Helical fiber grating manufacturing device and manufacturing method thereof

A fiber grating and manufacturing device technology, applied in the directions of cladding fiber, optical waveguide light guide, light guide, etc., can solve the problems of complicated manufacturing equipment, complicated manufacturing process and low efficiency of helical fiber grating, and achieve strong repeatability and manufacturing efficiency. High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

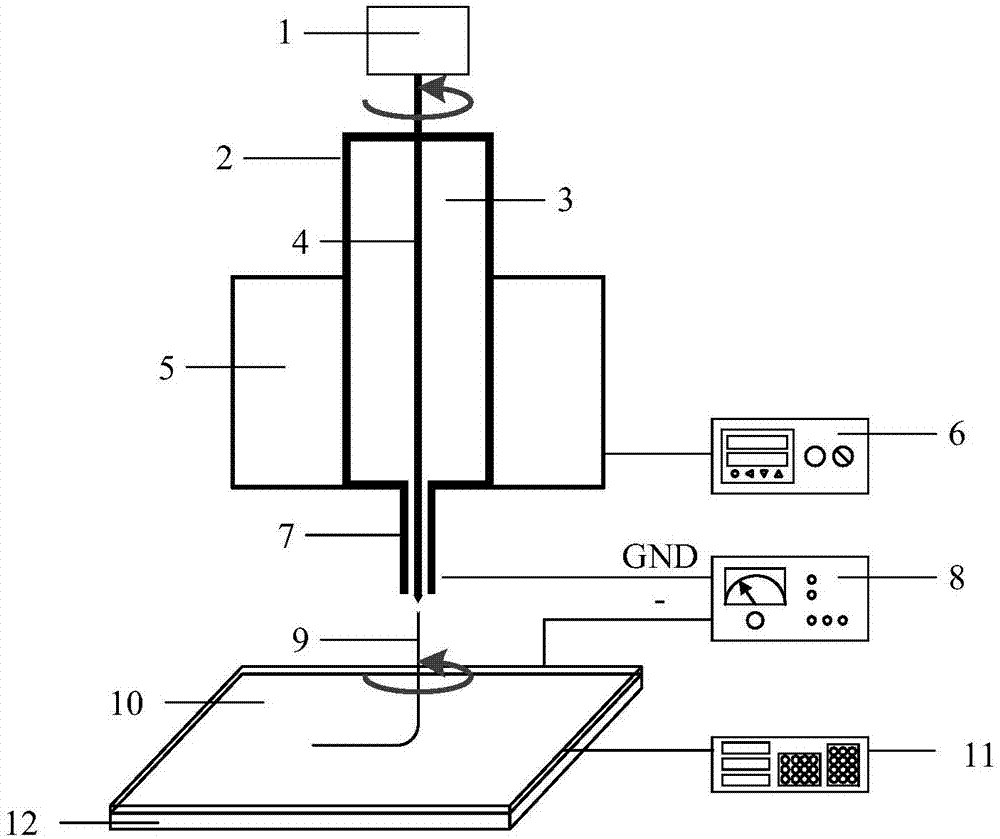

[0018] combine figure 1 , the flat end of the metal rod 4 with a needle point is connected with the DC motor 1 through a coupling, and the needle tip of the metal rod 4 slightly protrudes from the metal microchannel 7; the center of the metal cap on the upper end of the metal storage tube 2 is punched so that the metal rod can pass through The other end is connected to the metal microchannel through a standard interface; the heater 5 is in close contact with the metal storage pipe 2, and the temperature of the molten polymer raw material 3 in the storage pipe 2 is adjusted by the temperature controller 6; the metal microchannel 7 is connected to the ground terminal of the high-voltage DC power supply 8; the conductive substrate 10 is connected to the negative voltage terminal of the high-voltage DC power supply 8, and is insulated and placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com