Patents

Literature

55 results about "Industrial service" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

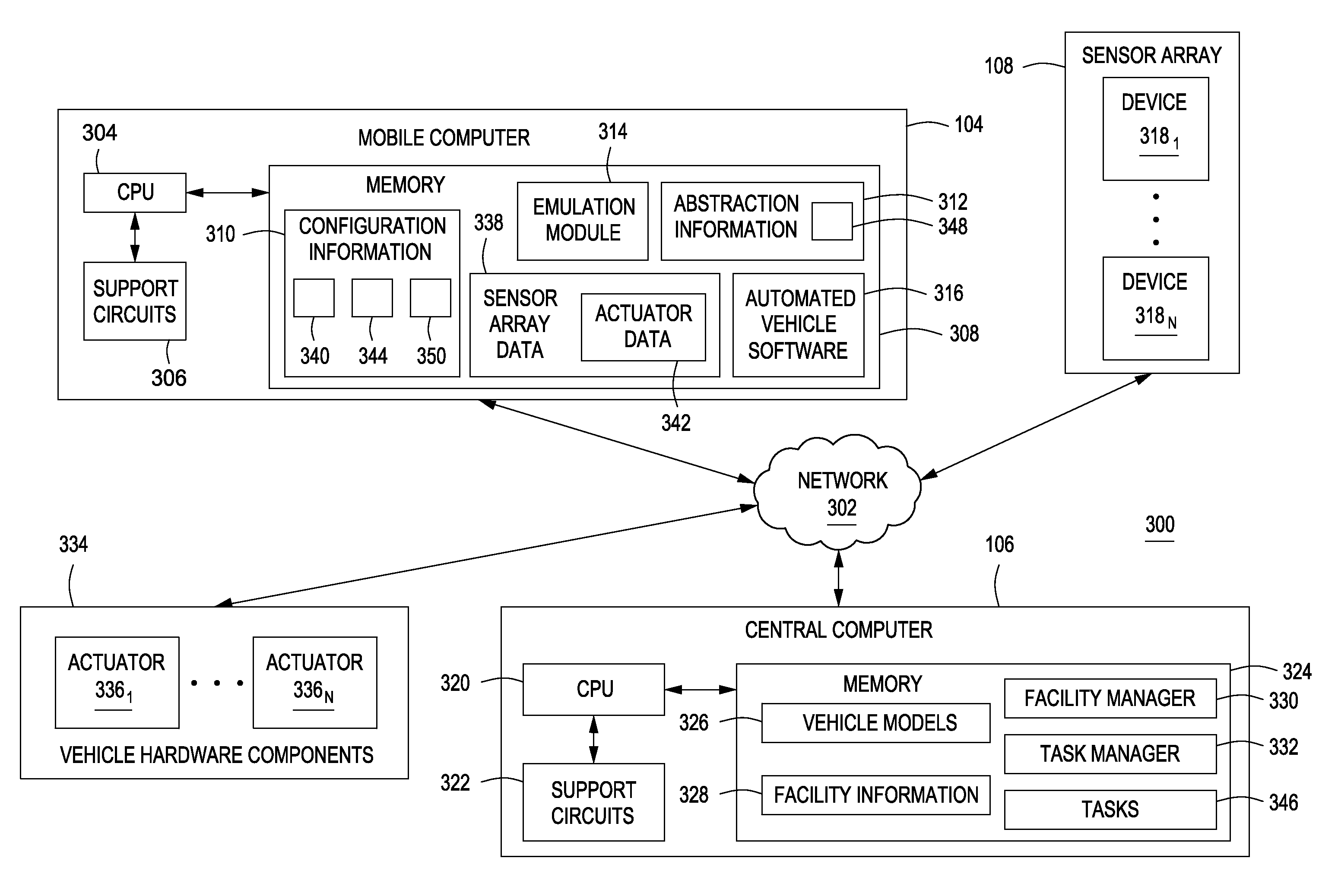

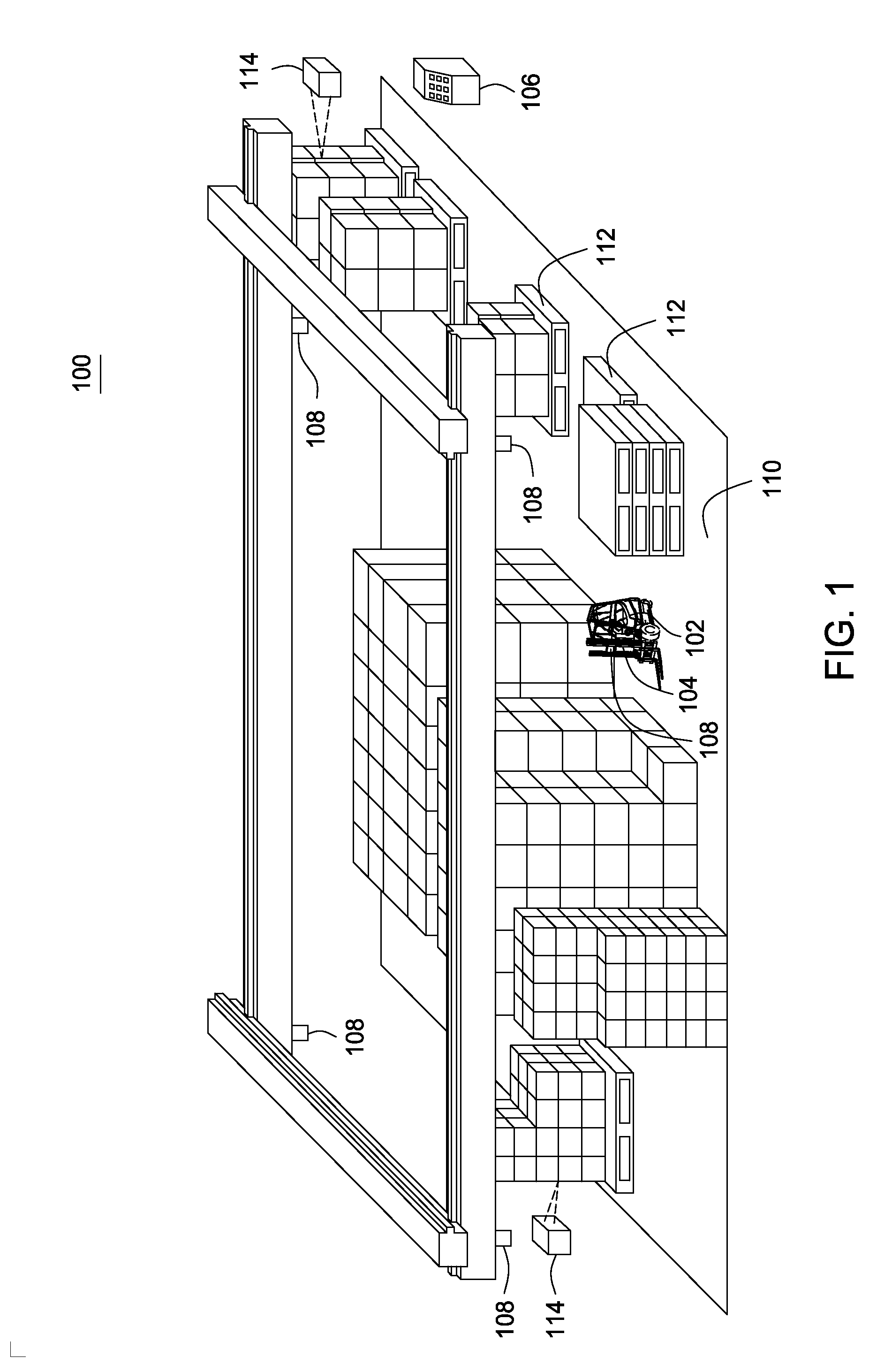

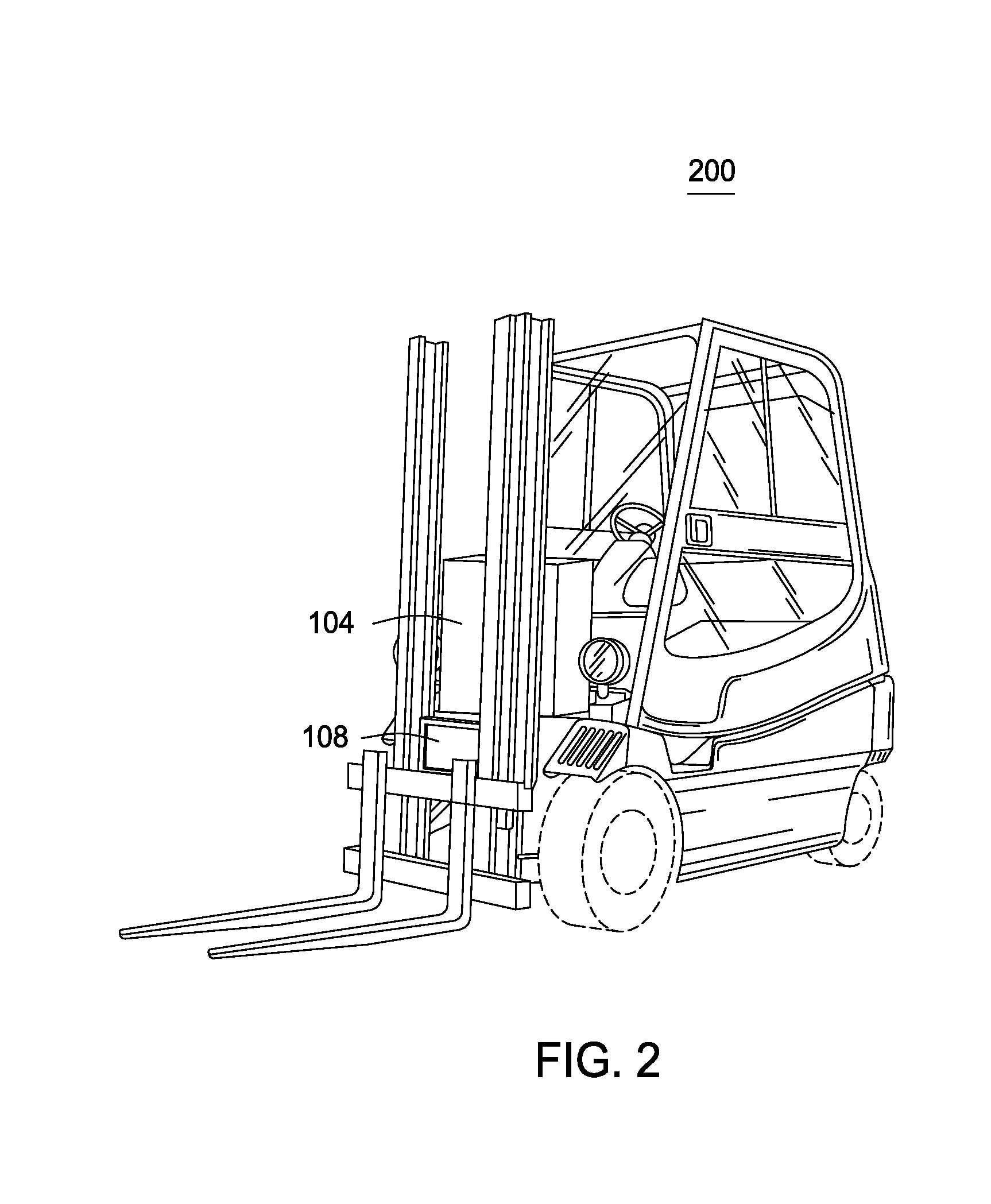

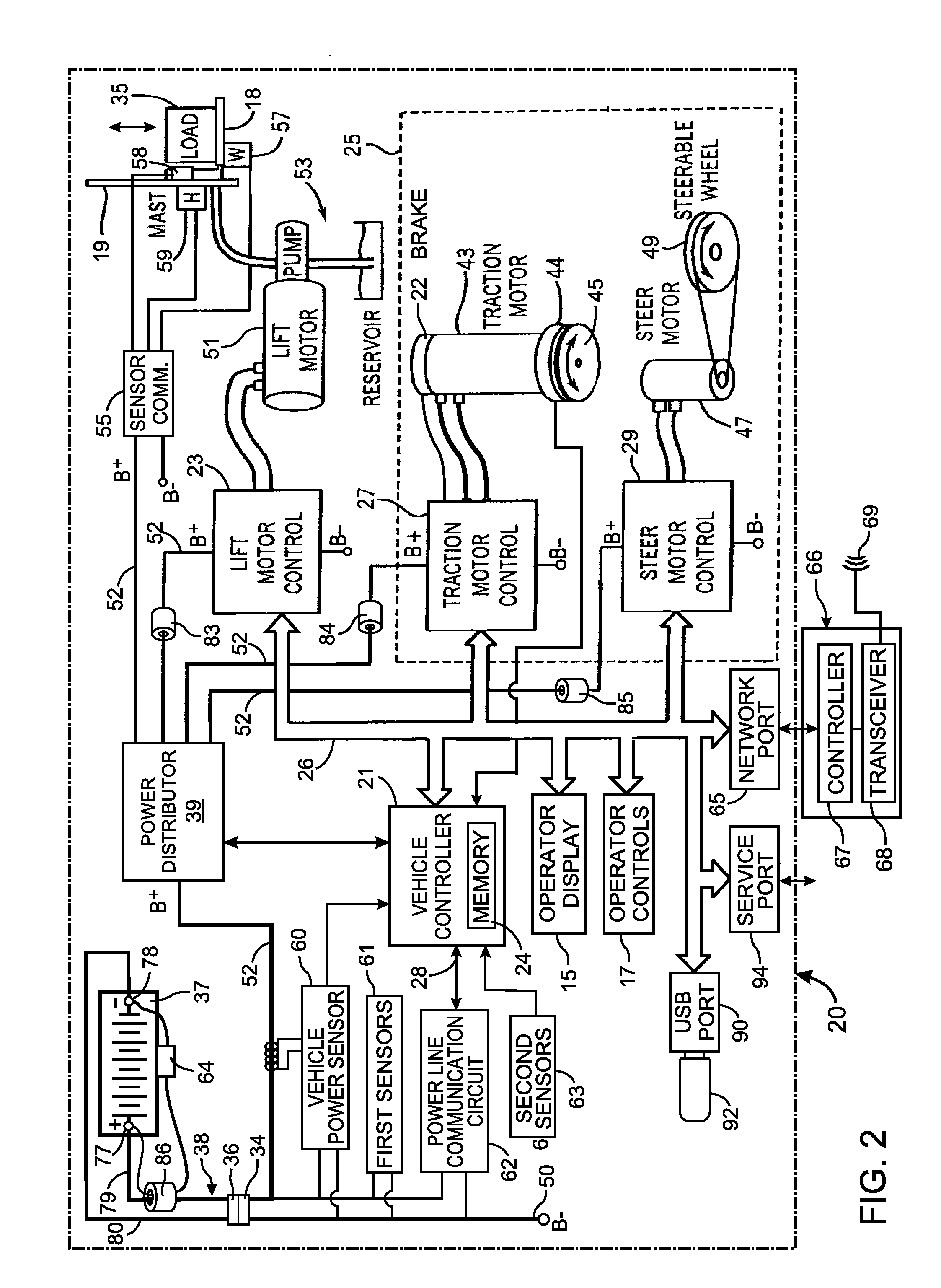

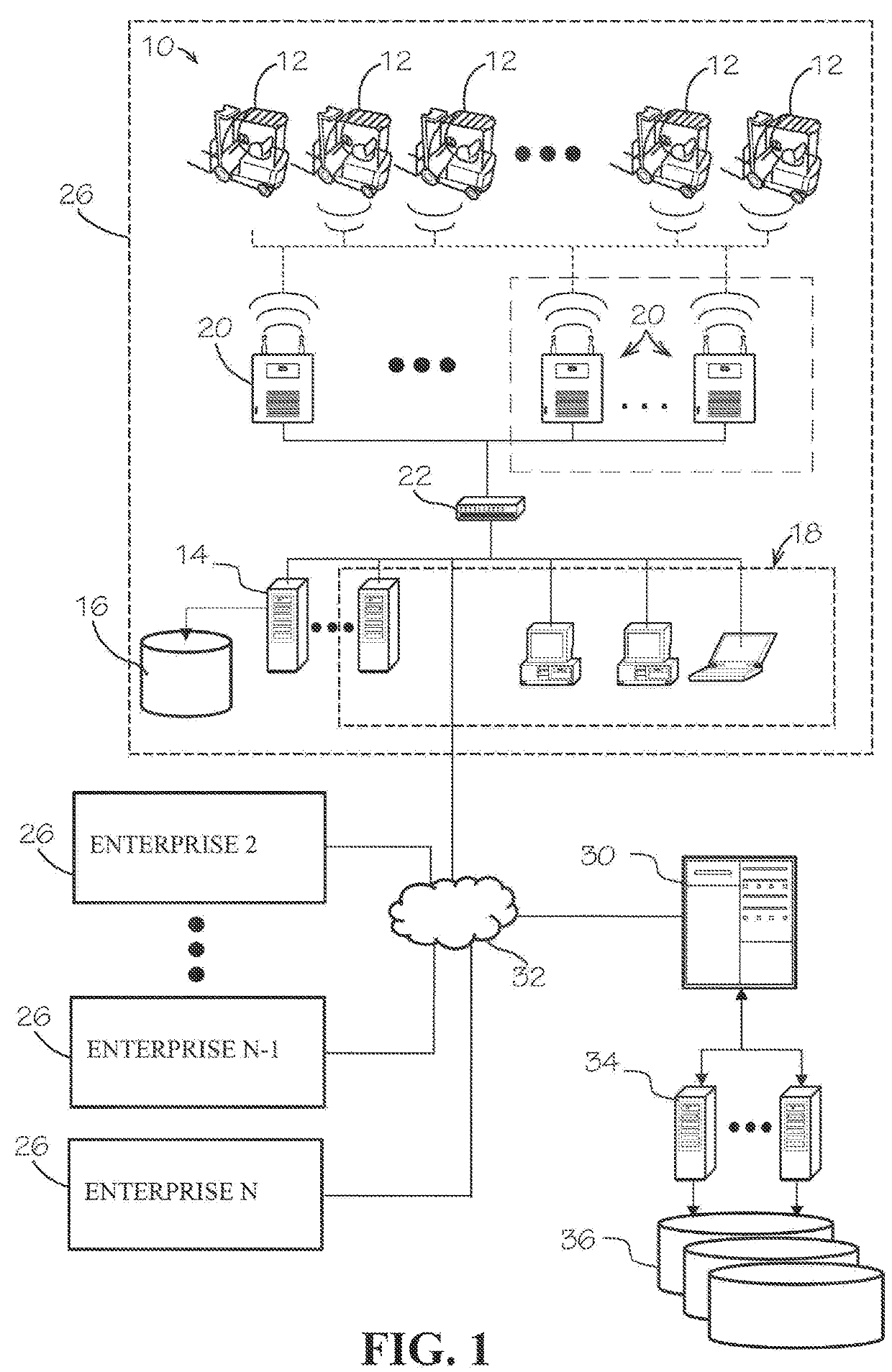

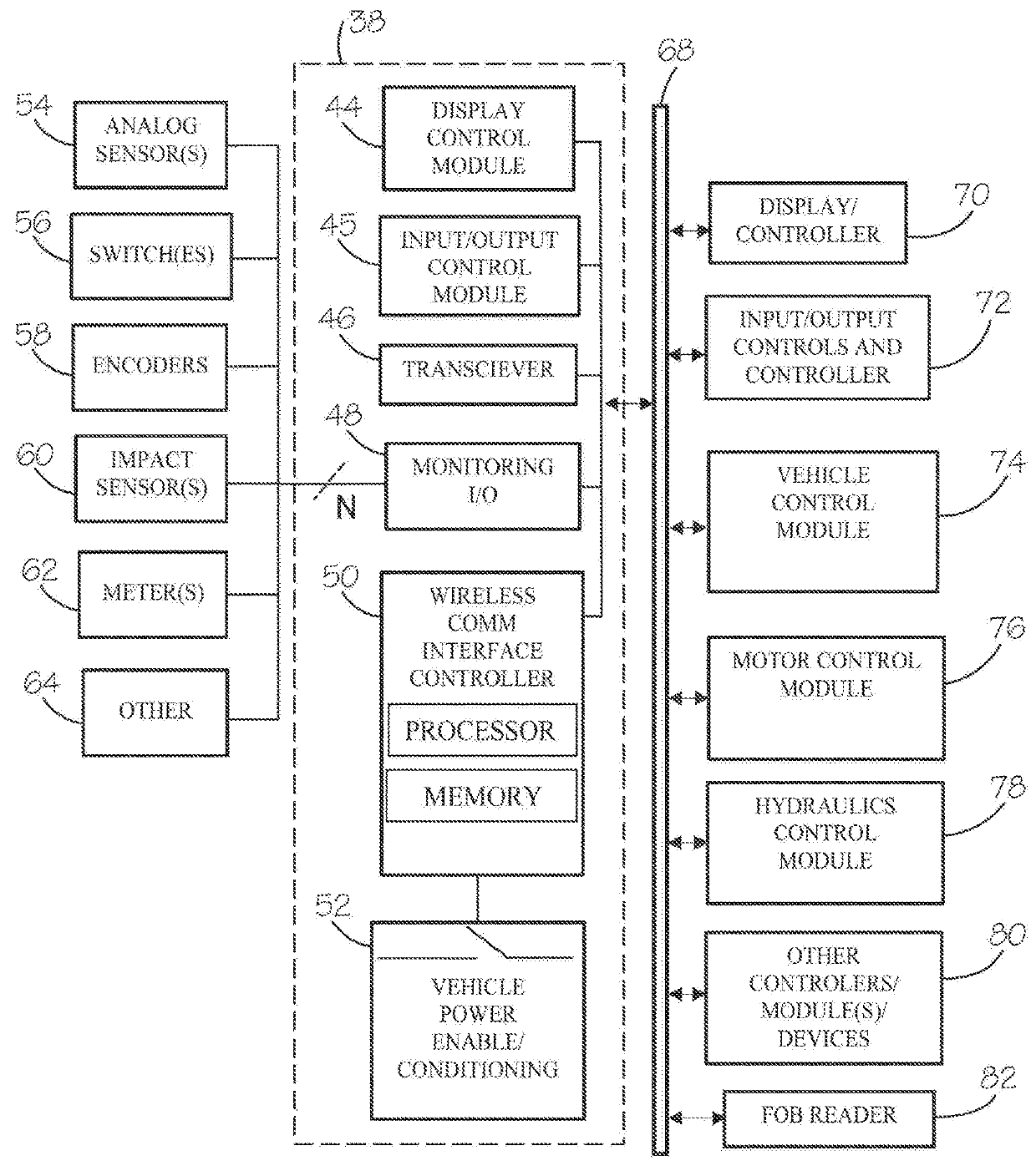

Method and apparatus for virtualizing industrial vehicles to automate task execution in a physical environment

A method and apparatus for virtualizing industrial vehicles to automate task execution in a physical environment is described. In one embodiment, the method includes determining input parameters for controlling vehicle hardware components, wherein the vehicle hardware components comprise actuators that are used to control hardware component operations, generating mappings between the input parameters and the hardware component operations, wherein each of the input parameters is applied to an actuator to perform an corresponding hardware component operation, correlating the mappings with vehicle commands to produce abstraction information and executing at least one task comprising various ones of the vehicle commands using the abstraction information.

Owner:CROWN EQUIP LTD

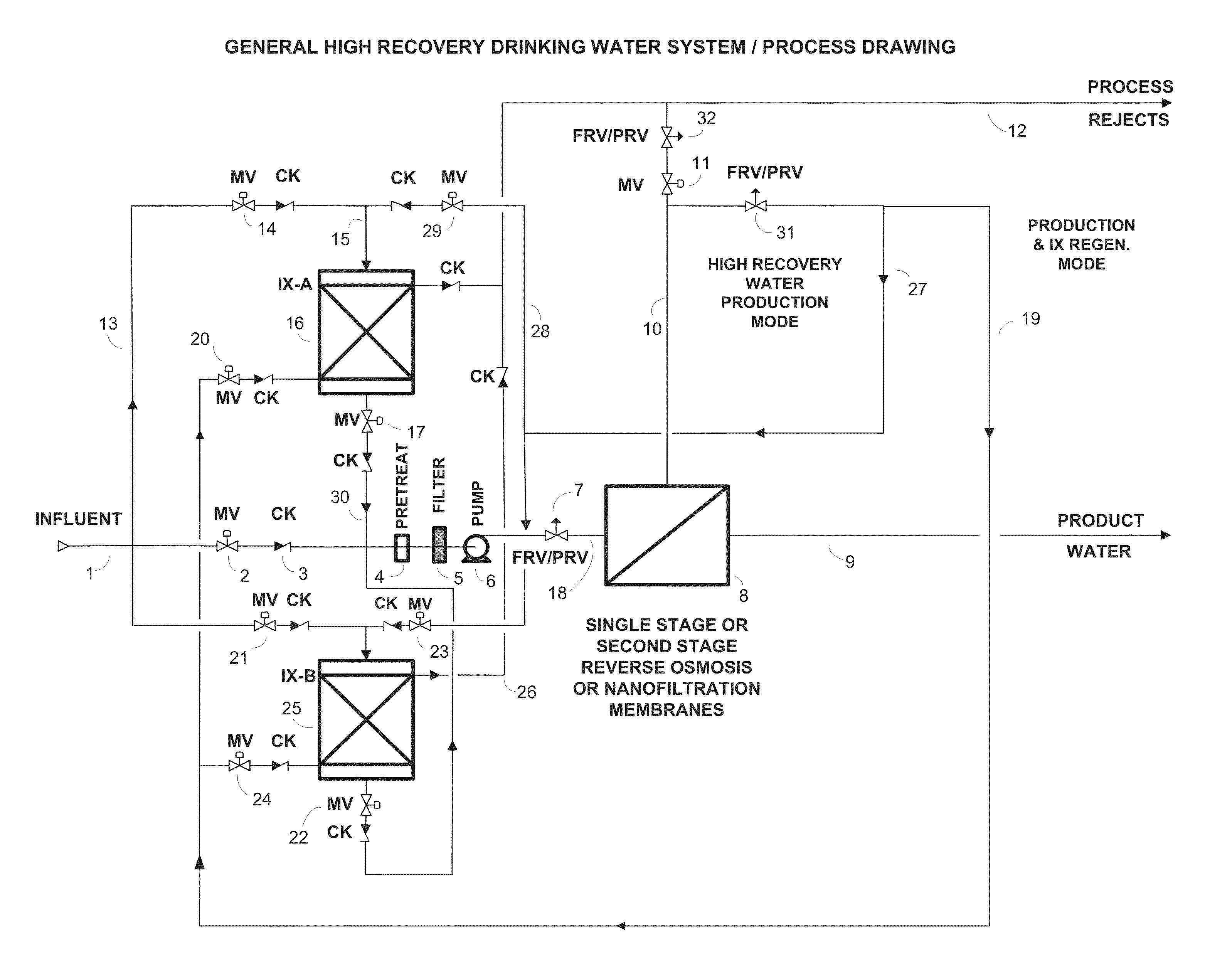

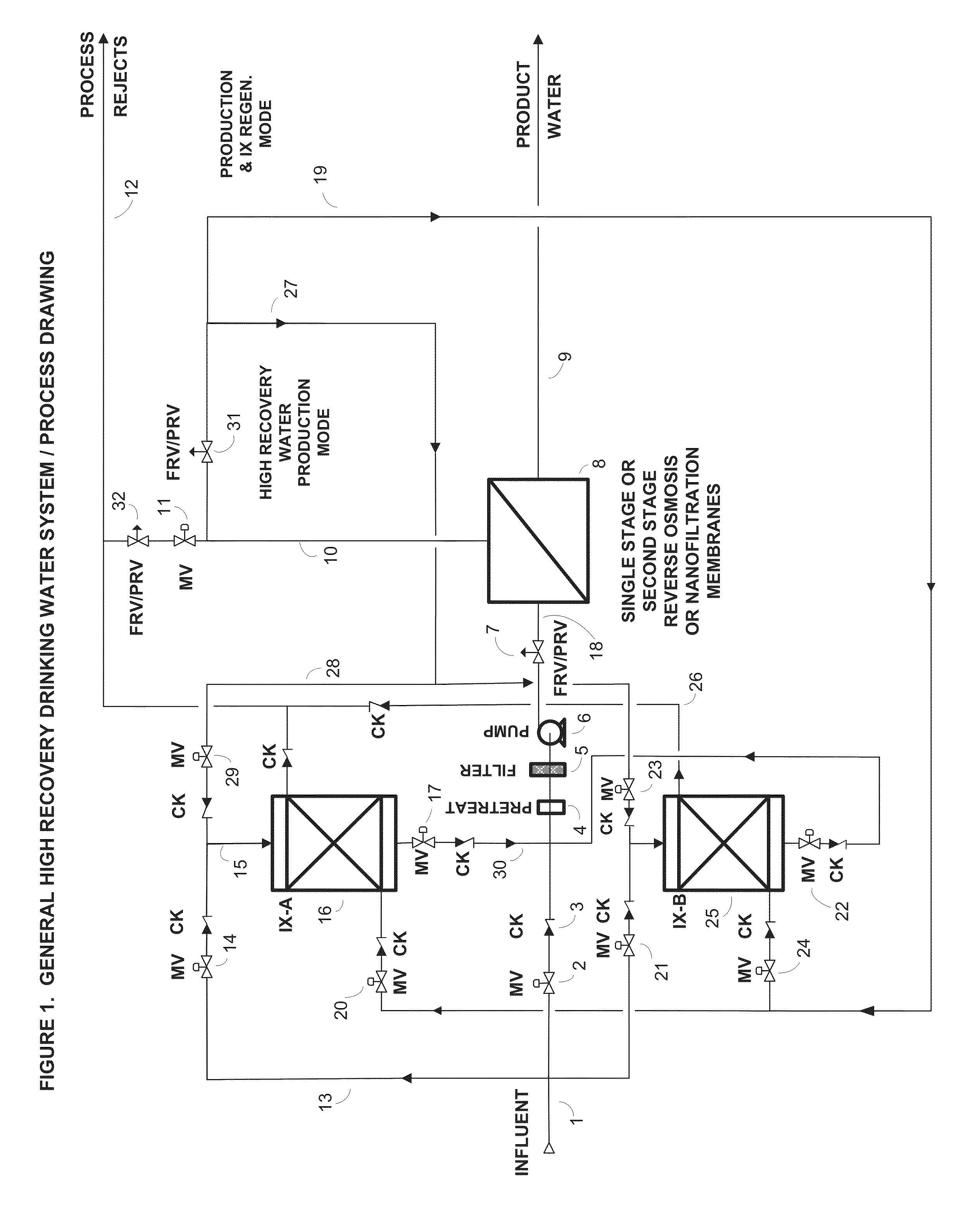

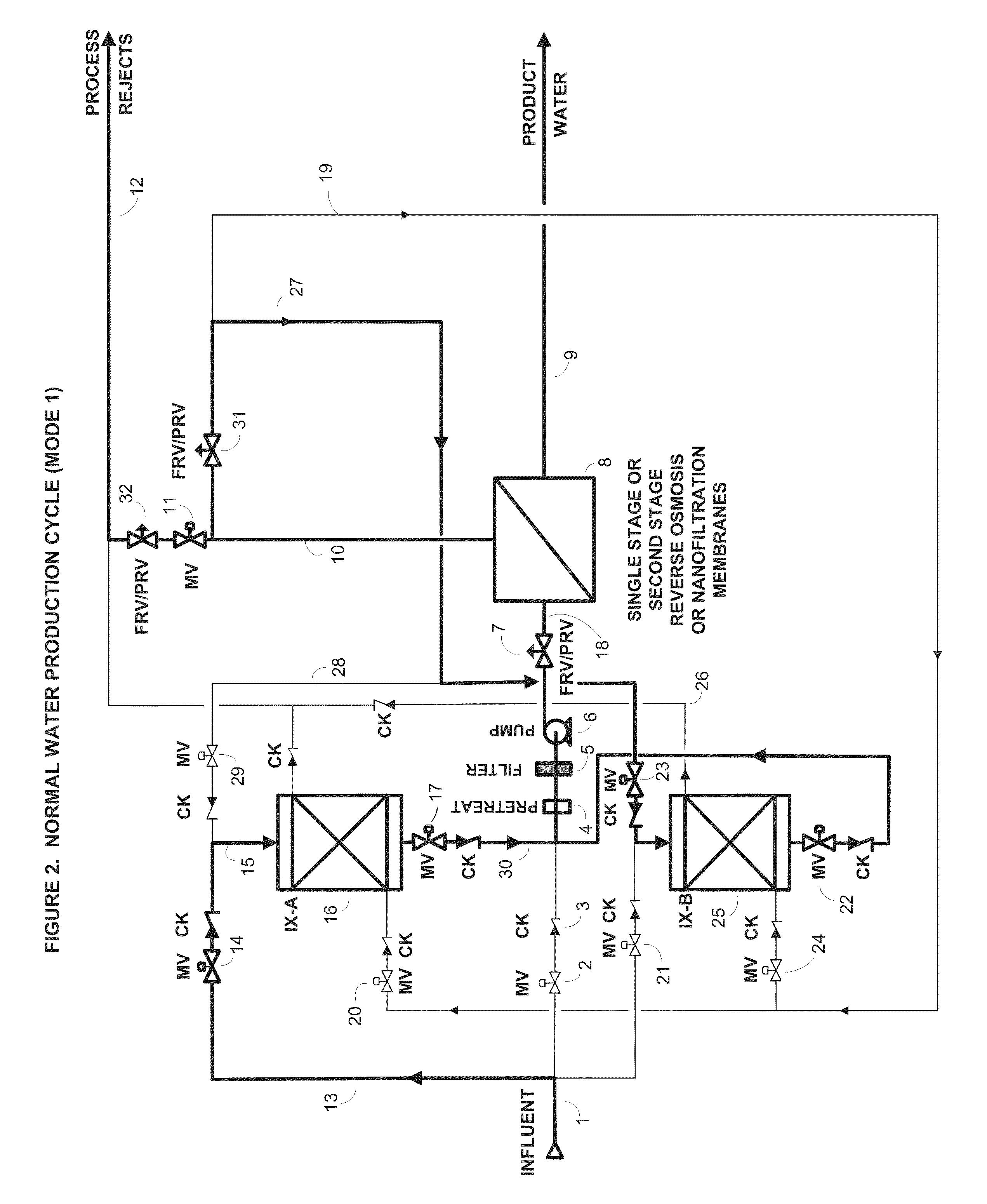

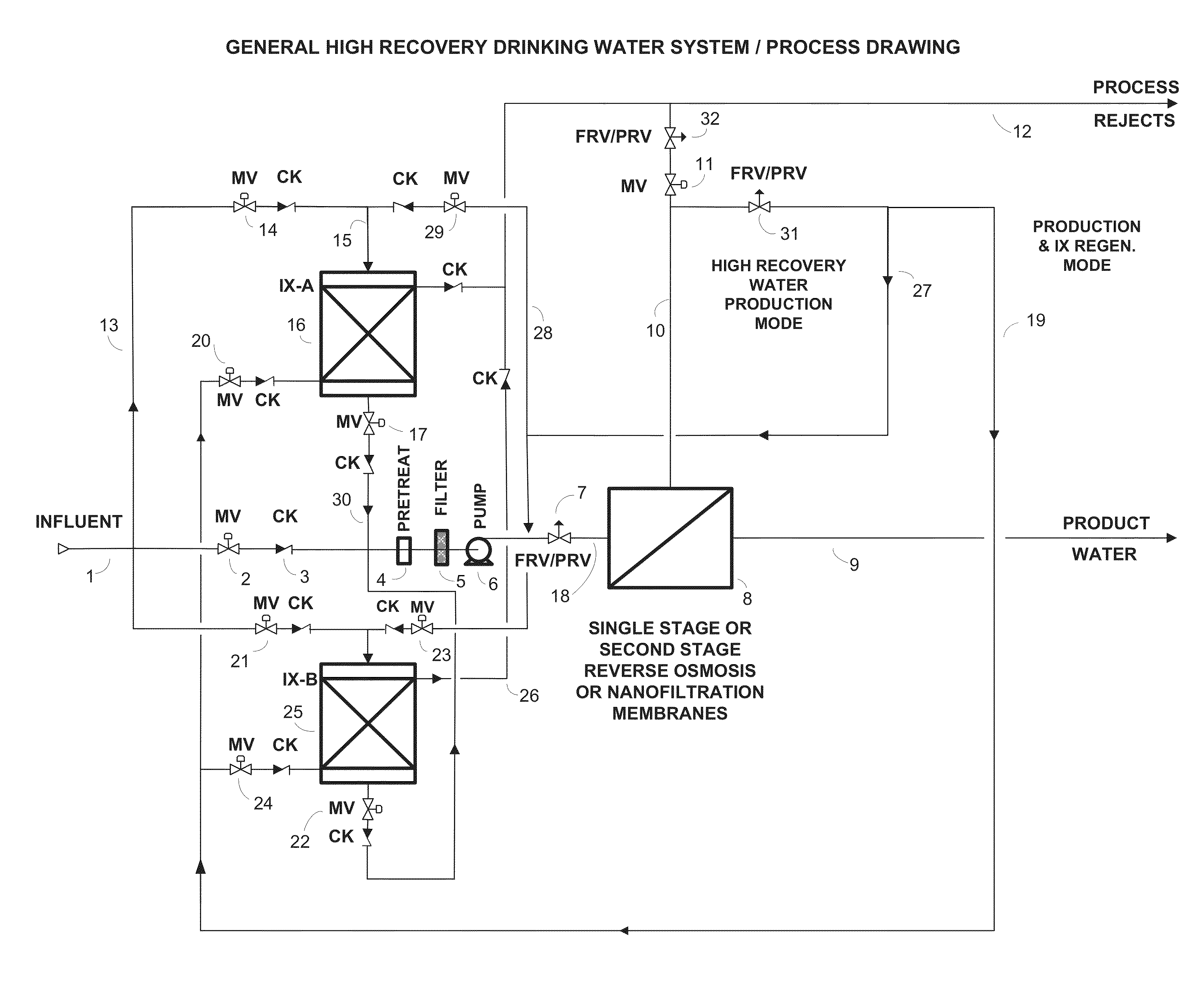

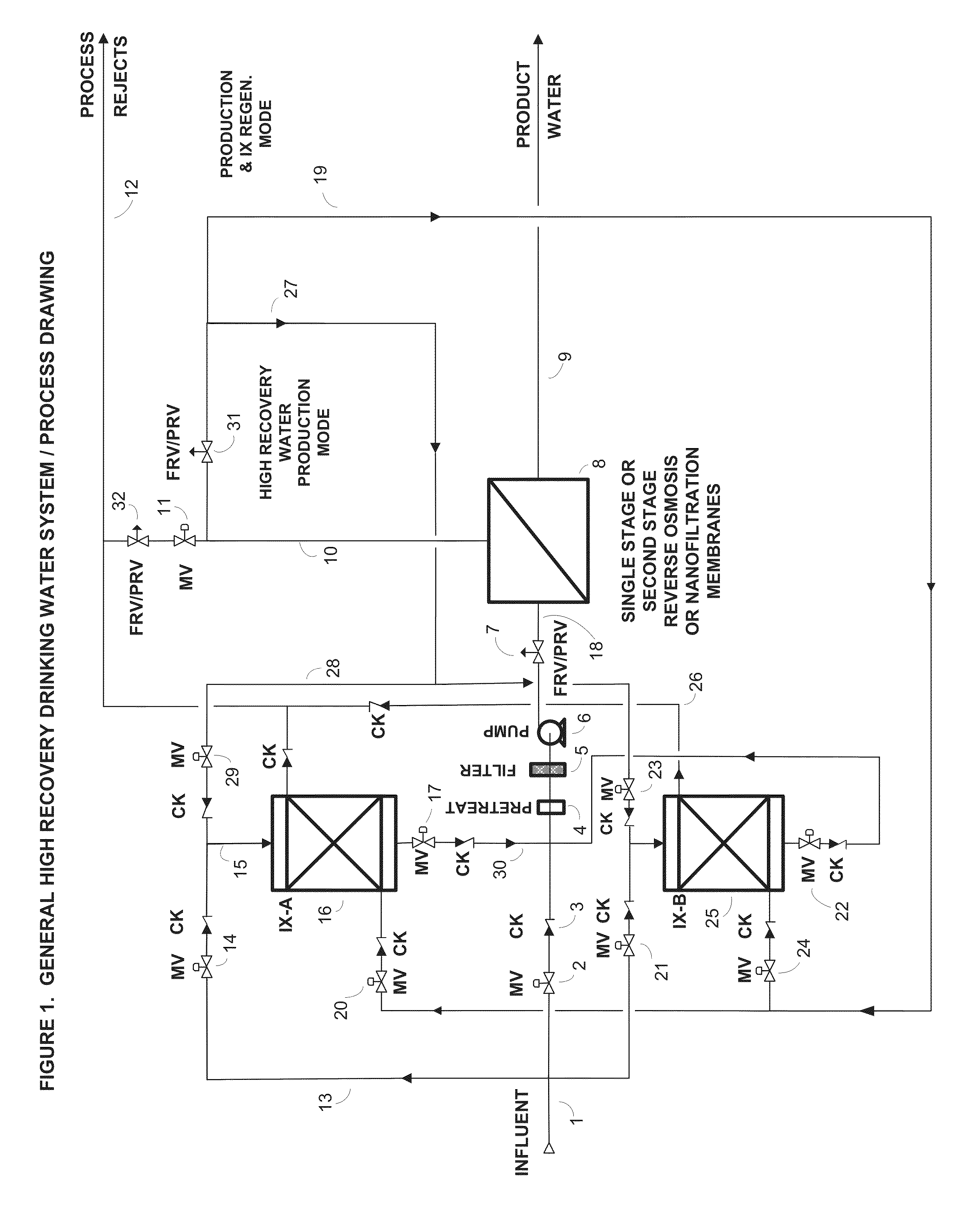

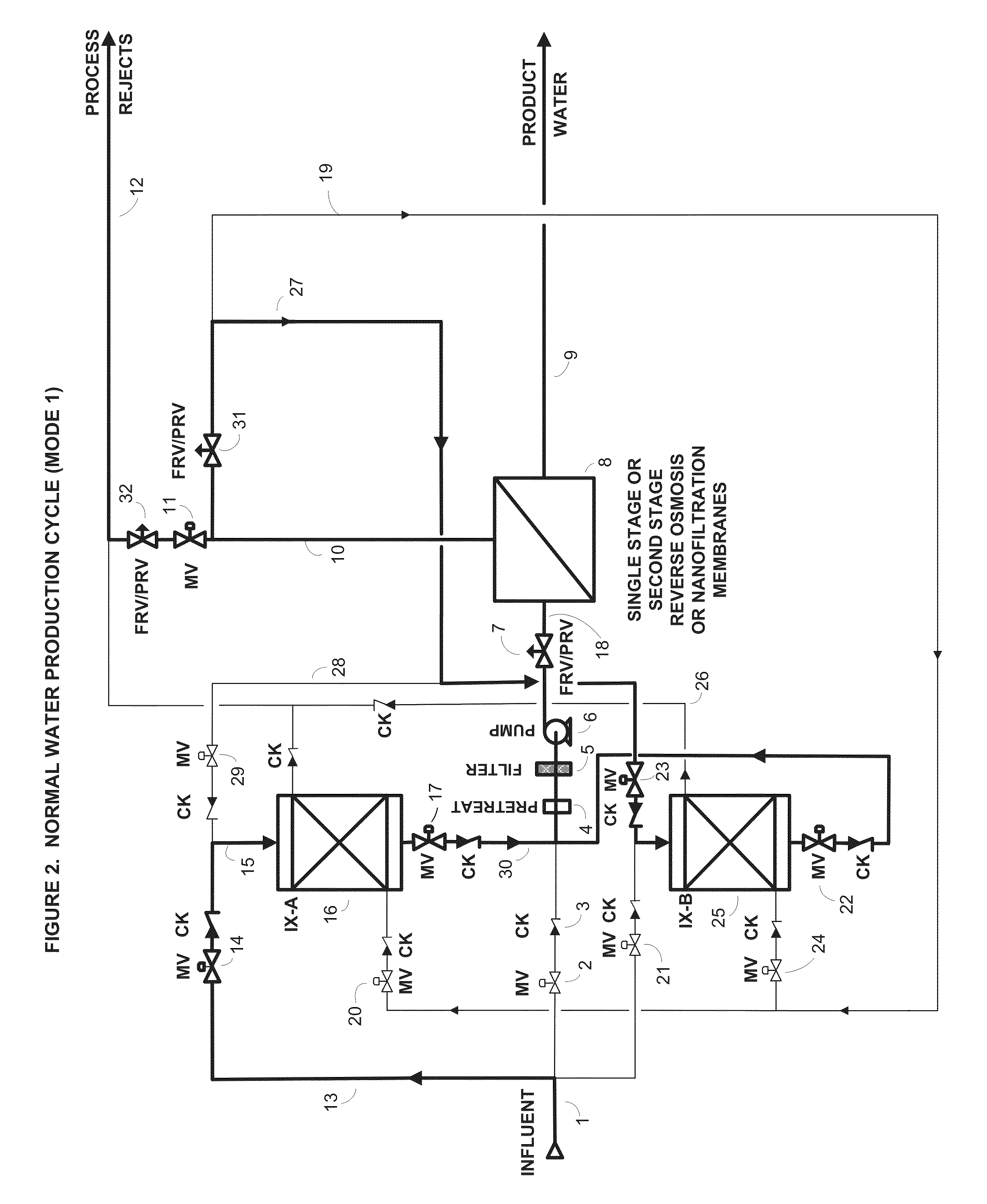

High Recovery Drinking Water Process

ActiveUS20130043190A1High water recoveryEliminate needIon-exchanger regenerationOrganic anion exchangersWater softeningIndustrial effluent

Disclosed is a process that uses reverse osmosis (RO) or nanofiltration (NF) membranes and ion exchange (IX) water softening resins to maximize the production of drinking water, purified industrial service water or recycled purified municipal or industrial effluents. The membrane and ion exchange units are configured in a manner that enables operation of the system at high permeate recoveries in the range 90% to 99%, thus producing purified drinking water with a minimum volume of wastewater to drains and a very low membrane cleaning or membrane replacement frequency. The process mitigates membrane fouling and scale formation and minimizes the use of water treatment chemicals including acidic and alkali solutions and sodium chloride salt that is normally required to regenerate the IX resin.

Owner:AL SAMADI RIAD A

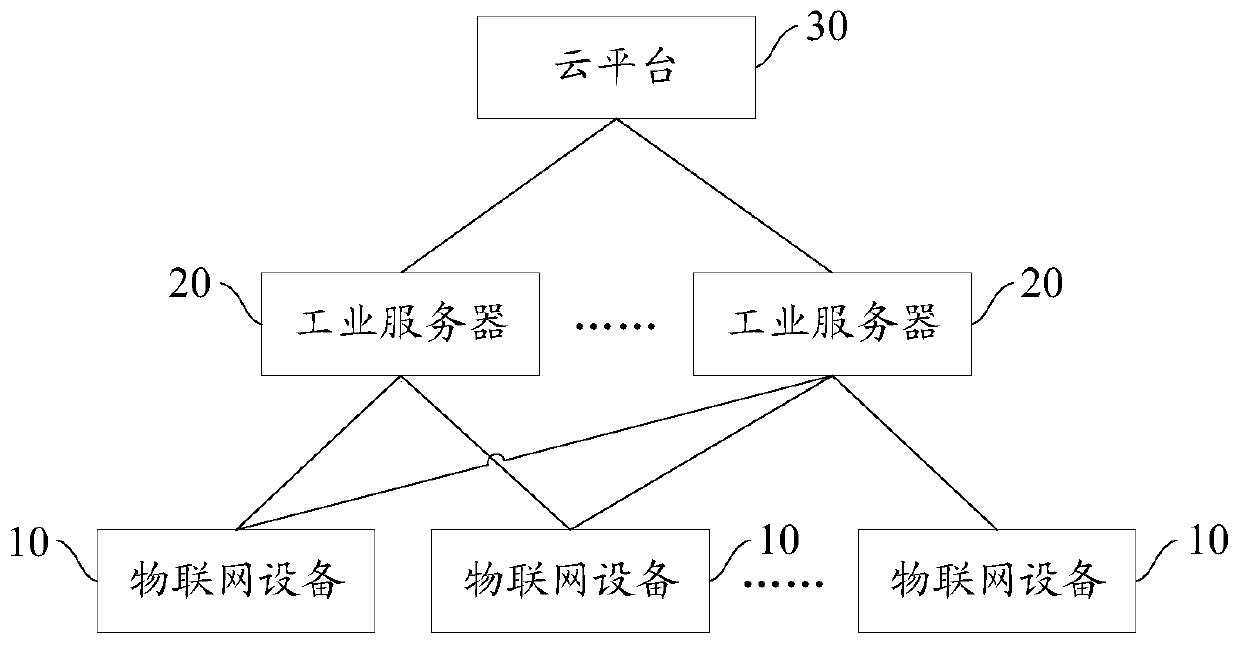

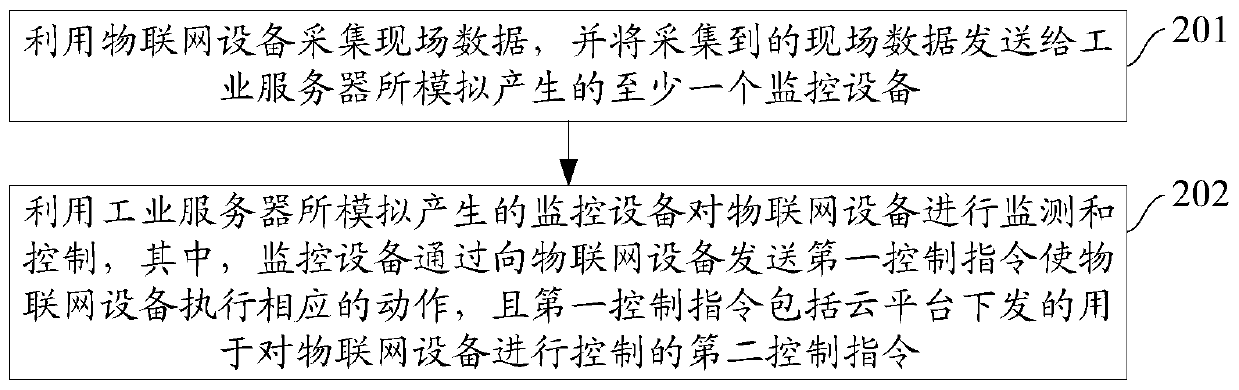

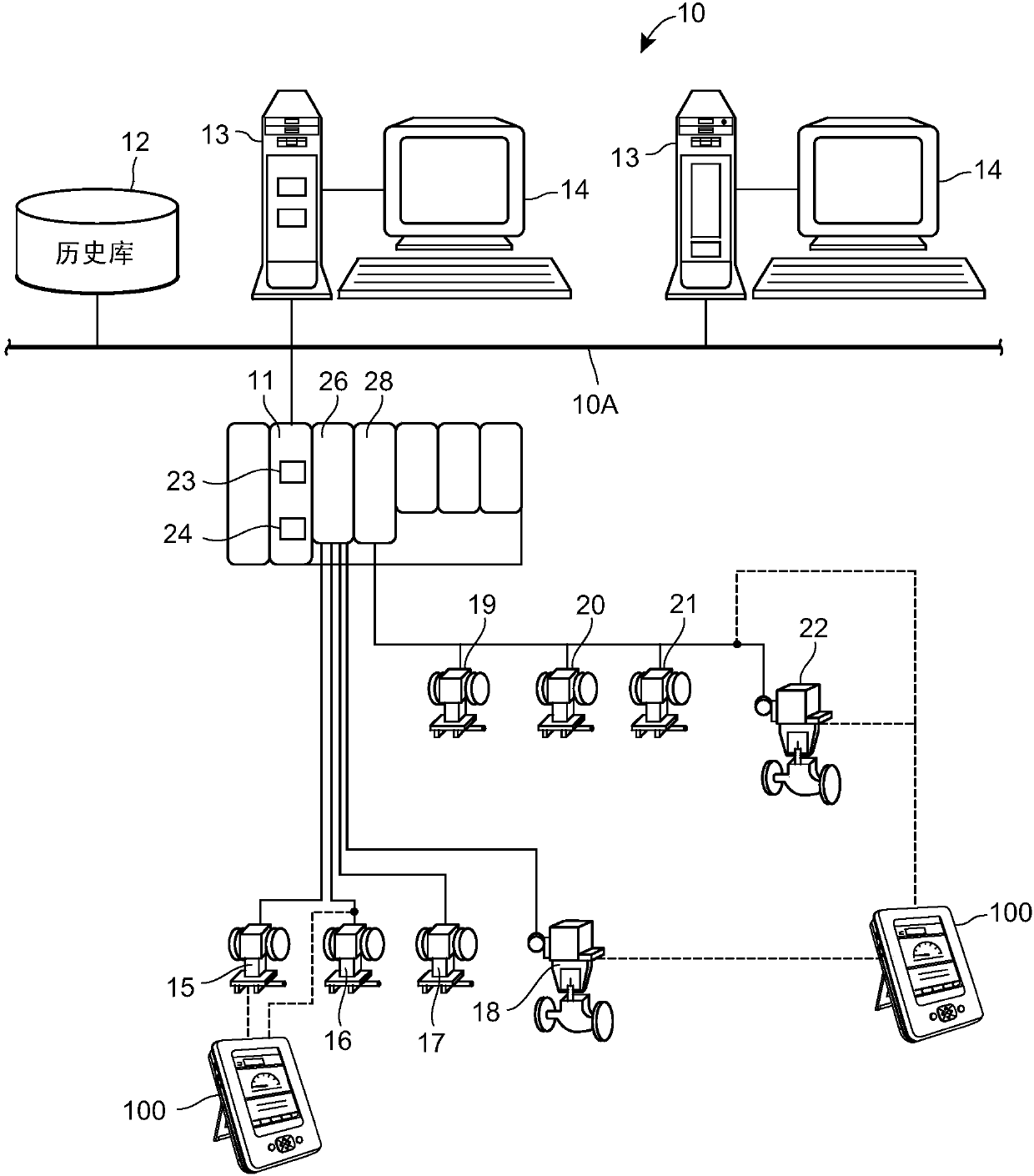

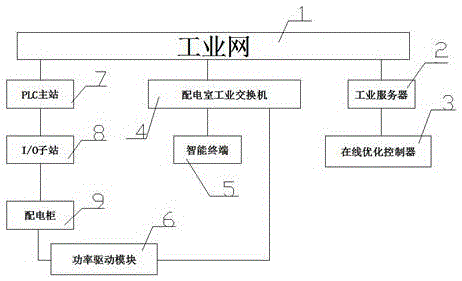

Internet-of-things platform and internet-of-things equipment monitoring method

ActiveCN110609512AImprove applicabilityProgramme control in sequence/logic controllersThe InternetField data

The invention provides an internet-of-things platform and an internet-of-things equipment monitoring method. The internet-of-things platform comprises at least one piece of internet-of-things equipment, at least one industrial server and a cloud platform. The industrial servers are used for simulating generation of at least one piece of monitoring equipment, wherein the monitoring equipment is used for monitoring and controlling the at least one piece of internet-of-things equipment. The internet-of-things equipment is used for sending collected field data to the at least one piece of monitoring equipment and executing corresponding actions according to first control instructions from the at least one piece of monitoring equipment. The cloud platform is used for receiving first data uploaded by the industrial servers and issuing second control instructions used for controlling the internet-of-things equipment to the industrial servers. The scheme can improve the applicability of the internet-of-things platform.

Owner:ENN CHINA GAS ENVESTMENT

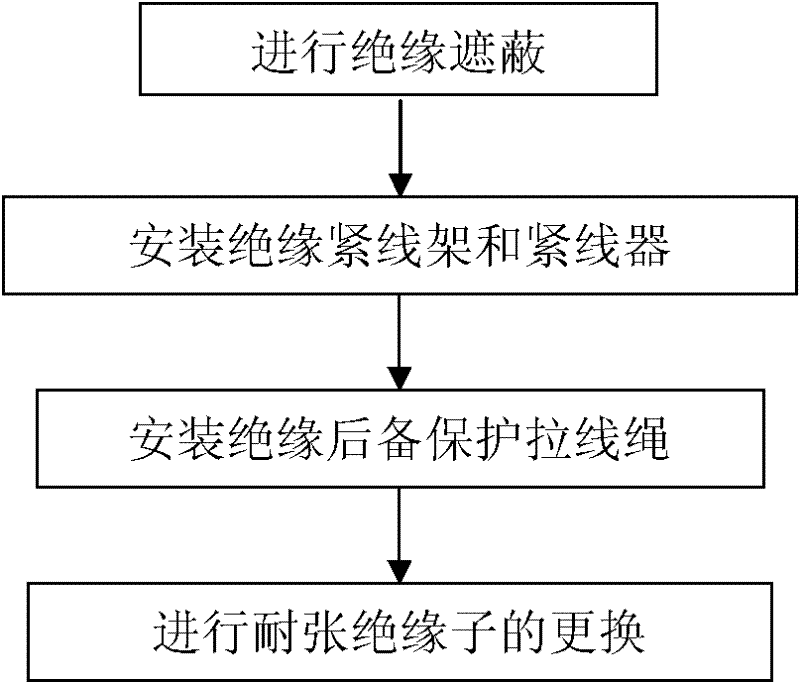

Method for changing tension simulators from live 10kV power supply line

InactiveCN102545094AEnsure safe and normal power supplyReduce adverse effectsApparatus for overhead lines/cablesQuality of serviceIndustrial service

The invention discloses a method for changing tension simulators on live 10kV power supply line, which includes steps: firstly, confirming weather conditions; secondly, preparing; thirdly, changing the tension insulators on the live 10kV power supply line and includes step 1 insulation shielding, step 2 mounting insulating tightening racks and insulating tighteners, step 3 mounting backup insulating protective pull cords, and step 4 changing the tension insulators. The method can change defective tension insulators timely when the power supply line supplies power normally, guarantee safe and normal power supply of the power supply line, avoid adverse effects of power outage upon power supply enterprises and power consumers, improve power supply reliability, increase power sales, improve industrial service quality, and guarantee uninterrupted power supply for the consumers.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

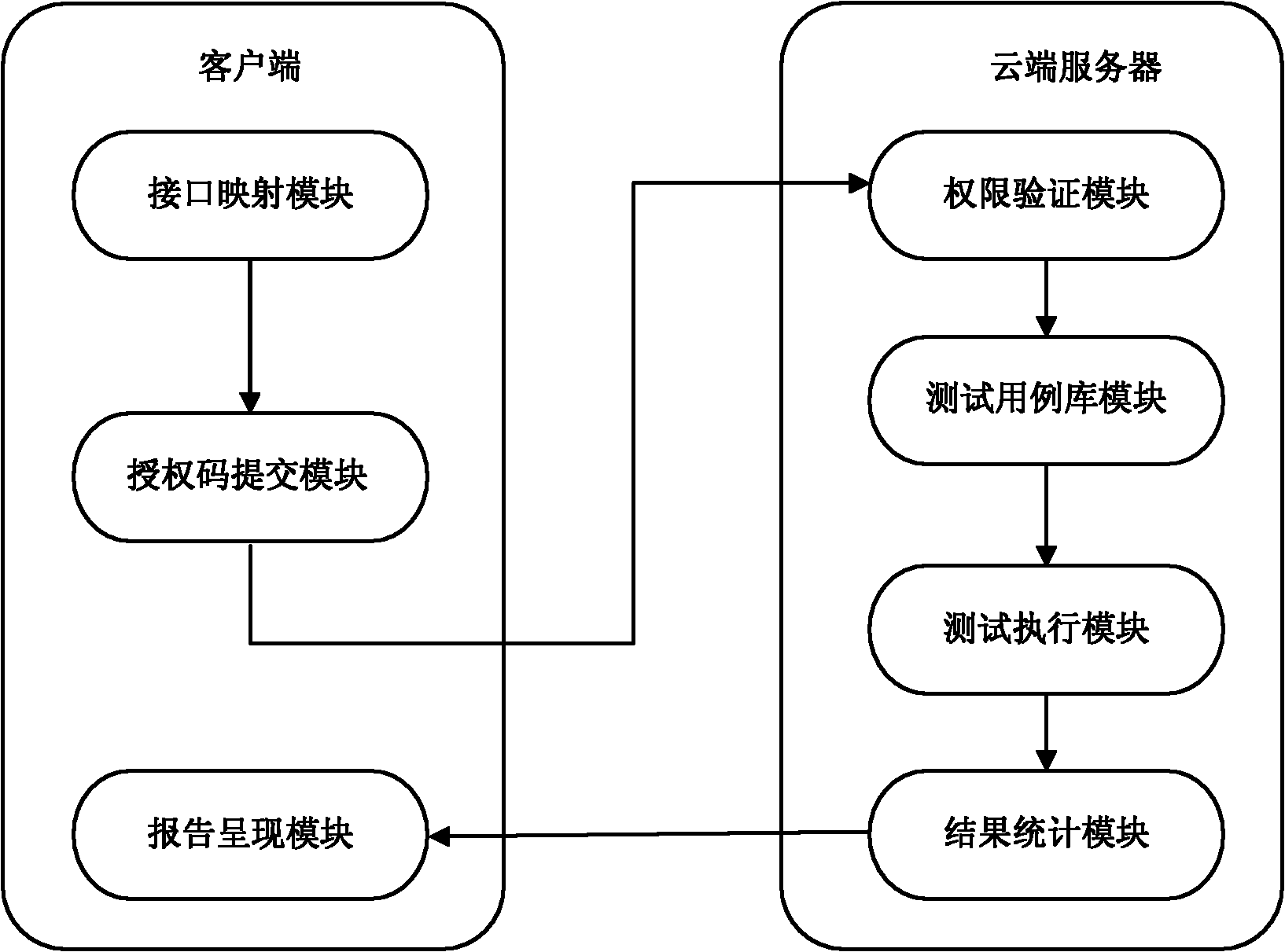

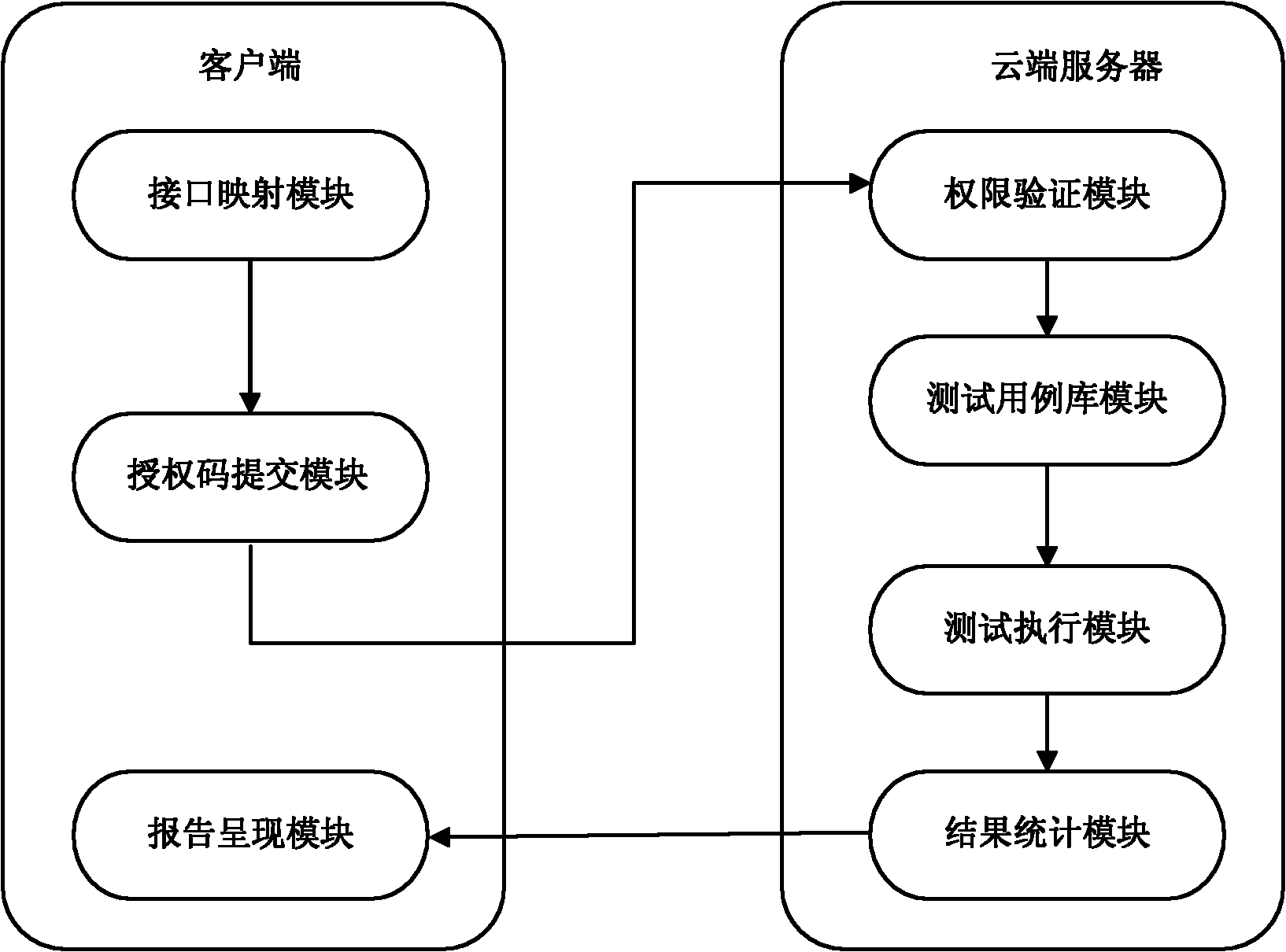

Cloud test device and method for general software system

InactiveCN102103540AImprove the efficiency of test executionReduced development effortSoftware testing/debuggingSpecific testTest script

The invention discloses a cloud test device for a general software system. The cloud test device for the general software system comprises a cloud server and a client; the cloud server comprises a cloud permission verification module, a test case library module which is preset and divided according to a service process in an industry, a test execution module and a test result counting module; and the client comprises an interface variable mapping module, a cloud test authority code submitting module and a test result counting report displaying module. The invention also discloses a cloud test method for the general software system. By the device and the method, repeated manual work of a test plan and a design of the industrial general software system can be reduced, so the work of a talent who is skillful at a certain industrial service is separated from a specific test case to the maximum extent, the test execution efficiency of the industrial general software system is improved, and the development and maintenance working capacity and difficulty of a needed automatic test script can be lowered.

Owner:ZHENJIANG RETECH INFORMATION TECH

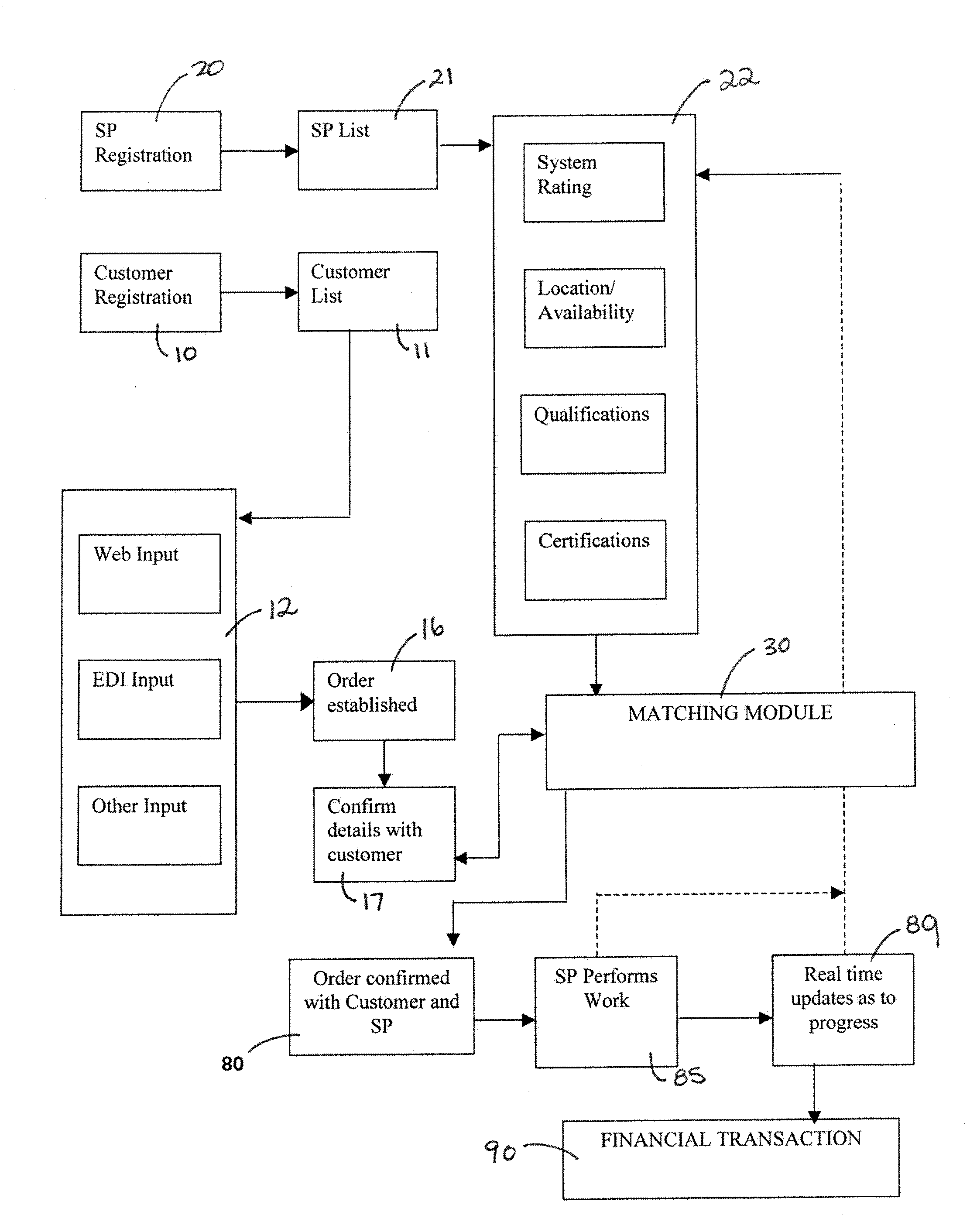

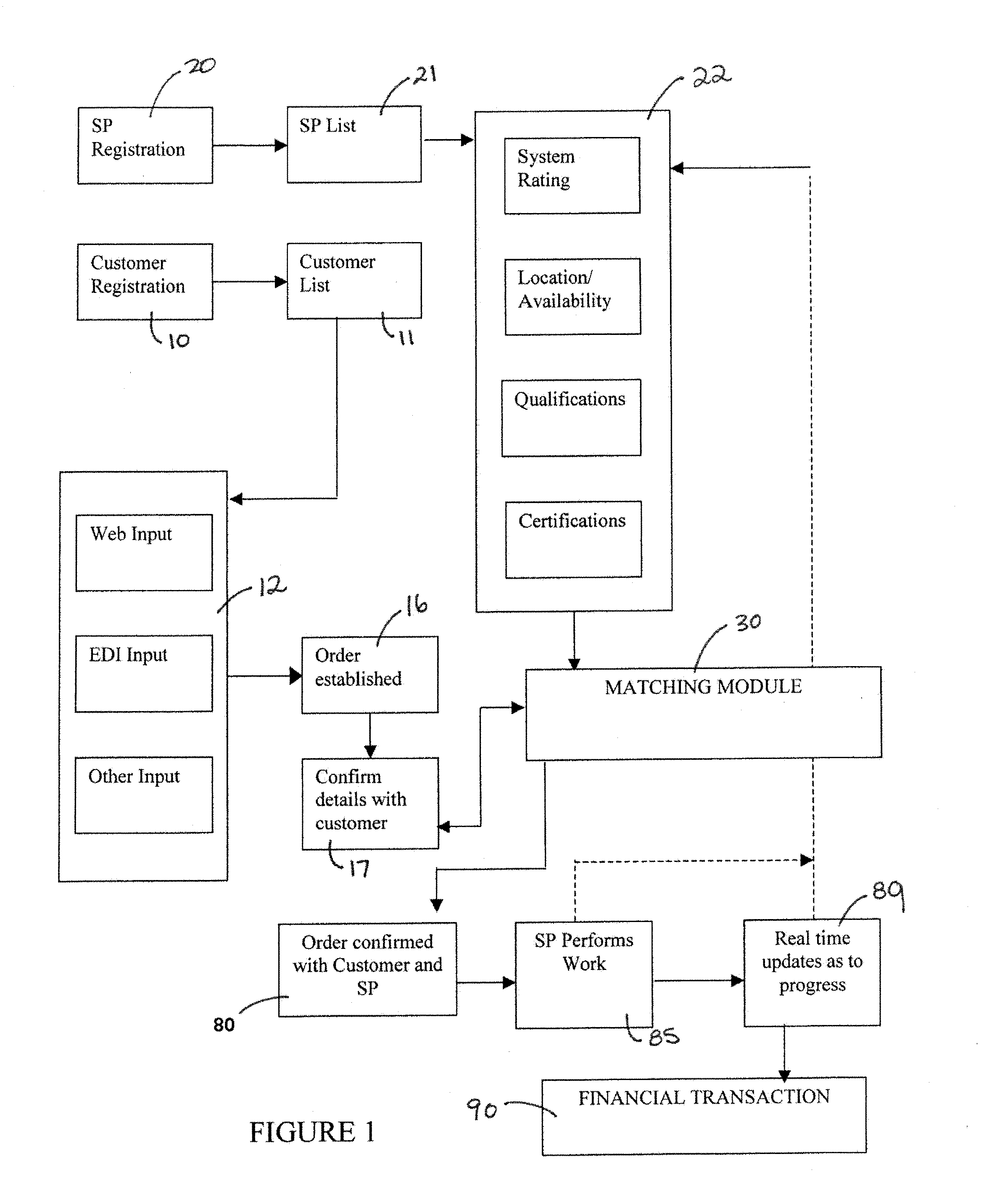

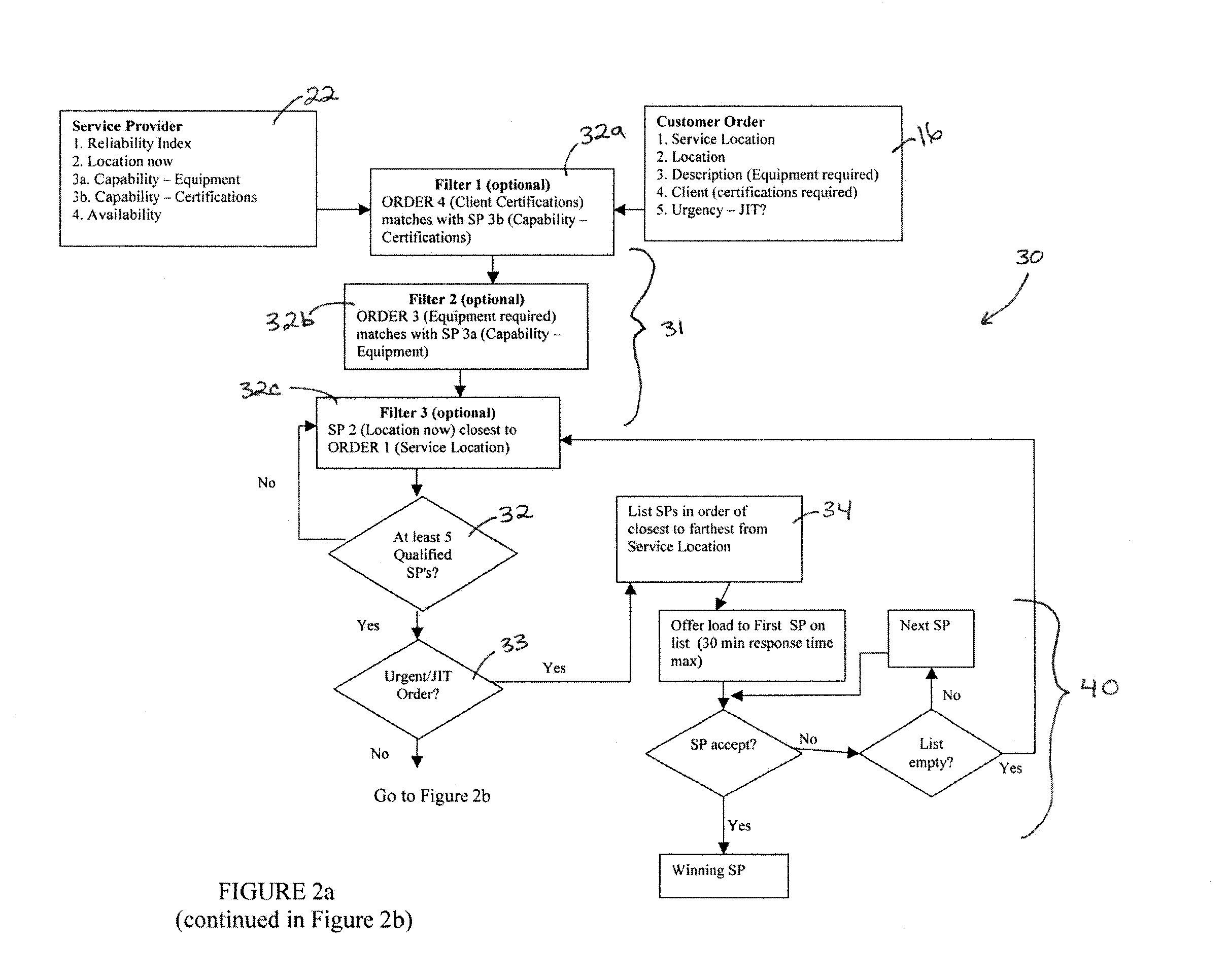

Method and system for brokering industrial service contracts

A system and method for brokering industrial service contracts is described. The system registers customer users and service provider users. Further, customers may enter order data corresponding to a request for industrial service. Service provider users may enter qualification data corresponding to their ability or capacity to take on service contracts. The system implements a matching module based on the customer user-entered order data to generate a ranked list of suitable service provider users. Sequential offers are made to the qualified service providers in ranked order until an offer is accepted.

Owner:WERKLUND DAVID PAUL MR

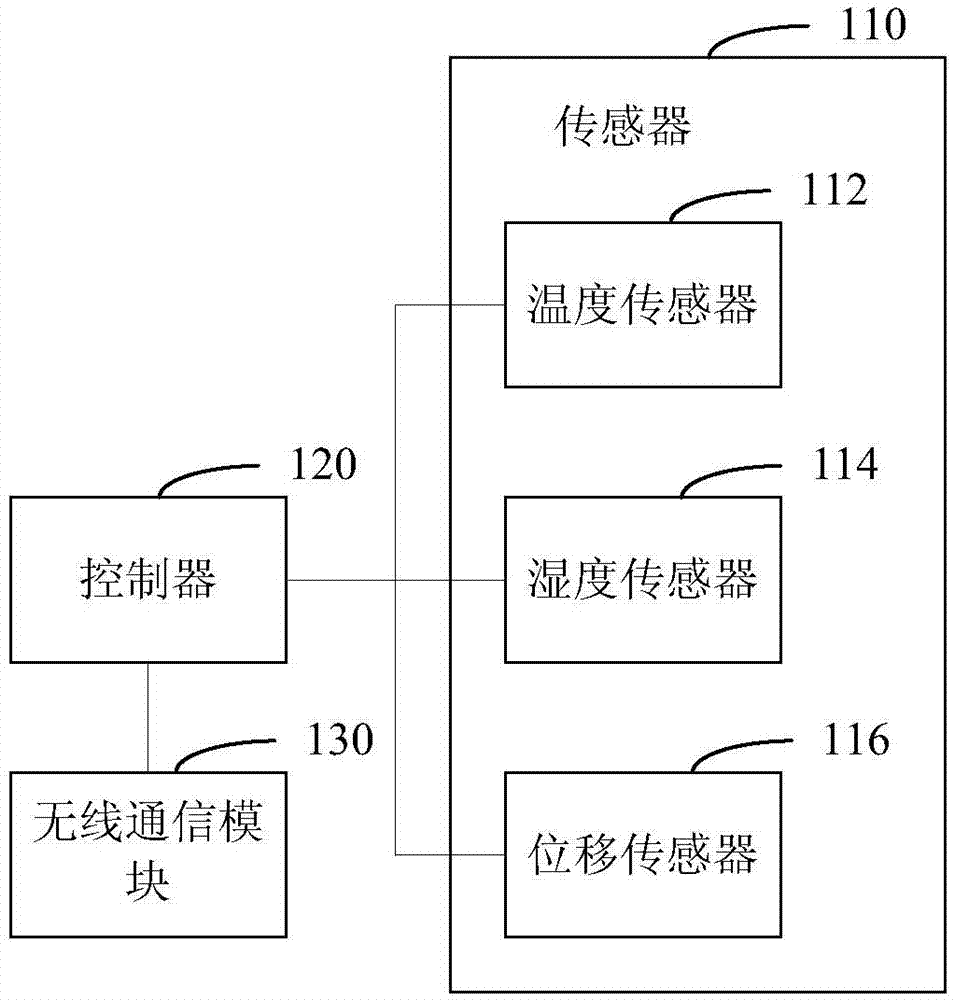

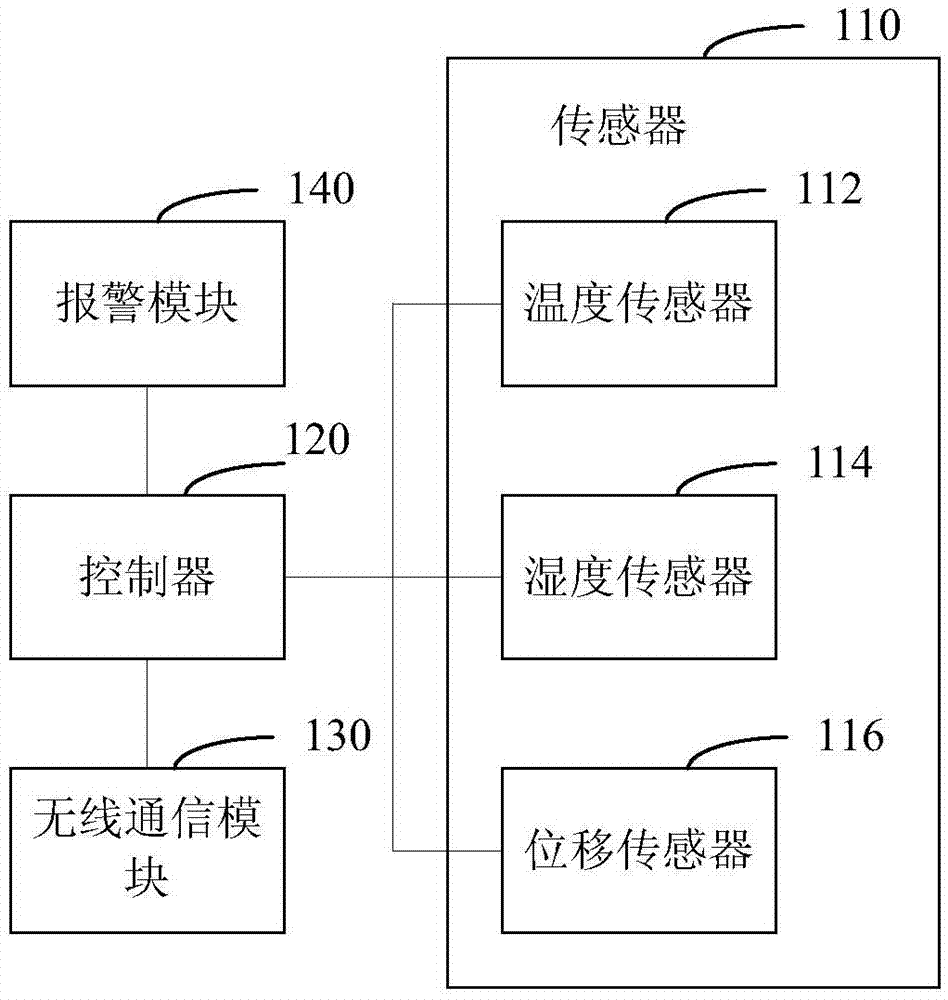

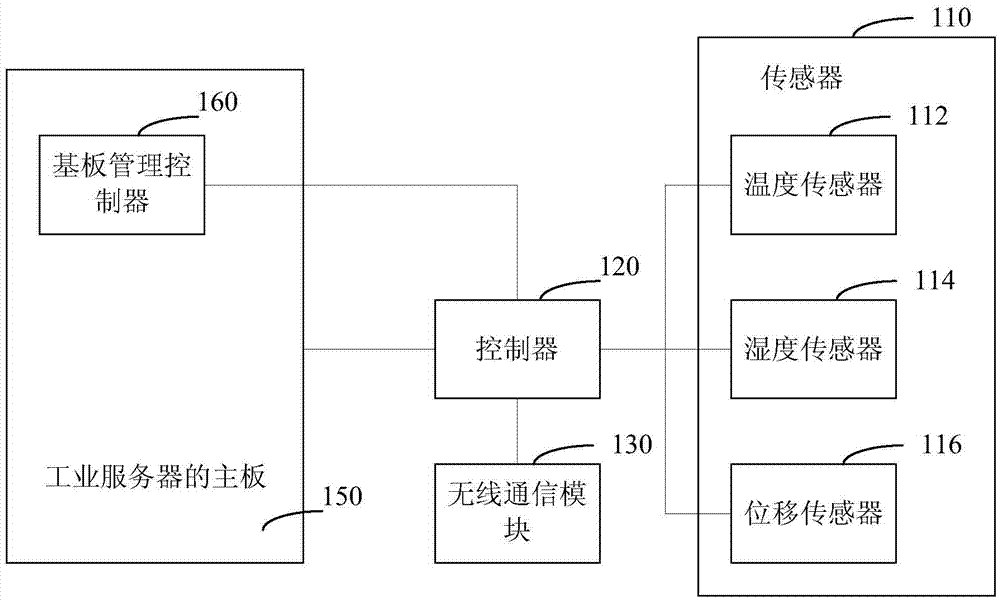

System and method of monitoring working environment of industrial server

The invention relates to a system and a method of monitoring the working environment of an industrial server. The monitoring system comprises a sensor, a controller, and a wireless communication module, wherein the sensor is used for acquiring parameter values of the working environment of the industrial server in real time; the controller is connected with the sensor for receiving the parameter values of the working environment of the industrial server acquired by the sensor, acquiring warning parameter values according to the parameter values of the working environment, comparing the warning parameter values with a corresponding parameter threshold range, generating an alarming message if the warning parameter values exceed the parameter threshold range and transmitting the alarming message to a monitoring center or a maintenance person through the wireless communication module; and the wireless communication module is connected with the controller. According to the system and the method of monitoring the working environment of the industrial server, if the parameter threshold range is exceeded, the alarming message is transmitted to the monitoring center or the maintenance person, the monitoring center or the maintenance person can find out fault of the industrial server, and timely maintenance is facilitated.

Owner:EVOC INTELLIGENT TECH

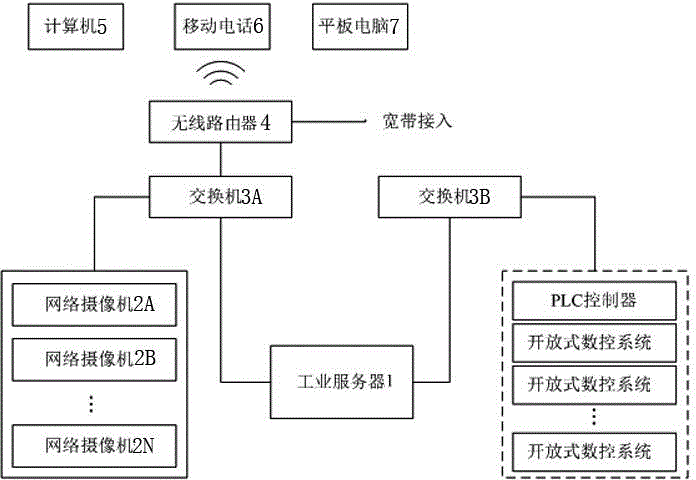

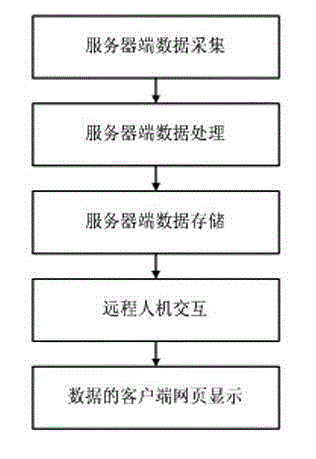

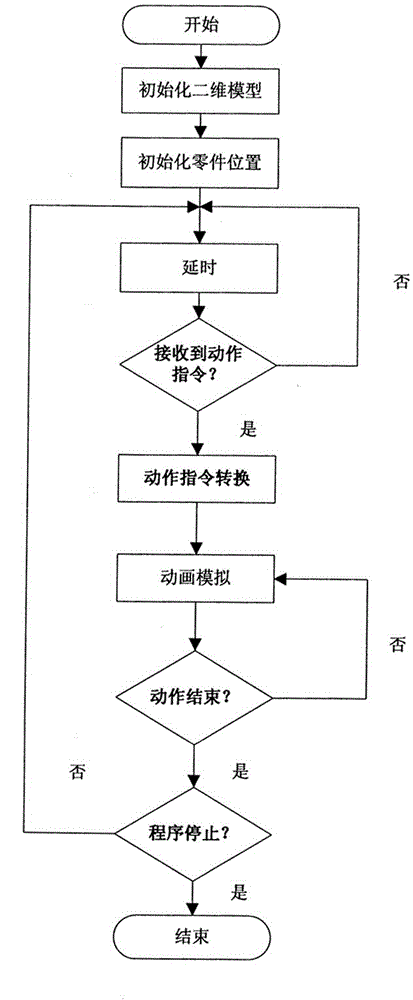

B/S-architecture-based cross-platform remote monitoring system for numerical control machining production line

InactiveCN104570980ARealize online transmissionSave the trouble of installing client softwareNetwork topologiesClosed circuit television systemsData informationIp address

The invention discloses a B / S-architecture-based cross-platform remote monitoring system for a numerical control machining production line and relates to a production line monitoring system in the field of numerical control machining. The system consists of an industrial server, a plurality of network cameras, two switches, a wireless router and terminal equipment, wherein one of the switches is networked with the corresponding network camera mounted at each station, and the other switch is networked with an open-type numerical control system of a numerical control machine tool in the production line and a PLC; the industrial server is used for collectively processing data information acquired by the switches and storing the data information to a database; the terminal equipment is connected with the industrial server through the router or the internet to complete checking and monitoring of the data information of the production line. According to the B / S-architecture-based cross-platform remote monitoring system for the numerical control machining production line, a B / S-architecture-based network monitoring mode is adopted, and the functions of real-time video monitoring, real-time animated simulation and the like are achieved. By inputting a domain name or an IP address into a browser on a terminal computer or a mobile phone, the numerical control machining production line can be remotely monitored.

Owner:通用技术集团沈阳机床有限责任公司

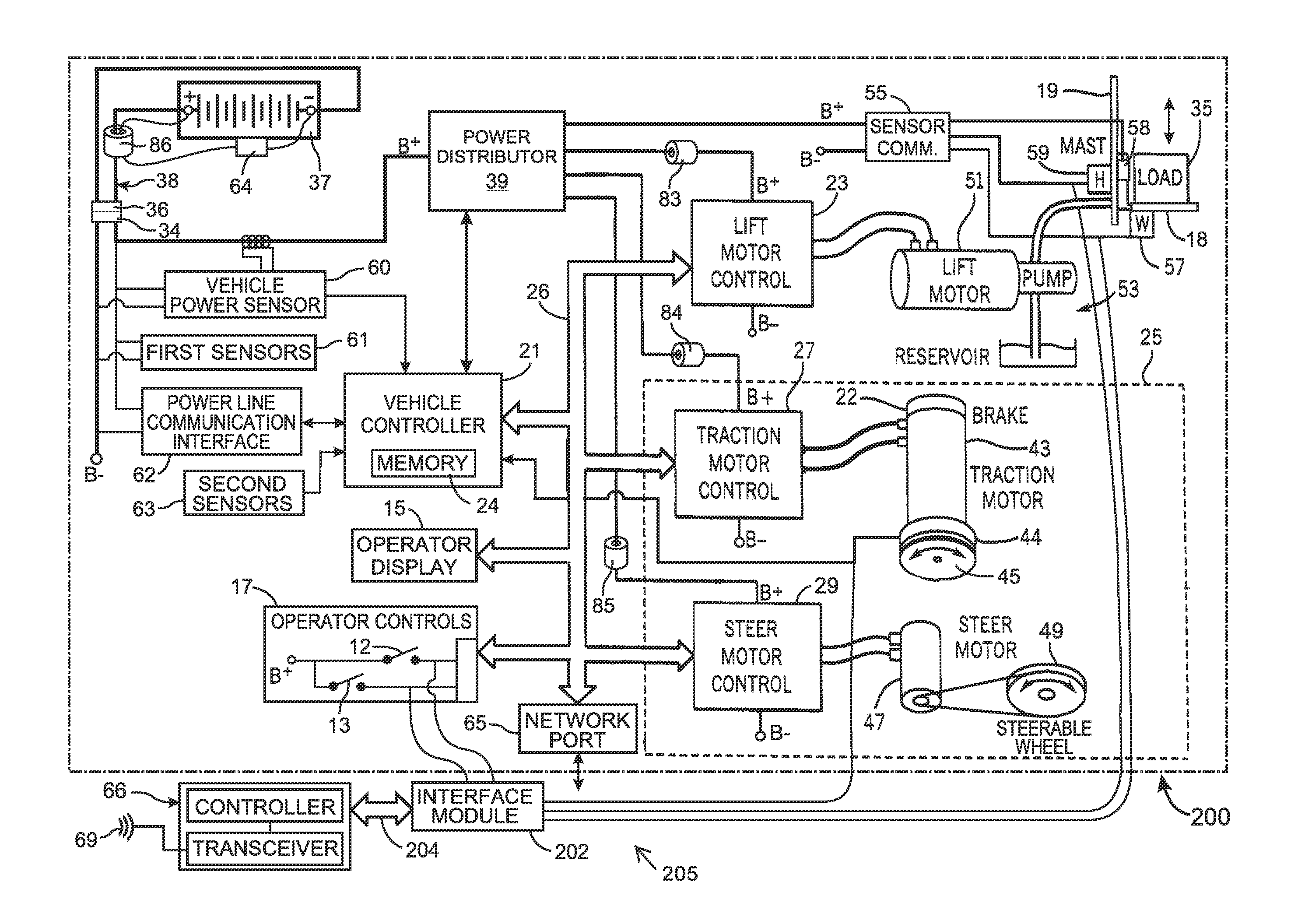

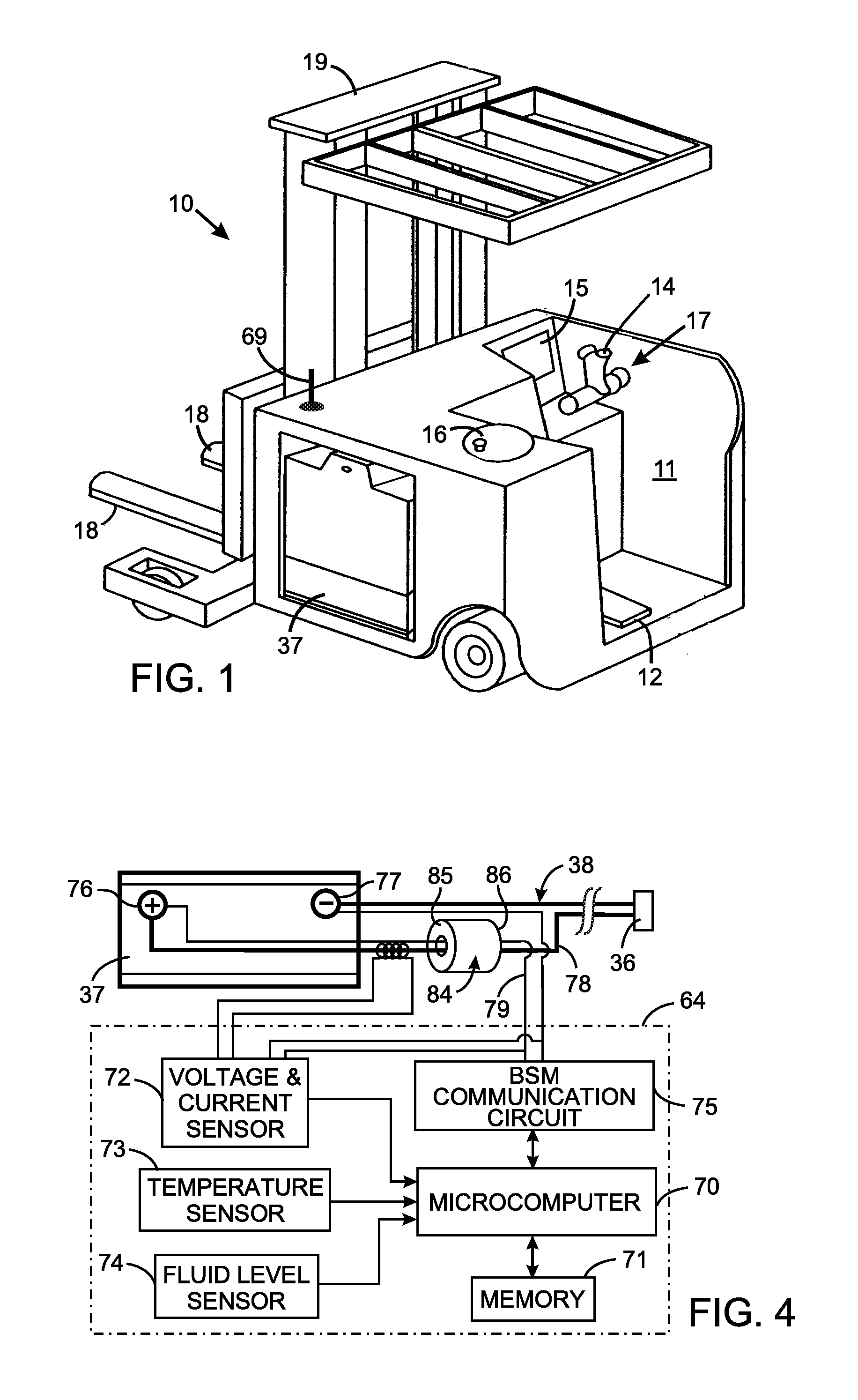

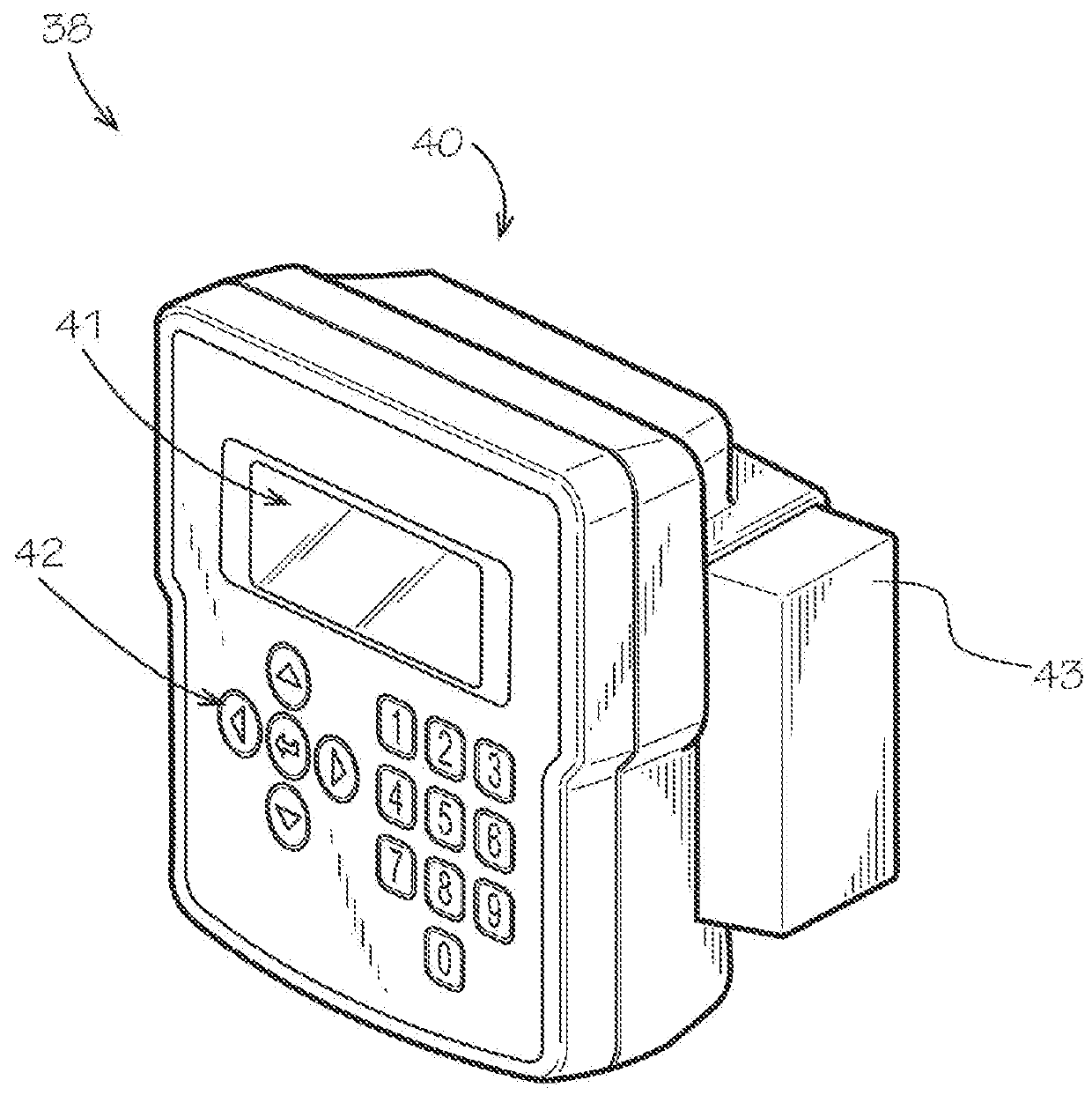

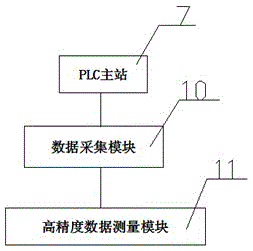

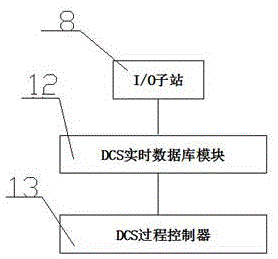

System for gathering data from an industrial vehicle

Operation of an industrial vehicle is managed by systems onboard that vehicle. One such management system monitors operation of vehicle components and produces performance data which is transmitted to an computer at the facility in which the industrial vehicle operates. That system includes an interface module with a plurality of inputs for receiving signals from components on the industrial vehicle. The interface module derives performance data from the signals and conveys the performance data over a communication network. A data acquisition module receives the performance data from the communication network and has a communicator for wirelessly transmitting the performance data.

Owner:RAYMOND LTD

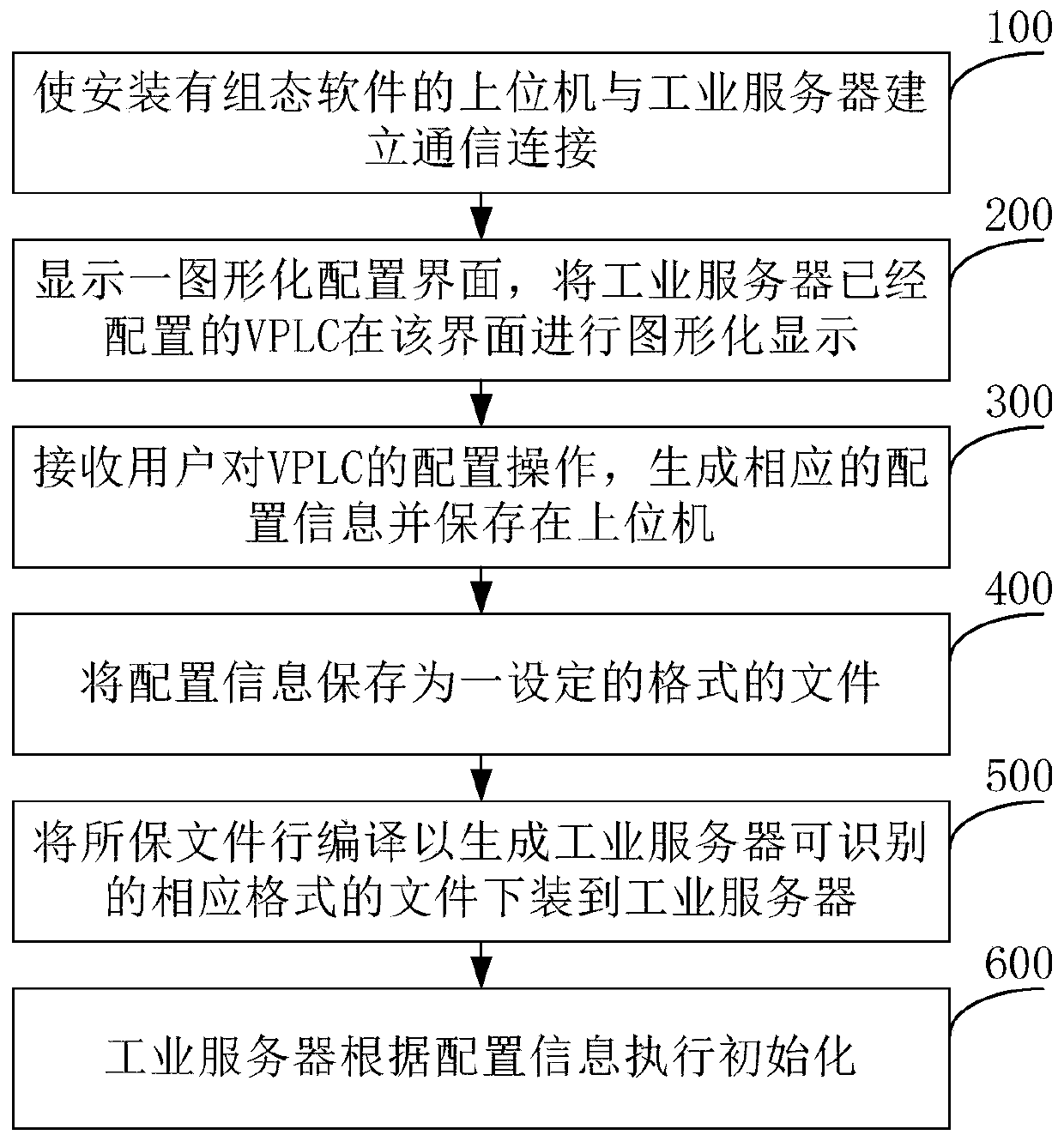

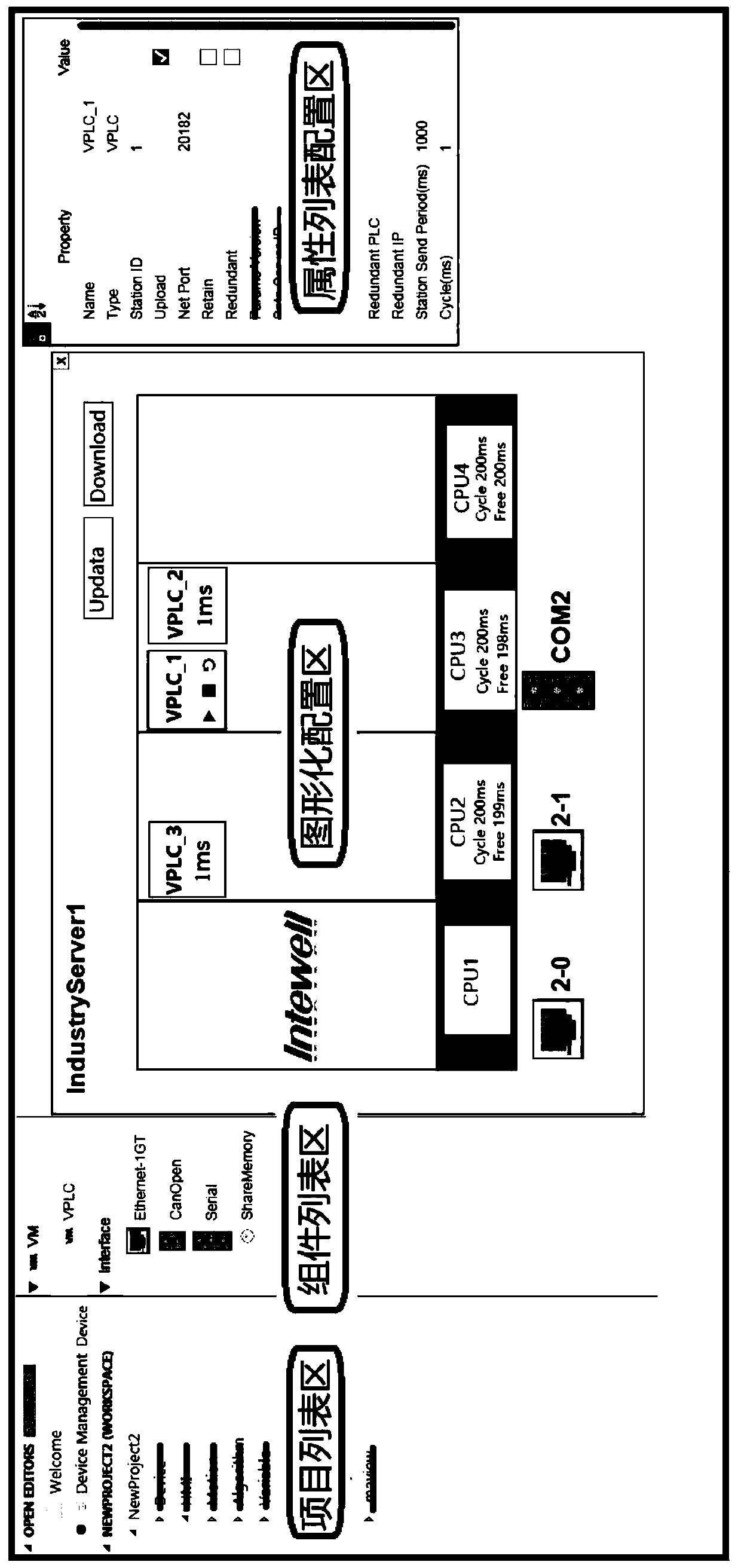

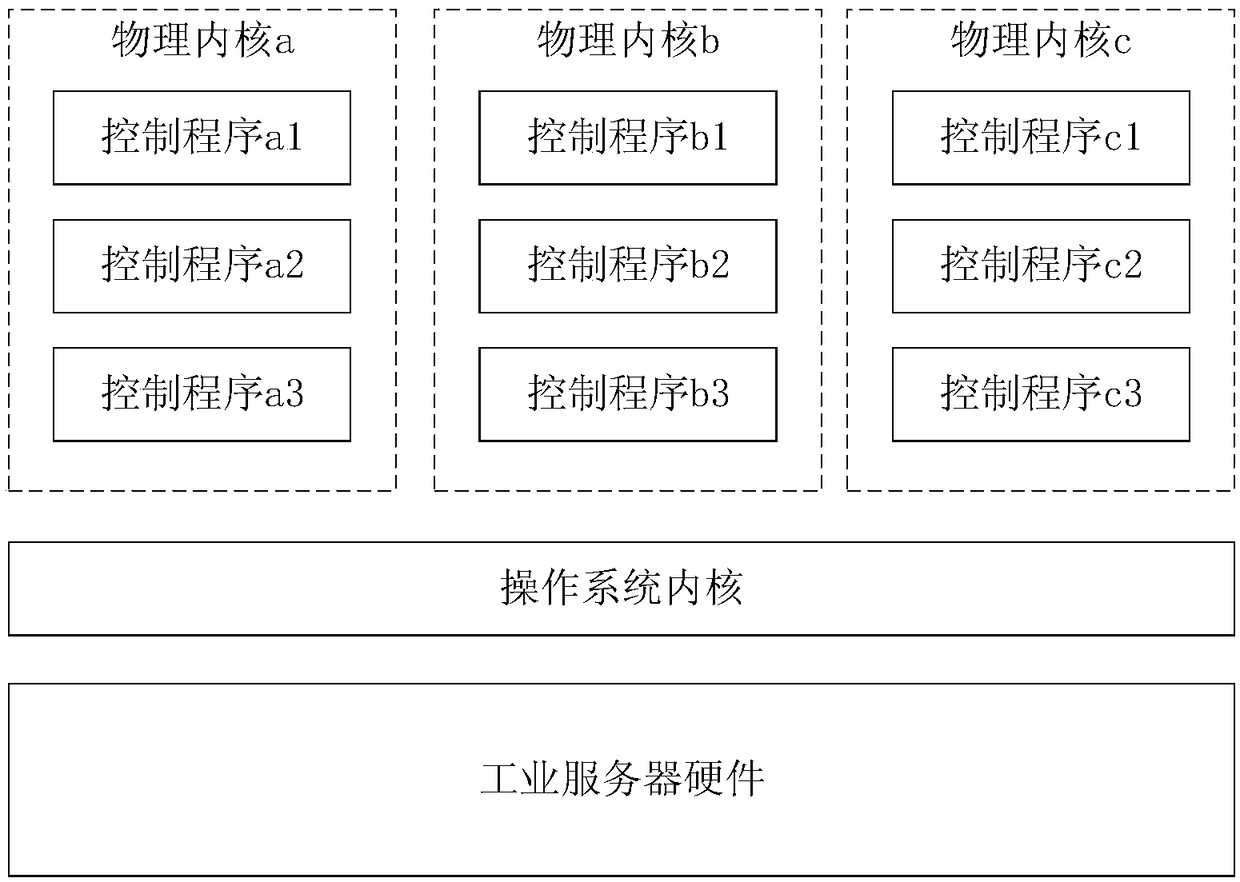

VPLC configuration method and device of industrial server and readable storage medium

ActiveCN111026387AEasy to configureTroubleshoot manual configuration issuesVisual/graphical programmingProgramme control in sequence/logic controllersDrag and dropConfiguration item

The invention provides a VPLC configuration method of an industrial server. The VPLC configuration method comprises the steps that a graphical configuration interface of an upper computer displays a component list area, a graphical configuration area and an attribute list configuration area; a configuration operation of a user on the graphical configuration interface is received; when it is judgedthat a VPLC assembly displayed in the assembly list area is dragged and dropped into a frame body corresponding to a physical kernel in the graphical configuration area, the VPLC assembly is added and displayed in the frame body, configuration items of a VPLC are displayed ina n attribute list configuration area, and configuration of a user is received; a physical kernel corresponding to the frame body is determined to generate configuration information of the VPLC for a physical kernel according to the configuration item of a VPLC; and the generated configuration information is compiled to generate a format which can be identified by the industrial server, and the format is downloaded to the industrial server. The invention further correspondingly provides a VPLC configuration device anda readable storage medium. The VPLC can be configured for the industrial server more conveniently.

Owner:KYLAND TECH CO LTD

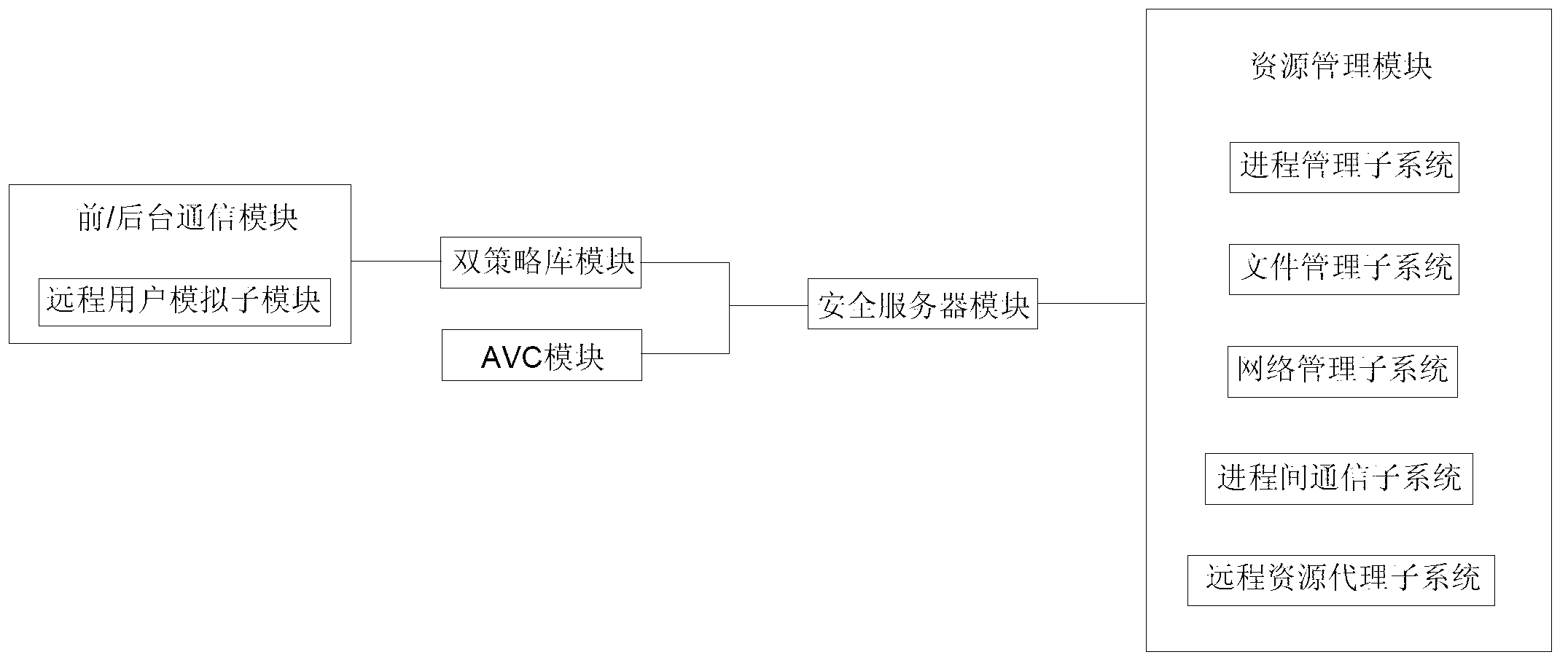

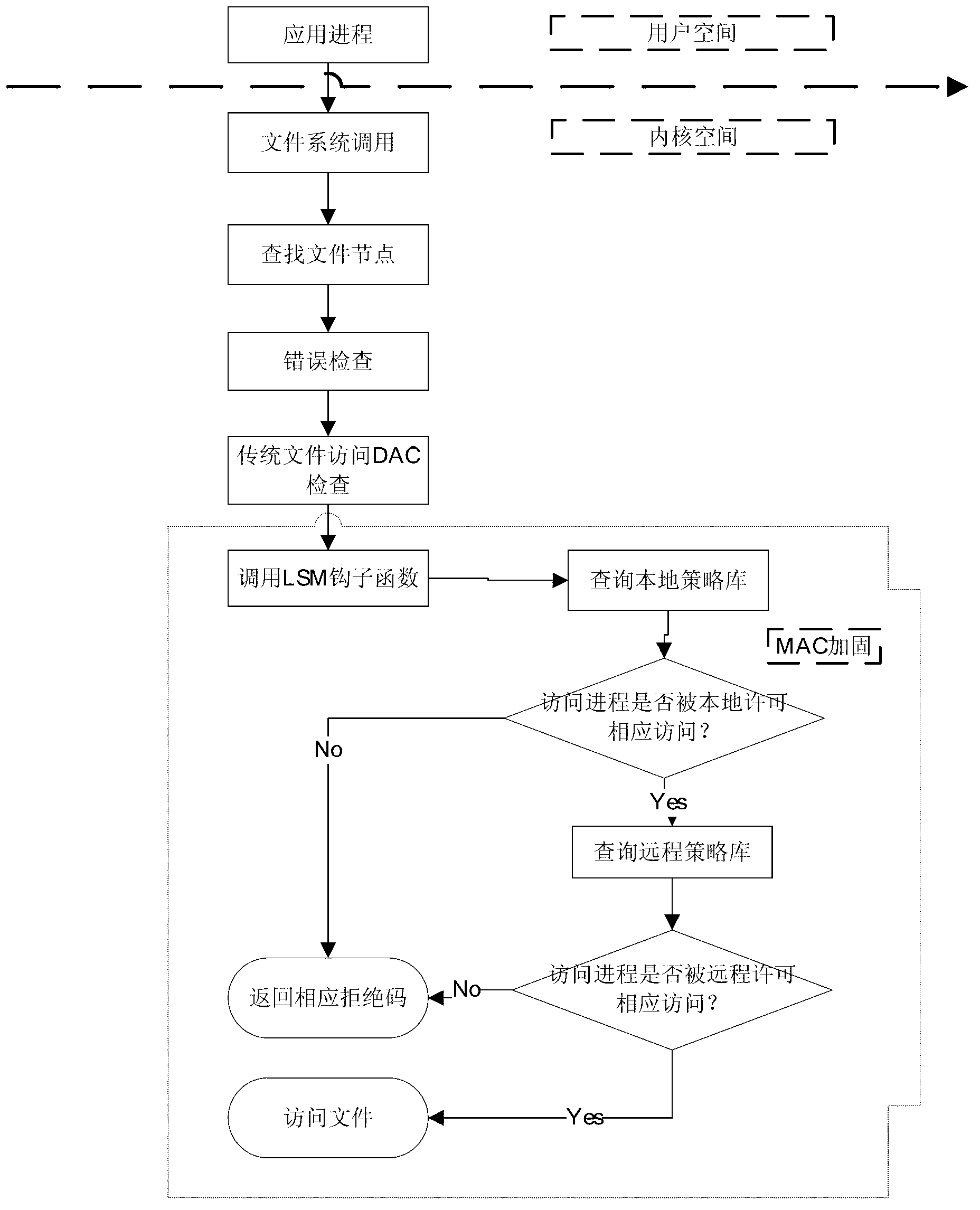

Safety controlling system of mobile terminal

The invention discloses a safety controlling system of a mobile terminal. The safety controlling system of the mobile terminal comprises a resource management module, a double strategy library module, an AVC module, a safety server module and a foreground / background communication module. The source management module is used for accomplishing safety contexts of all object resources of the safety controlling system and implementing practical visiting to the resource objects of a progress main body according to the judgment of the safety server module, the double strategy library module is used for maintaining a local strategy library and a remote strategy library, the AVC module is used for accelerating visiting controlling decisions, and the safety server module obtains a visiting controlling vector from the AVC module or the double strategy library module, then judges an access request, and finally delivers the judging result to the resource management module. The foreground / background communication module is responsible for the communication between a foreground and a background and is used for assisting the issuing and response of a safety strategy. The safety controlling system of the mobile terminal ensures that the communication between a mobile intelligent terminal and a background industrial service is unobstructed, and the mobile intelligent terminal and background business are safe.

Owner:SHANGHAI CHENRUI INFORMATION TECH

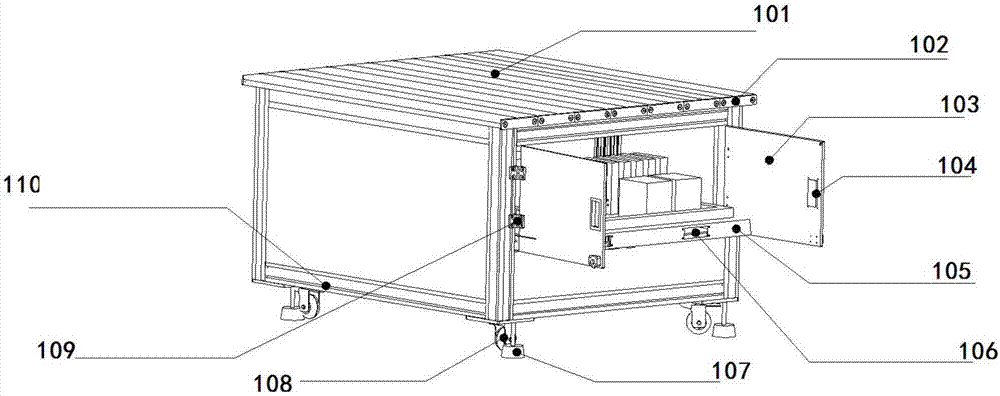

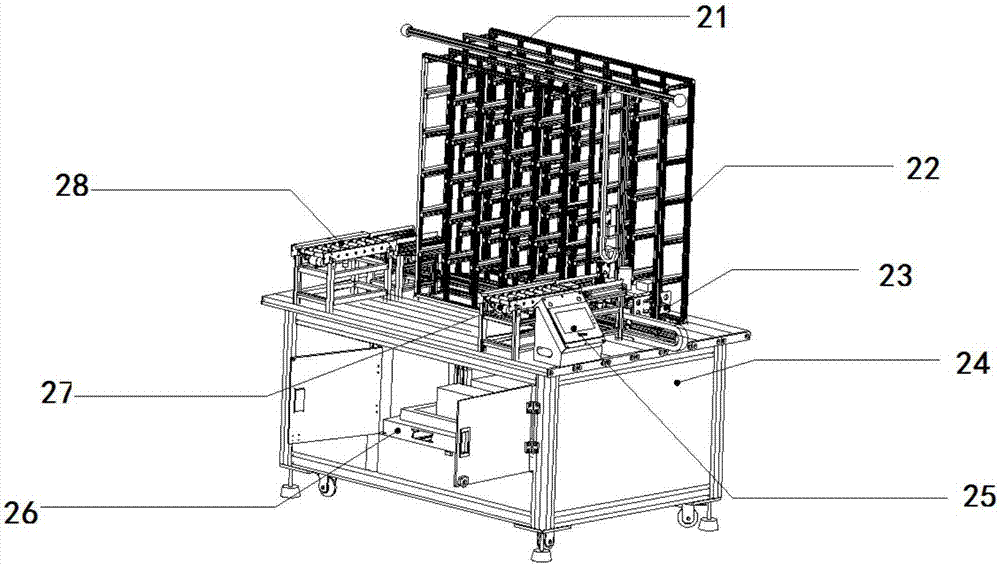

Micro intelligent factory experiment and research platform

PendingCN107145132ARealize intelligent warehousingRealize intelligenceElectric/hybrid propulsionTotal factory controlInterconnectivityProduction line

The invention belongs to the machine processing field and more particularly, to a micro intelligent factory experiment and research platform, comprising a production line system, a stereoscopic warehouse system, a sorting system, a manually assembling system, a transporting and dividing system, and an AGV material sending system. The micro intelligent factory experiment and research platform of the invention utilizes the industrial internet of things, the industrial service network and the intelligent-control-related technologies to make the platform intelligent and unattended by people. Compared with the traditional manufacturing mode, the platform allows for deeper and wider perceptions about the internet interconnectivity and more intelligence. The platform of the invention takes stamps, chesses, souvenirs and other handcrafts as its processing objects, and can realize the full processing and producing of work pieces including intelligent storage, intelligent manufacturing, intelligent detecting and intelligent assembly, making the platform more suitable for the manufacturing mode for the industrial 4.0 generation.

Owner:深圳市元创兴科技有限公司

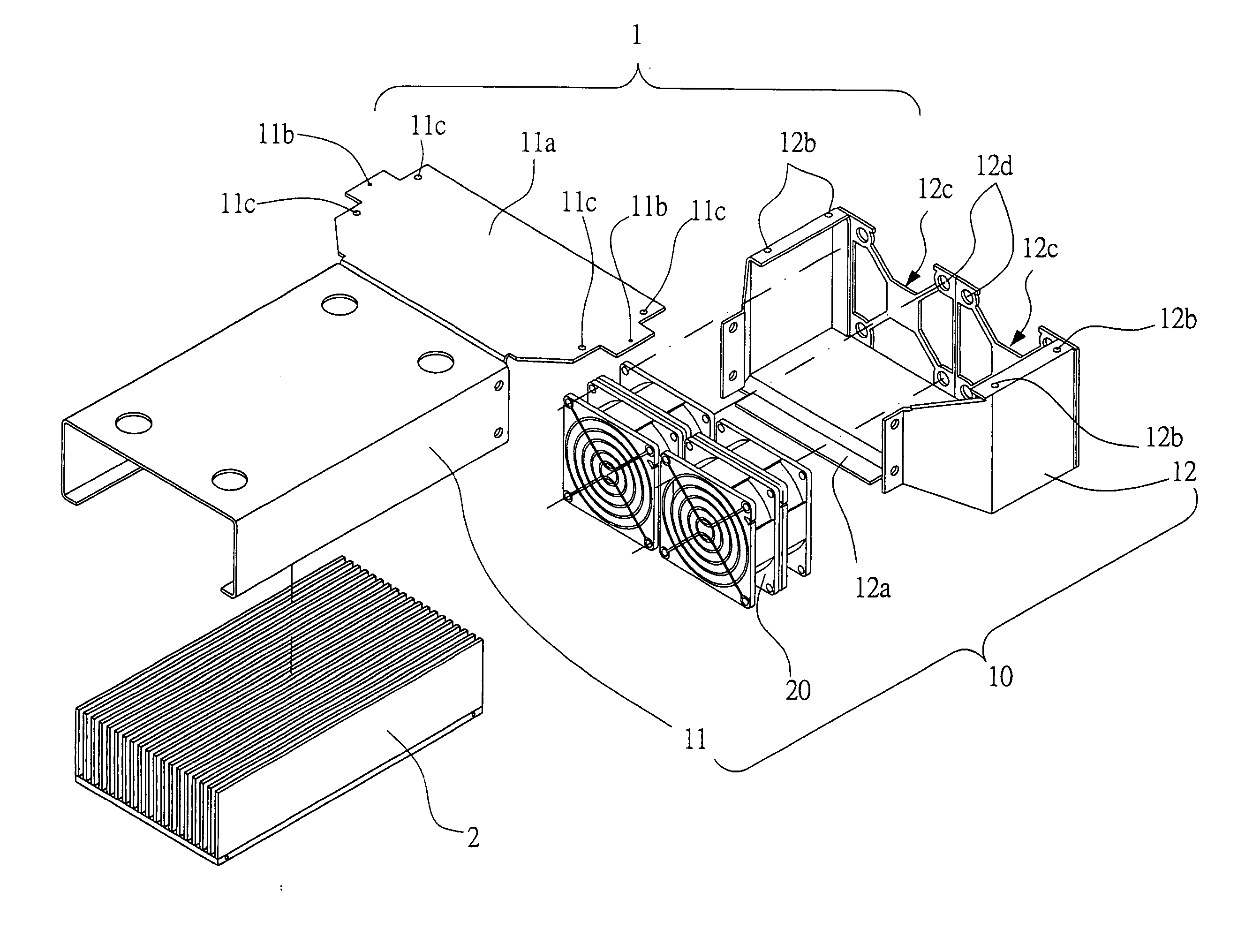

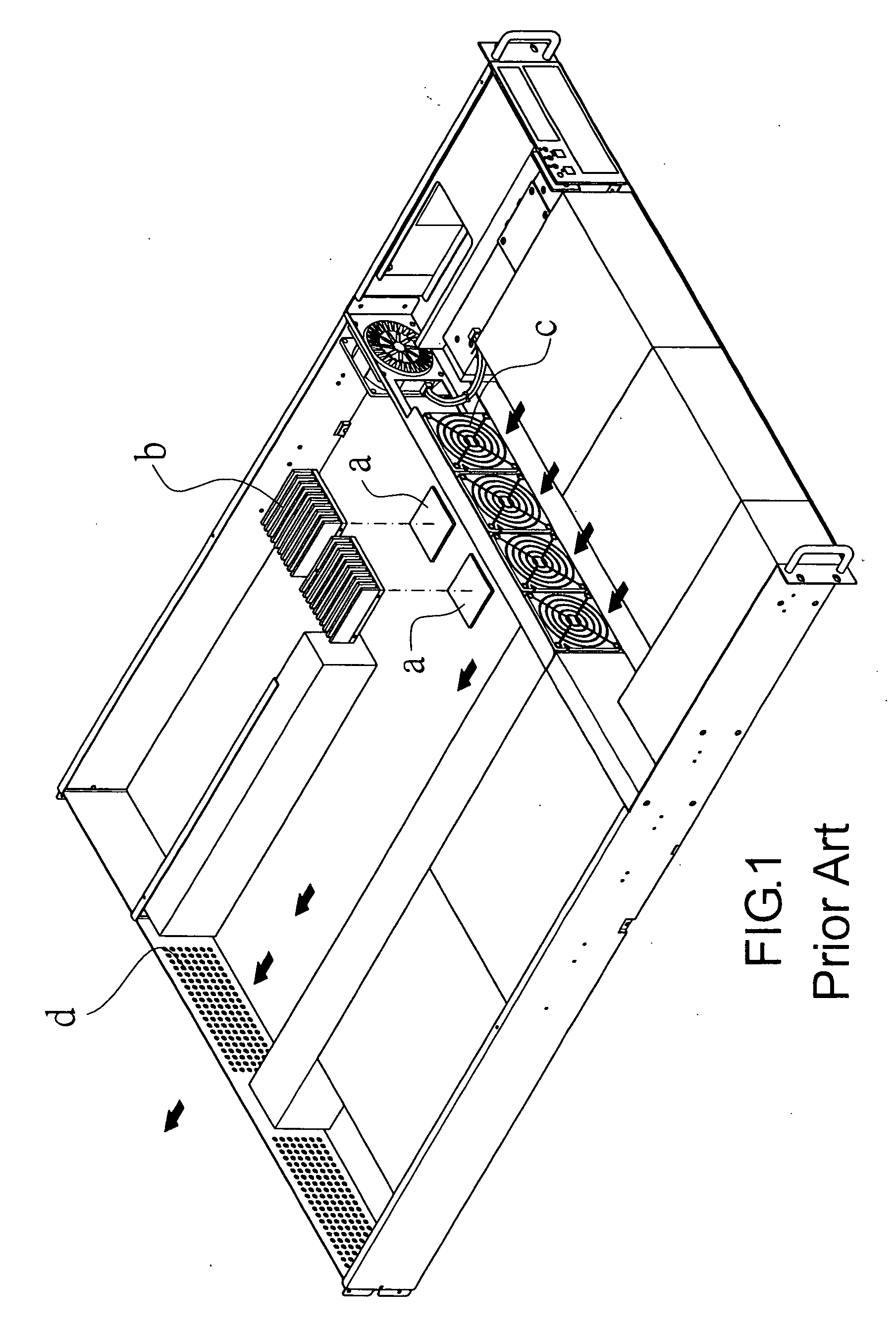

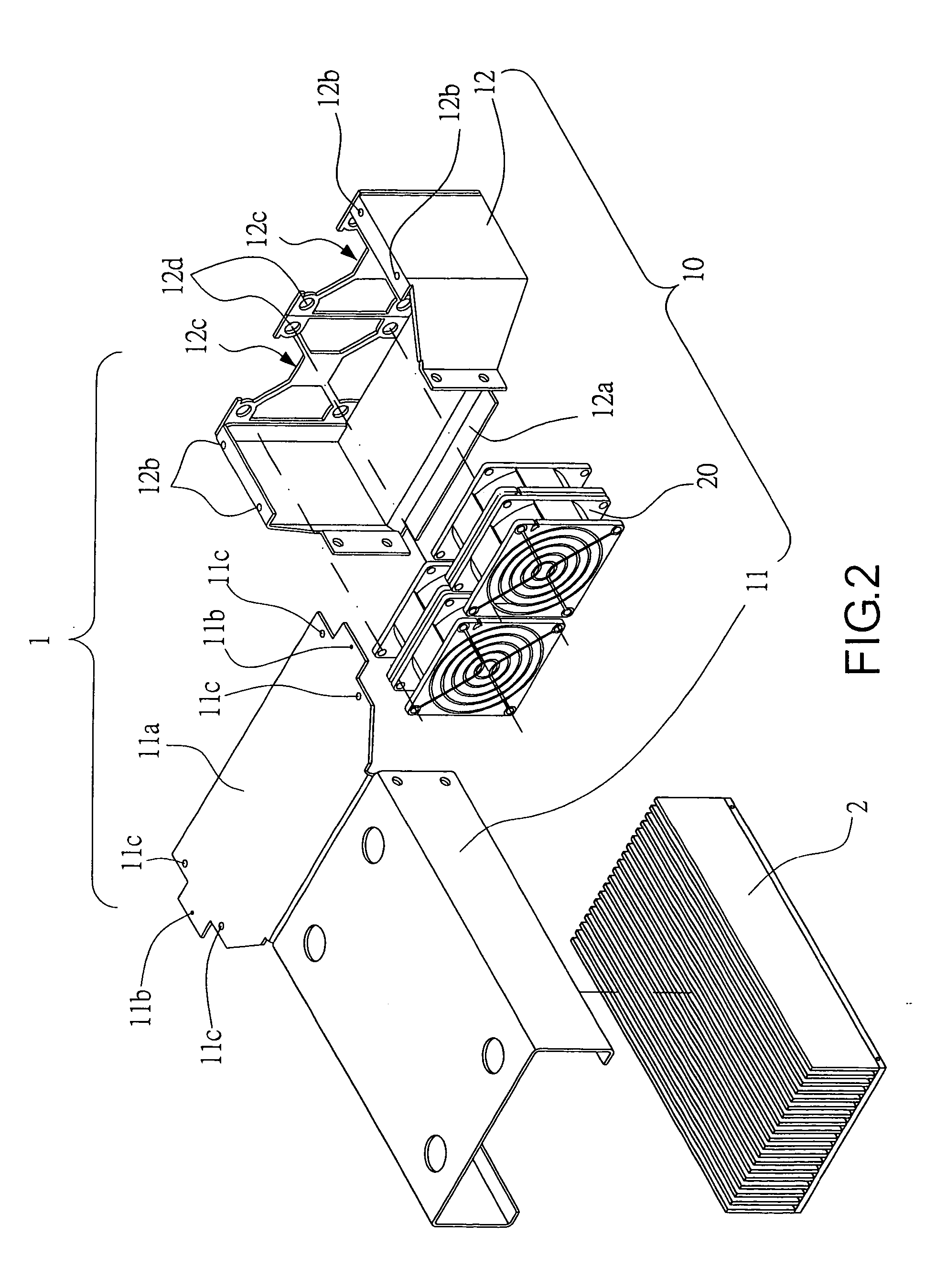

Fan cover heat dissipation assembly for a host computer CPU

InactiveUS20050141993A1Effectiveness of high-temperatureAffect efficiencyPump componentsDigital data processing detailsEngineeringIndustrial service

A fan cover assembly installed within a computer case of a host computer, thereby providing a heat dissipating effect of for a CPU (central processing unit). Configured for usage in a slim IU industrial server computer case, whereby the fan cover assembly is structured to comprise a fan cover body and fans installed therein. Wherein the fan cover body is constructed to include a wind tunnel cover configured at a front-end and a fan cover configured at a rear-end thereof. Width and height of the wind tunnel cover are established so as to correspond with width and height of the CPU with addition of heat dissipation fins configured atop thereof. Upon assembling the fan cover body, and tightly screwing down such onto a back panel of the computer case, the fans expel hot air outwards, thereby achieving effectiveness of high temperature (60° C. and above) heat dissipation.

Owner:HUNG KUO CHUAN

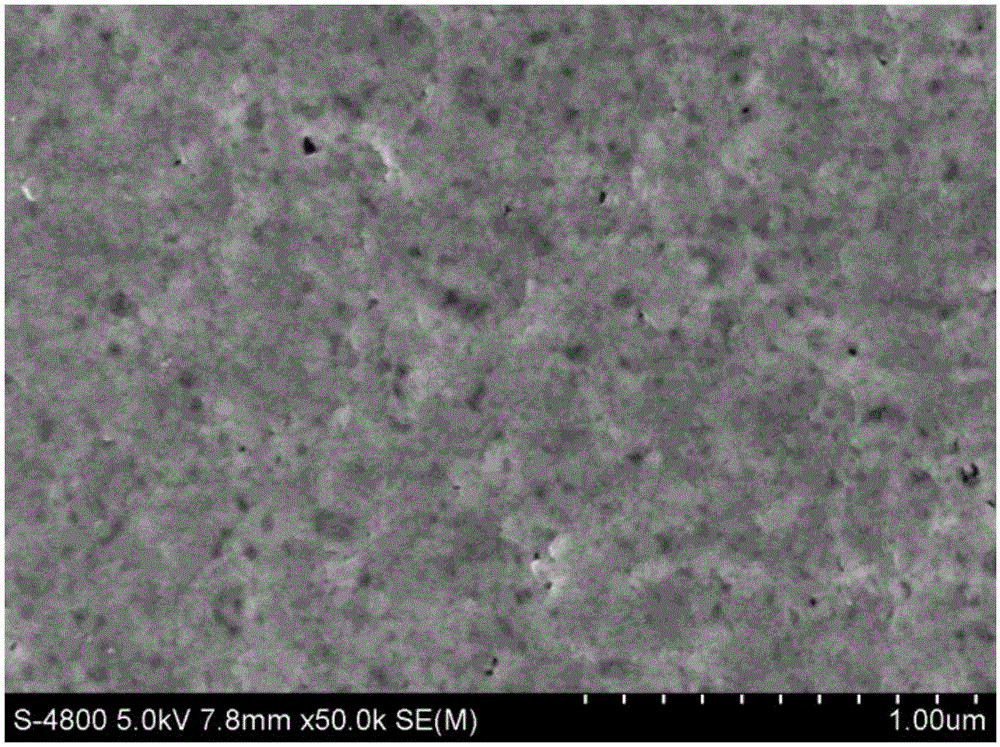

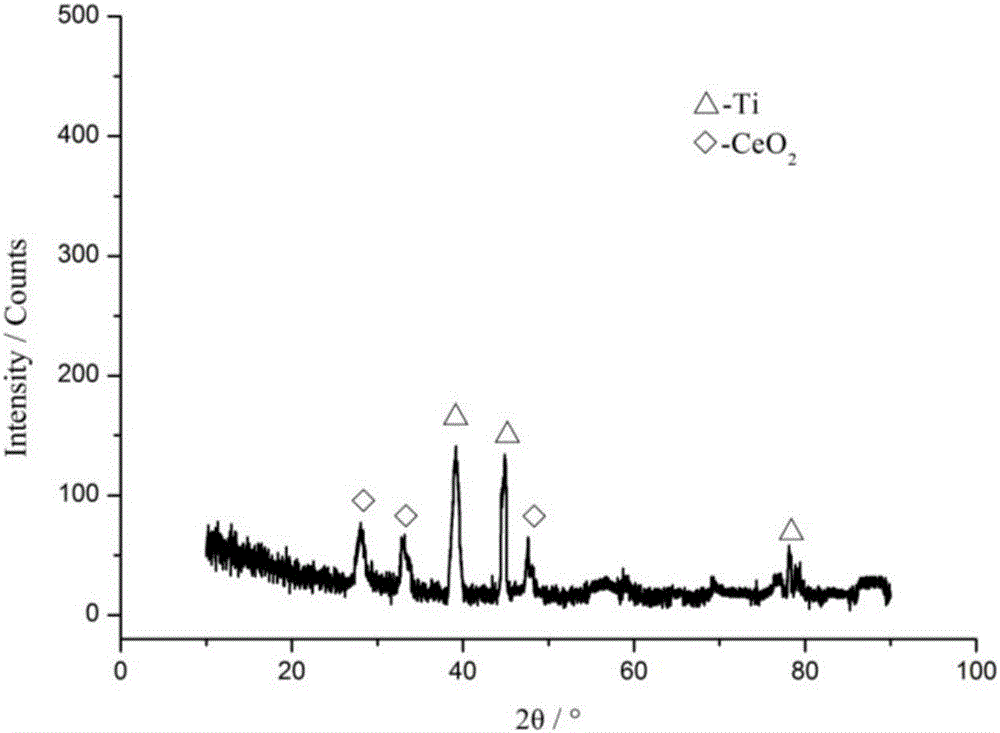

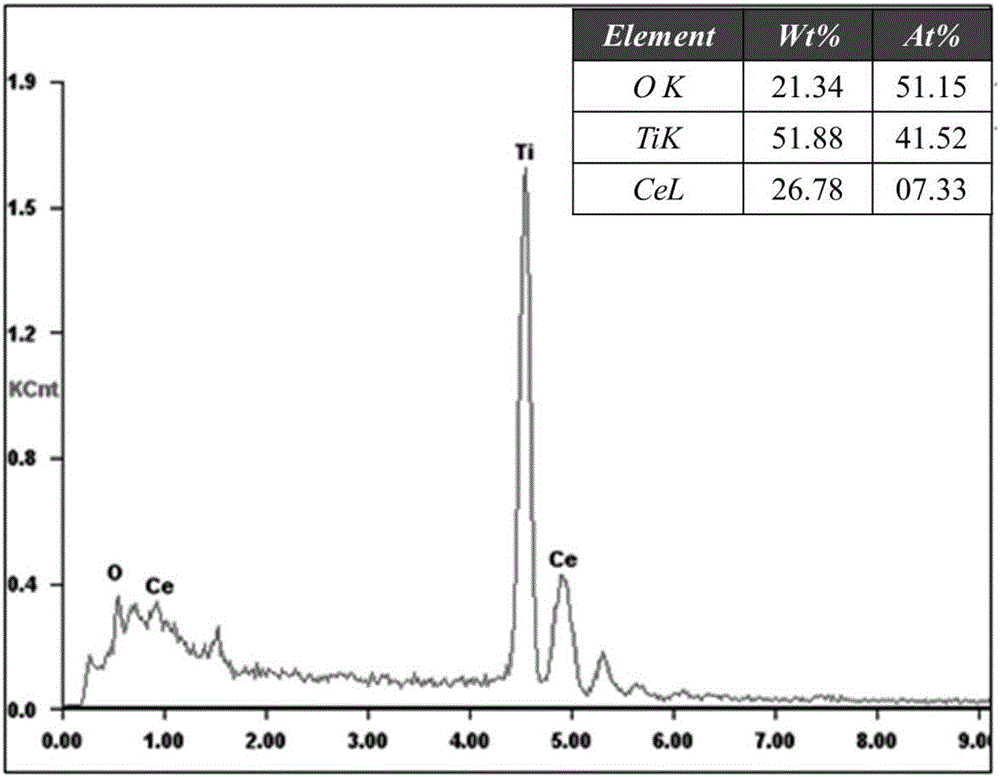

Intrinsic super-hydrophobic ceramic coating and preparing method thereof

ActiveCN106367726AExtended service lifeExhibit superhydrophobic propertiesVacuum evaporation coatingSputtering coatingOxide ceramicCeramic coating

The invention discloses an intrinsic super-hydrophobic ceramic coating and a preparing method thereof, and belongs to the technical field of metal base surface treatment. A titanium alloy or stainless steel serves as a base material, firstly, a double glow plasma permeability technology is adopted, lanthanide series metal serves as a double glow plasma permeability metal target material, a lanthanide metal coating is prepared on the surface of the base body material, and the plasma oxidization technology is adopted to convert the prepared lanthanide metal coating into a compact oxide ceramic coating. Due to the fact that in the plasma permeability and plasma oxidation process, the surface of the metal base body is continuously bombarded by Ar ions to form a certain micro rough structure, the prepared lanthanide metal oxide ceramic coating has a certain super-hydrophobic characteristic, and the contact angles are larger than 150 degrees. According to the provided method, the prepared super-hydrophobic ceramic coating has the stable environment adaptation, and compared with the super-hydrophobic surface prepared by the traditional technical means, the industrial service life of the coating is greatly prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

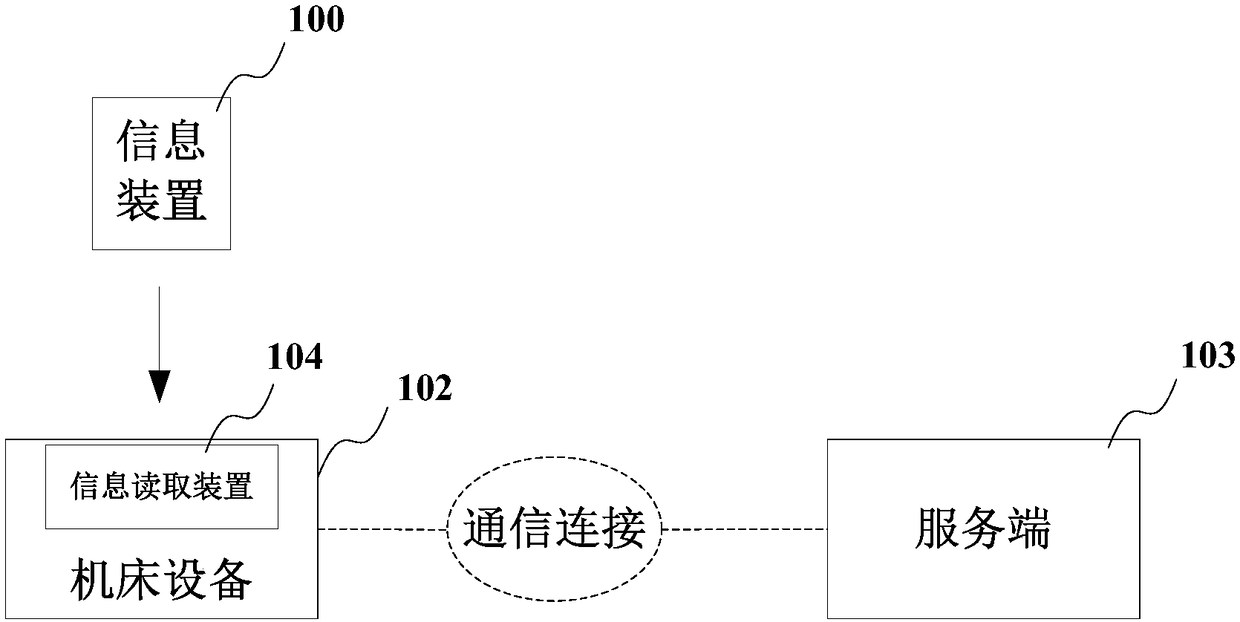

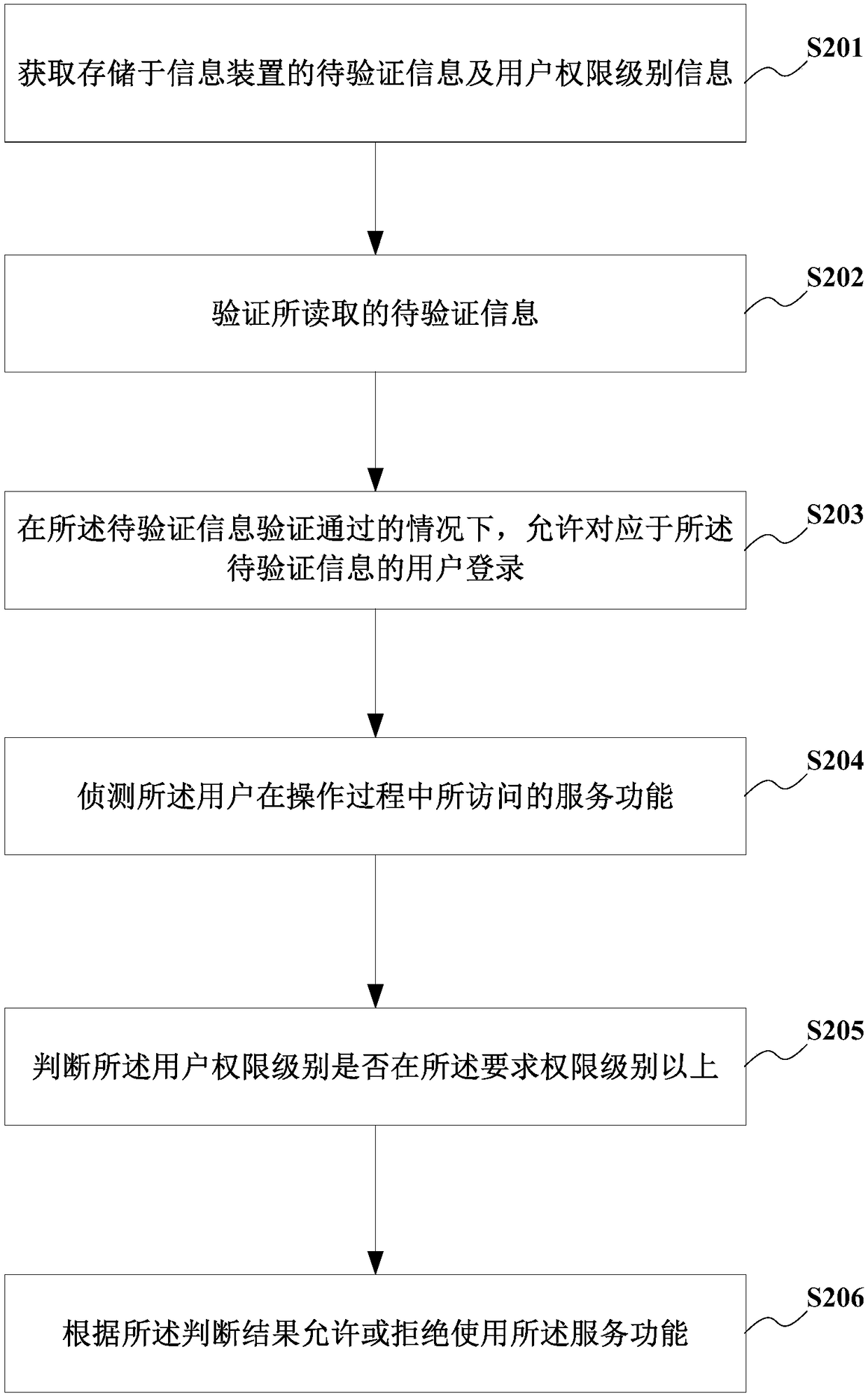

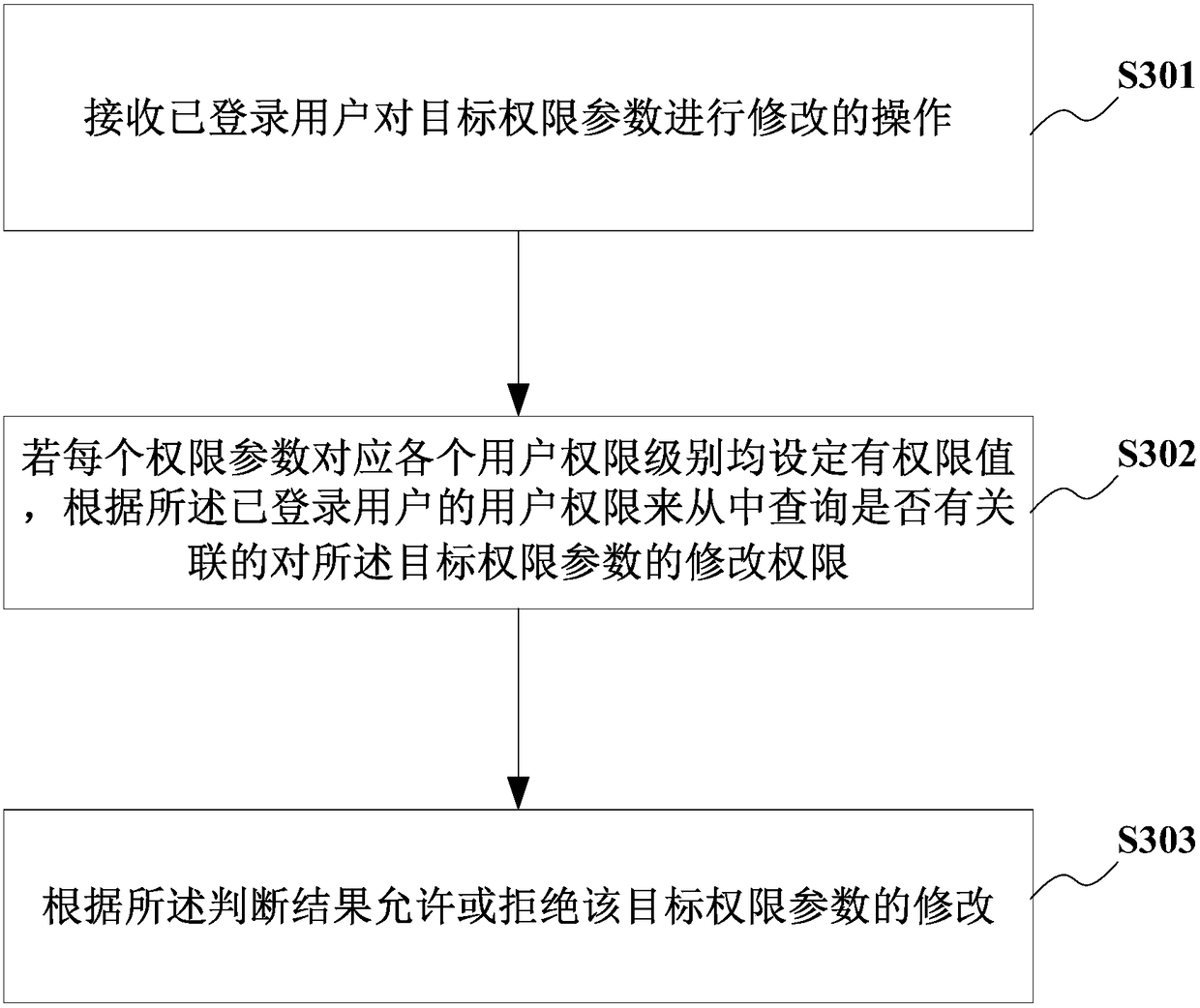

Industrial service authority management method and device, and machine tool equipment

The invention provides an industrial service authority management method and device, and machine tool equipment. The method comprises the following steps: acquiring information to be verified and userauthority level information that are stored in an information device; verifying the read information to be verified, wherein the information to be verified comprises one kind of device identifier information, unit identifier information or user information, or a plurality of kinds of combinations of the above information; if the information to be verified is successfully verified, permitting a user corresponding to the information to be verified to log in; detecting a service function accessed by the user during operation, wherein the service function is pre-associated with an authority parameter, and the authority parameter is provided with pre-assigned required authority level information; judging whether a user authority level is above a required authority level or not according to theuser authority level information; and permitting or rejecting use of the service function according to a judgment result. The method and device and the equipment provided by the invention have the advantages that the authority information in the information device is read through the machine tool equipment, and the various service functions corresponding to the authority information are determined through a preset authority identification mechanism for use, so that automatic authority management for the machine tool equipment is achieved.

Owner:SYMG SHANGHAI INTELLIGENCE SYST CO LTD

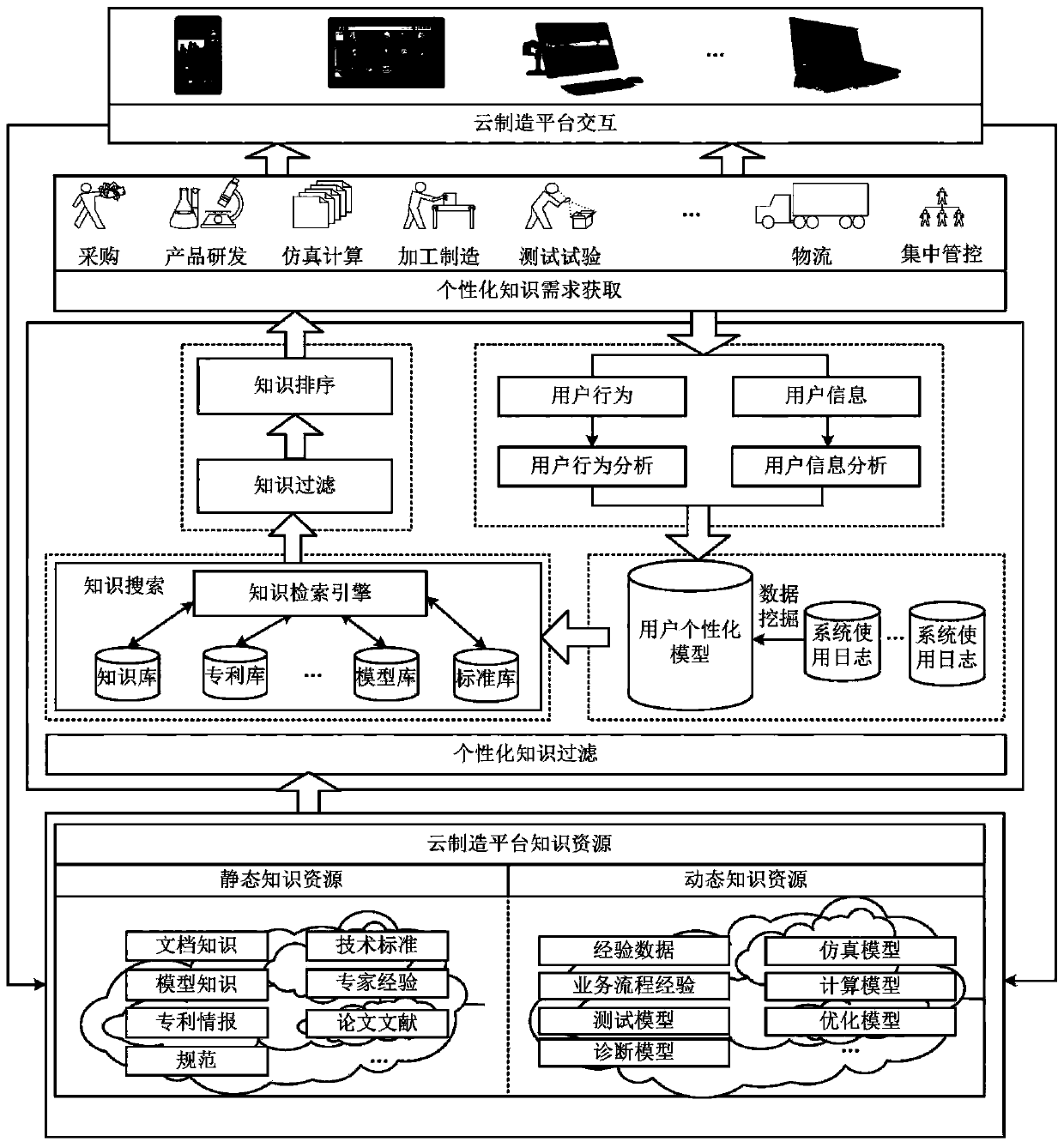

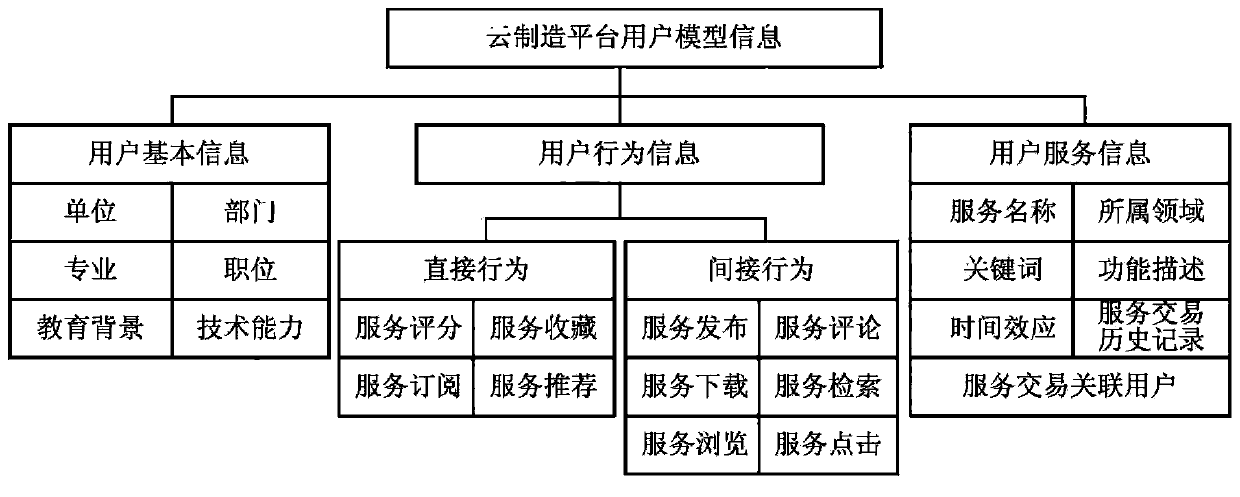

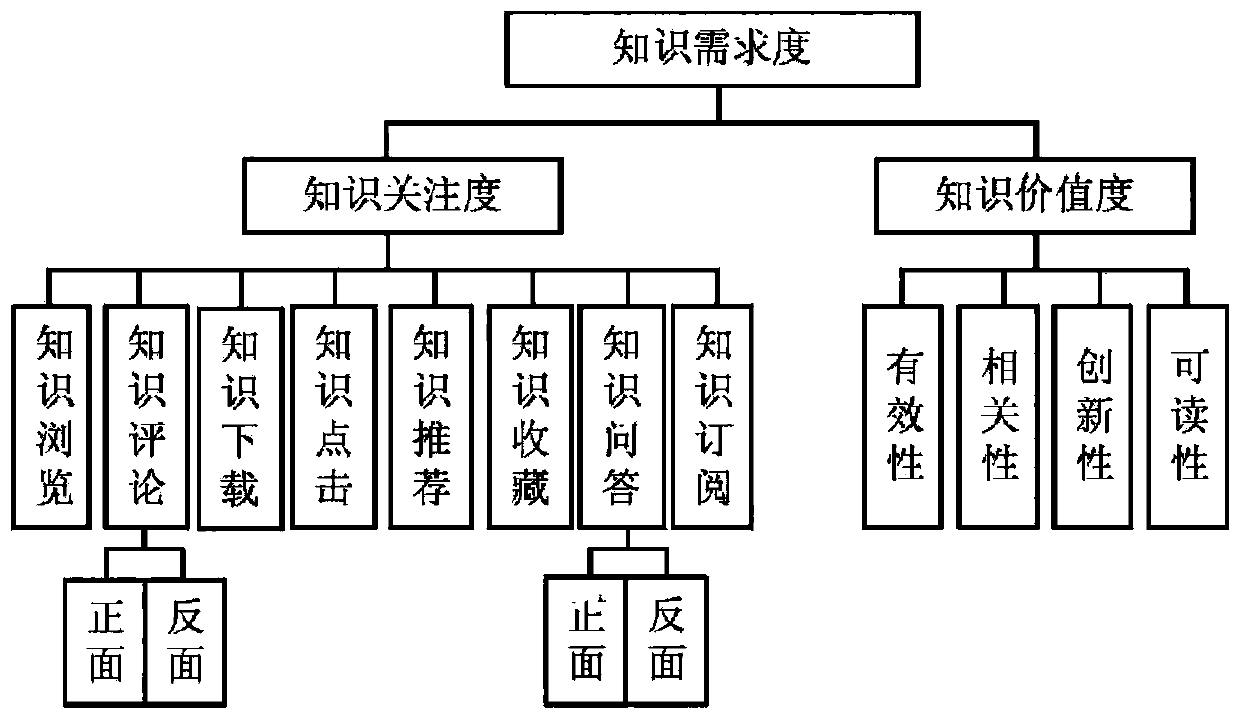

Knowledge service method and system based on industrial service cloud platform user behavior perception

ActiveCN109800249AIncrease profitHigh viscosityDigital data information retrievalSpecial data processing applicationsPersonalizationKnowledge services

The invention relates to a knowledge service method and system based on industrial service cloud platform user behavior perception. The method comprises the following steps: 1) uniformly describing knowledge resources in an industrial service cloud platform through an ontology, and eliminating the isomerism of different knowledge resources in structure and semantics; 2) obtaining personalized knowledge demands of the user according to business activities of the user in the industrial service cloud platform, and establishing a user personalized model according to the personalized knowledge demands of the user; and 3) on the basis of the established user personalized model, retrieving the knowledge resources of the industrial service cloud platform to obtain the knowledge resources meeting the personalized knowledge requirements of the user. According to the invention, personalized intelligent knowledge services of user behavior perception can be provided for various large, medium and small industrial manufacturing enterprises of the industrial internet, blindness of knowledge resource searching by a user can be greatly reduced, and required knowledge resources can be provided for the user quickly.

Owner:北京航天智造科技发展有限公司

High recovery drinking water process

ActiveUS9199866B2High water recoveryEliminate needIon-exchanger regenerationOrganic anion exchangersReverse osmosisIon exchange

Disclosed is a process that uses reverse osmosis (RO) or nanofiltration (NF) membranes and ion exchange (IX) water softening resins to maximize the production of drinking water, purified industrial service water or recycled purified municipal or industrial effluents. The membrane and ion exchange units are configured in a manner that enables operation of the system at high permeate recoveries in the range 90% to 99%, thus producing purified drinking water with a minimum volume of wastewater to drains and a very low membrane cleaning or membrane replacement frequency. The process mitigates membrane fouling and scale formation and minimizes the use of water treatment chemicals including acidic and alkali solutions and sodium chloride salt that is normally required to regenerate the IX resin.

Owner:AL SAMADI RIAD A

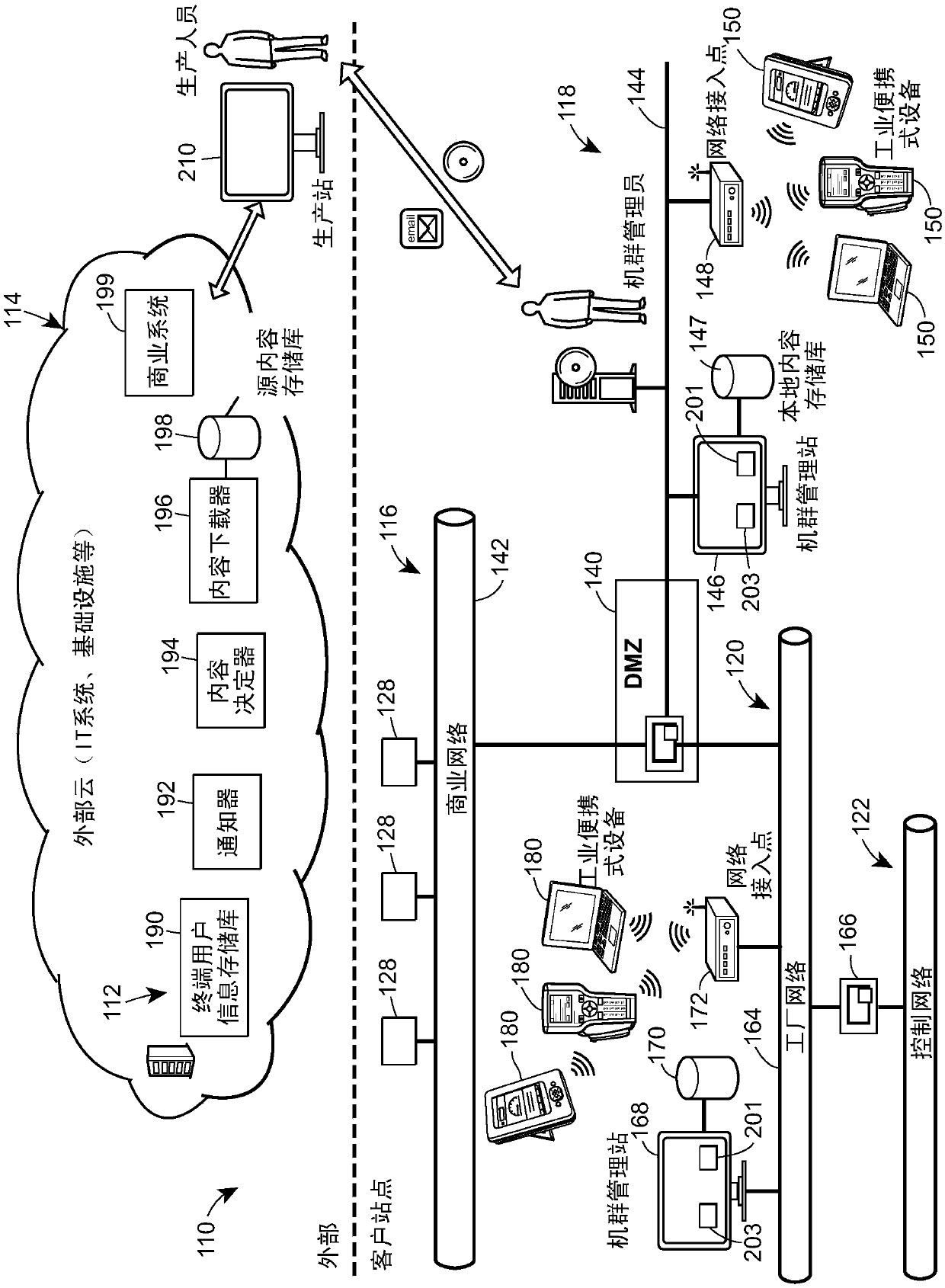

Fleet management system for portable maintenance tools

PendingCN107643734AEasy to manageProgram loading/initiatingTransmissionFleet managementDigital content

An industrial service device fleet management system implements an organized and easy to use methodology to manage the digital content stored on each of a plurality of portable or stationary devices used in a plant, such as portable maintenance devices, to assure that each of the portable devices receives or implements only the content that it is supposed to have and is upgraded at the appropriatetime to include new content, features, etc. The fleet management system includes a memory for storing information related to the fleet of portable or stationary devices including device identifications, device descriptions, end user names and privileges, the current content of each of the portable devices, and templates defining configuration parameters for the portable or stationary devices. Thesystem also includes a content downloader that obtains, stores, and downloads content (such as software and firmware upgrades, additional features, applications, drivers, knowledge articles, etc.) for execution or display in various ones of the portable or stationary devices, includes a content decider module that analyzes when and if various ones of the portable or stationary devices should be provided additional or new content, and includes a notification system that notifies users of the portable or stationary devices of the need to upgrade or provide new content to the portable or stationary devices.

Owner:FISHER-ROSEMOUNT SYST INC

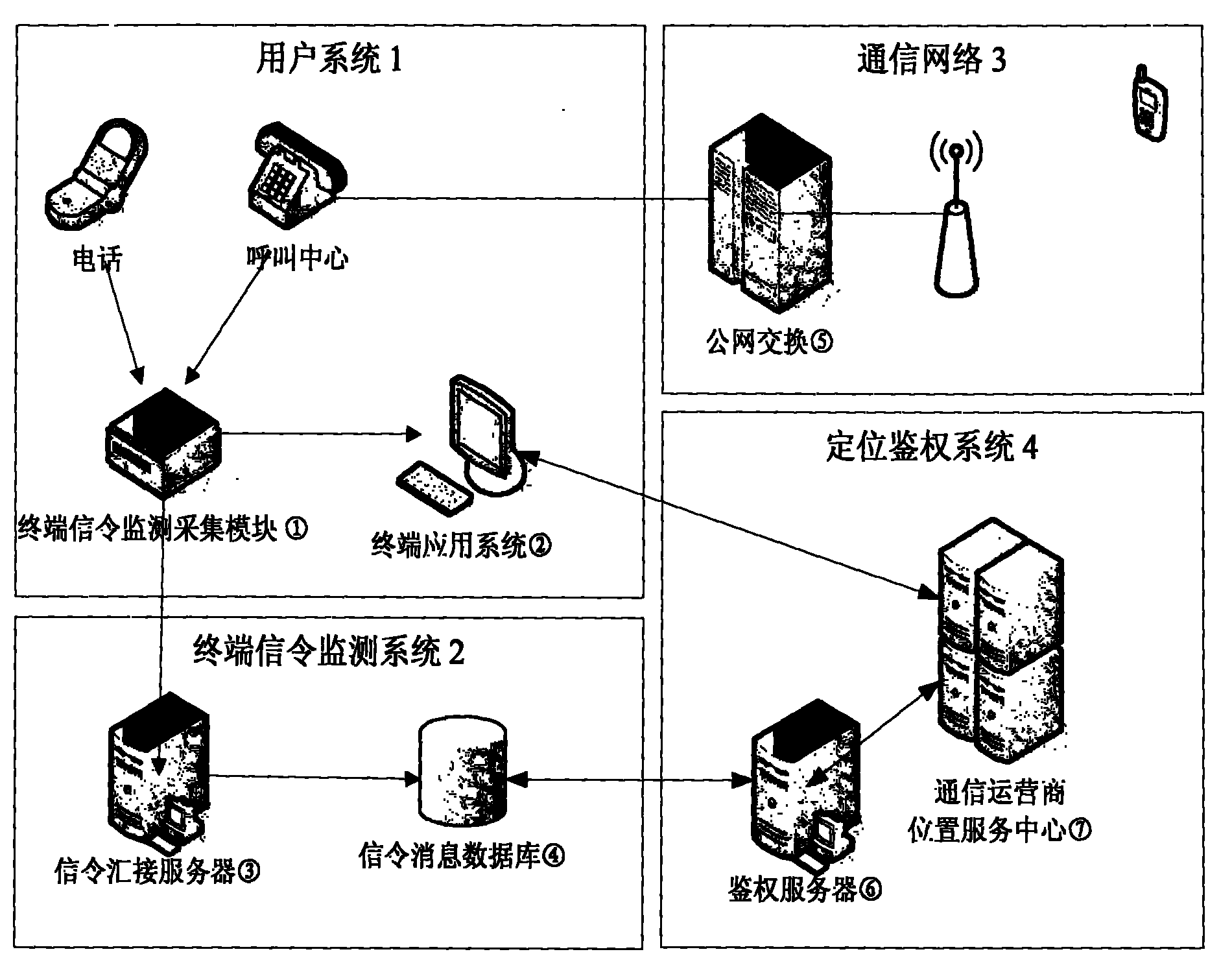

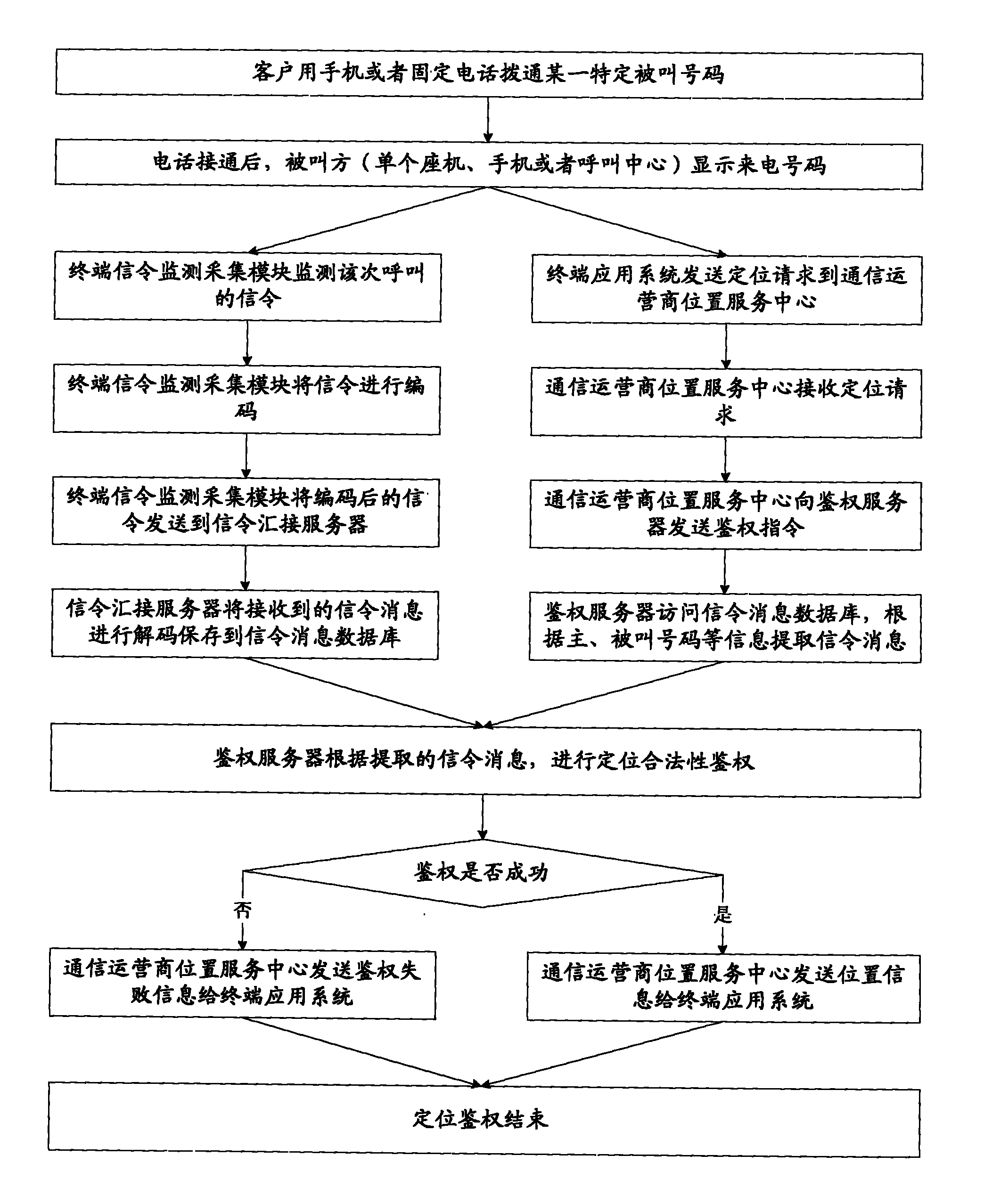

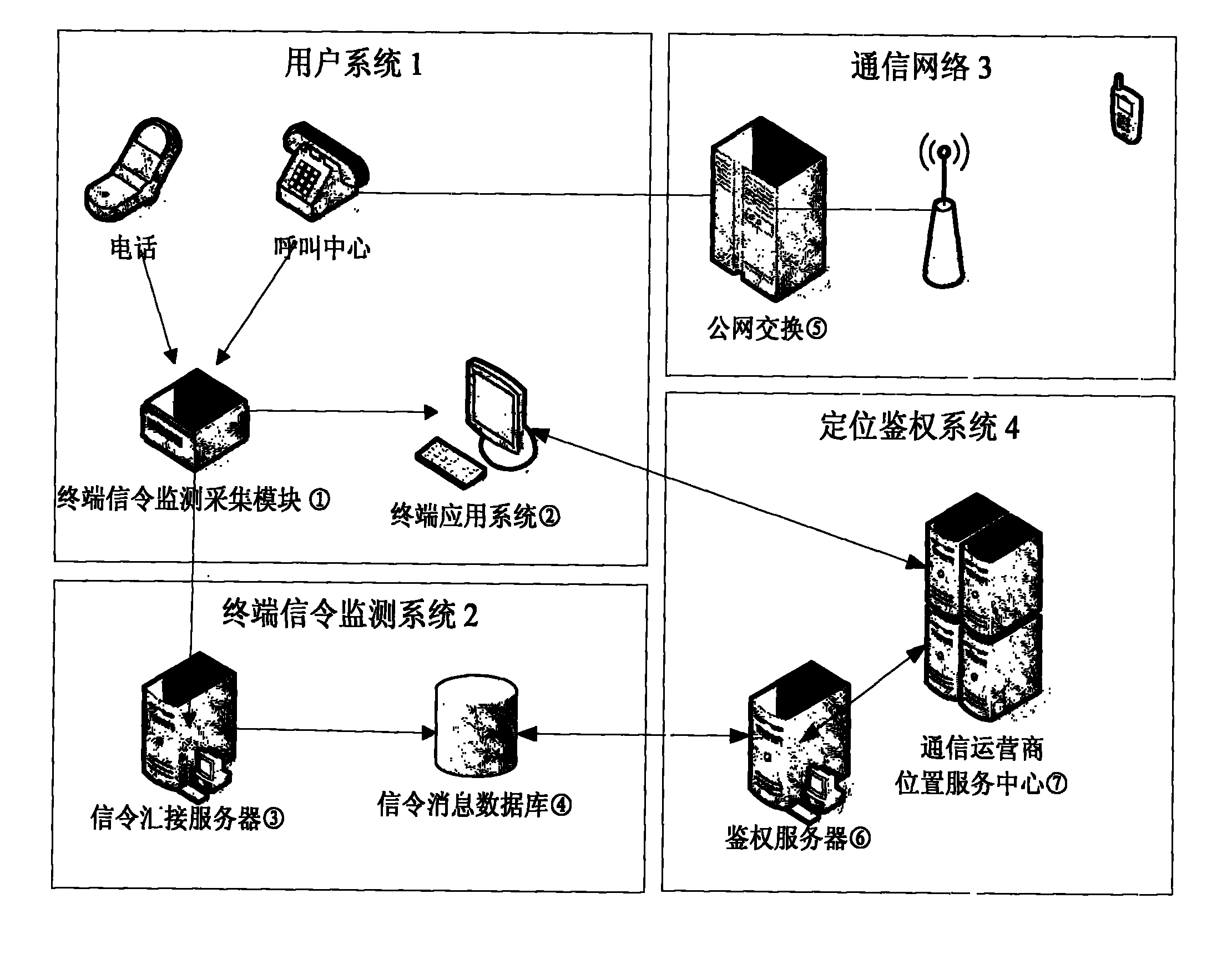

System and method for implementing positioning authentication by monitoring signaling of distributed terminal

InactiveCN102104828AReduce management difficultyAvoid abuseServices signallingLocation information based serviceOperabilityEngineering

The invention relates to an application system and a method for signaling monitoring and mobile phone positioning authentication, which are applied in the fields of public security, fire protection, medicinal first aid, traffic accident alarm, automobile maintenance and rescue and the like. The positioning technology provides a system and a method which are brand-new and strong in operability for the public and industrial services. The system consists of four parts, namely a user system, a terminal signaling monitoring system, a positioning authentication system and a communication network. The system avoids misuse of mobile phone positioning by monitoring the signaling scattered at the terminal, and provides brand-new thought and solution for authentication implementation of the whole position service industry.

Owner:韩军

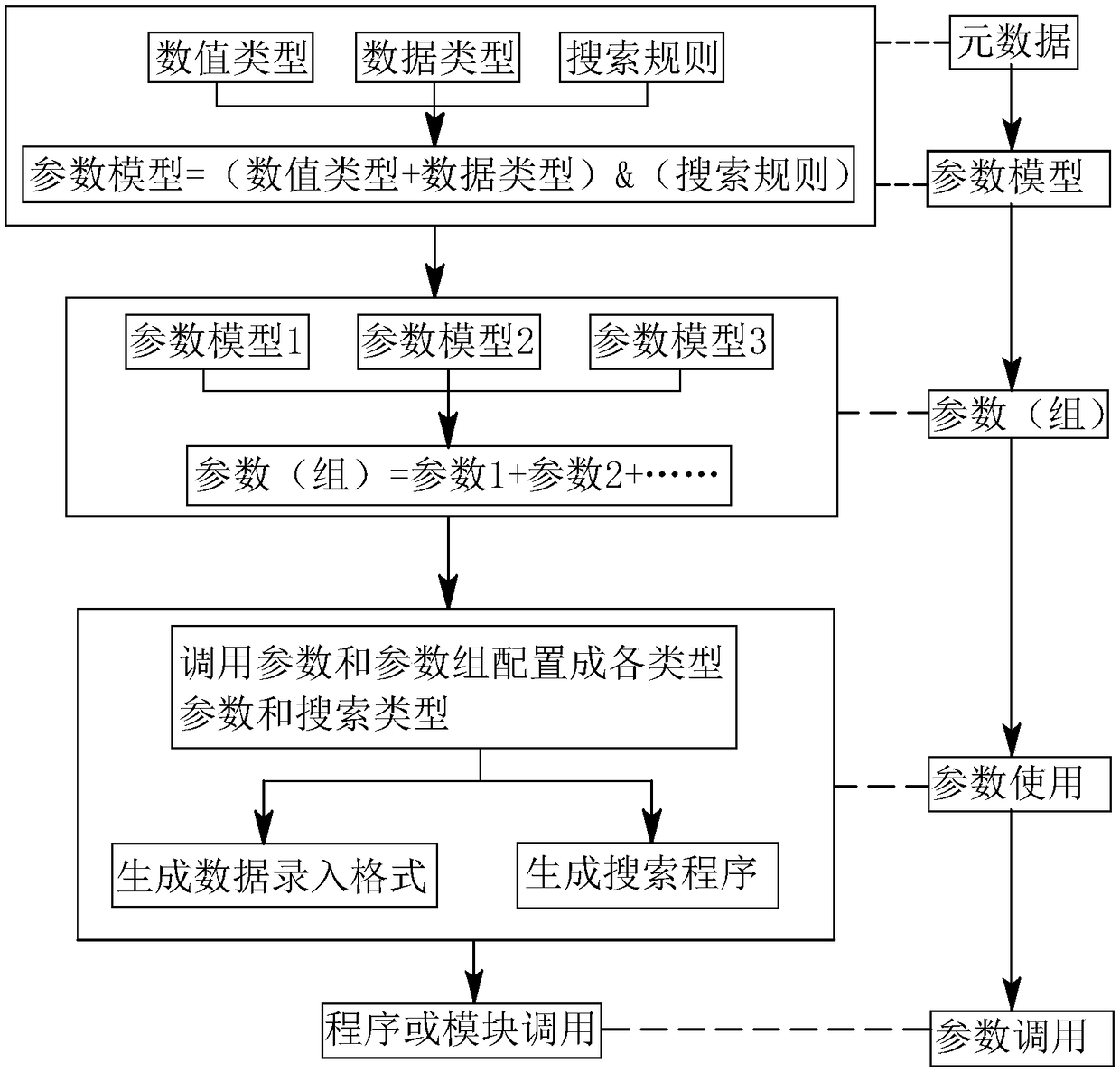

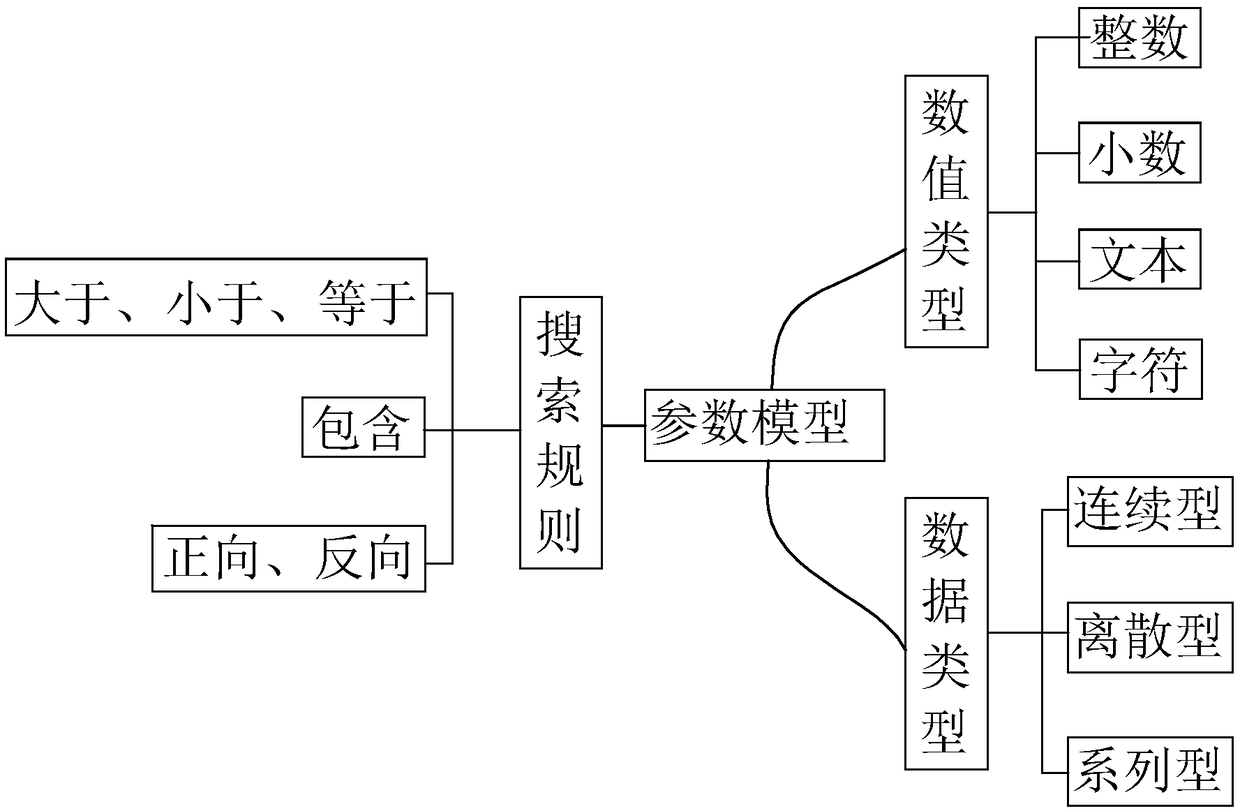

A parametric configuration search algorithm for industrial services

InactiveCN109508410ASearch for a wide range of adaptationStrong targetingOther databases indexingMetadata based other databases retrievalThe InternetNumerical models

The invention relates to the technical field of industrial Internet platform algorithms, in particular an industrial service parametric configuration search algorithm, the parameter model is extractedand designed, the parametric model is divided into numerical models, The most basic metadata, such as data models and search rules, Metadata creates a metadata database based on categories, Based onmetadata, According to the specific requirements, Data models and search rules, parametric model, Each parameter model includes a data type, Numerical Models and Search Rules, through different combinations, which can be used to construct parametric models of multiple modes, The parameter models are called from the parameter model library for combination, so as to form parameters satisfying various definitions and search rules. The parameters and parameter groups can be called and configured as special parameters of various industrial services. The data input format and search program can be generated due to the attributes of the parameter model models constituting the parameters. The invention has simple structure and is worth popularizing.

Owner:浙江优制网信息科技有限公司

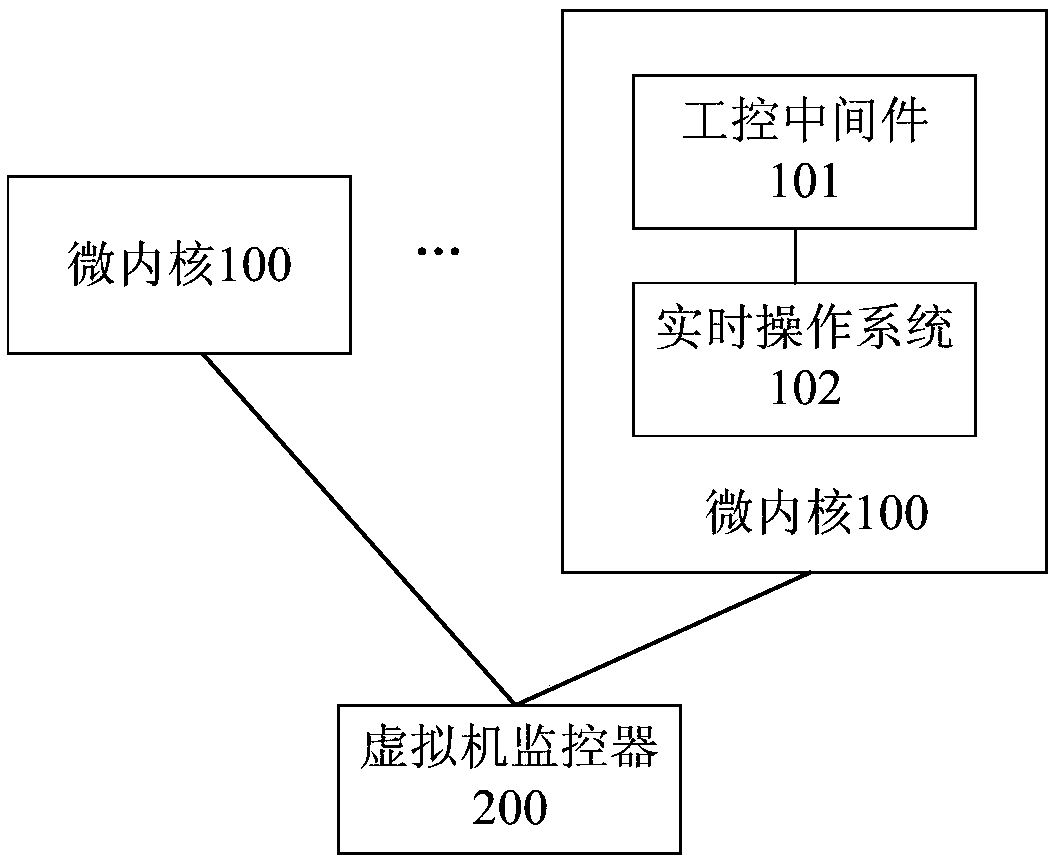

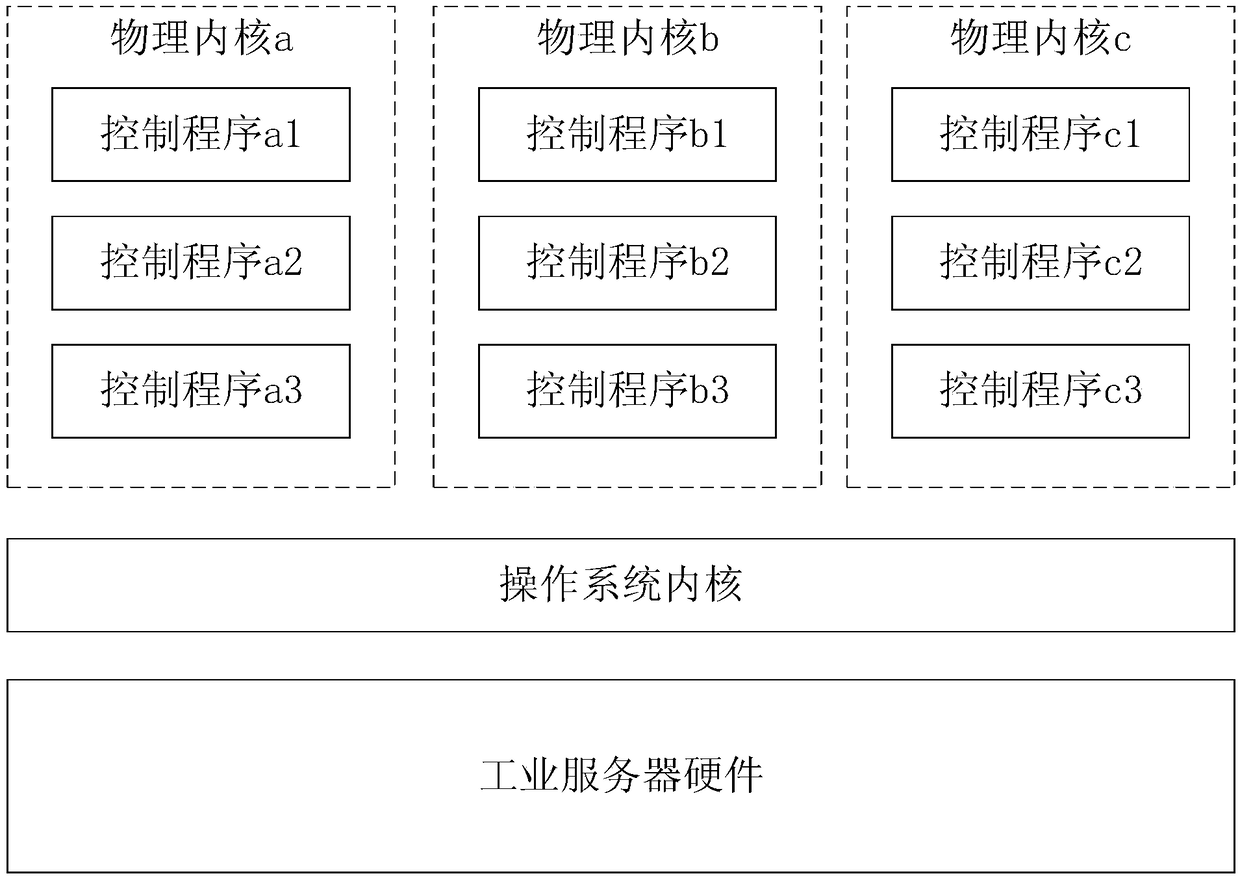

Micro-kernel architecture control system of industrial server and industrial server

ActiveCN108984267AReduce construction costsReduce maintenance costsProgram initiation/switchingResource allocationOperational systemControl system

The invention discloses a microkernel architecture control system of an industrial server and an industrial server, relating to the technical field of the industrial server, aiming at the fact that only one PLC control system runs on one hardware platform in the traditional industrial field, the functions are fixed and cannot be changed, however, once multiple control systems (PLC / DCS / Motion / CNC)are involved, the management and maintenance are difficult and the efficiency is low. On the basis of an architecture of a microkernel includes an industrial control middleware and a real-time operating system and a virtual machine monitor, custom configuration scheduling configuration information is defined before system start-up, real-time control and free combination of the industrial server microkernel is realized in industrial field layer, hardware equipment is simplified, construction and maintenance costs are reduced, and a software-defined industrial process is realized.

Owner:KYLAND TECH CO LTD

Information system for industrial vehicles

ActiveUS20180276909A1Safety devices for lifting equipmentsRegistering/indicating working of vehiclesIndustrial serviceEmbedded system

A system collects information related to a lockout event that occurs on an industrial vehicle. A lockout condition associated with an industrial vehicle is detected by a processor executing on the industrial vehicle. Responsive thereto, the industrial vehicle operator is locked out so that the industrial vehicle cannot be driven from its locked location. A message is wirelessly communicated to a server application that indicates that the industrial vehicle has been locked. When the processor executing on the industrial vehicle receives a command to unlock the industrial vehicle, the industrial vehicle is unlocked and the identity is stored, of the person who unlocked the industrial vehicle.

Owner:CROWN EQUIP CORP

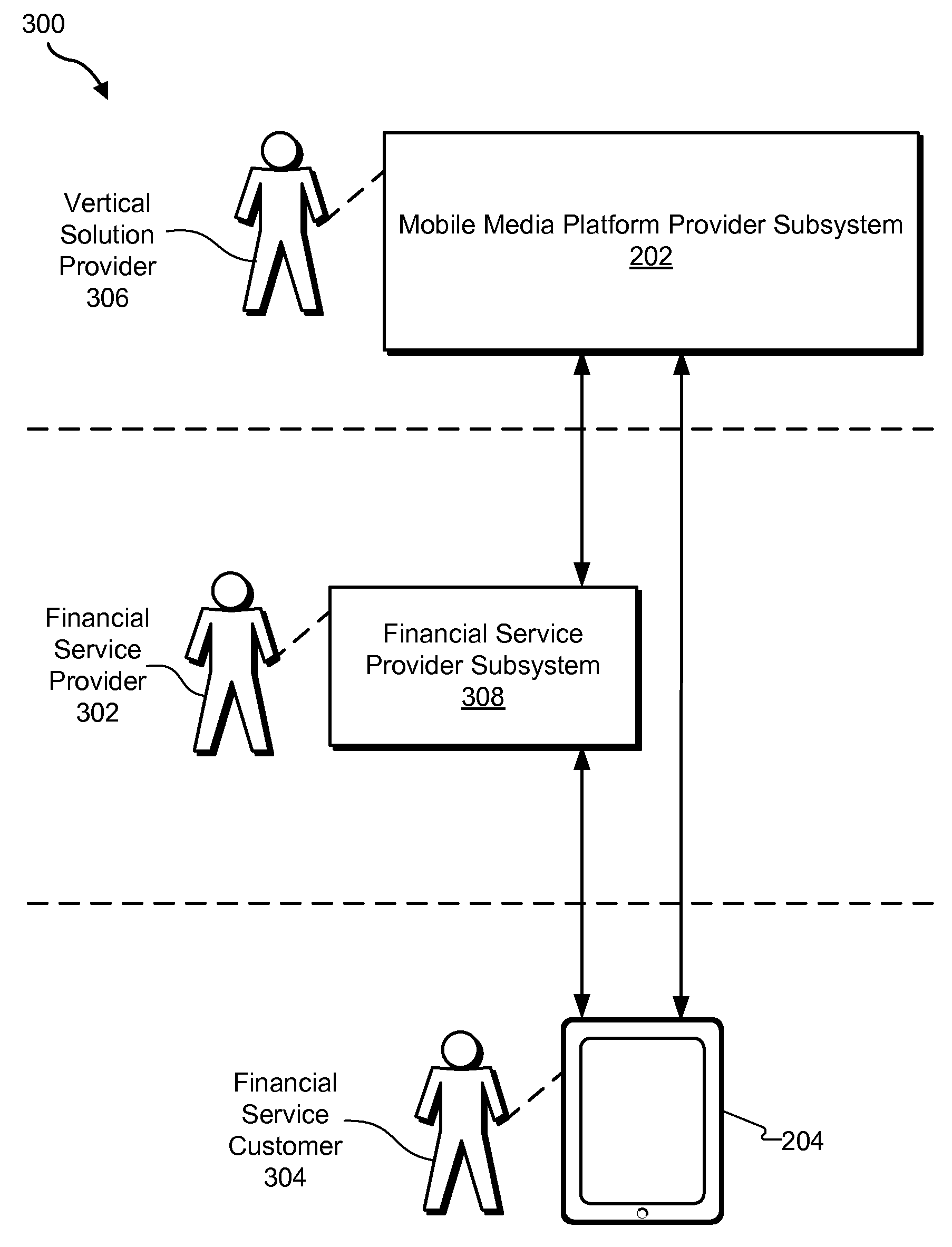

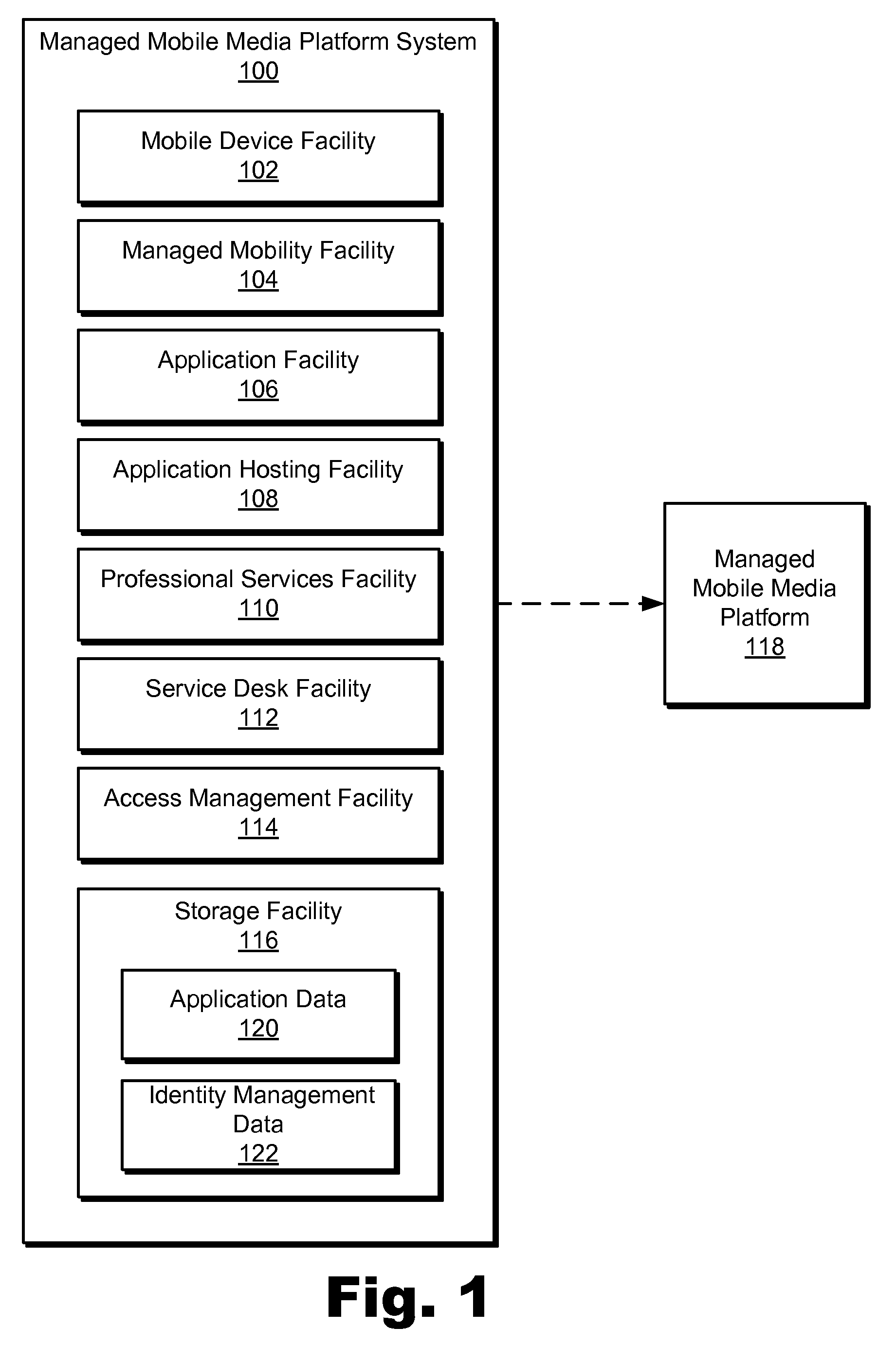

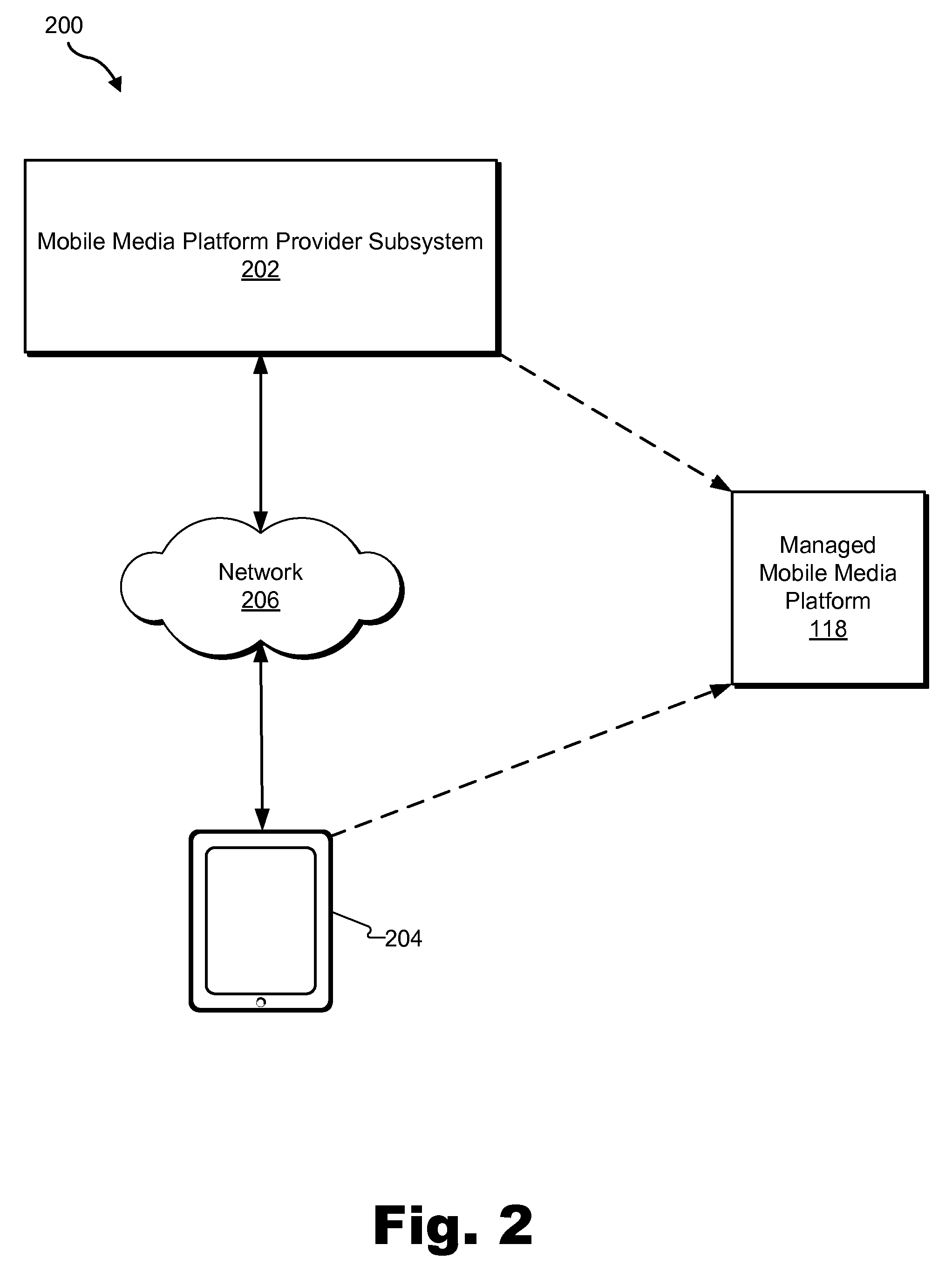

Managed mobile media platform systems and methods

ActiveUS9256717B2Digital data processing detailsMultiple digital computer combinationsIndustrial serviceMobile computing

An exemplary system includes 1) a mobile computing device provided by a vertical solution provider for use by a customer of an industry service provider to access one or more services provided by the industry service provider and 2) a mobile media platform provider subsystem operated by the vertical solution provider and configured to communicate with the mobile computing device. The mobile media platform provider subsystem and the mobile computing device are configured to provide a mobile media platform managed by the vertical solution provider and configured to facilitate the use of the mobile computing device by the customer to access the one or more services provided by the industry service provider.

Owner:VERIZON PATENT & LICENSING INC

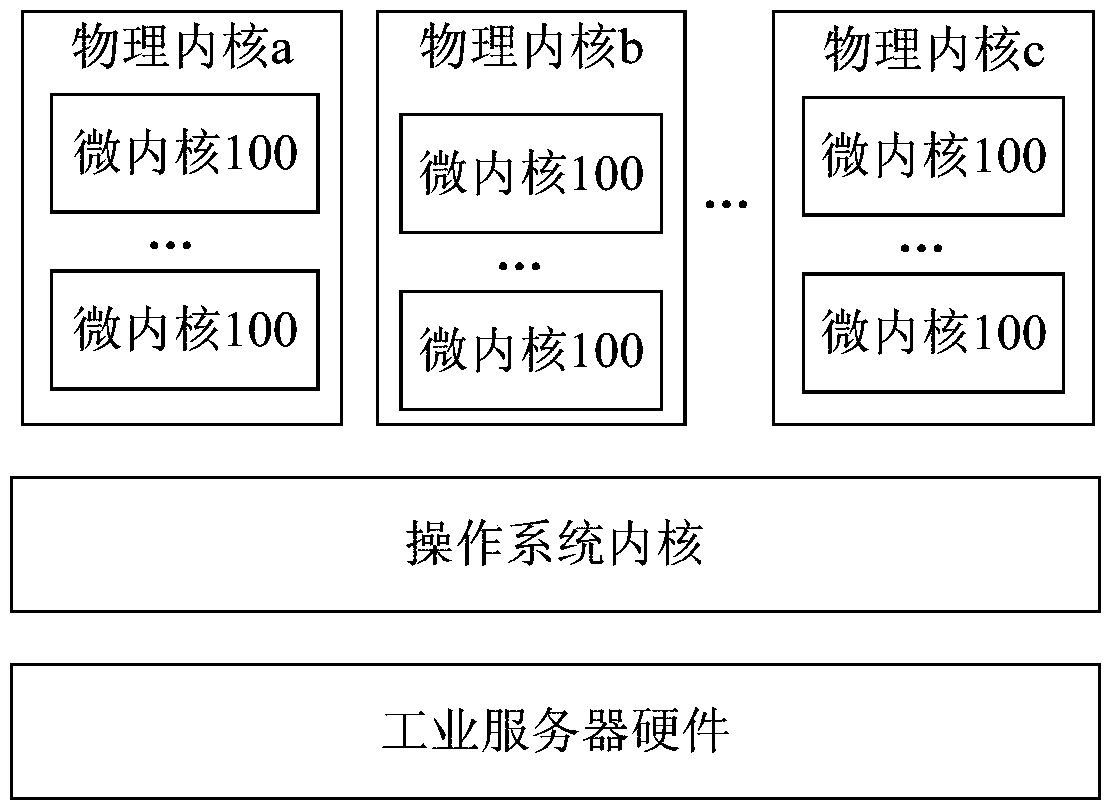

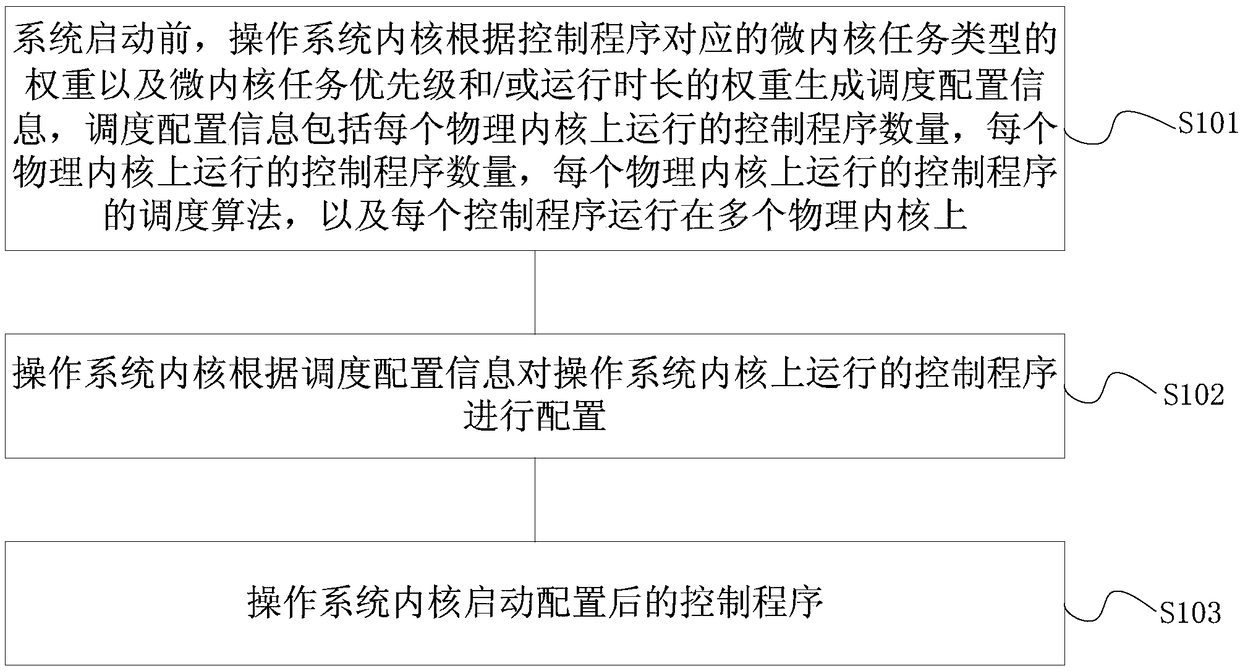

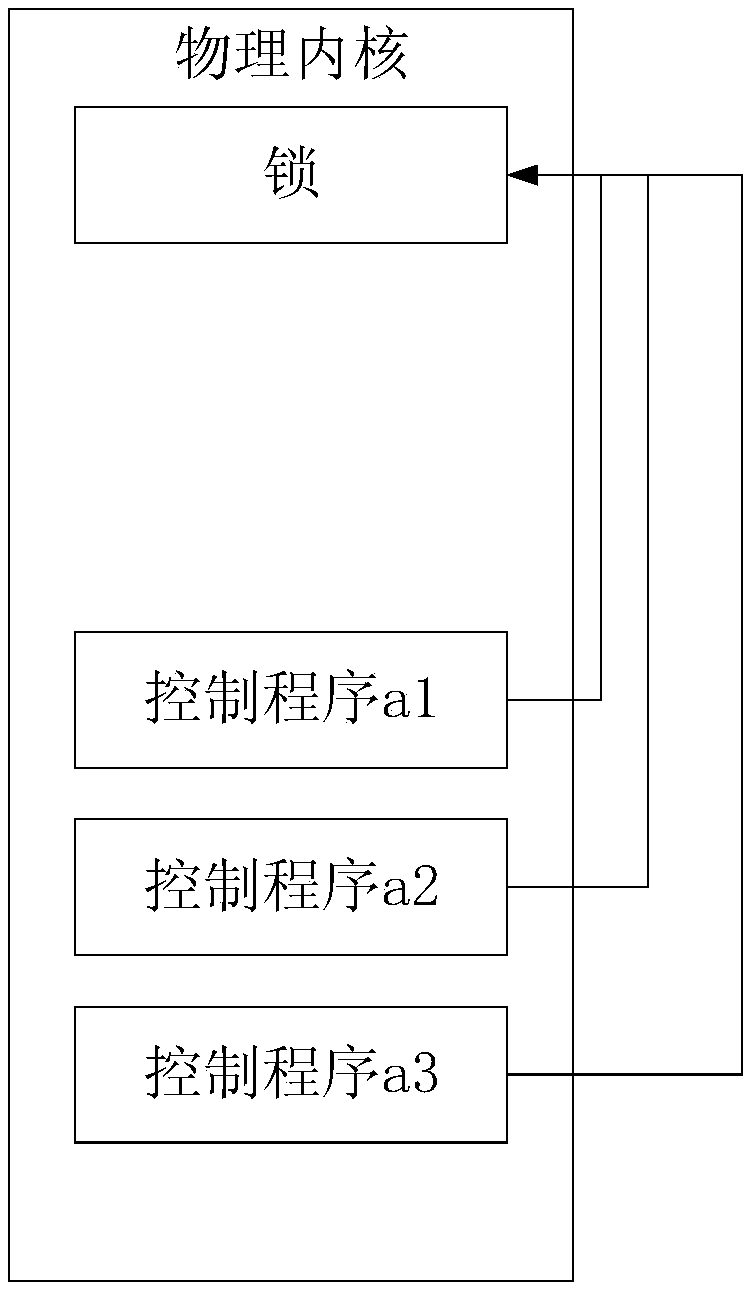

An implementation method of an industrial server microkernel architecture

ActiveCN109445847ARealize real-time controlRealize free combinationResource allocationMicrocontrol arrangementsTime controlMicrokernel

The invention discloses an implementation method of an industrial server microkernel architecture, which relates to the technical field of the industrial server. Aiming at the problem that a single physical core of the existing industrial field is fixed to run a single micro-core, or, a single microkernel can only utilize the computing resources of a single physical kernel, thereby resulting in inefficient use of computing resources in the physical kernel, according to user-defined, before the system starts, based on the microkernel task type, the weight of the microkernel task priority and / orruntime length, the dependency of control procedures is calculated, the number of control programs running on each physical kernel and the number of control programs running on multiple physical kernels according to the correlation are determined, user-defined scheme is not limited to the control of multiple microkernel time slices by a single physical kernel and the deployment of computing resources across physical kernels by a single microkernel, so as to achieve the real-time control and the free combination of industrial server microkernels in the industrial field layer.

Owner:KYLAND TECH CO LTD

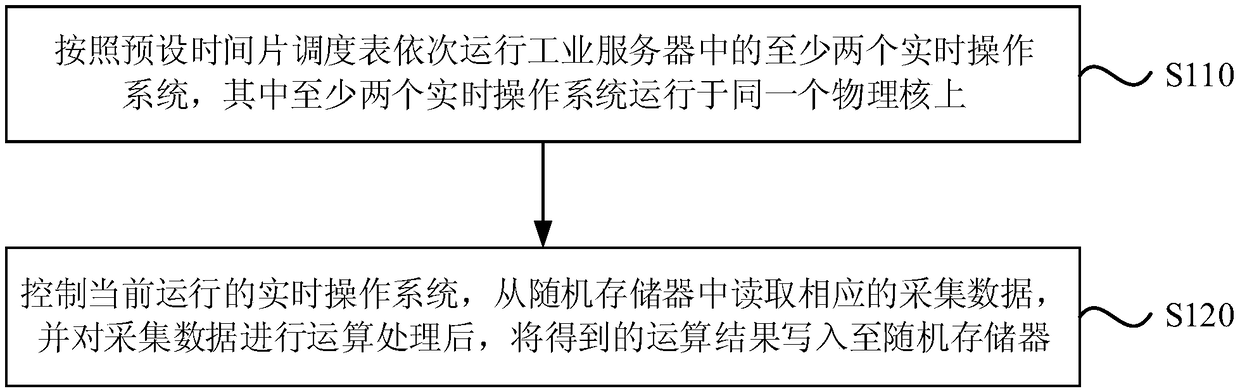

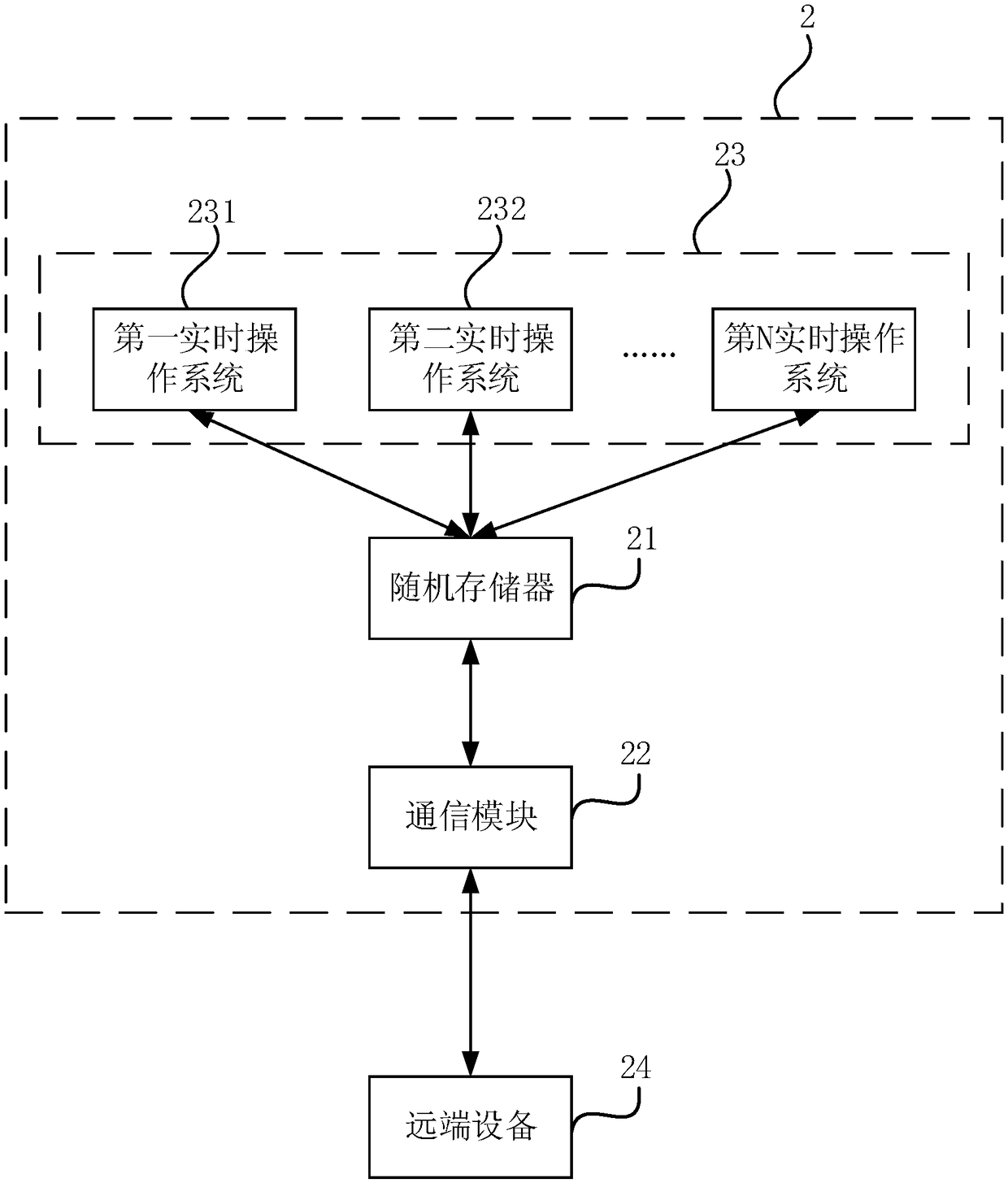

Method, system, and device for external communication of industrial server and industrial server

ActiveCN109032029ASolve the problem of low external communication efficiencyImprove the efficiency of external communicationProgramme controlComputer controlTechnical communicationOperational system

Embodiments of the invention disclose a method, a system and a device for external communication of an industrial server and the industrial server. The method comprises the following steps of: runningat least two real-time operating systems in the industrial server sequentially according to a preset time slice schedule, wherein the at least two real-time operating systems run on a same physical core; controlling the currently running real-time operating systems; reading corresponding collected data from a random access memory; performing operation processing on the collected data; and writingan obtained operation result into the random access memory. The collected data is the data acquired by a communication module from a remote device and written into the random access memory, and the communication module is independent of the at least two real-time operating systems. The technical solution of the method, the system, and the device for external communication of the industrial serverand the industrial server can improve the external communication efficiency of the industrial server.

Owner:KYLAND TECH CO LTD

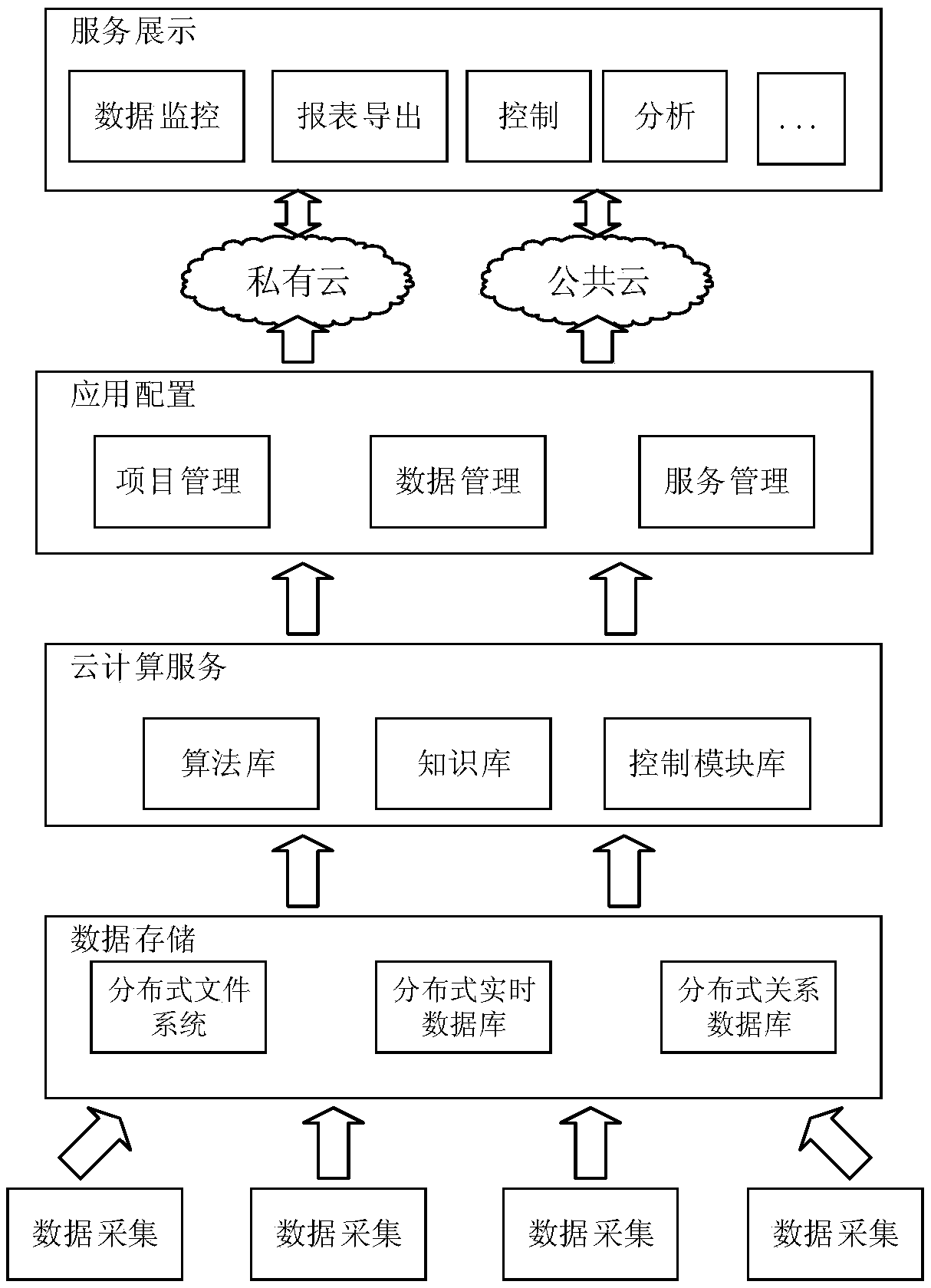

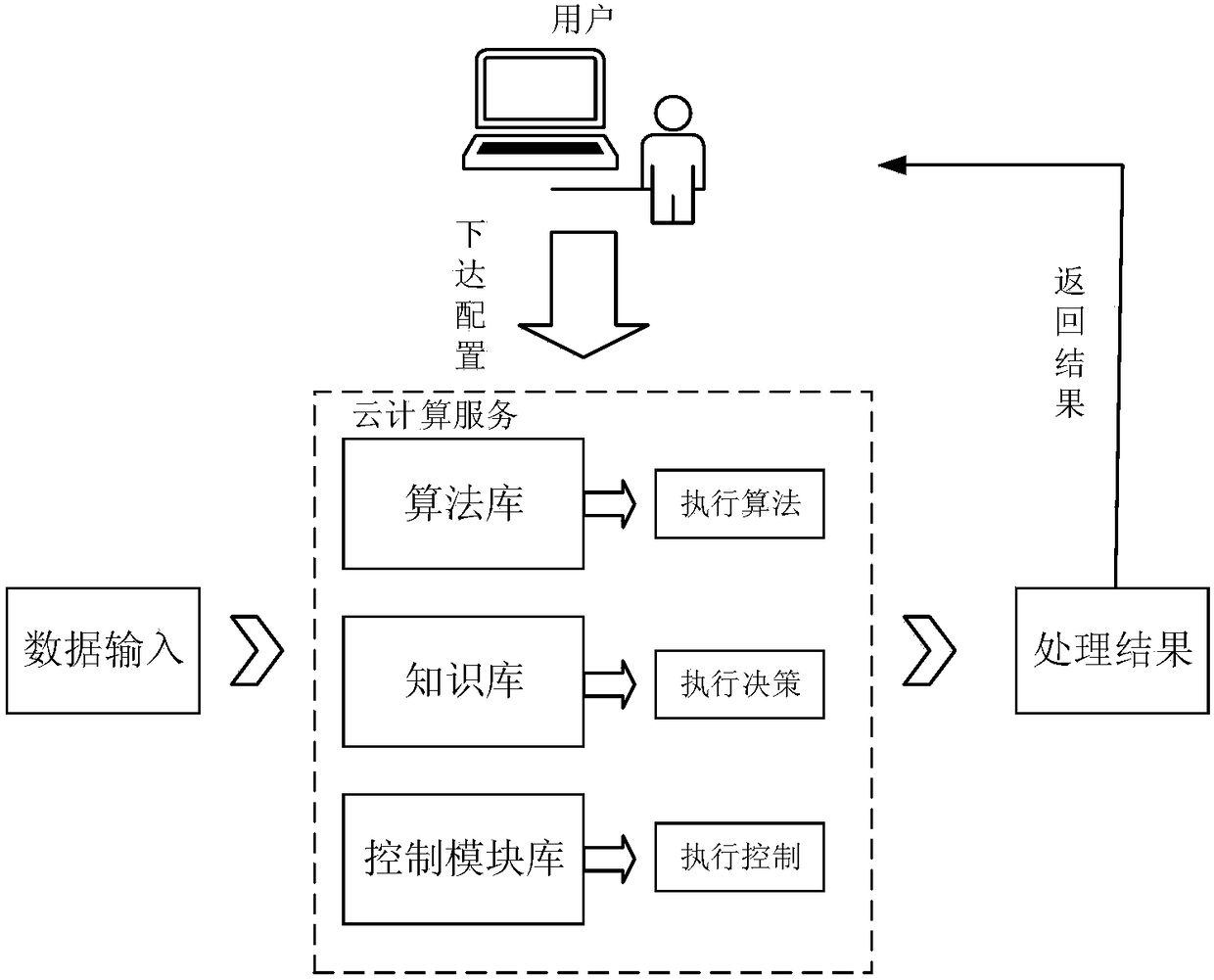

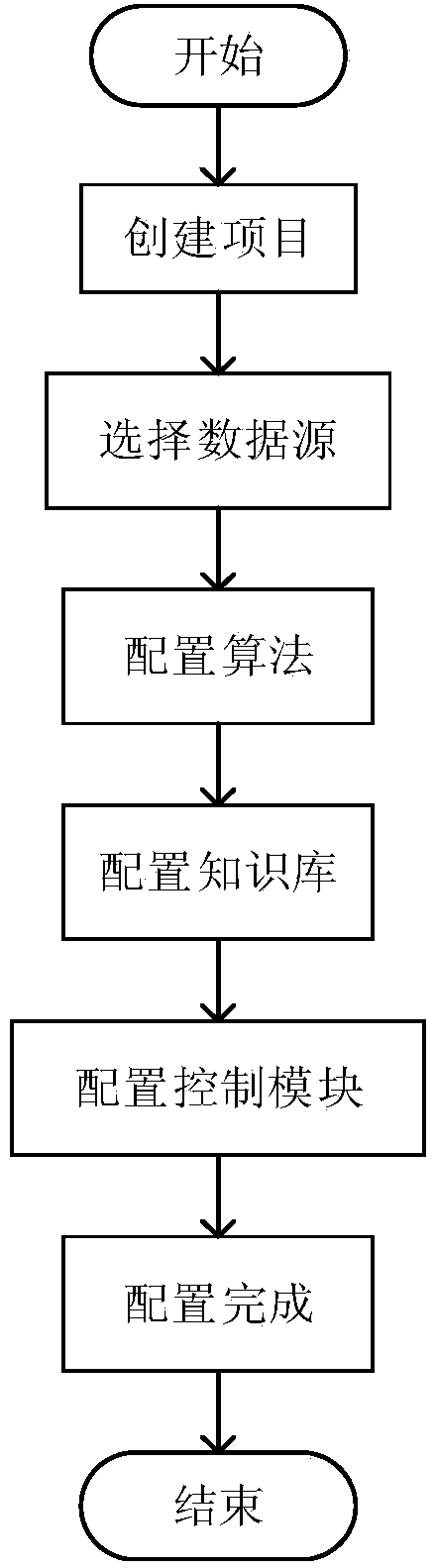

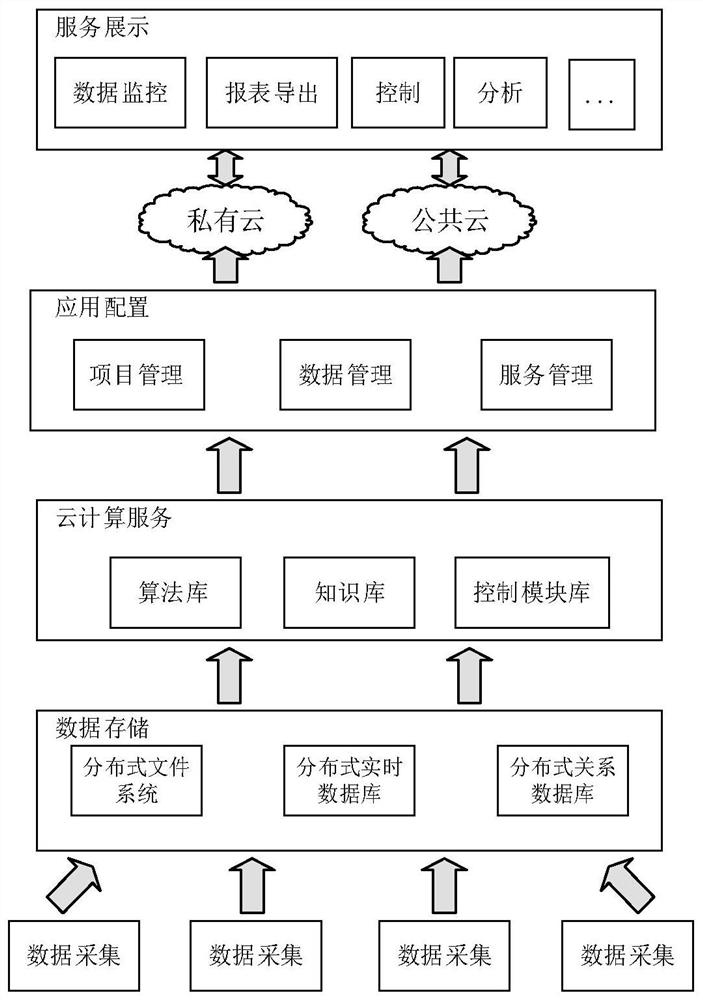

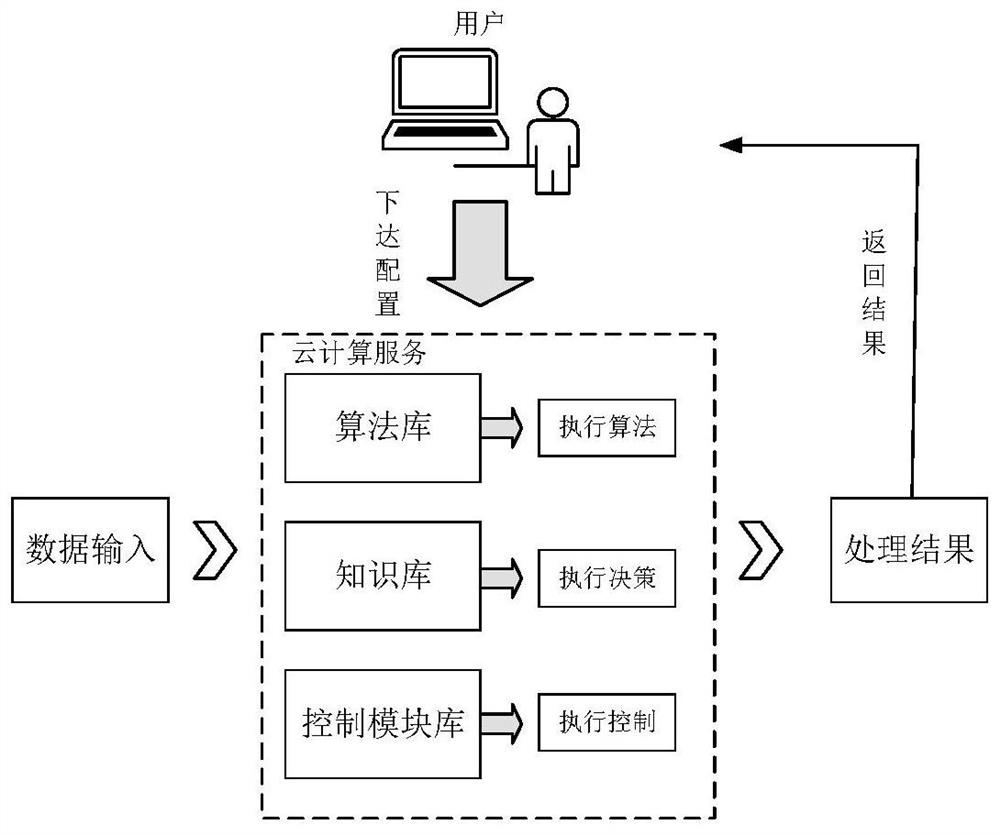

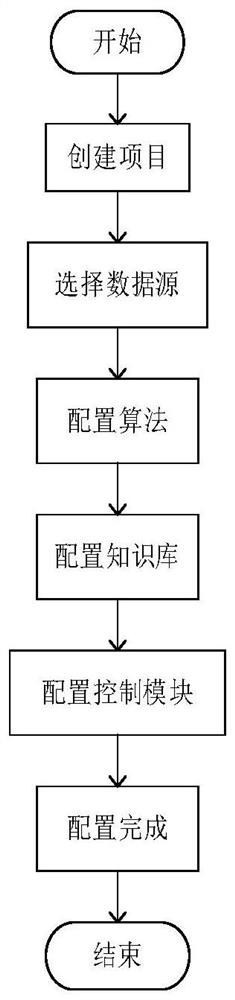

Modular industrial service platform, working method and configuration method

InactiveCN109308563AReasonable analysisImprove analytical performanceCharacter and pattern recognitionResourcesData acquisitionModularity

The invention provides a modular industrial service platform, a working method and a configuration method. The platform stores the encapsulated algorithm base, the knowledge base and the like at the cloud server end, so that a user can modularly configure items and manage items, thereby monitoring and processing industrial data and the like. The data is collected and transferred to the data storage part for storage. Data storage has many kinds of storage forms for different data forms; The service part includes all kinds of algorithms, knowledge base, control module and so on, and supports theuser to upload the module by himself. The application configuration part is used to create the project and modular configuration; Service presentations are used for end-user feedback. The invention can achieve the effect of monitoring, analyzing and controlling the industrial data through the modular configuration.

Owner:NANJING NARI GROUP CORP +2

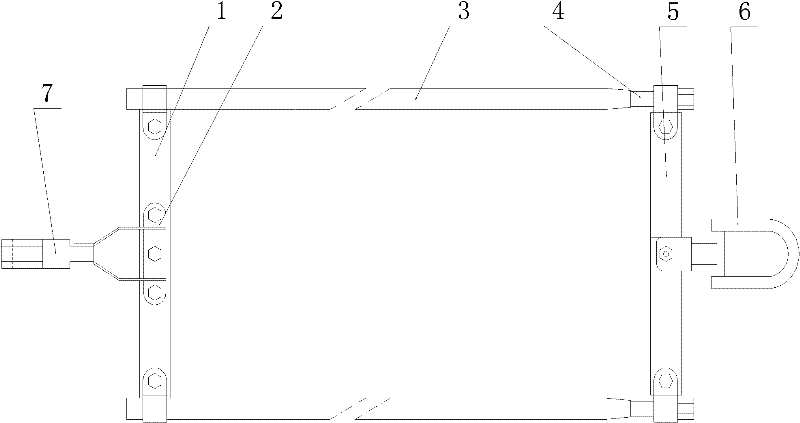

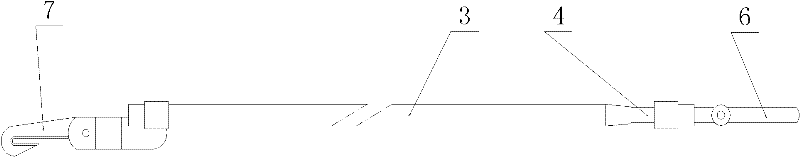

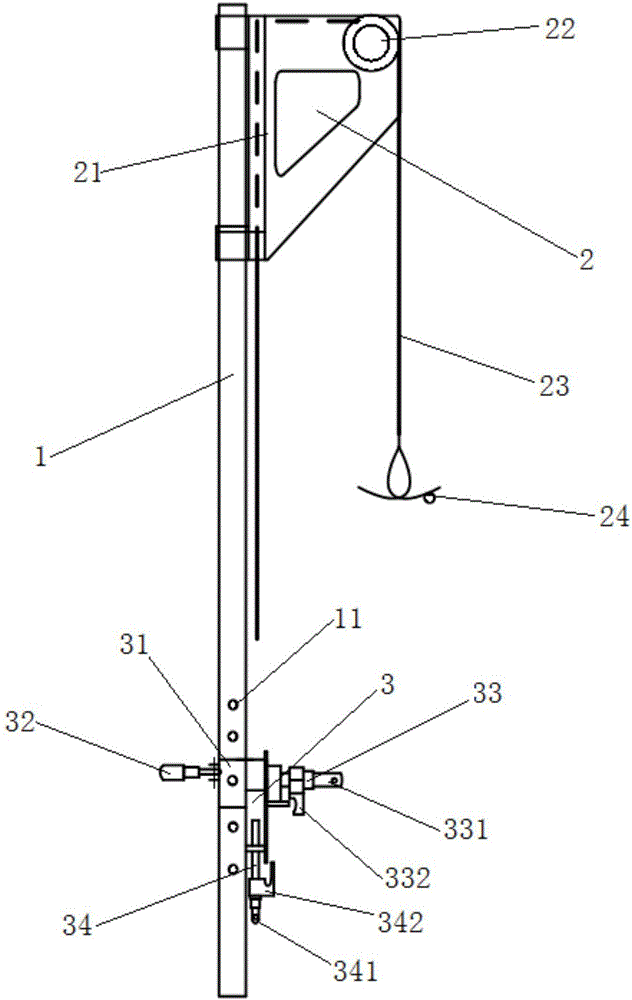

Device for replacing insulator in alive state

InactiveCN106025910ANo mobilityNo rotationApparatus for overhead lines/cablesQuality of serviceSocial benefits

The invention relates to a device for replacing an insulator in an alive state. The device is characterized by comprising a support, a fixed pulley assembly, and a fixing assembly. The fixed pulley assembly is fixed to one end of the support. The fixing assembly is in sliding connection with the support. The support is connected with a cross arm via the fixing assembly. When an insulator is replaced, the support is installed on the cross arm through the fixing assembly and a faulted cable is hoisted by the fixed pulley assembly. As a result, the insulator is replaced in the alive state. Compared with a product in the prior art, the device is safe and reliable, and easy to carry, satisfies a purpose of quickly replacing the insulator, enhances power supply reliability, increases power sales amount, improves industrial service quality, a guarantee clients uninterrupted power supply, has very positive significance to increase in power supply reliability and power sales amount, and increases social benefit and economic benefit.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

Modular industrial service platform architecture method based on cloud computing

PendingCN112257969AReasonable analysisReasonable useResourcesManufacturing computing systemsSoftware engineeringData acquisition

The invention relates to a modular industrial service platform architecture method based on cloud computing. The method comprises the steps of data acquisition, data storage, cloud computing service,application configuration and service display. After data acquisition, the data is transmitted to the data storage part for storage; the data storage has multiple storage forms for different data forms; the cloud computing service part comprises various algorithms, knowledge bases, control modules and the like for modular configuration, and supports a user uploading module; the application configuration part is used for creating projects and performing modular configuration; and the service display is used for finally feeding back to the user. According to the invention, modular configurationcan be carried out in a cloud service mode, so that the effects of monitoring, analyzing and controlling industrial data are achieved, meanwhile, the combination of cloud services can be customized bya user, and the flexibility of platform services is improved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

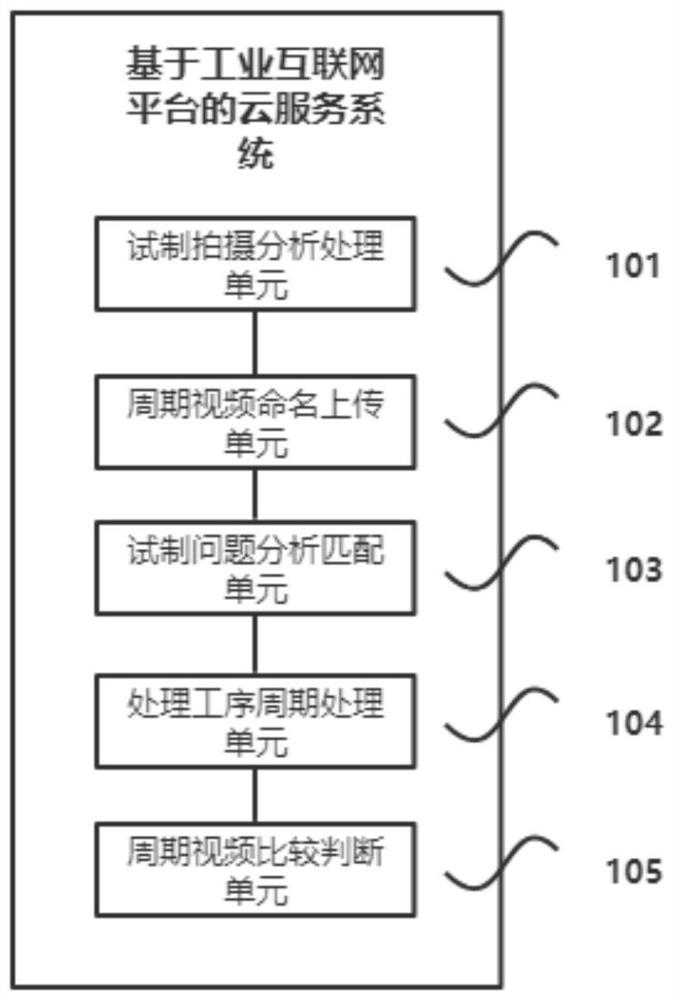

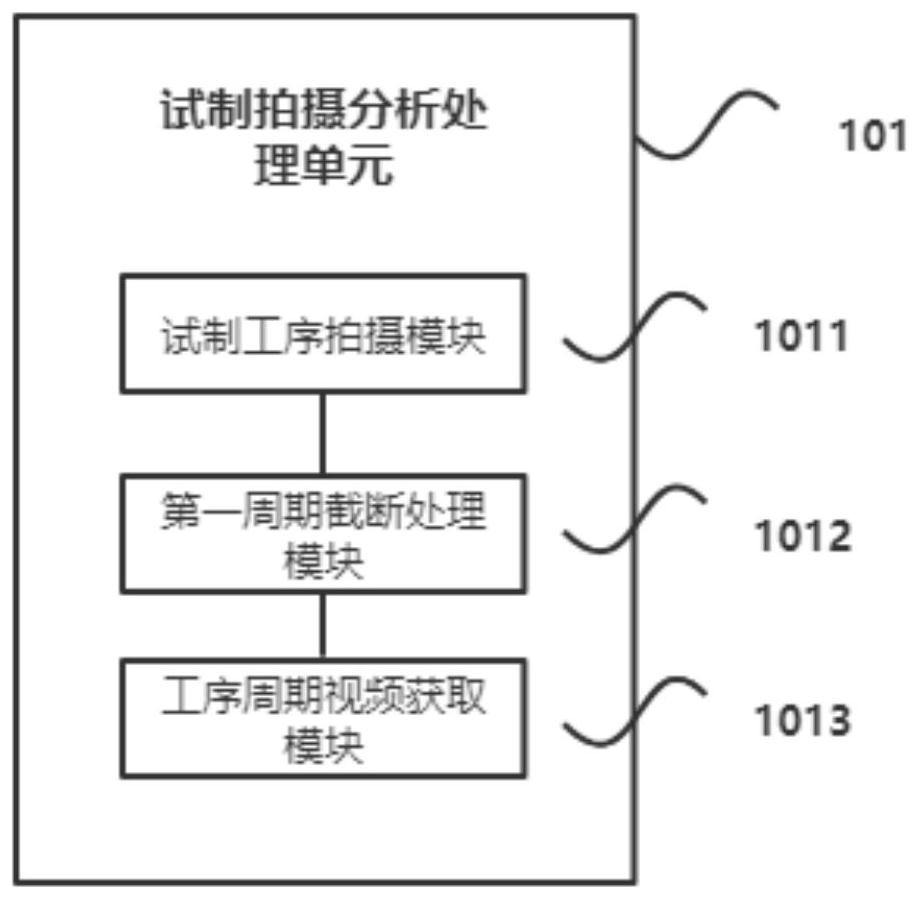

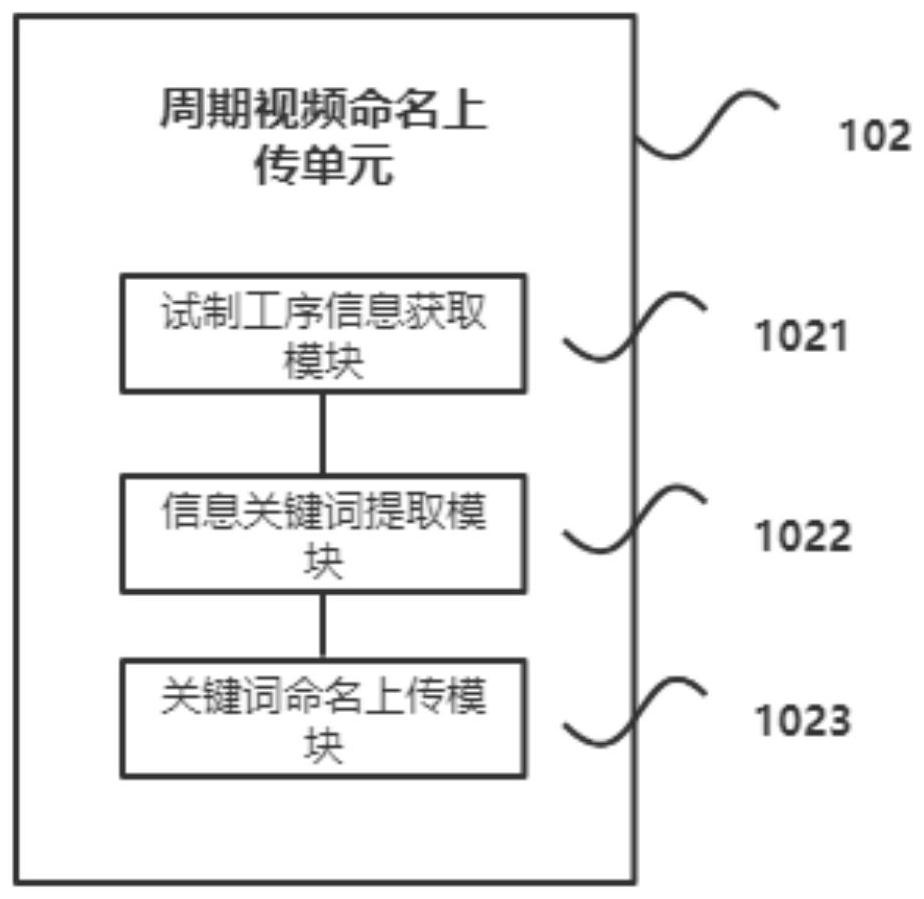

Cloud service system based on industrial internet platform

PendingCN114662886AShorten the trial production cycleMetadata video data retrievalResourcesThe InternetIndustrial Internet

The embodiment of the invention relates to the technical field of industrial services, and particularly discloses a cloud service system based on an industrial internet platform. The embodiment of the invention discloses a cloud service system based on an industrial internet platform. The cloud service system comprises a trial-production shooting analysis processing unit, a periodic video naming uploading unit, a trial-production problem analysis matching unit, a processing procedure periodic processing unit and a periodic video comparison judgment unit. Real-time shooting can be carried out in the product trial-production process, multiple process period videos are obtained, trial-production problem information is received, the process period videos are matched with a responsibility department according to the trial-production problem information, after the responsibility department solves the trial-production problem, the period videos are compared, whether the trial-production problem is solved or not is judged, and the trial-production problem is solved. Therefore, in the product trial-manufacturing process, personnel of multiple related departments do not need to carry out trial-manufacturing and line tracking, multiple problems found in trial-manufacturing can be gradually solved in one trial-manufacturing process, and the product trial-manufacturing period is shortened.

Owner:江苏欧软信息科技有限公司

Industrial intelligent control system

InactiveCN105068521AConvenient online controlFast online controlTotal factory controlProgramme total factory controlInformatizationAutomatic control

Owner:陈传海

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com