Patents

Literature

37results about How to "Convenient online control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bioelectricity synthesis system and method for synthesizing acetic acid and/or ethyl alcohol through same

ActiveCN105695319AAchieve restorationAvoid mass transfer processBioreactor/fermenter combinationsCellsPh controlEngineering

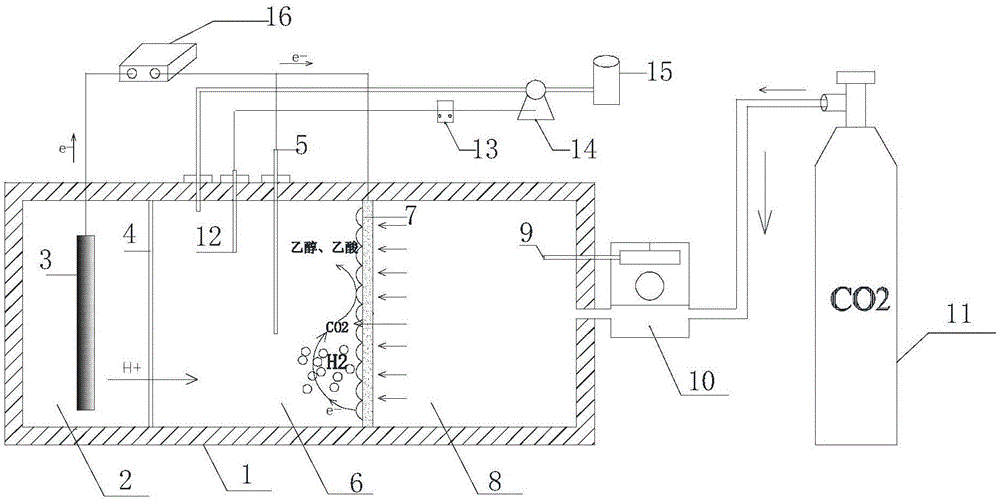

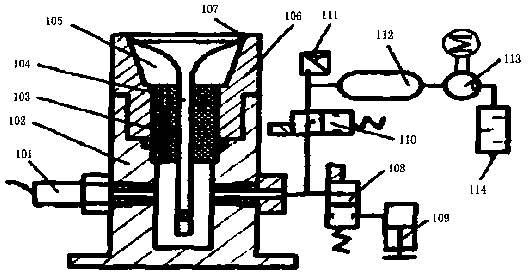

The invention discloses a bioelectricity synthesis system and a method for synthesizing acetic acid and / or ethyl alcohol through the same. The bioelectricity synthesis system comprises a reactor, an online pH control system, an air supply system and a power source. The reactor is a three-chamber reactor and comprises an air chamber, a negative electrode chamber and a positive electrode chamber, wherein the air chamber is connected with the air supply system; the negative electrode chamber is externally connected with the online pH control system, the negative electrode chamber and the air chamber are partitioned by an air negative electrode, and the negative electrode chamber is further internally provided with a reference electrode; the positive electrode chamber is internally provided with a positive electrode, the positive electrode chamber and the negative electrode chamber are partitioned by a cation exchange membrane, and the positive electrode, the air negative electrode and the reference electrode are externally connected with the power source through wires. Positive electrode electrolyte is added into the positive electrode chamber, a bioelectricity synthetic nutrient solution obtained after sterile and anaerobic treatment is added into the negative electrode chamber, and electrosynthesis bacteria are inoculated into the negative electrode chamber; carbon dioxide is sent into the air chamber through metering of the air supply system, and carbon dioxide penetrates through the air negative electrode and is converted into acetic acid and / or ethyl alcohol in the negative electrode chamber.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

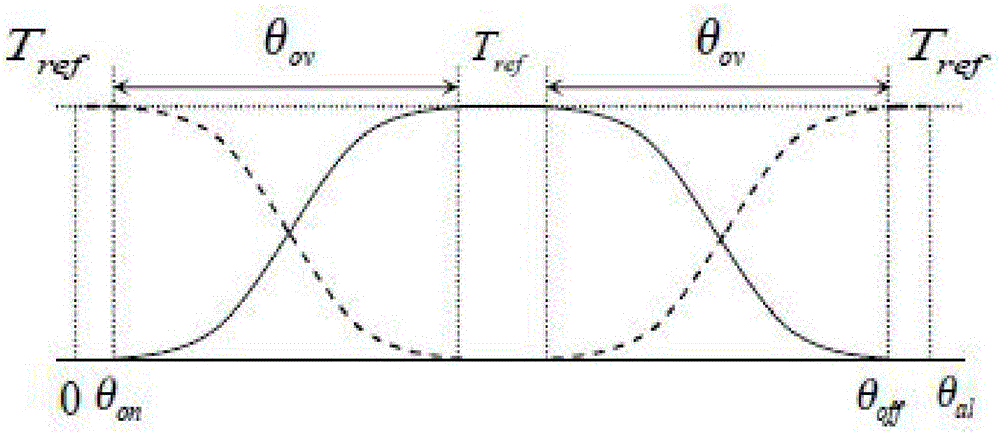

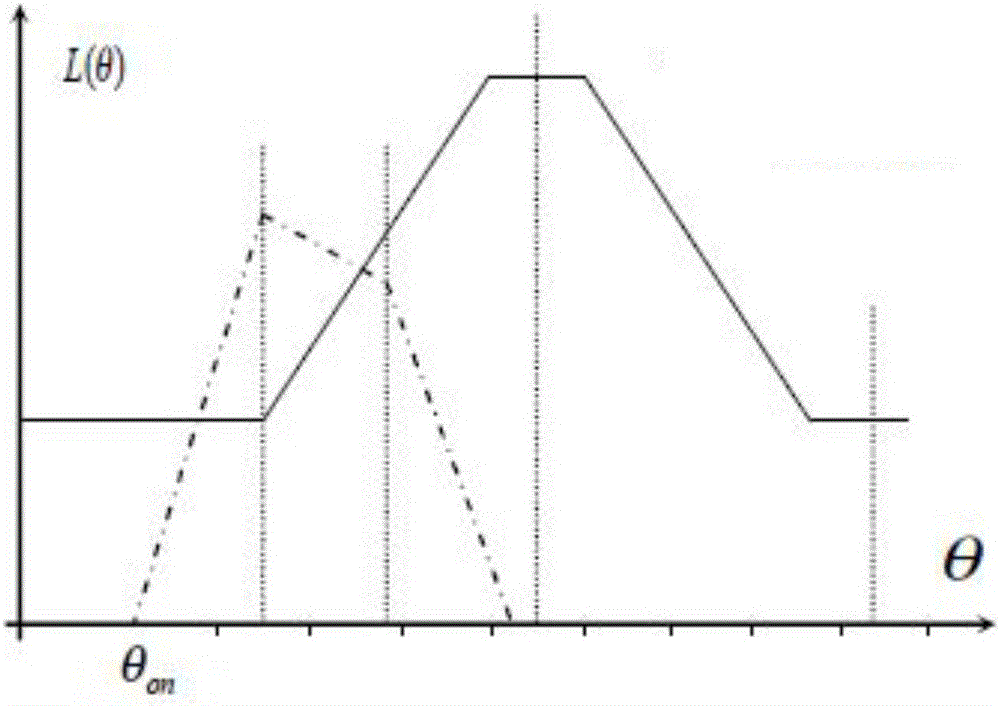

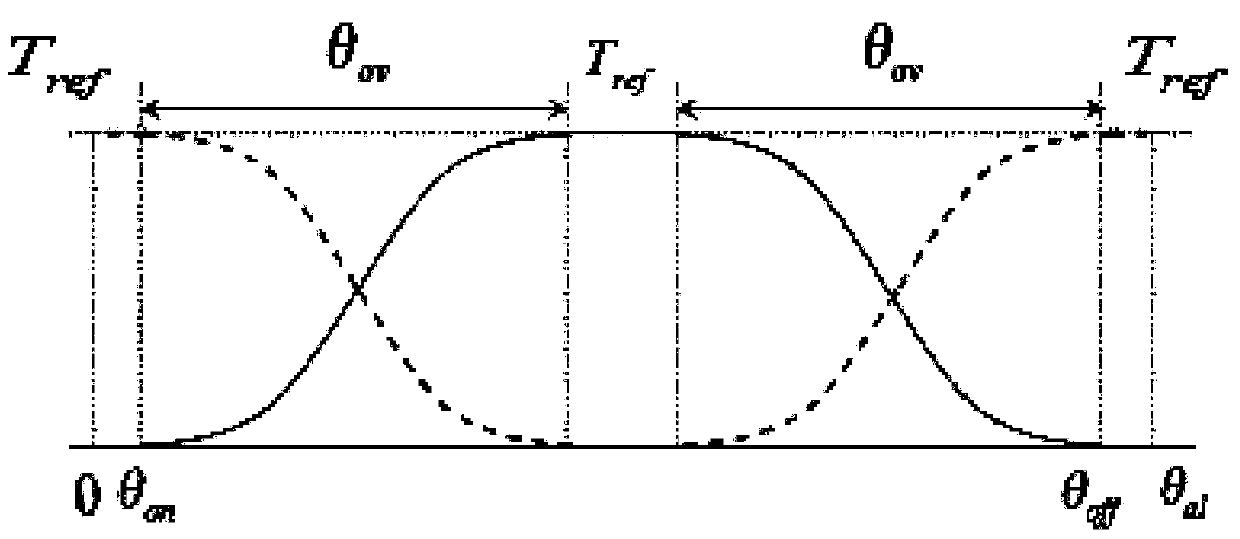

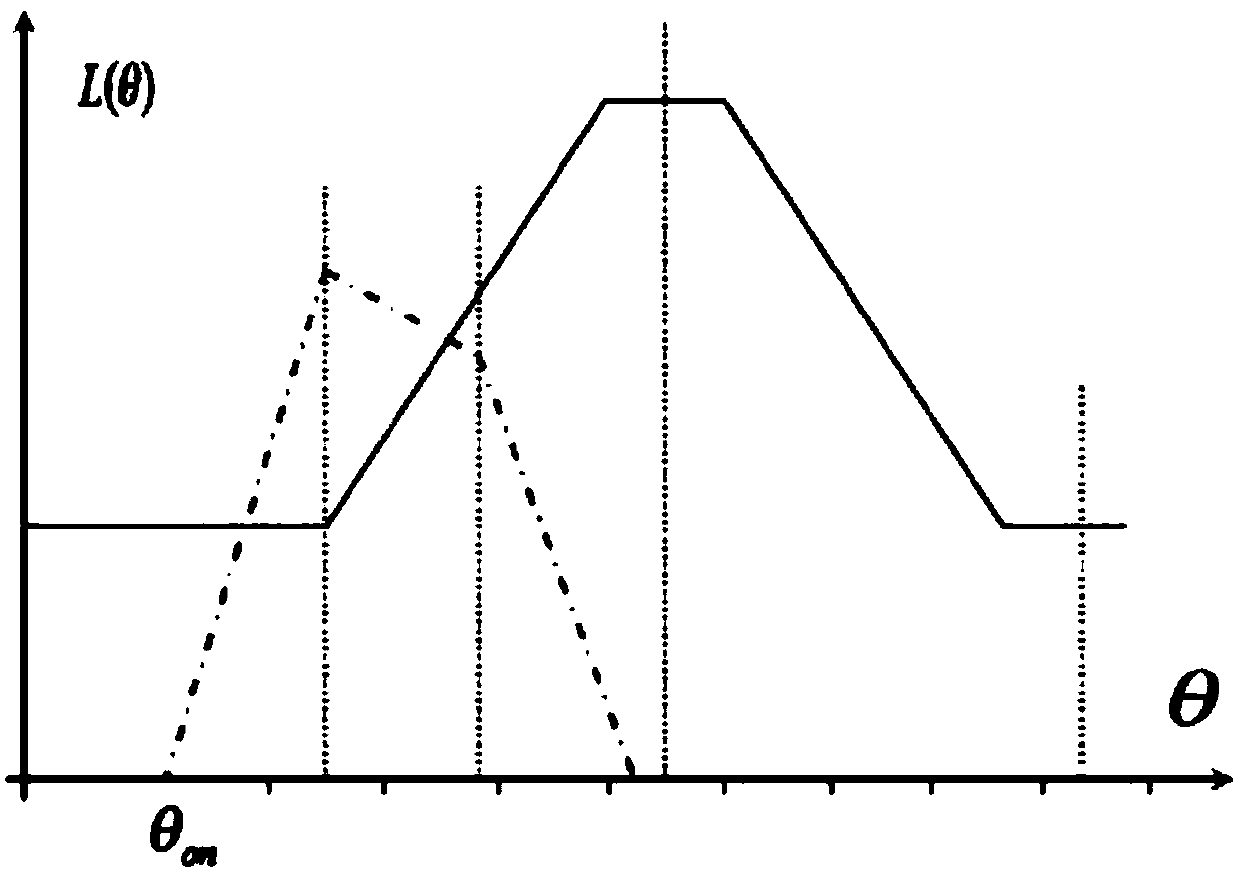

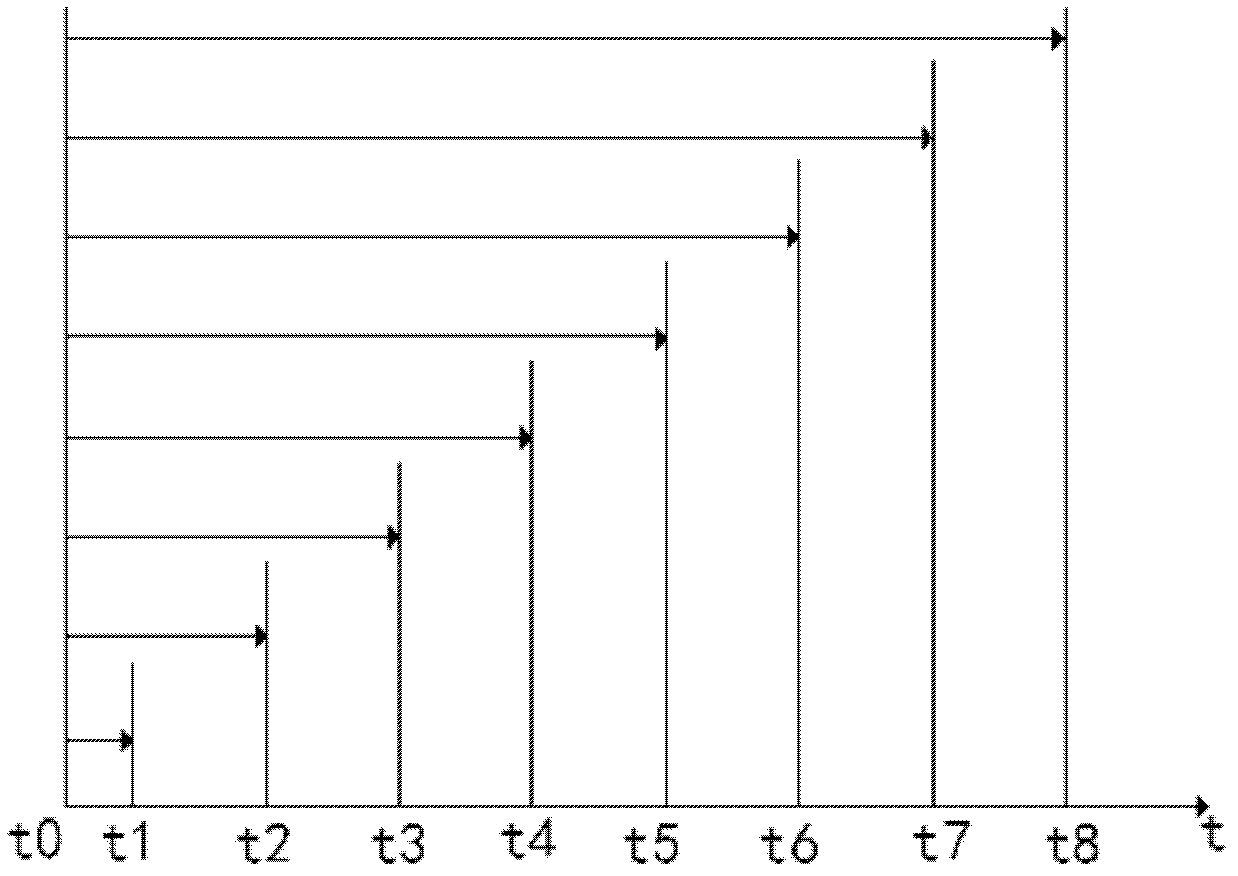

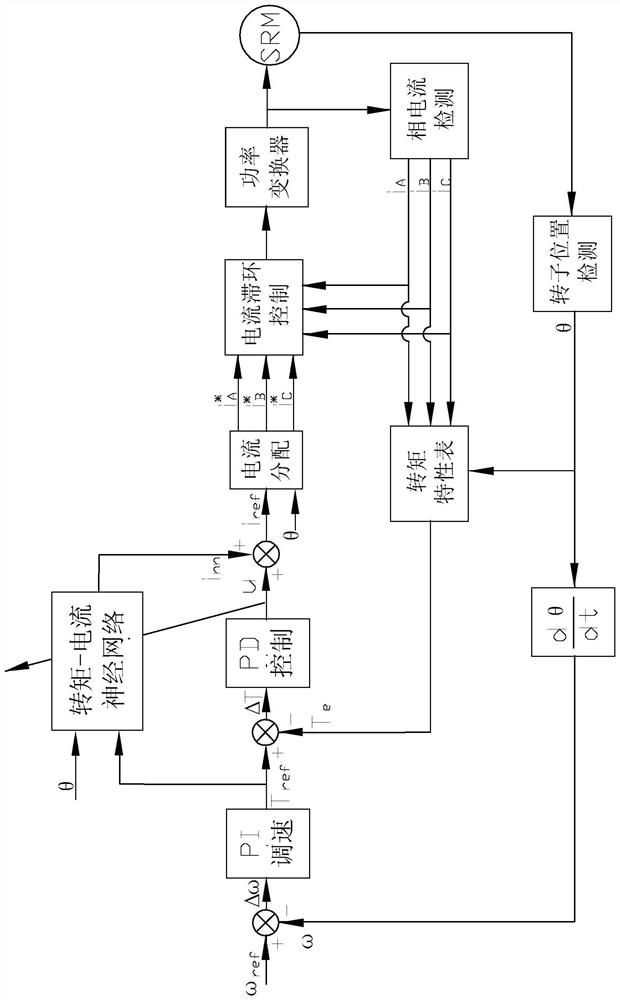

Switch reluctance machine (SRM) torque pulse control method and system of torque-current neutral network model

ActiveCN110022109AConvenient online controlElectric motor controlMotor control for motor oscillations dampingPulse controlActivation function

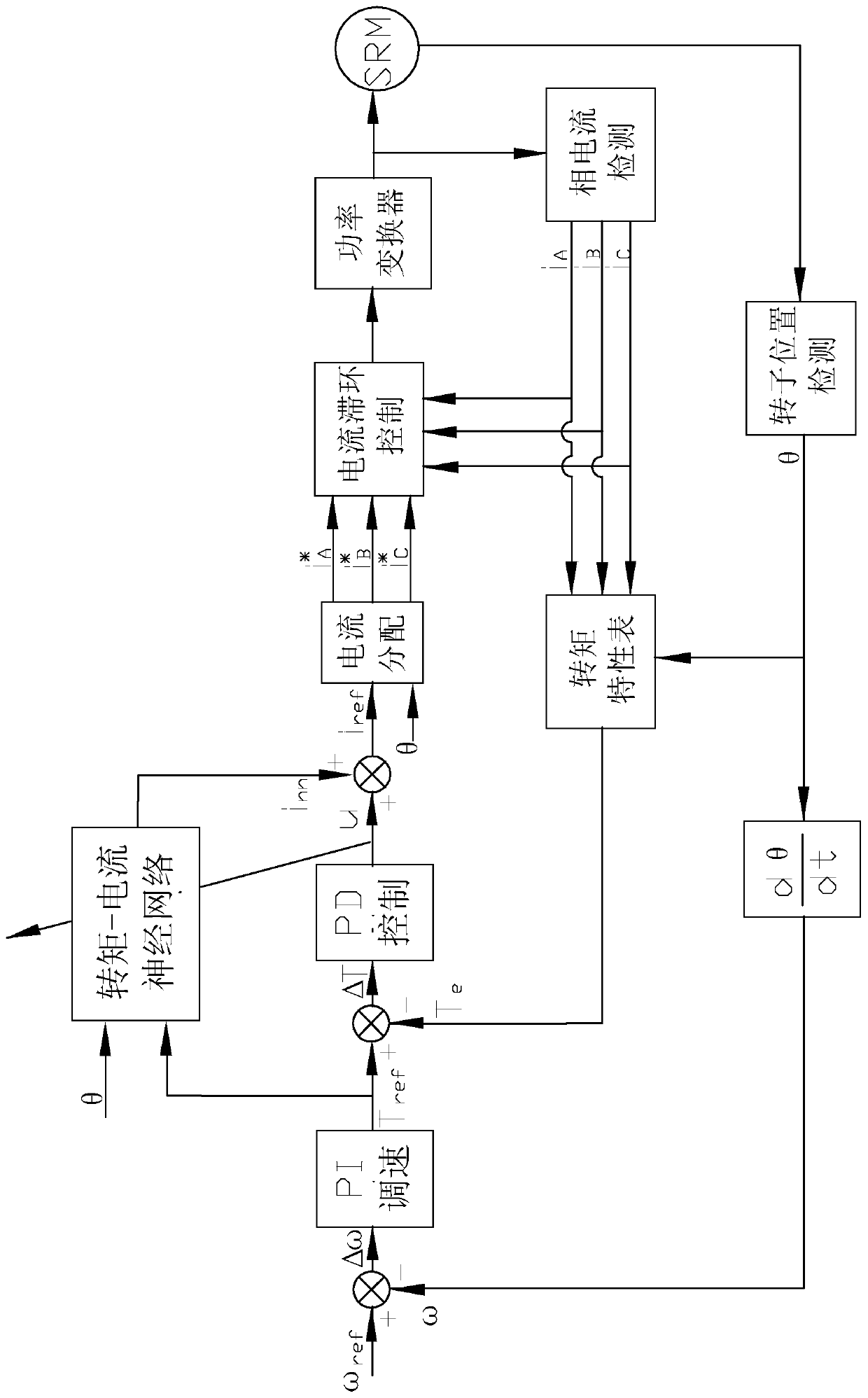

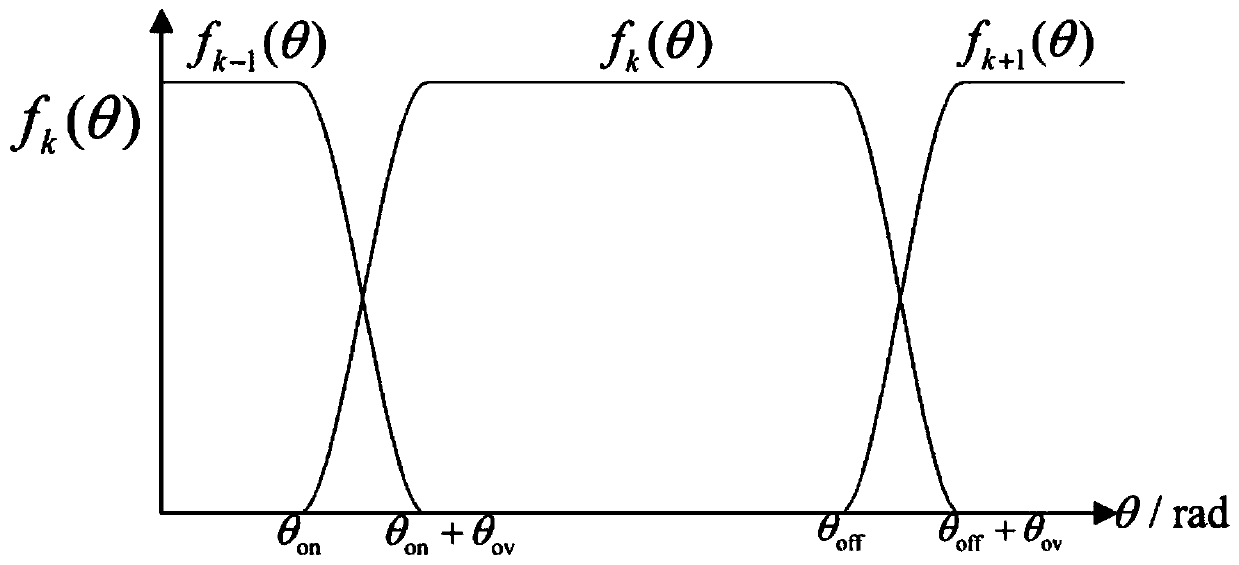

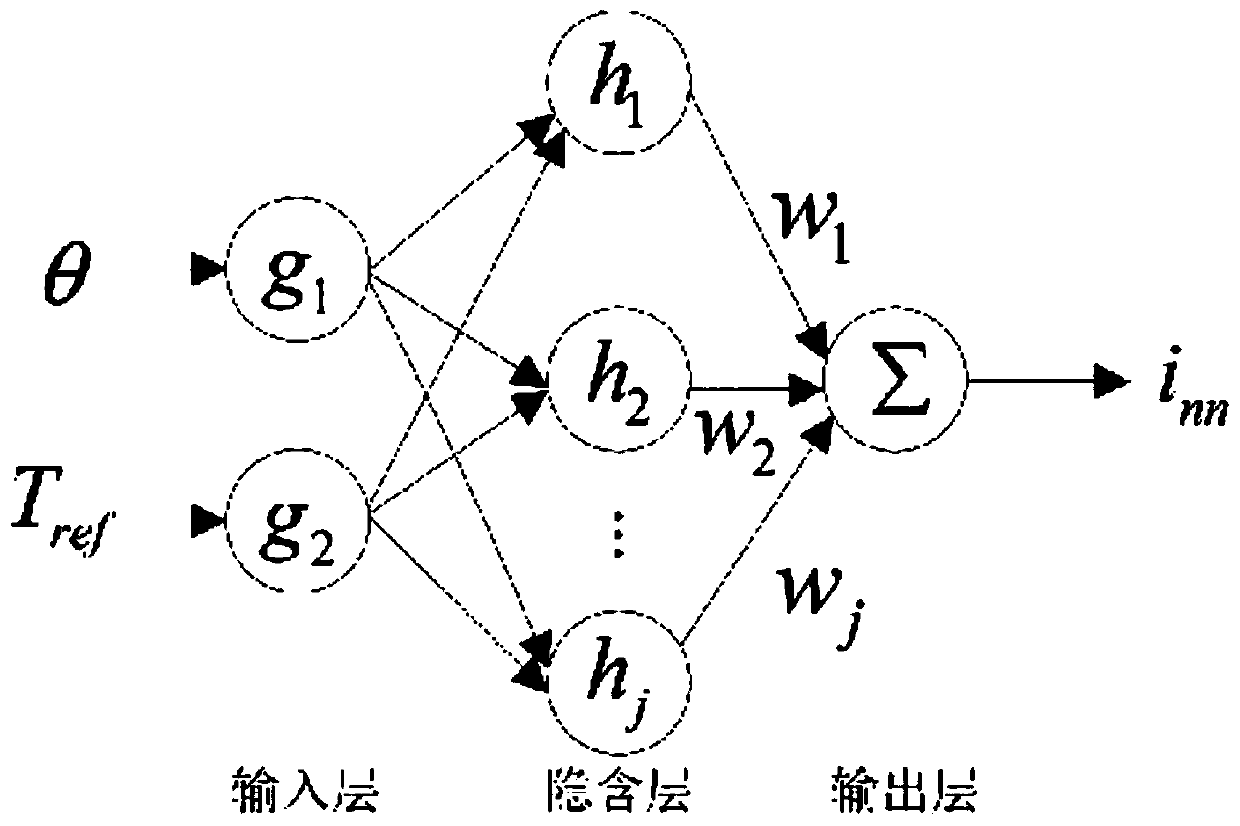

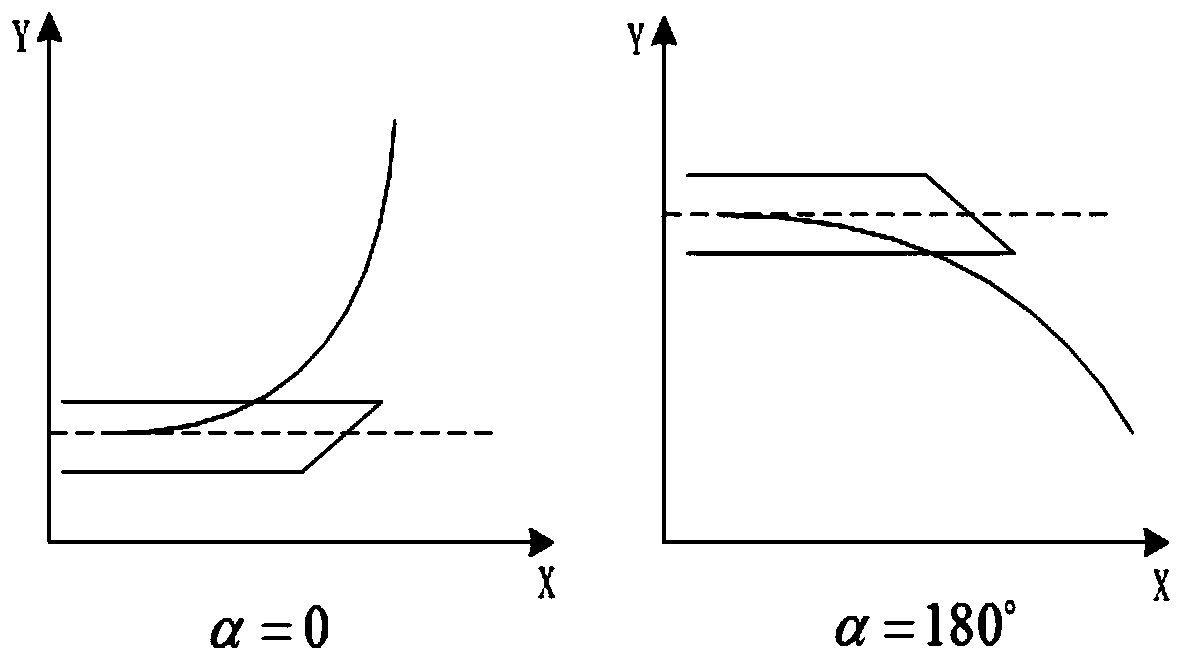

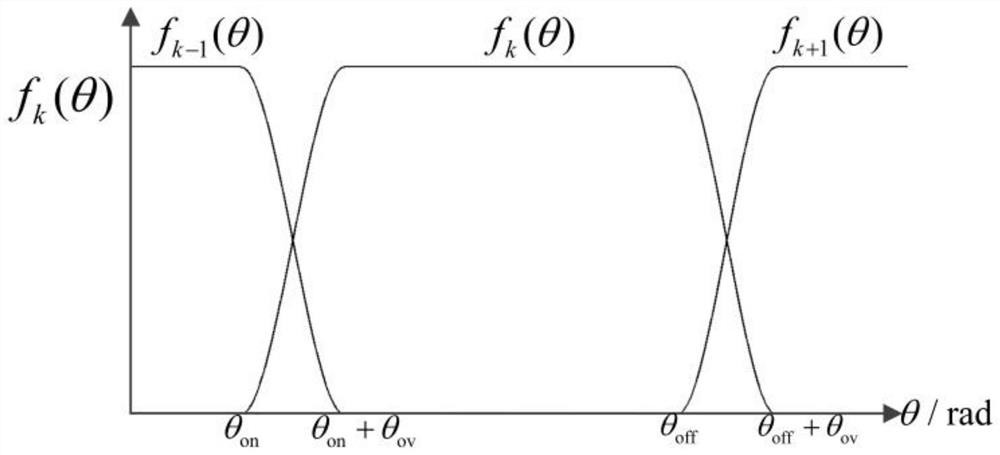

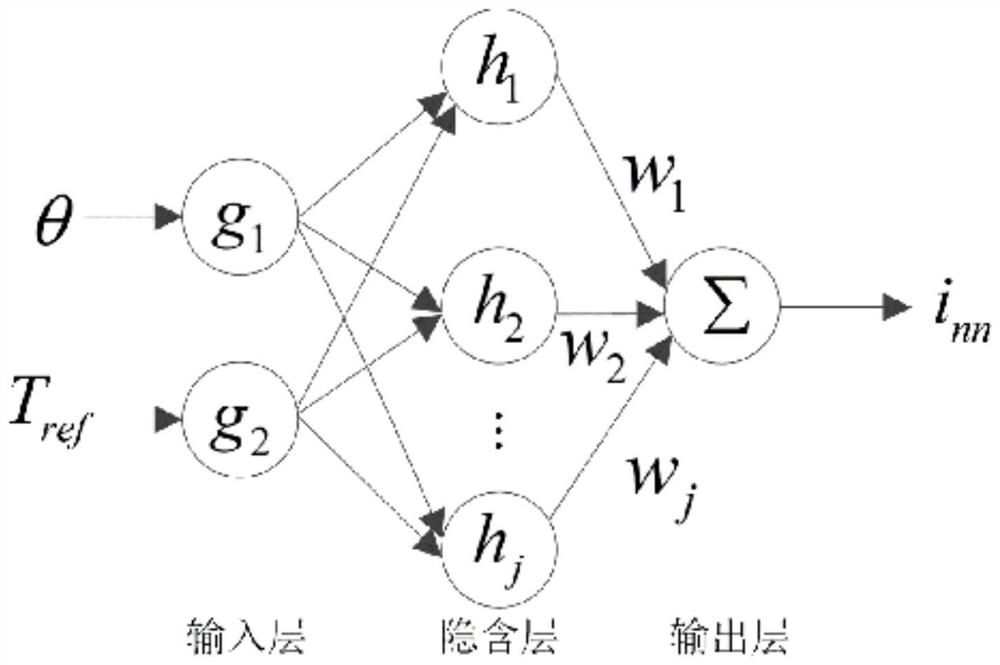

The invention relates to a switch reluctance machine (SRM) torque pulse control method and system of a torque-current neutral network model. According to the method, a torque-current conversion relation is obtained by an inductance model of an SRM, each phase control current is obtained by a current allocation function, so that torque pulse is prevented. According to a non-linear characteristic relation between the SRM torque and the current, a function of describing basic change rule of an SRM current is used as an implication layer simulation function, a torque-current neutral network modelof describing the strong non-linear characteristic of the SRM is designed, the total reference current corresponding to torque is calculated by self-learning of the torque-current neutral network model, a reference current corresponding to each phase is obtained by the current allocation function, and the SRM is controlled. A program storage device of a system microprocessor designed by the methodis provided with each program module for executing the method, each sensor signal on the SRM is connected to the microprocessor, and the SRM is connected and controlled by a power converter. By the method, effective control on torque pulse of the SRM is achieved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

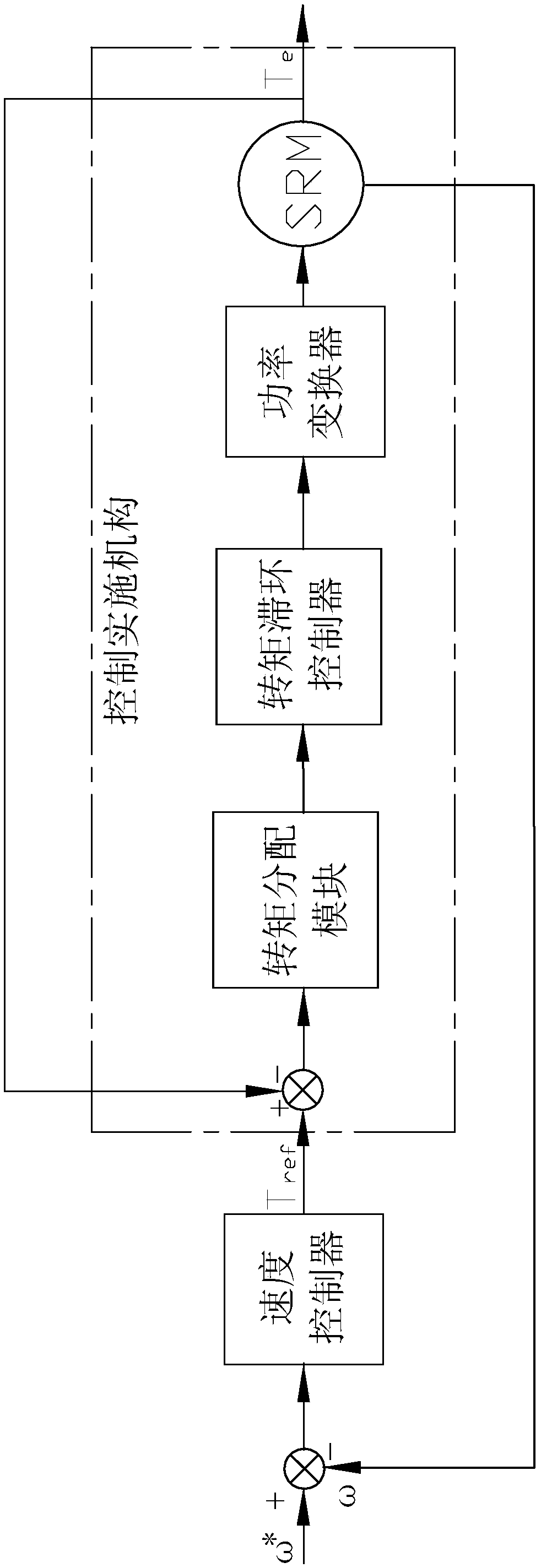

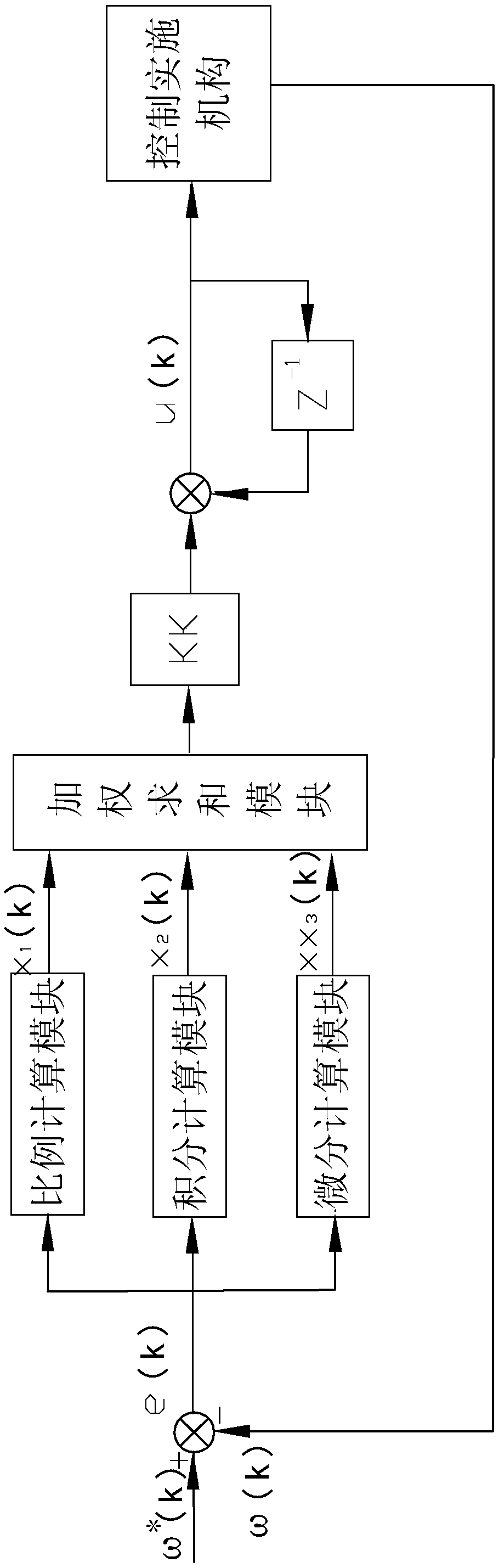

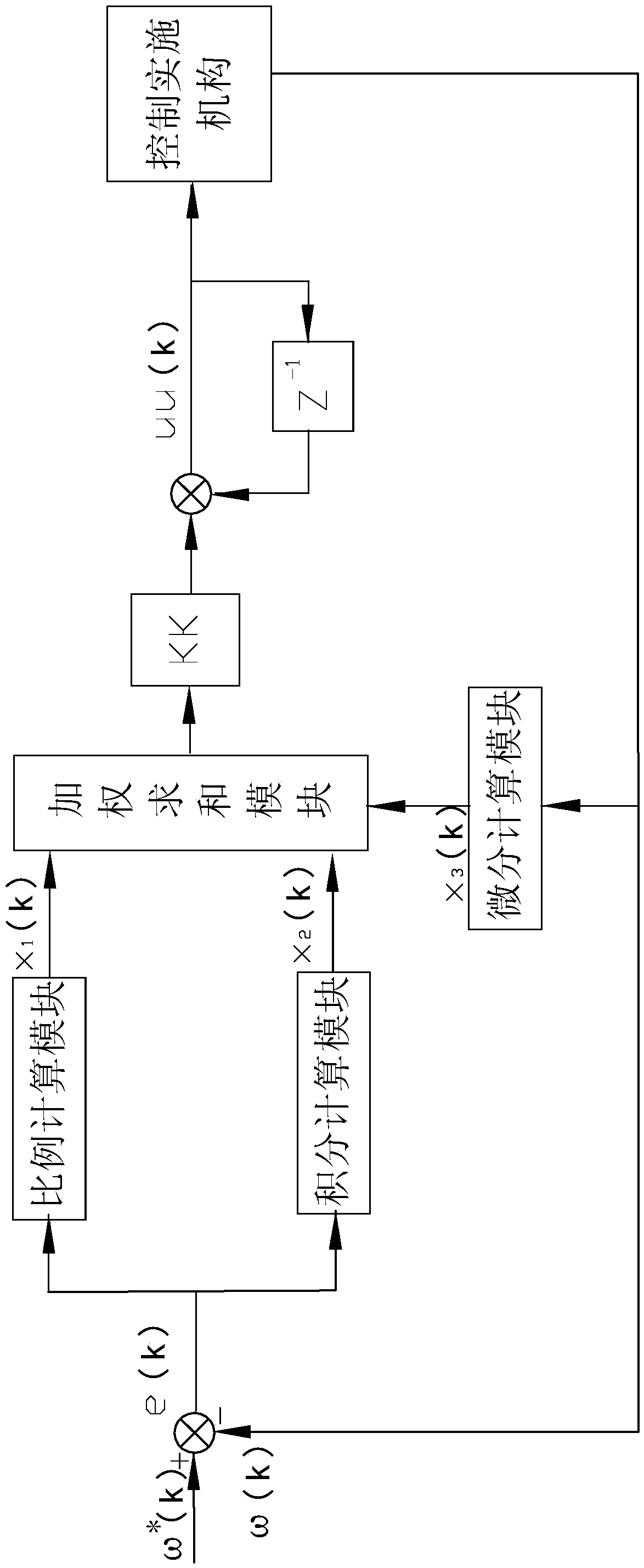

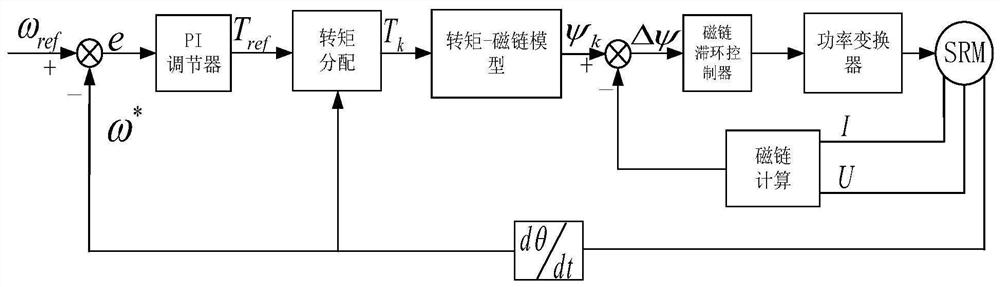

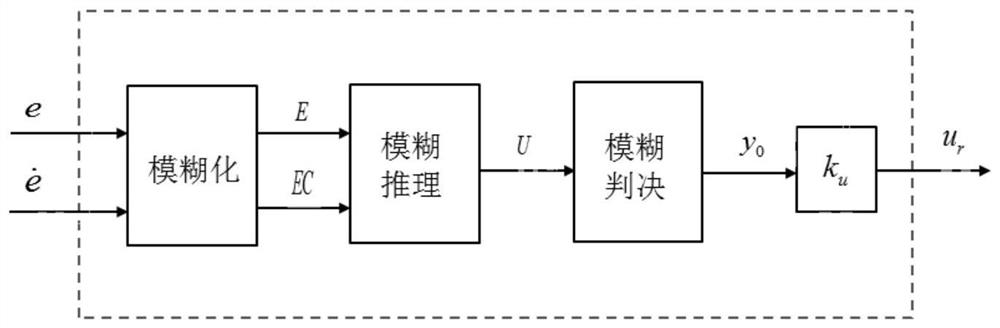

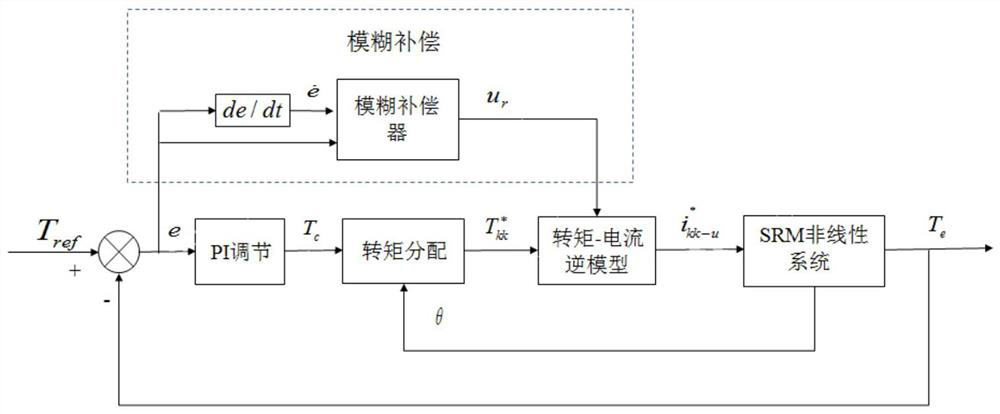

Switched reluctance motor torque control system based on improved PID control

ActiveCN109343351AReduce torque rippleQuick responseAdaptive controlControl systemFuzzy control system

The invention relates to a switched reluctance motor torque control system based on improved PID control. Based on a direct instantaneous torque control system, a differential calculation module of aforward channel in a single neuron PID speed controller is moved to a feedback channel of speed to constitute a differential advanced single neuron PID speed controller. Furthermore, a classical fuzzycontrol module and an integral calculation module are introduced to constitute an integral fuzzy control module through parallel connection, and the output gain of differential advanced single neuronPID is adjusted in real time to constitute a fuzzy-differential advanced single neuron PID controller. The control performance of the system is good. The torque ripple of switched reluctance motors is reduced, and the torque ripple rate is less than 2%. The dynamic performance of the system is good.

Owner:GUILIN UNIV OF ELECTRONIC TECH

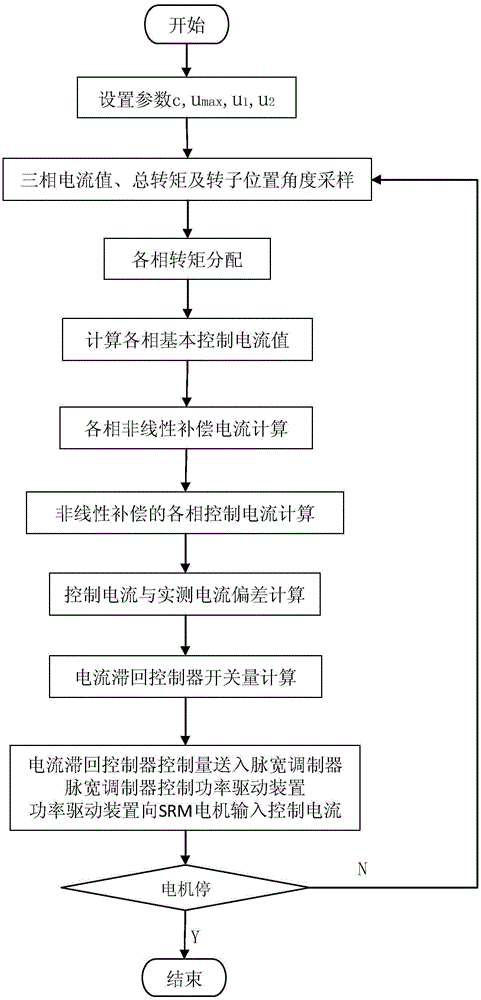

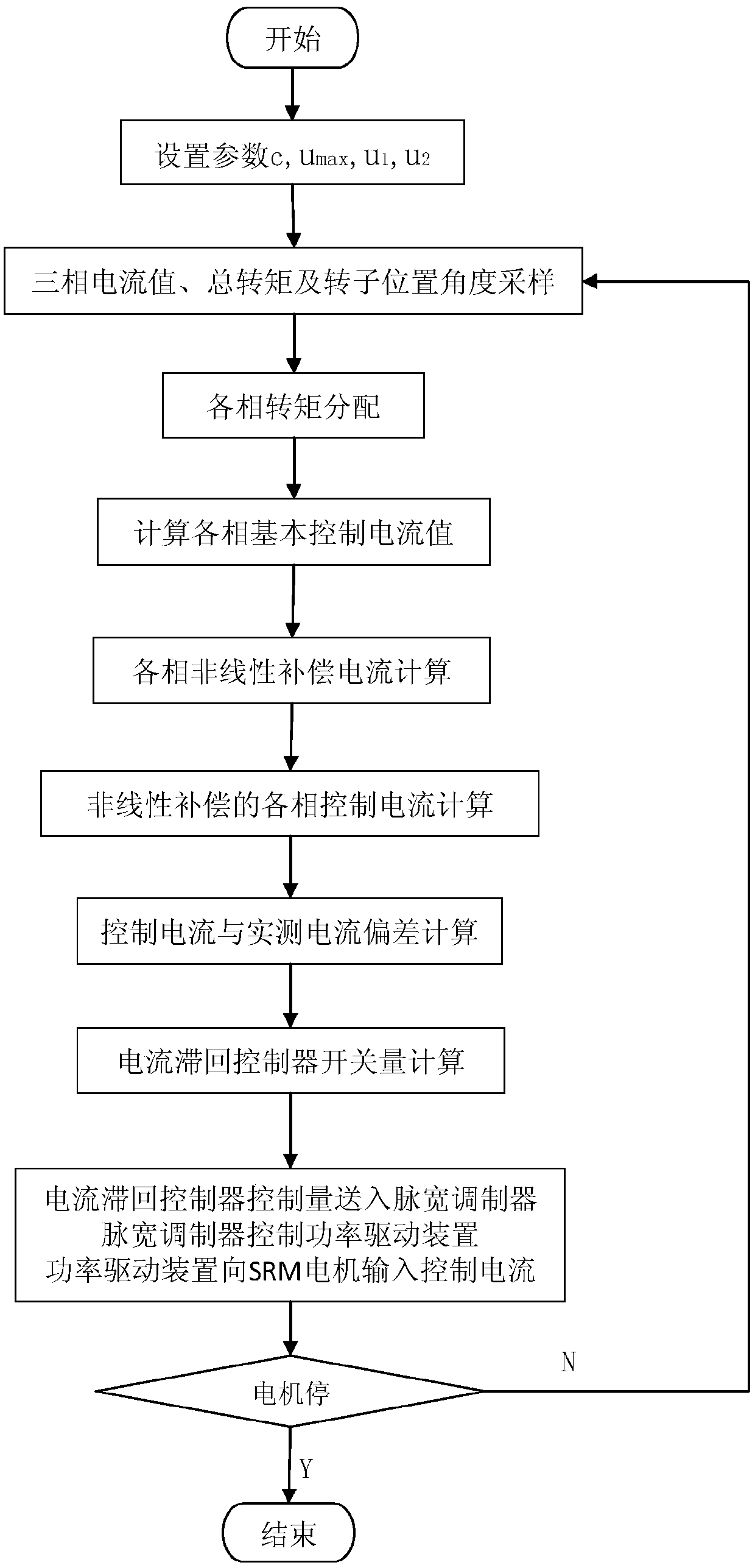

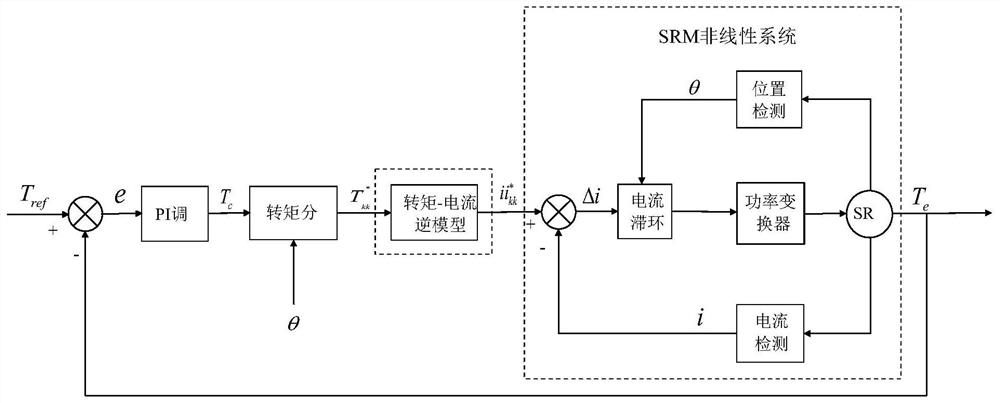

Torque control method and system of current nonlinear compensated switched reluctance motor

ActiveCN105811849AConvenient online controlSuppression of torque rippleAC motor controlHysteresisControl signal

The invention relates to a torque control method and system of a current nonlinear compensated switched reluctance motor. According to the method, a basic control current is calculated by an electromagnetic torque mathematical expression of a linear induction model of the switched reluctance motor, a set torque is allocated to allocation torques of a switch-on phase and a switch-off phase by an optimal torque-sharing function, and the basic control current of each phase is acquired through conversion; and a nonlinear current compensation value of each phase is figured out and is superposed to the basic control current of each phase to serve as the control current of each phase, and a current hysteresis loop controller is controlled according to the difference between the control current and actually-measured current. A microprocessor of the system is connected with three current sensors and a rotor position angle and torque sensor on the switched reluctance motor, a program storage is provided with a data acquisition module and each calculation module of the method, a control signal is obtained by calculation according to each actually-measured signal, and a pulse width modulator controls three-phase input current of the switched reluctance motor. By the method and the system, the torque ripple of the switched reluctance motor is effectively suppressed, an embedment system can be constructed, and on-line control is facilitated.

Owner:GUILIN UNIV OF ELECTRONIC TECH

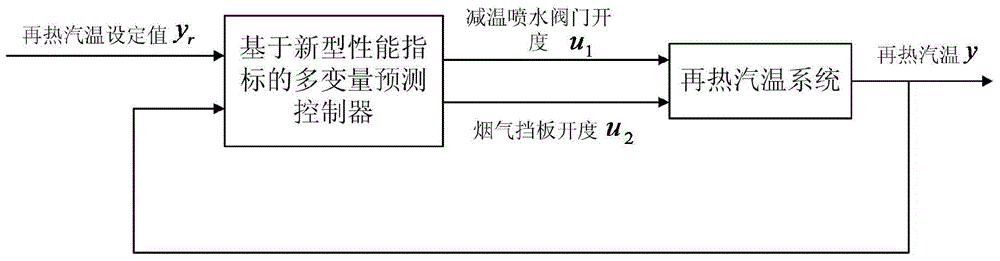

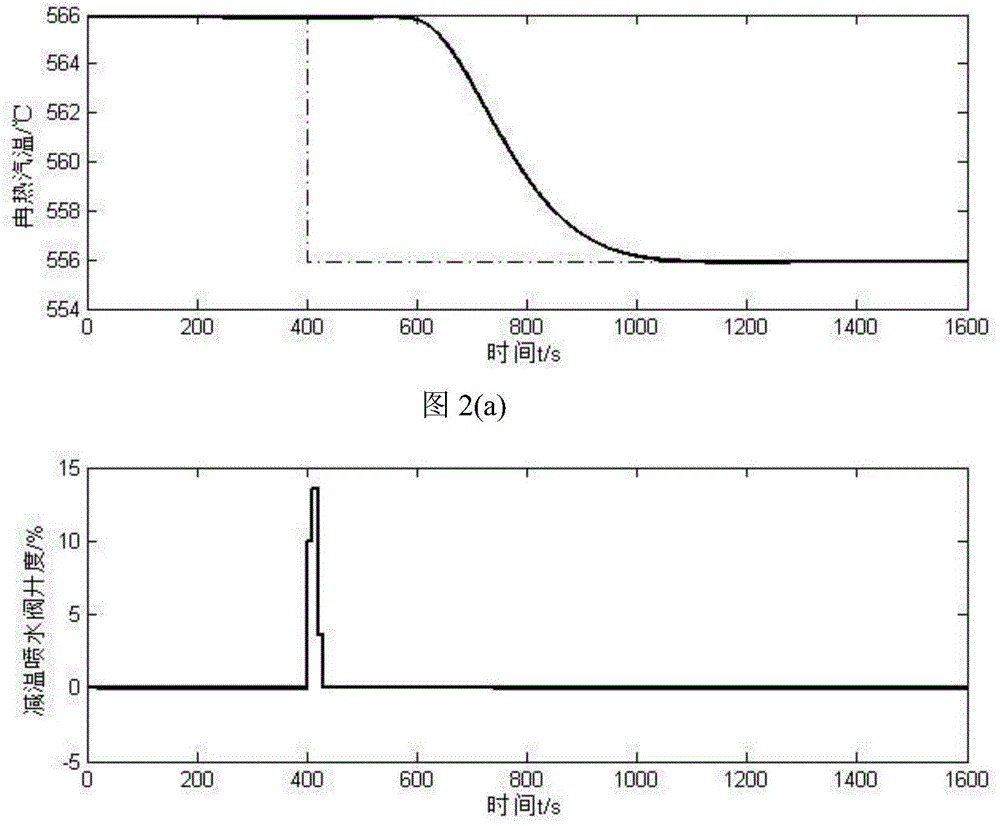

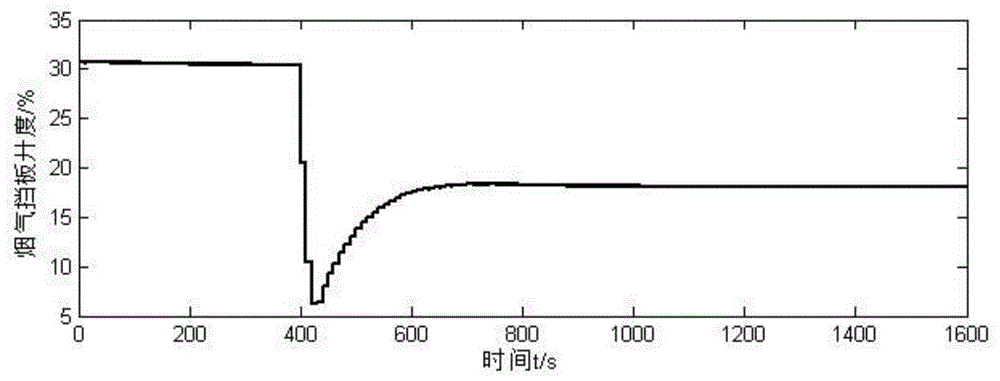

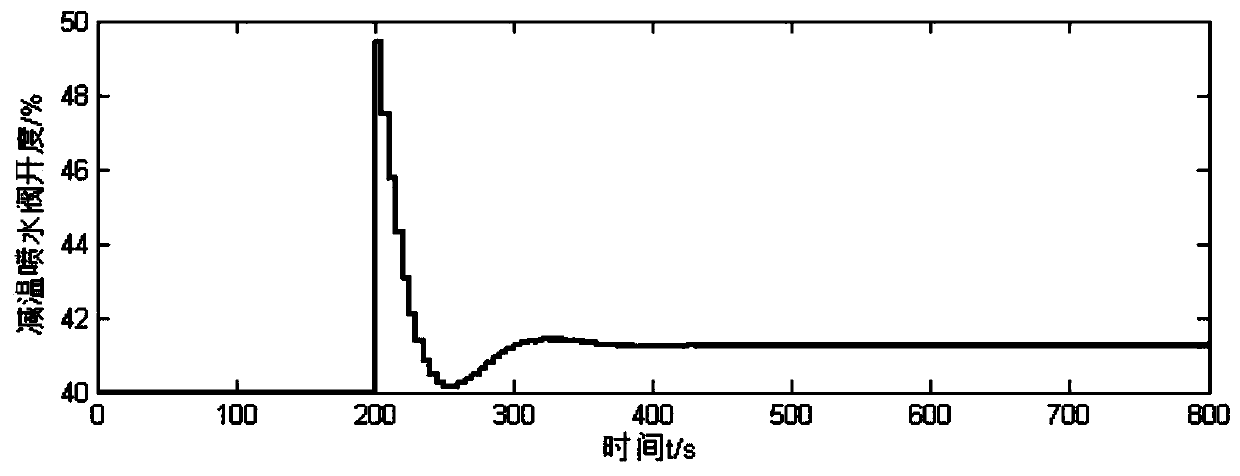

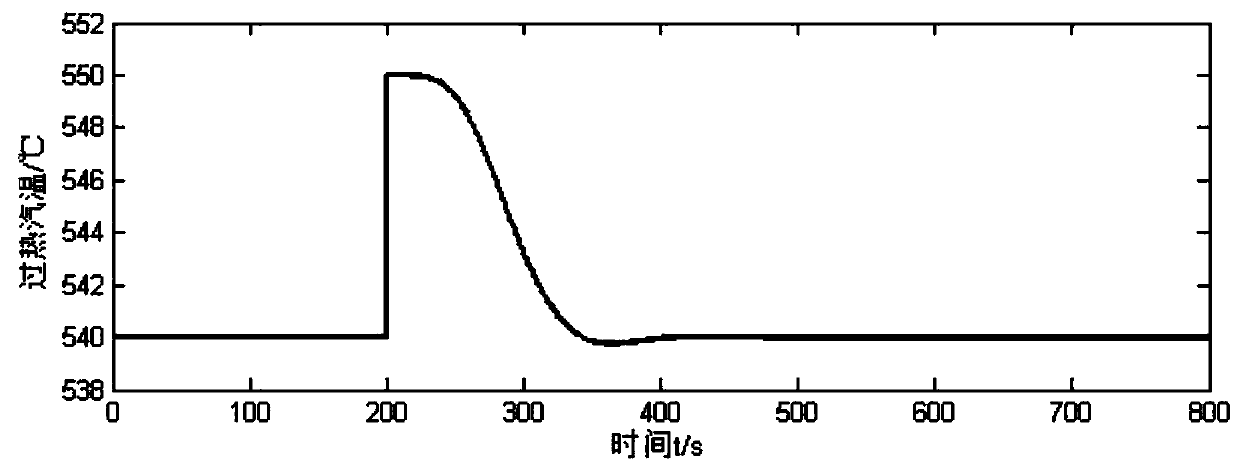

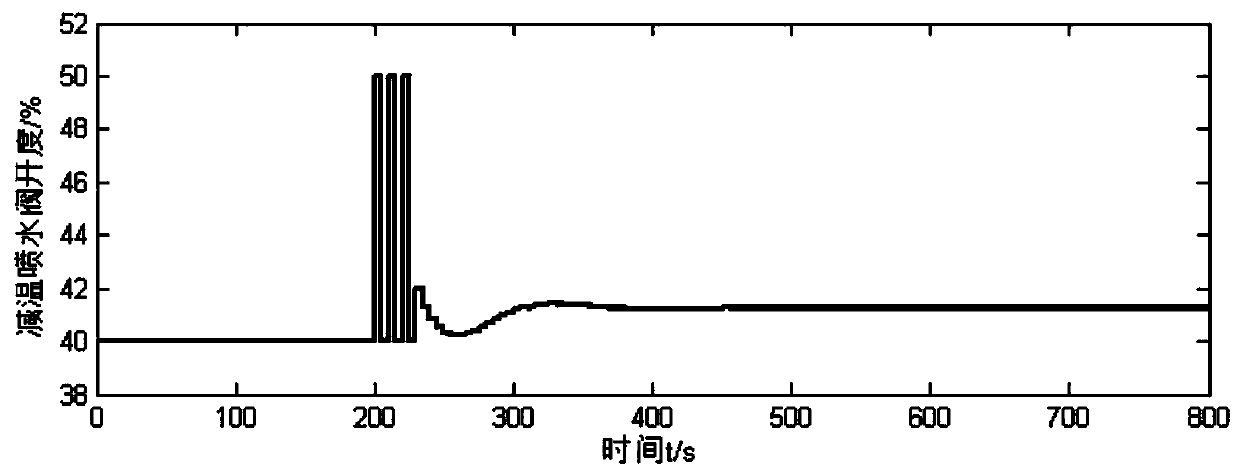

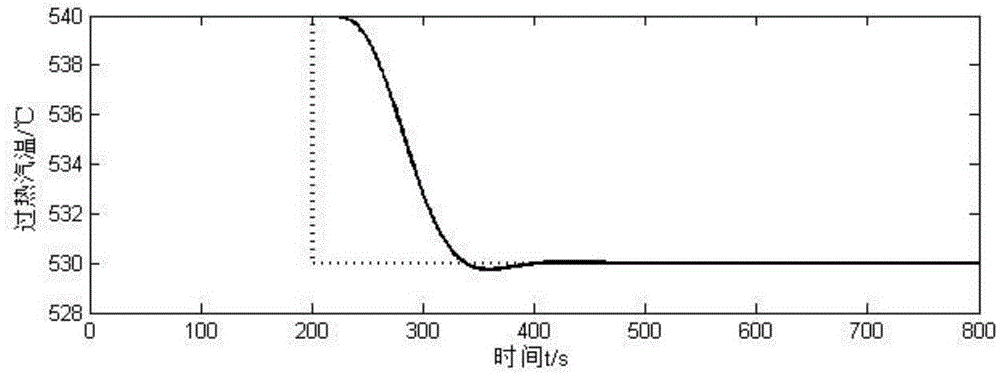

Method for realizing reheat steam temperature multivariable coordinate predictive control through performance indexes

InactiveCN104102134AStable controlGuaranteed dynamic coordinationTemperatue controlAdaptive controlControl systemPredictive controller

The invention discloses a method for realizing reheat steam temperature multivariable coordinate predictive control through performance indexes. According to the method, the reheat steam temperature system of a thermal power generating unit is regarded as a 2*1 multivariable system, a multivariable predictive controller is designed on the basis of novel performance indexes, and the opening degree of a reheat steam temperature reducing water-spray valve and the opening degree of a smoke baffle are controlled simultaneously. In the performance indexes, on one hand, an algorithm is simplified and rapid control is realized on the basis of requirements on a single-step prediction error and a prediction error change rate, and the control performance of a control system can also be effectively adjusted by adjusting a predictive length and a predictive error change rate weight; on the other hand, dynamic limit on the opening degree of the temperature reducing water-spray valve is added in the indexes, the part of the performance parameters is self-adaptive to changes during a control process, and the amount of temperature reducing water sprayed in reheat steam can be reduced while a reheat steam control quality is improved, thus effectively increasing the cycle efficiency of the unit.

Owner:SOUTHEAST UNIV

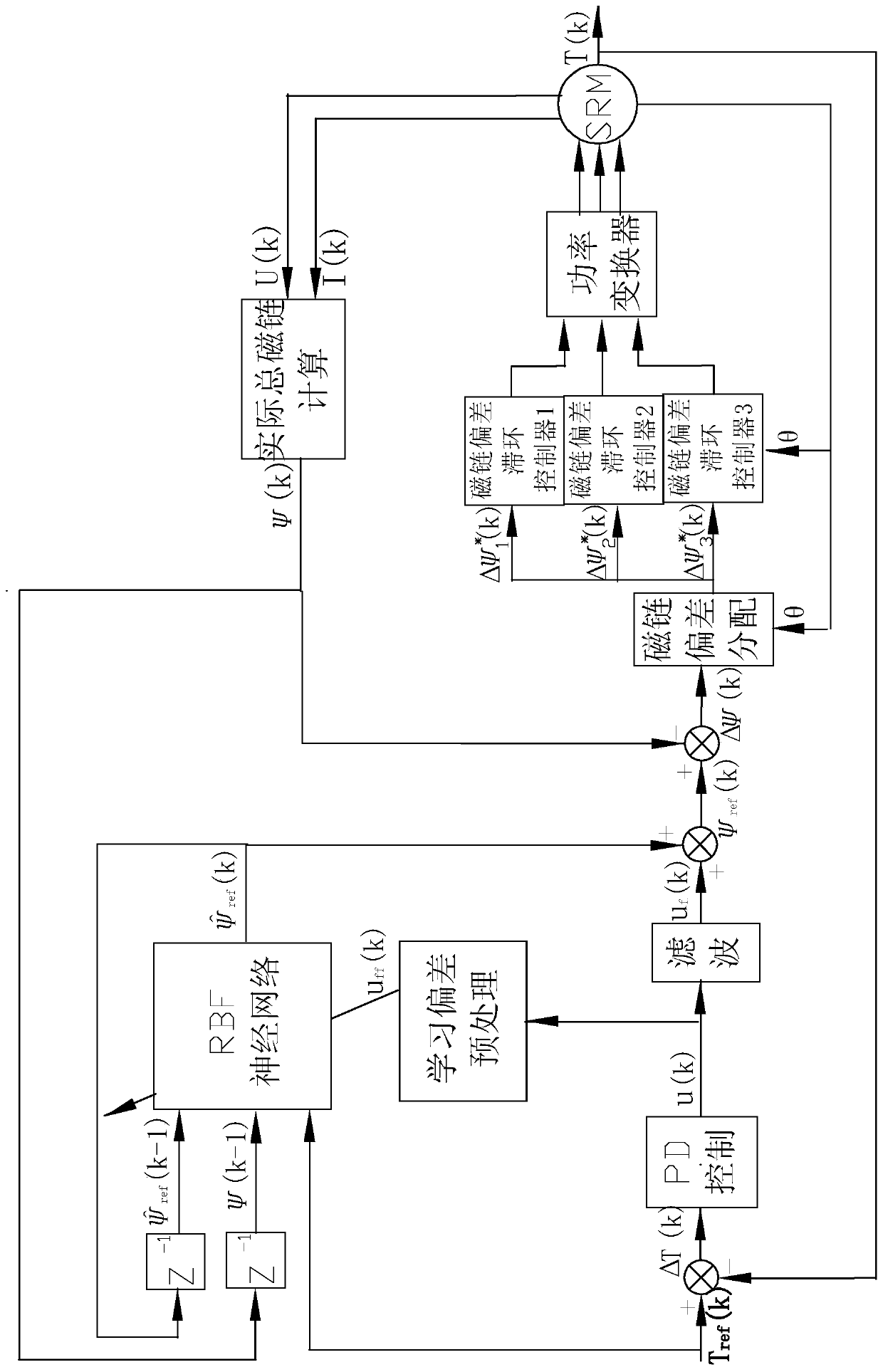

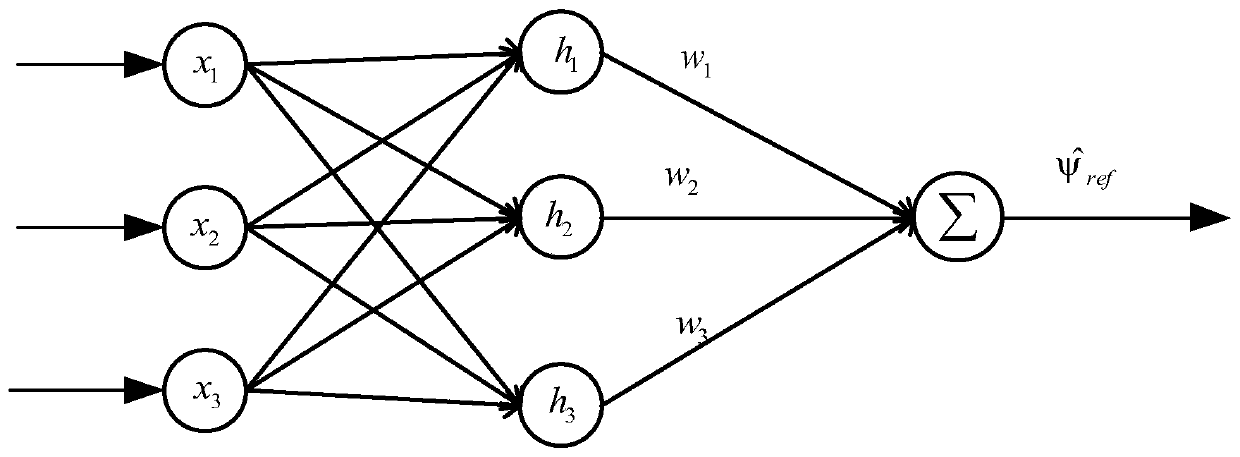

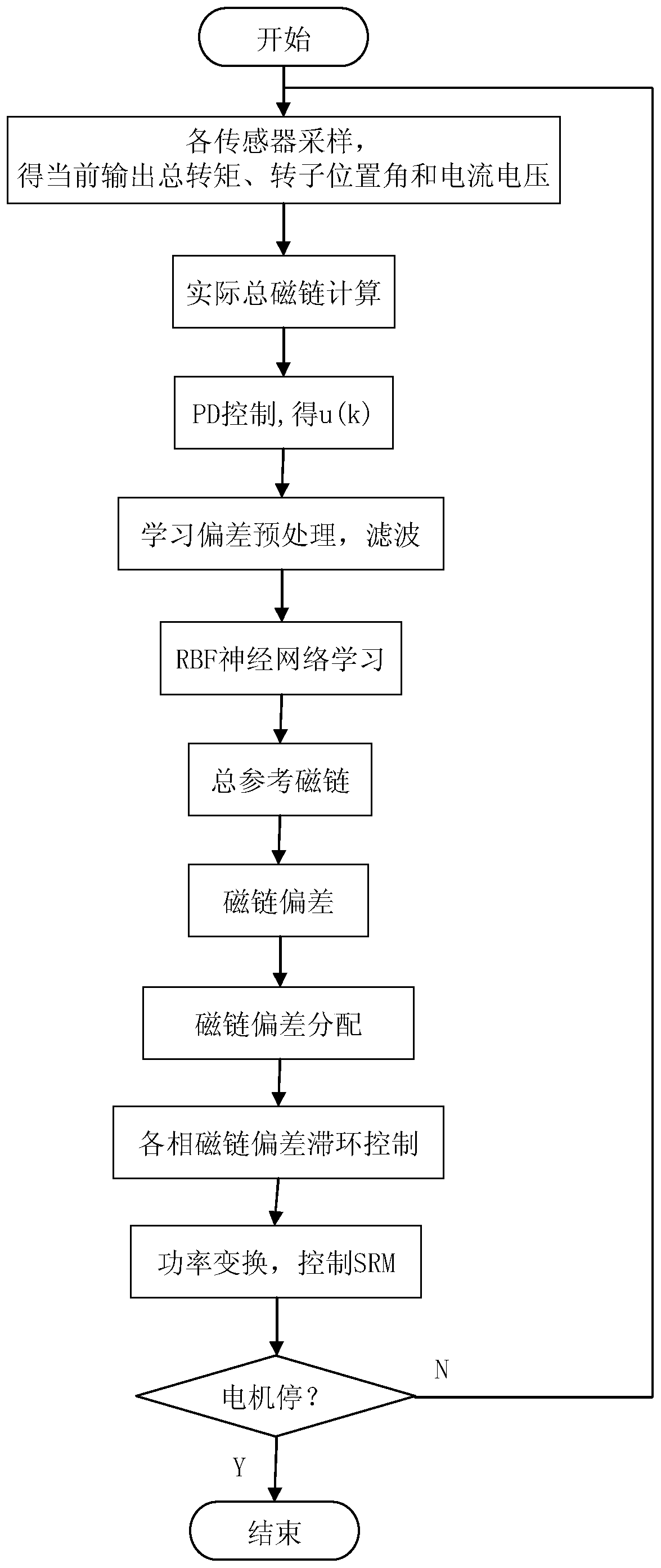

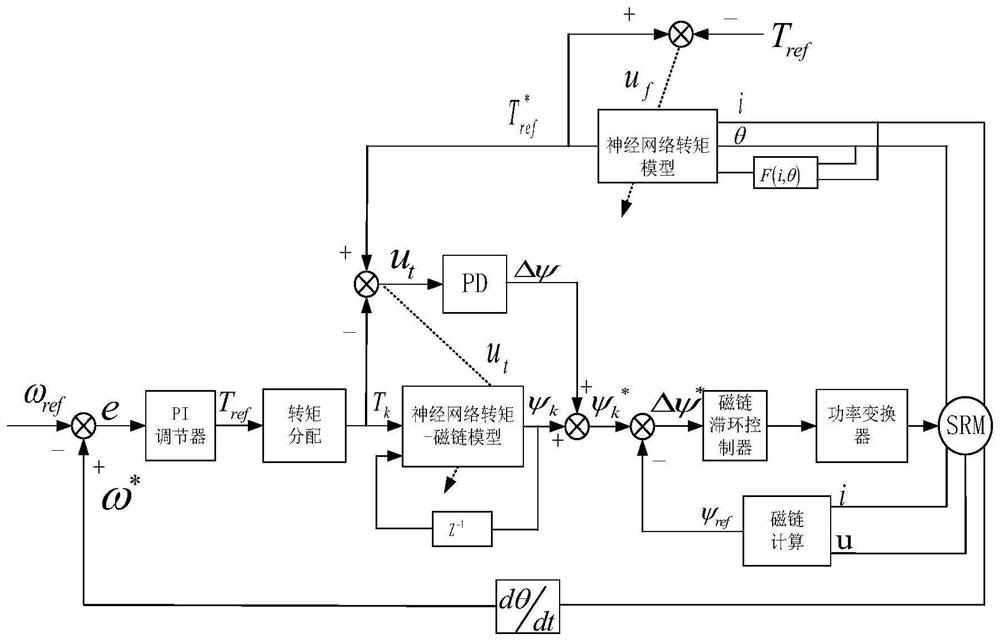

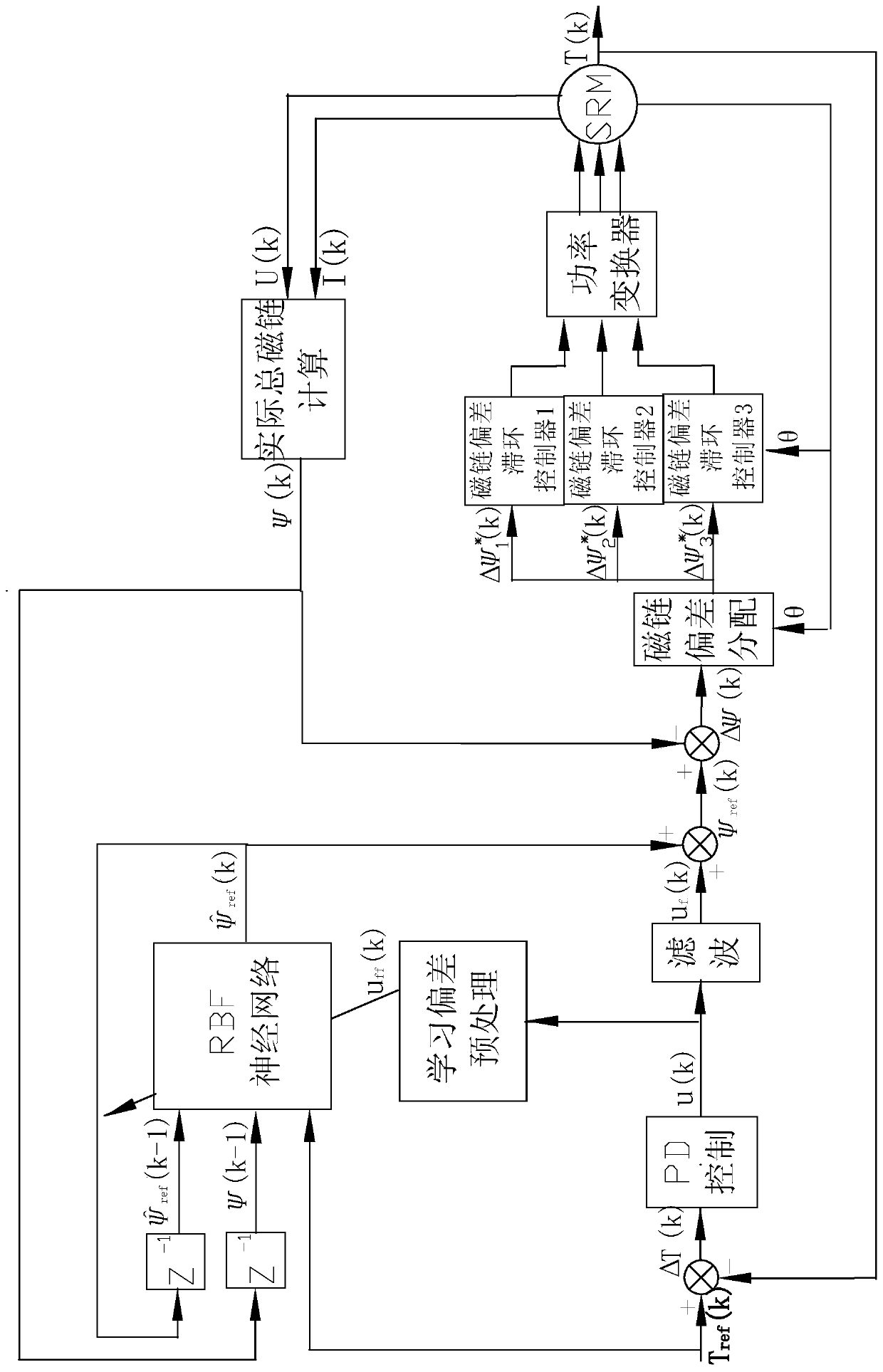

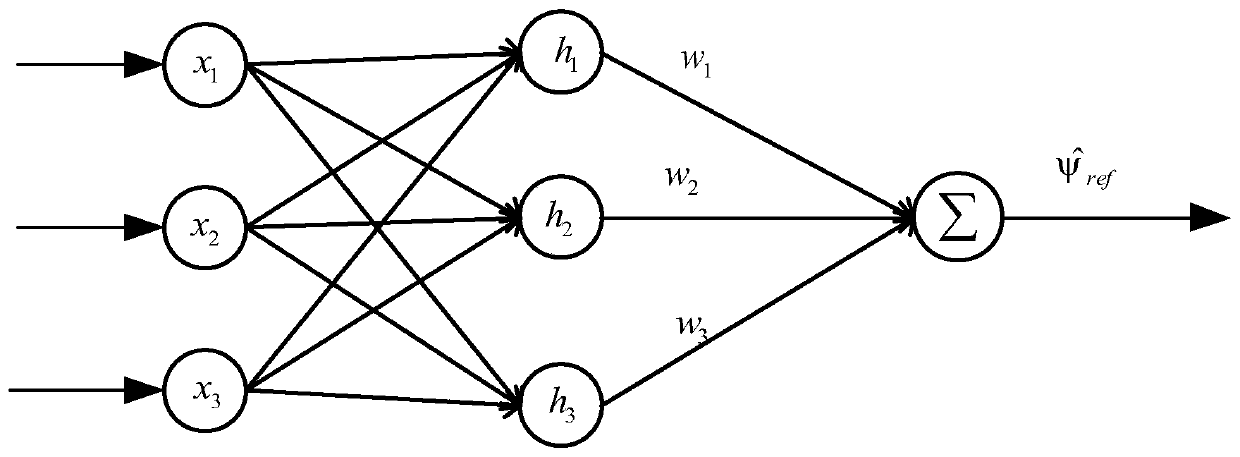

Dynamic neural network adaptive inverse SRM torque control method and system

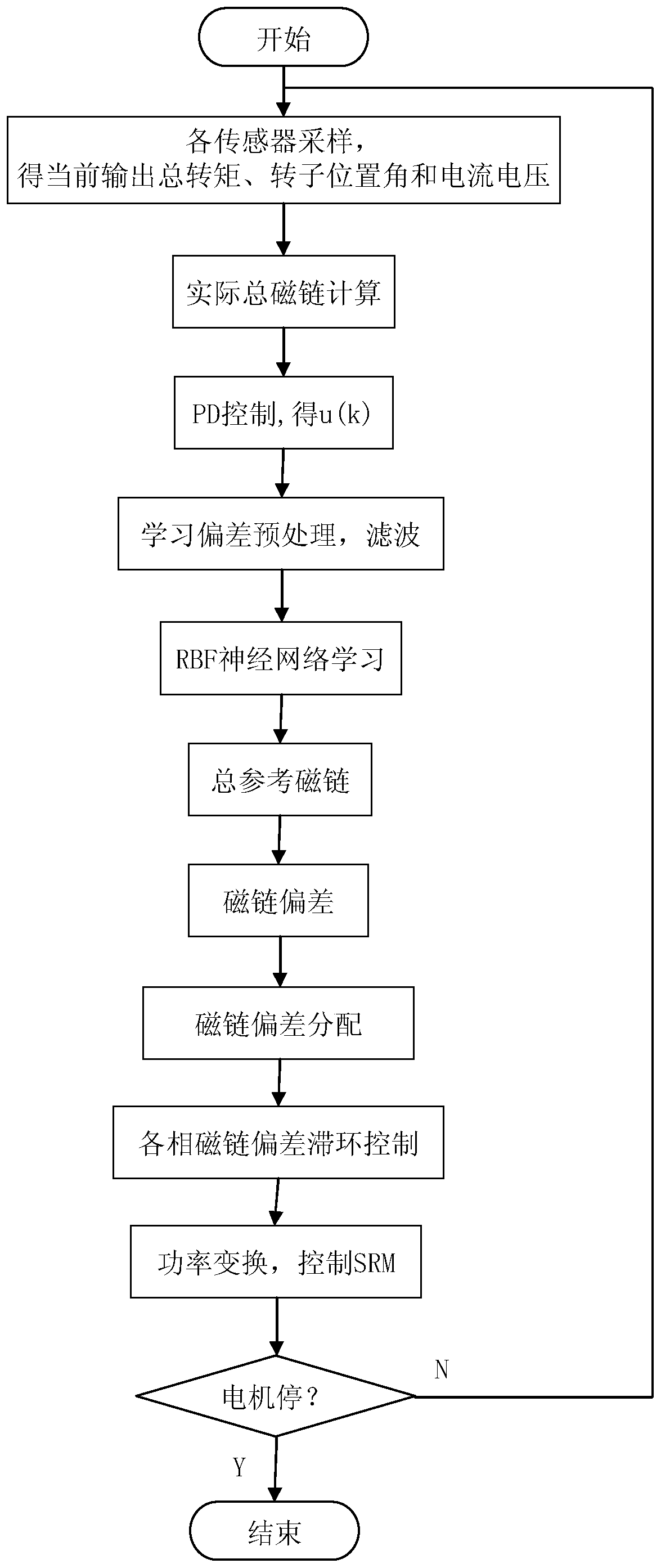

ActiveCN109742999AImprove modeling accuracyInhibition effectField acceleration method controlDirect torque controlDynamic neural networkNeural network modeling

The invention provides a dynamic neural network adaptive inverse SRM torque control method and system. An actual total flux linkage at a previous moment of a system, a current reference torque and a previous-moment reference flux linkage output by an RBF neural network serve as input signals of the RBF neural network, the reference flux linkage is output, and a dynamic RBF neural network, namely,a torque-flux linkage model is formed; and a torque deviation is subjected to PD control to obtain a control quantity, the control quantity is pre-processed to serve as a learning deviation of RBF neural network adaptive inverse control, and the control quantity is subjected to filtering processing to serve as part of a total reference flux linkage, thereby compensating an output of the flux linkage model. The total reference flux linkage and the actual total flux linkage are subjected to subtraction to obtain a flux linkage deviation, and through flux linkage deviation distribution, the fluxlinkage deviation hysteresis control of each phase is accessed, so that the torque pulsation of an SRM is effectively inhibited. The rapid control requirement of the motor is met; a feedback error learning method accelerates the neural network modeling and improves the modeling precision; and the influence of the torque pulsation is reduced.

Owner:GUILIN UNIV OF ELECTRONIC TECH

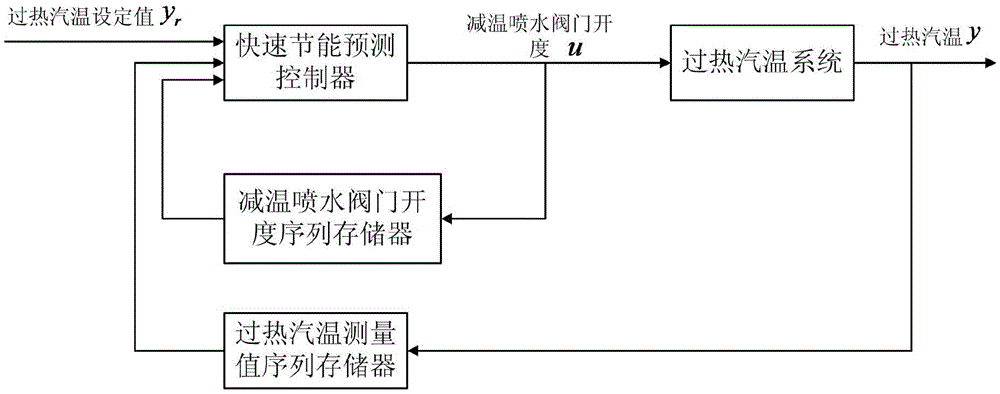

Rapid energy-saving prediction control method for overheat steam temperature

ActiveCN104181958AGuaranteed qualityStable controlAuxillary controllers with auxillary heating devicesAdaptive controlProcess dynamicsUnit operation

The invention discloses a rapid energy-saving prediction control method for an overheat steam temperature. The method obtains a prediction control model of a controlled object through step testing of an overheat steam temperature object. An overheat stream temperature control system records a temperature reduction water spraying valve opening degree control quantity sequence and an overheat steam temperature measurement value sequence in an online and real-time manner. According to novel performance indexes proposed in the method, the control system obtains the of a current temperature reduction water spraying valve opening degree through simple calculation. The control method solves problems, which exist in traditional limited prediction control, that optimization problems are complex, calculation quantity is large and effective control parameters for adjustment of the control performance of a system are lacked so that overheat steam temperature control is stable and rapid and a process dynamic deviation is small and no stable deviation exists. The method is capable of ensuring control quality and at the same time, also capable of reducing a temperature reduction water spraying quantity in a control process and thus economy of unit operation is improved.

Owner:NANJING GUITU TECH DEV

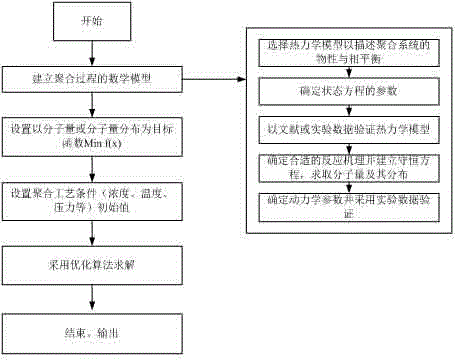

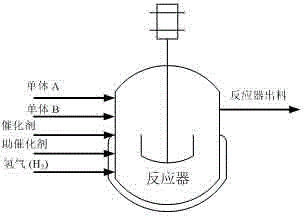

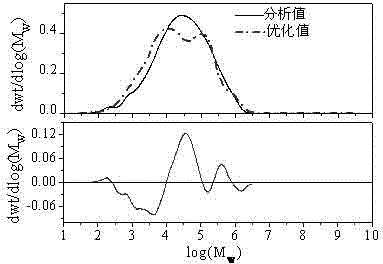

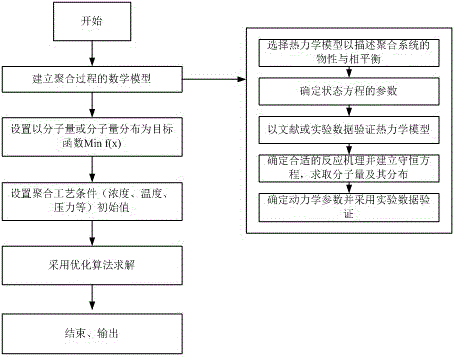

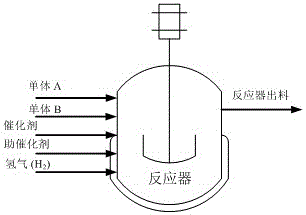

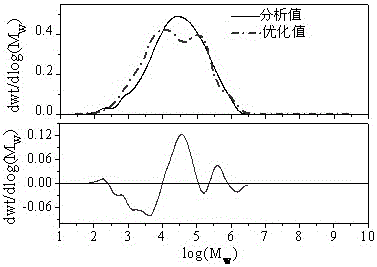

Polymerization process condition optimization method taking polyolefin microscopic quality as target

ActiveCN104570724AShorten the timeConvenient online controlAdaptive controlPolyolefinMathematical model

The invention discloses a polymerization process condition optimization method taking polyolefin microscopic quality as a target, belonging to the field of manufacture of chemical products. The polymerization process condition optimization method is characterized by building a process mathematic model based on reaction mechanism for an olefin polymerization process, and solving an optimal polymerization process condition which meets requirements on quality of specific products by taking average molecular weight or molecular weight distribution as an index of the microscopic quality of the polyolefin. The polymerization process condition optimization method can be used for calculating to obtain the optimal process operation condition under the condition with the given average molecular weight and molecular weight distribution of the polymers; the method can be applied to the design of structures of polymer products and can be used for shortening time for developing a novel type polymer, so that energy conservation and emission reduction are implemented; the economic benefit is increased; the polymerization process condition optimization method is simple and clear in principle and easy to understand and implement; the implementation of computer programming is facilitated; the on-line control of the quality of the polymer products is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

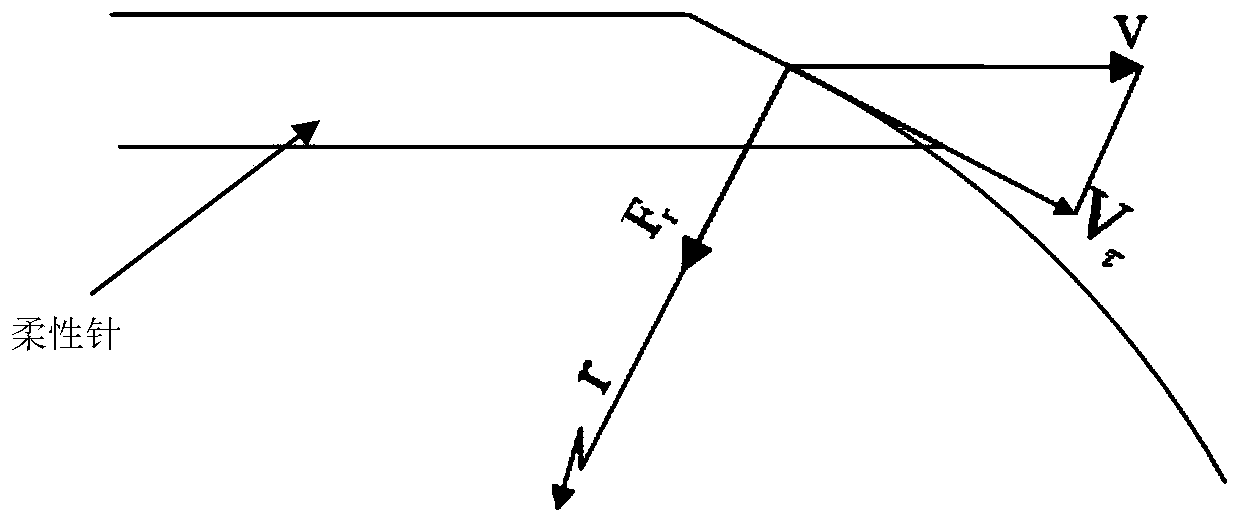

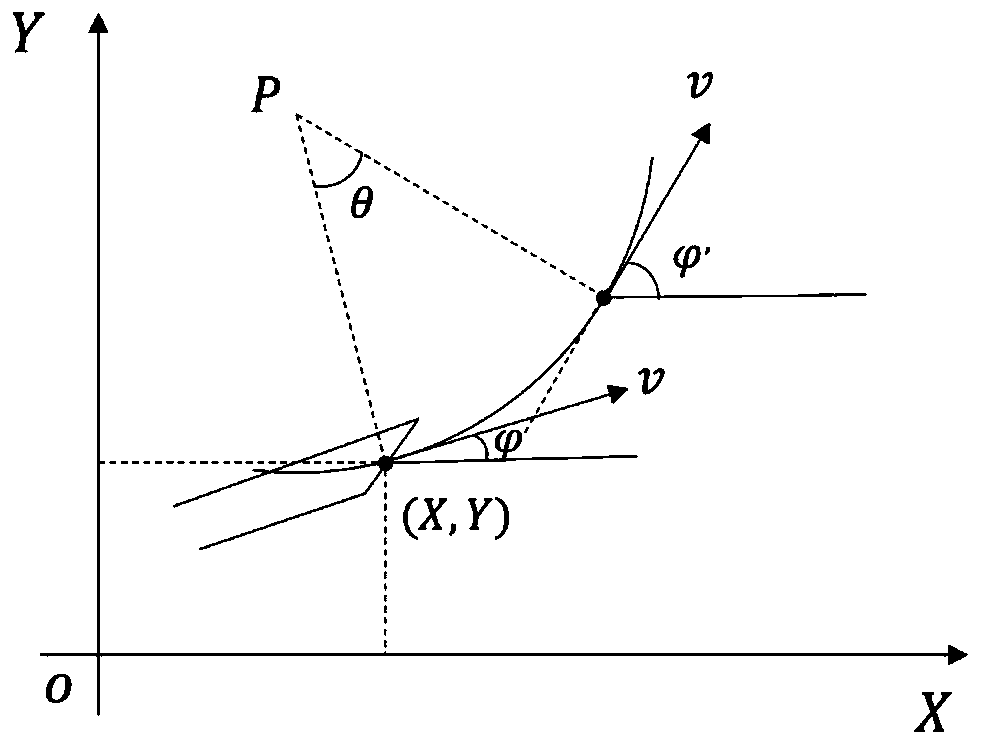

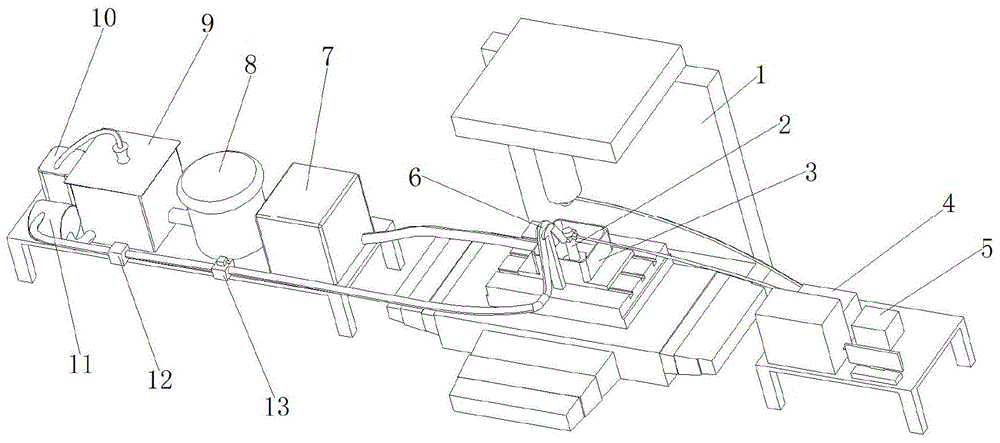

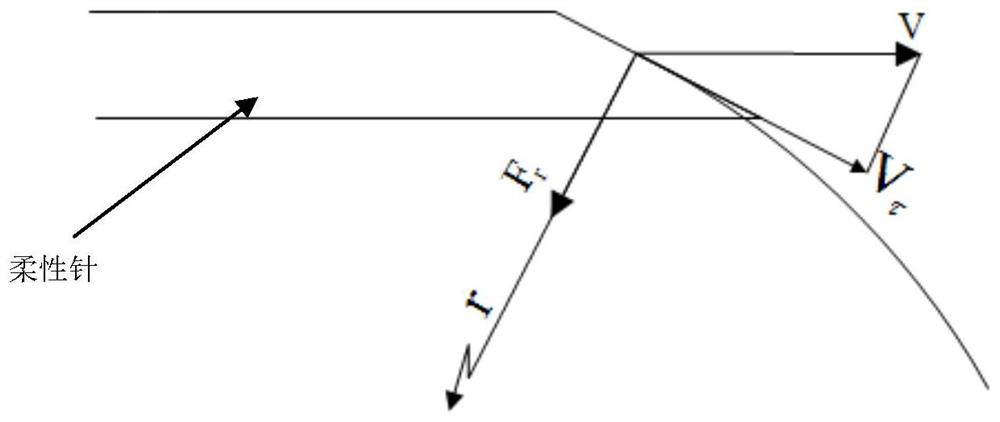

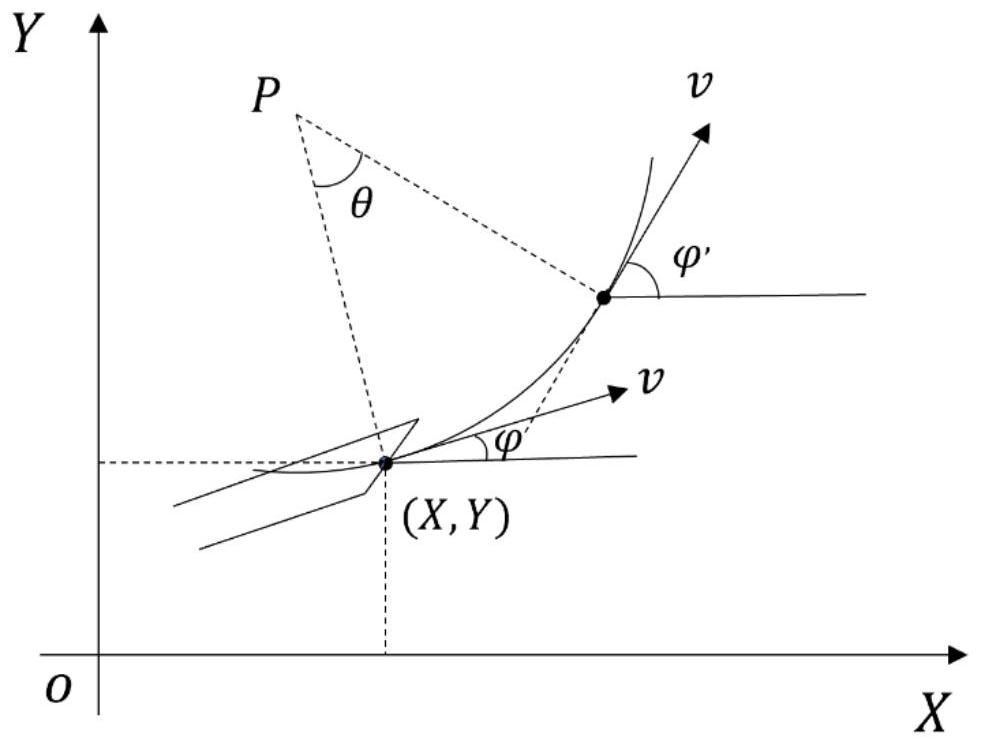

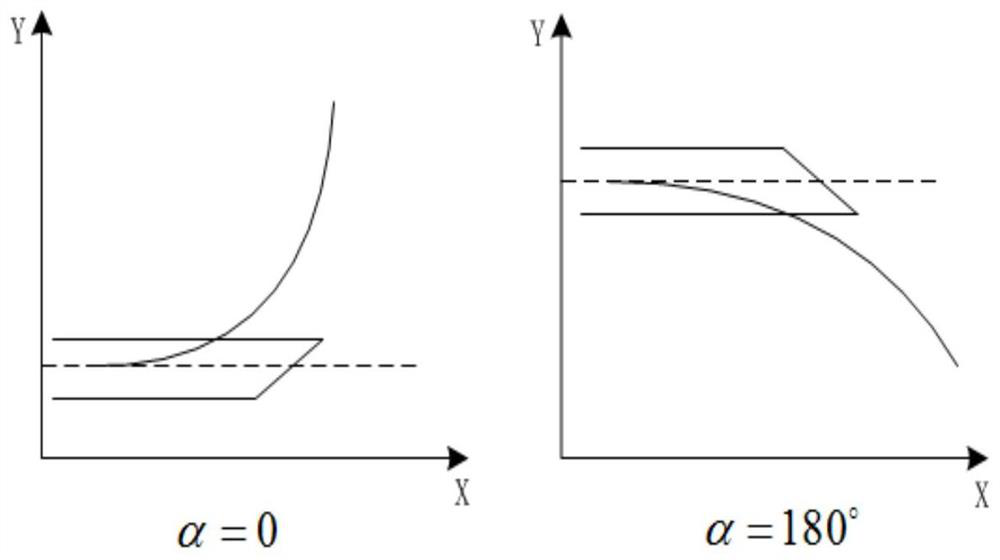

Flexible needle plane puncture controlling device based on brain emotion learning intelligent control algorithm and method thereof

ActiveCN109875659AReduced stateReduce parametersSurgical needlesAdaptive controlElectric machineTime control

The invention provides a flexible needle plane puncture controlling device based on a brain emotion learning intelligent control algorithm and a method thereof. The flexible needle motion control is achieved using computer programs and the device. The device includes a feed motor for controlling the feed speed of a flexible needle and a rotary motor for controlling the rotation of a flexible needle tip, a sensor for acquiring the position and heading angle information of the flexible needle, and a computer for flexible needle motion control. The method of the invention is characterized in thata pre-planned path is subjected to discretization to obtain a target point set, and then the current target position of the flexible needle is compared to the next target point to obtain the positionerror, and the voltage of the feed motor is obtained by a designed brain emotion learning intelligent controller; and a rotating electric machine is controlled by the actual heading angle error. Thedevice simplifies a flexible needle model, has fewer control parameters and less calculation amount, realizes online real-time control and precise control, and can finally reach the target accurately.

Owner:BEIHANG UNIV

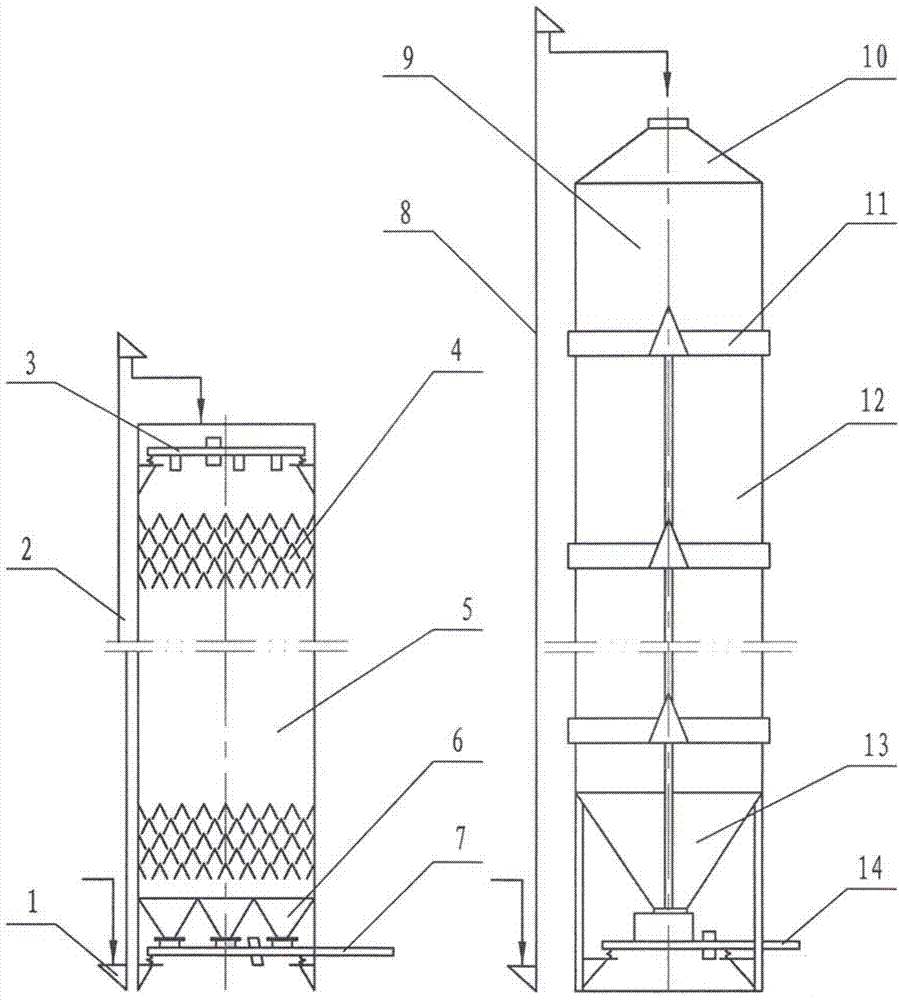

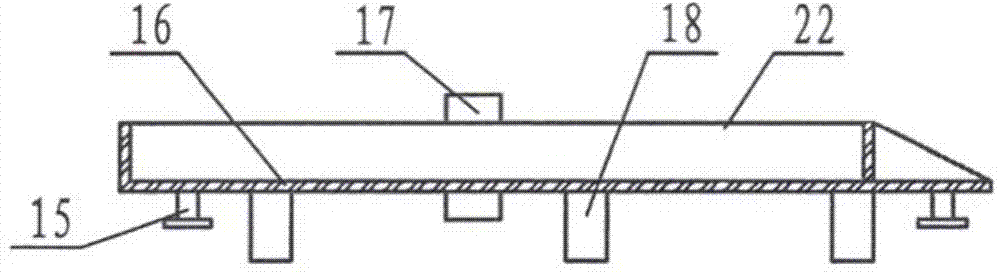

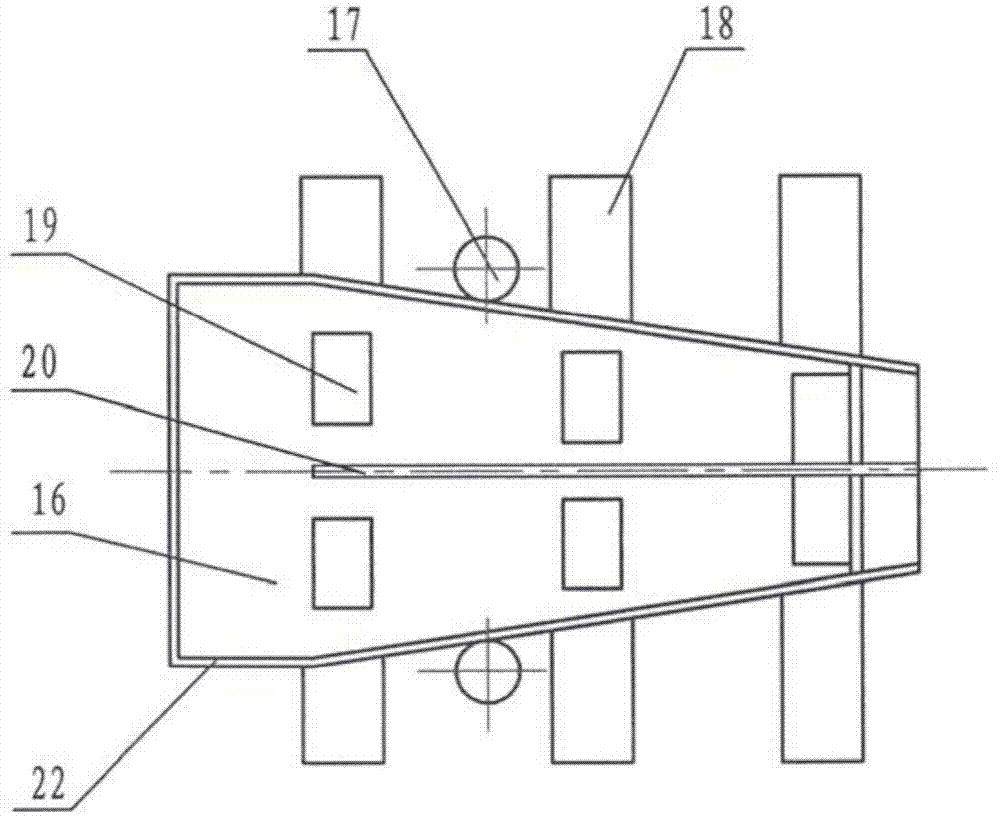

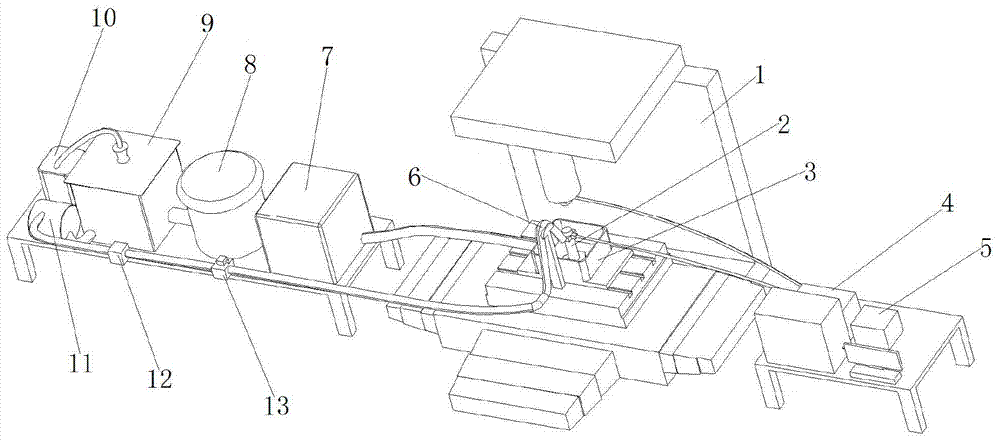

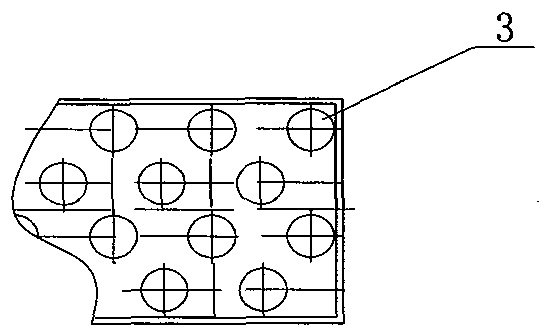

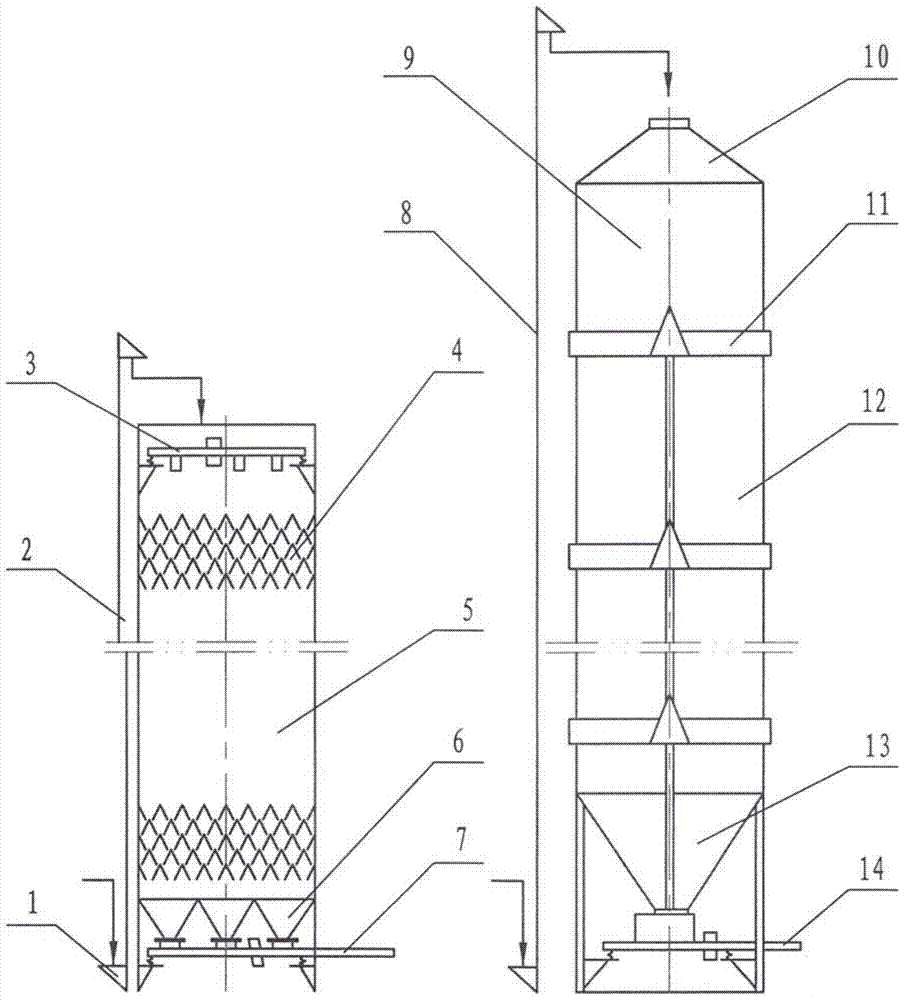

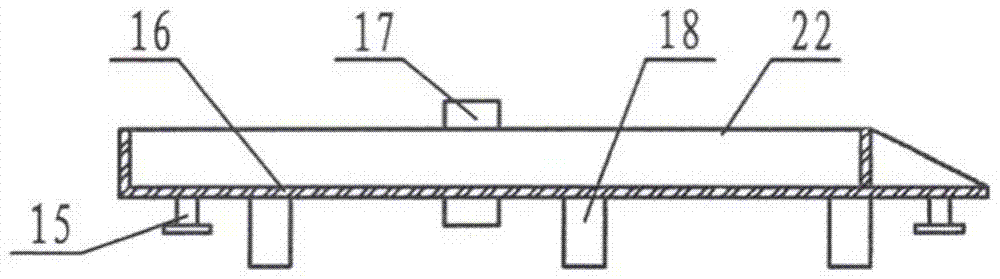

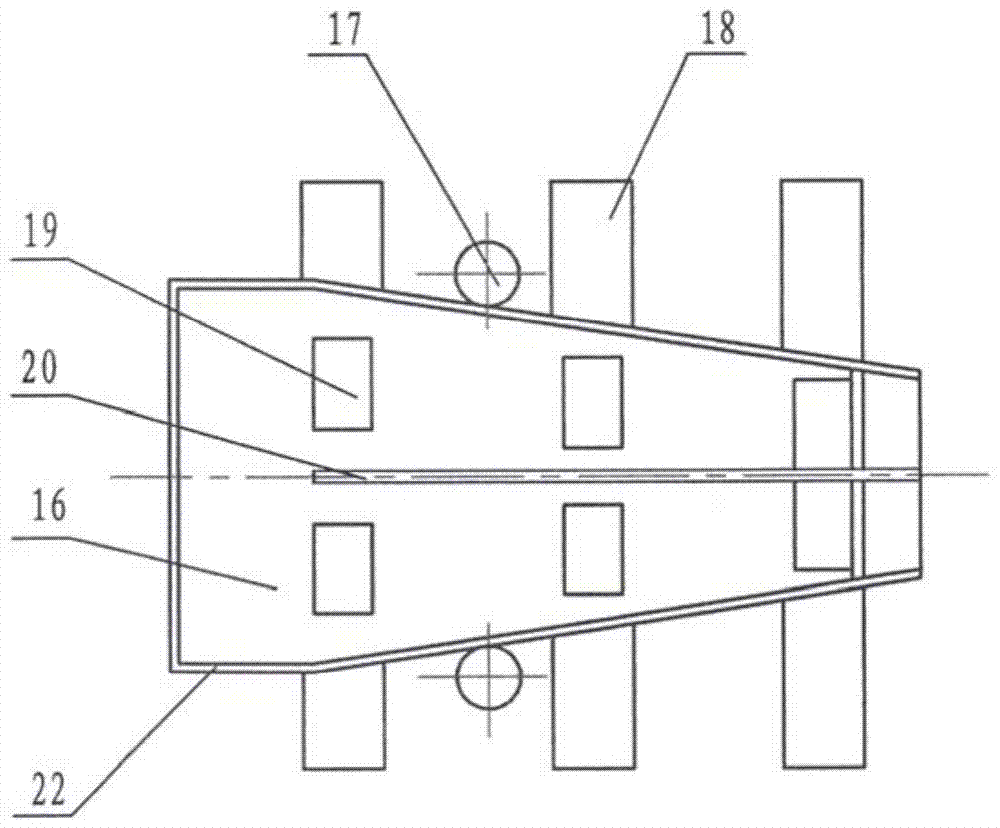

Double-section double-body grain drying device

InactiveCN104719460AEasy to adjustConvenient online controlSeed preservation by dryingAgricultural engineeringGrain drying

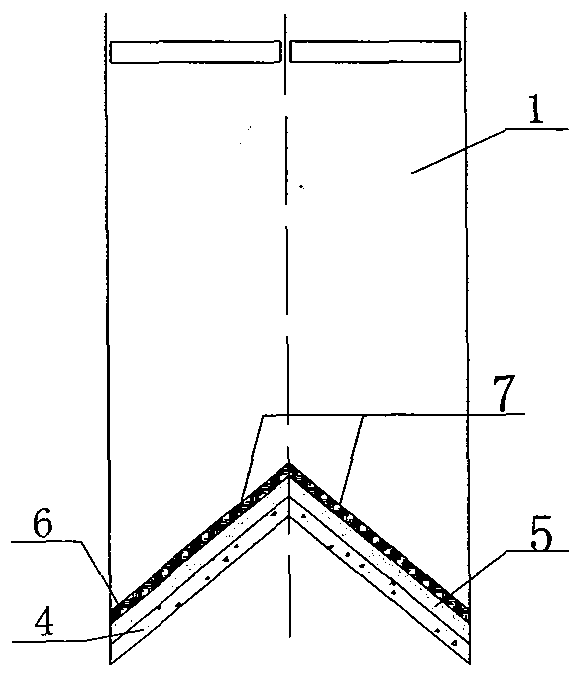

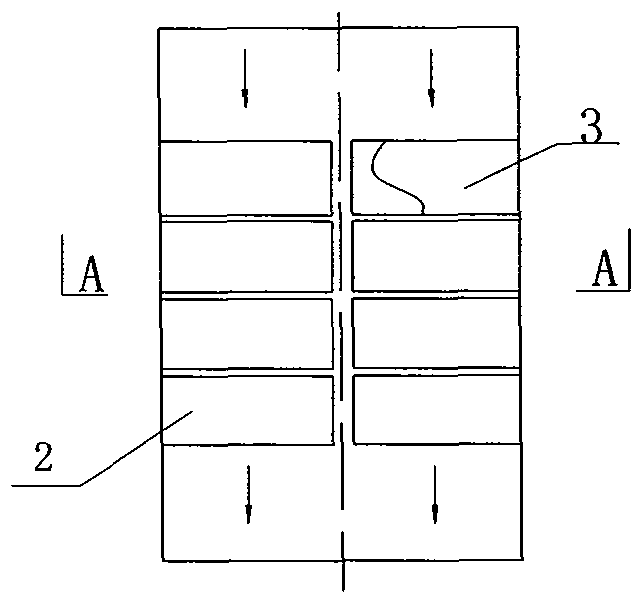

The invention discloses a double-section double-body grain drying device. The double-section double-body grain drying device is mainly composed of a drying body, a tempering body, an elevator and the like, wherein the drying body is a cuboid, the top of which is opened; a grain distributing groove is arranged at the upper end of the drying body; a grain discharging hopper is arranged at the lower end of the drying body; 1-9 drying layers are arranged between the grain distributing groove and the grain discharging hopper; the tempering body is a cylinder; an upper cone is arranged at the upper end of the tempering body; a lower cone is arranged at the lower end of the tempering body; 1-9 ventilation layers are arranged between the upper cone and the lower cone; and a tempering layer B is arranged between every two ventilation layers. The double-section double-body grain drying device disclosed by the invention has the beneficial effects that: adjustment and online control of a drying section process and a tempering and cooling section process are easily carried out; therefore, grains are slowly tempered and cooled integrally; the ratio of grain drying to tempering can be adjusted; the advantages of a grain variable-temperature drying technology are realized easily; the purposes of slowly tempering and cooling the grains are achieved; and the quality of the grains is increased.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Valve negative pressure detecting system

InactiveCN104236814AEasy to testConvenient online controlMeasurement of fluid loss/gain rateVacuum pressureEngineering

The invention discloses a valve negative pressure detecting system. The valve negative pressure detecting system comprises a vacuum pressure sensor, a testing base, a positioning guide block, a valve, a testing cavity and a die. The vacuum pressure sensor is connected with the testing base, the die is arranged on the testing base, and the testing cavity is formed in the die. One end of the valve is located in the testing cavity, and the other end of the valve penetrates through the die and extends into the testing base. The positioning guide block is located on the circumference of the middle of the valve. According to the valve negative pressure detecting system, a detecting device only needs to be calibrated one time according to different detected valves, calibration can be stored in a PLC in the form of parameters so that the valve negative pressure detecting system can test the different valves conveniently, online control can be conveniently carried out in real time according to the different working conditions, and the valve negative pressure detecting system is especially suitable for industrial control.

Owner:印波

A torque control method and system for a switched reluctance motor with current nonlinear compensation

ActiveCN105811849BConvenient online controlSuppression of torque rippleAC motor controlPhase currentsHysteresis

The present invention is a switched reluctance motor torque control method and system with current nonlinear compensation, the method uses the electromagnetic torque mathematical expression of the switched reluctance motor linear inductance model to calculate the basic control current, and uses the optimal torque distribution function The set torque is allocated as the distribution torque of the on-phase and off-phase, and the basic control current of each phase is obtained by conversion; the nonlinear current compensation value of each phase is superimposed with the basic control current of each phase as the control current of each phase, and The deviation of the measured current controls the current hysteresis controller. The microprocessor of this system is connected with three current sensors and rotor position angle and torque sensors on the switched reluctance motor, and its program memory is equipped with a data acquisition module and each calculation module of the method, and the control signal is calculated according to each measured signal, The three-phase input current of the switched reluctance motor is controlled by a pulse width modulator. The invention effectively suppresses the torque ripple of the switched reluctance motor, can constitute an embedded system, and is convenient for on-line control.

Owner:GUILIN UNIV OF ELECTRONIC TECH

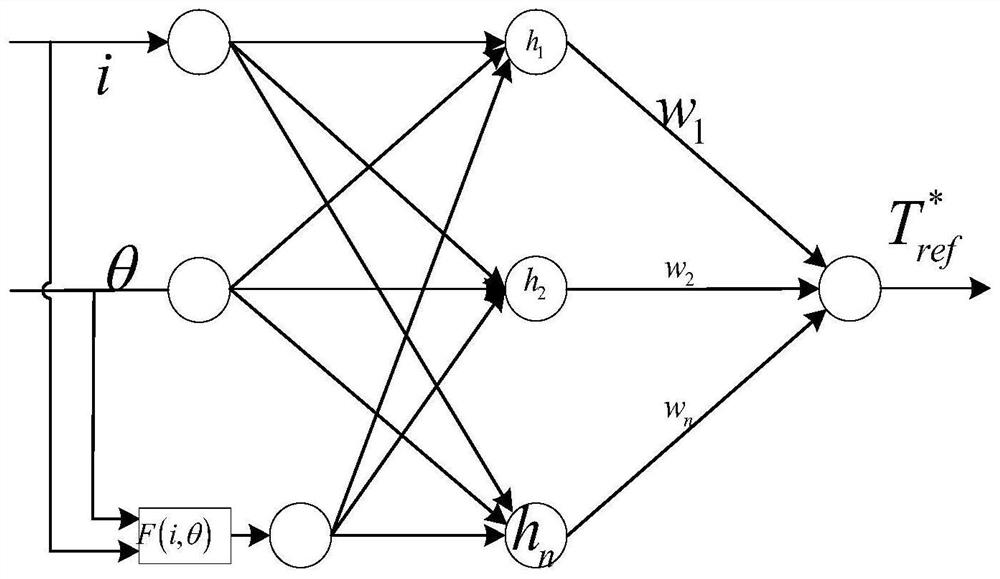

Torque ripple suppression control system and method for switched reluctance motor based on flux linkage

ActiveCN112928965AEasy to controlSuppression of torque rippleAC motor controlElectric machinesElectric machineryTorque ripple

The invention discloses a torque ripple suppression control system and method for a switched reluctance motor based on flux linkage. The system employs a neural network torque estimation model to estimate the torque, employs a dynamic RBF neural network torque-flux linkage model to achieve the conversion from a phase reference torque to a flux linkage, carries out the real-time feed-forward compensation of the flux linkage based on the estimated torque information, so that accurate flux linkage information is obtained, flux linkage control of the SRM is realized, torque pulsation is suppressed, and the method is small in calculation amount; the constructed neural network torque estimation model has an excitation function capable of reflecting an SRM torque change rule, and preprocessing the input of the neural network to realize estimation of the instantaneous torque; and the system can form an embedded system, instantaneous torque estimation is realized through a neural network torque estimation model, conversion from phase reference torque to flux linkage and flux linkage feed-forward compensation are realized through a dynamic RBF neural network torque-flux linkage model, flux linkage control and torque pulsation suppression of the SRM are realized, and online control of the switched reluctance motor is facilitated.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Online monitoring method for electrolytic grinding process

ActiveCN104722863AConvenient online controlHigh precisionProgramme controlElectrical-based auxillary apparatusData descriptionFeature fusion

The invention discloses an online monitoring method for the electrolytic grinding process. The online monitoring method for the electrolytic grinding process comprises the steps that 1, electrolyte is obtained and diluted; 2, particles in the diluted electrolyte are analyzed; 3, particle features obtained through analysis are reasonably selected through a feature fusion technology, so that reasonable feature indexes are obtained for identifying the types of the particles; 4, based on fuzzy C-means and the support vector data description theory, an electrolytic grinding process evaluating model is established, and the electrolytic grinding process is monitored according to the mapping relationship between the types of the particles and the electrolytic grinding process. By the adoption of the online monitoring method for the electrolytic grinding process, the ratio parameter between the mechanical removal amount and the electrochemical removal amount in the electrolytic grinding process can be obtained, the purpose of monitoring the electrolytic grinding process on line can be achieved so that the electrolytic grinding process can be controlled on line, and therefore the online monitoring method for electrolytic grinding precision is effectively improved.

Owner:常州常工院技术转移有限公司

A Method for Optimizing Polymerization Process Conditions Aiming at the Microscopic Quality of Polyolefin

ActiveCN104570724BShorten the timeConvenient online controlAdaptive controlPolyolefinMathematical model

Owner:CHINA PETROLEUM & CHEM CORP +1

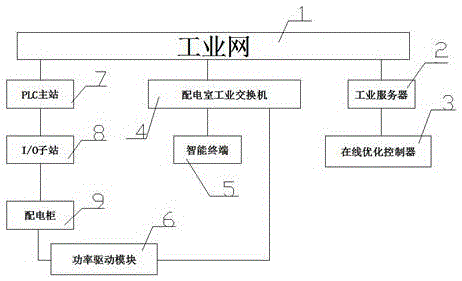

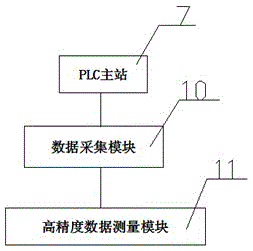

Industrial intelligent control system

InactiveCN105068521AConvenient online controlFast online controlTotal factory controlProgramme total factory controlInformatizationAutomatic control

Owner:陈传海

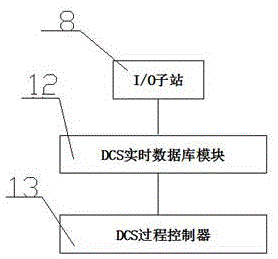

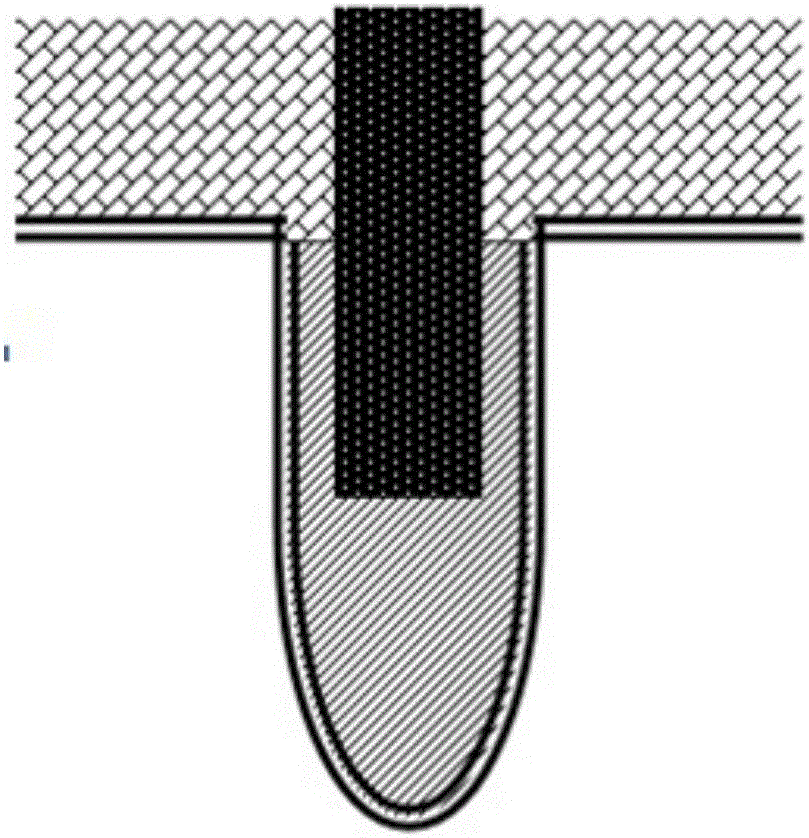

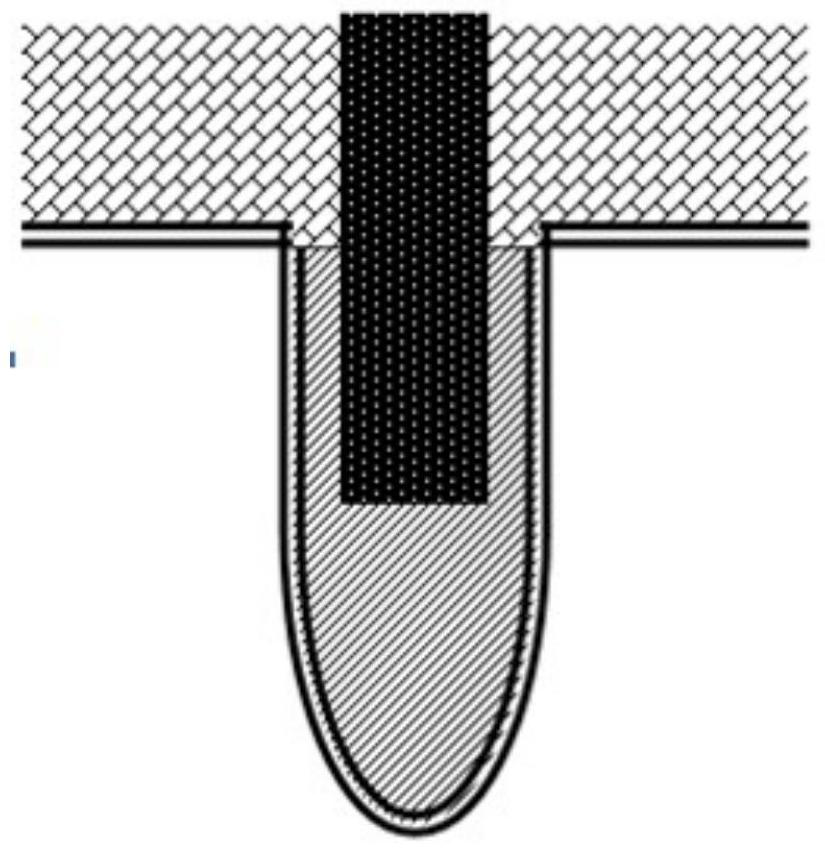

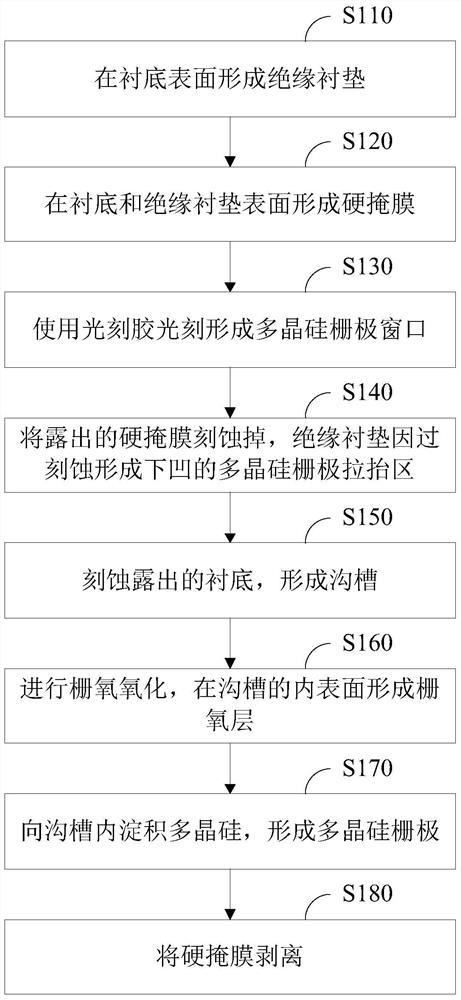

Trench gate structure and fabrication method thereof

ActiveCN107527800AFlexible designPrevent leakageSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingEngineering

The present invention relates to a trench gate structure and a fabrication method thereof. The trench gate structure includes a substrate, a trench on the surface of the substrate, an insulating liner on the substrate, a gate oxide layer on the inner surface of the trench, and a polysilicon gate on the gate oxide layer; the insulating liner adjoins the trench through the ramp structure of the insulating liner; the polysilicon gate extends along the ramp structure from the trench to the insulating liner; the insulating liner comprises a polysilicon gate lifting region which is recessed relative to the other portions of the liner; and the polysilicon gate extending out from the trench is supported on the polysilicon gate lifting region. According to the trench gate structure of the invention, a portion of the polysilicon gate in the trench is independent from a portion of the polysilicon gate which extends to the insulating liner, and therefore, the depth of the trench and the depth of a contact hole will not limit each other. The photo-etching of the polysilicon gate and polysilicon photo-etching of a device are performed in the same step, and therefore, additional photo-etching masks and photo-etching layers are not needed to be adopted, and cost increase can be avoided.

Owner:CSMC TECH FAB2 CO LTD

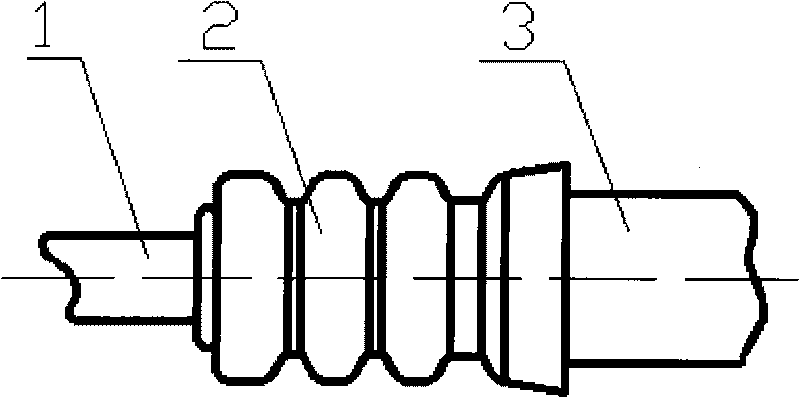

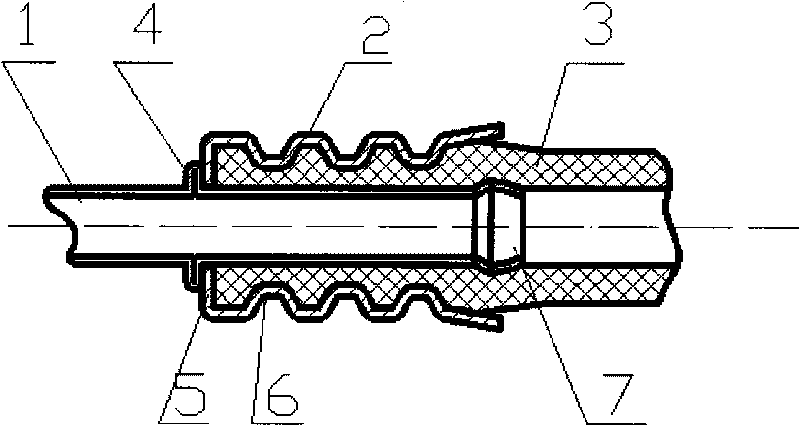

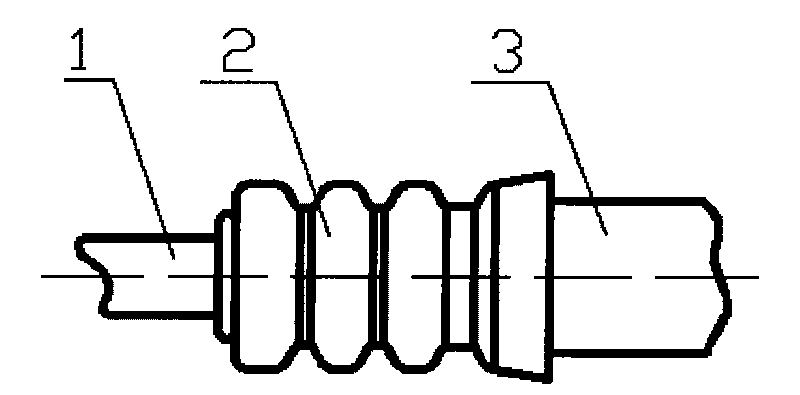

Pipe expanding connection structure of vehicle high-pressure oil pipe

InactiveCN101758806AReach molding size requirementsLow costElectric/fluid circuitMachine partsHigh pressure

The invention relates to a pipe expanding connection structure of a vehicle high-pressure oil pipe. The structure comprises a metal pipe, wherein a rubber hose is sleeved outside the front end of the metal pipe, and a metallic sheath is sleeved outside the rubber hose; the front end of the metal pipe is directly expanded and molded; a circular bulge and a circular check ring are molded in sequence at the position near the end of the metal pipe; the rubber hose is sleeved correspondingly outside the circular bulge of the metal pipe, and the end of the rubber hose closes to the circular check ring of the metal pipe; the metallic sheath is sleeved outside the rubber hose, and the end of the metallic sheath is provided with a circular blocking edge to be pressed on the circular check ring of the metal pipe; and the part of the metallic sheath correspondingly closing to the position between the circular check ring and the circular bulge of the metal pipe is locked in the radial direction to form a contraction part. Compared with the connection structure of the prior art, the combination of the parts such as machining parts and the like can be reduced, and the sealing risk and the production cost are lowered, therefore, the pipe expanding connection structure improves the flexibility, the variety and the reliability of connection, so as to be more applicable to more extensive product forms and higher design requirements.

Owner:邱强

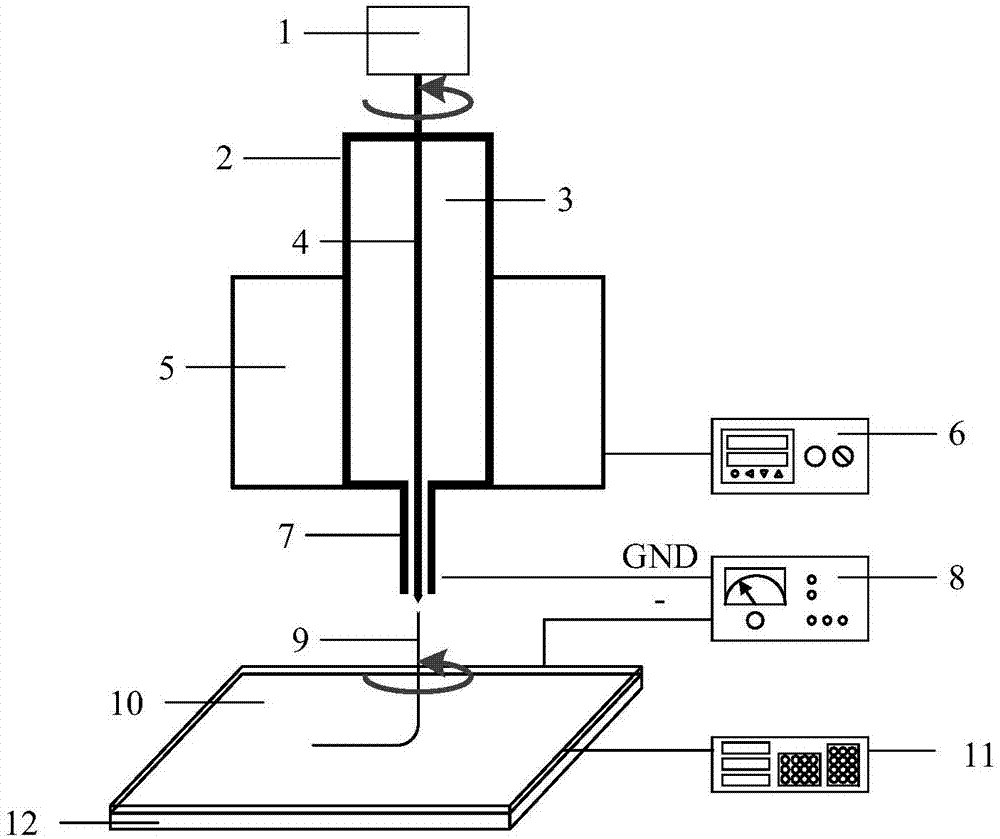

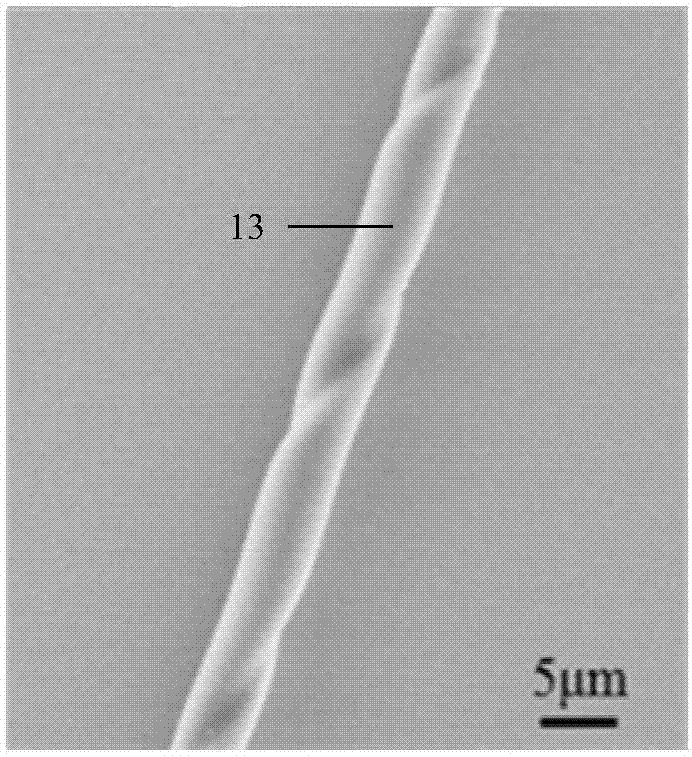

Helical fiber grating manufacturing device and manufacturing method thereof

ActiveCN107462949AImprove performanceConvenient online controlCladded optical fibreOptical waveguide light guideFiberGrating

The invention discloses a helical fiber grating manufacturing device and a manufacturing method thereof and relates to helical fiber gratings. The device comprises a direct current motor, a storage pipe, a metal rod, a heater, a temperature controller, a micro-channel, a power supply, a conductive base, a translation stage controller and an X-Y-axis precision translation stage. The manufacturing method comprises the following steps: adding electrostatic spinning raw materials into the storage pipe, regulating the temperature controller to heat so as to remove the moisture in the raw material, and regulating the temperature to the melting point of the raw materials; inserting the metal rod into a melt polymer, extending out of a discharge hole below the micro-channel, and regulating the rotating speed of the direct current motor until the needle tip is coated by the melt polymer, so that the molten liquid stably flows out; switching on the power switch, regulating the voltage of the conductive base to a preset negative pressure, starting the electrostatic spinning process, collecting electrospun fibers on the conductive base, reducing the temperature for curing in the deposition process, and forming a helical structure; enabling the X-Y-axis precision translation stage to drive the conductive base to move by virtue of the translation stage controller, thereby obtaining the helical fiber grating with the controllable diameter and screw pitch.

Owner:XIAMEN UNIV

A method for online monitoring of electrolytic grinding process

ActiveCN104722863BConvenient online controlImproving the Precision of Electrolytic GrindingProgramme controlElectrical-based auxillary apparatusElectrolysisData description

The invention discloses an online monitoring method for the electrolytic grinding process. The online monitoring method for the electrolytic grinding process comprises the steps that 1, electrolyte is obtained and diluted; 2, particles in the diluted electrolyte are analyzed; 3, particle features obtained through analysis are reasonably selected through a feature fusion technology, so that reasonable feature indexes are obtained for identifying the types of the particles; 4, based on fuzzy C-means and the support vector data description theory, an electrolytic grinding process evaluating model is established, and the electrolytic grinding process is monitored according to the mapping relationship between the types of the particles and the electrolytic grinding process. By the adoption of the online monitoring method for the electrolytic grinding process, the ratio parameter between the mechanical removal amount and the electrochemical removal amount in the electrolytic grinding process can be obtained, the purpose of monitoring the electrolytic grinding process on line can be achieved so that the electrolytic grinding process can be controlled on line, and therefore the online monitoring method for electrolytic grinding precision is effectively improved.

Owner:常州常工院技术转移有限公司

Trench gate structure and manufacturing method thereof

ActiveCN107527800BFlexible designPrevent leakageSemiconductor/solid-state device manufacturingSemiconductor devicesPolysilicon gateTrench gate

The invention relates to a trench gate structure and a manufacturing method thereof. The trench gate structure includes a substrate, a trench on the surface of the substrate, an insulating pad on the substrate, a gate oxide layer on the inner surface of the trench, and a polysilicon gate on the gate oxide layer. The liner is adjacent to the groove through its own slope structure, and the polysilicon gate extends from the groove along the slope structure to the insulating liner, and the insulating liner includes The concave polysilicon gate pull-up region, the polysilicon gate protruding from the trench rides on the polysilicon gate pull-up region. The polysilicon gate in the trench of the present invention is relatively independent from the part extending to the insulating substrate, so the depth of the trench and the depth of the contact hole do not constrain each other. The photolithography step of the polysilicon gate is carried out in the same step as the polysilicon photolithography of the device, and no additional photolithography plate (mask) and photolithography layers are required, so the cost in this aspect will not be increased.

Owner:CSMC TECH FAB2 CO LTD

A dynamic neural network adaptive inverse SRM torque control method and system

ActiveCN109742999BImprove modeling accuracyInhibition effectField acceleration method controlDirect torque controlDynamic neural networkElectric machinery

The invention provides a dynamic neural network adaptive inverse SRM torque control method and system. An actual total flux linkage at a previous moment of a system, a current reference torque and a previous-moment reference flux linkage output by an RBF neural network serve as input signals of the RBF neural network, the reference flux linkage is output, and a dynamic RBF neural network, namely,a torque-flux linkage model is formed; and a torque deviation is subjected to PD control to obtain a control quantity, the control quantity is pre-processed to serve as a learning deviation of RBF neural network adaptive inverse control, and the control quantity is subjected to filtering processing to serve as part of a total reference flux linkage, thereby compensating an output of the flux linkage model. The total reference flux linkage and the actual total flux linkage are subjected to subtraction to obtain a flux linkage deviation, and through flux linkage deviation distribution, the fluxlinkage deviation hysteresis control of each phase is accessed, so that the torque pulsation of an SRM is effectively inhibited. The rapid control requirement of the motor is met; a feedback error learning method accelerates the neural network modeling and improves the modeling precision; and the influence of the torque pulsation is reduced.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Flexible needle planar puncture control device and method based on brain emotion learning intelligent control algorithm

ActiveCN109875659BPracticalConvenient online controlSurgical needlesAdaptive controlElectric machineSimulation

The invention provides a flexible needle plane puncture controlling device based on a brain emotion learning intelligent control algorithm and a method thereof. The flexible needle motion control is achieved using computer programs and the device. The device includes a feed motor for controlling the feed speed of a flexible needle and a rotary motor for controlling the rotation of a flexible needle tip, a sensor for acquiring the position and heading angle information of the flexible needle, and a computer for flexible needle motion control. The method of the invention is characterized in thata pre-planned path is subjected to discretization to obtain a target point set, and then the current target position of the flexible needle is compared to the next target point to obtain the positionerror, and the voltage of the feed motor is obtained by a designed brain emotion learning intelligent controller; and a rotating electric machine is controlled by the actual heading angle error. Thedevice simplifies a flexible needle model, has fewer control parameters and less calculation amount, realizes online real-time control and precise control, and can finally reach the target accurately.

Owner:BEIHANG UNIV

Inductance model nonlinear compensation and control method and system for switched reluctance motor

ActiveCN110572108BAchieving non-linear compensationRealize nonlinear adaptive optimization compensationAC motor controlControl systemAdaptive optimization

The invention discloses a nonlinear compensation and control method and system for an inductance model of a switched reluctance motor. The method comprises the steps of designing a fuzzy reasoning rule by using a torque deviation capable of reflecting errors of an SRM linear model and a change rate of the torque deviation as fuzzy reasoning input information, constructing a fuzzy compensator, andachieving the nonlinear feedforward compensation for a linear inductance model; and introducing reinforcement learning, designing a return function, and matching the return function with the fuzzy compensator to further realize nonlinear adaptive optimization compensation of the inductance model and achieve the purpose of indirectly describing strong nonlinear characteristics of the inductance. According to the invention, the dynamic quality of the control system can be effectively improved, and the SRM torque ripple is inhibited. The system can form an embedded system, avoids direct modelingof nonlinear characteristics, is small in calculation amount, and facilitates the online control of the switched reluctance motor.

Owner:GUILIN UNIV OF ELECTRONIC TECH

A fast energy-saving predictive control method for superheated steam temperature

ActiveCN104181958BGuaranteed qualityStable controlAuxillary controllers with auxillary heating devicesAdaptive controlProcess deviationsSequence control

Owner:NANJING GUITU TECH DEV

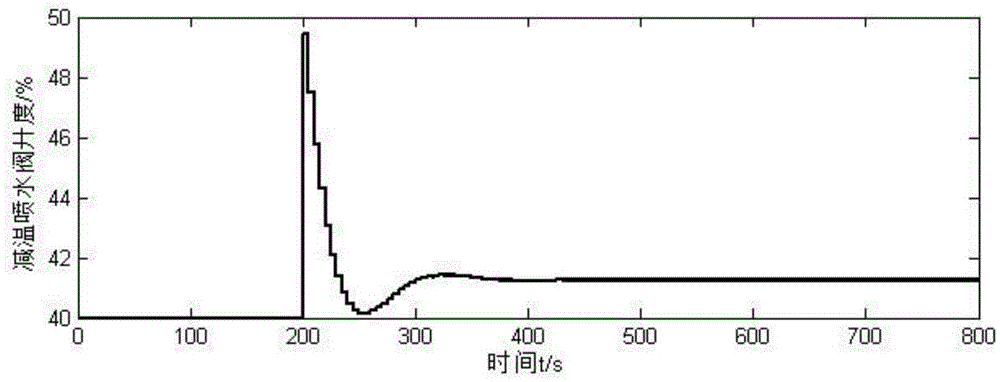

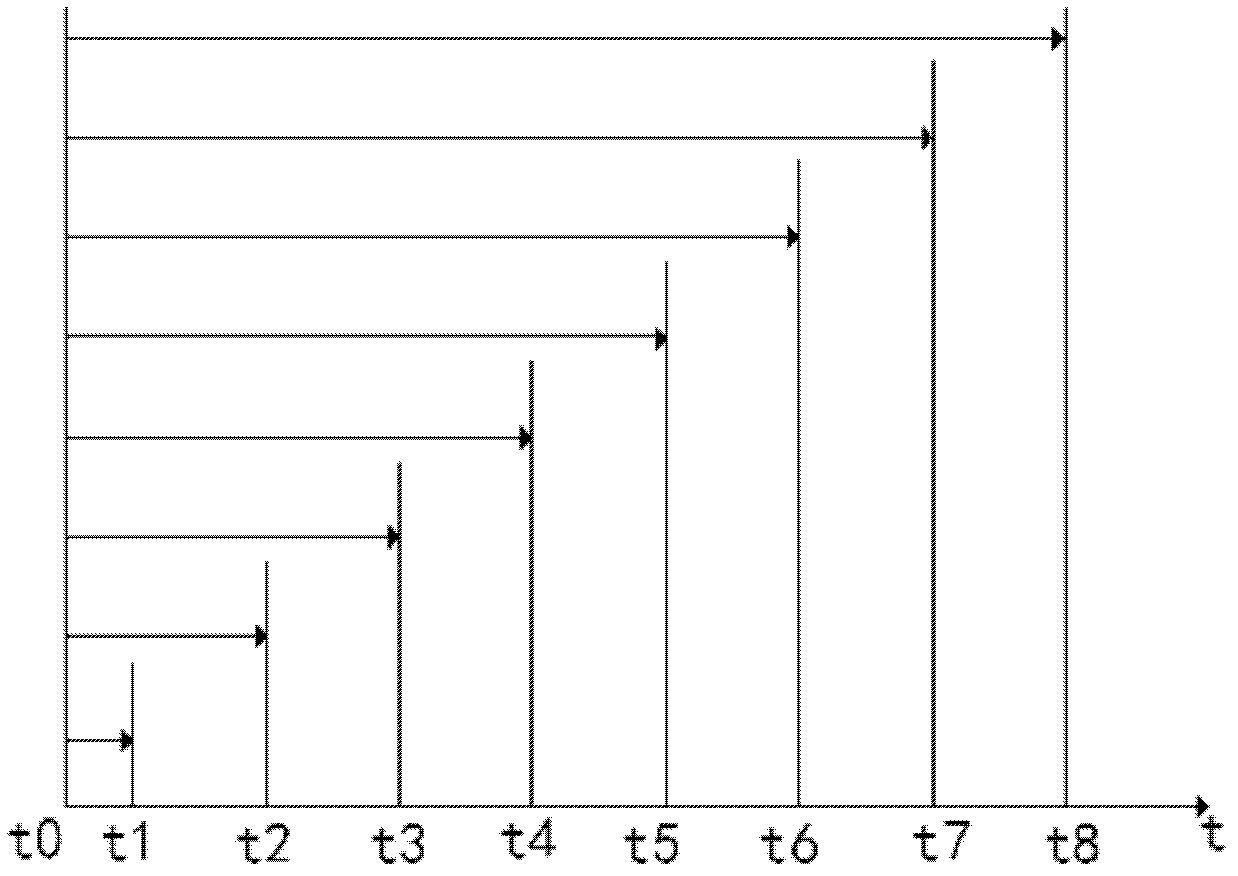

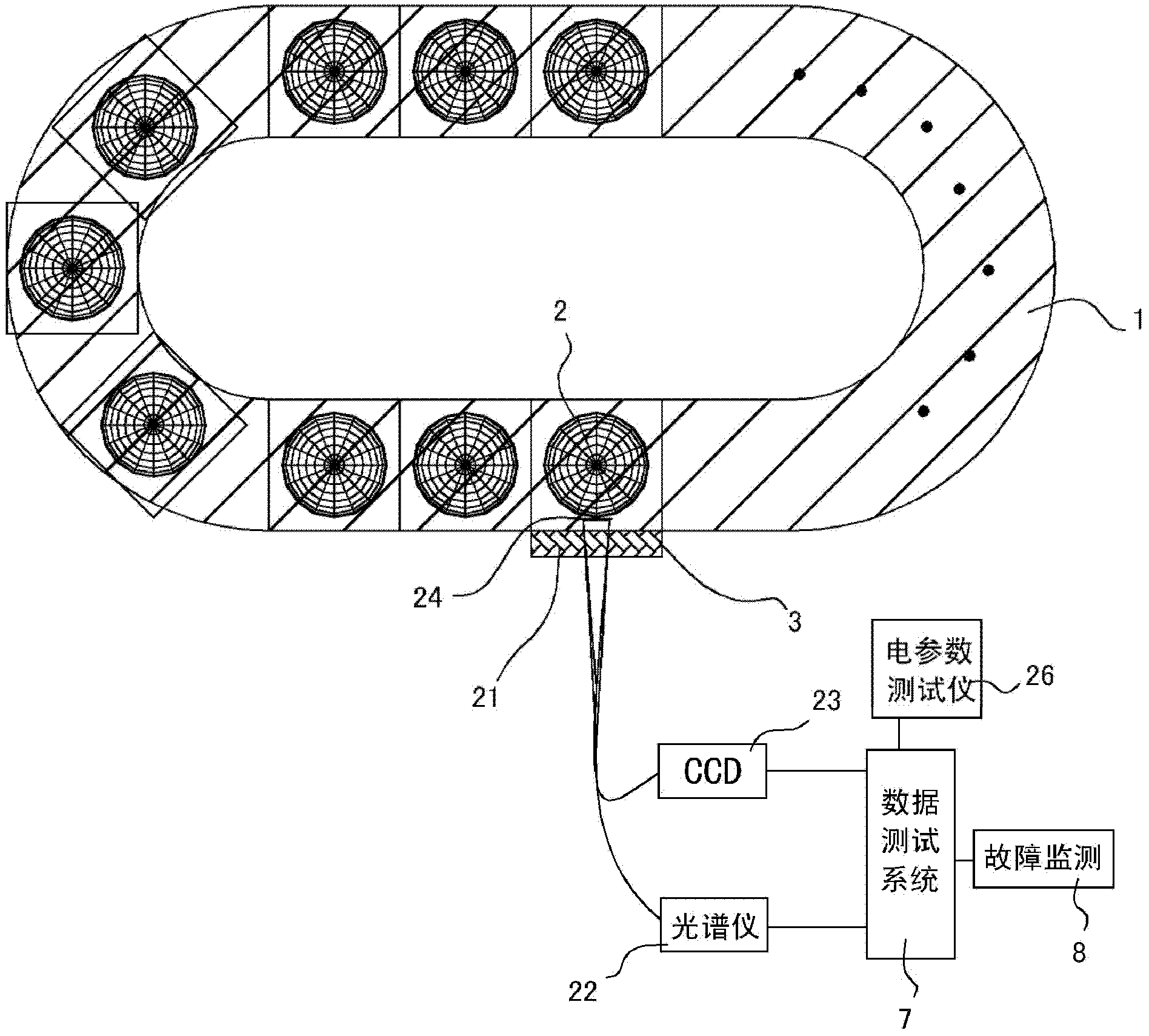

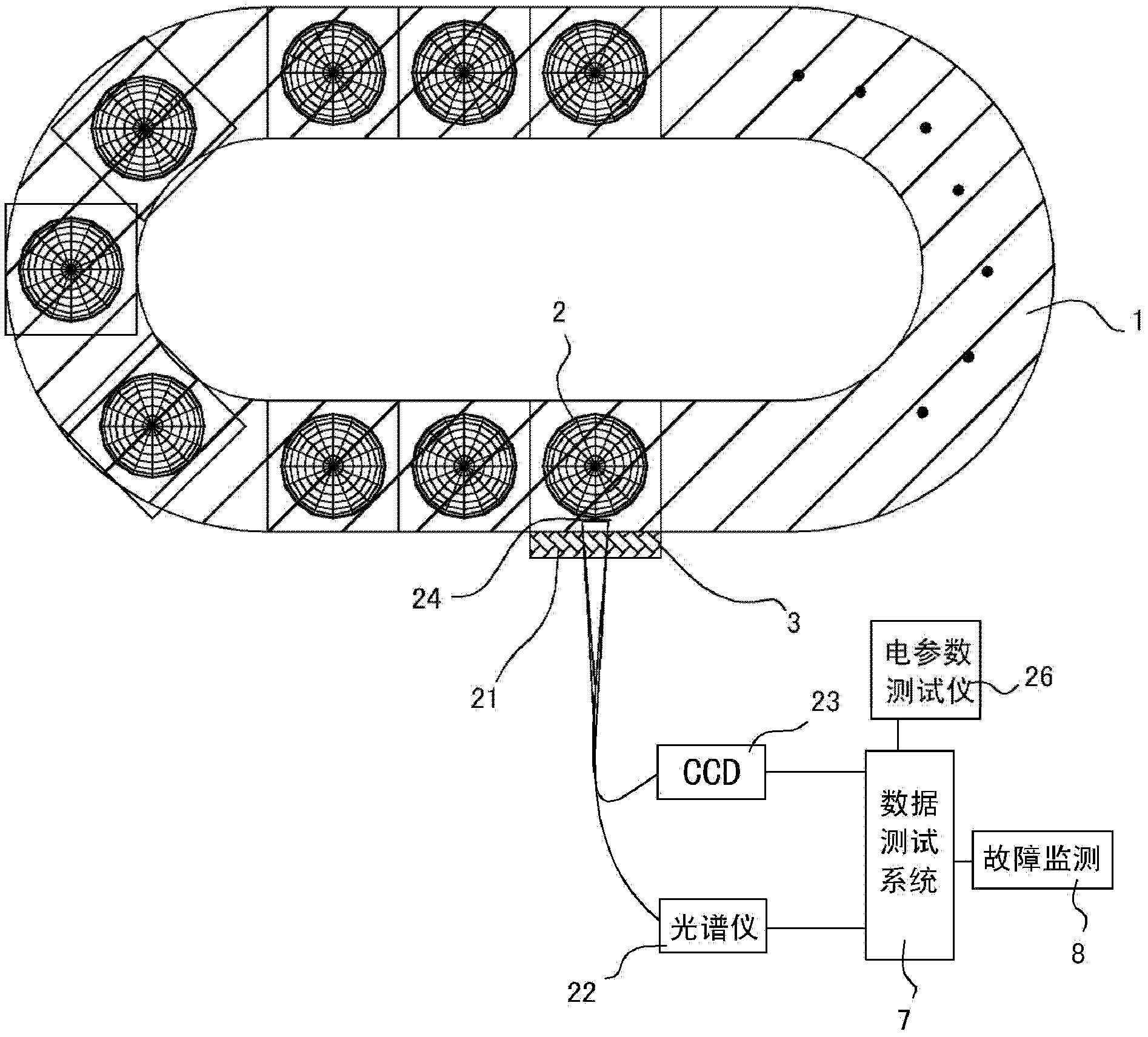

Online detection system for single-capped electrodeless fluorescent lamps

InactiveCN102623281BObtain performance parameters in real timeConvenient online controlManufacture testing/measurementsData processing systemControl signal

The invention discloses an online detection system for single-capped electrodeless fluorescent lamps, which is characterized in that a test area of a light source aging operating device is provided with a positioning device, and when a detected light source moves to a position at which the positioning device is arranged, the positioning device emits positioning signals; the online detection system is provided with an online testing system for responding to the positioning signals emitted by the positioning device, and a data processing system; in the test area of the light source aging operating device, the online testing system carries out signal acquisition on the detected light source so as to obtain an acquisition signal, and the data processing system carries out data conversion and processing on the acquisition signal; and the data processing system provides an online test control signal. According to the invention, an online test is performed in the aging link of a single-capped electrodeless fluorescent lamp so as to obtain the performance parameters and matching effects of products in real time, thereby facilitating the quality management and control on products.

Owner:季晓东

Online detection system for single-capped electrodeless fluorescent lamps

InactiveCN102623281AObtain performance parameters in real timeConvenient online controlManufacture testing/measurementsData processing systemControl signal

The invention discloses an online detection system for single-capped electrodeless fluorescent lamps, which is characterized in that a test area of a light source aging operating device is provided with a positioning device, and when a detected light source moves to a position at which the positioning device is arranged, the positioning device emits positioning signals; the online detection system is provided with an online testing system for responding to the positioning signals emitted by the positioning device, and a data processing system; in the test area of the light source aging operating device, the online testing system carries out signal acquisition on the detected light source so as to obtain an acquisition signal, and the data processing system carries out data conversion and processing on the acquisition signal; and the data processing system provides an online test control signal. According to the invention, an online test is performed in the aging link of a single-capped electrodeless fluorescent lamp so as to obtain the performance parameters and matching effects of products in real time, thereby facilitating the quality management and control on products.

Owner:季晓东

Torque-current neural network model srm torque ripple control method and system

ActiveCN110022109BConvenient online controlElectric motor controlMotor control for motor oscillations dampingPulse controlNerve network

The invention relates to a switch reluctance machine (SRM) torque pulse control method and system of a torque-current neutral network model. According to the method, a torque-current conversion relation is obtained by an inductance model of an SRM, each phase control current is obtained by a current allocation function, so that torque pulse is prevented. According to a non-linear characteristic relation between the SRM torque and the current, a function of describing basic change rule of an SRM current is used as an implication layer simulation function, a torque-current neutral network modelof describing the strong non-linear characteristic of the SRM is designed, the total reference current corresponding to torque is calculated by self-learning of the torque-current neutral network model, a reference current corresponding to each phase is obtained by the current allocation function, and the SRM is controlled. A program storage device of a system microprocessor designed by the methodis provided with each program module for executing the method, each sensor signal on the SRM is connected to the microprocessor, and the SRM is connected and controlled by a power converter. By the method, effective control on torque pulse of the SRM is achieved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

A Method of Applying Ultrasonic Wave Energy to Suspended Matter to Accelerate Settling

InactiveCN104045126BReduced footprintReduce footprintWater/sewage treatment with mechanical oscillationsFiberPolyester

Owner:中国市政工程西北设计研究院有限公司浙江分公司 +1

A double-stage double-body grain drying device

InactiveCN104719460BEasy to adjustConvenient online controlSeed preservation by dryingAgricultural engineeringSlow cooling

The invention discloses a double-stage double-body grain drying device, the technical gist of which is that the double-stage double-body grain drying device is mainly composed of a drying body, a damper body, a hoist and a hoist, and the drying body is A cuboid with an open top. A grain distributing trough is arranged at the upper end of the drying body, a grain discharging hopper is arranged at the lower end of the drying body, and 1 to 9 drying layers are arranged between the grain distributing trough and the grain discharging hopper; the slowing body is a cylinder. The upper cone is set on the upper end of the bradycere). The lower end of the bradysum body is provided with a lower cone). Between the upper cone and the lower cone, 1 to 9 ventilation layers are set, and between the 2 ventilation layers, a slow soot layer B is set. The beneficial effect of the present invention is: it is beneficial to the drying section process and slow soot cooling The adjustment and online control of the section process. The grain can achieve the functions of slow drying and slow cooling, which can adjust the ratio of grain drying to slow cooling, which is beneficial to the advantages of grain variable temperature drying technology. Make the grain achieve the goal of slow recovery and slow cooling, and improve the quality of the grain.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com