Patents

Literature

328 results about "Grain distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grain Systems Distribution (GSD) is an agricultural wholesale company that specializes in providing top-quality products with excellent customer service.

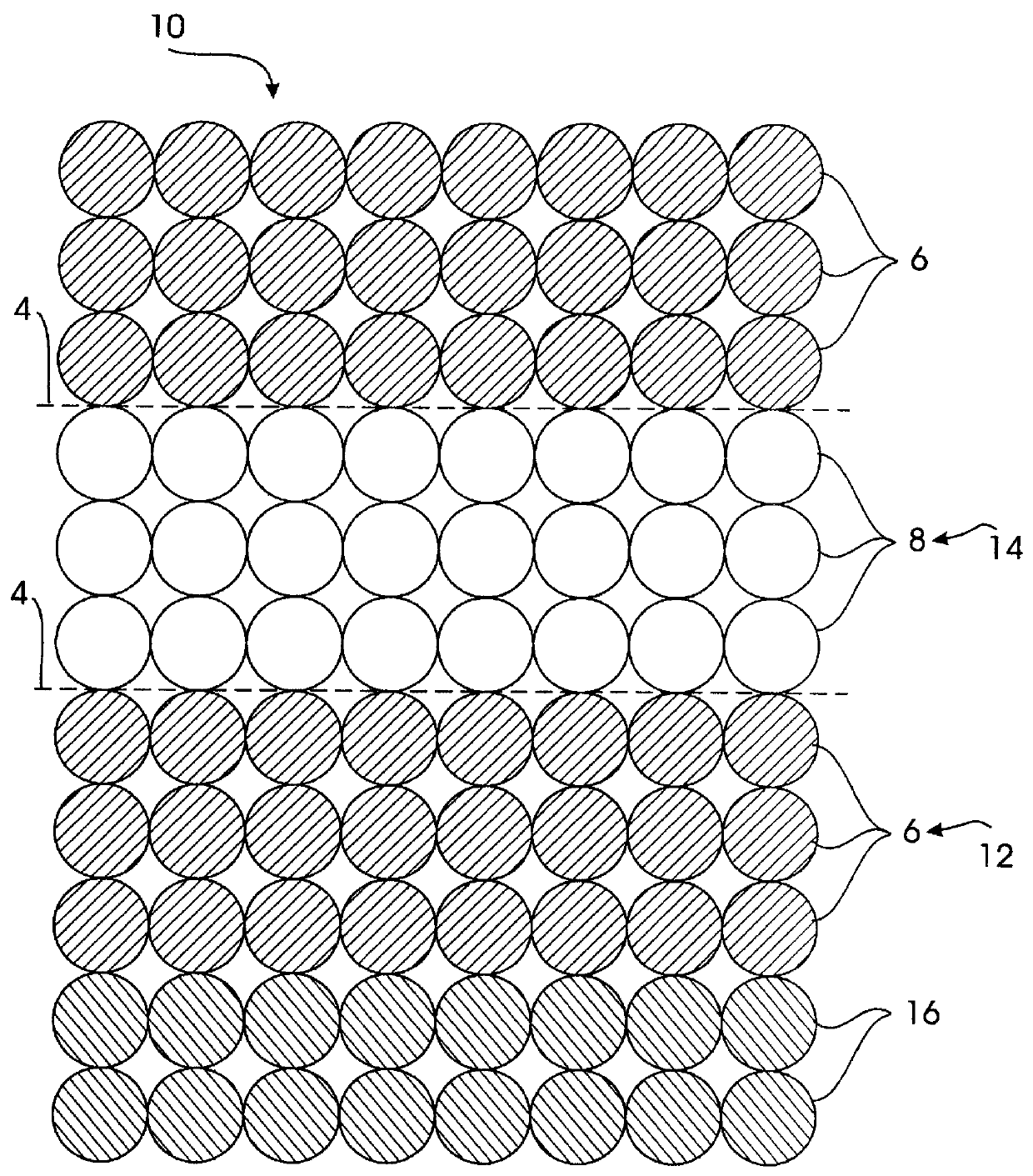

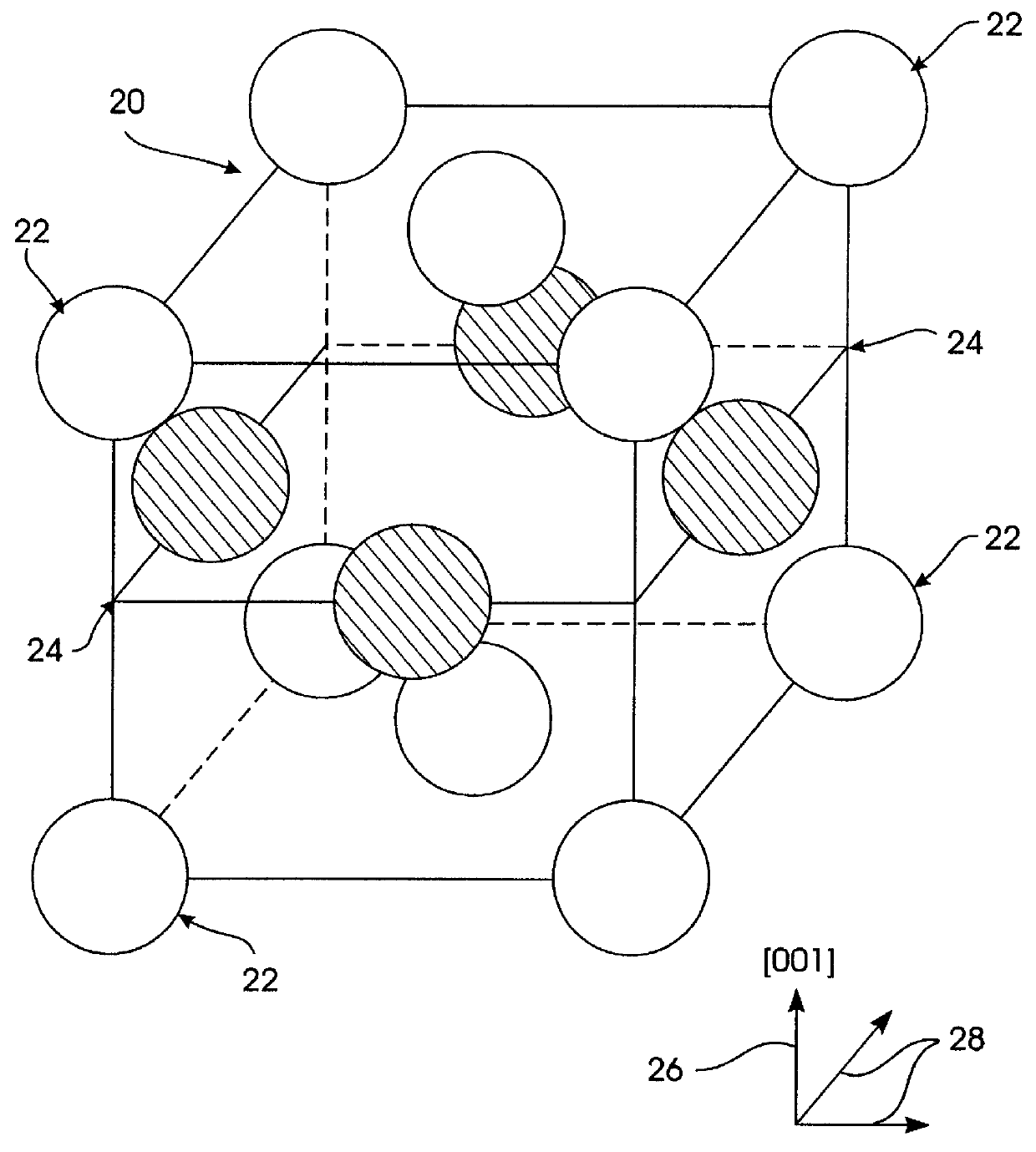

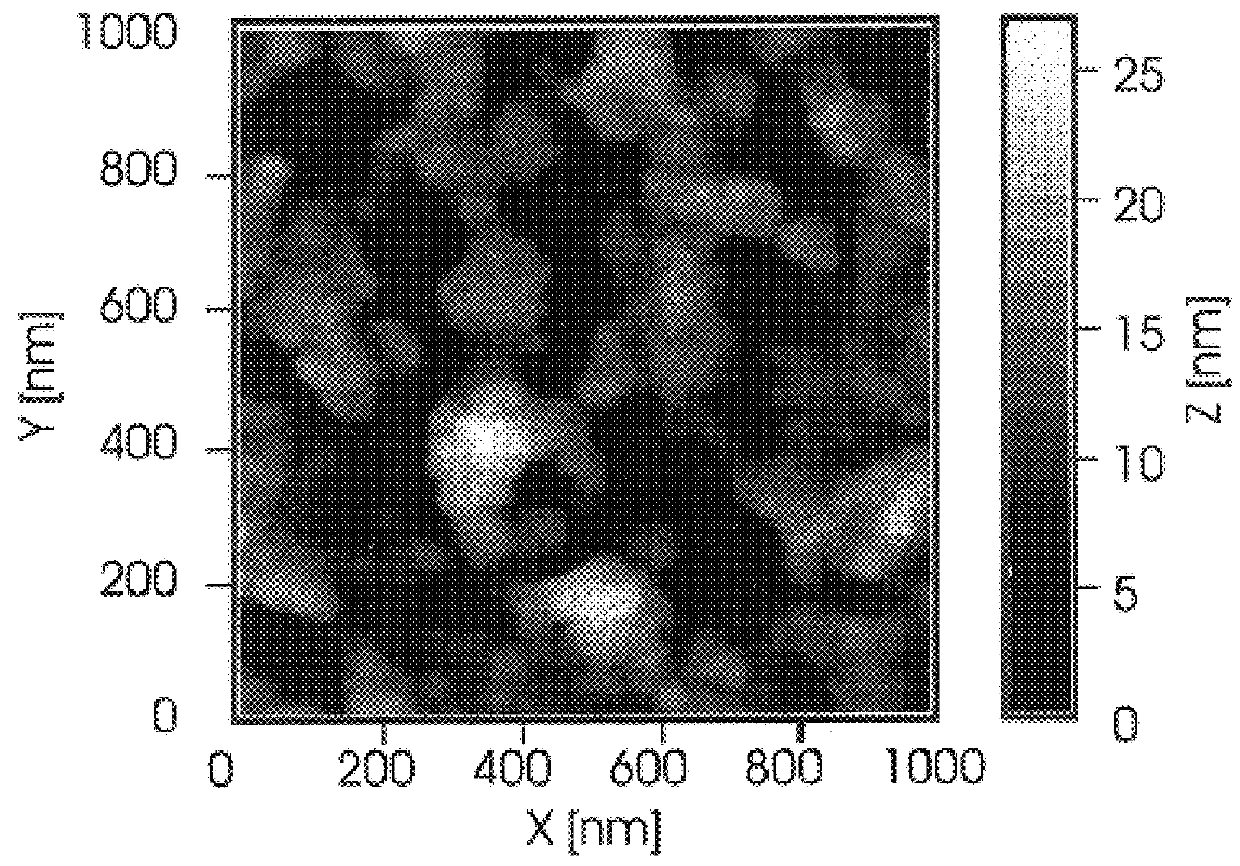

Horizontal magnetic recording media having grains of chemically-ordered FEPT of COPT

InactiveUS6086974ABase layers for recording layersRecord information storageAlloyMagnetocrystalline anisotropy

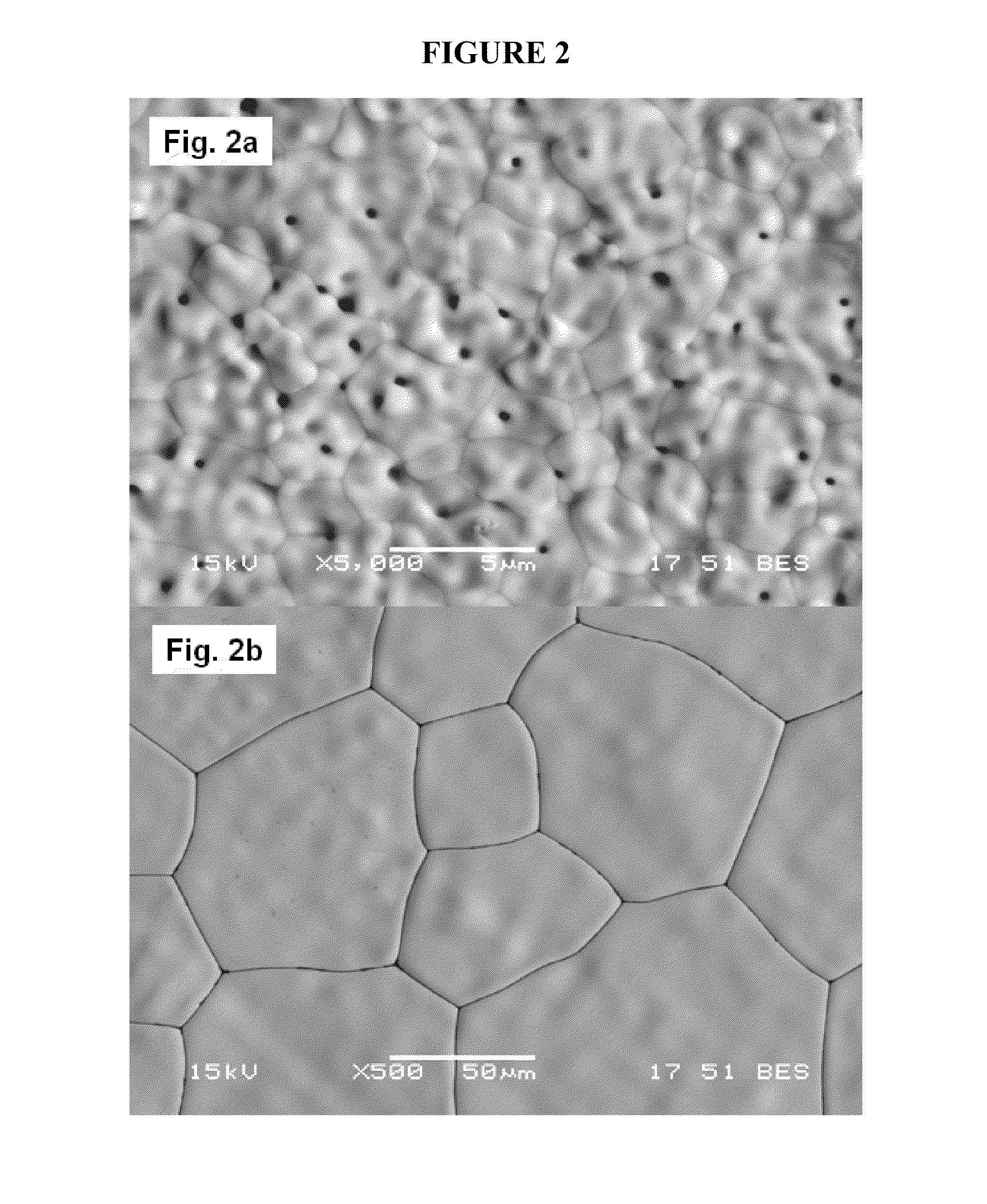

A horizontal magnetic recording medium that has as its magnetic film a granular film with grains of a chemically-ordered FePt or FePtX (or CoPt or CoPtX) alloy in the tetragonal L10 structure uses an etched seed layer beneath the granular film. The granular magnetic film reveals a very high magnetocrystalline anisotropy within the individual grains. The film is produced by sputtering from a single alloy target or cosputtering from several targets. The granular structure and the chemical ordering are controlled by means of sputter parameters, e.g., temperature and deposition rate, and by the use of the etched seed layer that provides a structure for the subsequently sputter-deposited granular magnetic film. The structure of the seed layer is obtained by sputter etching, plasma etching, ion irradiation, or laser irradiation. The magnetic properties, i.e., Hc and areal moment density Mrt, are controlled by the granularity (grain size and grain distribution), the degree of chemical ordering, and the addition of one or more nonmagnetic materials, such as Cr, Ag, Cu, Ta, or B. The resulting granular magnetic film has magnetic properties suitable for application in high-density, horizontal magnetic recording media.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

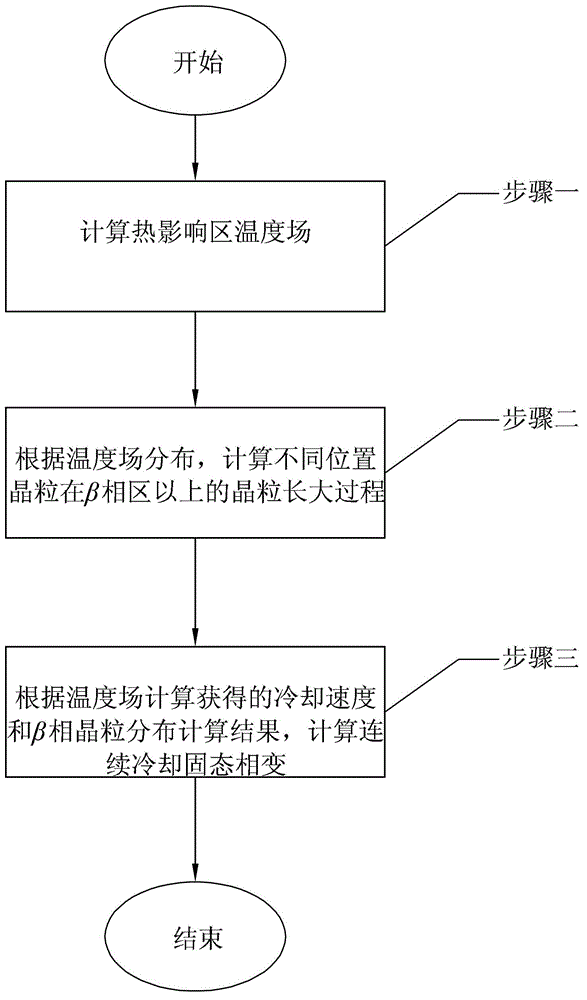

Simulation method of texture evolvement of heat affected zone in welding process

ActiveCN102750425AImprove microstructureImprove mechanical propertiesFurnace typesHeat treatment process controlHeat-affected zoneMaterials science

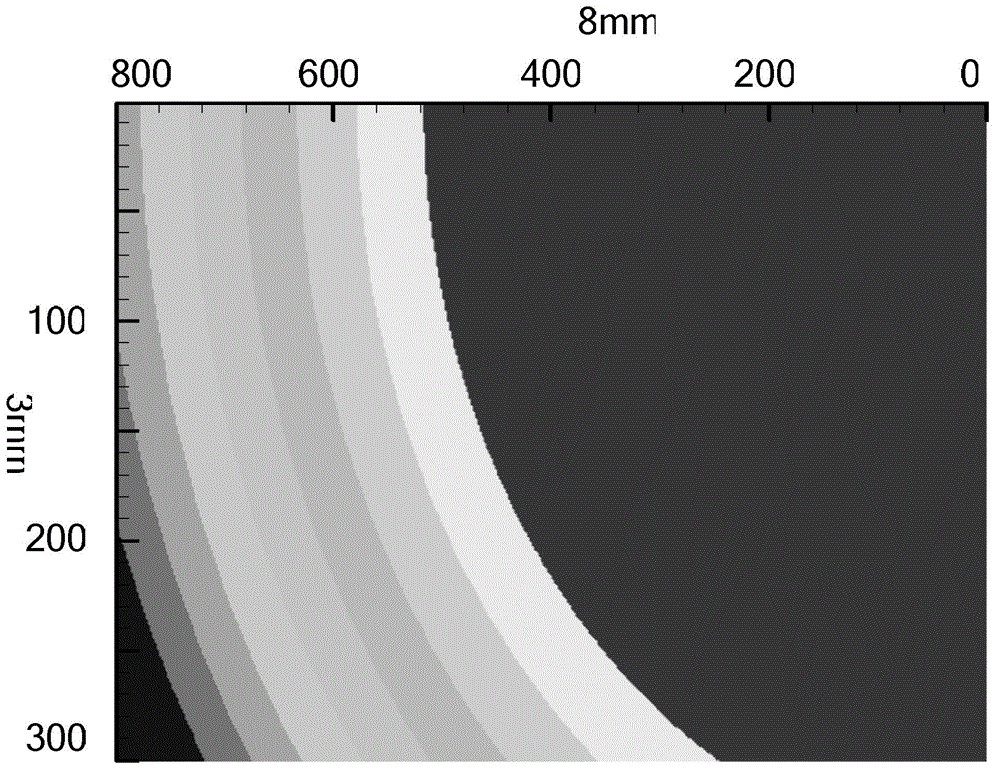

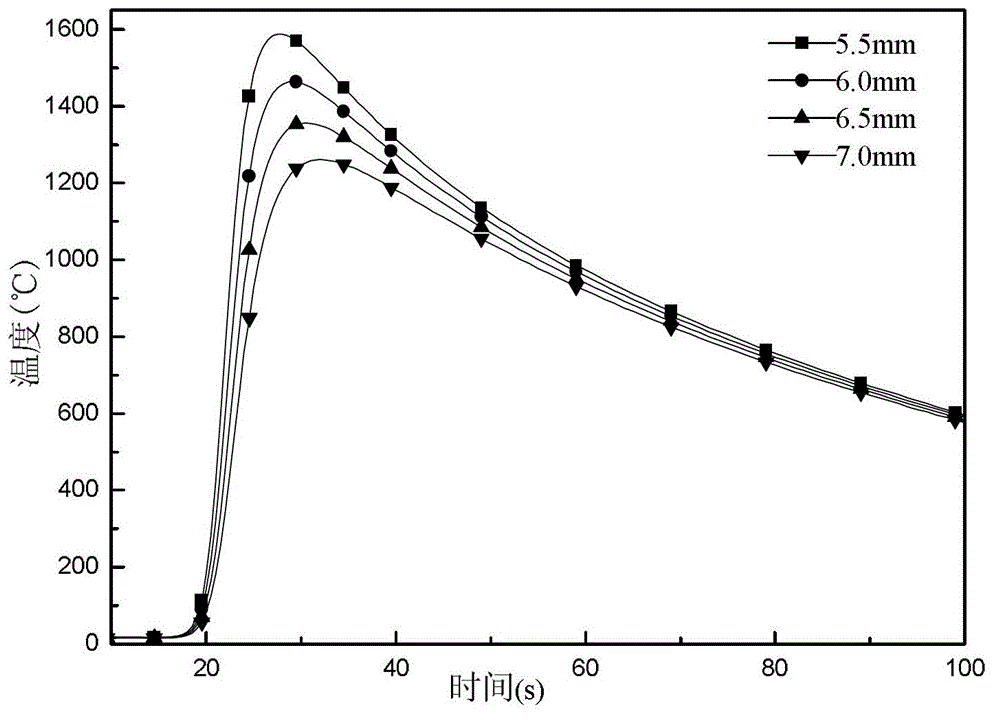

The invention discloses a simulation method of texture evolvement of a heat affected zone in a welding process, relating to a fine texture simulation method of a welding connector and aiming at solving the problems that the quantification of the present fine texture evolvement of a weld joint is mainly based on an experiential or half experiential deterministic model or analysis calculation, and only the texture content is calculated but the state, the size and the distribution of the texture cannot be reflected dynamically. The method comprises the following steps: step 1, calculating the temperature fields of the heat affected zone; step 2, calculating the crystalline grain growth process of crystalline grains at different positions above a beta phase zone according to the distribution of the temperature fields; and step 3, calculating continuous cooling solid state phase change according to the cooling velocity and the beta phase crystalline grain distribution calculation result obtained through the temperature field calculation. The simulation method is used for the fine texture simulation of the welding connector.

Owner:HARBIN INST OF TECH

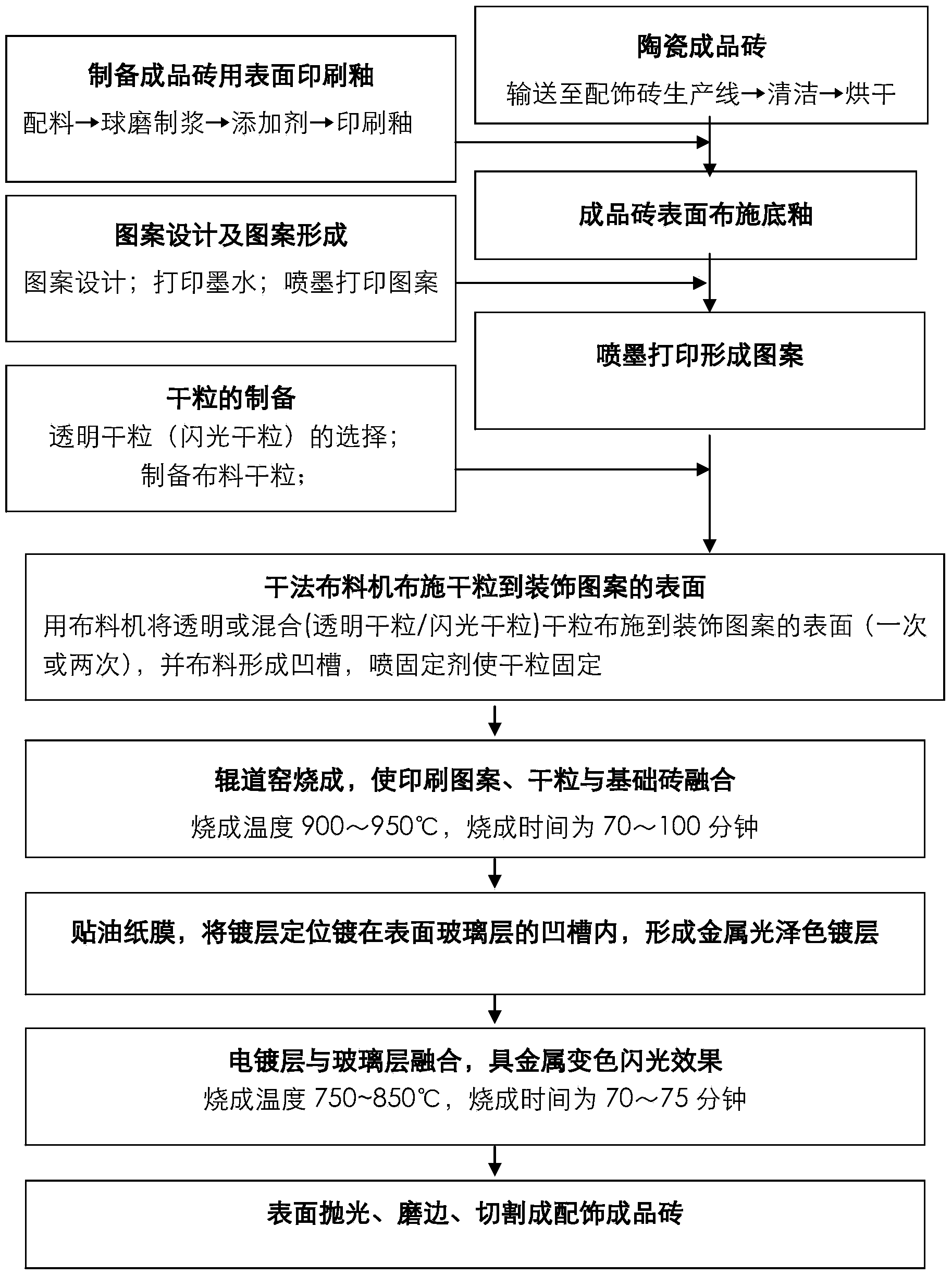

Manufacturing process of ceramic accessory tile and ceramic accessory tile manufactured by the process

The invention relates to a manufacturing process of a ceramic accessory tile and the ceramic accessory tile. The manufacturing process comprises the steps of: (1) printing a ground coat on the surface glass layer of sintered ceramic tile; (2) conducting ink-jet printing on the printing ground coat to form patterns; (3) applying transparent dry grains on the surface of the pattern layer for two times, and sintering; (4) electroplating metal color on a groove of the surface glass layer by adopting a lamination positioning electroplating method, and sintering; (5) polishing the surface of the sintered product; and (6) cutting the sintered accessory tile blank to prepare the accessory tile. The ceramic accessory tile comprises a base tile, ground coat applied on the surface of the base tile, the pattern layer attached on the ground coat, and the first dry grain layer and the second dry grain layer applied on the pattern layer. Irregular pits, grooves or concave curves, wherein the irregular pits, the grooves or the concave curves are hollowed towards the inside and are arranged on the layer surface of the second dry grain distribution layer. The accessory tile varieties include ground flowers, ground line, waist line and corner, and is used for supporting the ceramic wall and floor tiles.

Owner:JIANGXI HEMEI CERAMICS

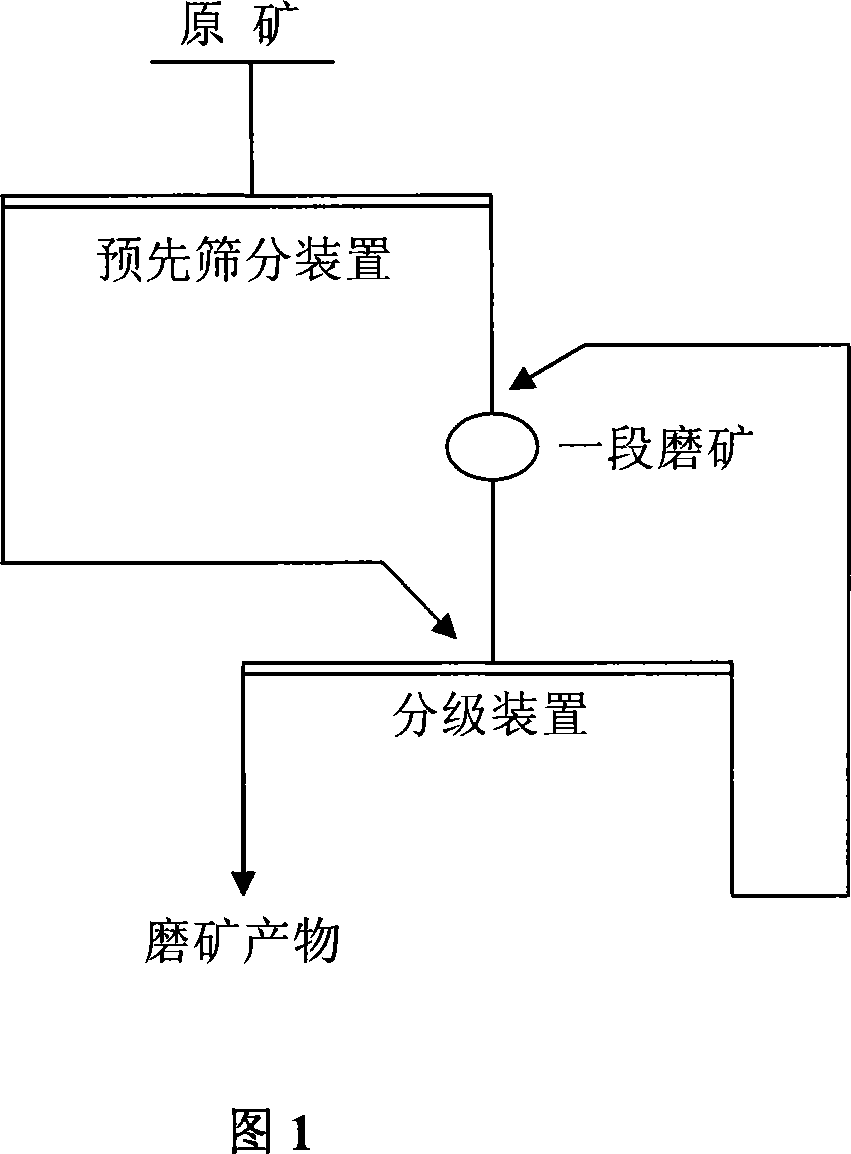

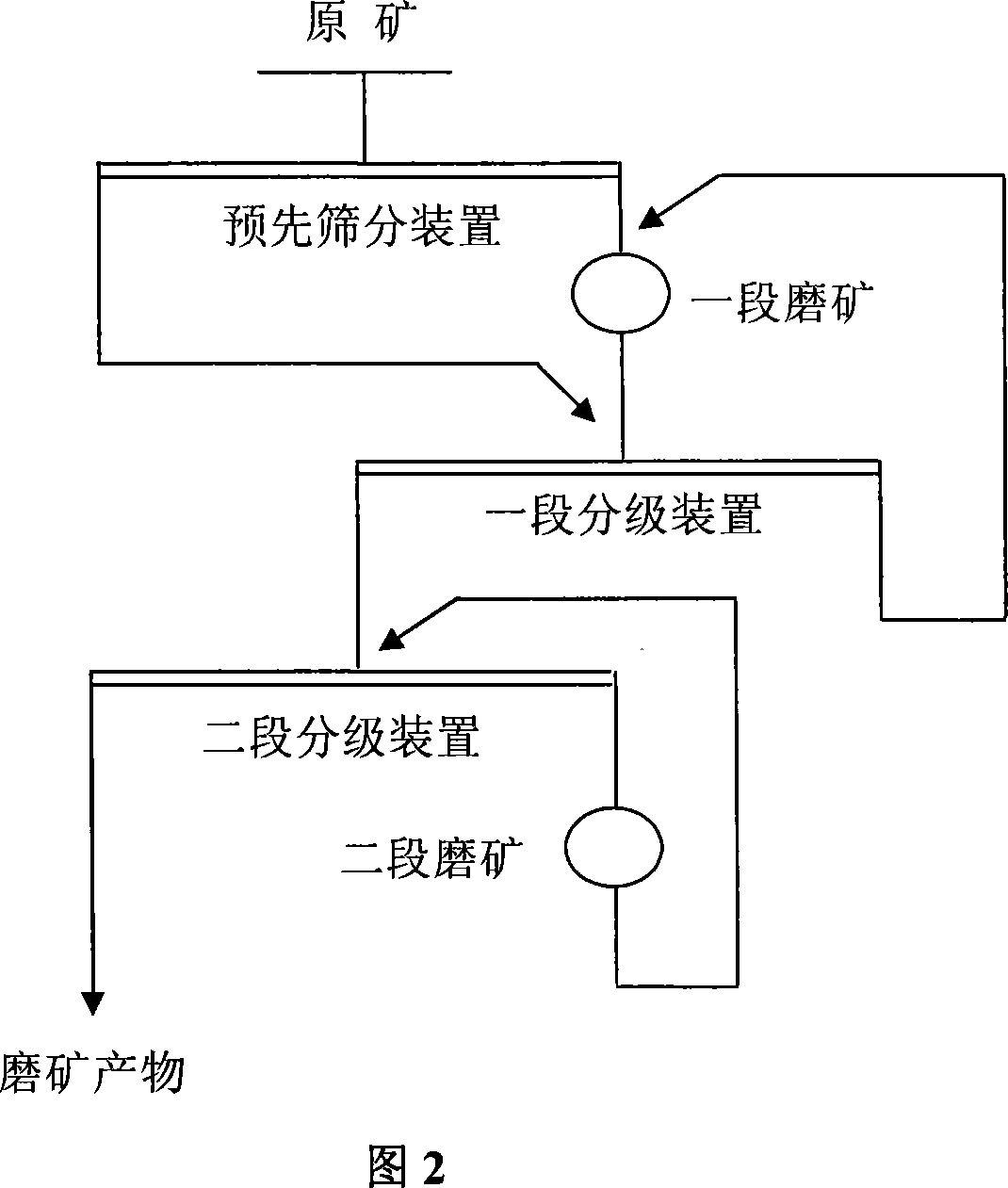

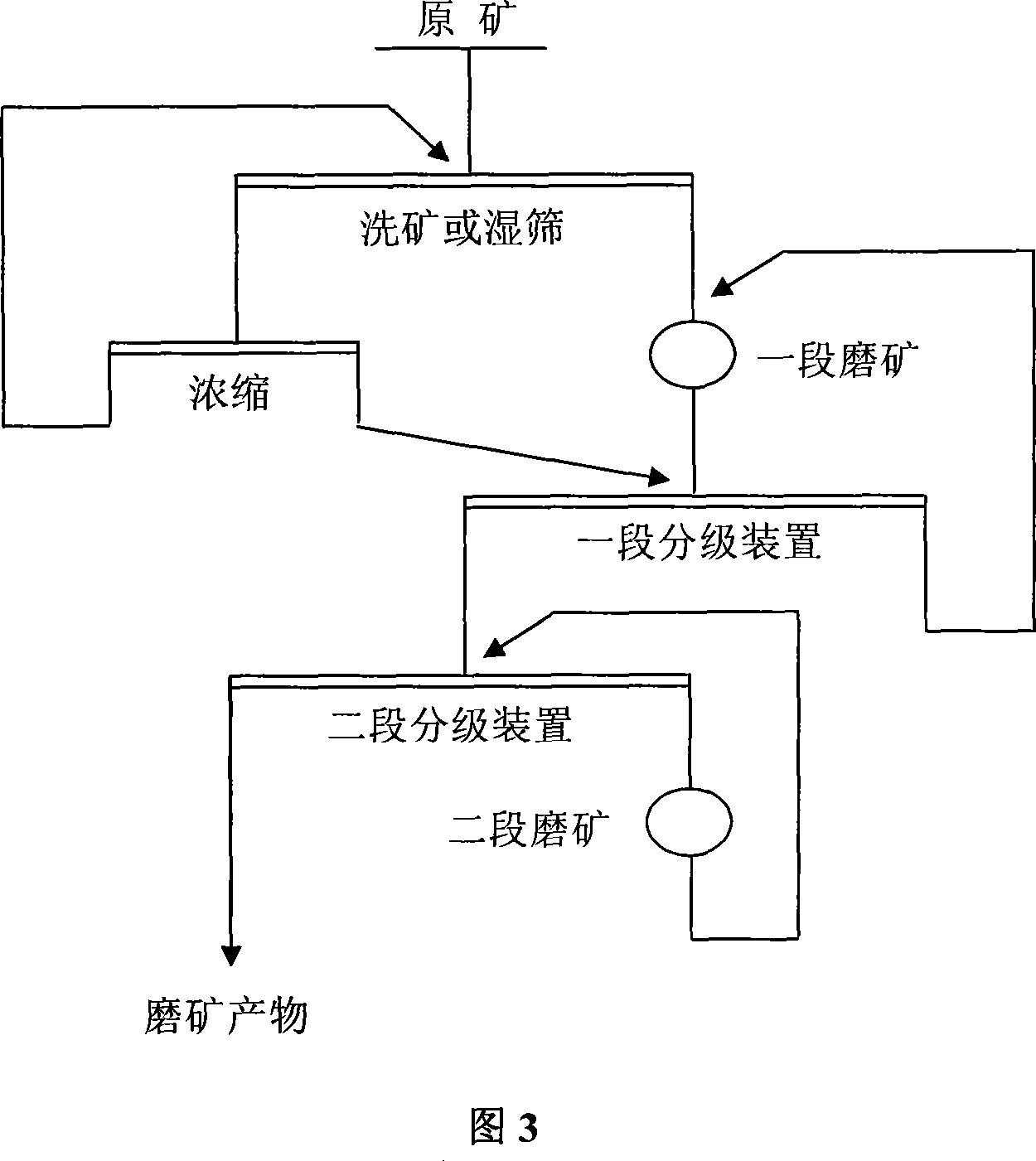

Mine milling method for improving particles size distribution of bauxite mine milling products

The invention relates to a grinding method to improve aluminum ore grinding particle distribution. It screens or separates the fine aluminum ore or paste, with thick particles or block ore for grinding. Using quick grinding, forced ore extraction and highly efficient leveling technique, it reduces the regrinding for acceptable grain product, reducing pelitization or overgrinding, especially fine level content, with -200 being 85%, reducing -400 content lower than 40%, significantly improving grain distribution of the grind ore and reduced grinding energy consumption.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Preparation of nano-ferriferrous oxide

InactiveCN101323466ASimple processSave raw materialsFerroso-ferric oxidesDispersityHeat pretreatment

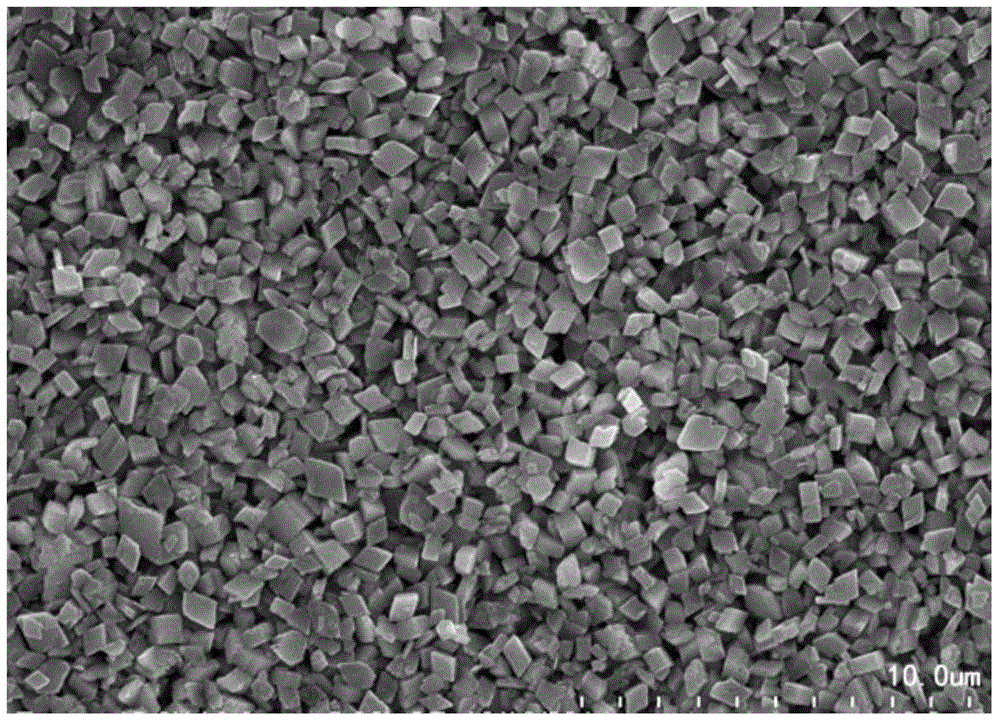

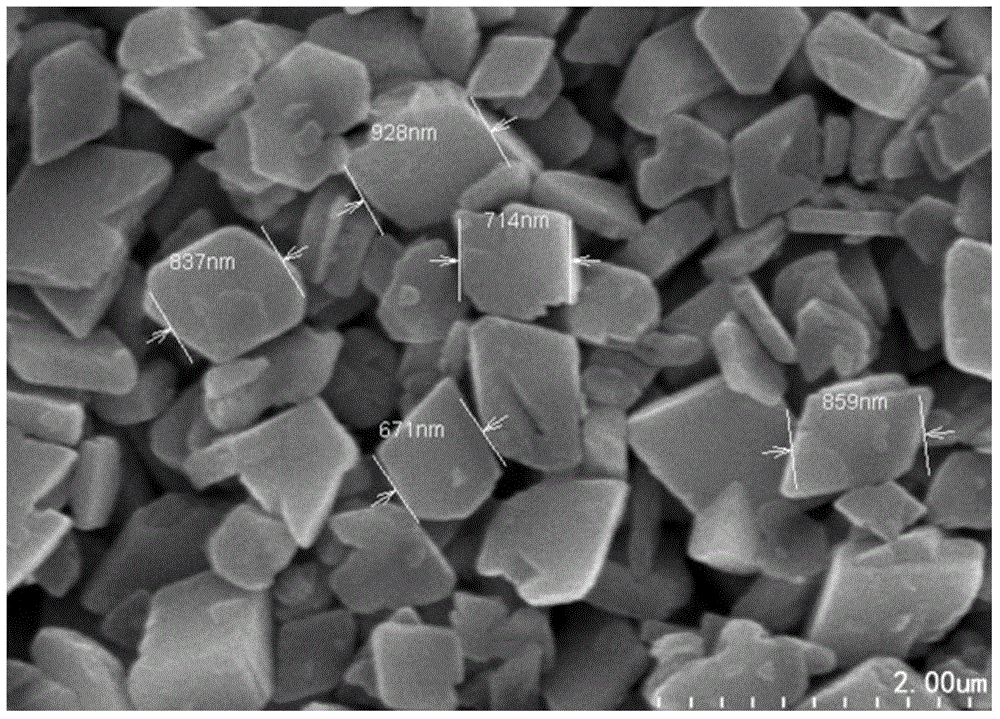

The invention discloses a chemical processing method, in particular to a preparation method for utilizing a solvothermal method to synthesize nano iron oxide. The invention adopts a certain amount of ferric chloride and dissolves the ferric chloride into a certain amount of methanol, ethanol or glycol and then a certain amount of sodium hydroxide is added, and later ultrasonic sound is adopted to equally disperse the mixture, and then the prepared mixture is transferred into a hydro-thermal reactor for a hydro-thermal processing under the temperature of 140 to 200 DEG C, and de-ethanol and / or deionized water for reaction liquid are adopted to wash reactants, and a centrifuge is adopted to remove the glycol solution and spare sodium hydroxide; the reactant is dried to obtain the iron oxide powder. The invention has the advantages that the method is simple, safe and reliable; the material is cheap; the output is high; the dispersity is better and the grain distribution is narrow, etc. The invention can be widely used by iron oxide manufacturers.

Owner:HANGZHOU NORMAL UNIVERSITY

Hard alloy blade and preparation method thereof

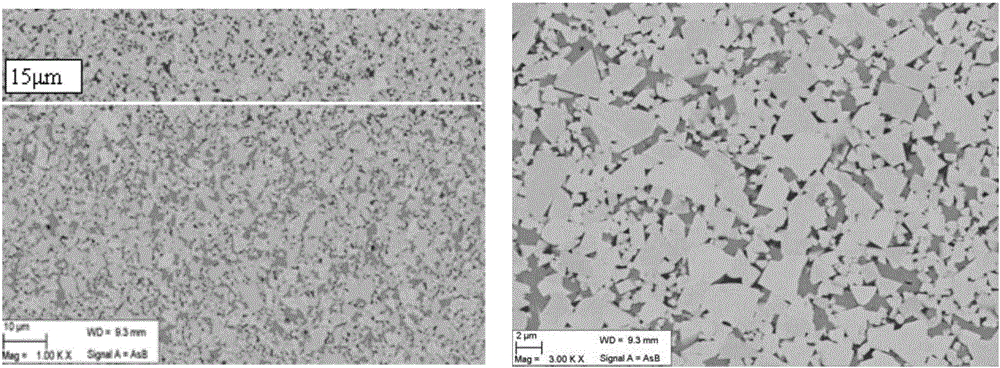

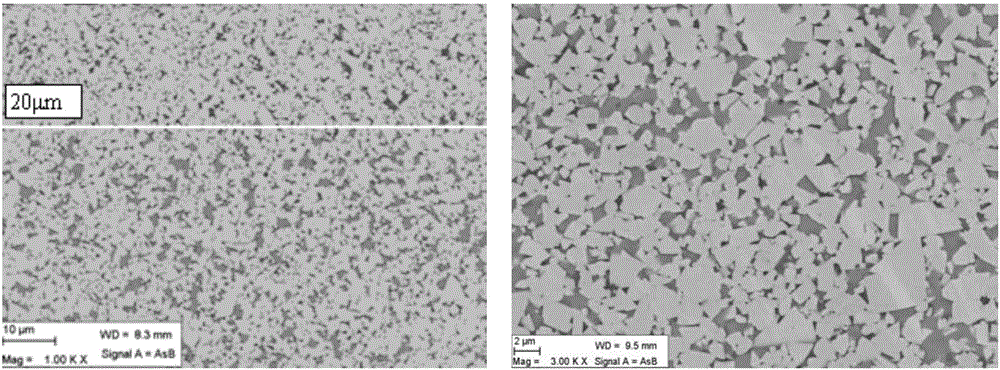

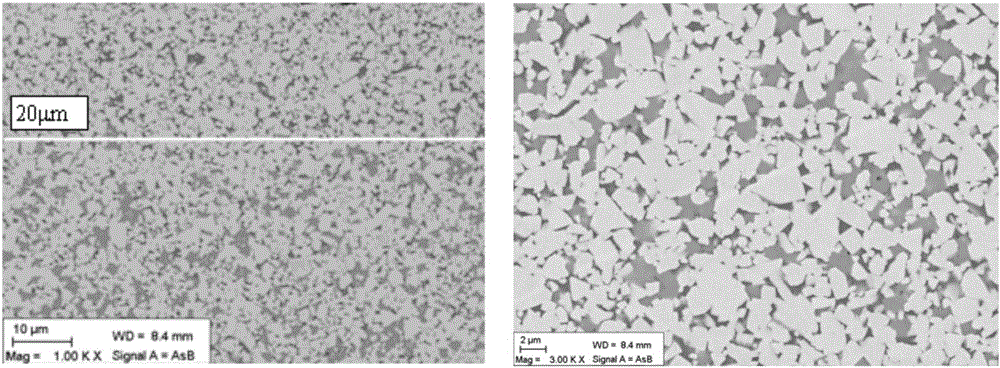

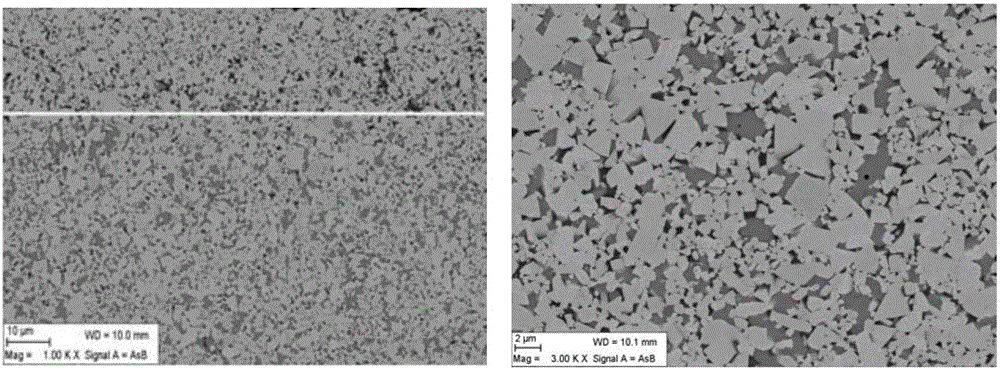

ActiveCN105950937AHigh hardnessImprove high temperature performanceTurning toolsTi elementTungsten carbide

The invention discloses a hard alloy blade and a preparation method thereof. The hard alloy blade comprises a hard alloy blade basal body and a coating layer; the hard alloy blade basal body uses Co as a binding phase, and uses tungsten carbide and a titanium-contained cubic-phase compound as a hard phase; the solid solution is performed for a W element and a Cr element in the binding phase; the mass fraction of the W element in the binding phase is 2-10 wt.%; the mass fraction of the Cr element in the binding phase is 1-10 wt.%; the titanium-contained cubic-phase compound is a carbon-nitrogen compound containing one or two in a Ta element and a Nb element and a Ti element; and the grain distribution of tungsten carbide has a double-peak structure. The preparation method comprises batching, powder preparation by mixing, molding by pressing, sintering and preparation of a coating layer. The hard alloy blade has the advantages of high hardness, toughness and strength and excellent and stable cutting performance, and is high in generality, suitable for various processing fields, simple in preparation method and low in cost.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Non-homogeneous gradient hard alloy and preparation method thereof

ActiveCN105803288AImprove toughnessHigh strengthTransportation and packagingMetal-working apparatusMetallic materialsMaterials science

The invention discloses non-homogeneous gradient hard alloy and a preparation method thereof. According to the non-homogeneous gradient hard alloy, Co serves as a binding phase, a tungsten carbide and titanium-containing cubic phase compound serves as a hard phase, the titanium-containing cubic phase compound accounts for 2-8 wt.% of the mass fraction of the non-homogeneous gradient hard alloy, tungsten carbide grain distribution has a double-peak structure, the original particle size is rough and fine, and the non-homogeneous gradient hard alloy is of a surface structure without a titanium-containing cubic phase compound with the average binding phase content 1-2 times of a nominal binding phase content. The preparation method includes the steps of material preparation, mixing, milling, compression molding and sintering. The non-homogeneous gradient hard alloy has higher hardness, toughness and bending strength and can meet the machining requirement of cast iron, alloy steel, stainless steel and other metal materials, the preparation method is simple in process, and cost is low.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Heat Stable Formed Ceramic, Apparatus And Method Of Using The Same

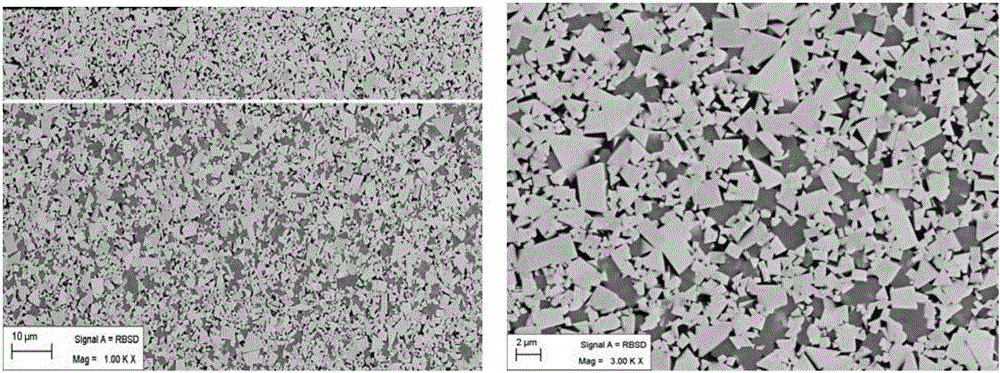

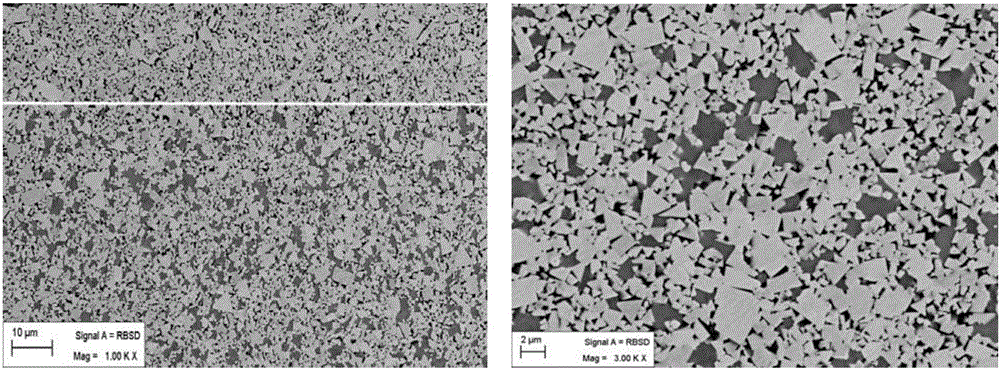

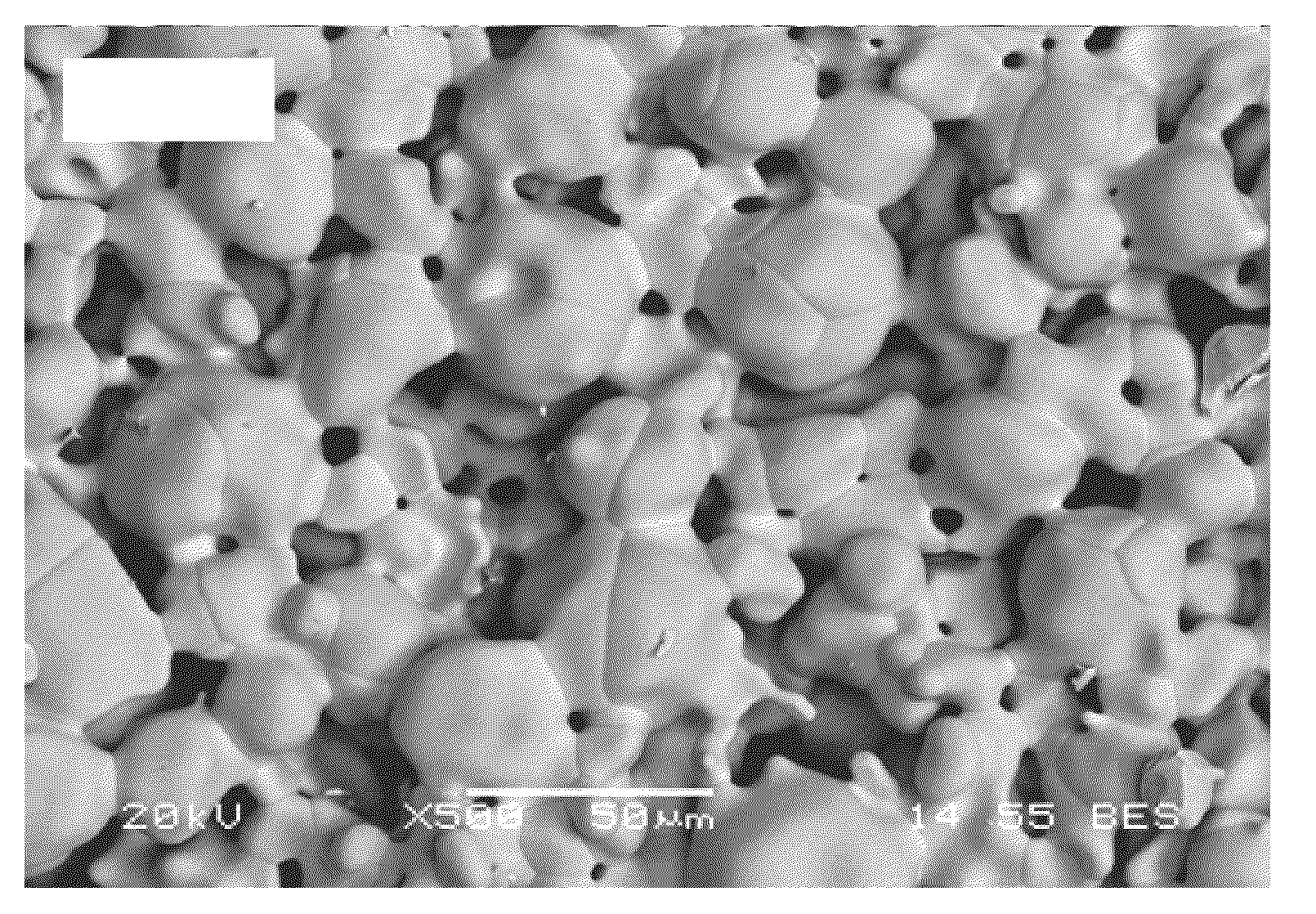

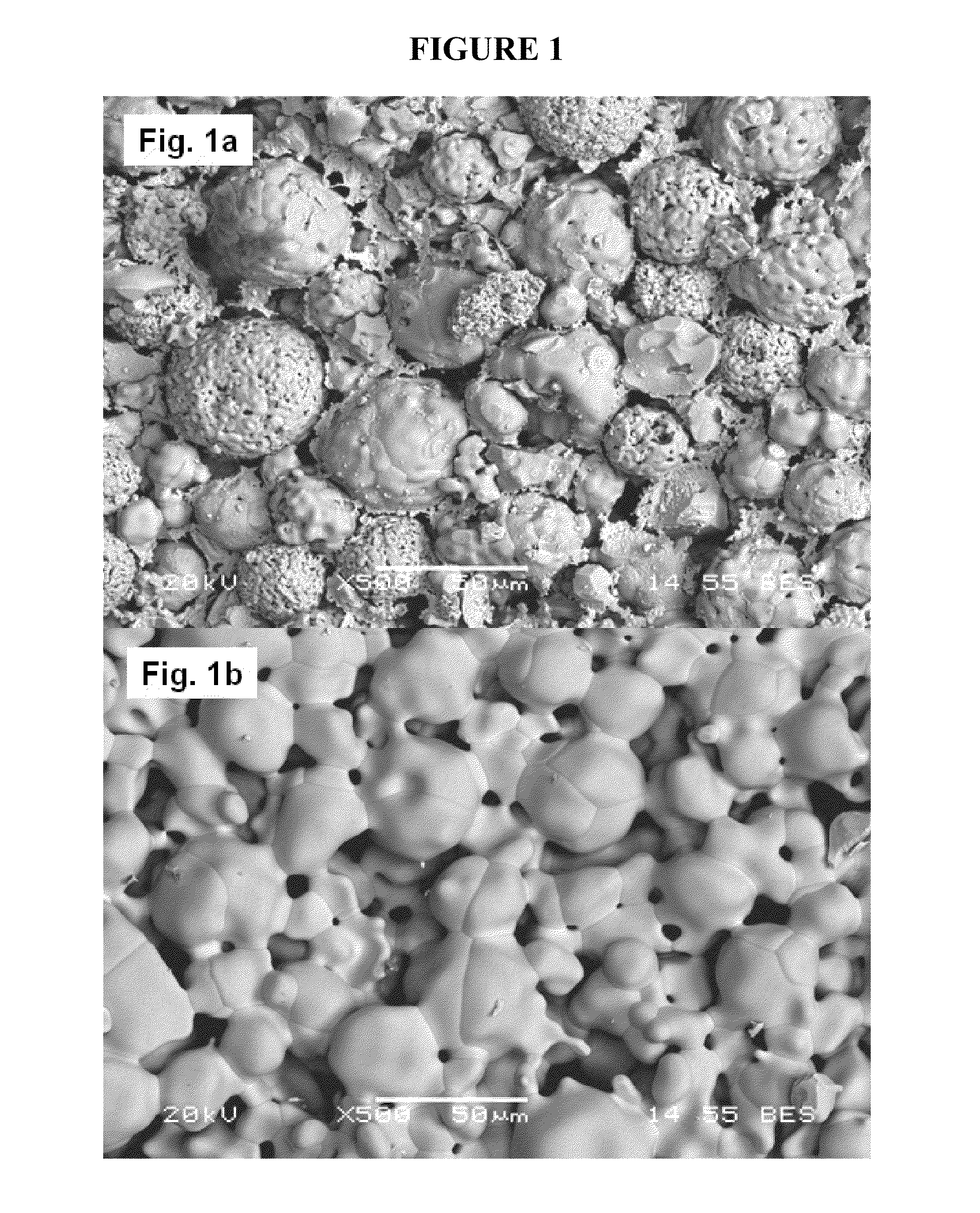

ActiveUS20100126907A1Thermal non-catalytic crackingPhysical/chemical process catalystsPorosityBi modal

In one aspect, the invention includes a heat stable, formed ceramic component that includes a multimodal grain distribution including (i) at least 50 wt % of coarse grains including stabilized zirconia, the coarse grains comprising a D50 grain size in the range of from 5 to 800 μm, based upon the total weight of the component; and (ii) at least 1 wt % of fine grains comprising a D50 average grain size not greater than one-fourth the D50 grain size of the coarse grain, dispersed within the coarse grains, based upon the total weight of the component; wherein after sintering, the component has porosity at ambient temperature in the range of from 5 to 45 vol. %, based on the formed volume of the component. In other embodiments, the invention includes a process for the manufacture of a hydrocarbon pyrolysis product from a hydrocarbon feed using a regenerative pyrolysis reactor system, comprising the steps of: (a) heating a pyrolysis reactor comprising a bi-modal stabilized zirconia ceramic component to a temperature of at least 1500° C. to create a heated reactive region, wherein after exposing the component to a temperature of at least 1500° C. for two hours the component has a bulk porosity measured at ambient temperature in the range of from 5 to 45 vol. %, based on the bulk volume of the component; (b) feeding a hydrocarbon feed to the heated pyrolysis reactor to pyrolyze the hydrocarbon feed and create a pyrolyzed hydrocarbon feed; and (c) quenching the pyrolyzed hydrocarbon feed to produce the hydrocarbon pyrolysis product.

Owner:EXXONMOBIL CHEM PAT INC

Method and system for reconstruction and analysis of earth-rock aggregate three-dimensional microstructure

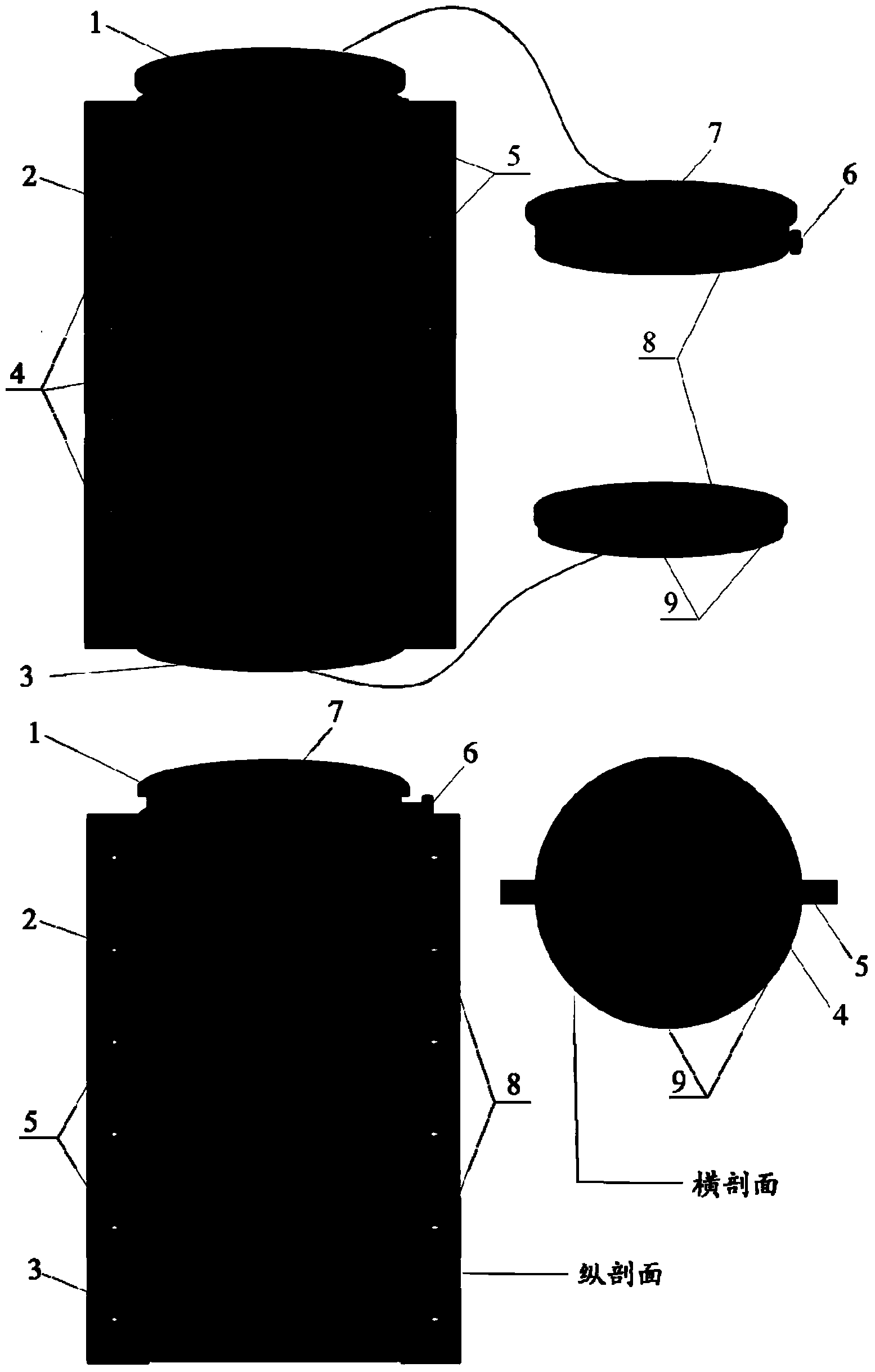

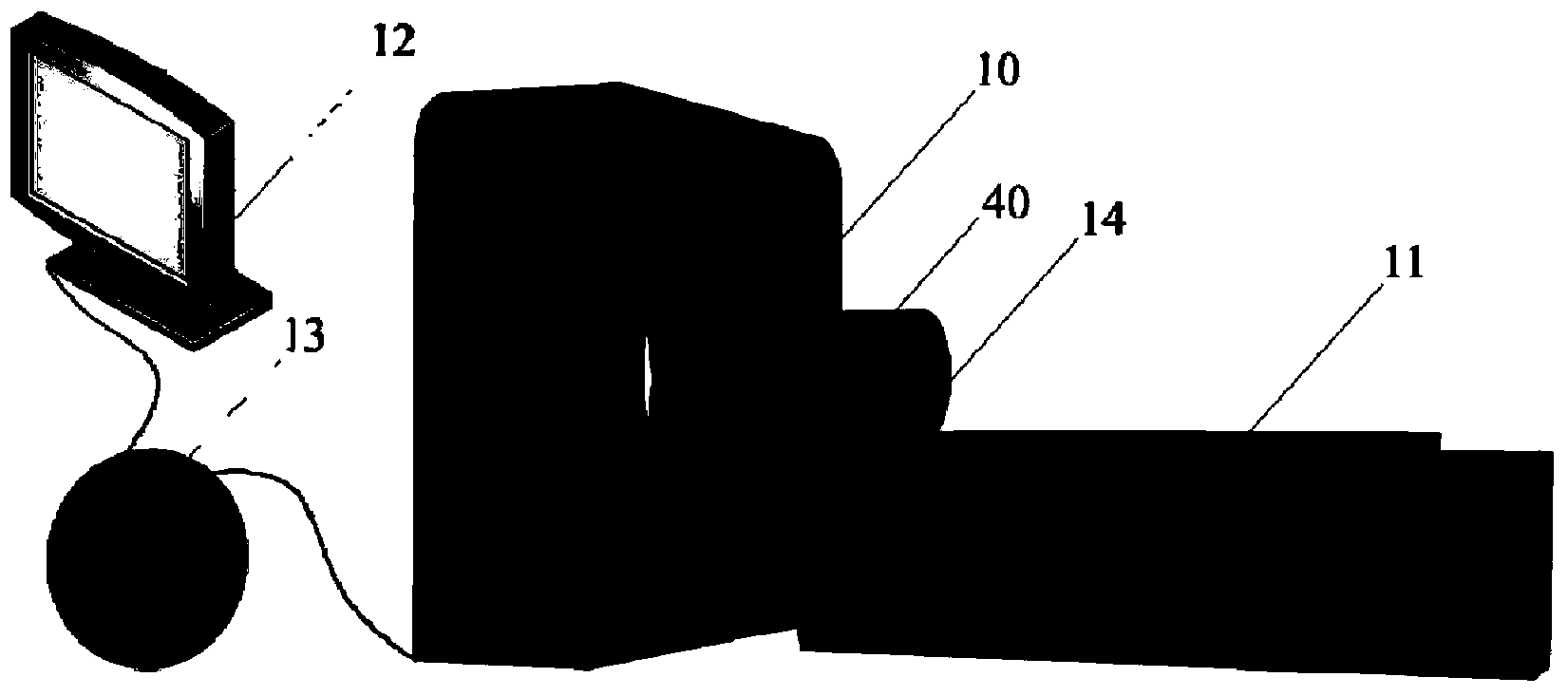

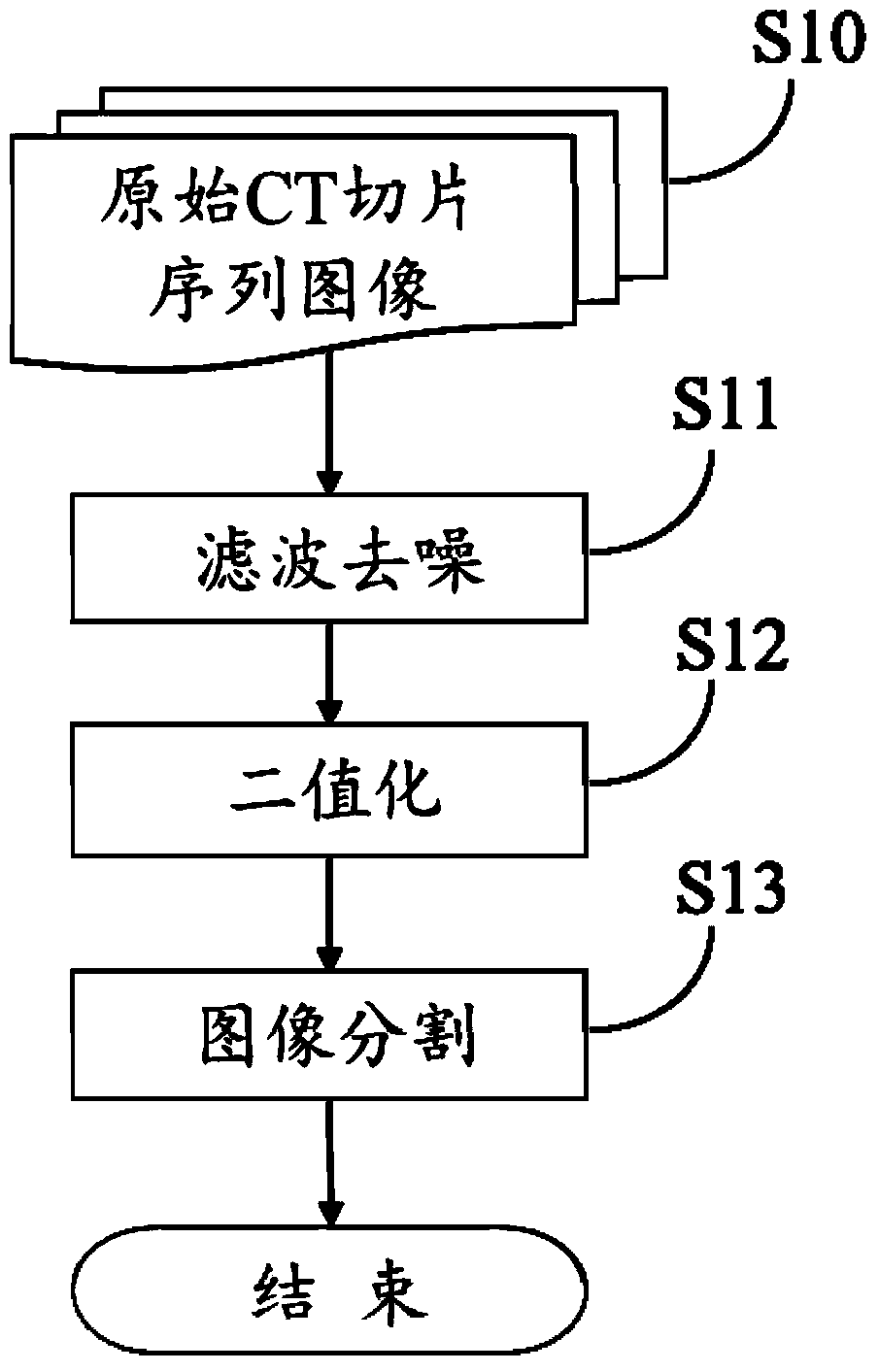

InactiveCN104036538AEasy to set upRealize 3D visualization displayImage analysis3D-image renderingThree dimensional microstructureComputing tomography

The invention provides a method and a system for reconstruction and analysis of an earth-rock aggregate three-dimensional microstructure. The method includes preparing an earth-rock aggregate sample, subjecting the earth-rock aggregate sample to computed tomography (CT) scanning to acquire a CT cross-section image sequence of the earth-rock aggregate sample, acquiring rubble cross-section area of each CT cross-section image of the CT cross-sectional image sequence and dividing the rubble cross-section area into multiple independent rubble cross sections, registering the independent rubble cross sections in each CT cross-section image to generate a three-dimensional microstructure model of rubbles according to a registration result, analyzing the three-dimensional microstructure model to determine rock percentage, grain distribution, rubble spatial distribution, rubble geometrical features and rubble morphological characteristics of the earth-rock aggregate sample. The three-dimensional microstructure model is easy to generate by the method and the system. The method and the system have the advantage of accurate and reliable analysis result of the earth-rock aggregate and can be applied to numerical calculation and analysis directly.

Owner:TSINGHUA UNIV

Direct synthesis method of nanometer oxide powder

InactiveCN101804968AHigh chemical activityAvoid growing upOxide/hydroxide preparationFerroso-ferric oxidesUltra fineSurface-active agents

The invention relates to a synthesis method of nanometer oxide powder, which belongs to the technical field of ultra fine powder preparation. The method comprises the following steps: respectively adding acid substances and alkaline substances into proper dispersing agents and surface active agents; carrying out mixing reaction again on two mixtures under a certain mixing condition at the proper temperature after being uniformly dispersed under a certain dispersing condition; and thus, directly synthesizing the required oxide nanometer powder. The synthesis method does not need high-temperature calcination, and inhibits the generation of the glomeration and the excessive growth of crystal grains, and the oxide powder with the grain diameter between 5 and 100 nm, uniform grain granular size, narrow grain distribution and uniform and stable ingredient can be directly prepared from the solution. The powder prepared by the synthesis method has high chemical activity and wide application range.

Owner:TSINGHUA UNIV

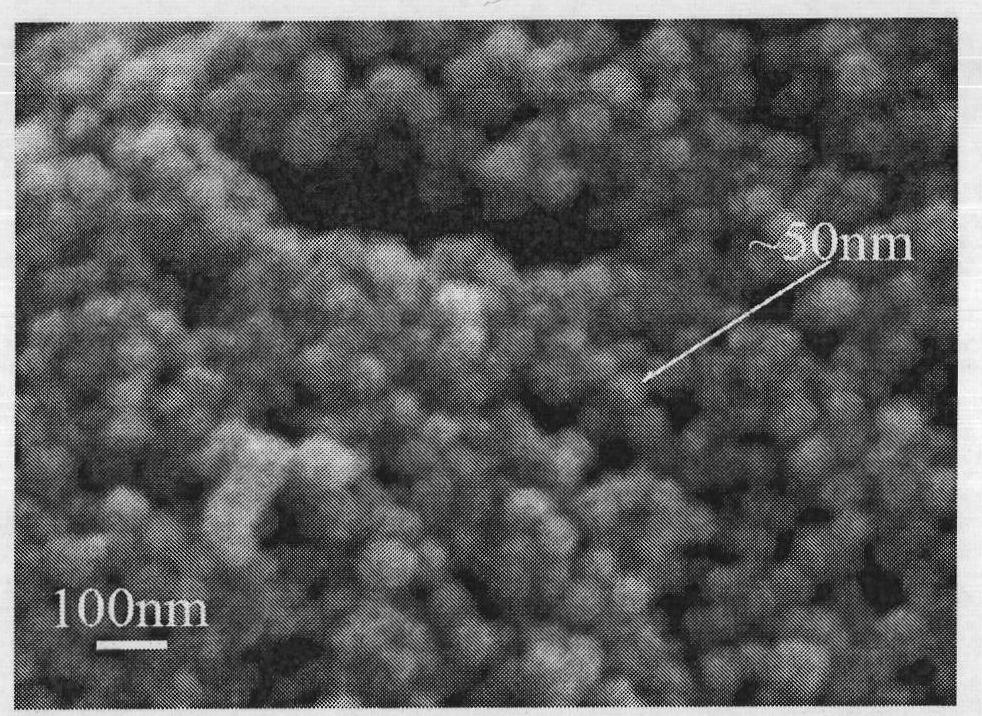

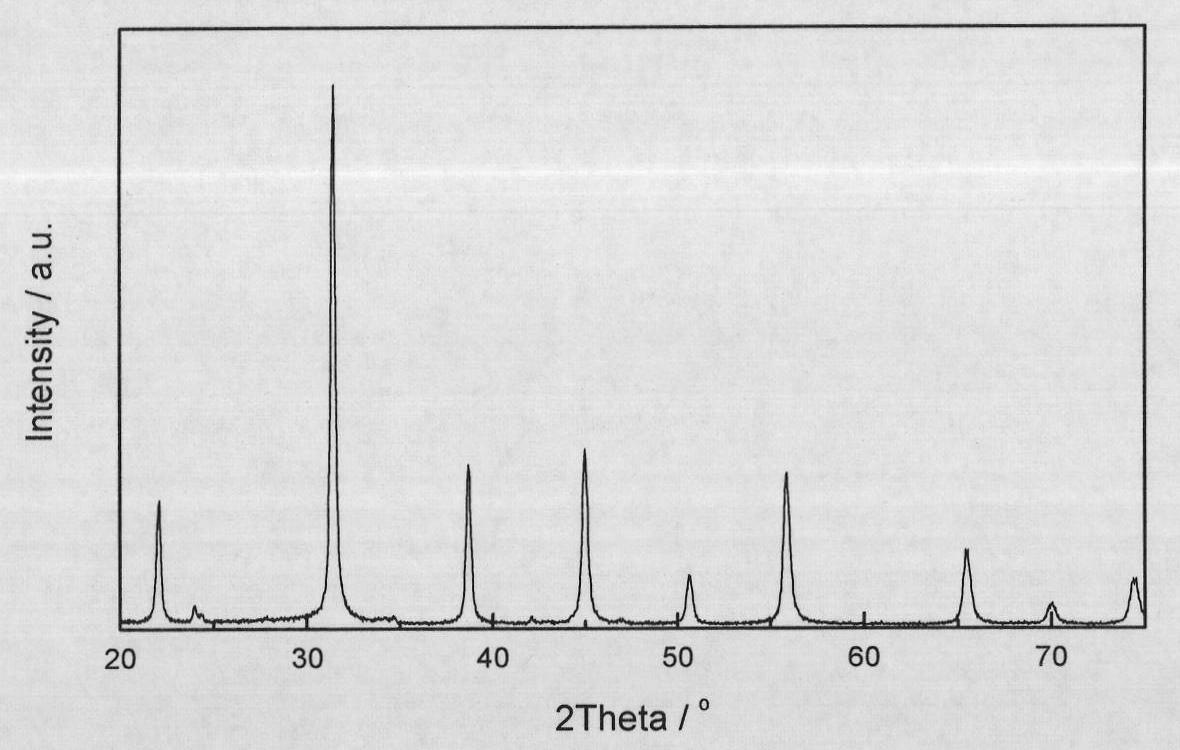

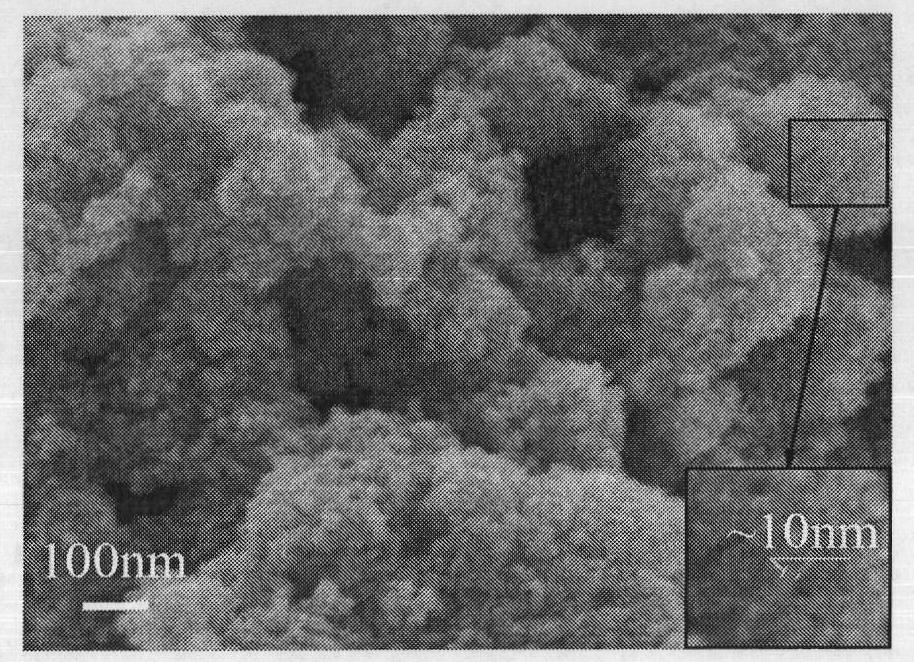

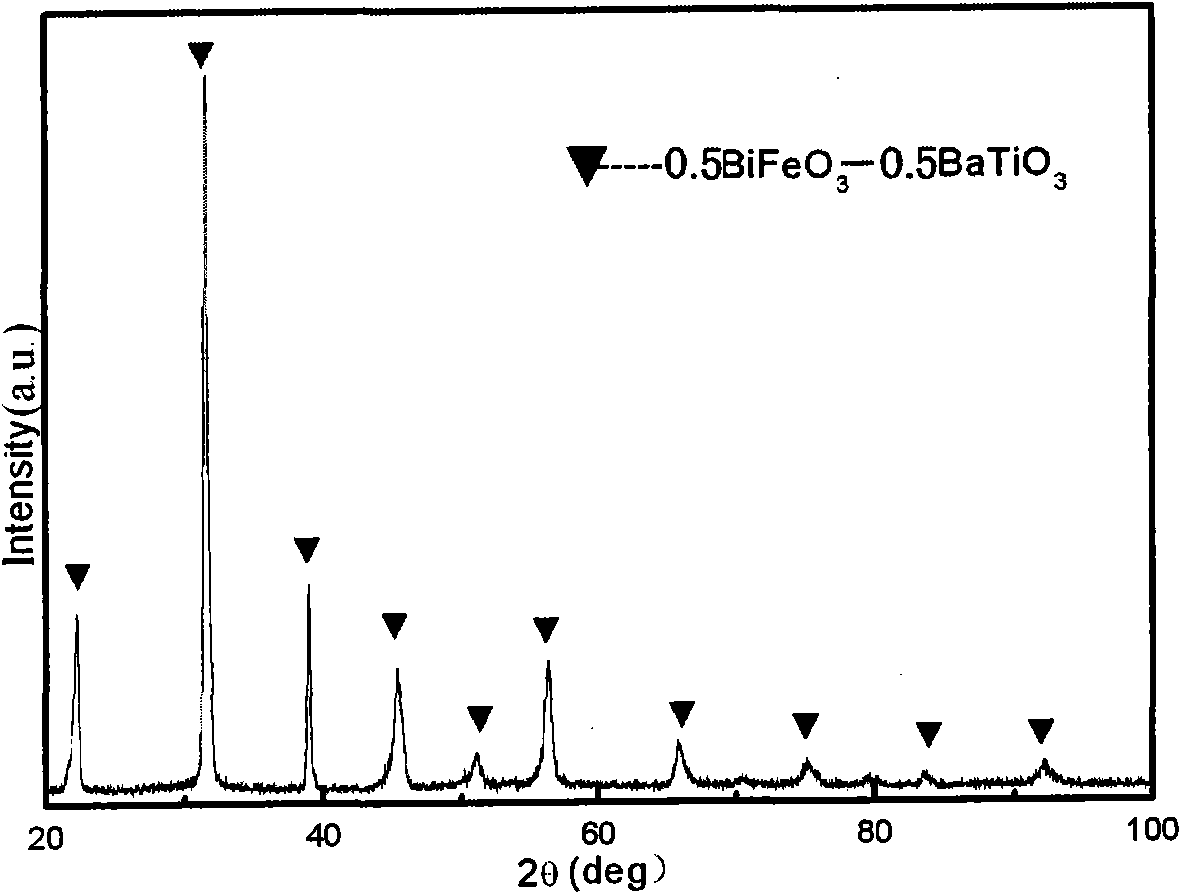

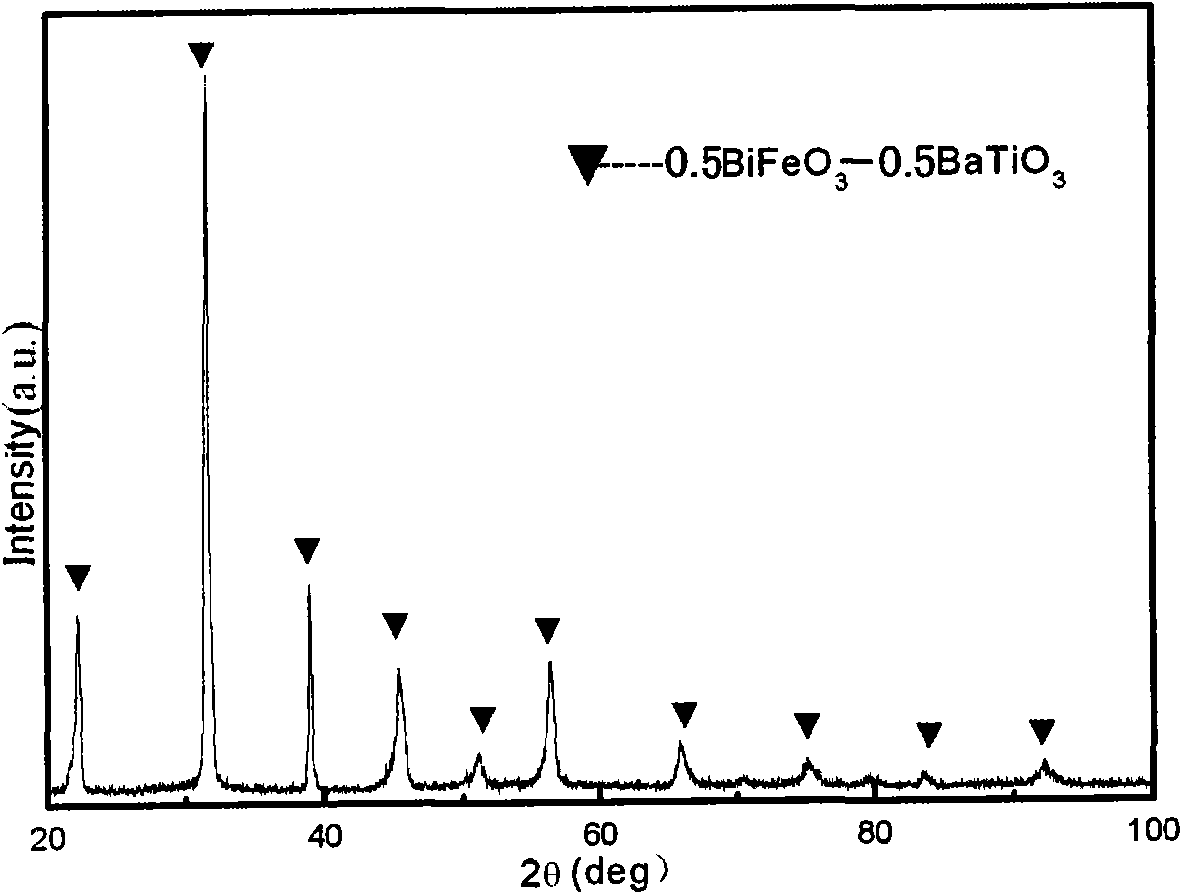

Method for preparing bismuth titanate-barium titanate powder by hydrothermal method

InactiveCN101913853AShort reaction timeReaction is easy to controlBarium titanateParticle-size distribution

The invention provides a method for preparing bismuth titanate-barium titanate powder by hydrothermal method. The method is characterized by belonging to the hydrothermal synthesis technique and the field of functional ceramics. The method comprises the following steps of: preparing KOH and deionized water into mineralizer solution of which the concentration is 4 to 10mol / L; blending Bi(NO3)3.5H2O, Fe(NO3)3.9H2O, BaCl2 and TiCl4, which serve as raw materials, according to the following chemical formula: xBiFeO3-(1-x)BaTiO3 (x is more than or equal to 0.1 and less than or equal to 0.9), addinghydrochloric acid and the deionized water dropwise into the raw materials, and uniformly stirring to completely dissolve the raw materials; slowly adding the mixture into the KOH mineralizer solutiondropwise, and uniformly stirring to obtain fulvous precursor solution; and adding the precursor solution into a reactor, putting the reactor in a 200 DEG C oven for keeping the temperature for 6 to 36 hours, and naturally cooling and filtering to the reactor to obtain the reaction product, namely the bismuth titanate-barium titanate powder. The bismuth titanate-barium titanate powder solid solution powder prepared by the invention has the advantages of good crystallization, uniform grain distribution, simple process flow, short reaction time and energy conservation.

Owner:UNIV OF SCI & TECH BEIJING

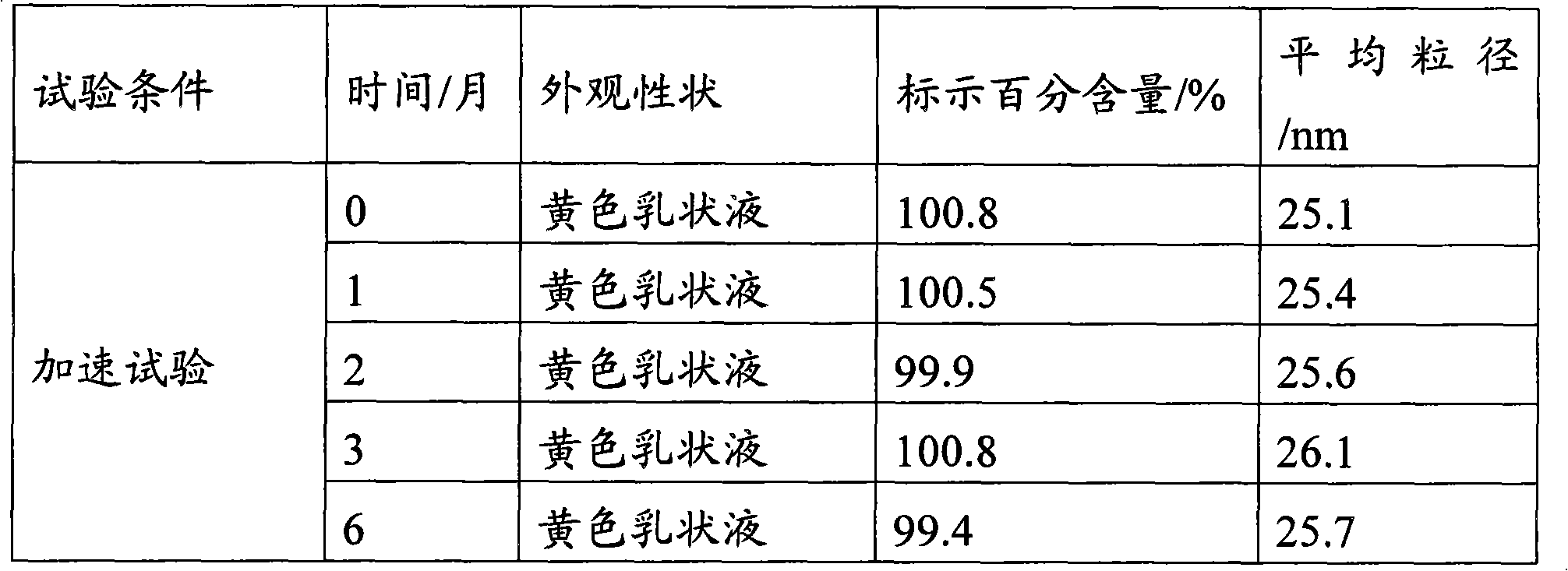

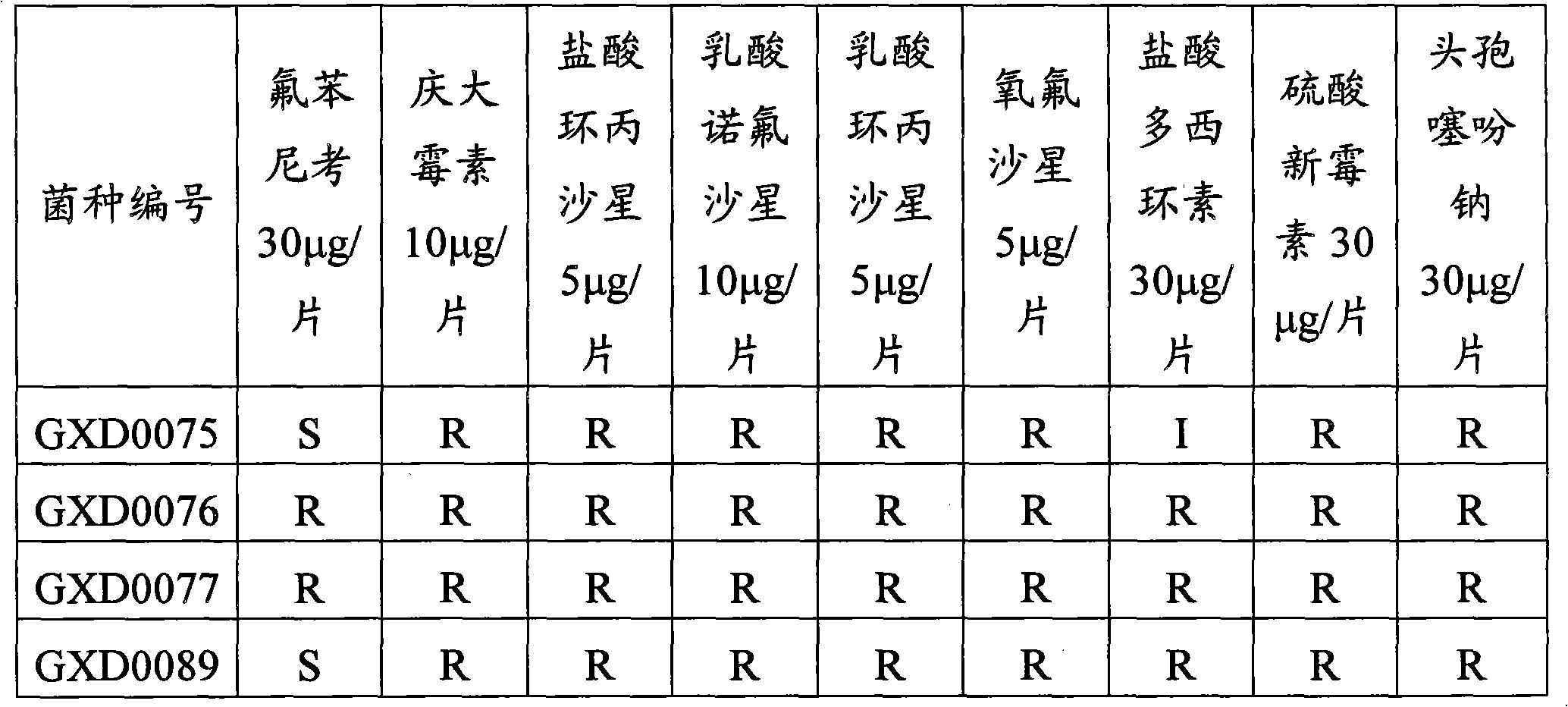

Microemulsion for animals and preparation method thereof

InactiveCN101947202AAids in absorbencyHelp to take advantage ofAntibacterial agentsOrganic active ingredientsWater basedCurative effect

The invention discloses microemulsion for animals and a preparation method thereof. The microemulsion for animals comprises effective components and auxiliary solvents, which are 1 to 30 percent of effective components, 10 to 20 percent of surfactant, 5 to 10 percent of cosurfactant, 10 to 25 percent of oil phase, and the balance of water based on the total amount of 100 percent. The microemulsion prepared by the method has the advantages of small grain sizes, narrow distribution range, uniform grain distribution and good stability, has better curative effect compared with conventional preparation, and can be used for preparing medicament which is widely used in clinical veterinarian.

Owner:LUOYANG HUIZHONG ANIMAL MEDICINE

High-toughness and high-thermal-stability hot work die steel and preparation method thereof

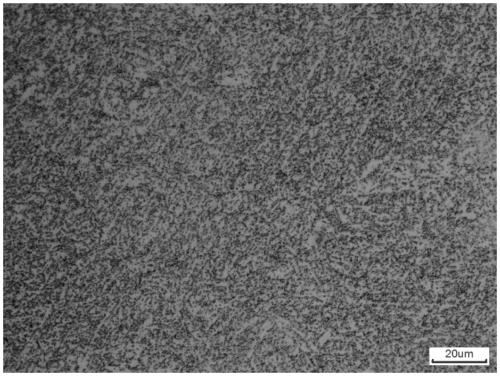

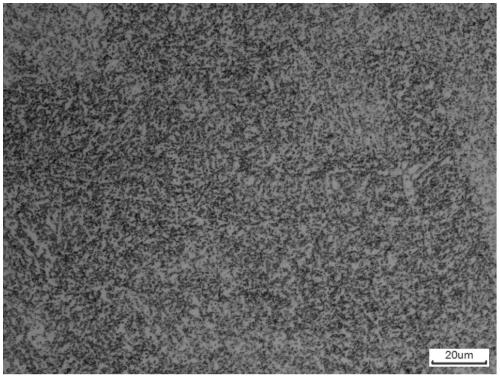

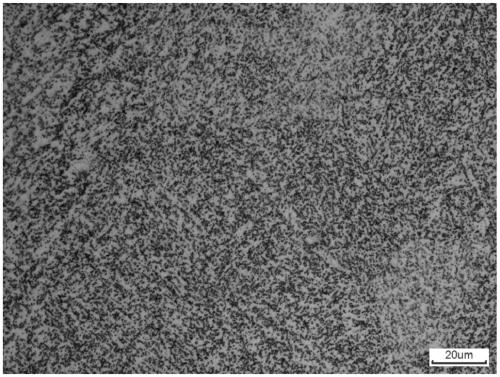

ActiveCN111593257AImprove toughnessImprove thermal stabilityProcess efficiency improvementMaterials scienceMicrostructure

The invention relates to a preparation method of high-toughness and high-thermal-stability hot work die steel. The preparation method comprises the following steps of optimizing alloy components, andstrictly controlling the production process; and the specific process route is as follows, electric furnace smelting, ladle refining furnace refining, vacuum refining furnace refining, electrode blankcasting, protective atmosphere electroslag furnace remelting, forging, ultrafine treatment and spheroidizing annealing production processes are adopted at the same time. The invention further relatesto the high-toughness and high-thermal-stability hot work die steel prepared through the preparation method. The product has the advantages of uniform annealed microstructure, favorable spheroidizedstructure, fine and uniform grain distribution and uniform quenched and tempered structure, and the fine precipitated phases of the Mo and Cr carbides have the dispersion strengthening action in the use process, thereby enhancing the properties of the material and endowing the material with high toughness and high isotropy. The product can be widely used for manufacturing hot extrusion dies, mandrels, hammer dies of die forging hammers, dies of forging presses and dies for precision forging machines, and particularly can be used as a high-end die-casting die made of aluminum, copper and alloysthereof.

Owner:江苏宏晟模具钢材料科技有限公司

Granularity-controllable boehmite preparation method

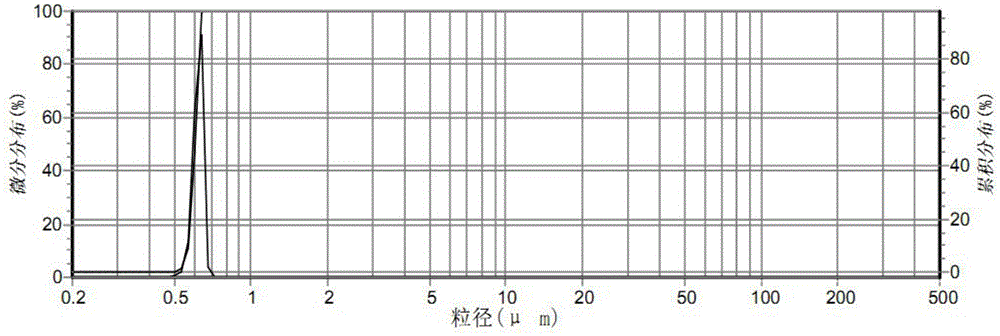

InactiveCN104944454AGranularity controllableNarrow particle size distributionMaterial nanotechnologyAluminium oxides/hydroxidesDispersityMicrometer

The invention provides a granularity-controllable boehmite preparation method and relates to the field of new materials. The granularity-controllable boehmite preparation method comprises the following steps: mixing Al(OH)3 and water to form a suspension with the concentration of 20-60% (by weight percent); adjusting the pH of the suspension to be 2-9; treating the suspension for 24-40 h at the temperature of 170-240 DEG C and the pressure of 1.0-1.7 MPa; filtering, drying and dispersing the treated suspension to obtain monodispersed boehmite with the granularity of 0.1-10 micrometers. The granularity-controllable boehmite preparation method is a wet preparation method of boehmite, and the prepared high-purity boehmite is narrow in grain distribution, uniform in appearance, controllable in granularity and favorable in dispersity. The granularity of boehmite can be adjusted through adjusting the pH value and the time of reaction and the granularities of the raw materials.

Owner:ANHUI ESTONE MATERIAL TECH CO LTD

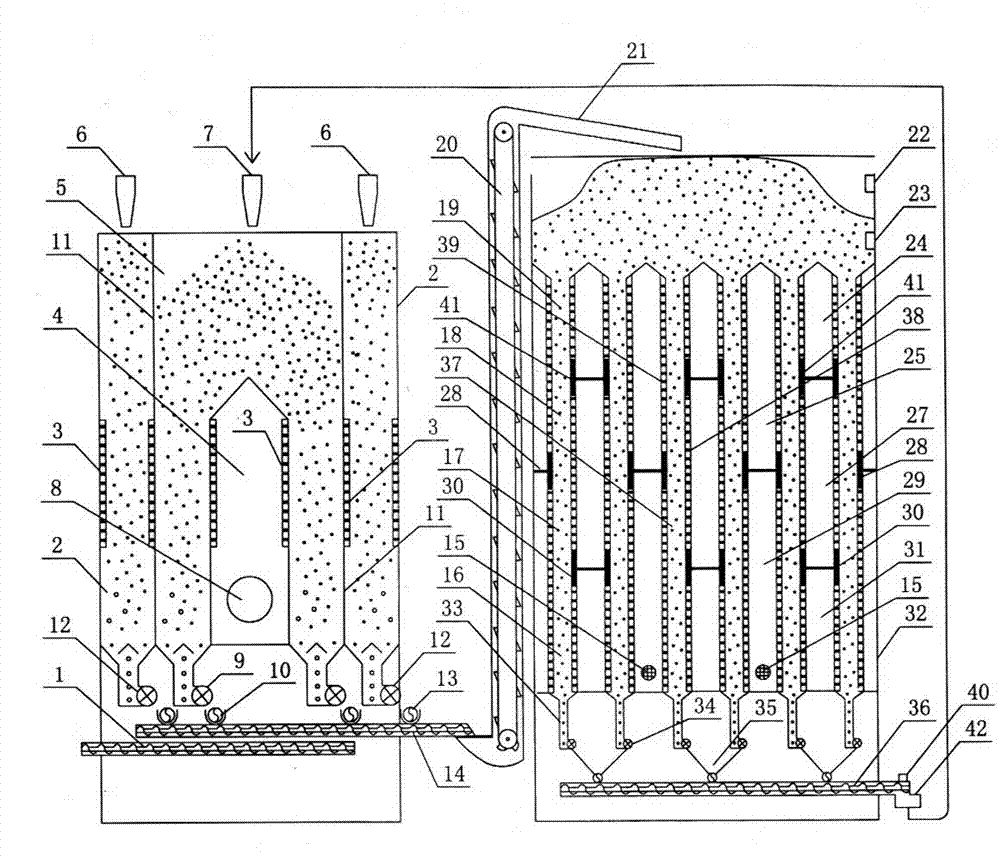

Quality-guaranteeing and energy-saving drying machine for grains

The invention discloses a quality-guaranteeing and energy-saving drying machine for grains. The drying machine comprises two wet grain preheating bins, a hot grain cooling bin and a drying bin, wherein the two wet grain preheating bins are arranged on the left side and the right side of the hot grain cooling bin respectively and are spaced from the hot grain cooling bin through baffles; a ventilating net plate is arranged between the baffles; a cold air chamber is formed in the middle of the hot grain cooling bin; a cold air inlet is formed in the bottom end of the cold air chamber; wet grain outlets are formed in the bottom sides of the wet grain preheating bins; a dry grain outlet is formed in the bottom side of the hot grain cooling bin; a hot grain shifting wheel is arranged on the right side of the dry grain outlet; a dry grain helical collector is arranged on the bottom side of the dry grain shifting wheel; a dry grain helical conveyer is arranged on the bottom side of the dry grain helical collector; the drying bin is arranged on the right sides of the wet grain preheating bins; 2-30 groups of grain distribution channels are formed in the middle of the drying bin; ventilating net plates are arranged on the left and right sides of each grain distribution channel; a hopper type lifting machine is arranged on the left side of the drying bin. The drying machine is reasonable in structure, unique in design and good in using effect.

Owner:HUNAN NONGYOU SHENGTAI AGRI TECH

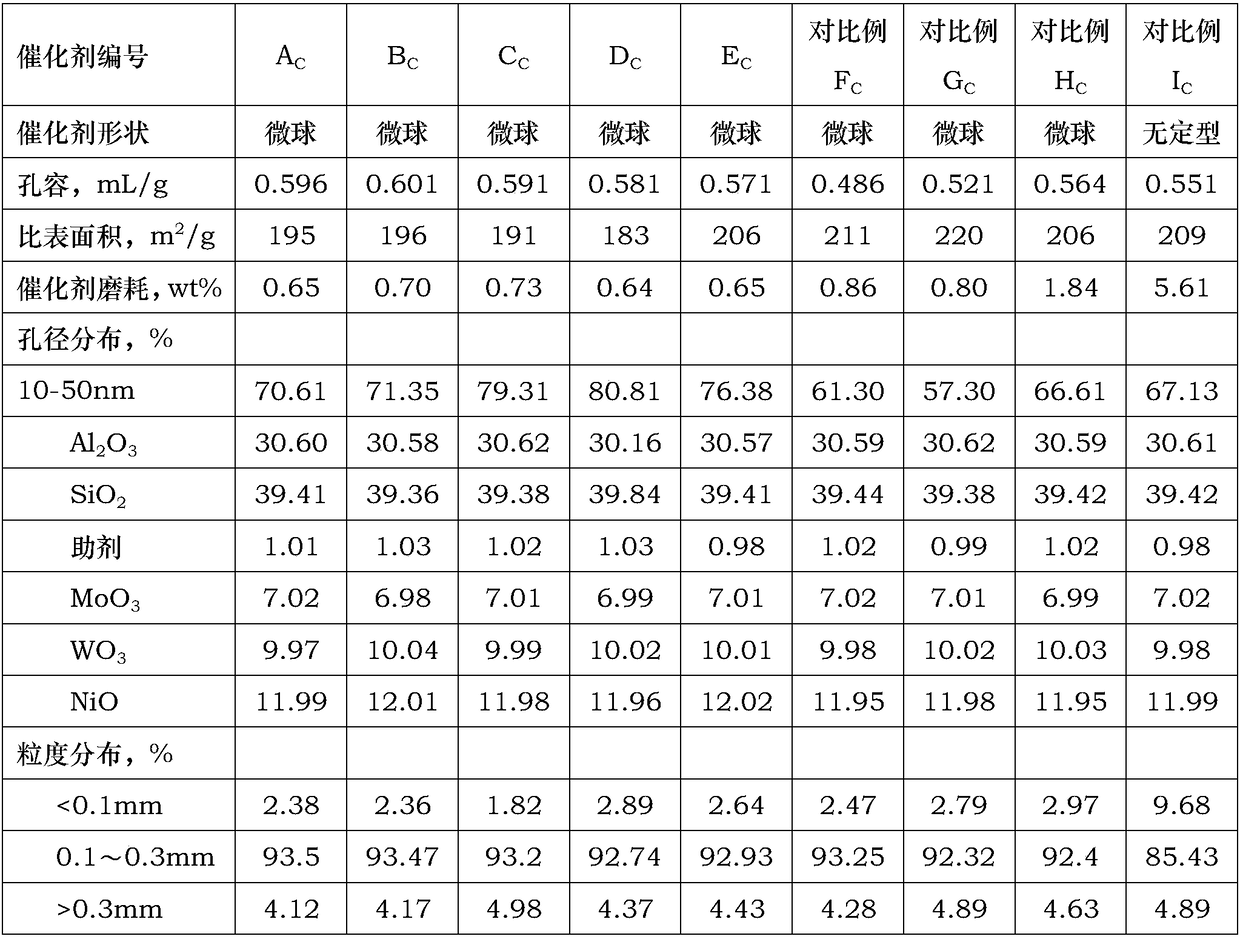

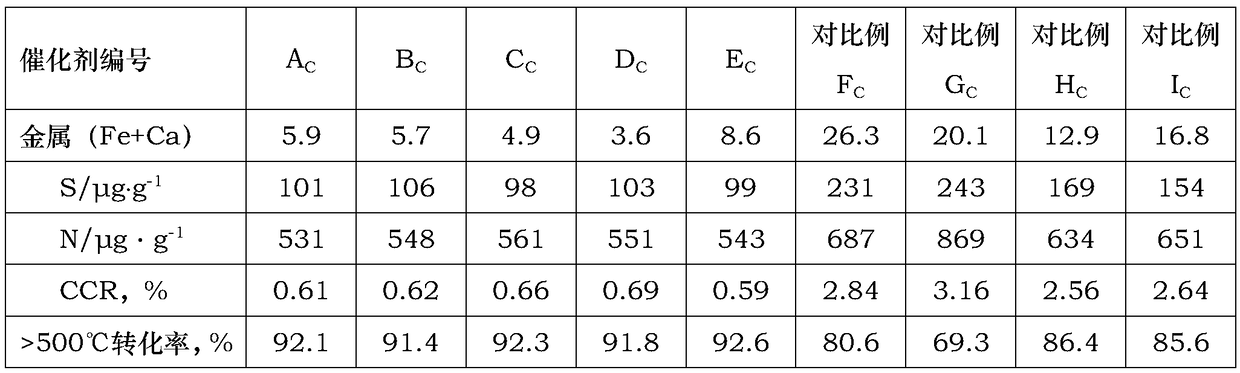

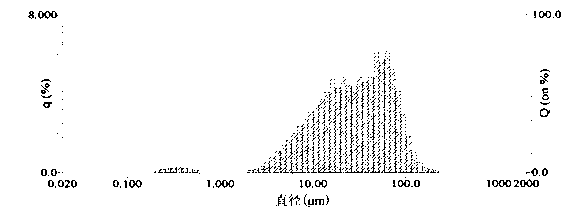

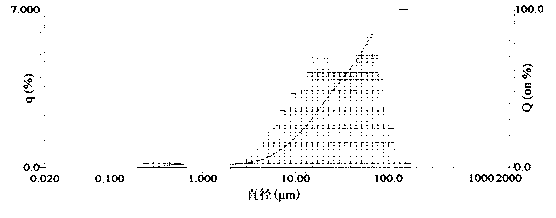

Boiling bed coal tar hydrotreating-hydrocracking composite catalyst and preparation method thereof

ActiveCN108686702ALarge hole volumeLarger than surfaceMolecular sieve catalystsHeterogenous catalyst chemical elementsMicrosphereSilicon oxide

The invention relates to a boiling bed coal tar hydrotreating-hydrocracking composite catalyst and a preparation method thereof. The boiling bed coal tar hydrotreating-hydrocracking composite catalystis prepared from the following components in percentage by mass: MoO3, WO3, NiO, aluminum oxide, silicon oxide molecular sieve and assistant. An acidized silicon-containing raw material and alkali gas react with each other, and the reaction product is cured to generate microsphere gel which has higher scale-accommodating capability and proper cracking performance. Active metal nickel, the assistant and a carrier raw material are prepared into slurry, the NiO is highly dispersed on the catalyst carrier, and nickel aluminum spinel is formed by a small amount of nickel and aluminum, so that thewater resistance and friction resistance of the catalyst are enhanced. Spray drying is performed, so that the grain distribution is concentrated, and high mechanical strength and abrasion resistance are achieved. A curing agent is added into the slurry, and the channel of the catalyst is enlarged in the escaping process of ammonia gas released in a drying process, so that the channel distributionis concentrated, and larger pore volume, larger specific surface area and higher abrasion resistance are achieved. The boiling bed coal tar hydrotreating-hydrocracking composite catalyst has higher hydrogenation activity, proper cracking activity and higher stability. The preparation method is simple and is low in cost.

Owner:一重集团大连工程建设有限公司

Preparation method of precision casting fused quartz powder and quartz powder produced by same

ActiveCN103130405AHigh purityWide particle size distributionSilicaGlass shaping apparatusZirconImpurity

The invention relates to a preparation method of precision casting fused quartz powder and quartz powder produced by the method. The preparation method comprises the following steps of: smashing, sieving, purifying, fusing by an electric furnace, smashing, dry type ball-milling and sieve for a quartz raw material to obtain a product. An ultrasonic field is introduced in the scouring purifying and washing process of quartz, so that the content of impurities in powder is effectively reduced, and the step time is greatly shortened and the production efficiency is improved. Full grain fused quartz powder required is directly obtained by optimizing ball-milling process parameters and adopting a unique feeding mode, so that the grain composition step in conventional method is reduced. The method is simple in technical process, short in period, low in energy consumption and low in cost, and is beneficial for large-scale batch production. The fused quartz powder produced is high in purity, wide in grain distribution, free from graduation, mellow and full on surface of grains and good in rheological property of paint, and can be better applied to the field of investment casting and can partially or completely replace expensive shell material zircon power, so that the production cost of precision casting is effectively reduced.

Owner:LIANYUNGANG RISTAR ELECTRONICS MATERIALS

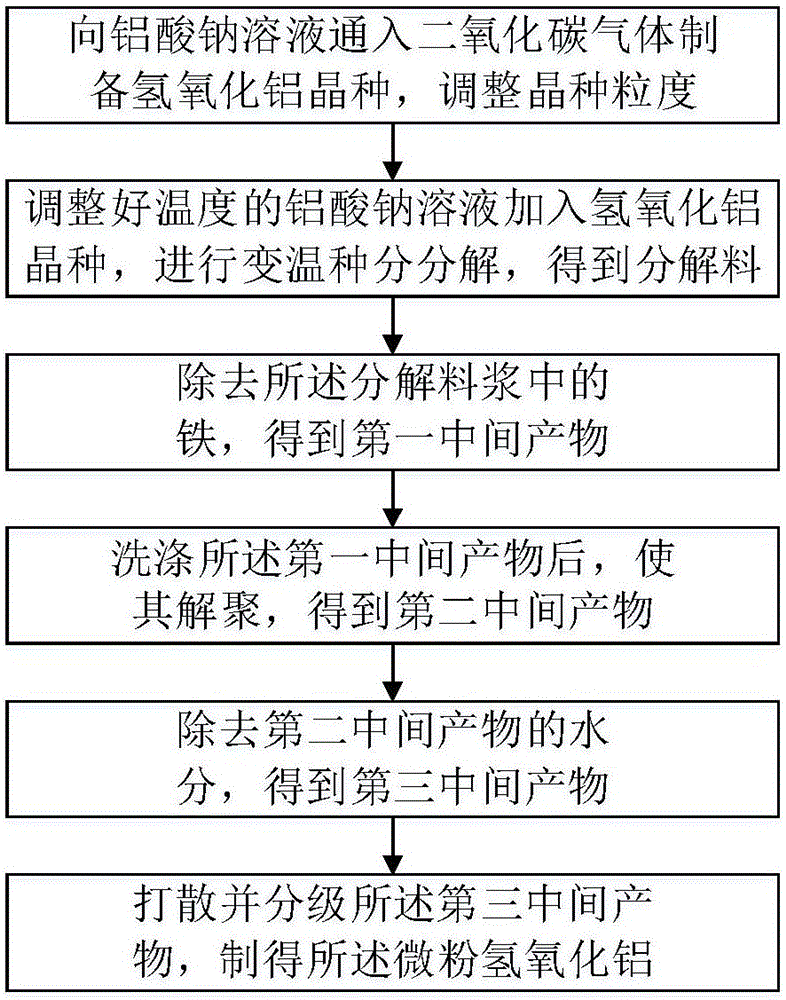

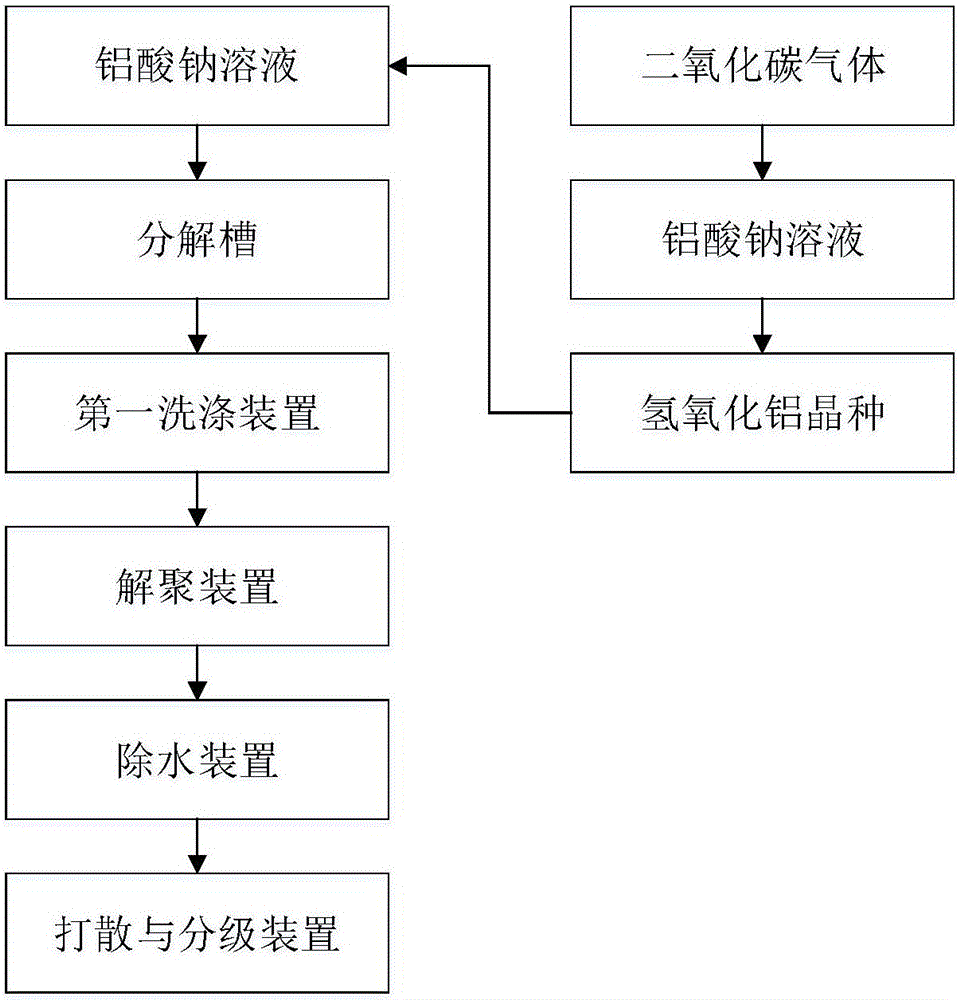

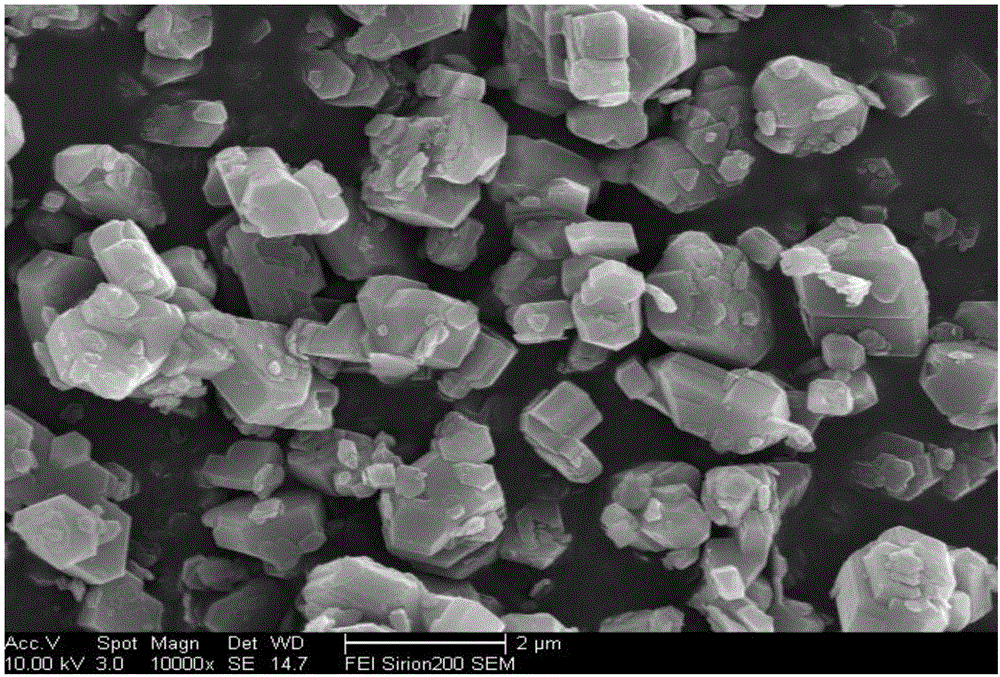

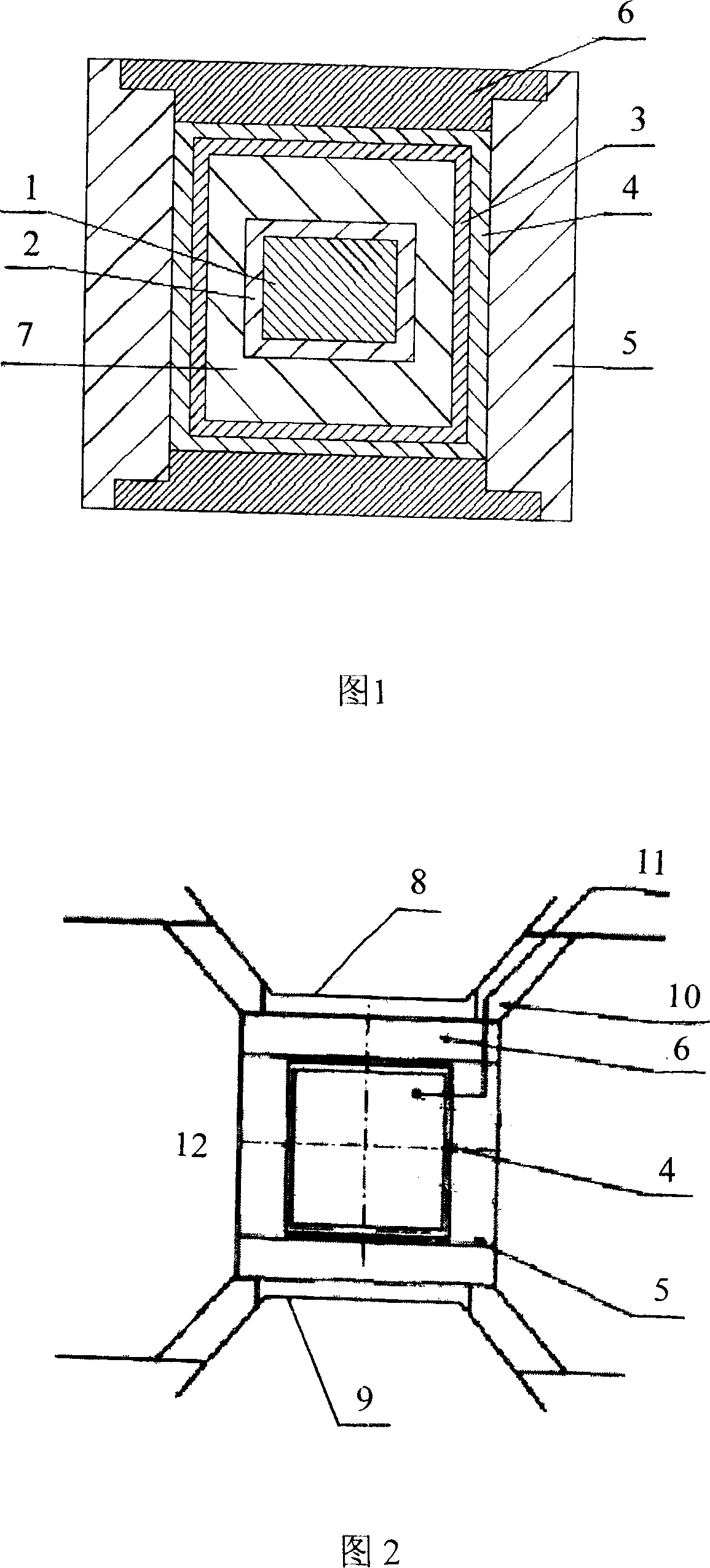

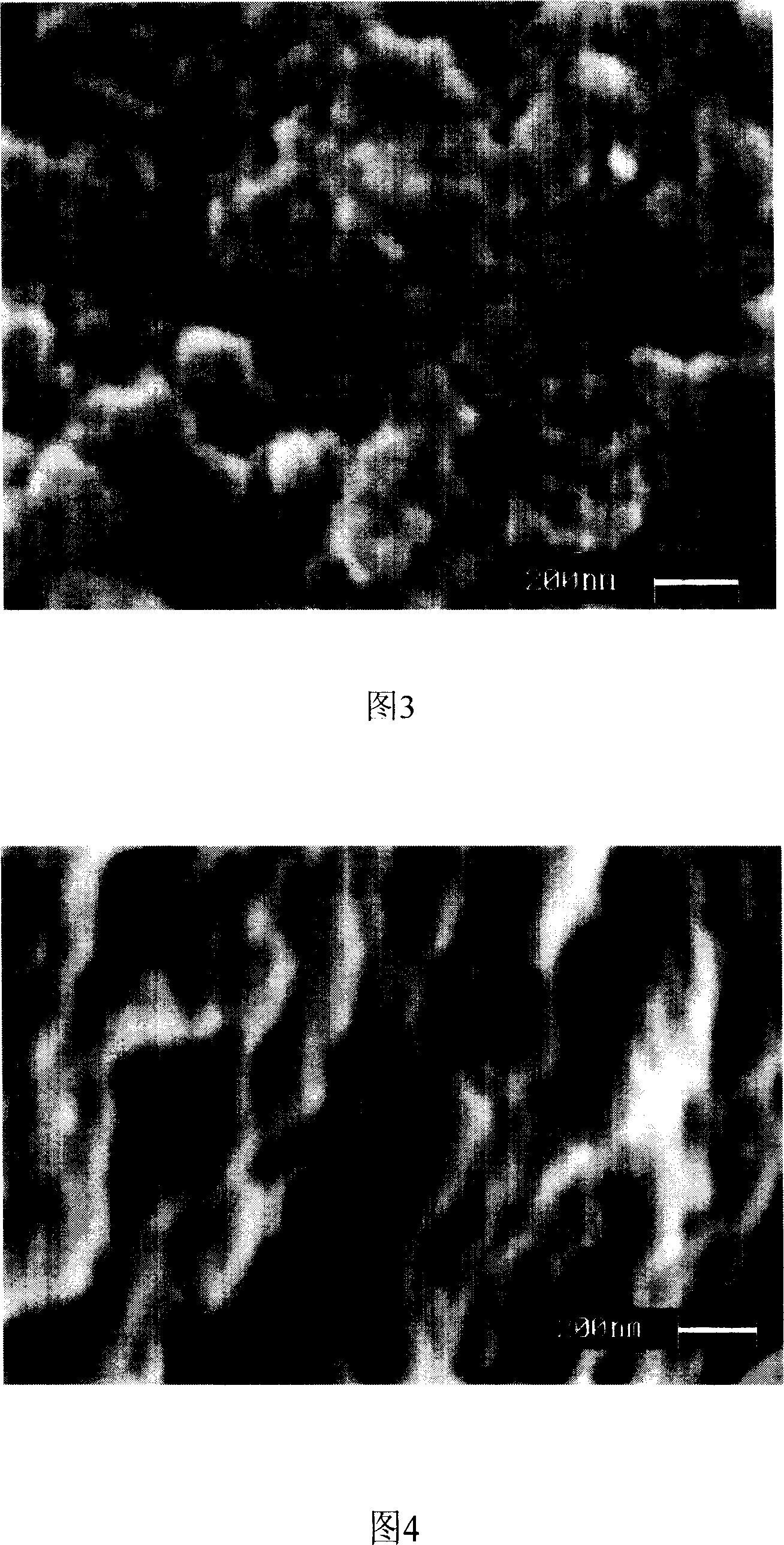

Micro-powder aluminum hydroxide preparation method and device and micro-powder aluminum hydroxide

ActiveCN105776269AAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationDepolymerizationDecomposition

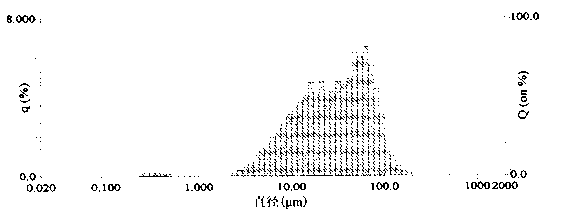

The invention discloses a micro-powder aluminum hydroxide preparation method and device and micro-powder aluminum hydroxide. The preparation method comprises the steps of adding aluminum hydroxide seed crystals obtained through carbonation decomposition of a sodium aluminate solution into the sodium aluminate solution to perform variable-temperature seed decomposition to obtain decomposition slurry; removing iron in the decomposition slurry to obtain a first intermediate product; washing the first intermediate product to depolymerize the first intermediate product to obtain a second intermediate product; removing water in the second intermediate product to obtain a third intermediate product; scattering and grading the third intermediate product to obtain micro-powder aluminum hydroxide. The preparation device comprises a decomposition tank, an iron removing device, a first washing device, a depolymerization device, a water removing device, and a scattering and grading device. The micro-powder aluminum hydroxide is prepared by using the preparation device according to the preparation method, such that the grain distribution of the micro-powder aluminum hydroxide product with a median particle diameter of 1mu m is even, the oil absorption is reduced to 30mL / 100g to 35mL / 100g, the impurity content of the obtained product is low, the whiteness is high and the product quality is stable.

Owner:中铝山东新材料有限公司

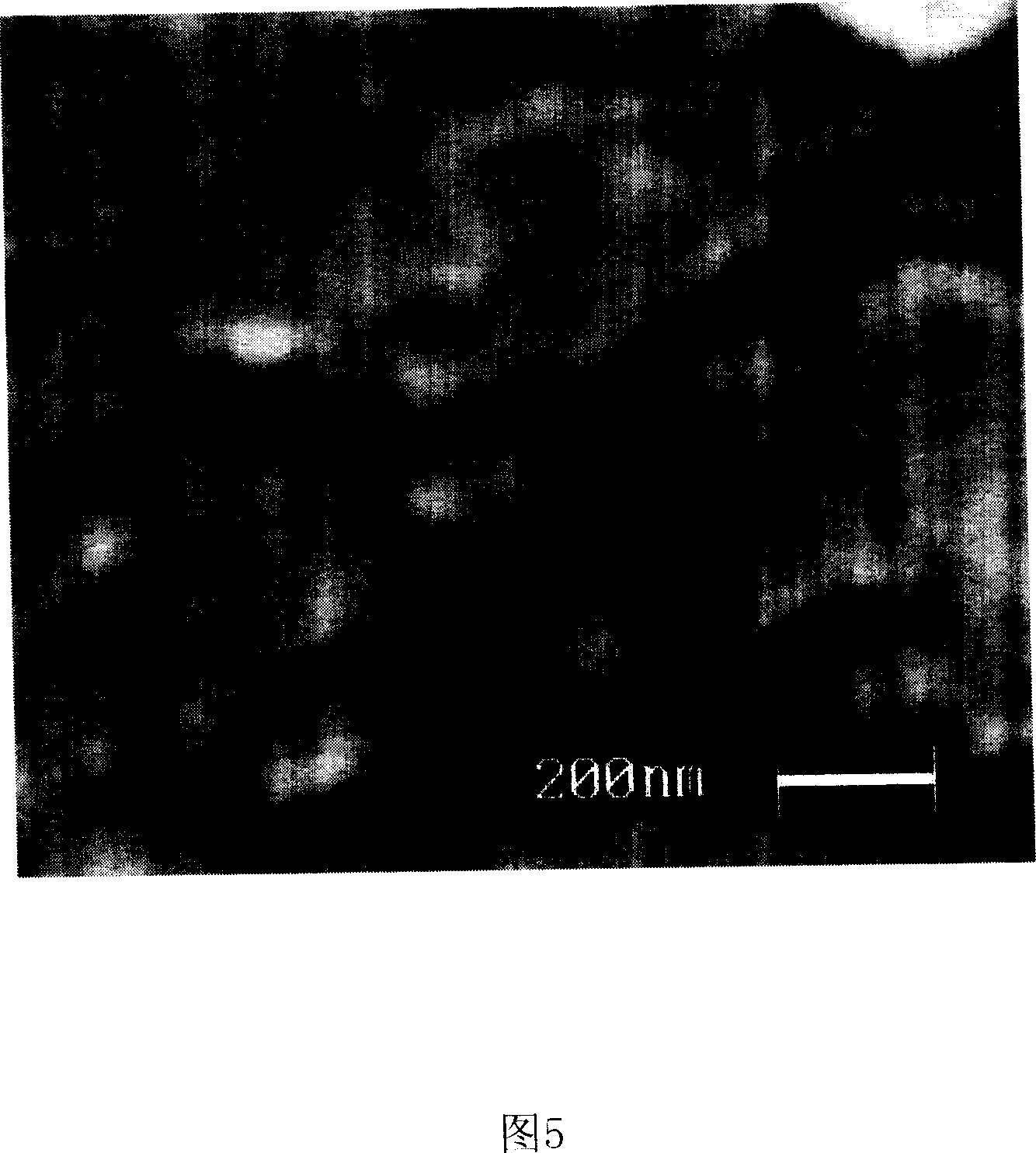

Nano-nano type Al2O3-base heterogeneous ceramic and its preparing method

The nanometer-nanometer type Al2O3-base heterogeneous ceramic consists of nanometer Al2O3 50-95 vol%, and nanometer SiC, TiC, Si3N4, AlN, BN, TiN or ZrB2 5-50 vol%. Its preparation process includes steps of preparing material, ball milling, forming, heat treatment of biscuit, assembling biscuit, high pressure sintering, etc. The present invention adopts high pressure and low temperature fast sintering without need of atmosphere control, and the produced nanometer-nanometer type Al2O3-base heterogeneous ceramic has homogeneously nanometer level crystal grain distribution, high density and excellent performance, and may be used in crucial conditions, such as being used as ceramic cutter, antiwear and anticorrosive device, high temperature utensil, etc.

Owner:SOUTHWEAT UNIV OF SCI & TECH

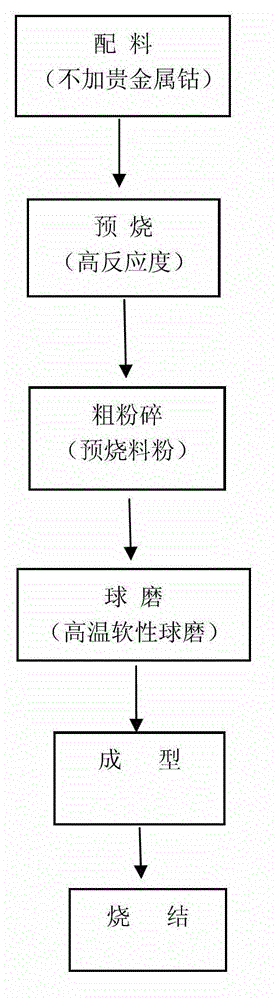

Preparation method of high-performance sintering permanent magnetic ferrite magnet

ActiveCN102942357ASolve the costSolve efficiency problemsInductances/transformers/magnets manufactureGrain distributionCobalt

The invention discloses a preparation method of high-performance sintering permanent magnetic ferrite magnet. The magnet is prepared by the method that pre-sintered powder with main phase of Ca(x1)Sr(x2)Ba(x3)La(x)O nFe2O3 is added with second additive to obtain high-performance magnet with Br higher than 4200Gs, Hcj higher than 4500Oe and rectangularity Hk / Hcj higher than 0.94 through high-temperature soft ball milling process, wherein x1 is 0.05-0.40, x2 is 0.20-0.60, x3 is 0-0.15, x is 0.1-0.5, and n is 6.0-6.5. The preparation method disclosed by the invention has the advantages that the rare precious metal cobalt is not added into the preliminary pre-sintered powder, thus being favorable for large-scale production; the second additive is reasonable, the adjustability of addition of the rare precious metal cobalt is high, thus being more economical; and the high-temperature soft ball milling process is adopted in the ball milling process, so the ball milling time is short, the grain distribution is narrow, the average grain size is large, no dispersant is added, the dehydration property is good, and the molding efficiency is high.

Owner:ANHUI SINOMAG TECH

Hard alloy raw material and method for preparing hard alloy cutter material through hard alloy raw material

InactiveCN106086570AShorten the production cycleAvoid deposition coating processMethod testTitanium nitride

The invention relates to the field of hard alloy materials, in particular to a hard alloy raw material and a method for preparing a hard alloy cutter material through the hard alloy raw material. The hard alloy raw material comprises, by weight percentage, 80% to 90% of tungsten carbide, 6%-12% of cobalt powder, 0%-5% of titanium carbide, 0%-5% of titanium nitride and 0%-0.5% of microelements. The grain distribution of raw material powder ranges from 0.5 micrometer to 2 micrometers. The method for preparing the hard alloy cutter material through the hard alloy raw material includes the steps of powder mixing, ball milling, drying, sieving, block pressing, presintering, high-temperature vacuum sintering and high-temperature nitrogen sintering. The hard alloy cutter material prepared through the method is low in manufacturing cost, high in hardness, good in wear resistance and high in film-substrate cohesion, and the surface has the gold or reddish brown appearance; and the relative density of the hard alloy cutter material prepared through the method is higher than 99%, the hardness ranges from 20 GPa to 28 GPa, the breakage toughness ranges from 6 MPa.m<1 / 2> to 8 MPa.m<1 / 2>, and the film-substrate cohesion critical load obtained through a scratch method test is larger than 80 N.

Owner:LINGNAN NORMAL UNIV

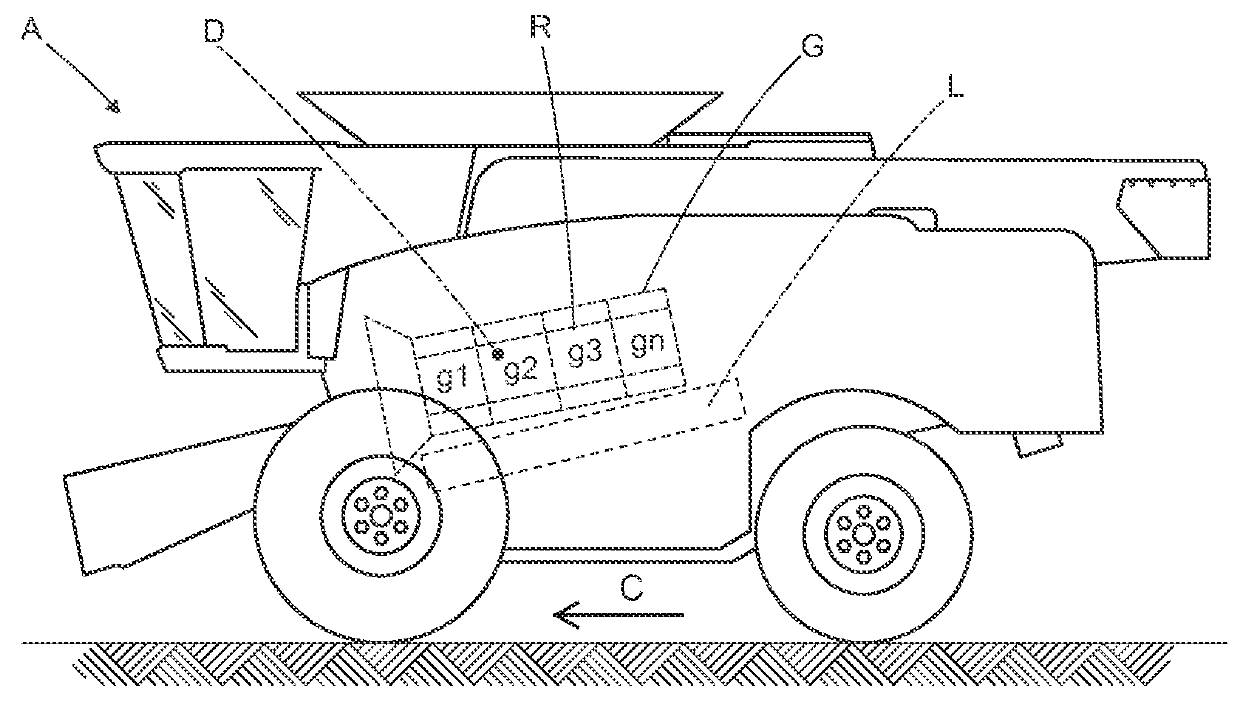

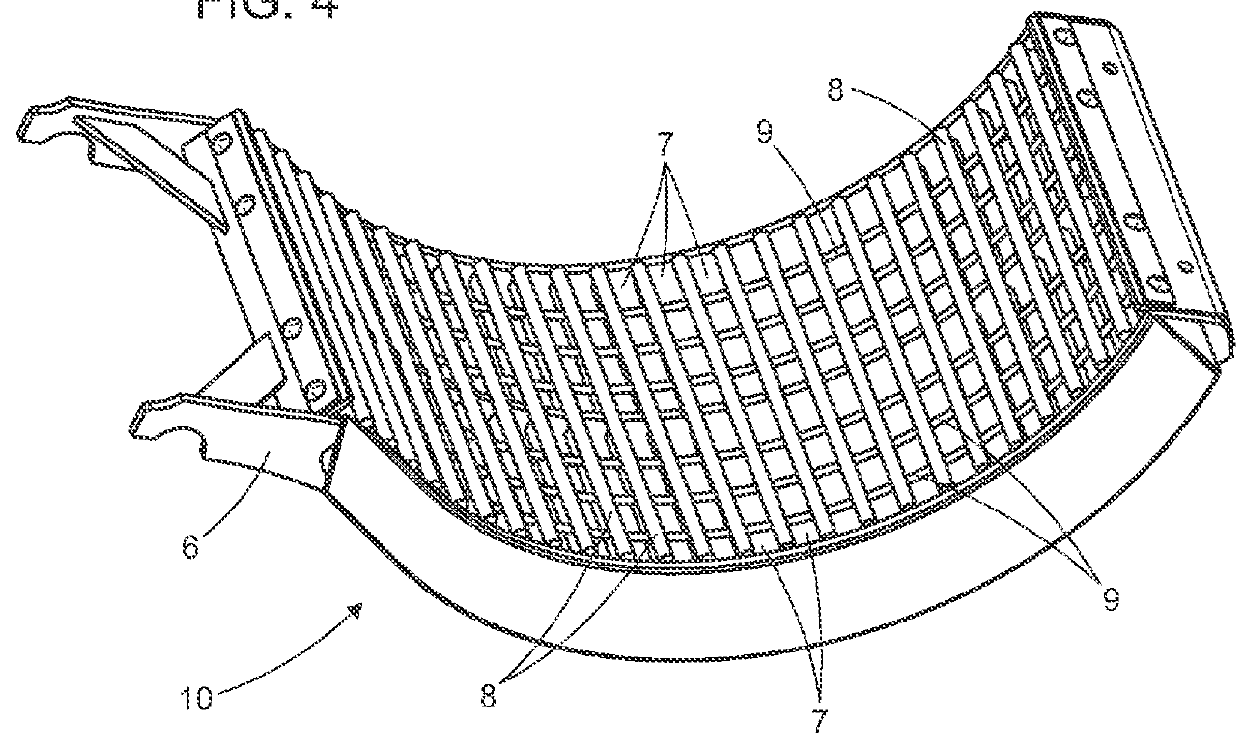

Perforated Covers for Threshing Concaves

A removable cover plate to be used in a threshing module of an agricultural machine, e.g., a grain harvester. The removable cover plate provides a uniform and homogeneous distribution of grains onto a cleaning and harvesting system of the machine. The removable cover plate is designed to be applied to at least one part of a concave of the cleaning and harvesting system of the machine. The cleaning and harvesting system includes at least one rotor and a least one concave mounted around the rotor, to which is attached and installed a removable structure that has a material retention surface, in which there are provided openings to limit grains and / or MOG passage.

Owner:BLUE LEAF I P INC

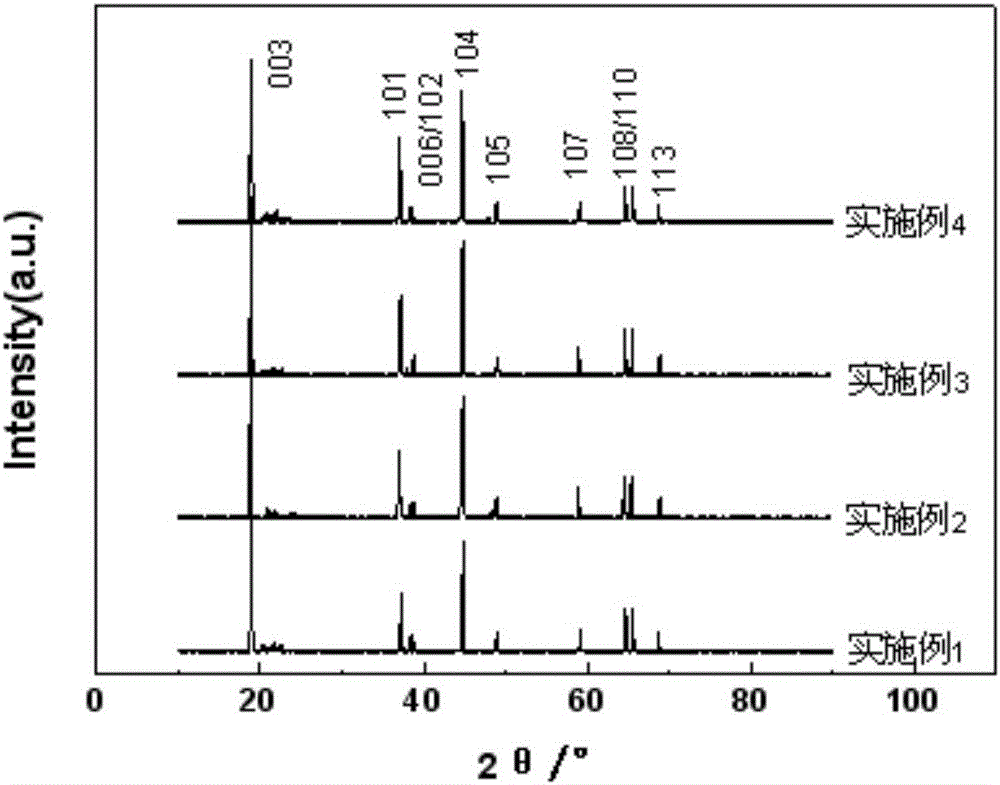

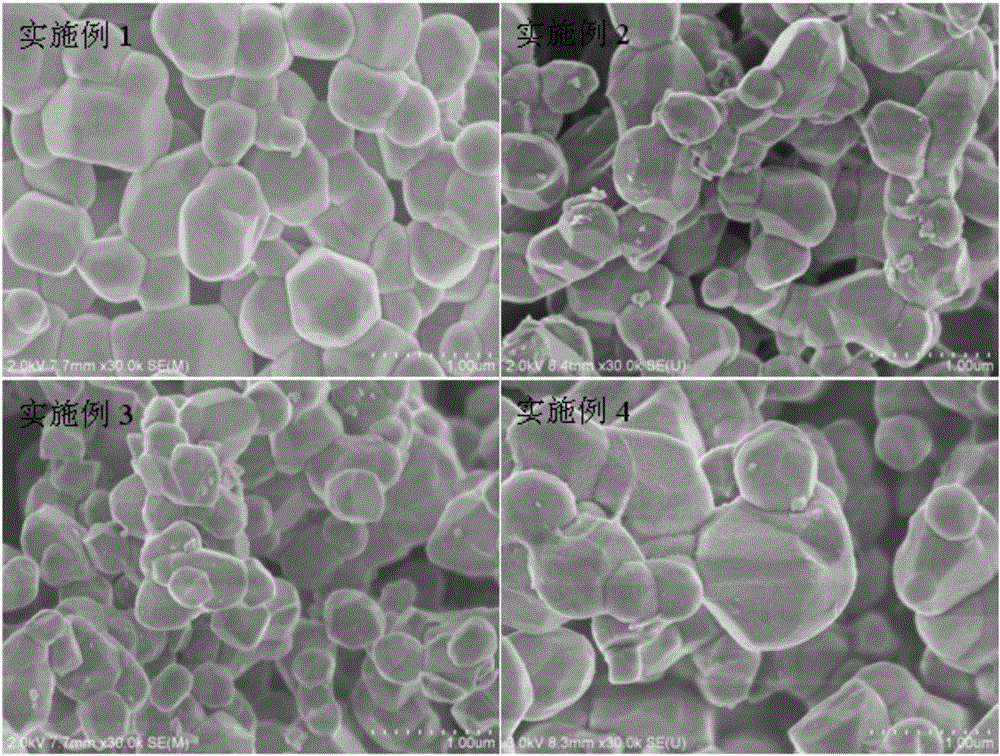

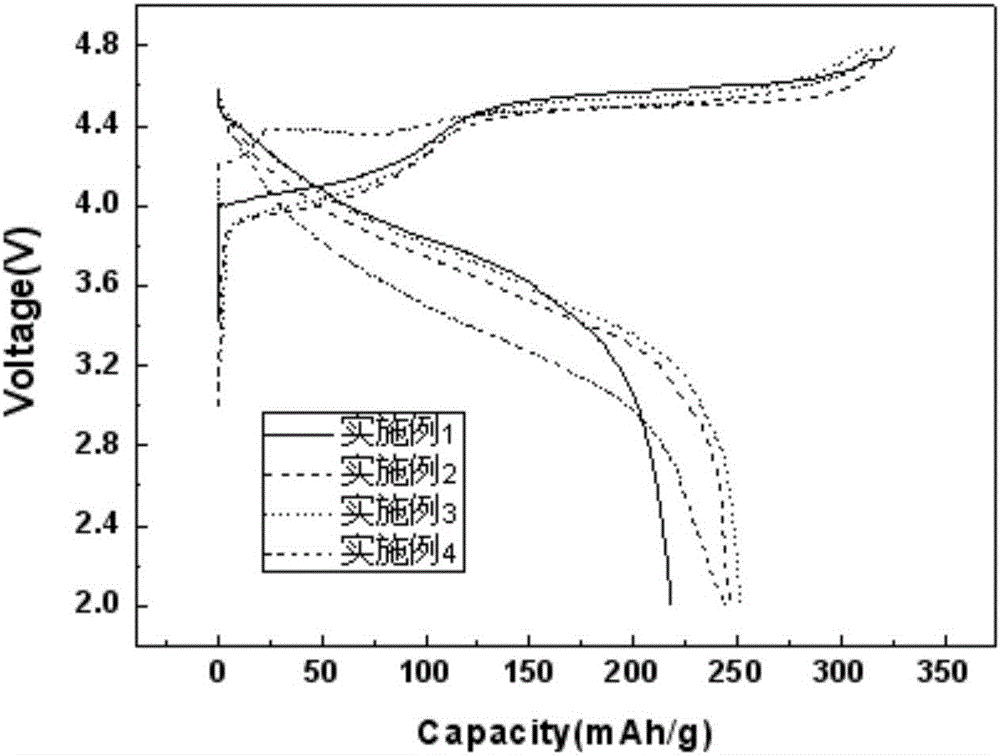

Lithium-rich positive electrode modified material of lithium ion battery and preparation method of lithium-rich positive electrode modified material

InactiveCN106602009AHigh puritySmall particle sizeCell electrodesSecondary cellsWater bathsSodium-ion battery

The invention relates to a lithium-rich positive electrode modified material of a lithium ion battery and a preparation method of the lithium-rich positive electrode modified material, and belongs to the technical field of a positive electrode material of the lithium ion battery. The lithium-rich positive electrode modified material comprises a positive electrode material and a three-class metal oxide cladding material, wherein the cladding material is TiO2, MnO2 or Al2O3. The preparation method comprises the steps of performing water bath stirring and heating to obtain gel by a sol-gel method, performing drying to obtain dried gel, respectively performing low-temperature pre-sintering and high-temperature calcination, obtaining the positive electrode material after cooling and grinding, dispersing the prepared positive electrode material and TiO2 and MnO2 cladding materials in deionized water, performing constant-temperature stirring, and performing standing, filtering, washing, drying and calcination to obtain the lithium-rich positive electrode modified material of the lithium ion battery. While for Al2O3, a liquid phase cladding method is adopted, the positive electrode material is dispersed in an aluminum nitrate nonahydrate solution, and the required modified material is obtained after constant-temperature stirring, standing, filtering, washing, drying and calcination. The preparation method is simple and easy to operate, the lithium-rich positive electrode modified material obtained through preparation is uniform in particle grain distribution and high in crystallinity, and the rate performance and the cycle performance of the material after cladding both are obviously improved.

Owner:JIANGNAN UNIV

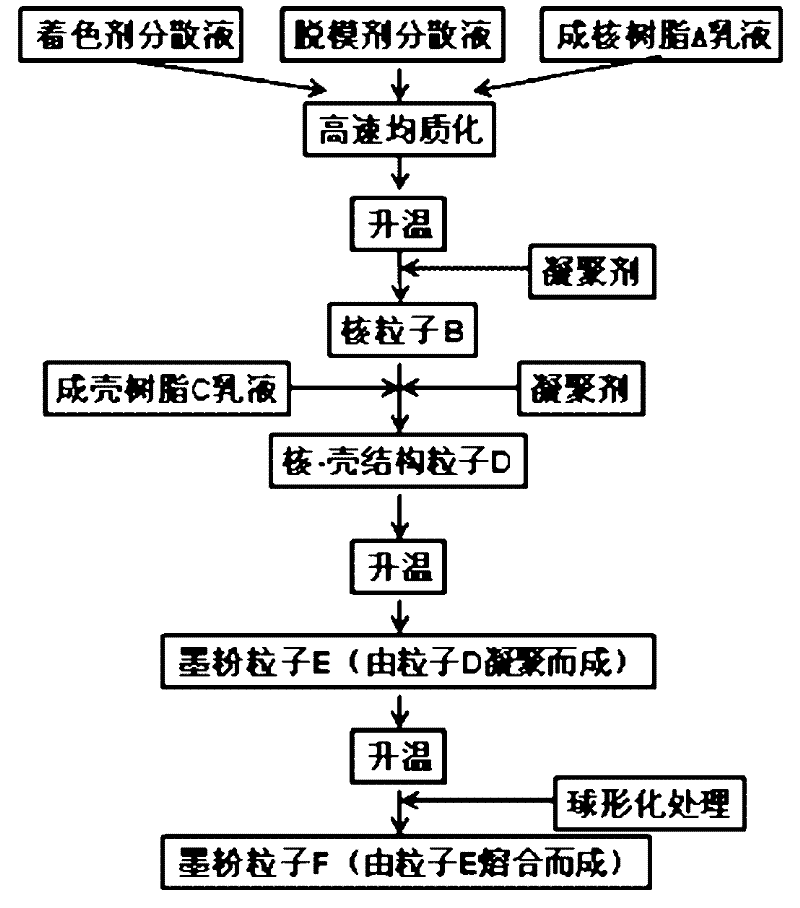

Colorful powdered ink used for static development and preparation method thereof

The invention provides a colorful powdered ink used for static development. Grains with nucleus-shell structures are formed into powdered ink grains in an agglomeration mode; the powdered ink grains contain a nucleus-forming resin A and a shell-forming resin C which are made of same or different components; and the total content of the two resins accounts for 60%-85% of the powdered ink grains. The invention also provides a preparation method of the colorful powdered ink, and the method comprises the following steps: quickly dispersing a colorant dispersing solution, a wax dispersing solutionand an emulsion of the nucleus-forming resin A, thereby forming agglomerated nucleus grains B in a system; then adding a mixture of the emulsion of the shell-forming resin C and a charge control agent, thereby agglomerating into the grains D with the nucleus-shell structures around the nucleus grains B; increasing the temperature so that the grains D with the nucleus-shell structures are agglomerated into powdered ink grains E; and performing spherical treatment on the powdered ink grains E, thereby forming the powdered ink grains F. The powdered ink grains F prepared according to the preparation method provided by the invention are excellent in spherical degree, narrow in grain distribution, excellent in electric property and excellent in durability. The problems of photosensitive drums and developing roller pollution caused by easy separation between a colorant and a release agent are solved.

Owner:SHENZHEN LEPUTAI TECH CO LTD

Manufacture method for staining resistant artificial quartz stone

The invention particularly relates to a manufacture method for a staining resistant artificial quartz stone, which includes the steps of quartz stone powder sand surface modification, mixed pressing, sizing and solidifying and the like to generate a transparent film on the surface of the artificial quartz stone. The manufacture method has the advantages that by means of mechanical activation and modification of quartz stone powder sand serving as raw materials of the artificial quartz stone, flowability of the quartz stone powder sand during pressing is enhanced so that the quartz stone powder sand tends to be accumulated orderly and most densely, and binding of the quartz stone powder sand and resin during solidification is enhanced; the proportion and the grain distribution range are strictly controlled in an artificial quartz stone formula so that micron-sized pore quantity on the surface of the artificial quartz stone is decreased maximally; the surface of the artificial quartz stone is filled to form chemical adsorption so as to improve glossiness of the surface of the artificial quartz stone; and the micron-sized film formed on the surface of the artificial quartz stone has the hydrophobic feature, oil stains within 24 hours can be cleaned by wet cotton cloth, and hidden dirt and bleeding are effectively prevented, therefore, the artificial quartz stone is high in staining resistance. The manufacture method is simple in process, easy in operation and short in consumed time.

Owner:BENYEE NEW MATERIAL CO

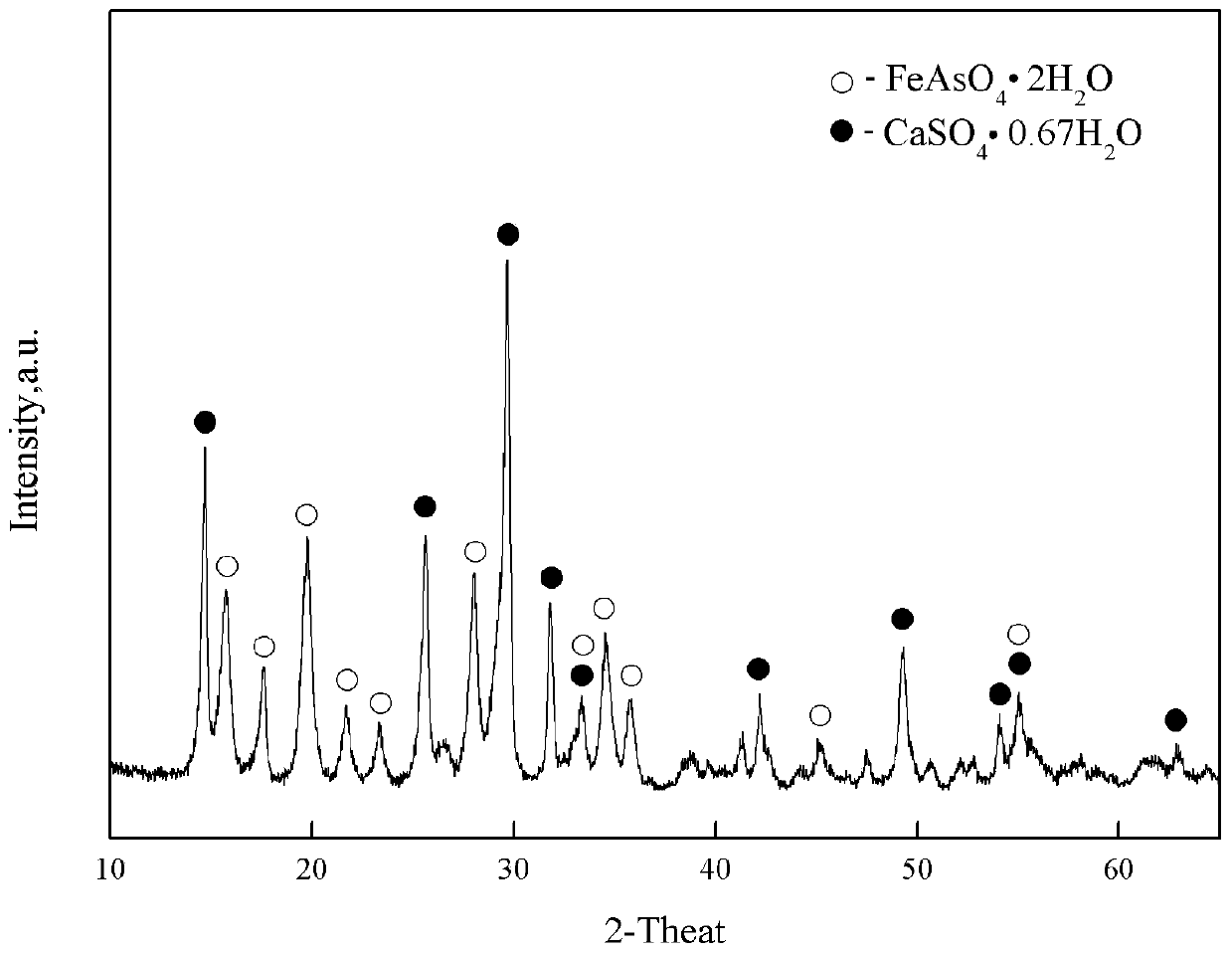

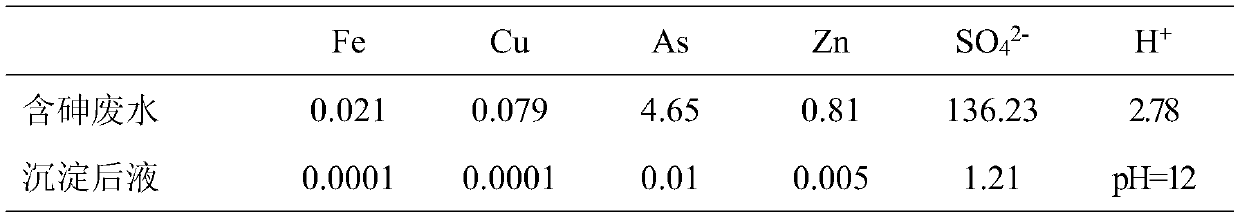

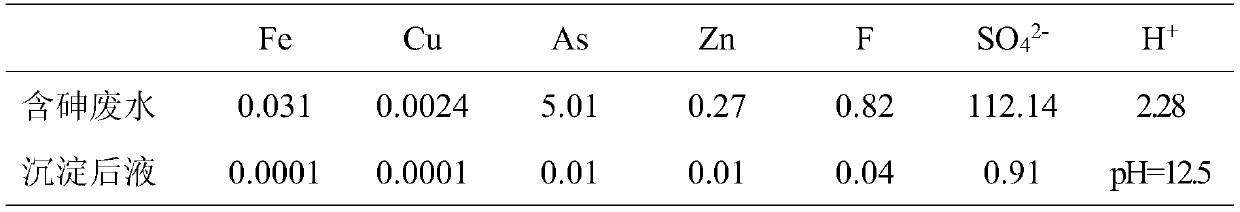

Method for treating arsenic-containing wastewater and solidifying arsenic

ActiveCN111170510AHigh removal rateReduce the temperatureWater contaminantsTreatment involving filtrationIron sulfateArsenous acid

The invention discloses a method for treating arsenic-containing wastewater and solidifying arsenic. The method comprises the following steps: separating and enriching arsenic in the arsenic-containing wastewater in the form of calcium arsenate or / and calcium arsenite precipitate; and oxidizing the obtained arsenic enriched product in a ferric sulfate or ferrous sulfate solution, and carrying outnormal-pressure reaction or pressurized hydrothermal reaction or normal-pressure hydrothermal reaction, so that arsenic in the arsenic enriched product is solidified in the form of scorodite crystals.The obtained scorodite crystals are complete in grain development, uniform in grain distribution and stable in structure under acidic conditions. The method has the advantages of high operation efficiency, good arsenic fixation effect, convenience in operation, low arsenic solidification treatment cost and the like, and is suitable for industrial application of harmless treatment of arsenic-containing wastewater.

Owner:宁波弗镁瑞环保科技有限公司 +2

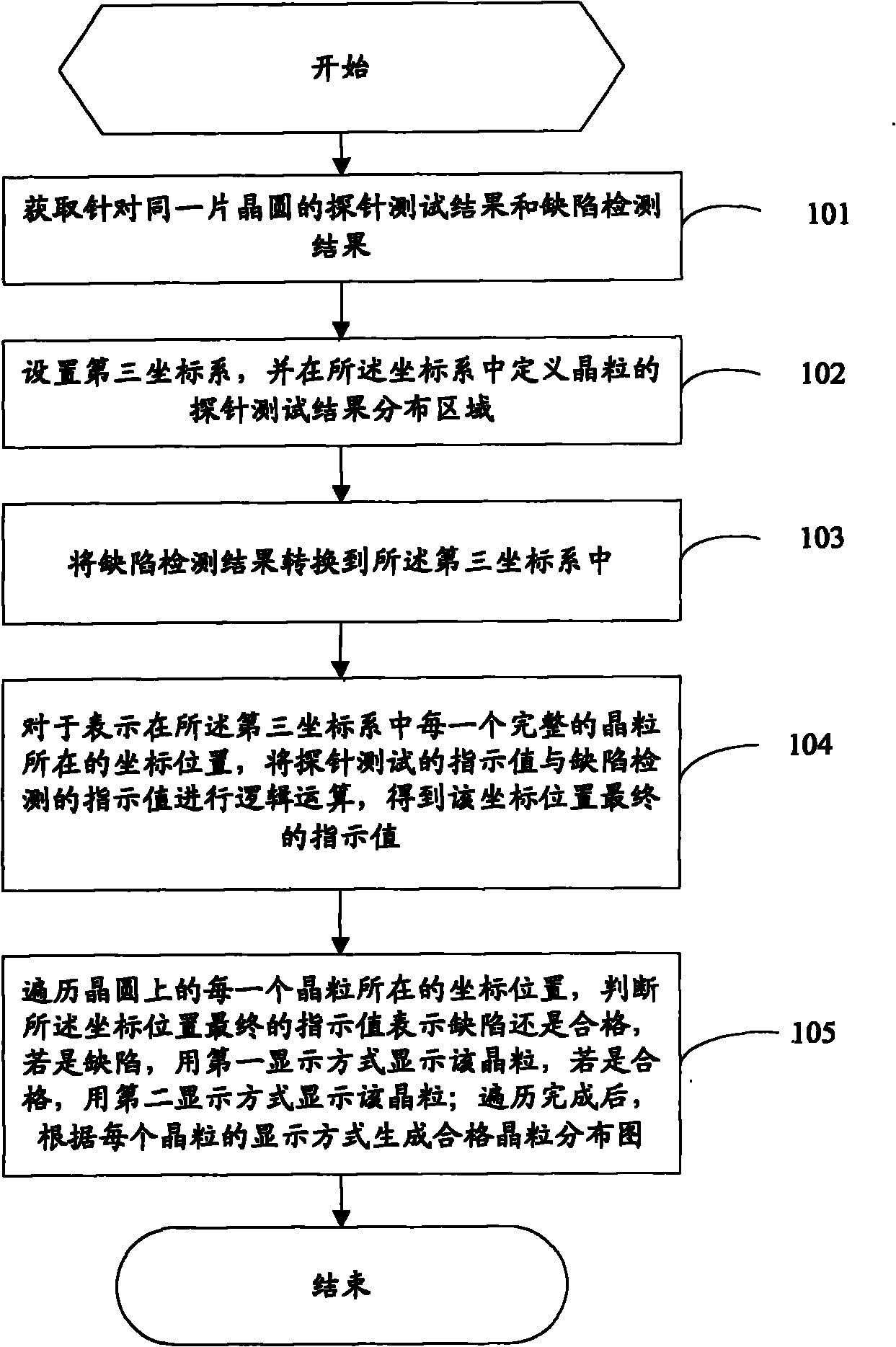

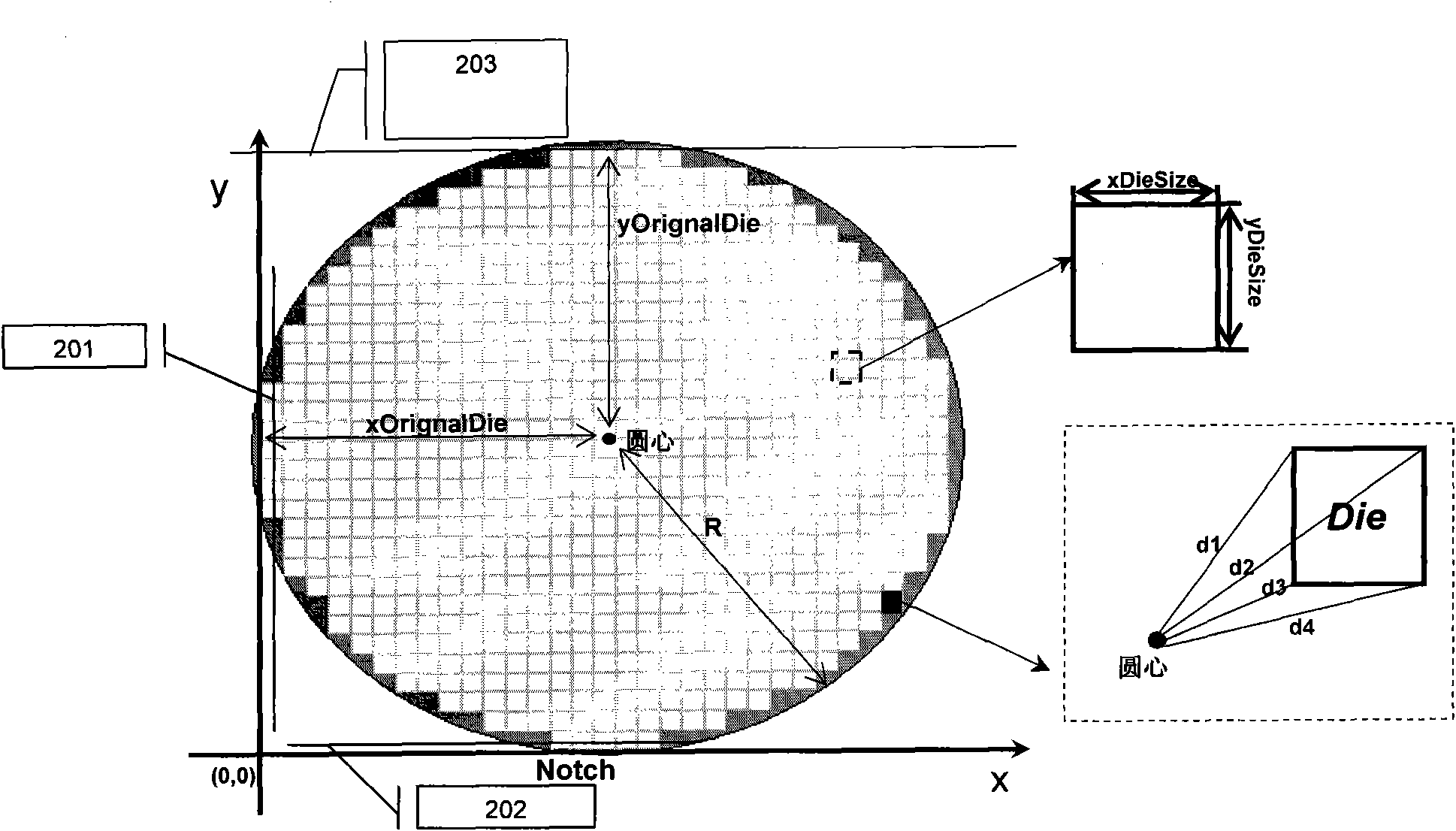

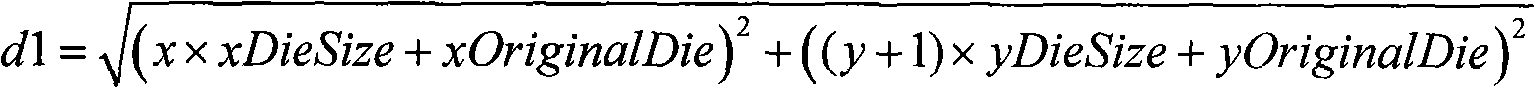

Generation method and device of qualified crystal grain distribution pattern

ActiveCN102376599ARealize automatic generationImprove efficiencyMeasurement devicesSemiconductor/solid-state device testing/measurementLogical operationsGrain distribution

The invention provides a generation method of a qualified crystal grain distribution pattern. The generation method comprises the following steps of: obtaining a probe test result and a defect detection result of the same wafer; arranging a third coordinate system, defining a probe test result distribution region of the crystal grains in the third coordinate system and converting the defect detection result into the third coordinate system; with regard to a coordinate position of each crystal grain in the third coordinate system, carrying out logical operation on an indication value of a probe test and an indication value of a defect detection to obtain a final indication value of the coordinate position; determining a display way of the grain crystal according to the final indication value of each crystal grain on the wafer and generating the qualified crystal grain distribution pattern. The invention also provides a generation device of the qualified crystal grain distribution pattern. According to the scheme provided by the invention, the manual operation can be reduced to a large extent, and efficiency and accuracy of the wafer test and delivery are greatly improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

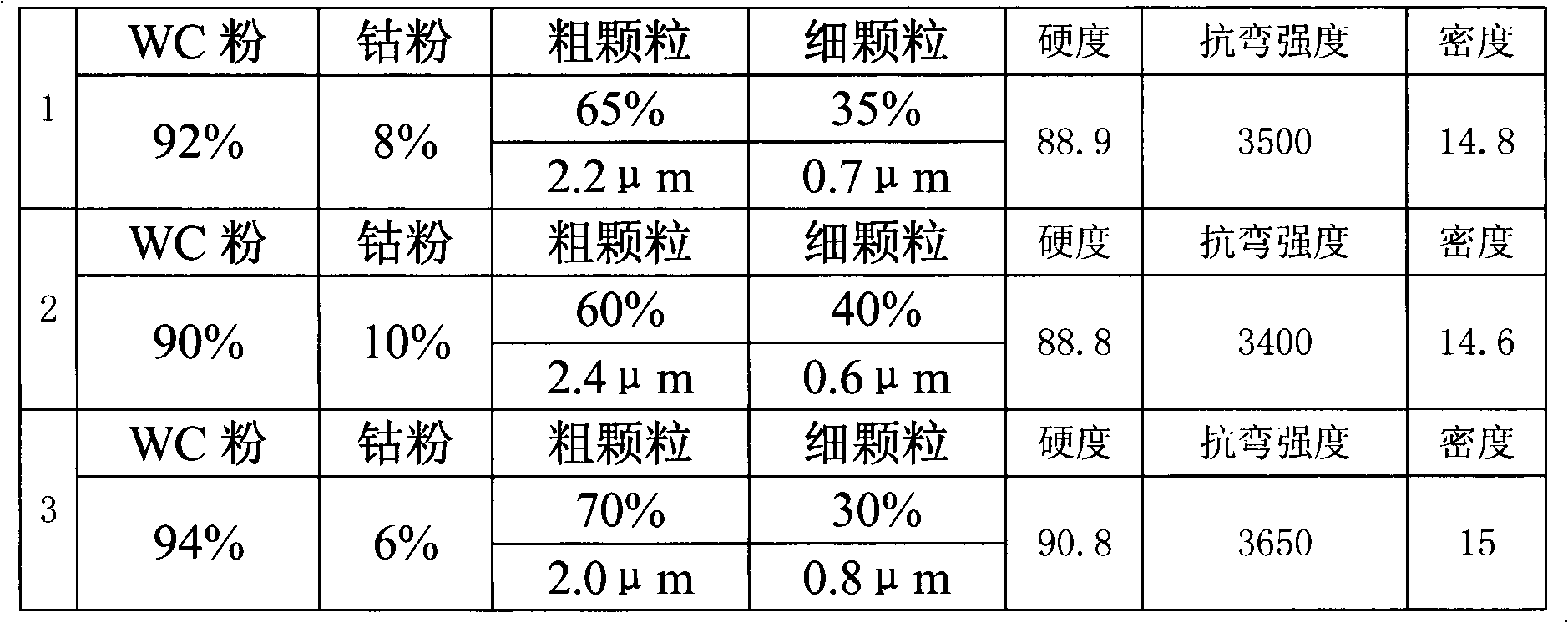

Formula of tungstate and cobalt hard alloy

The invention discloses a formula of a tungstate and cobalt hard alloy and can effectively solve the problem that the conventional formula of the tungstate and cobalt hard alloy does not enhance the thermal fatigue resistance and wear resistance of the tungstate and cobalt hard alloy and has difficulty in ensuring the uniform grain distribution in all ranges in each batch of alloys. The formula of the tungstate and cobalt hard alloy comprises the following components in percentage by mass: 90 to 94 percent of WC powder and 6 to 10 percent of cobalt powder, wherein the WC powder contains 60 to 70 percent of coarse WC powder and 30 to 40 percent of fine WC powder, the particle size of the coarse WC powder ranges from 2.0 to 2.4, and the particle size of the fine WC powder ranges from 0.6 to 0.8 mu m. The formula of a tungstate and cobalt hard alloy has the advantage that the alloy with bimodal size distribution of the WC grains has much higher wear resistance and thermal fatigue resistance and can better meet the requirements for making alloy teeth of roller cutter bits compared with the conventional hard alloys which have uniform or continuous size distribution of the WC grains.

Owner:ZHEJIANG HENGCHENG CEMENTED CARBIDE CO LTD

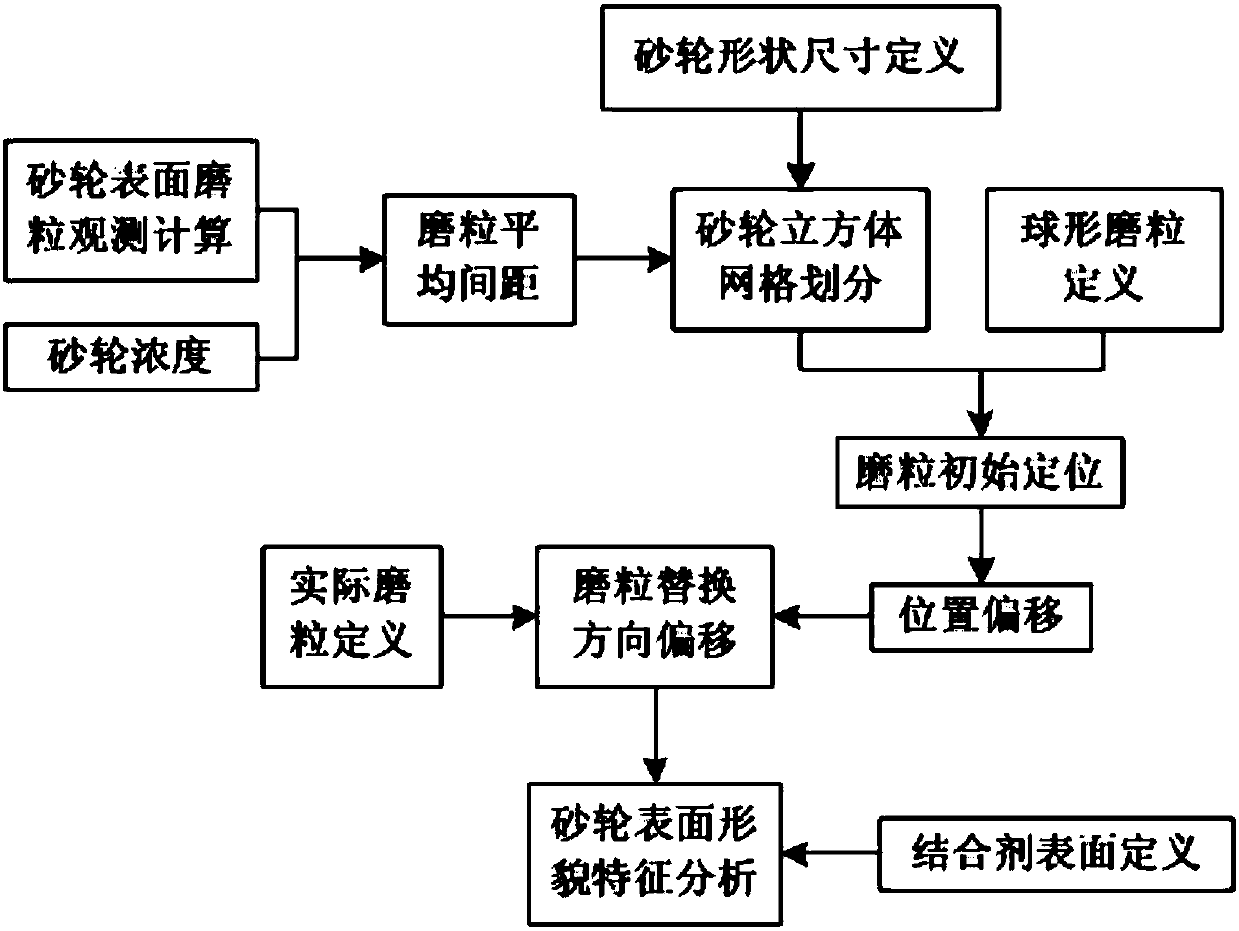

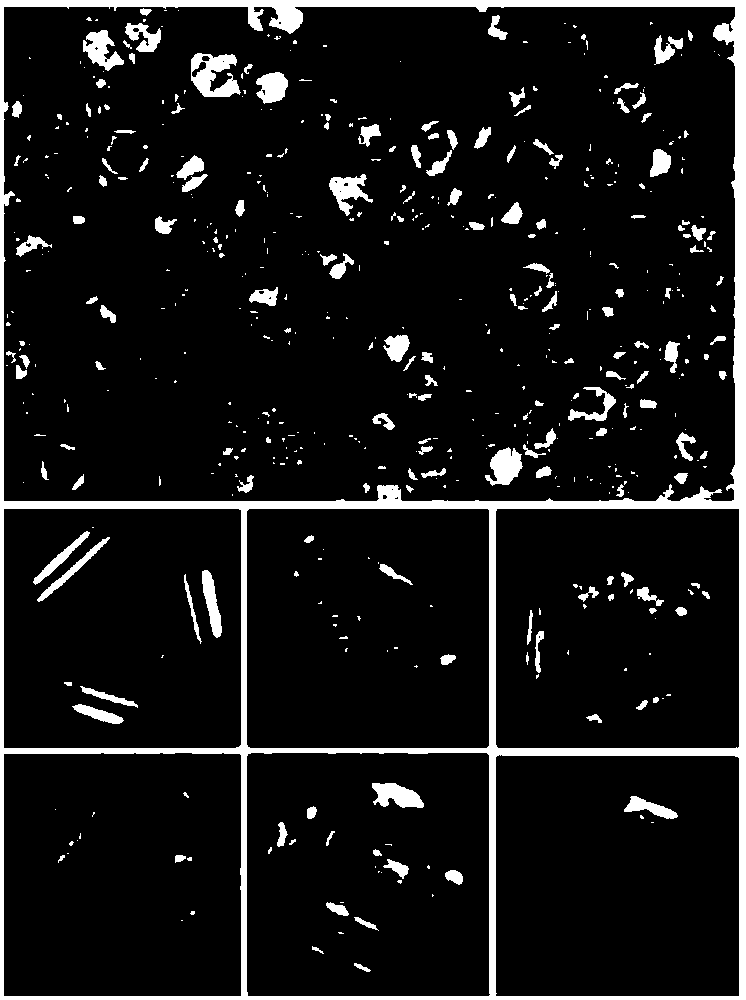

Three-dimensional modeling method of surface morphology of parallel diamond grinding wheel

ActiveCN107657661ADesign optimisation/simulationSpecial data processing applicationsDimensional modelingGrain distribution

The invention discloses a three-dimensional modeling method of the surface morphology of a parallel diamond grinding wheel. The method comprises the steps of defining a parallel diamond grinding wheelmodel and an abrasive grain model, calculating an average space of the abrasive grains according to the surface morphology of a grinding wheel and a grinding wheel concentration, carrying out cube mesh division on the grinding wheel and establishing a cube virtual lattice, carrying out spherical abrasive grain initial positioning in the center of a cube such that spherical abrasive particles randomly move in the virtual lattice, replacing the spherical abrasive particles with defined actual abrasive grains and carrying out turning of different directions to realize direction offset, definingthe surface of a bonding agent to obtain a plate-shaped grinding wheel surface morphology model, and carrying out circular bending on the plate-shaped grinding wheel surface morphology model to obtaina parallel diamond grinding wheel surface morphology model. According to the method, multiple shapes of abrasive particles are used, an abrasive grain size, an abrasive grain distance and abrasive grain distribution are considered to establish the grinding wheel surface morphology model, the model is more close to the actual parallel diamond grinding wheel surface morphology, and the grinding performance and result of the grinding wheel can be accurately evaluated and predicted.

Owner:HUNAN UNIV OF SCI & TECH

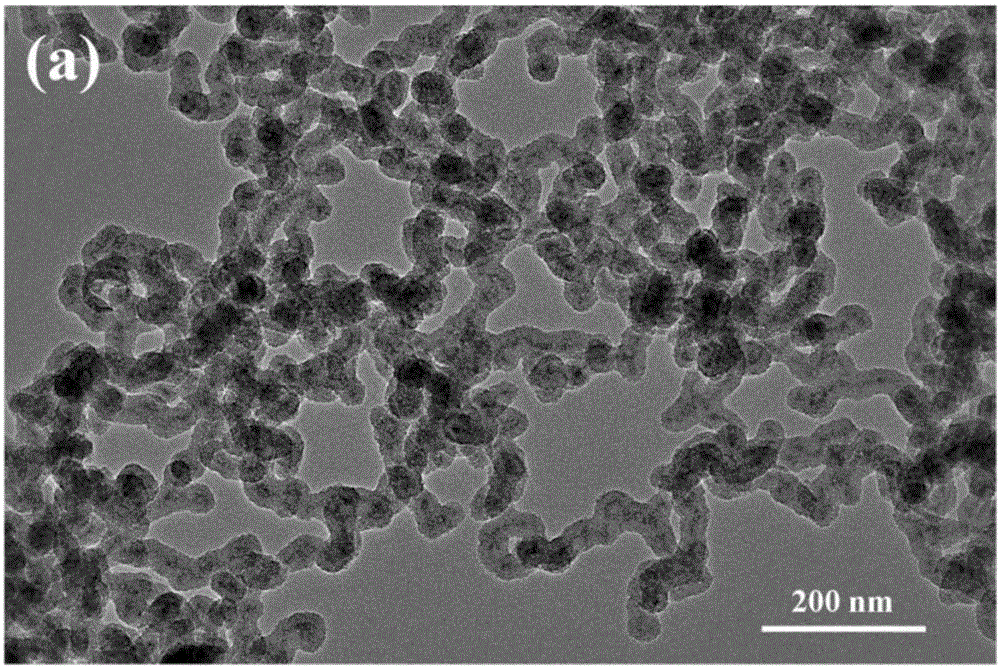

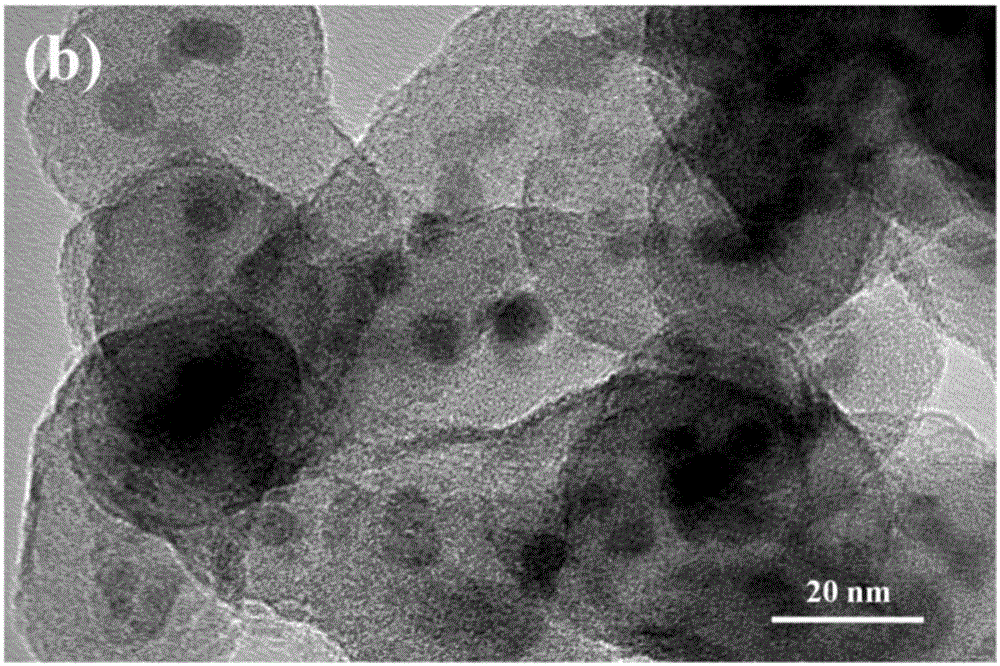

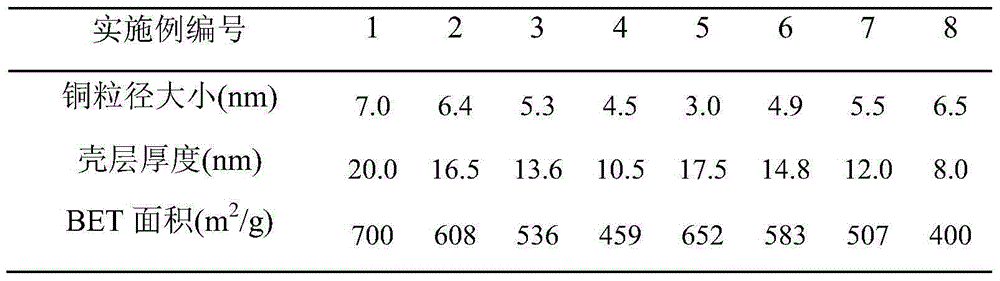

Core-shell structure type copper-based catalyst as well as preparation method and application thereof

ActiveCN105170151AUniform particle size distributionGood dispersionOrganic compound preparationHydroxy compound preparationHydrogenation reactionCopper

The invention provides a core-shell structure type copper-based catalyst as well as a preparation method and application thereof. The catalyst takes Cu as a core and takes mesoporous SiO2 as a shell layer material, the weight percentage of Cu is 8-25%, and the weight percentage of SiO2 is 75-92%. The core-shell structure type nano-composite catalyst material is uniform in grain distribution, adjustable in size, good in dispersibility, small in inner core copper grain, large in specific surface area, good in stability performance, and long in service life; in CO2 hydrogenation reaction operation, the catalyst is stable in performance, and high in activity, and can be operated at a high temperature (240-300 DEG C); the high CO2 conversion per pass can be still kept after long period evaluation, and the core-shell structure type copper-based catalyst has the advantages of being low in cost, easy to operate, easy to enlarge in industry and the like.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com