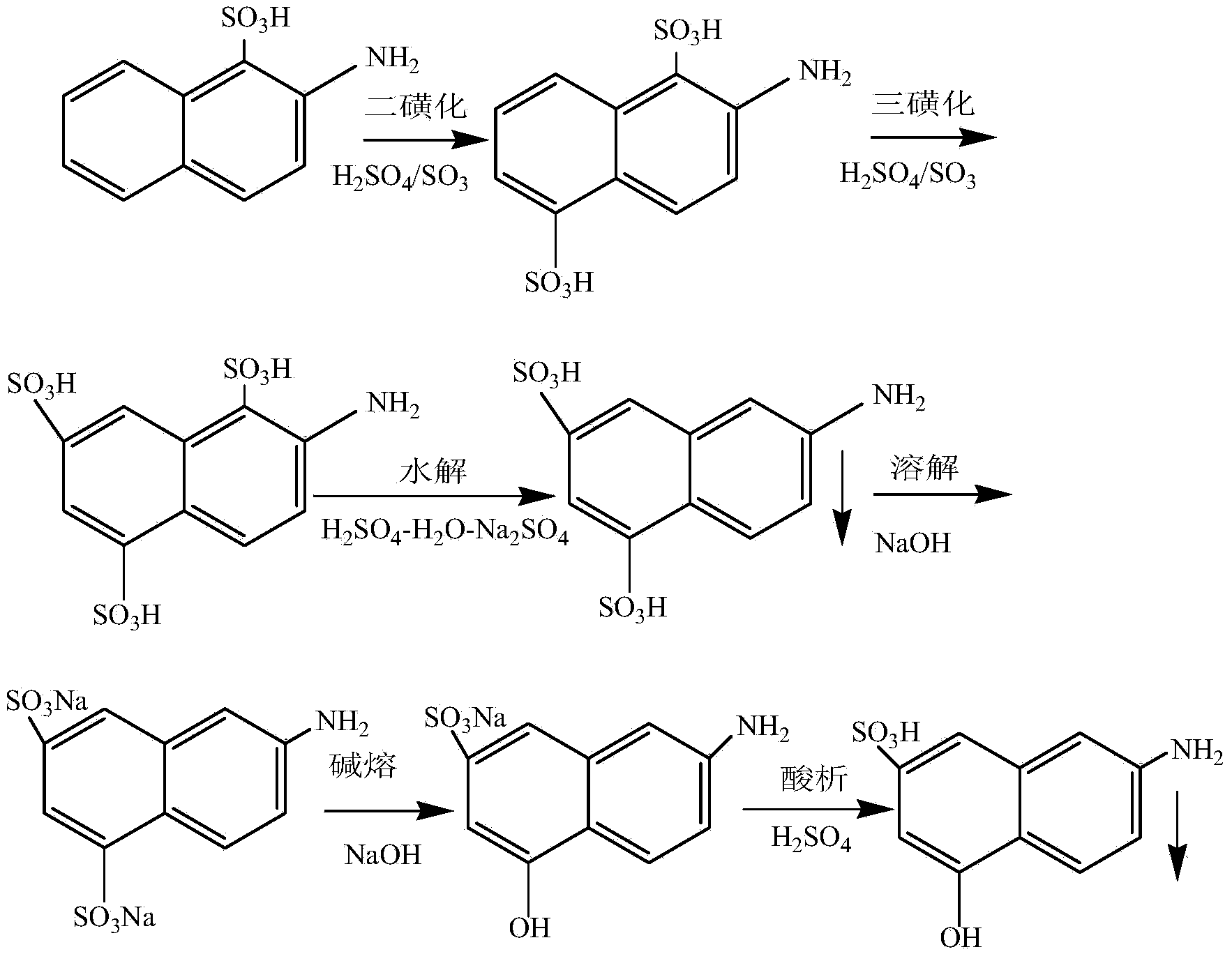

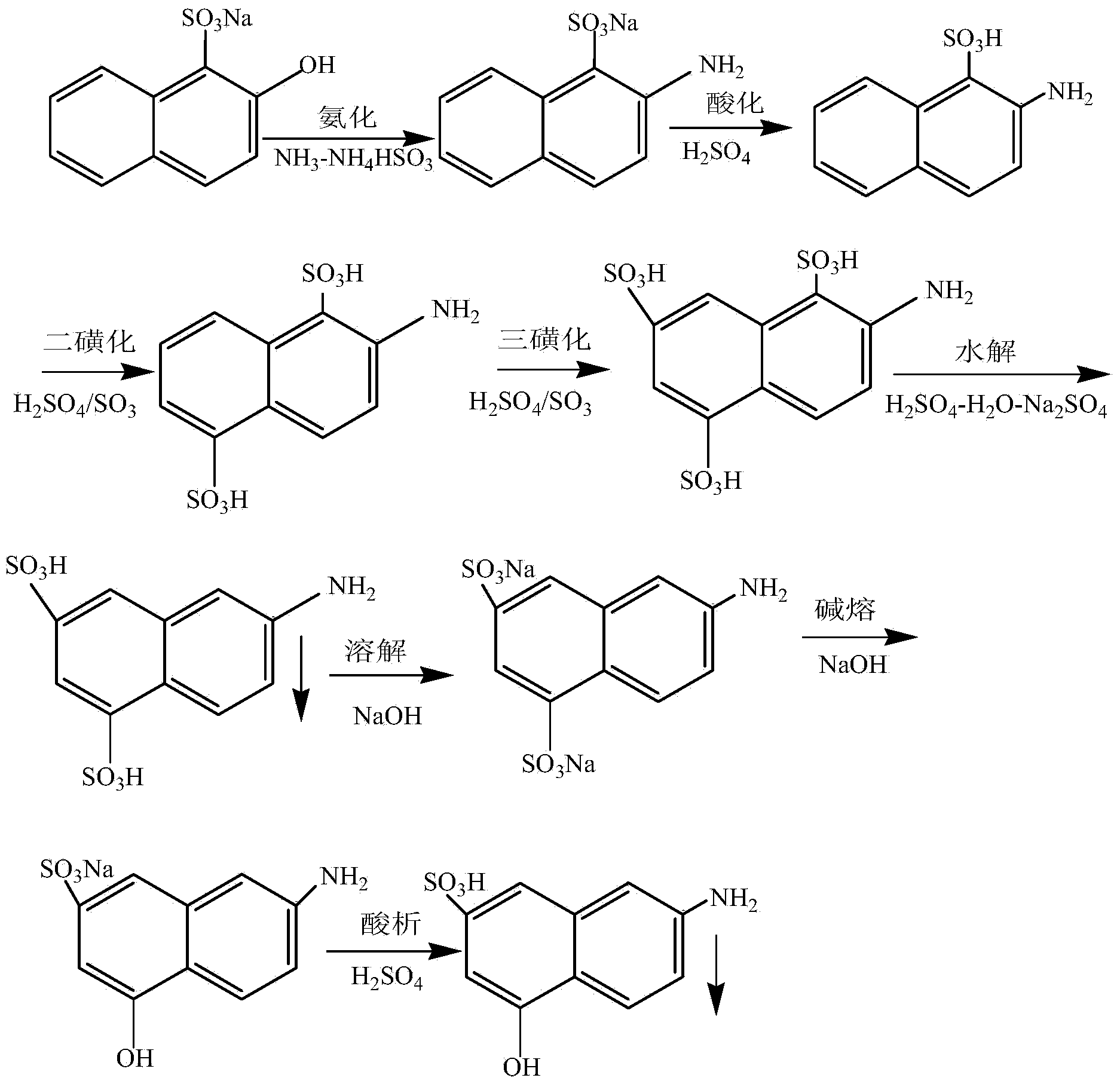

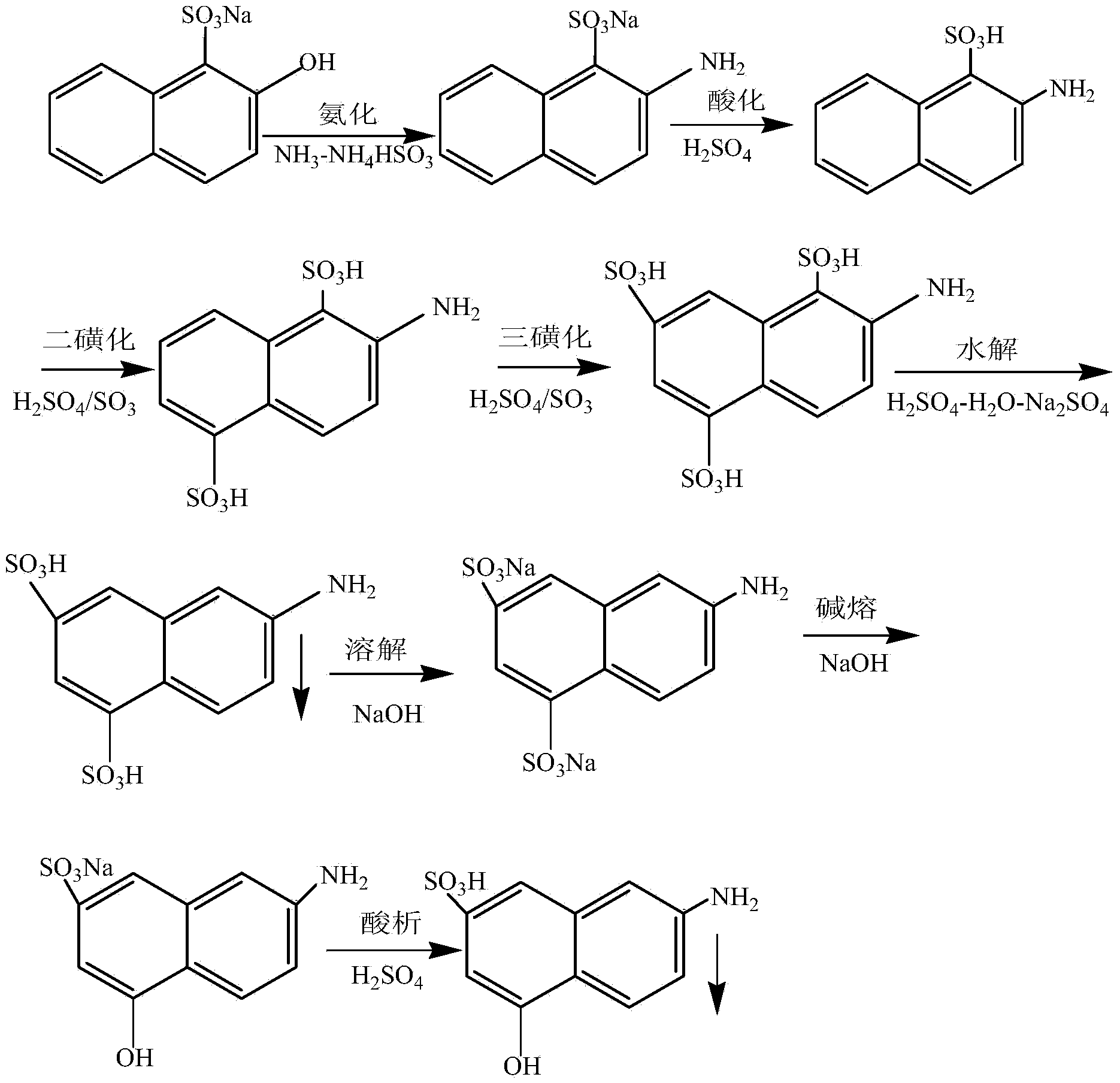

Preparation method of J acid and J acid waste water comprehensive treatment and recycling method

ActiveCN103896438ALow costDoes not affect productivityMultistage water/sewage treatmentSulfonic acid preparationWastewaterHydrolysis

The invention relates to a preparation method of J acid and a J acid waste water comprehensive treatment and recycling method. The J acid waste water comprehensive treatment and recycling method is as follows: the following treatment is carried out on hydrolysis waste water: (1) 30-40% of the total quantity of the hydrolysis waste water is used in an acidification reaction for preparing 2-naphthylamine-1-sulphonic acid by utilizing sodium 2-naphthylamine-1-sulphonate; (2) extraction and reextraction are carried out on the residual hydrolysis waste water, so that Na2SO4 and extraction waste liquor are obtained, the extraction waste liquor is used in a hydrolysis working procedure in a J acid production process, an extraction agent adopted during extraction is composed of 10-30wt% of complex agent, 30-70wt% of diluent and 5-20wt% of tributyl phosphate, and the complex agent is trioctylamine, or trialkyl tertiary amine or combination of trioctylamine and trialkyl tertiary amine. By adopting the preparation method of the J acid, the cost of water for the J acid and waste water treatment cost can be greatly reduced, and environmental pollution can be reduced.

Owner:XIANGSHUI HENRYDA TECH CHEM

Surface water desalting apparatus by-producing saline waste water treatment method

ActiveCN104370394AReduce water consumptionReduce comprehensive water production costsGeneral water supply conservationSpecific water treatment objectivesIon-exchange membranesChemistry

The present invention provides a surface water desalting apparatus by-producing saline waste water treatment method. According to the surface water desalting apparatus by-producing saline waste water treatment method, saline waste water is pretreated by adopting a pure alkali-caustic soda-flocculation precipitation method to remove hard, reduce silicon and remove organic matters, and then a bipolar membrane electrodialysis device filled with a monovalent selective ion exchange membrane is adopted to carry out a resource treatment to convert the salt in the saline waste water into the corresponding acid and the corresponding alkali, wherein the acid and the alkali obtained from the electrodialysis can be used for the regeneration and pretreatment process of the desalting apparatus ion exchange resin, and the diluted saline water obtained from the electrodialysis can be used as the influent of the desalting apparatus. The method has characteristics of high treatment capacity, low treatment cost and significant reduction of the water consumption of the desalting apparatus, and is suitable for industrialization.

Owner:BEIJING LINISPLENDOUR EMPYRERL ENVIRONMENTAL ENG TECH +1

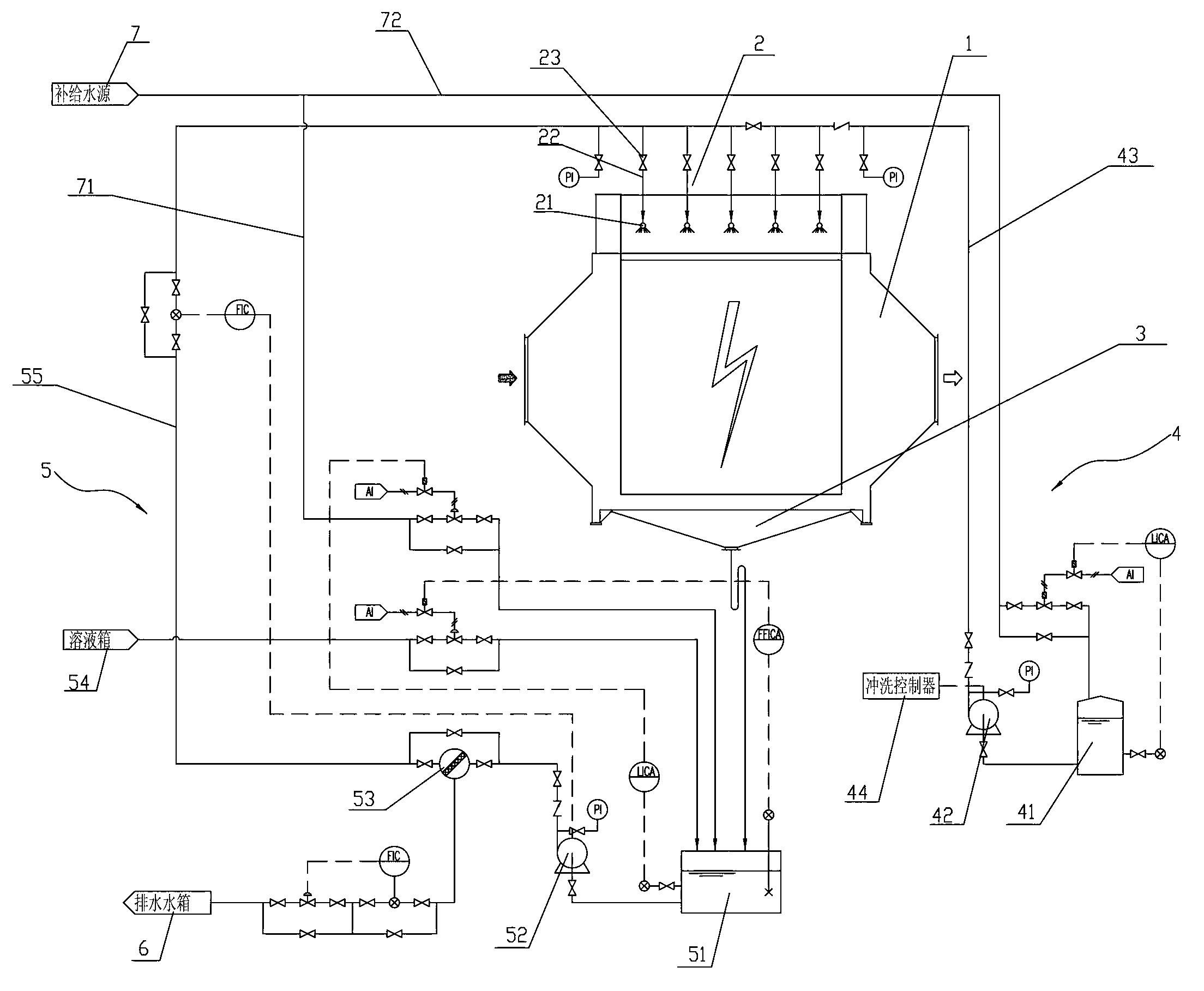

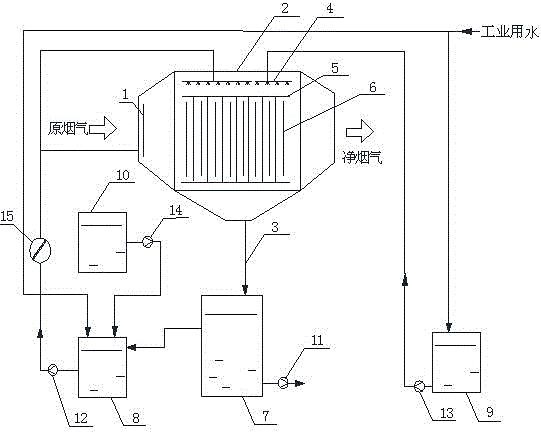

Ash water circulation treatment system of wet-type electric dust remover

ActiveCN103056031AAvoid secondary pollutionLower water costsMultistage water/sewage treatmentExternal electric electrostatic seperatorWater dischargeWater circulation

The invention discloses an ash water circulation treatment system of a wet-type electric dust remover. The ash water circulation treatment system comprises an ash water tank used for collecting ash water discharged from the wet-type electric dust remover, a supplementary branch and a circulating branch, wherein the supplementary branch comprises a supplementary water tank and a flush water pump; a water inlet of the flush water pump is connected with the supplementary water tank; a water outlet of the flush water pump is connected with the spraying mechanisms of the wet-type electric dust remover through a water conveying pipe; the circulating branch comprises a circulating water tank, a circulating water pump, a solution tank filled with an alkali solution and an automatic filter; a water outlet of the ash water tank and a water outlet of the solution tank are connected with the circulating water tank respectively; a water inlet of the circulating water pump is connected with the circulating water tank; a water outlet of the circulating water pump is connected with a water inlet of the automatic filter; and a water outlet of the automatic filter is connected with the spraying mechanisms of the wet-type electric dust remover through the water conveying pipe. The ash water circulation treatment system is simple in structure and scientific and reasonable in arrangement; water can be continuously supplied for self circulation; the water consumption is greatly reduced; the water consumption cost is saved; and the ash water can be prevented from causing secondary pollution.

Owner:FUJIAN LONGKING

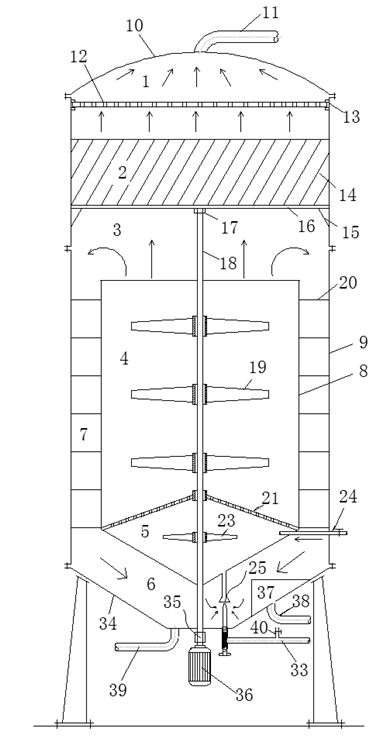

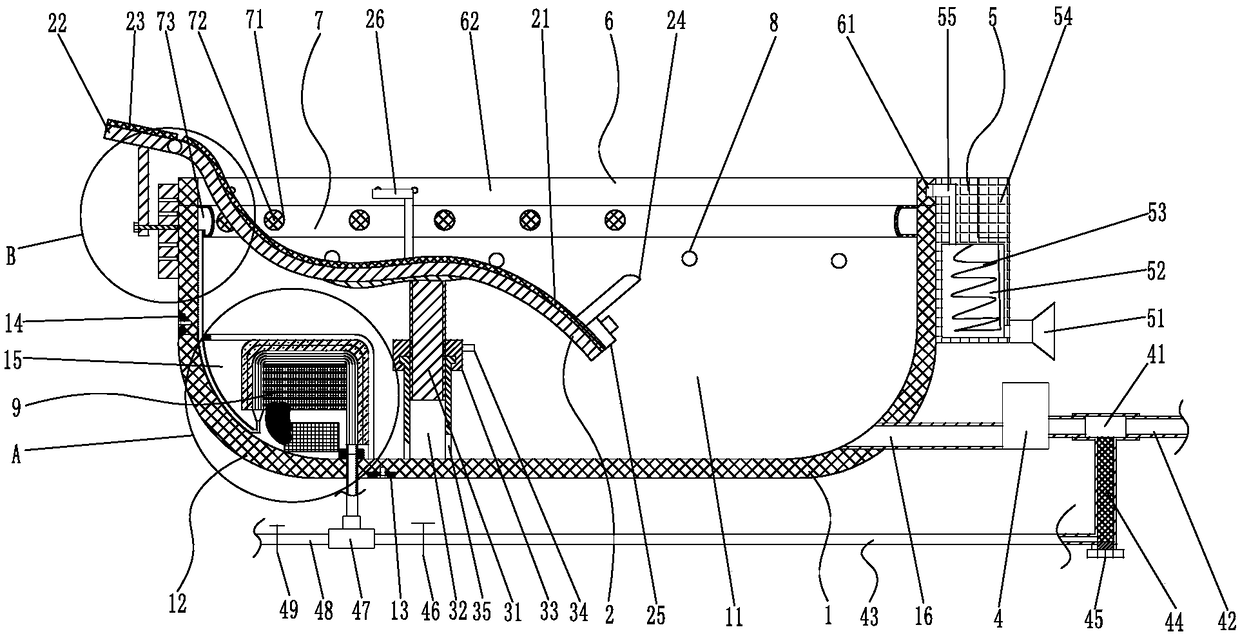

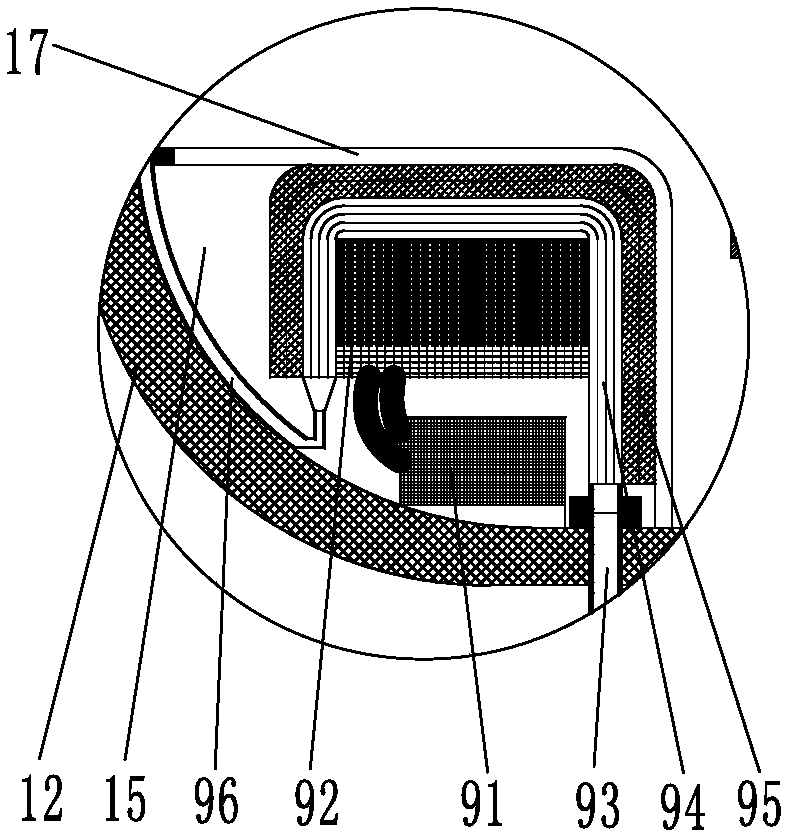

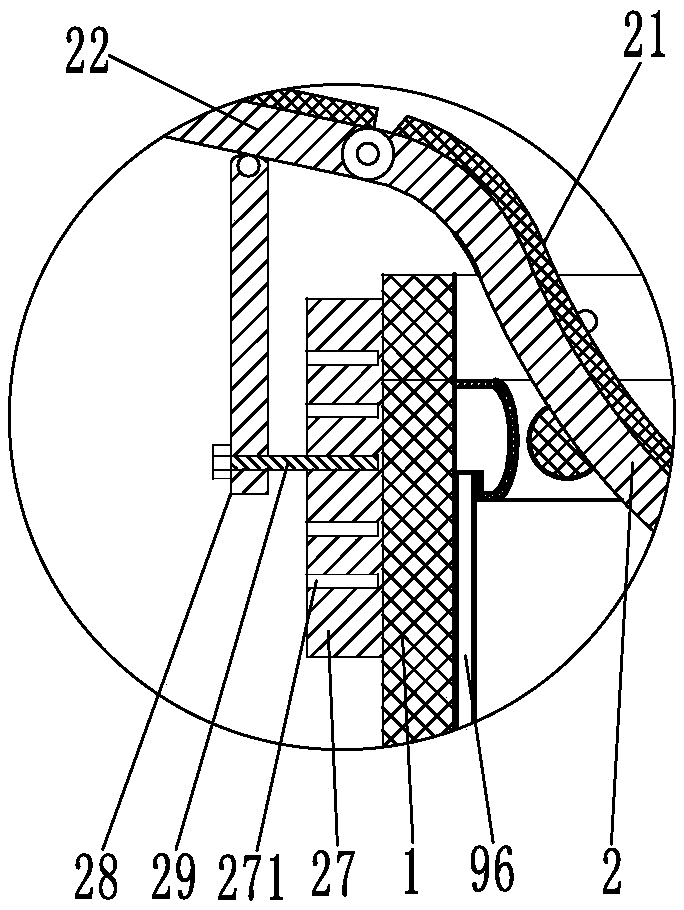

Integrated water purifying and processing equipment

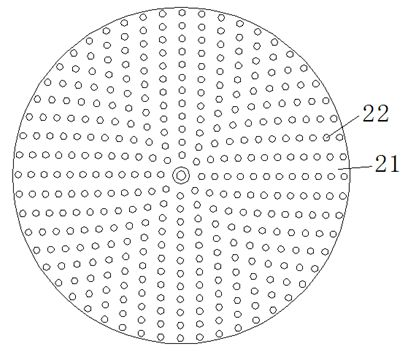

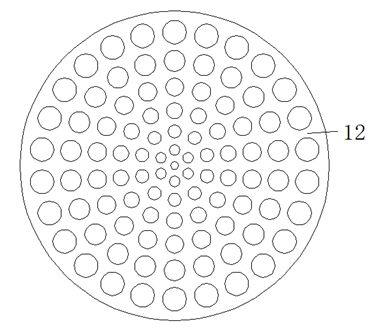

ActiveCN102001769AGuaranteed concentrationReduce dosageMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationSludge

The invention discloses integrated water purifying and processing equipment. The equipment comprises an external barrel and an internal barrel, wherein a convex head is arranged at the top of the external barrel; a water outlet is formed in the center of the convex head; a conical bottom plate is arranged at the bottom of the external barrel; a mixer motor and a speed reducer are arranged in the center of the bottom of the conical bottom plate; the speed reducer is provided with a stirring shaft; the side wall of the conical bottom plate is provided with a dredge pipe; an escape pipe is arranged at the bottom of the conical bottom plate; the inner side of the external barrel is divided into a clean water zone, an inclined tube settling zone, a mud and water separating zone, a secondary cluster flocculation zone, a primary flocculation reaction zone and a mud collection zone in turn from top down; a sludge concentrating zone is arranged between the internal barrel and the external barrel; the equipment is provided with a coagulant quick coagulation device and a sludge hydraulic automatic backflow device to keep the concentration of the sludge in the reaction zone stable; the sludge concentrating zone is provided with a spiral bevel plate to efficiently concentrate the sludge; and the clean water zone is provided with a water collecting plate to realize pressure effluent. The equipment has a simple structure, compact layout and high space utilization rate, is convenient to operate, and is suitable for clarifying tap water in middle-sized and small cities and purifying industrial water by primarily removing turbidity.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

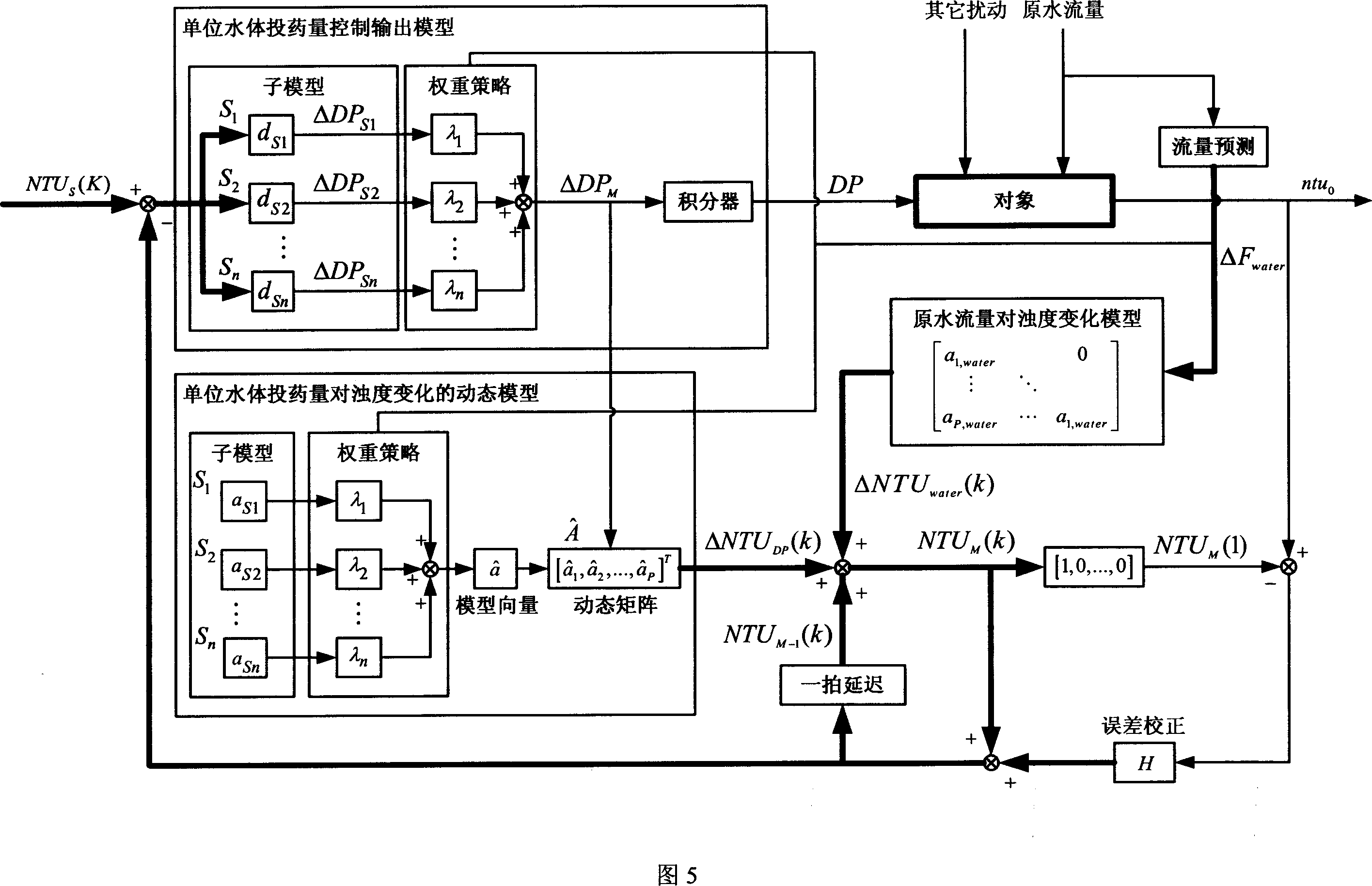

Multi-model dynamic matrix feeding amount control method for coagulation system in waterworks

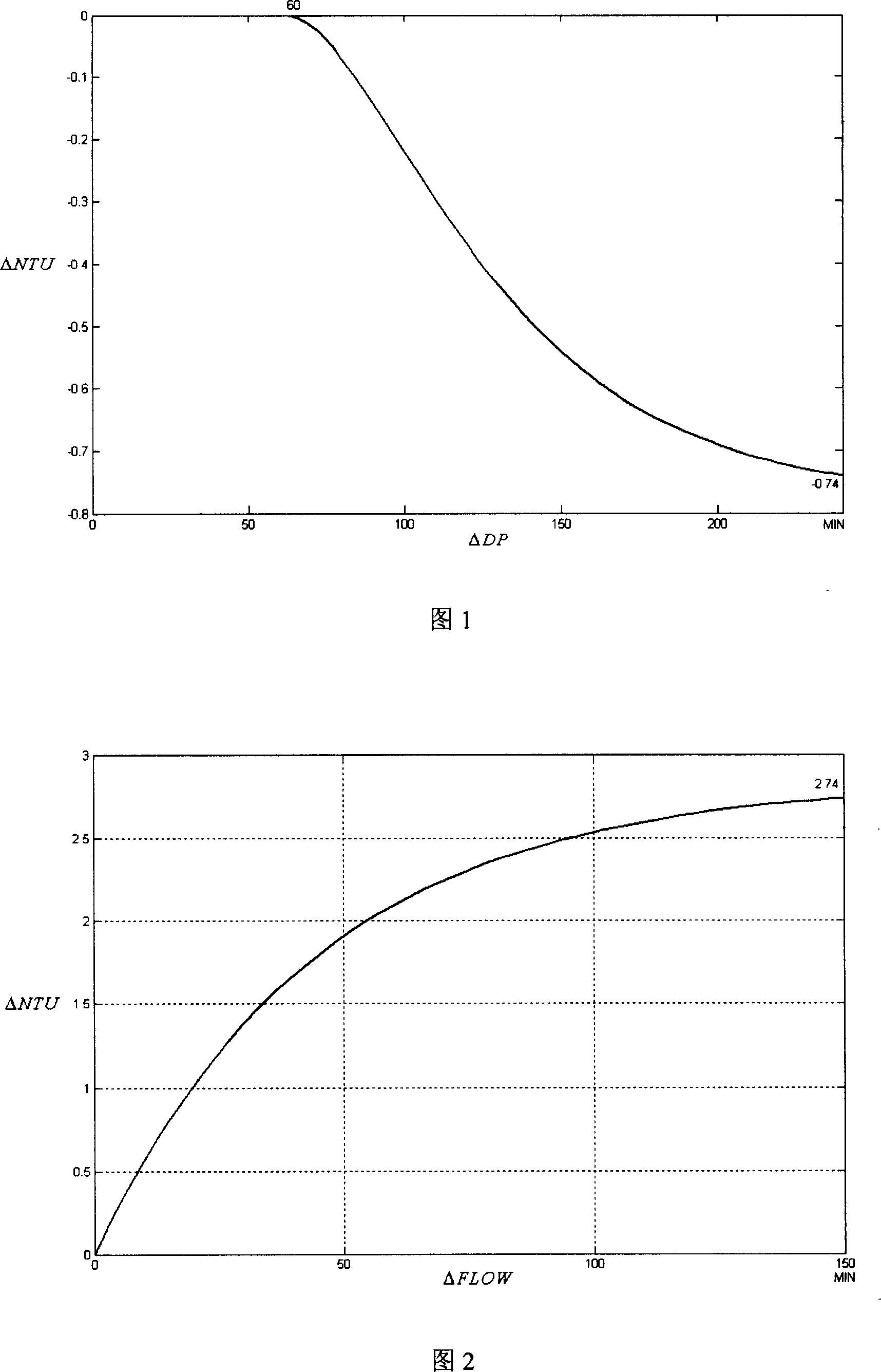

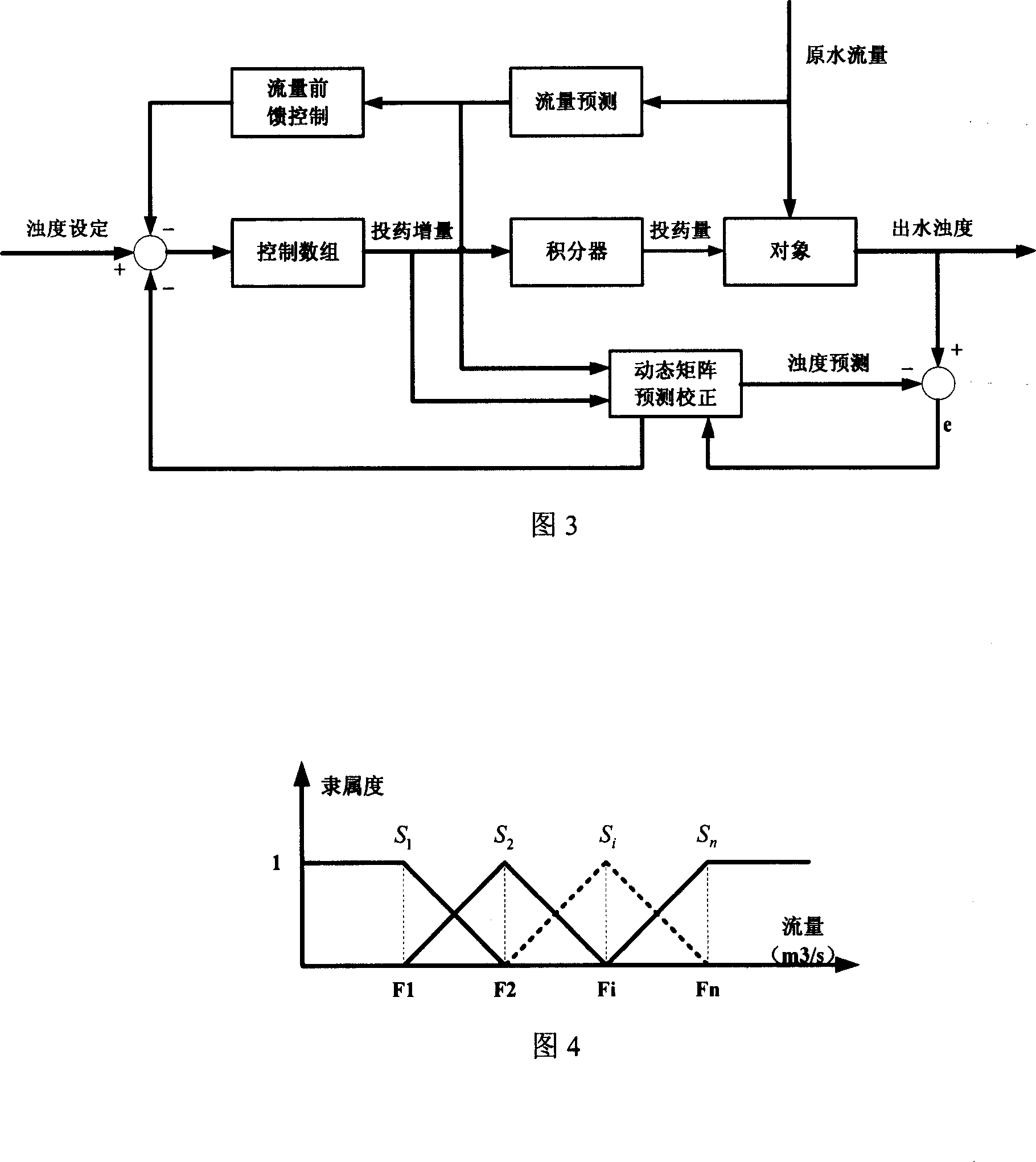

InactiveCN101020128AApplicable to coagulation dosing controlSmall amount of calculationSedimentation separationWater/sewage treatment by flocculation/precipitationModel dynamicsDynamic models

The multi-model dynamic matrix feeding amount control method for coagulation system in waterworks features that dynamic matrix predicting controller is constituted based on comprehensive multi-model dynamic matrix control theory and by means of using raw water flow rate as the control target, separating the whole system into several subspaces and separate experiments to obtain sectional linear models of the subspaces; and that outflow water turbidity is controlled through determining the dynamic model of the system, predicting the outflow water turbidity, weighting treatment to obtain overall control increment and regulating the feeding amount based on the current work conditions, practical water flow rate and certain weighting police. The present invention can ensure smooth outflow water turbidity, system running economic performance, high robustness and low cost.

Owner:SOUTHEAST UNIV +1

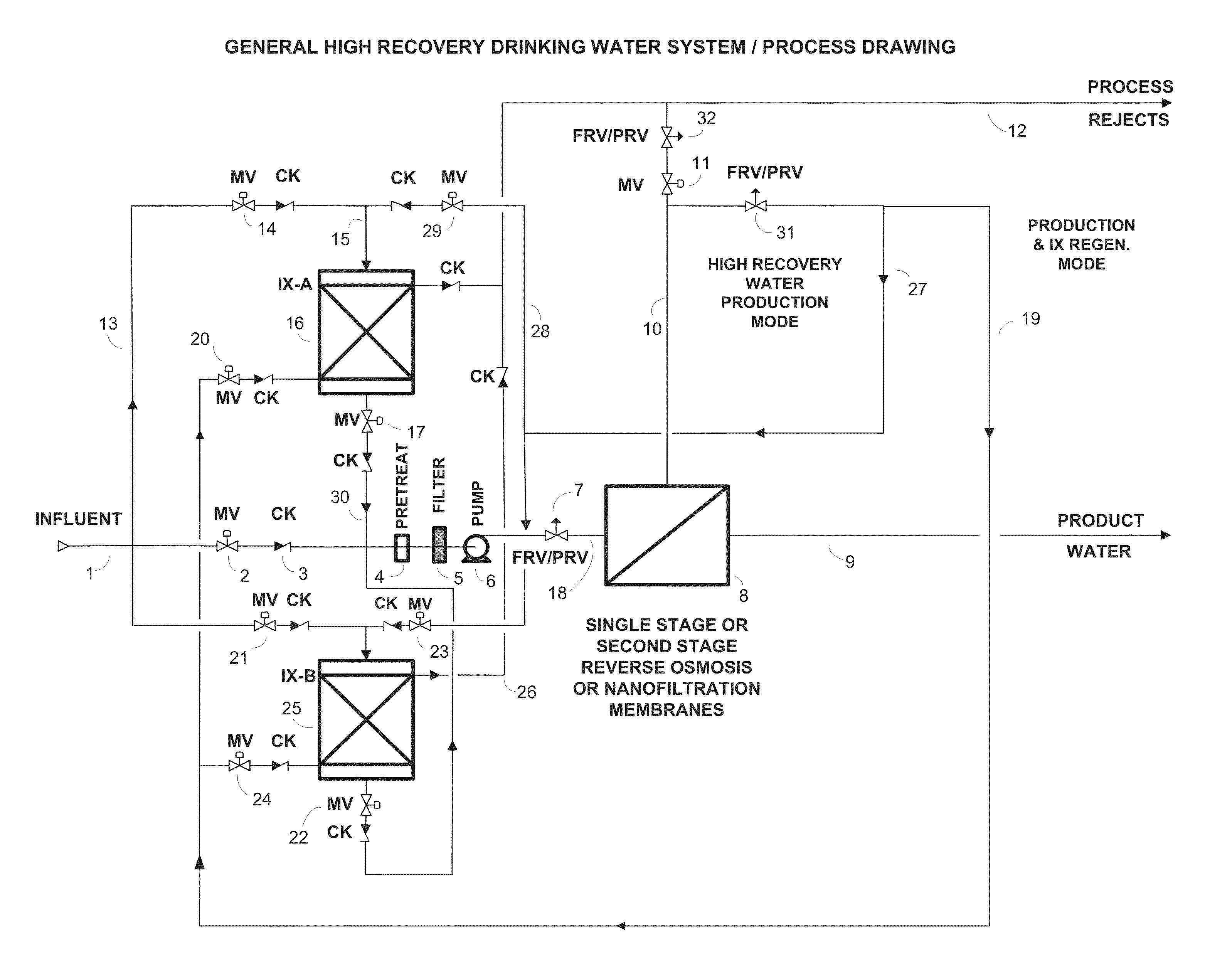

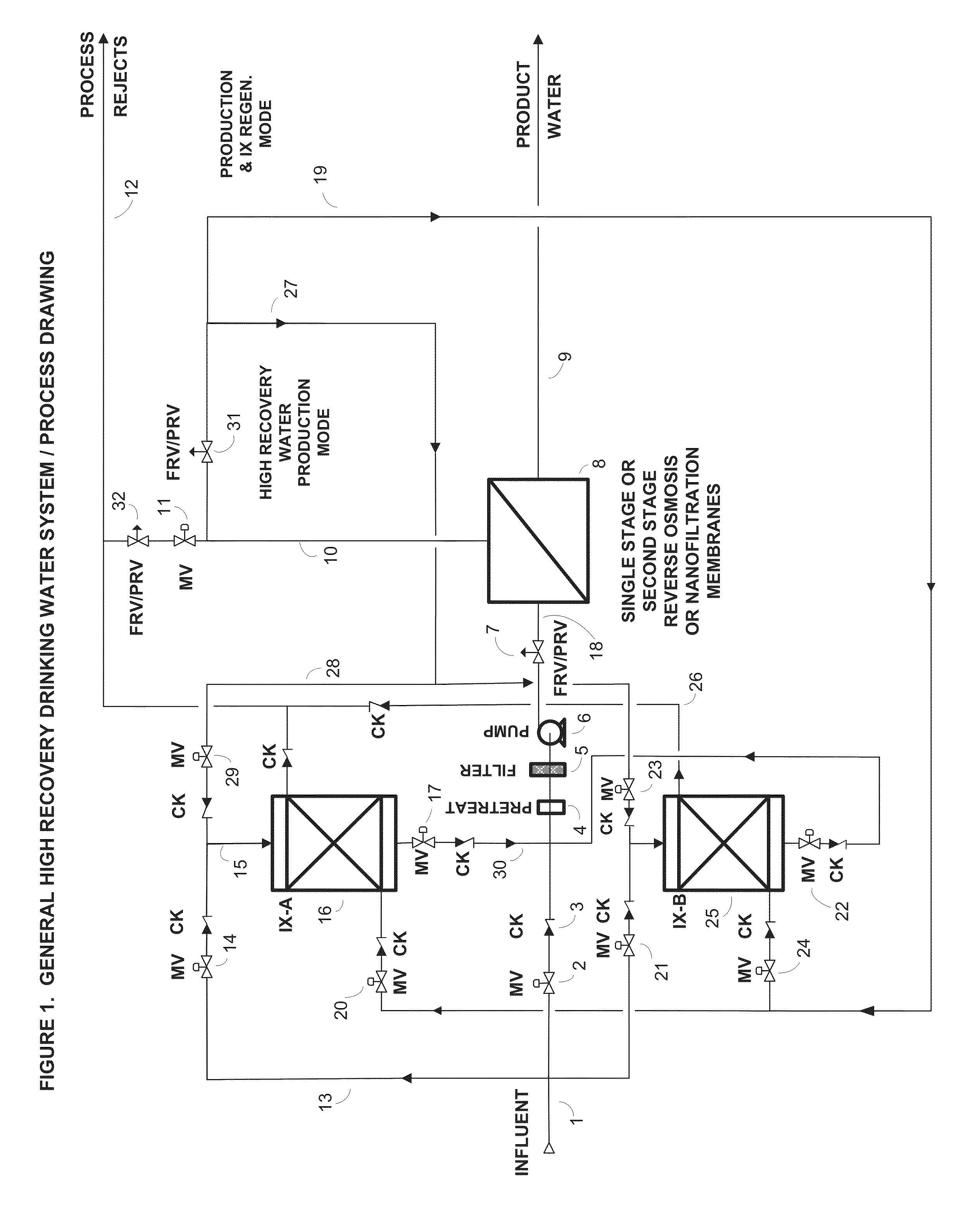

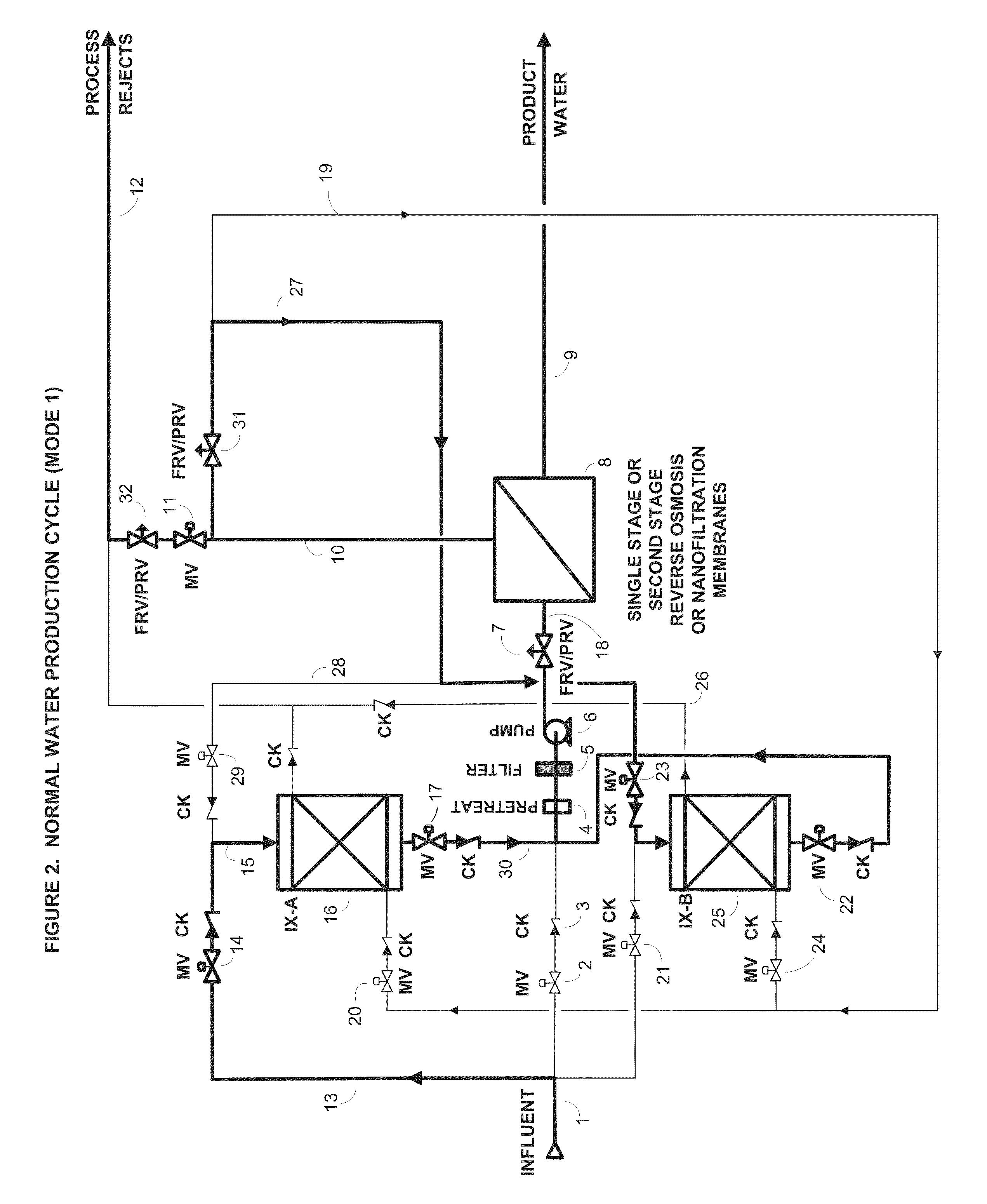

High Recovery Drinking Water Process

ActiveUS20130043190A1High water recoveryEliminate needIon-exchanger regenerationOrganic anion exchangersWater softeningIndustrial effluent

Disclosed is a process that uses reverse osmosis (RO) or nanofiltration (NF) membranes and ion exchange (IX) water softening resins to maximize the production of drinking water, purified industrial service water or recycled purified municipal or industrial effluents. The membrane and ion exchange units are configured in a manner that enables operation of the system at high permeate recoveries in the range 90% to 99%, thus producing purified drinking water with a minimum volume of wastewater to drains and a very low membrane cleaning or membrane replacement frequency. The process mitigates membrane fouling and scale formation and minimizes the use of water treatment chemicals including acidic and alkali solutions and sodium chloride salt that is normally required to regenerate the IX resin.

Owner:AL SAMADI RIAD A

Submersible aquatic algae cultivation system

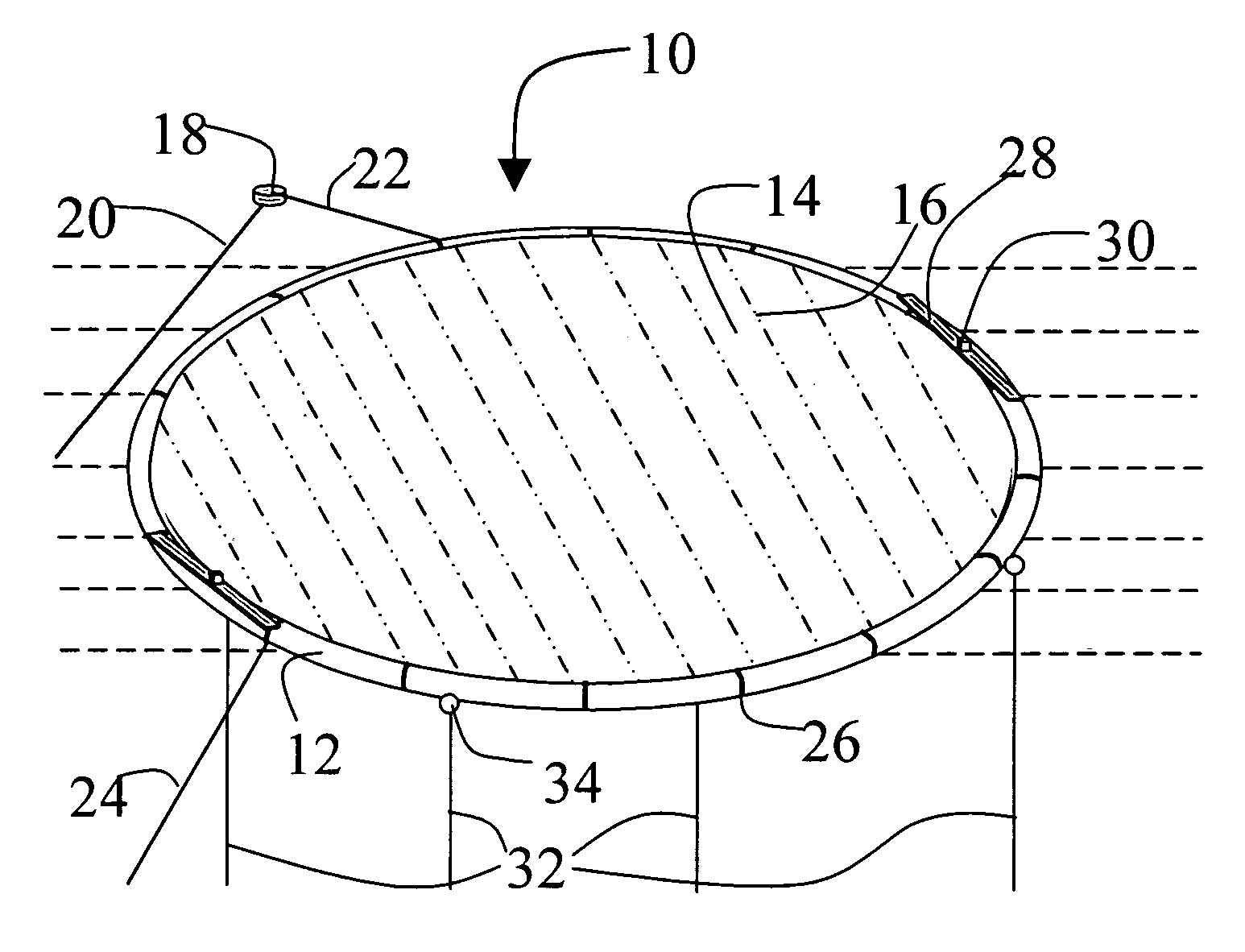

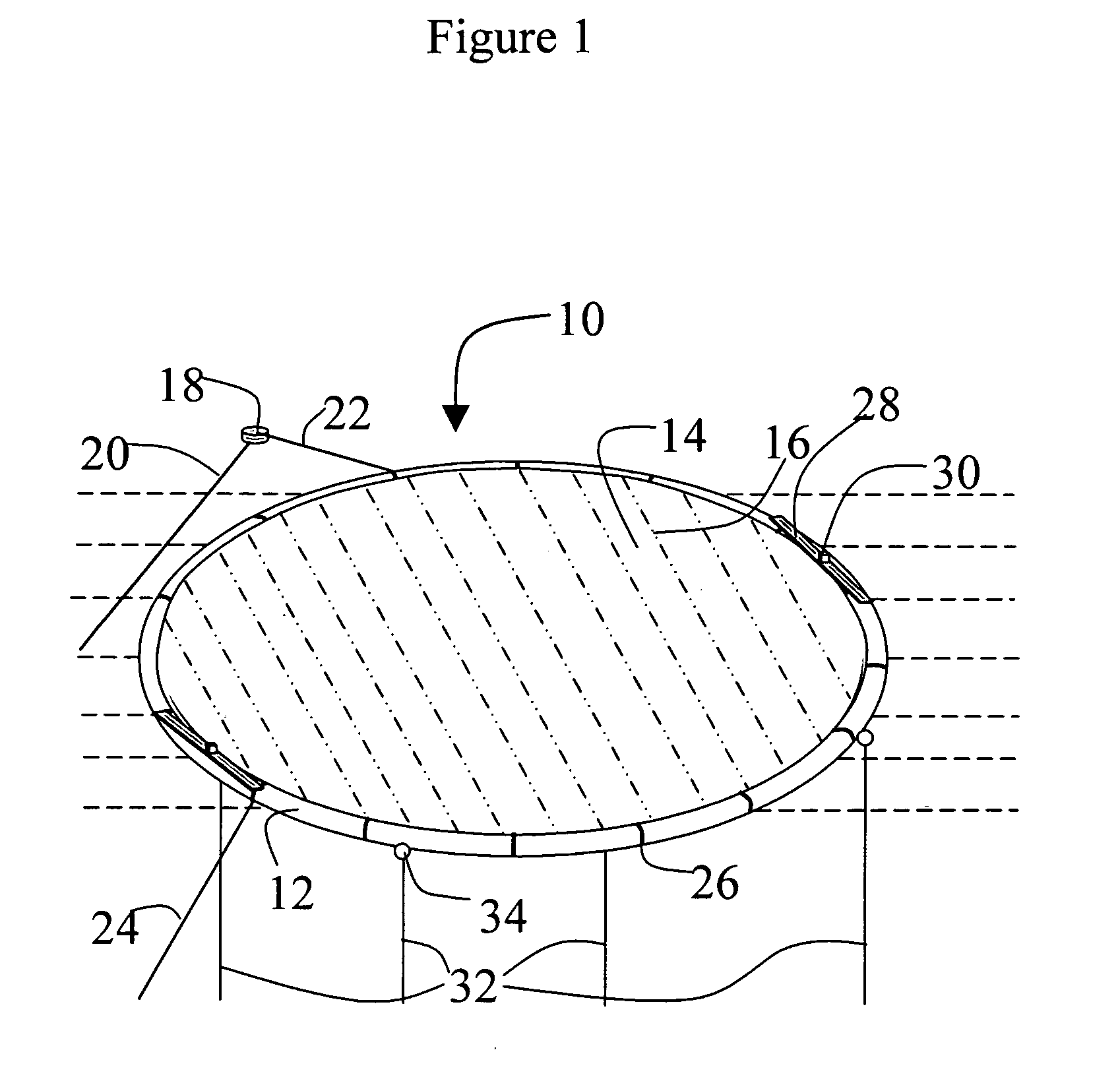

ActiveUS20100287829A1Quick upgradeReduces contributing costAlgae productsClimate change adaptationMooring systemFishery

Floating ponds for the cultivation of algae are disclosed. The floating ponds consist of a buoyant framework, a liner, a culture, and a mooring system. Submersible floating ponds are disclosed with a buoyant framework built from tubes that may be filled or partially filled with, for example, air, or water, or the surrounding water, or the culture, and thereby the present invention provides a framework in which the buoyancy may be modulated. Use of submerging lines and spools are disclosed to control the orientation and depth of the floating pond during submersion.

Owner:BUSSELL STUART

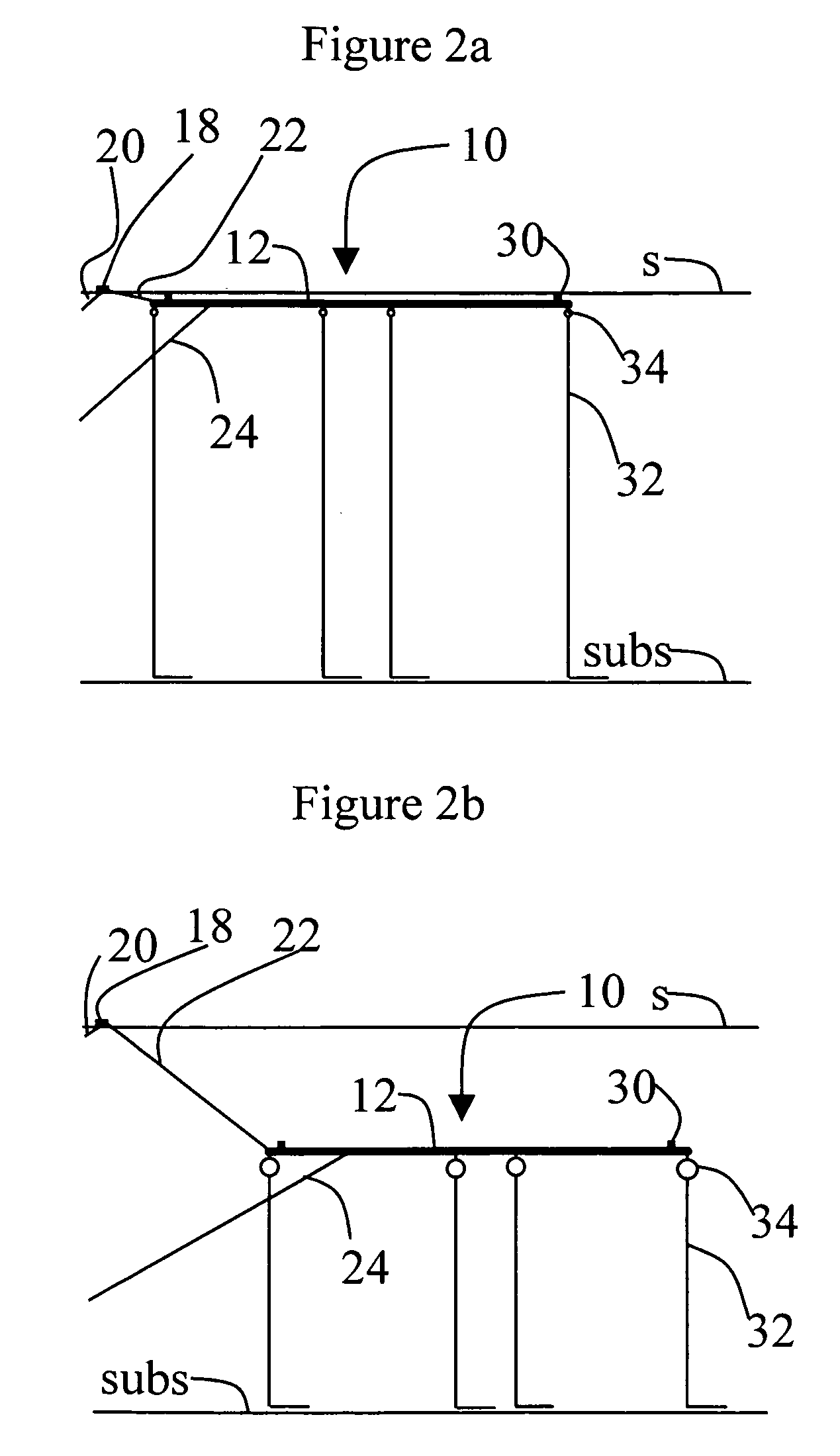

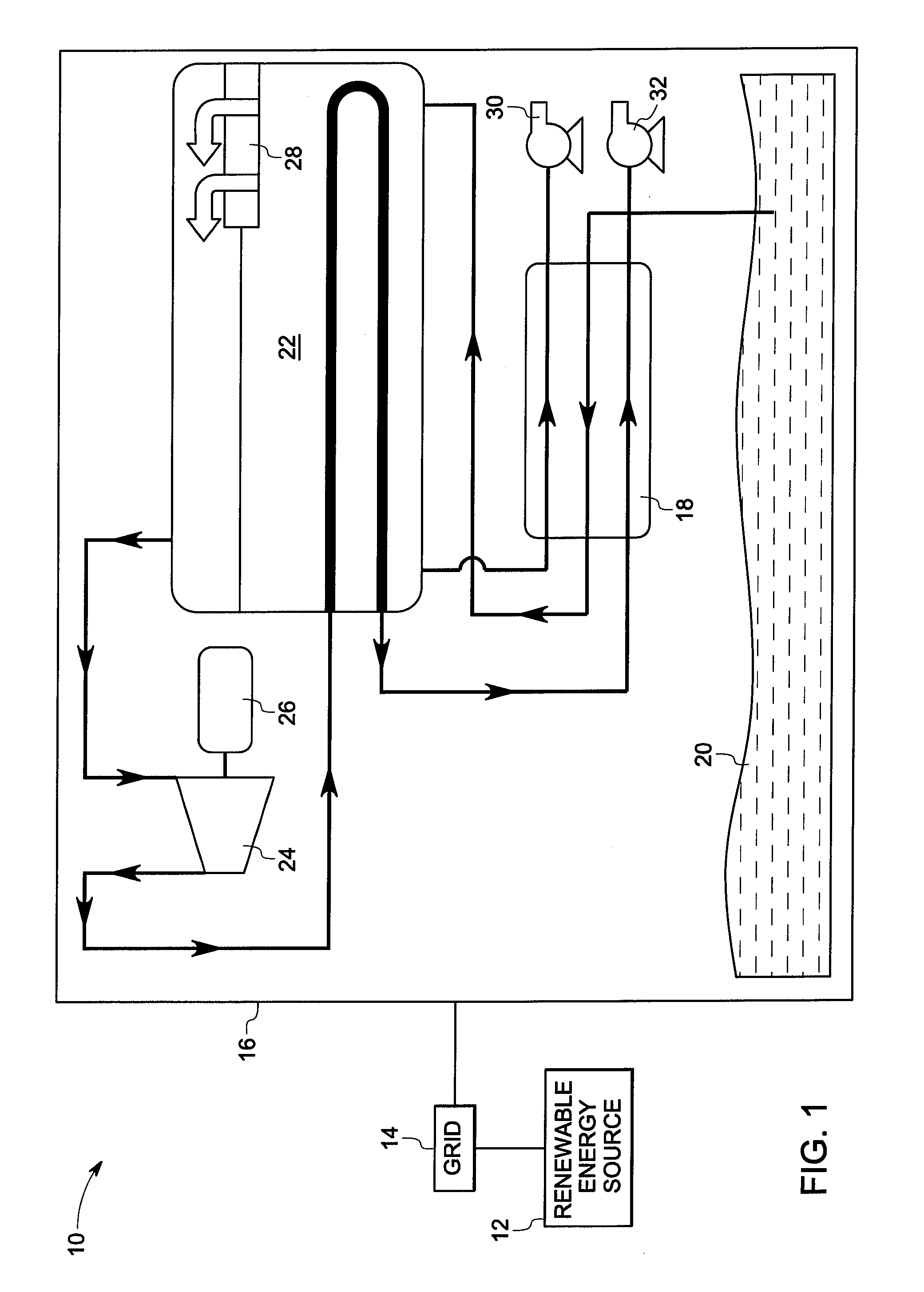

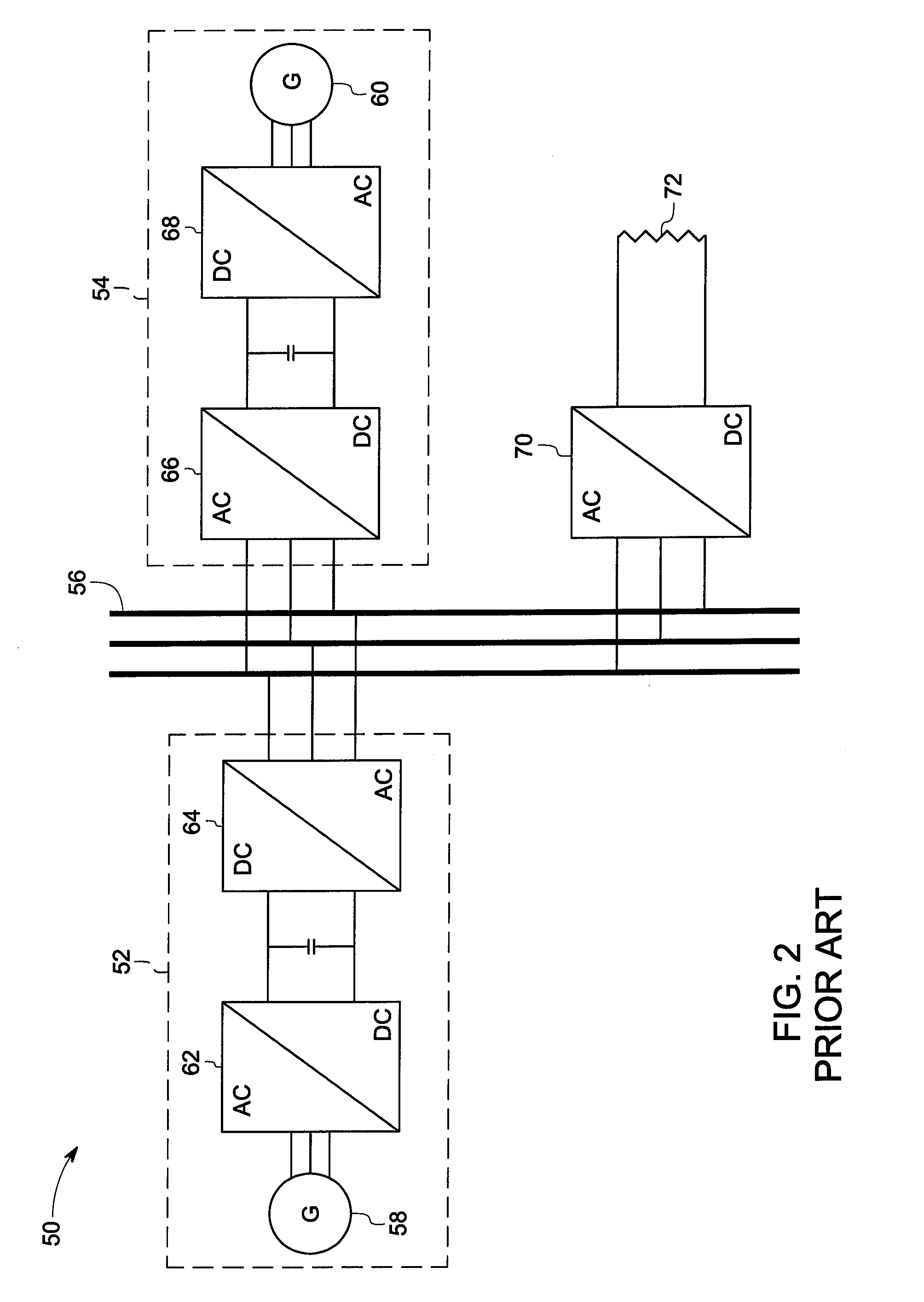

Hybrid water desalination system and method of operation

InactiveUS20070235383A1Improve efficiencyLower water costsGeneral water supply conservationSeawater treatmentWater desalinationTurbine

A hybrid water desalination system is provided. The desalination system includes a wind turbine configured to drive an electrical generator for producing electrical power and a mechanical vapor compression (MVC) desalination unit configured to receive electrical power from the electrical generator for driving a compressor of the desalination unit. The desalination system also includes a first converter coupled to the electrical generator and a second converter coupled to the compressor, wherein the first and second converters are coupled via a common direct current (DC) link.

Owner:GENERAL ELECTRIC CO

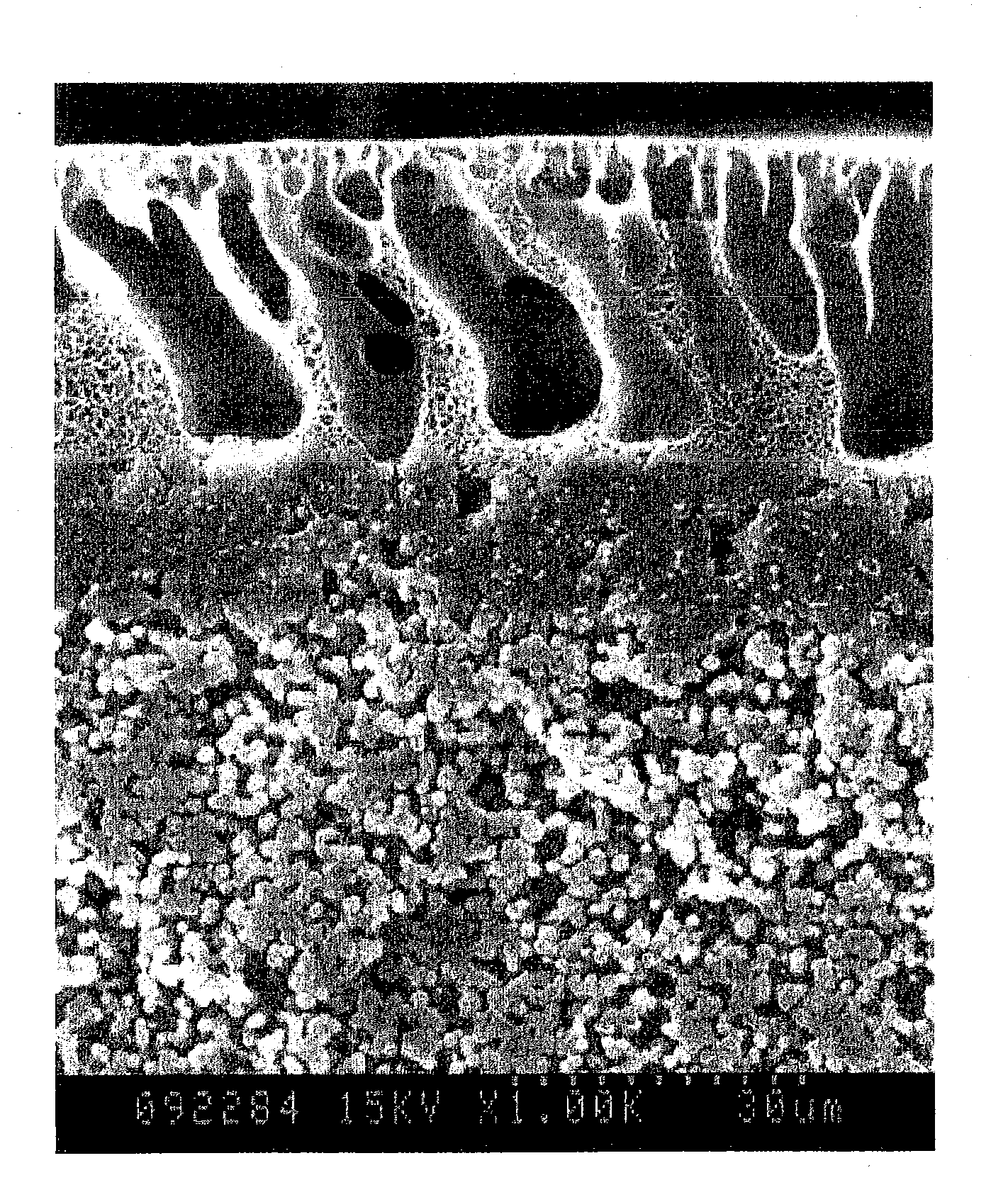

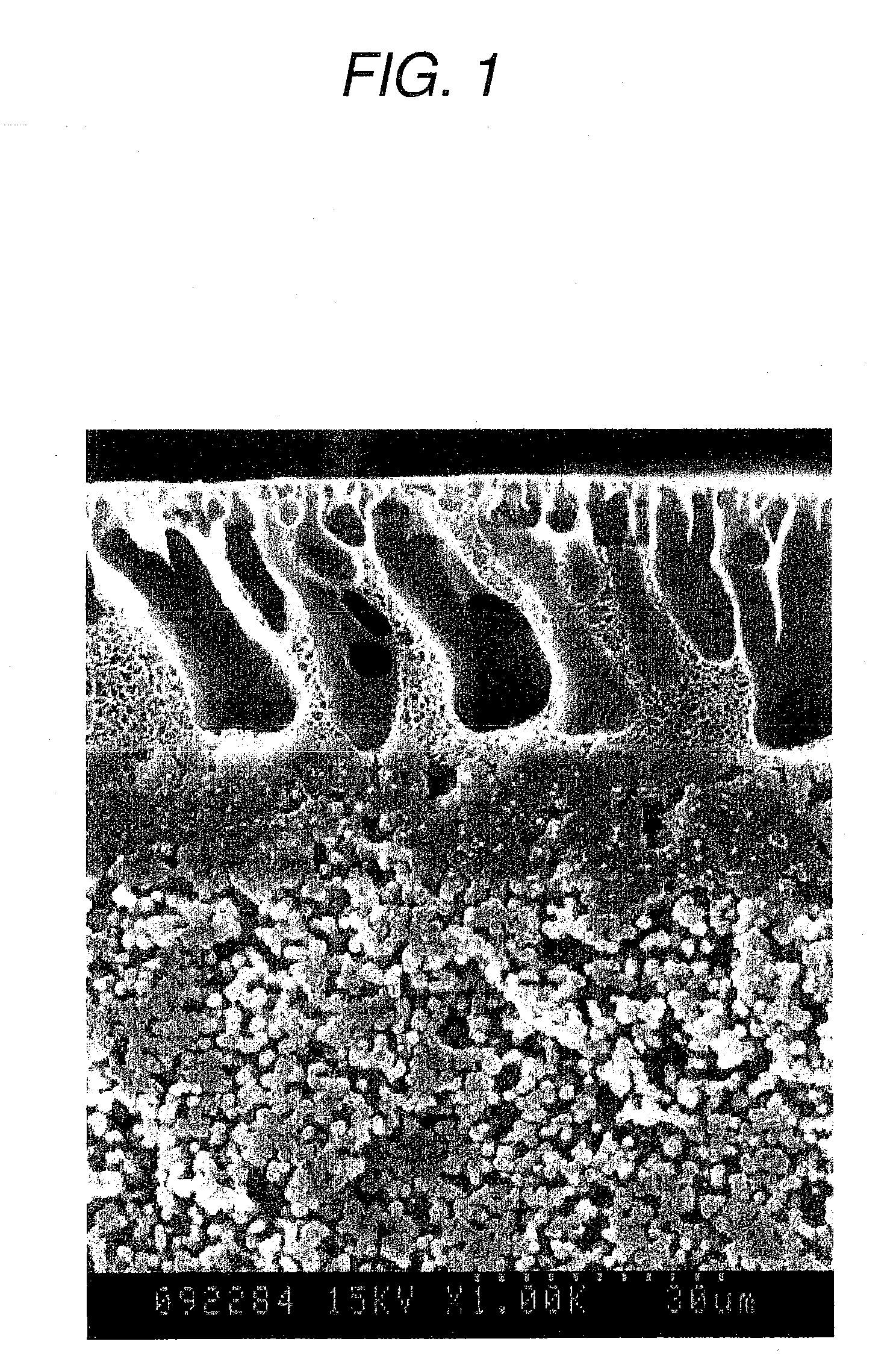

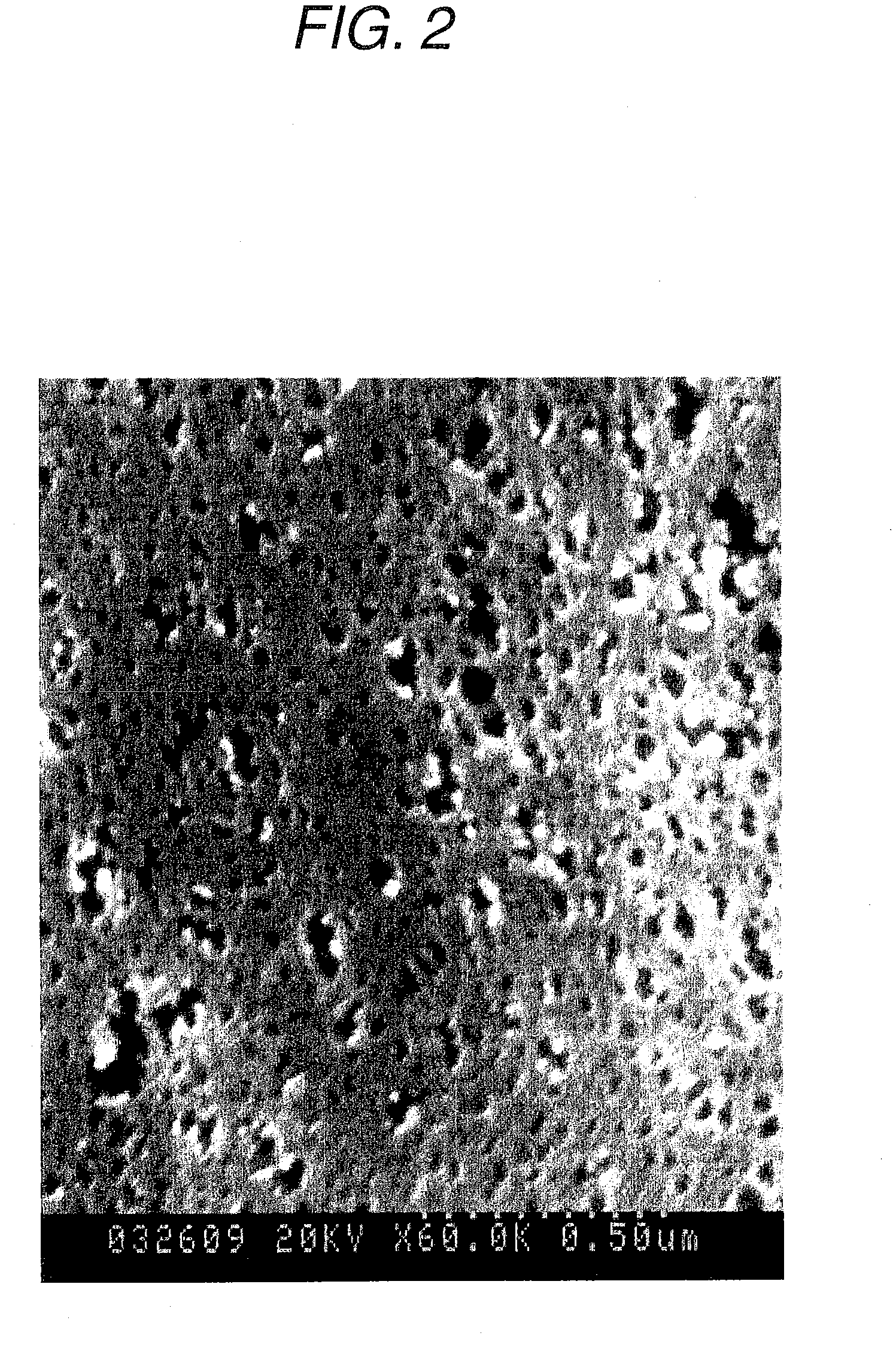

Polymer separation membrane and process for producing the same

ActiveUS20090178969A1Solve the lack of resistanceLoss of physical strengthMembranesSemi-permeable membranesCelluloseFiltration membrane

The invention provides a polymer separation membrane that is excellent in separating characteristics, a permeating ability, a chemical strength (particularly chemical resistance) and a physical strength, and also excellent in a stain resistance, and a producing method therefor. The fluorinated resin-type polymer separation membrane includes a layer having a three-dimensional network structure, and a layer having a spherical structure, wherein the layer of three-dimensional network structure is formed by a fluorinated resin-type polymer composition containing a hydrophilic polymer, and the hydrophilic polymer is a substantially water-insoluble hydrophilic polymer containing at least one of a cellulose ester, an aliphatic vinyl ester, vinylpyrrolidone, ethylene oxide and propylene oxide as a polymerization component. The polymer separation membrane is applicable as a filtration membrane for water treatment, a battery separator, a charged membrane, a fuel cell membrane or a blood cleaning filtration membrane.

Owner:TORAY IND INC

Wet type electrostatic dust collector for semidry method (CFB) waste water zero discharging

InactiveCN104874481AAvoid secondary pollutionReduce processingDispersed particle separationWaste water treatment from gaseous effluentsSocial benefitsWastewater

The invention discloses a wet type electrostatic dust collector for semidry method (CFB) waste water zero discharging. The wet type electrostatic dust collector comprises a smoke humidification device, a wet type electrostatic smoke purifying system and a waste water circulating utilizing system. The wet type smoke purifying system mainly comprises a spraying device, an anode plate and a cathode wire. The waste water circulating utilizing system comprises a waste water tank, a circulation water tank, a waste water pump, a circulation water pump, an alkali liquor tank, an alkaline pump, an automatic filter, a technology water tank and a technology water pump. By means of the wet type electrostatic dust collector, tiny dust, SO3, heavy metal and the like in smoke can be efficiently removed, meanwhile, waste water zero discharging is achieved, environmental friendliness is achieved, and good economic benefits and social benefits are achieved.

Owner:ZHEJIANG ZHONGTAI ENVIRONMENTAL PROTECTION EQUIP CO LTD

Method for filtering various water sources into drinking water

InactiveCN102107993AAchieve protectionMeet the needs of drinking multifunctional healthy waterMultistage water/sewage treatmentEnergy based wastewater treatmentWater sourceWater quality

The invention discloses a method for filtering various water sources into drinking water. In the method, a first-level biological purification water preparation unit is added before the conventional water treatment process according to a water purification principle; pollutants harmful to a human body are removed from water without performing sterilization by using ozone and chlorine; a water purification device manufactured by the method has a simple structure and low water preparation cost and is reliable to operate; and people in vast rural areas and rural towns can drink and use the purified water produced by the device. The method is implemented by the following technical scheme: the public biological purification water preparation unit and the conventional water purification treatment unit are designed and manufactured into standard combined filter element modules; according to the sequence of a water purification treatment process, the combined filter element modules are buckled from top to bottom into a tower-shaped water purification device; according to requirements of different water sources and different clients, the modules of the combined filter elements by different processes are replaced only according to the local water quality condition, so that various water sources are filtered into the driving water.

Owner:郑高宽

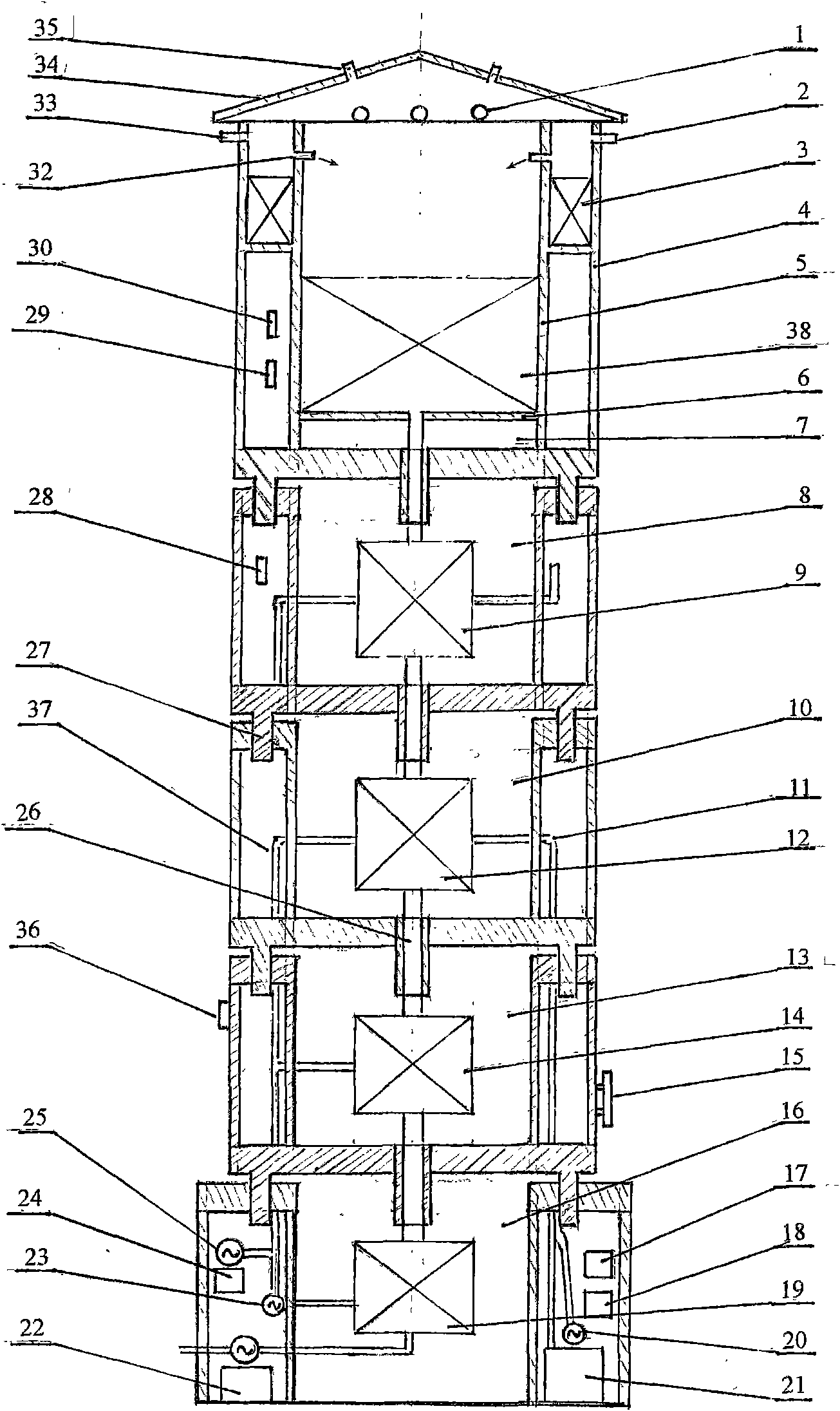

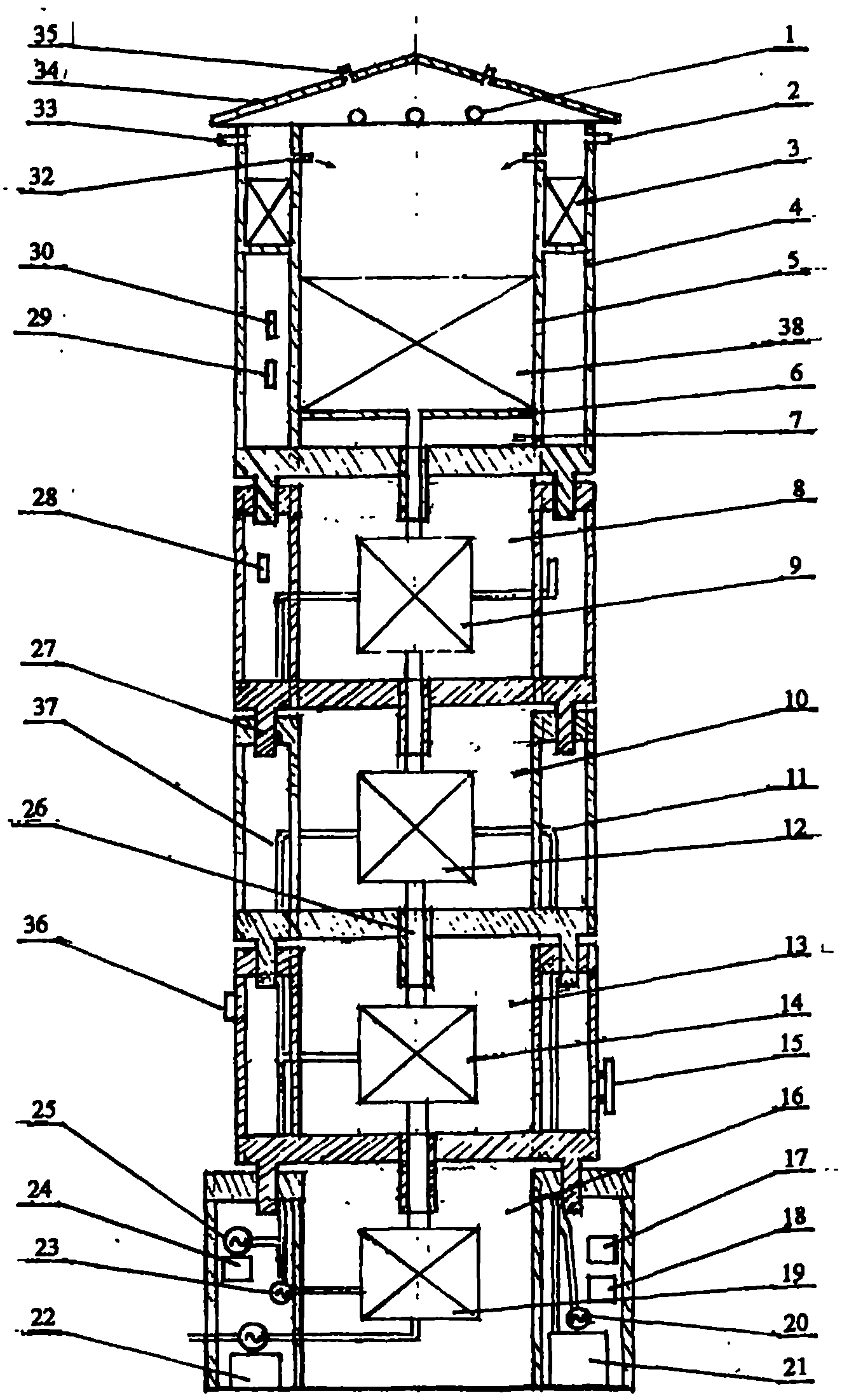

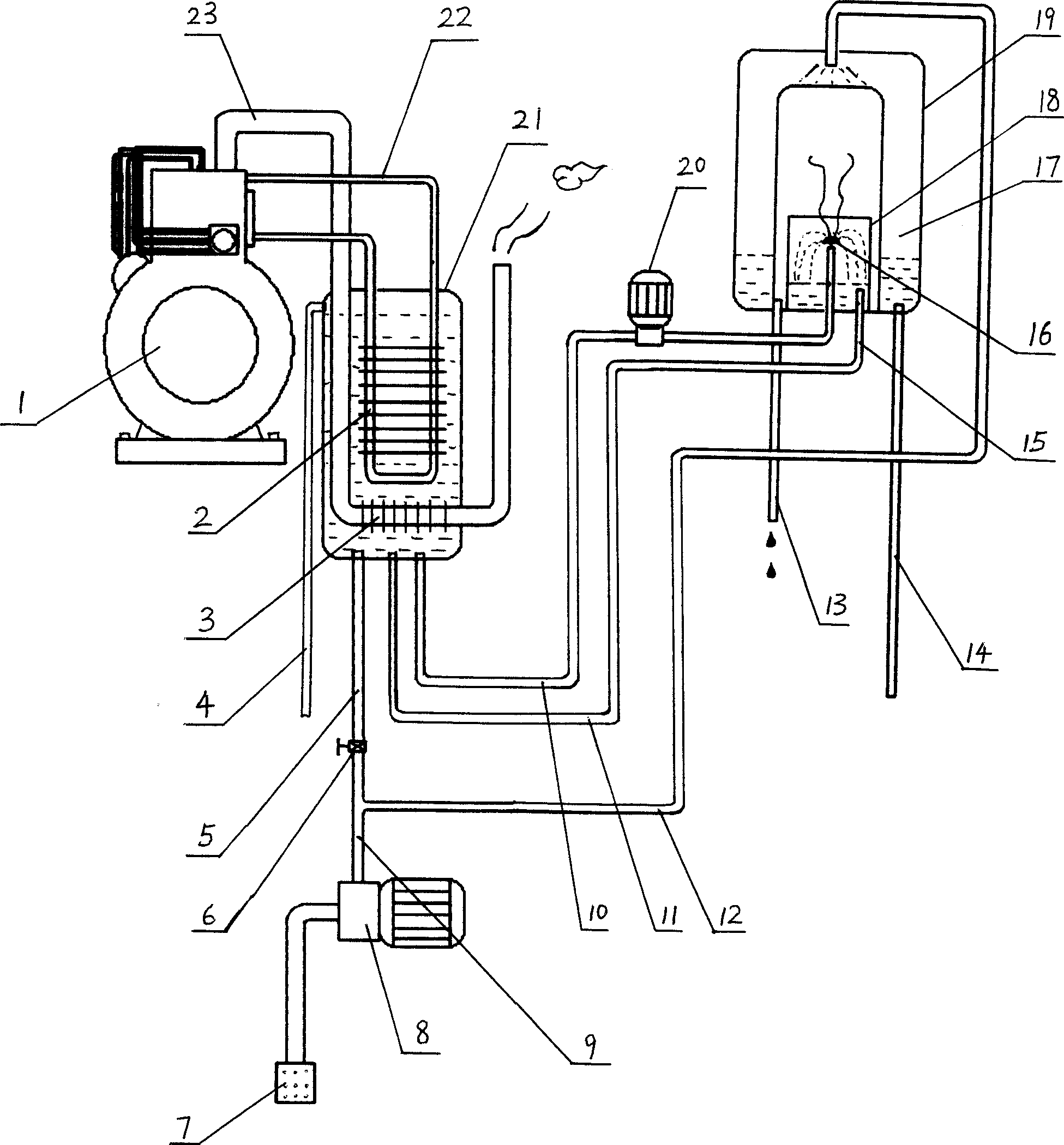

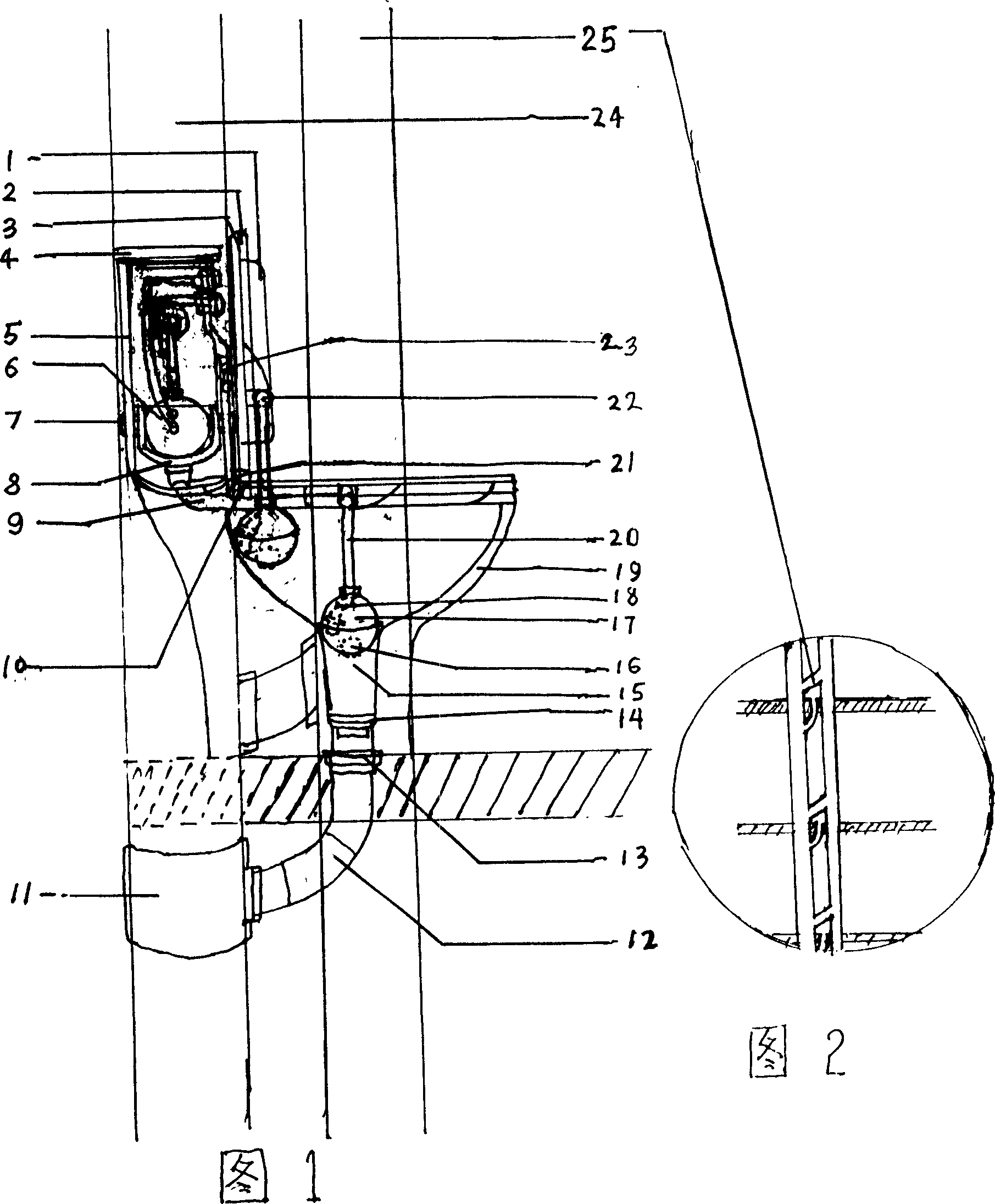

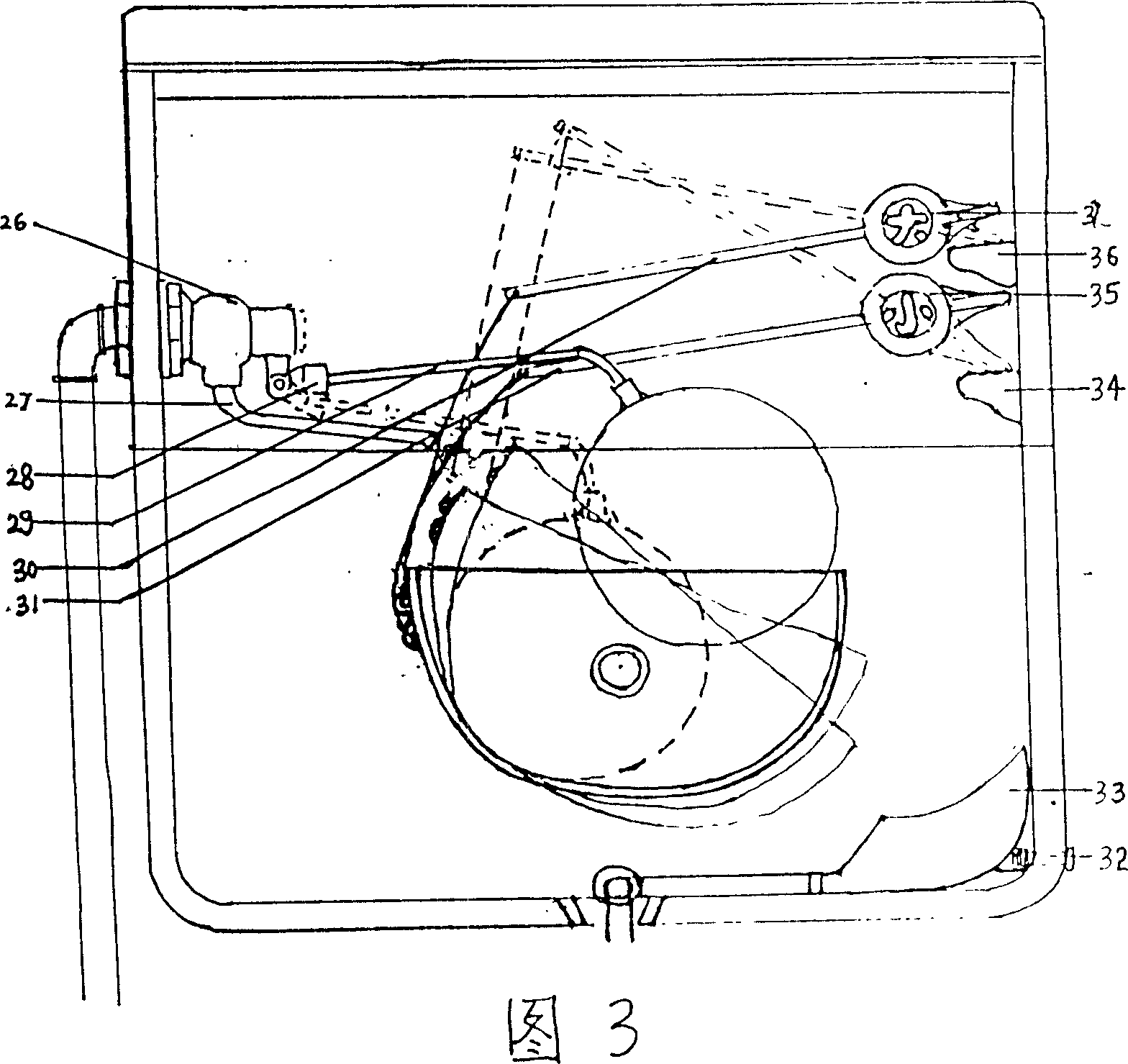

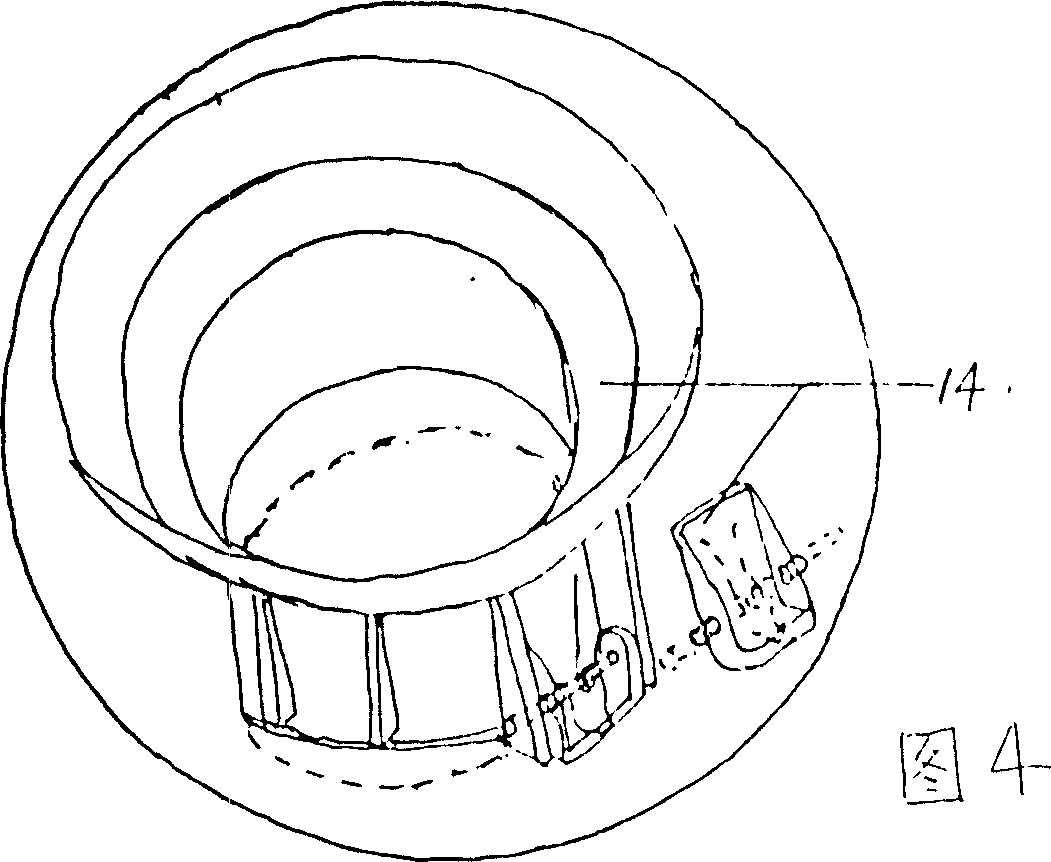

Seawater desalting device peculiar to vessel

InactiveCN1754776AReduce energy consumptionLower water costsAuxillariesFresh water producing installationsWater desalinationCooling chamber

This invention relates to sea water process device on boat, which comprises heater, condenser, wherein, the heater adopts exchanger water box; the motor cooling tube and exchanger box are connected sealed; the exchanger box and condenser evaporation are connected; the box is located with sea supply tube connected with sea water tube; the condenser cooling chamber is connected to sea entrance water tube. The sea water enters the heat exchanging water box through motor cooling water through heat exchanger and then into condenser to process drinking water.

Owner:卢能晓

Biochemical treatment method for waste water from small and medium-sized starch factories

InactiveCN102249498AGood flocculation effectReduce dosageAnimal feeding stuffAccessory food factorsMembrane bioreactorWaste treatment

The invention discloses a biochemical treatment method for waste water from small and medium-sized starch factories. The biochemical treatment method comprises the following steps of: stirring an organic flocculating agent and an inorganic flocculating agent in waste water, so that flocculate is formed in mixed solution; performing air floating separation on the mixed solution formed by stirring by using an air floating tank to separate suspended matters from the waste water; filtering separated effluent and dehydrating to obtain starch protein and filter liquor; guiding the filter liquor into an internal circulation (IC) reactor to perform biochemical treatment, and guiding liquid which is subjected to the biochemical treatment into a membrane biological reactor (MBR) for separating; and drying and recycling sludge obtained by separation, and discharging or recycling obtained subnatant which meets the national sewage discharge standard directly. By the biochemical treatment method, a large amount of starch waste water can be treated effectively and the starch protein and methane can be recovered in the waste treatment process, so that resources are utilized to a maximum degree to create obvious economic and environmental benefit.

Owner:菏泽三垒塑业股份有限公司

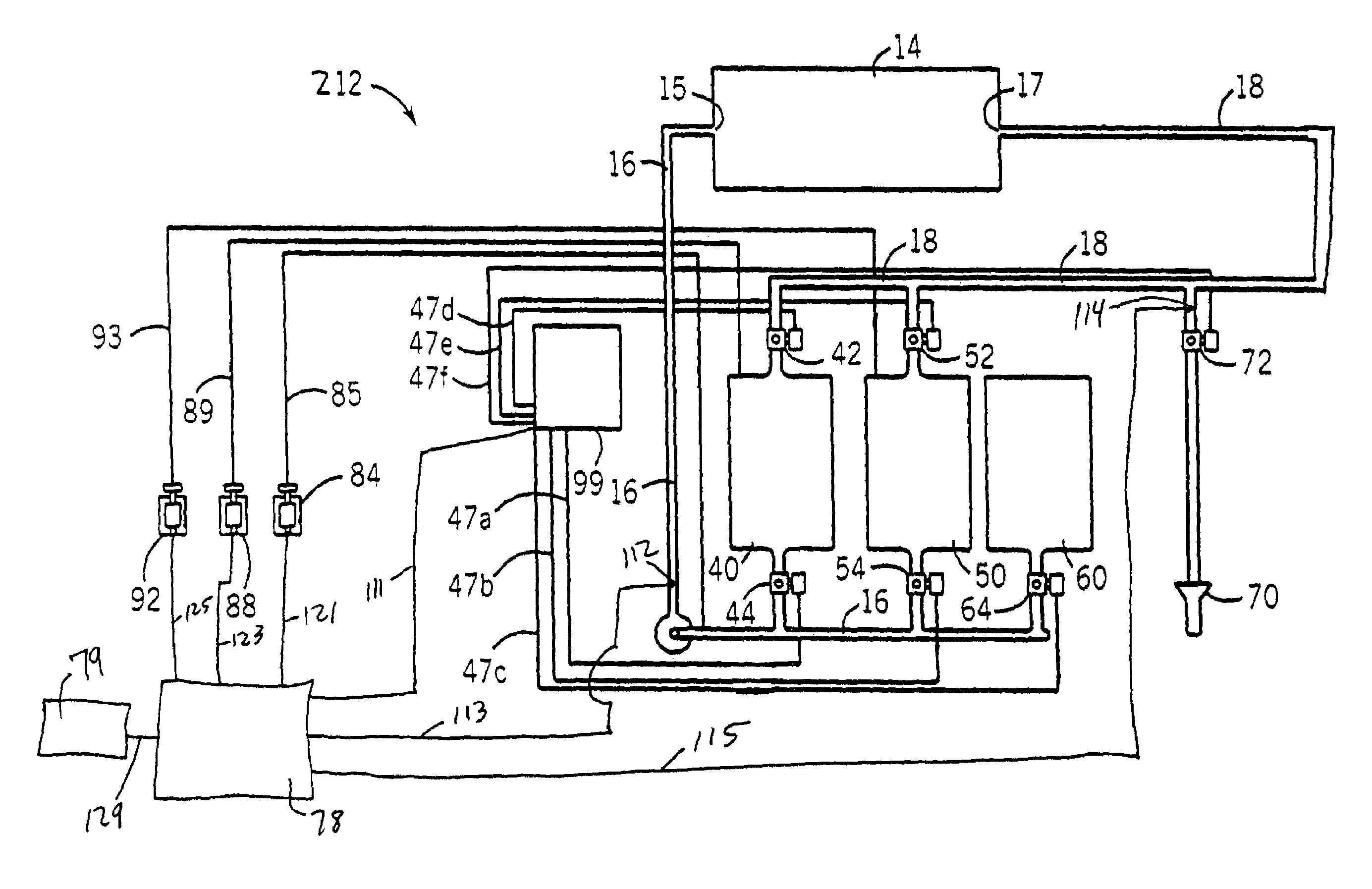

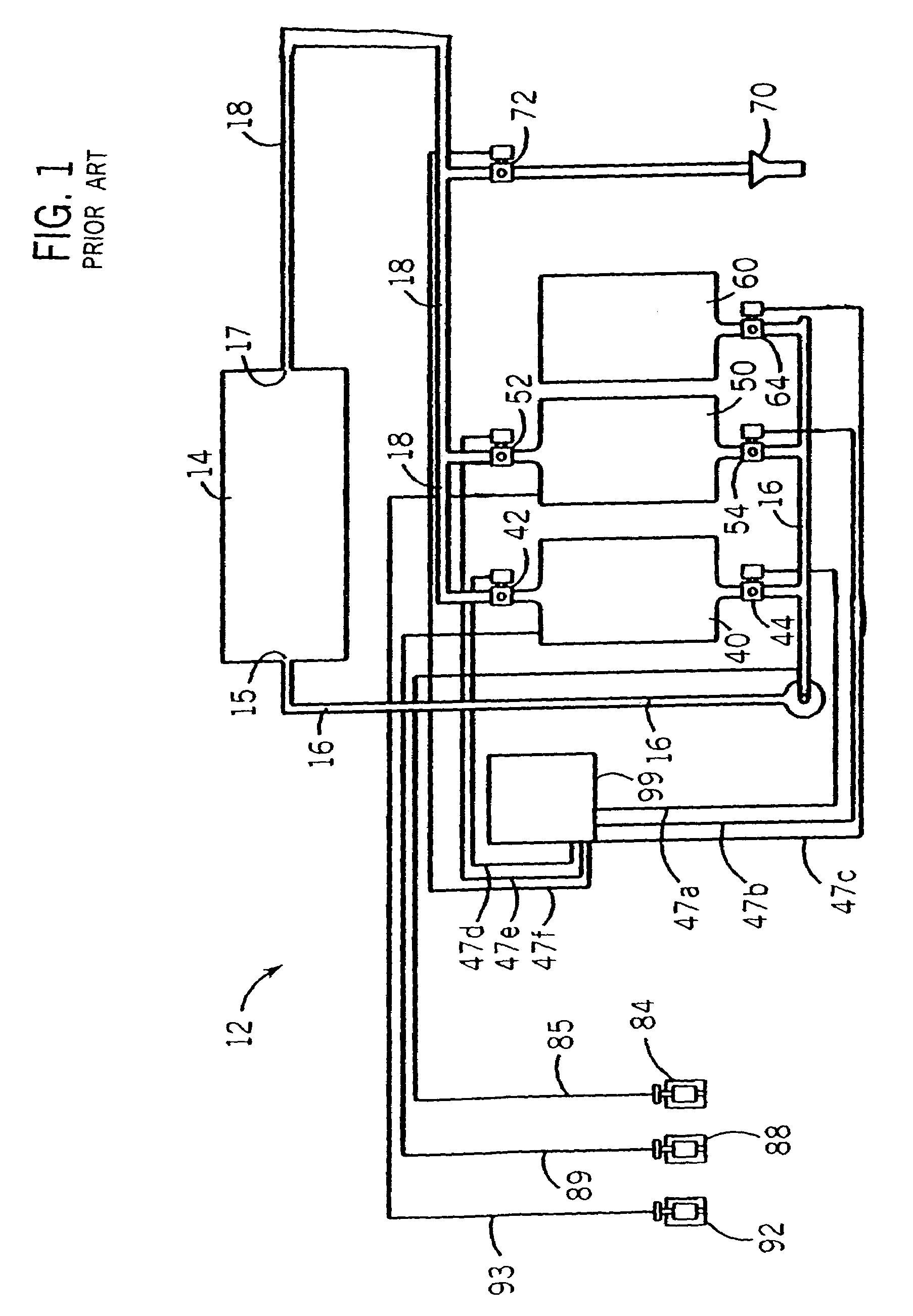

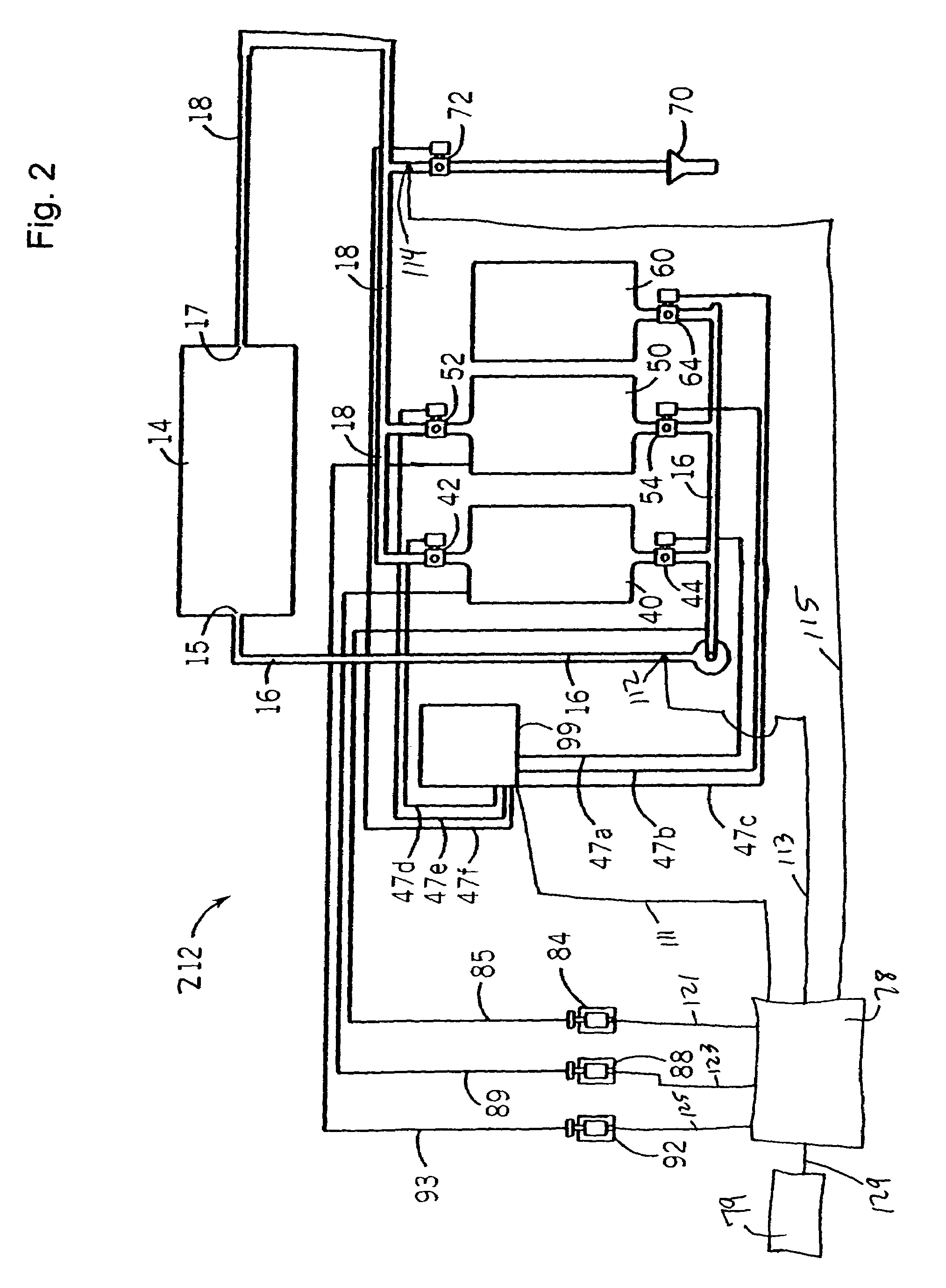

Chemical concentration controller and recorder

InactiveUS7614410B2Lower water costsHollow article cleaningCleaning using liquidsCost ControlsEngineering

A chemical concentration controller and recorder is disclosed for controlling and recording chemical concentrations in a cleaning system. The invention allows a user to control the concentration of two or more chemicals in the cleaning system simultaneously using either concentration-based feed or timed feed. The invention records and archives chemical concentration data from sensors in the cleaning system tanks or the cleaning system fluid conduits during operation of the cleaning system. The data may then be downloaded by a user and analyzed for efficiency and cost control purposes. For example, the data may indicate the overfeeding of chemicals to the cleaning system or leaking valves in the cleaning system.

Owner:HYDRITE CHEM

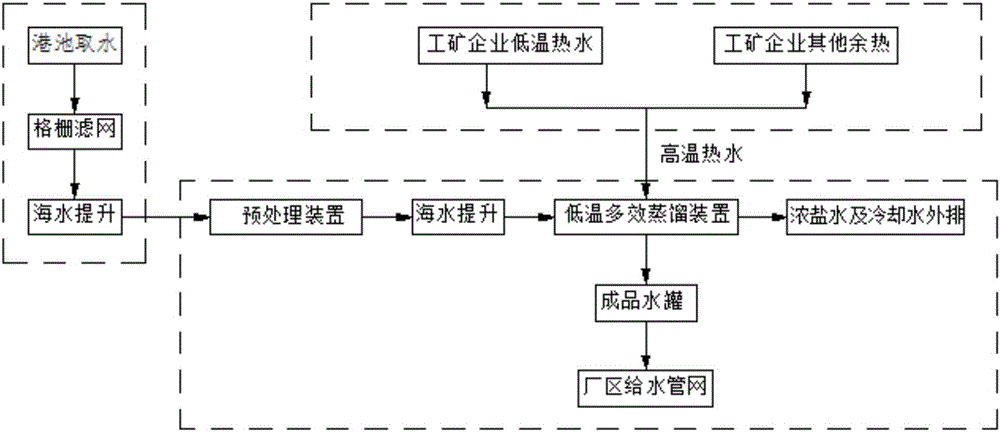

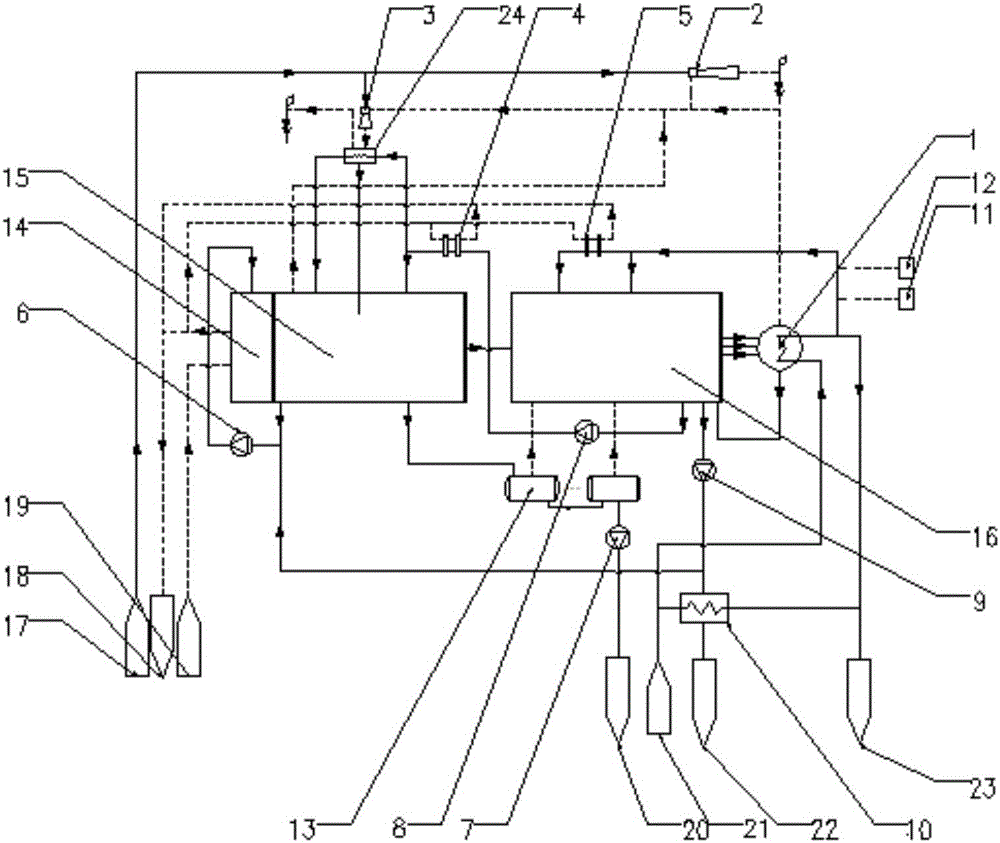

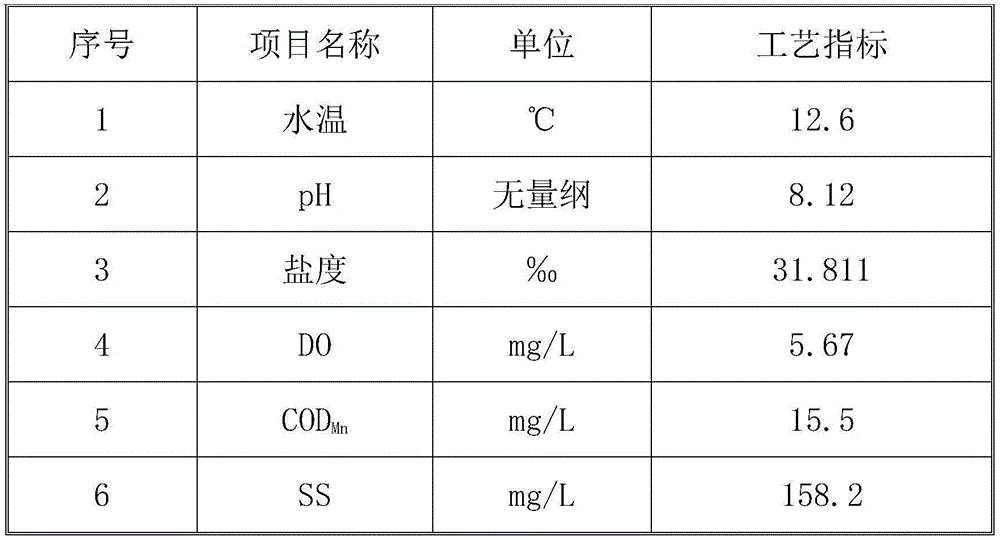

Low-temperature multiefffect distilled seawater desalination system

InactiveCN106115825ALower water costsReduce power consumptionGeneral water supply conservationSeawater treatmentCounter flowWater production

The invention relates to a low-temperature multiefffect distilled seawater desalination system, which comprises a zero-effect vapor generator, n-effect evaporators, a vapor condenser and a vacuumizing system, wherein high-temperature hot water flows in the zero-effect vapor generator through a high-temperature hot water pipe, the zero-effect vapor generator generates starting vapor, the vapor flows in the first-effect evaporator through a pipeline, vapor generated in the first-effect evaporator flows in the next-effect evaporator through a pipeline, until flows in the nth-effect evaporator, and vapor generated in the nth-effect evaporator flows in the vapor condenser to form finished water. By directly utilizing low-temperature residual heat unutilized by industrial mining enterprises, the water production cost of seawater desalination can be greatly lowered, the low-temperature multiefffect distilled seawater desalination system is an important action of offshore industrial and mining enterprises to realize energy saving and emission reduction, electricity consumption is reduced by adopting a hot water direct driven optimized scheme, and the water productivity and energy utilization rate of the whole system can be improved by adopting width counter flowing feeding mode through reasonable design optimization.

Owner:BEIJING JINDAYU ENVIRONMENT TECH CO LTD

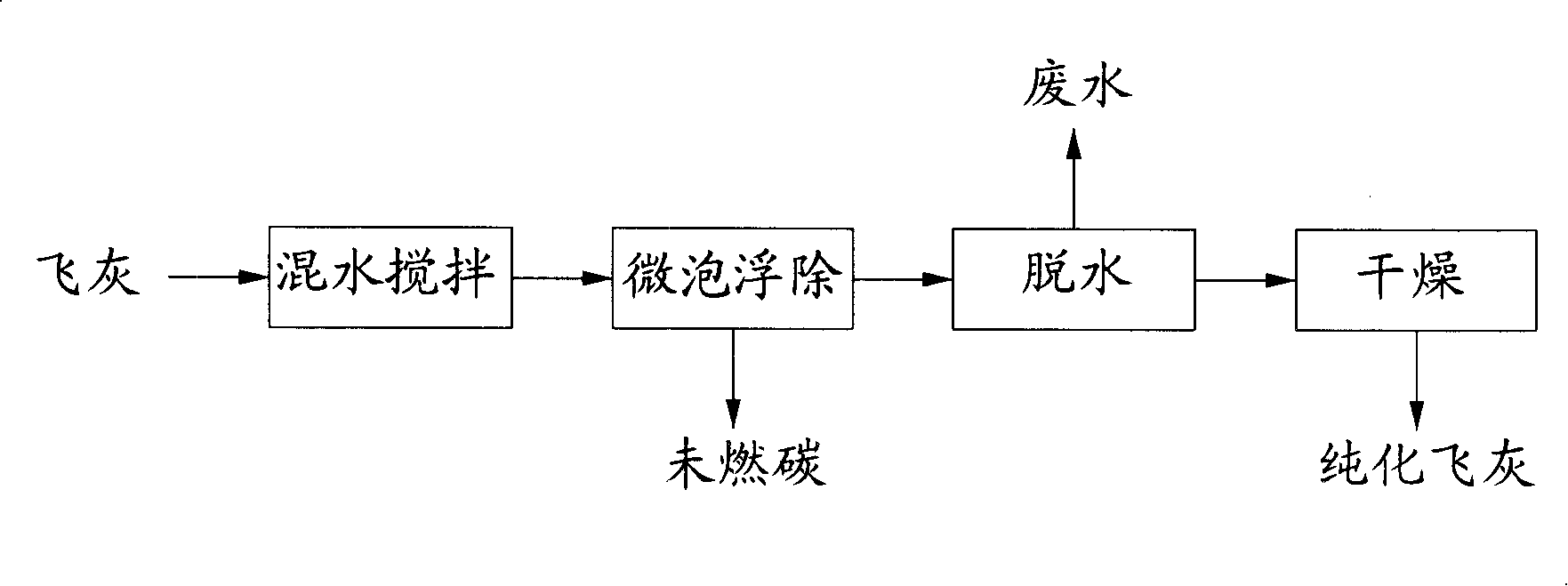

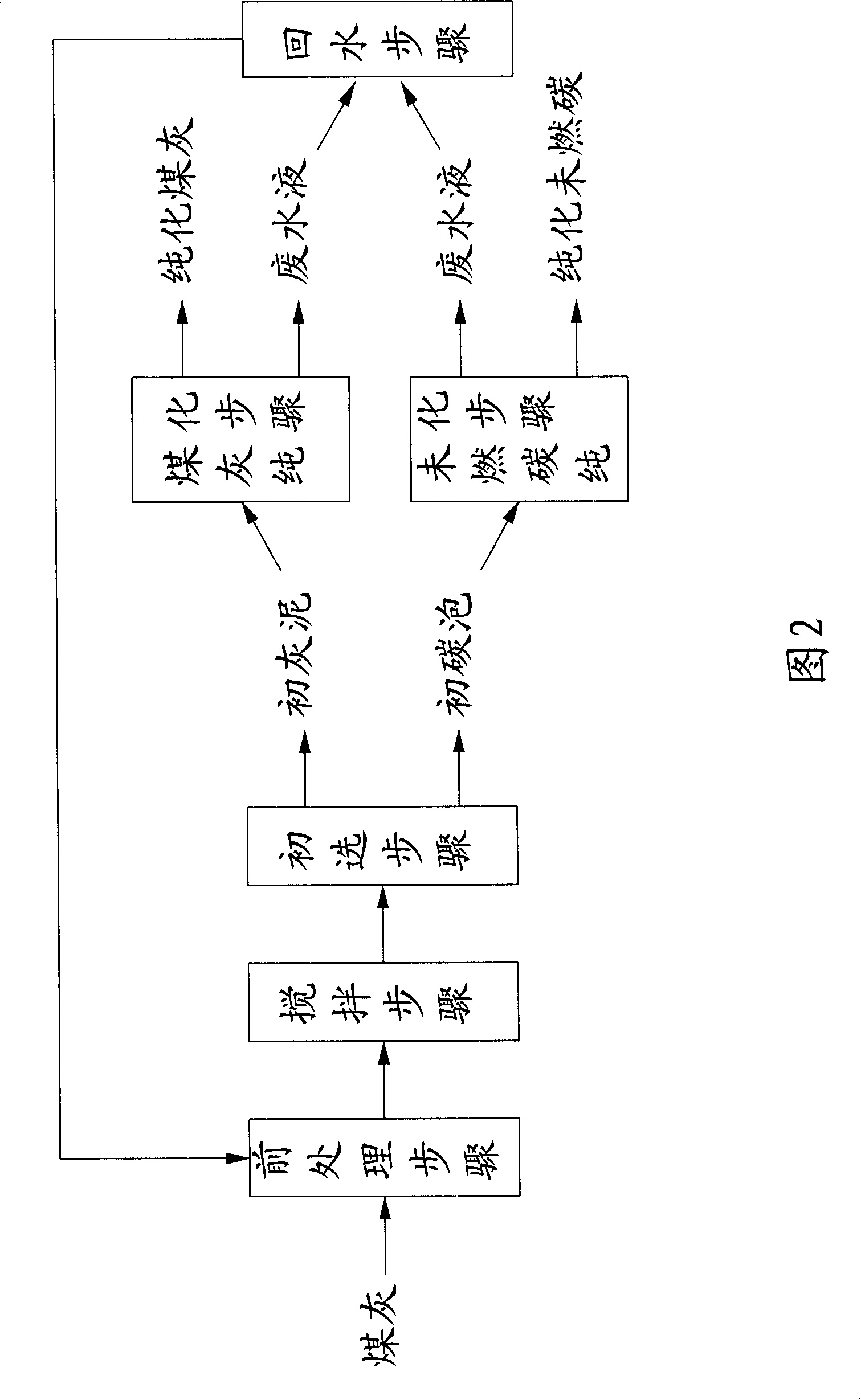

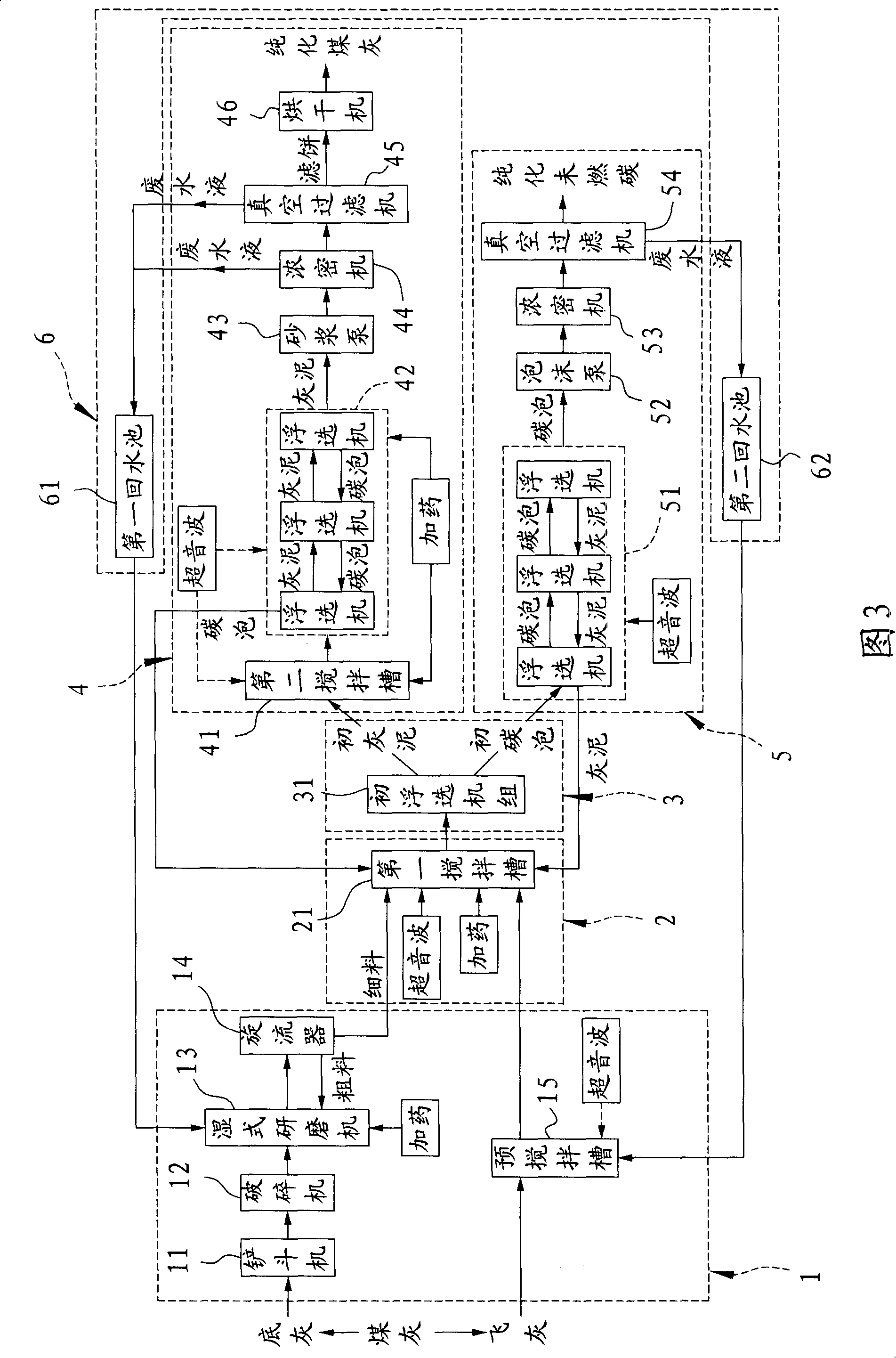

Coal ash resource treating method

InactiveCN101185933AEnhanced carbon removal capacityHigh puritySolid waste disposalFlotationTreatment effectPulverized fuel ash

The invention relates to a processing method of reclamation of ash, comprising a pretreatment procedure, a stirring procedure, a primary selection procedure, an ash purification procedure, an unburned carbon purification procedure and a water returning procedure. The procedures of stirring and floatation and the using of the ultrasonic concussion effect can obviously enhance the separation effect of ash and unburned carbon and get purified ash and purified unburned carbon with high purity so as to produce high utilization value and application hierarchy. Furthermore, water produced in the process of dehydration and drying can return and be reused, which greatly reduces the cost of water consumption and ensures the whole structure to achieve the best reclamation treatment effect.

Owner:MIRACLE ENVIRONMENTAL TECH

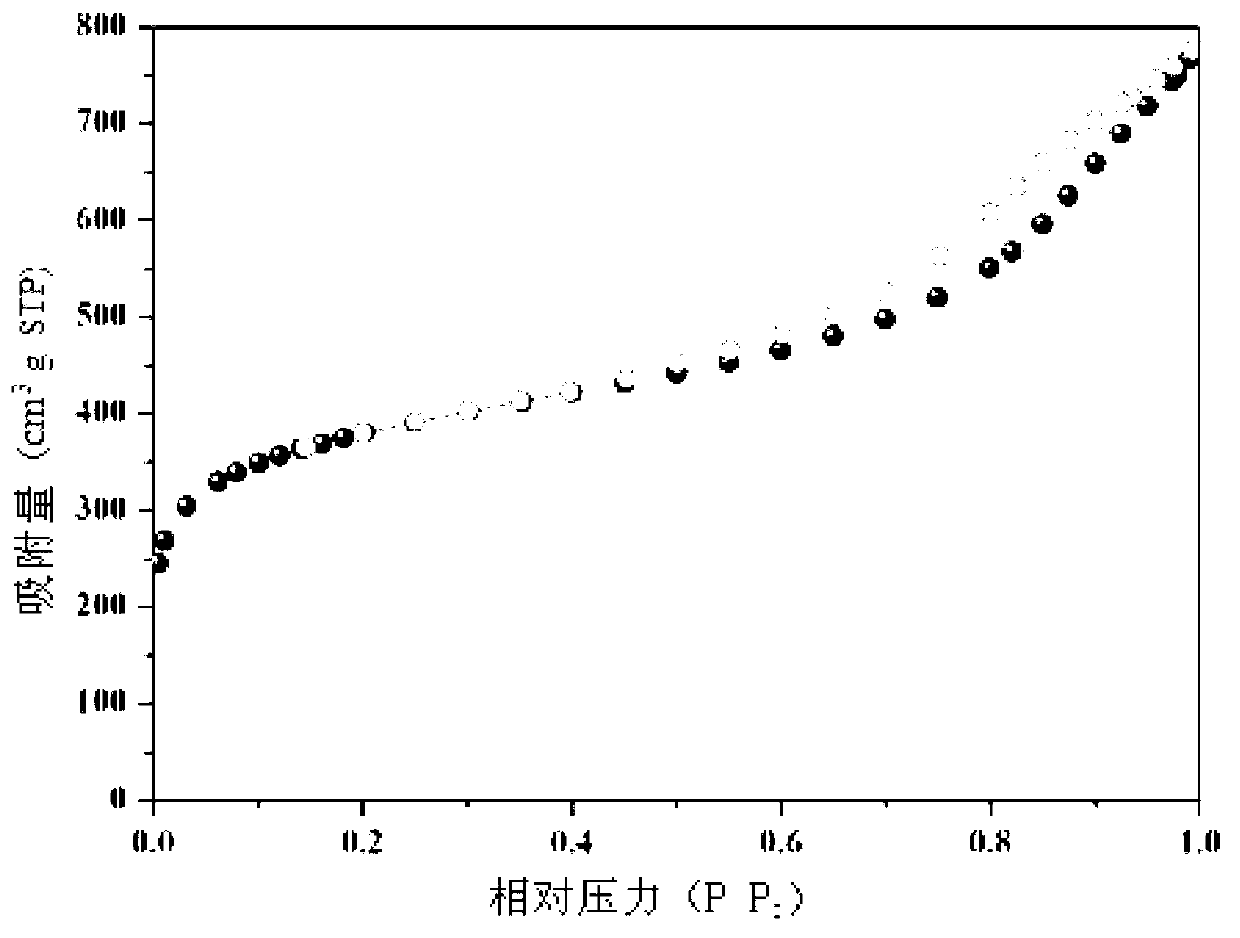

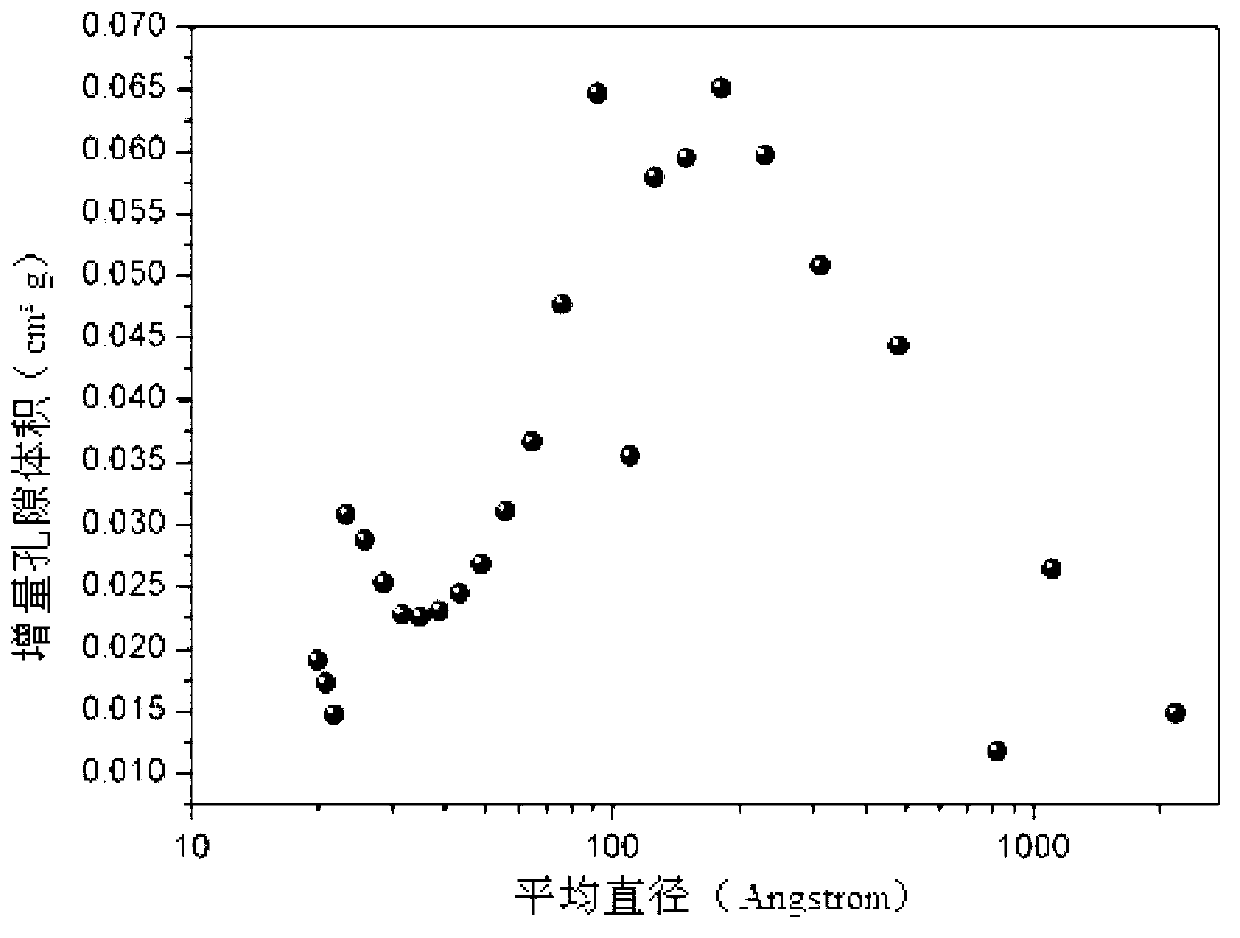

High-performance mesoporous active carbon suitable for biological enhancement and preparation method thereof

The invention discloses high-performance mesoporous active carbon suitable for biological enhancement and a preparation method thereof, relates to a preparation method of active carbon, and in particular to a preparation method of high-performance mesoporous active carbon which is suitable for biological enhancement and is applied to water treatment ozone-biological active carbon and ozone-biological enhanced active carbon processes. The invention aims to solve the problems that the existing active carbon has low mesopore rate and low biological loading amount on the surface and in pore passages of the active carbon. The preparation method comprises the following steps of: firstly respectively crushing and screening blind coals, candle coals and coconut shells which are used as precursors, and then matching in proportion; then, performing briquetting, carbonization, oxidization before activation, activation and modification after activation on the matched raw material; and finally, screening to obtain the mesoporous active carbon. The mesopore rate of the obtained mesoporous active carbon reaches 40-70%, and the biological loading amount can be improved to 106-107CFU / g, so that the high-performance mesoporous active carbon can be applied to the field of water treatment.

Owner:HARBIN INST OF TECH

System for biochemically recovering and regenerated saving water in urban residence

InactiveCN101074566ASignificant water saving and deodorizing functionImprove indoor air qualityFlushing devicesDomestic plumbingFertilizerUltrafiltration

The invention is a biochemical recovery and regeneration water saving system of town building and district. Seal the feces by plastic barrel and trailer for conveniently carrying. The air drafting and the water removing of the lower feeding pipe, the smell-proof air feeding pipe, the wind power fan and its canal fan prolong the period of storing feces to make them harmless to be fertilizer with good quality, improve the price and reduce the times of delivering fertilizer. It is the best to use the ground floor of the building, parkland for body-building or the basic of underground garage to resolve the problems of ladle car saving and channels. Otherwise, the scheme that one unit shares one basement and one channel has to be adopted as civil air defence facilities. The new type lavatory rushes the small pellet inside the pallet through soft hose and link rod all the way. It washes the plastic smell-proof device via round export and forms water seal by the pellet at the channel port through the urinal inner wall, which can save 95% water. The bathwater and the rainwater are purified by the sedimentation tank and the ultrafiltration membrane and flow into the pool for washing lavatory, cars and greening to save more water. It is a good technique to change the problem of high cost without economic benefit of urban wastewater treatment factory.

Owner:郭厚德

Non-phosphorus type environment-friendly slow-release scaling inhibitor

InactiveCN105776589ASimple production processHigh anti-scaling efficiencySpecific water treatment objectivesScale removal and water softeningAraboascorbic AcidFatty alcohol

The invention discloses a non-phosphorus type environment-friendly slow-release scaling inhibitor which is prepared from the following components: tannin, polyacrylic acid, ammonium salt, D-erythorbic acid, silicate, a non-phosphorus polymeric corrosion inhibitor, a maleic acid-crylic acid copolymer, fatty alcohol-polyoxyethylene ether, zinc salt, a dispersing agent and deionized water. The non-phosphorus efficient slow-release scaling inhibitor with safe and environment-friendly components is provided, due to the reasonable design, all the substances in the formula can be prepared into the environment-friendly corrosion inhibitor with a good corrosion inhibition effect and high storage stability.

Owner:SUZHOU NENGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Negative pressure strengthened multi-stage laminated disc type solar energy distillation system for desalination

InactiveCN101880069AReduce energy consumptionLow costGeneral water supply conservationWater/sewage treatmentDistillationEvaporation

The invention provides a negative pressure strengthened multi-stage laminated disc type solar energy distillation system for desalination, which takes solar energy as a heat source to heat brackish water in laminated discs, and under the negative pressure chimney effect of a vacuum pump, the multi-stage cyclic utilization of condensation heat and evaporation heat between the multi-stage laminated discs is realized, the heat transfer efficiency is increased, and pure distilled water can be obtained with less energy consumption. The system has the advantages of compact structure, small floor area, and low cost for water preparation, and is suitable for desalinating brackish water in western villages and small towns.

Owner:王鹤立

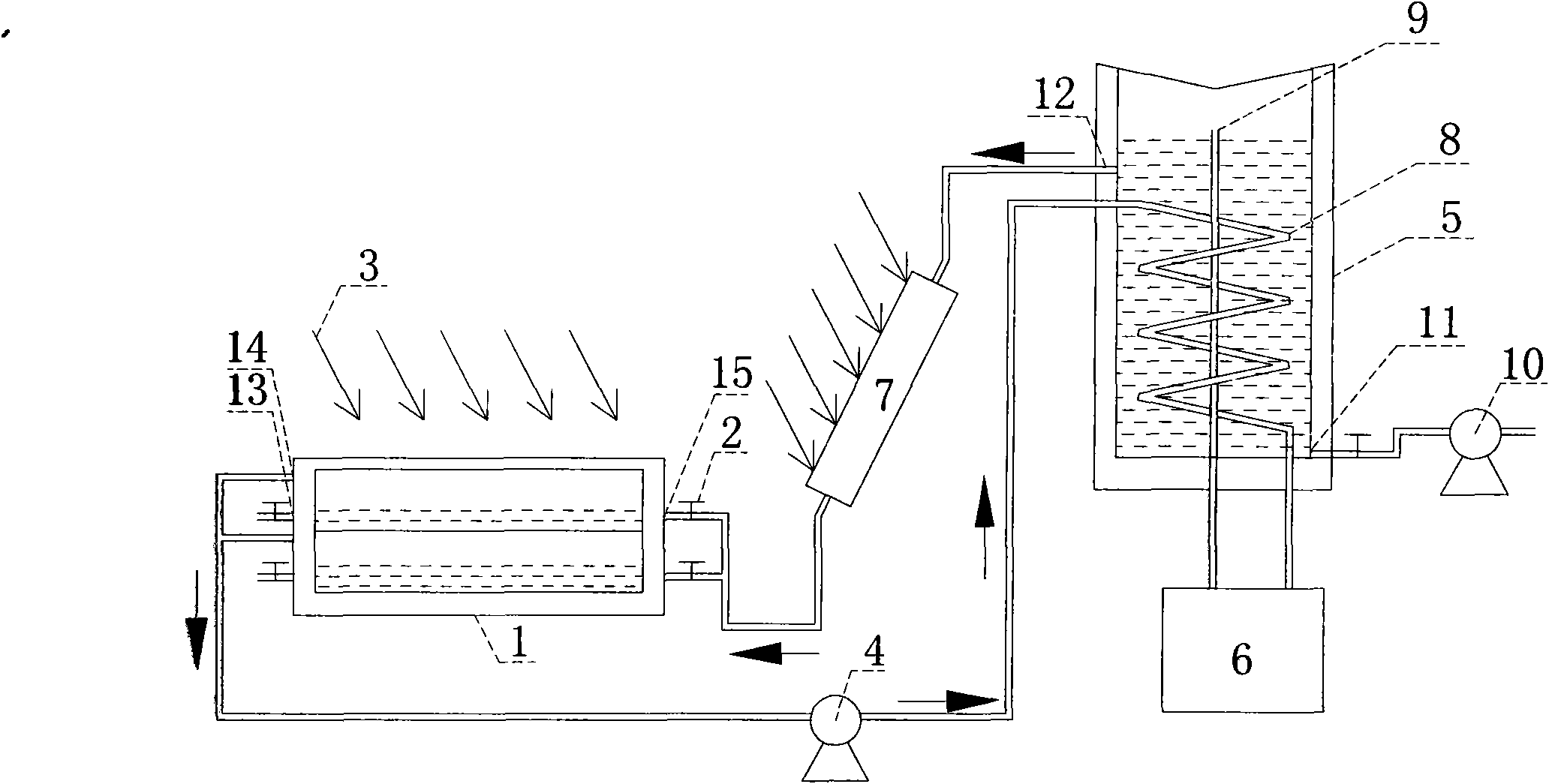

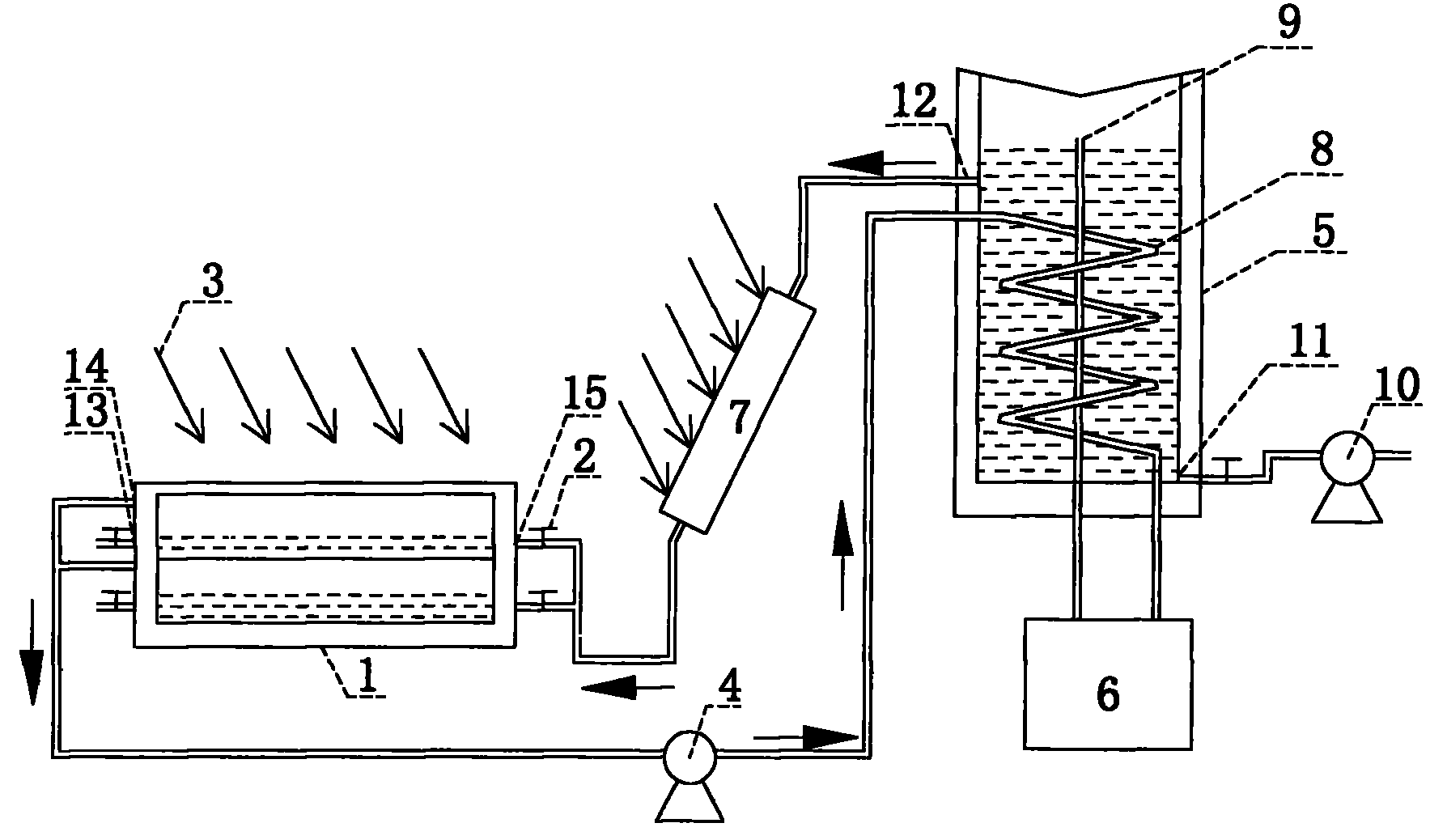

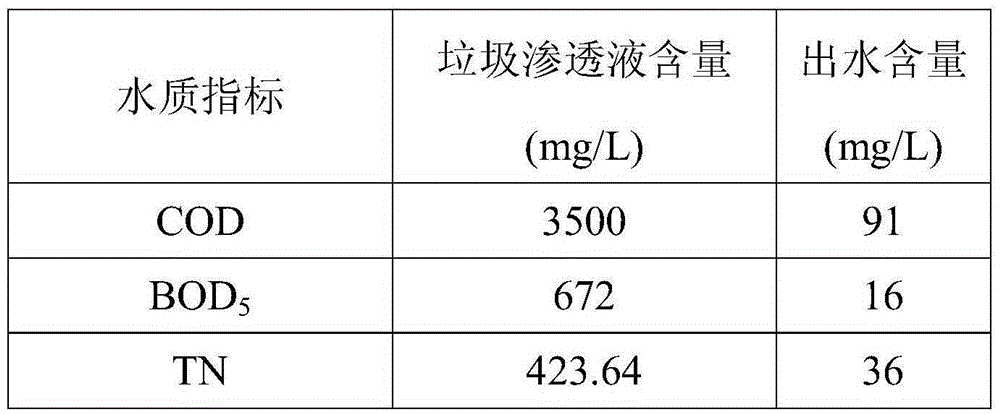

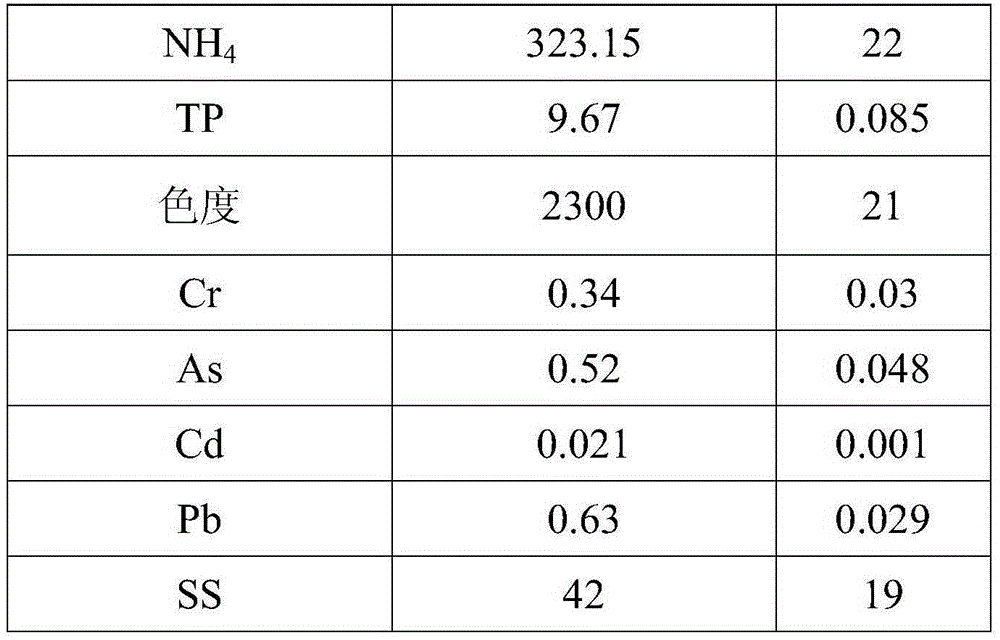

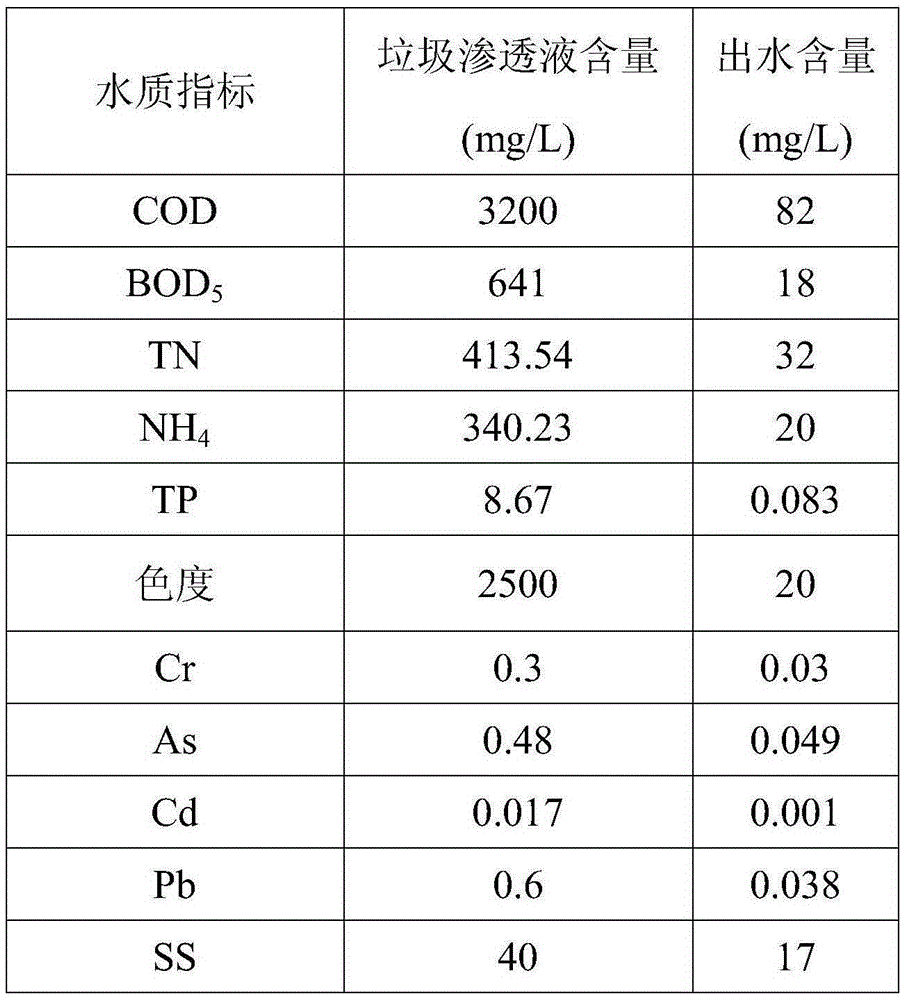

Rubbish penetrating fluid treatment method

InactiveCN105293771AEfficient removalGood decolorization effectMultistage water/sewage treatmentEmission standardMaterial resources

The invention provides a rubbish penetrating fluid treatment method. The rubbish penetrating fluid treatment method comprises flocculent settling treatment, Fenton oxidation treatment and activated carbon adsorption treatment which are performed in sequence. First in the flocculent settling treatment step, by combined use of a decolorizing agent, PAC and PAM, the very good decolorizing effect is achieved, the chromaticity can be reduced by at least two orders of magnitude, and CODs, BODs and heavy metal ions such as arsenite, lead and mercury in water can be removed effectively. Next, organic pollutants difficult to degrade can be removed more effectively through Fenton oxidation under the acidic conditions. Finally, adsorption is performed by utilizing activated carbon. Therefore, the rubbish penetrating fluid treatment method is low in cost, high in effect and simple to operate and saves manpower and material resources. Moreover, the treatment degree is high, the effect is stable, the penetrating fluid chromaticity, CODs, BODs, the heavy metal content and ammonia nitrogen of rubbish treated through the method reach the emission standard.

Owner:NANJING RUNZHONG BIOTECH

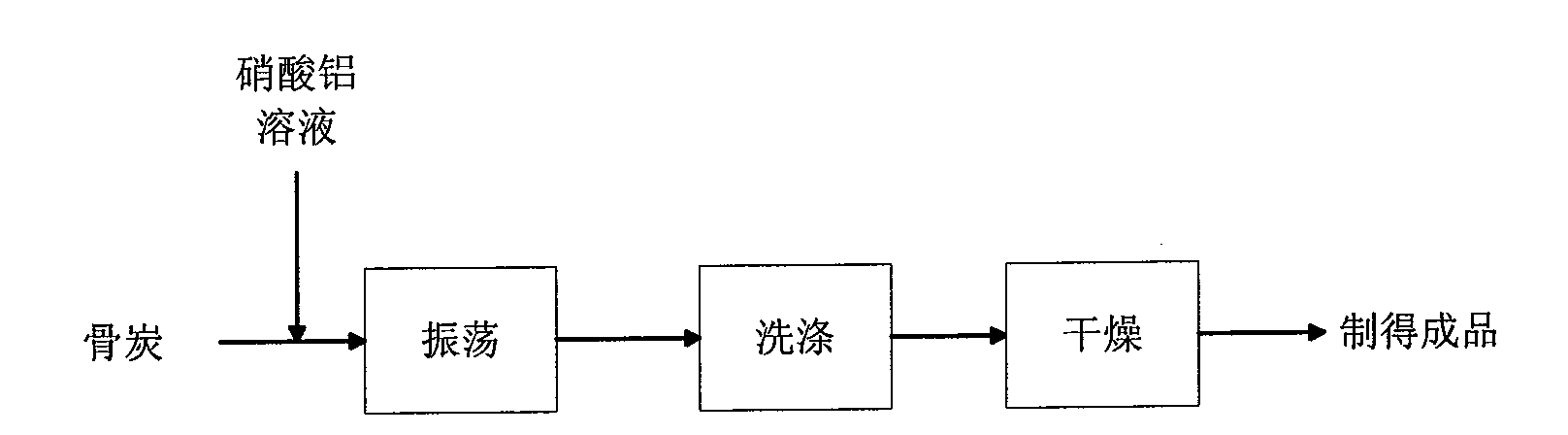

Preparation method of bone char fluoride removal agent loaded with aluminium ions

InactiveCN101596446AImprove adsorption capacityAnti-interferenceOther chemical processesWater/sewage treatment by sorptionHigh fluorideRoom temperature

The invention relates to a preparation method of a bone char fluoride removal agent loaded with aluminium ions, belonging to the field of drinking water fluoride removal treatment. In the method, bone char of certain mass is put into an aluminium salt solution of certain volume; the mixture of the bone char and the aluminium salt solution is oscillated for certain time under certain condition; the bone char is taken out, washed by clear water and dried under room temperature. The mass ratio between the bone char and the aluminium salt solution is 1:8-1:12. The condition of the oscillation is as follows: the bone char and the aluminium salt solution is fully mixed in the process of oscillation, the time of oscillation is not less than 24h, the temperature of the mixture is kept at 20-40 DEG C during oscillation. Batch adsorption tests show that the adsorption capacity of the aluminium-loaded bone char fluoride removal agent is 60% higher than that of ordinary bone char fluoride removal agents. Used in the areas taking high-fluoride ground water as drinking water resource, the fluoride removal agent can effectively ensure the residents with drinking water safety, reduce the cost for producing water and the workload of daily maintenance of water supply engineering simultaneously.

Owner:TSINGHUA UNIV

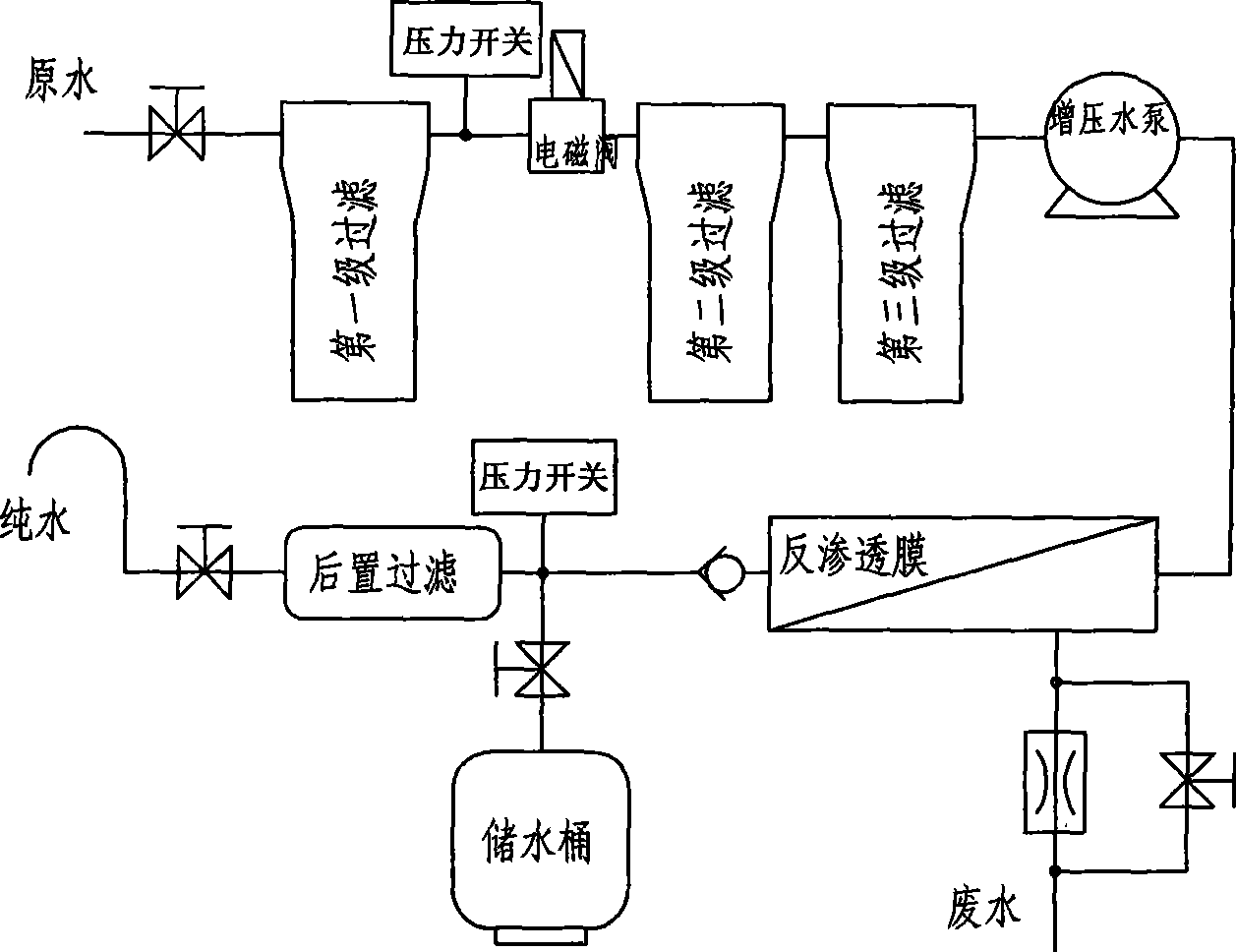

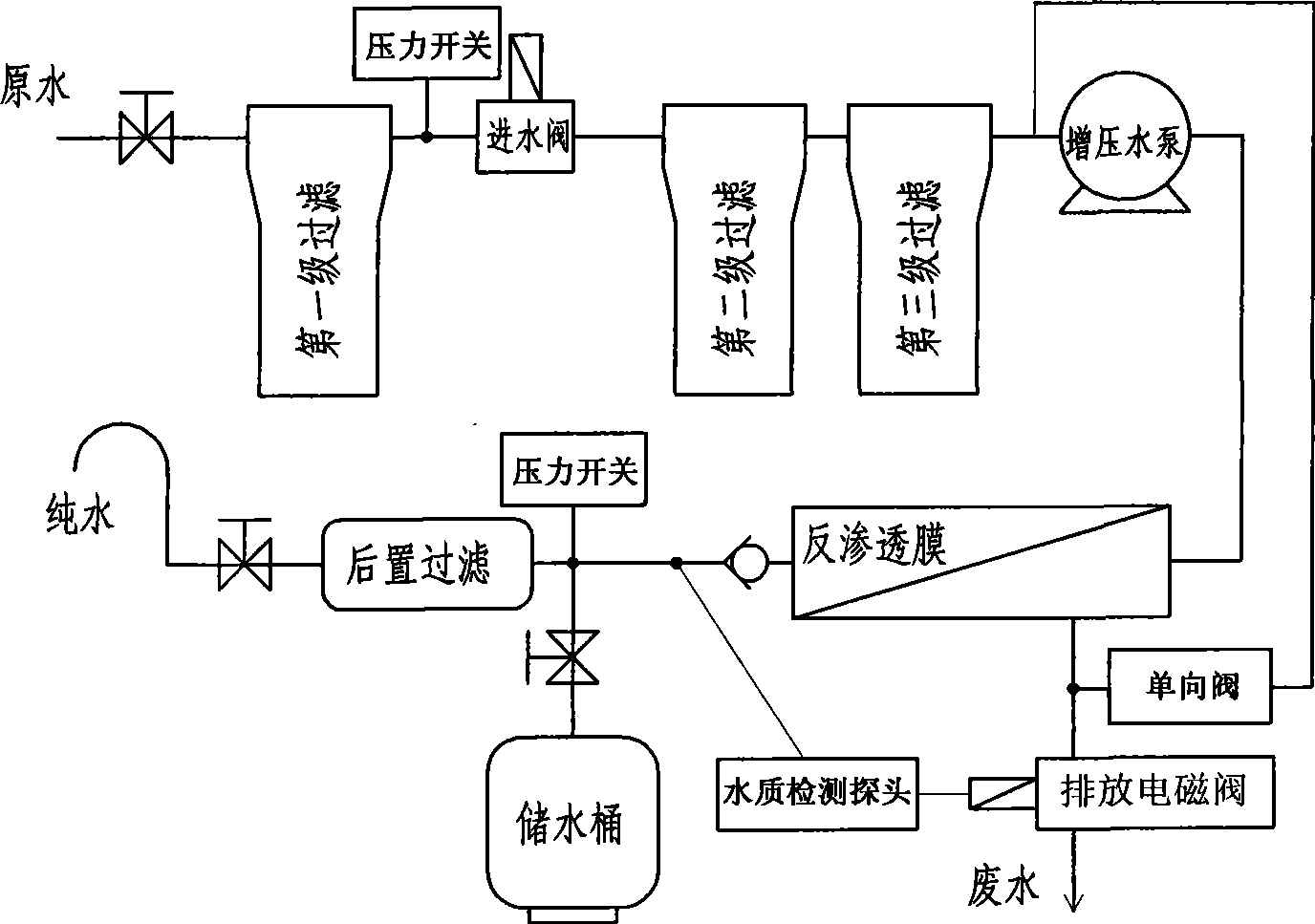

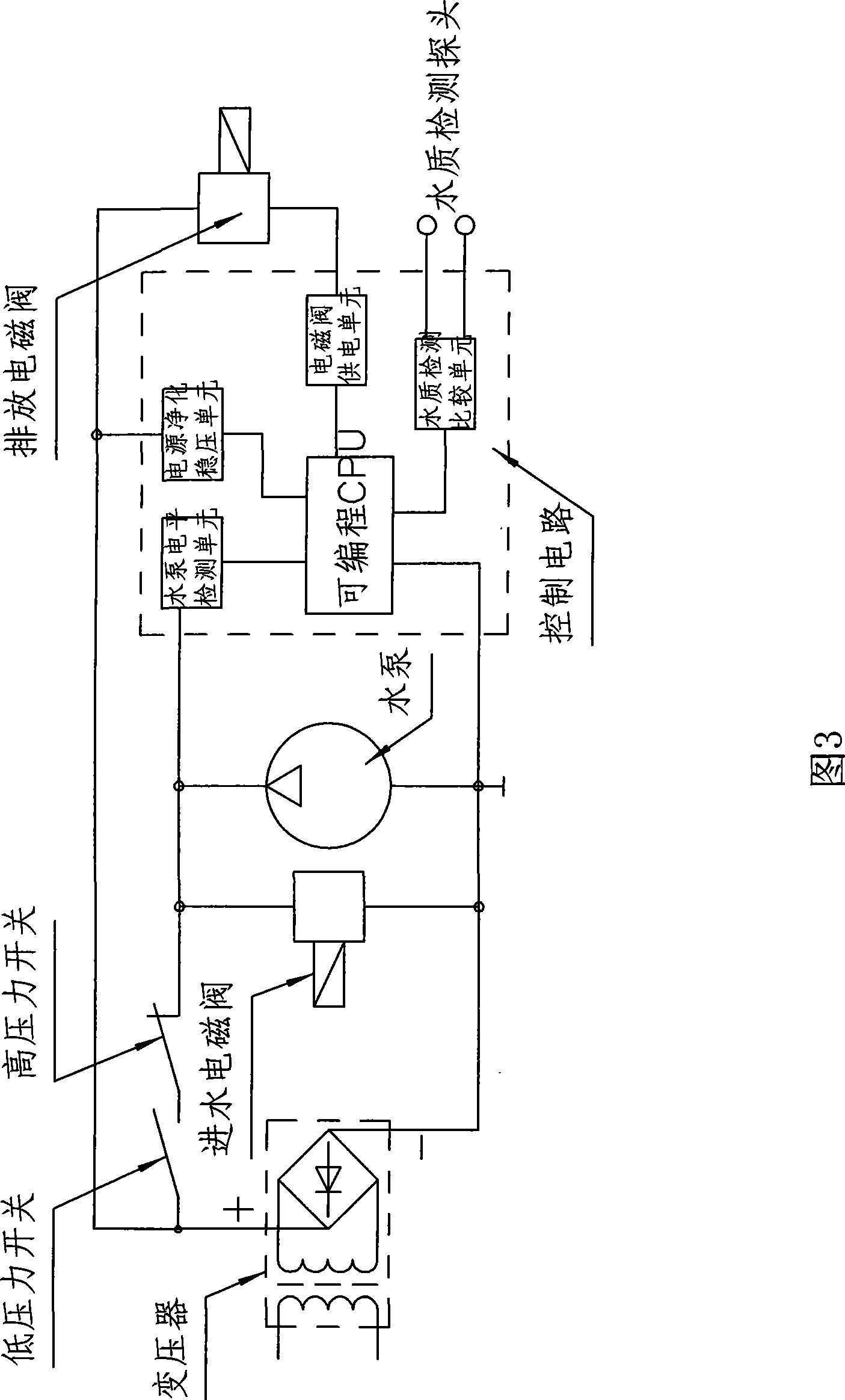

Water-saving type pure water production system

InactiveCN101362609AHigh recovery rateEfficient use ofWater/sewage treatment bu osmosis/dialysisNon-contaminated water treatmentWater savingWater production

The invention discloses a water-saving type pure water making system which comprises a reverse osmosis membrane filter, a pure water outlet pipeline, a concentrated water discharge pipeline and a raw water inlet pipeline. The water-saving type pure water making system is provided with a pure water quality detection and control discharge pipeline, the pure water quality detection and control discharge system comprises a discharge electromagnetic valve, a control circuit of the discharge electromagnetic valve and a water quality detection probe, the water quality detection probe is arranged on the pure water outlet pipeline, the concentrated water discharge pipeline is divided into two parts, one branch is connected with the raw water inlet pipeline to constitute a concentrated water return pipeline via an one-way valve and a throttle valve or a combined one-way throttle valve thereof, and the discharge electromagnetic valve is arranged on the other branch to constitute a concentrated wastewater discharge pipeline. The pure water quality detection and control discharge system does not discharge wastewater when a pure water machine makes pure water, when the water quality of the made pure water is deteriorated to a certain extent, the water-saving type pure water making system adopts the time large-flow discharge of the over-concentrated wastewater.

Owner:黄彪

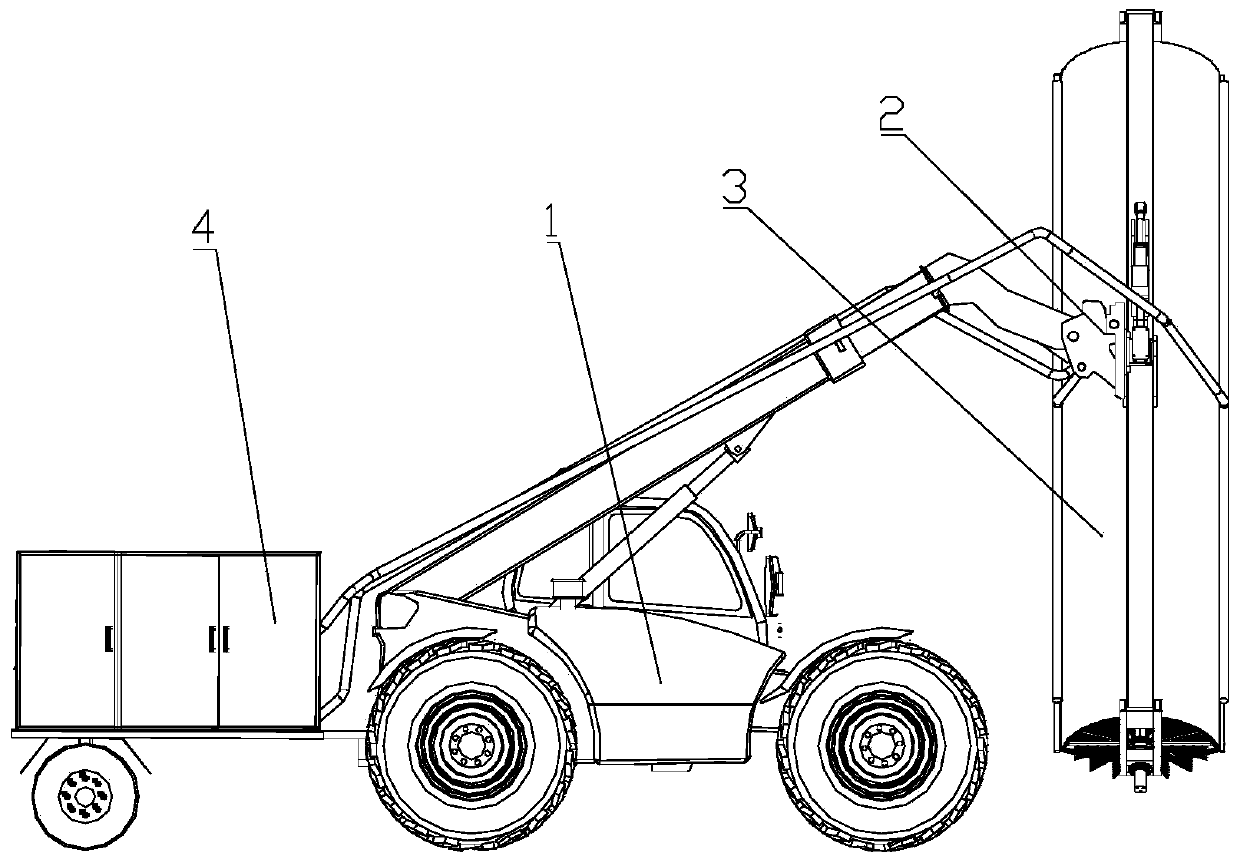

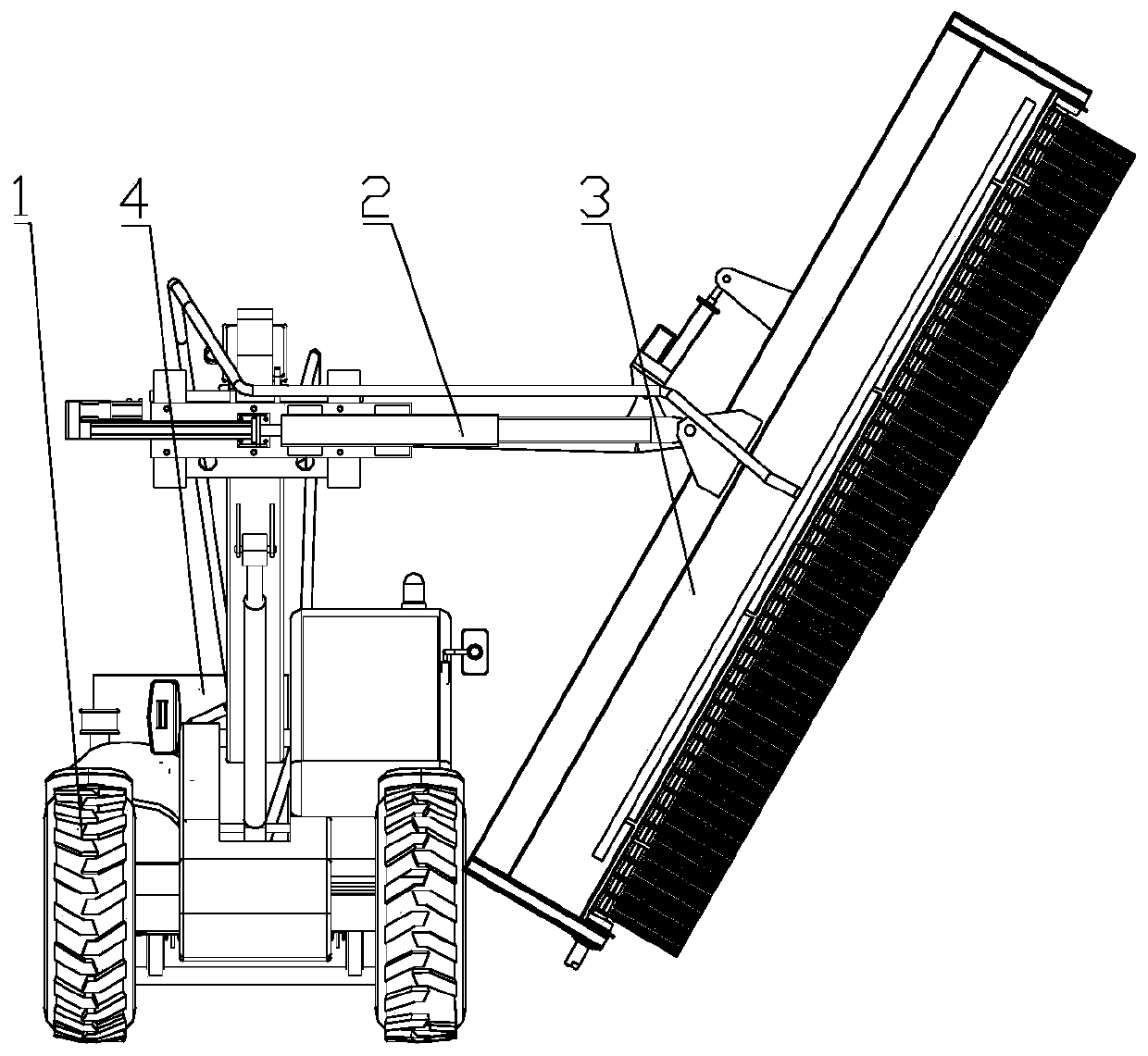

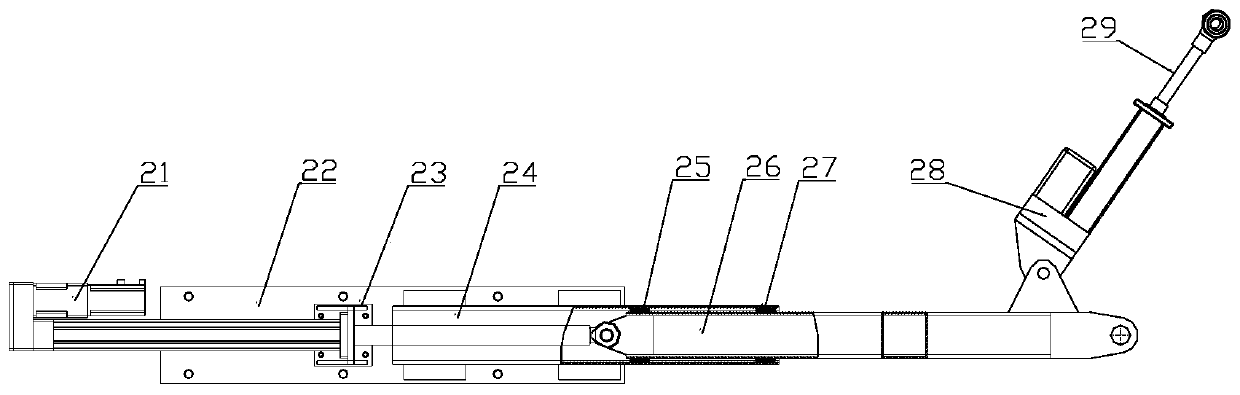

Photovoltaic panel cleaning car

PendingCN110538834AHigh degree of automationImprove cleaning efficiencyDrying gas arrangementsPhotovoltaicsCavitationEngineering

The invention discloses a photovoltaic panel cleaning car. The photovoltaic panel cleaning car comprises a forklift serving as a moving platform, a cleaning device used for cleaning a photovoltaic panel, a cleaning telescopic arm for supporting and being connected with the cleaning device and an auxiliary equipment loading trailer. The cleaning device is a roller type cleaning device and comprisesa support connected with the telescopic arm and a roller type roll brush set hinged to the support in a drive manner. A water stop arc plate covering at least 1 / 3 of the circumference of the roll brush set in the circumferential direction is arranged in the axial direction of the roller type roll brush set. High-pressure water curtain type water spray sets are mounted on the two edges and the front side of the water stop arc plate, and an air knife air spray set is mounted on the rear side of the water stop arc plate. Multiple cleaning modes are combined to clean the photovoltaic panel, the displacement and angular displacement of the cleaning device and a cleaning target line are automatically adjusted with high precision, and it is guaranteed that the technical requirements for optimalcleaning parameters of the cavitation jet water washing distance, the cleaning contact area of the roll brush set and the high-pressure air washing angle are met; and the cleaning efficiency and the cleaning effect are high, and the power generation efficiency of photovoltaic conversion of the solar photovoltaic panel is greatly improved.

Owner:成都新一驱动科技有限责任公司

Process for treating and reclaiming polymer-contained sewage

InactiveCN1381410AViscosity unchangedPut an end to the phenomenonMultistage water/sewage treatmentDisinfectantSewage

A process for deeply treating and reclaiming polymer-contained sewage incldues such steps as loading the said sewage in regulation pool, adding disinfectant; adsorbing 20-30% of suspended substance and bacteria, stage-1 membrane filtering to remove over 99% of suspended substance and bacteria, and filtrate out 80% of Ca2+ and Mg+2 ions, stage-2 membrane filtering to filtrate out 90% of Ca2+, Mg2+, K+ and Na+ ions, storing cleaned water 80%-85% in water tank, and using 15%-20% of concentrated liquid back for preparing polymer solution. Its advantages are high recovery rate of wate (72-81%), and no drainage.

Owner:大庆东昊投资有限公司

Midwifery delivery bed

ActiveCN108245355AIncrease surface frictionPrevent slippingDiagnosticsOperating tablesEngineeringCirculating pump

The invention discloses a midwifery delivery bed. The midwifery delivery bed is used for underwater delivery. The bed comprises a delivery pool, a delivery bed body, a lifting mechanism, a circulationpump, a heating mechanism, a drainage pipe, a circulation water pipe and a controller. The delivery bed body is arranged in the delivery pool and connected with the lifting mechanism, the lifting mechanism is fixed to the bottom of the delivery pool, and an equipment mounting cavity of a closed structure is separated from the interior of the delivery pool through an arc partition plate; the heating mechanism is arranged in the equipment mounting cavity and provided with a water inlet and a water outlet, and the water outlet is communicated with the delivery pool through a hot water pipe; thecirculation pump is connected to a drainage port of the delivery pool, an outlet of the circulation pump is connected with the drainage pipe and the circulation water pipe separately, and the water inlet of the heating mechanism is connected with an external water supply pipe and the circulation water pipe separately. When water of the circulation water pipe or the external water supply pipe enters the heating mechanism, the water is heated by the heating mechanism, and the heated water is conveyed into the delivery pool through the hot water pipe connected with the water outlet of the heatingmechanism. The midwifery delivery bed is reliable to implement, convenient to operate and low in cost.

Owner:仇迪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com