A double-stage double-body grain drying device

A technology of grain drying and drying body, applied in the direction of storing seeds by drying, etc., can solve the problems of large drying equipment, low cost performance and high investment cost, achieve non-destructive grain discharge technology and technology, reduce precipitation, The effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] The following combination and examples further describe the present invention in detail.

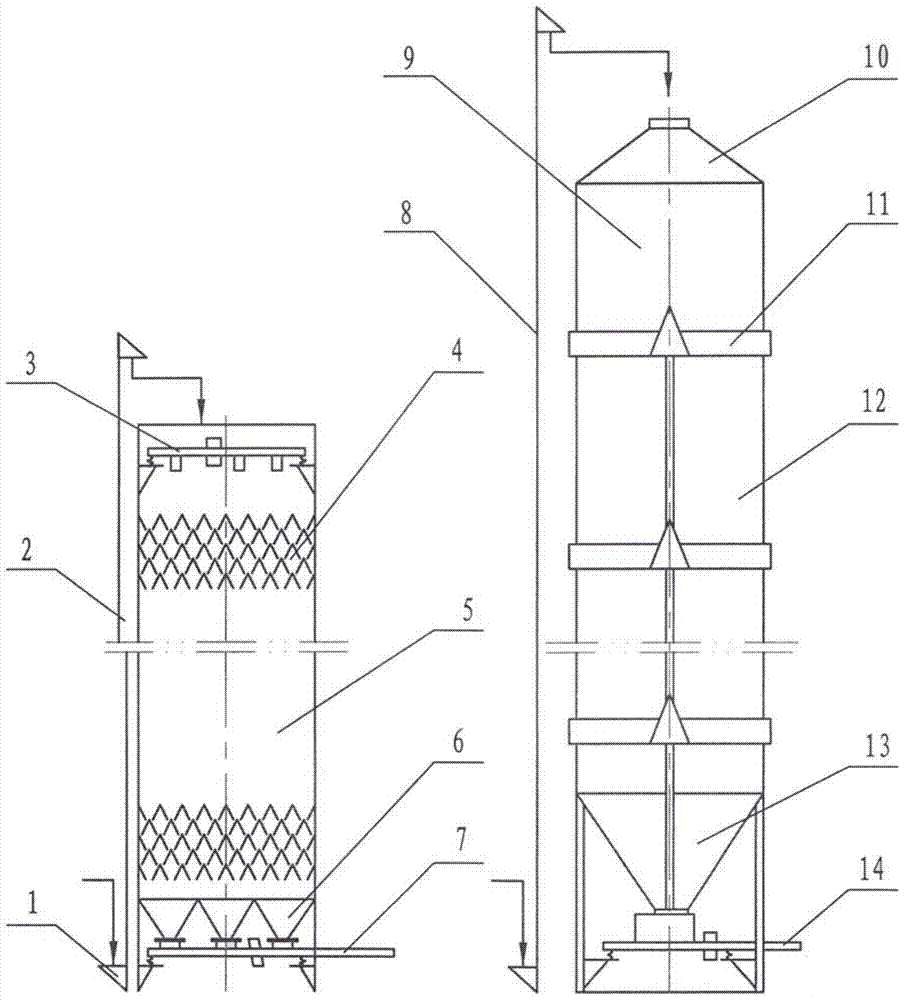

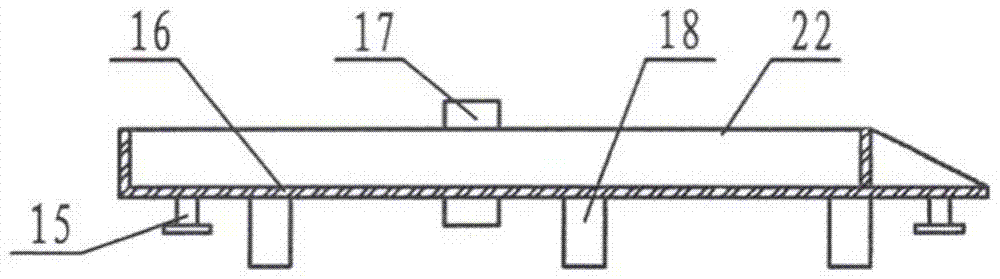

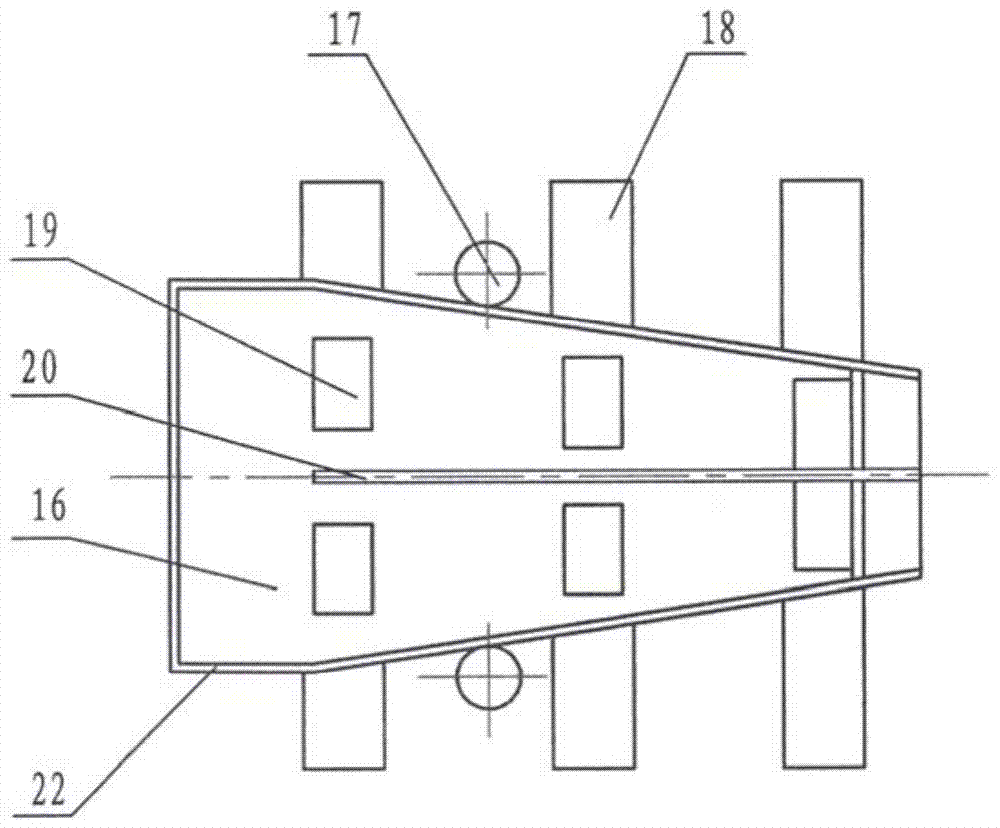

[0063] See attached figure 1 ----16, such as figure 1 As shown, the double-stage double-body grain drying device is mainly composed of a drying body (2), a slowing body (9), hoist I (1) and hoist II (8). The described drying body (2) is a cuboid with an open top. A grain distributing trough (3) is arranged at the upper end of the drying body, and a grain discharge hopper (6) is arranged at the lower end of the drying body. 1 to 9 drying layers (4) are arranged between the grain distribution trough and the grain discharge hopper. Between the two dry layers (4), a slow sore layer A (5) is provided. The grain delivery trough A (7) is set below the grain discharge hopper (6).

[0064] Bradylum (9) is a cylinder. Upper cone (10) is arranged on the upper end of slow sous body. The lower cone (13) is set at the lower end of the bradycere. Between the upper cone and the lower cone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com