Lithium-rich positive electrode modified material of lithium ion battery and preparation method of lithium-rich positive electrode modified material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low initial energy utilization, large irreversible capacity loss, and poor rate performance, and achieve the purpose of suppressing interface side reactions and improving Effect of rate performance, cycle performance, and stability maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

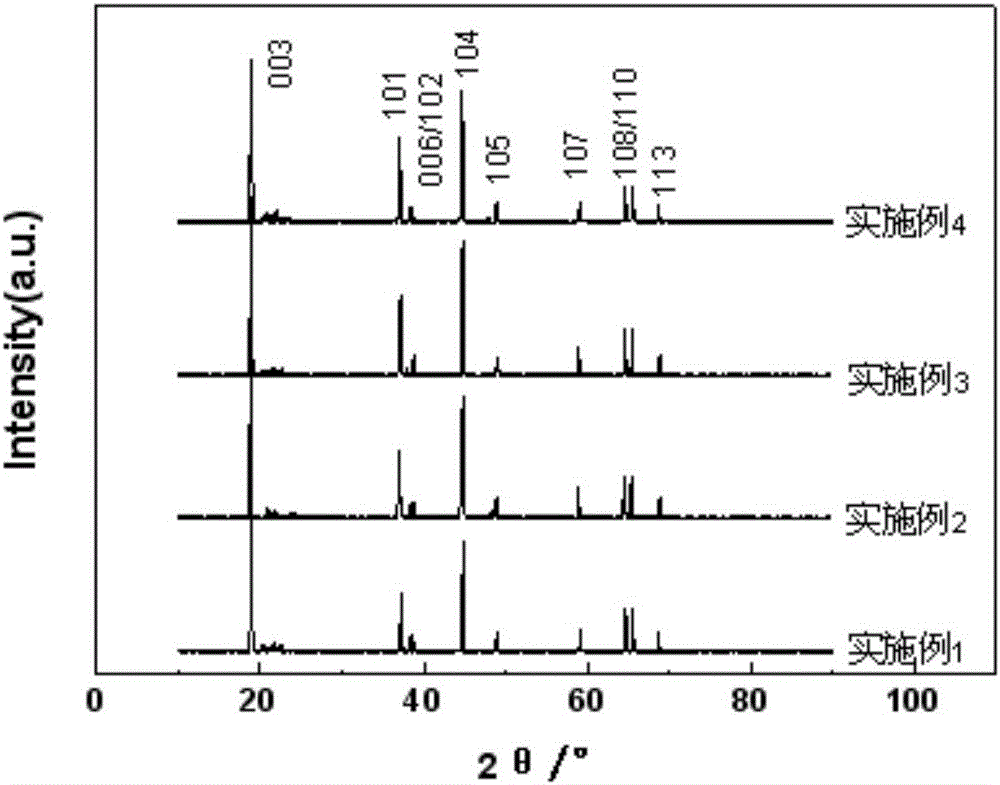

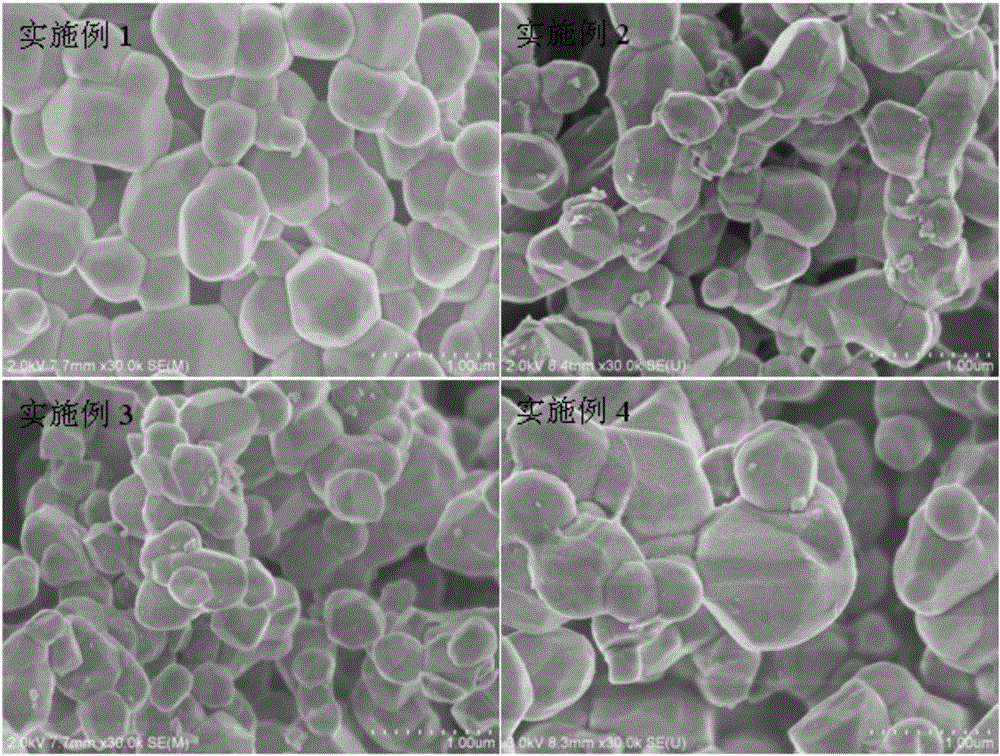

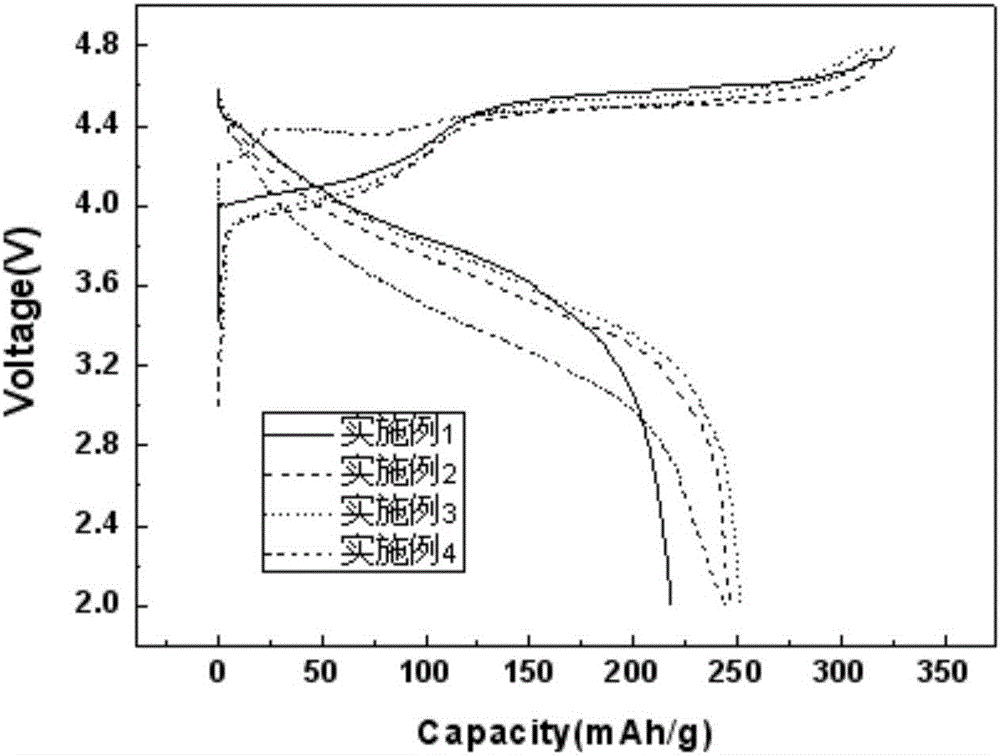

[0025] Example 1 A lithium-rich cathode material for a lithium ion battery is Li[Li 0.2 Ni 0.15 Mn 0.55 Co 0.1 ]O 2 , including the following steps:

[0026] (1) Mixing: Weigh analytically pure CH according to the stoichiometric ratio (1.26:0.15:0.55:0.1). 3 COOLi·2H 2 O, Ni (CH 3 COO) 2 ·4H 2 O, Mn (CH 3 COO) 4H 2 O, Co(CH 3 COO) 2 ·4H 2 O, dissolve in deionized water respectively, gradually add citric acid solution dropwise, the addition of citric acid solution is equal to the sum of the molar amounts of transition metal ions, and adjust the pH value of the mixed solution to about 7 with concentrated ammonia water;

[0027] (2) Heating: the mixed solution system obtained in step (1) is heated and stirred in a water bath at 80° C. to evaporate water to gradually obtain a gel;

[0028] (3) Drying: drying the gel obtained in step (2) in a blast drying oven at 120°C for 24 hours to obtain a dry gel;

[0029] (4) Preparation of precursor: pre-sintering the dried ge...

Embodiment 2

[0031] Example 2 A surface coated with 3wt% TiO 2 Lithium-rich cathode materials for lithium-ion batteries Li[Li 0.2 Ni 0.15 mn 0.55 co 0.1 ]O 2 , including the following steps:

[0032] With the Li[Li prepared by embodiment 1 0.2 Ni 0.15 mn 0.55 co 0.1 ]O 2 The positive electrode material and mass fraction ratio are 3wt%TiO 2 Disperse into ethanol solution with 10 times the mass, heat and stir at 40°C until the solvent is basically volatilized, dry at 80°C for 24 hours, and finally calcinate at 450°C for 6 hours to obtain the final product surface coated with 3wt% TiO 2 Li[Li 0.2 Ni 0.15 mn 0.55 co 0.1 ]O 2 .

Embodiment 3

[0033] Example 3 A surface coated with 3wt% MnO 2 Lithium-rich cathode materials for lithium-ion batteries Li[Li 0.2 Ni 0.15 mn 0.55 co 0.1 ]O 2 , including the following steps:

[0034] The prepared Li[Li 0.2 Ni 0.15 mn 0.55 co 0.1 ]O 2 The positive electrode material and mass fraction ratio are 3wt% MnO 2 Disperse into an ethanol solution with 6 times the mass, heat and stir at 40°C until the solvent is basically volatilized, dry at 80°C for 24 hours, and finally calcinate at 450°C for 6 hours to obtain the final product surface coated with 3wt% MnO 2 Li[Li 0.2 Ni 0.15 mn 0.55 co 0.1 ]O 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com