Patents

Literature

65results about How to "Good particle dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

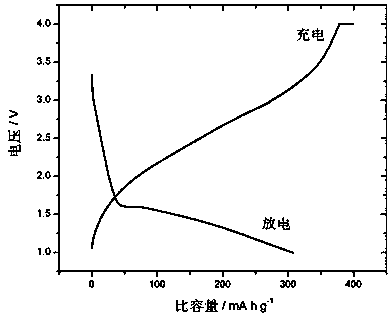

Two-dimensional porous graphitized carbon-coated nickel-tin alloy material and preparation and application thereof

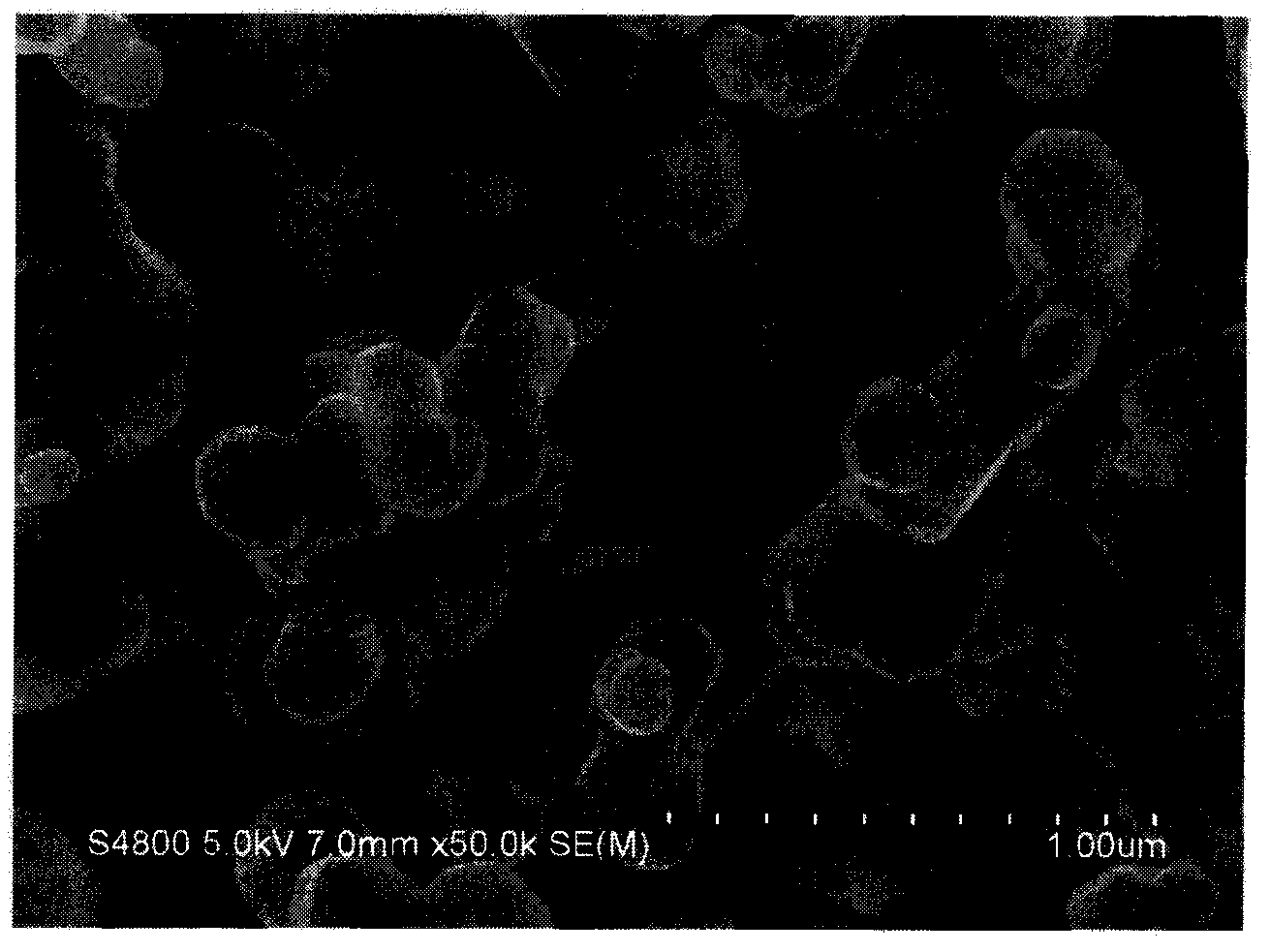

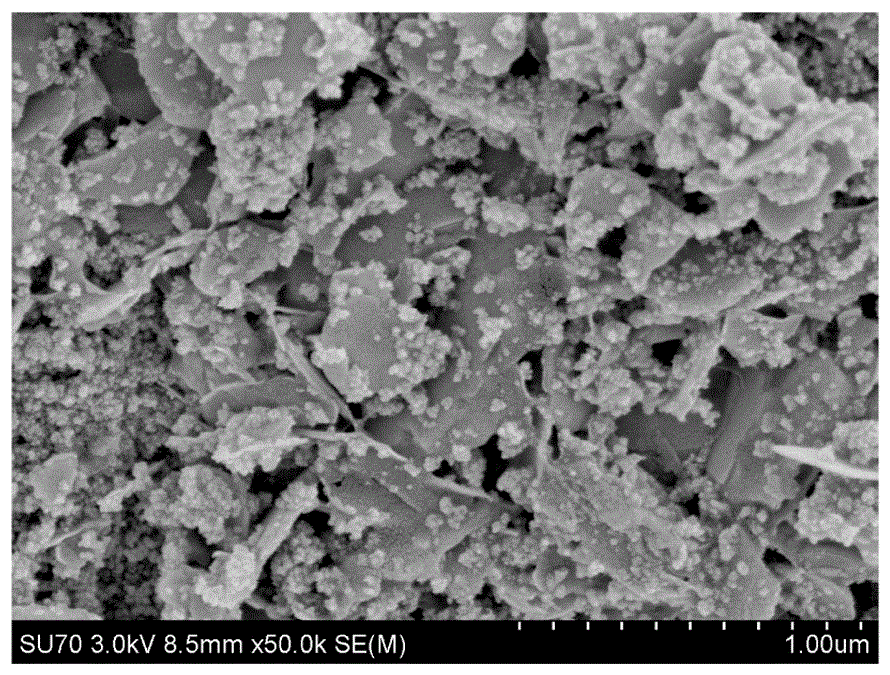

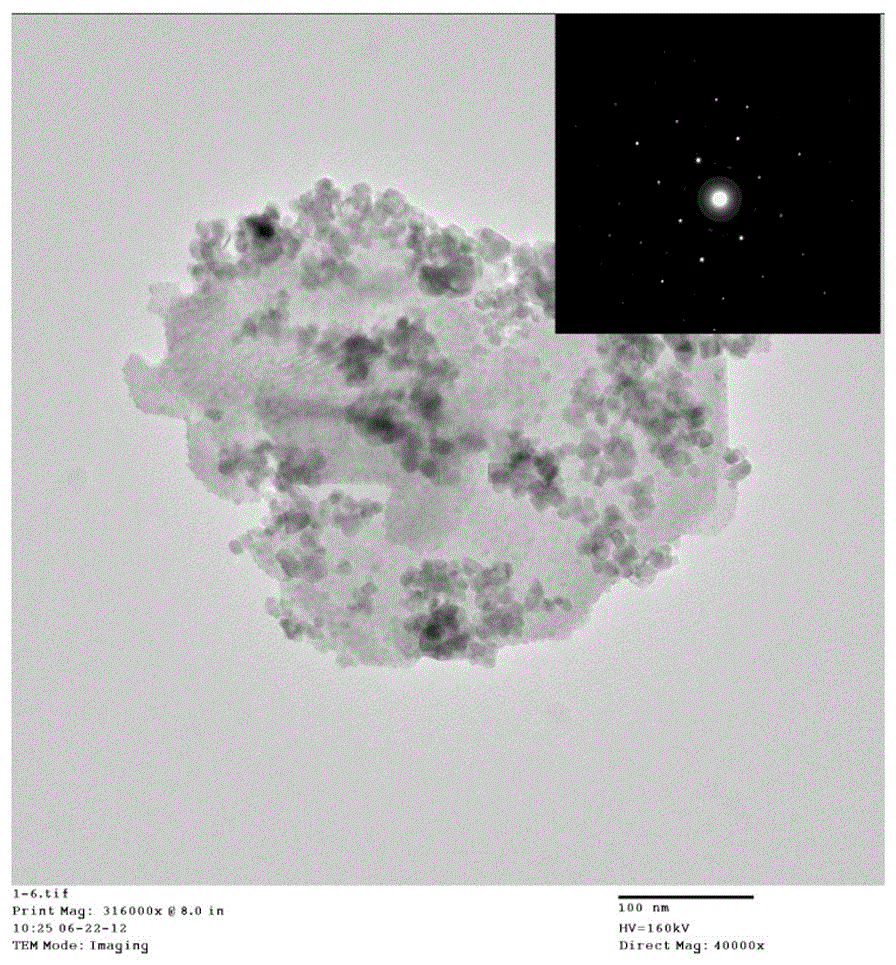

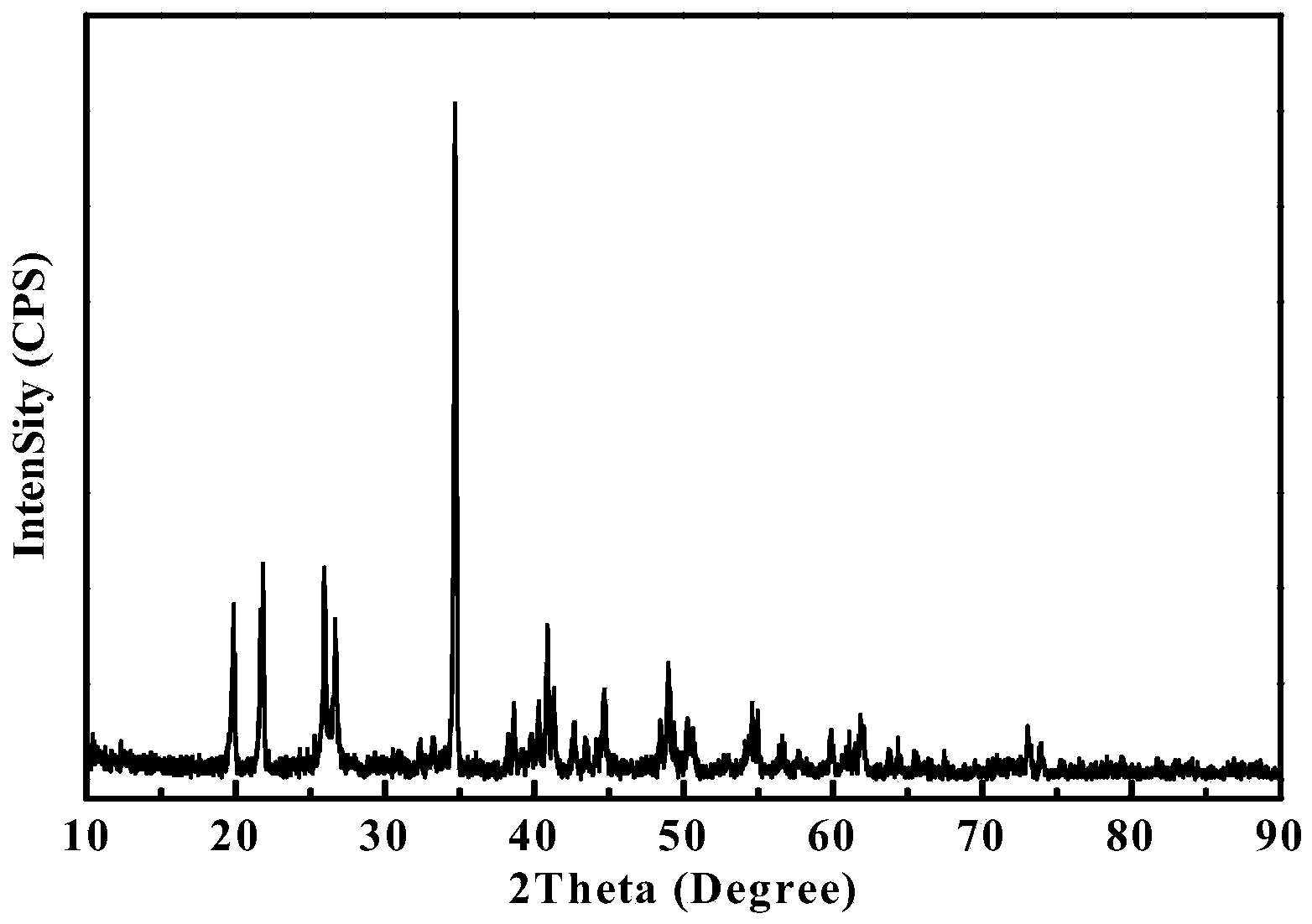

InactiveCN103722169AImprove controllabilityGood particle dispersionCell electrodesTube furnaceCarbon source

The invention discloses a two-dimensional porous graphitized carbon-coated nickel-tin alloy material and preparation and application thereof. Carbon-coated nickel-tin alloy nano-particles are uniformly embedded into two-dimensional porous graphitized carbon plates to form the material. A preparation procedure for the material includes utilizing NaCl as a dispersing agent and a carrier, dissolving the NaCl in a nickel source and a carbon source, mixing the NaCl, the nickel source and the carbon source, drying the NaCl, the nickel source and the carbon source under a vacuum condition and finely grinding the NaCl, the nickel source and the carbon source to obtain a mixture; placing the mixture and a tin source to be subjected to gas-phase exchange into a tube furnace, and calcining the mixture and the tin source under the protection of inert gas to obtain a calcined product; washing the calcined product to obtain the two-dimensional porous graphitized carbon-coated nickel-tin alloy material. The two-dimensional porous graphitized carbon-coated nickel-tin alloy material, the preparation and the application have the advantages that the preparation procedure is safe and harmless, operation is simple, the yield is high, and the prepared two-dimensional porous graphitized carbon-coated nickel-tin alloy material which is used as a cathode material of a lithium ion battery is high in reversible capacity and cycle stability.

Owner:TIANJIN UNIV

Nano microcapsule type dry garment piece, and preparation method and application thereof

The invention relates to a fragrant microcapsule type finishing agent which comprises the following constituents by mass percentage: 35-45 percent of fragrant nano microcapsule, 35-45 percent of thickening agent, 15-25 percent of adhesive and 1-5 percent of color paste, wherein the sum of the percentages of all the constituents is 100 percent. The invention also discloses a nano microcapsule type dry garment piece which has lasting fragrance more than 1 year, is sterile, has high safety, has no stimulation to the skin and no allergic response, and is suitable for fragrance finishing and storing of fabrics and ready-to-wear clothing made of cotton, wool, silk, linen and chemical fiber; and the fragrant nano microcapsule has good particle dispersivity on base cloth and is extremely easy to embed into the base cloth tissue structure.

Owner:无锡翔隆高分子面料有限公司

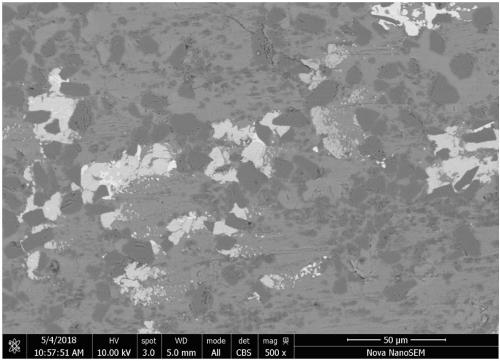

SiC particle-enhanced aluminum based composite with high-temperature wear resistance and preparation method of SiC particle-enhanced aluminum based composite

The invention provides a SiC particle-enhanced aluminum based composite with high-temperature wear resistance and a preparation method of the SiC particle-enhanced aluminum based composite and belongsto the field of aluminum alloy materials. The preparation method comprises the following steps of smelting industrial pure aluminum, aluminum-silicon alloy, aluminum-copper alloy, pure magnesium, thealuminum-copper alloy, aluminum-nickel alloy, aluminum-zinc alloy, aluminum-titanium alloy and aluminum-magnesium alloy at 700-800 DEG C according to a mass ratio; performing degassing refining; performing casting at 700-750 DEG C; using vacuum smelting, stirring and casting equipment to smelt a substrate at 700-800 DEG C; adding micron-size SiC particles; performing semi-solid state stirring at550-570 DEG C; performing casting at 700-750 DEG C; and performing T6 heat treatment. For the SiC particle-enhanced aluminum based composite with the high-temperature wear resistance and the preparation method, the substrate alloy components are designed self according to an alloy phase diagram, and a proper element content is selected, so that a high temperature resistant hard phase occurs aftersubstrate alloy heat treatment, and the substrate hardness at high temperature is ensured; and meanwhile, by adding an SiC-enhanced phase, the high temperature resistance of the composite is further improved.

Owner:TONGJI UNIV

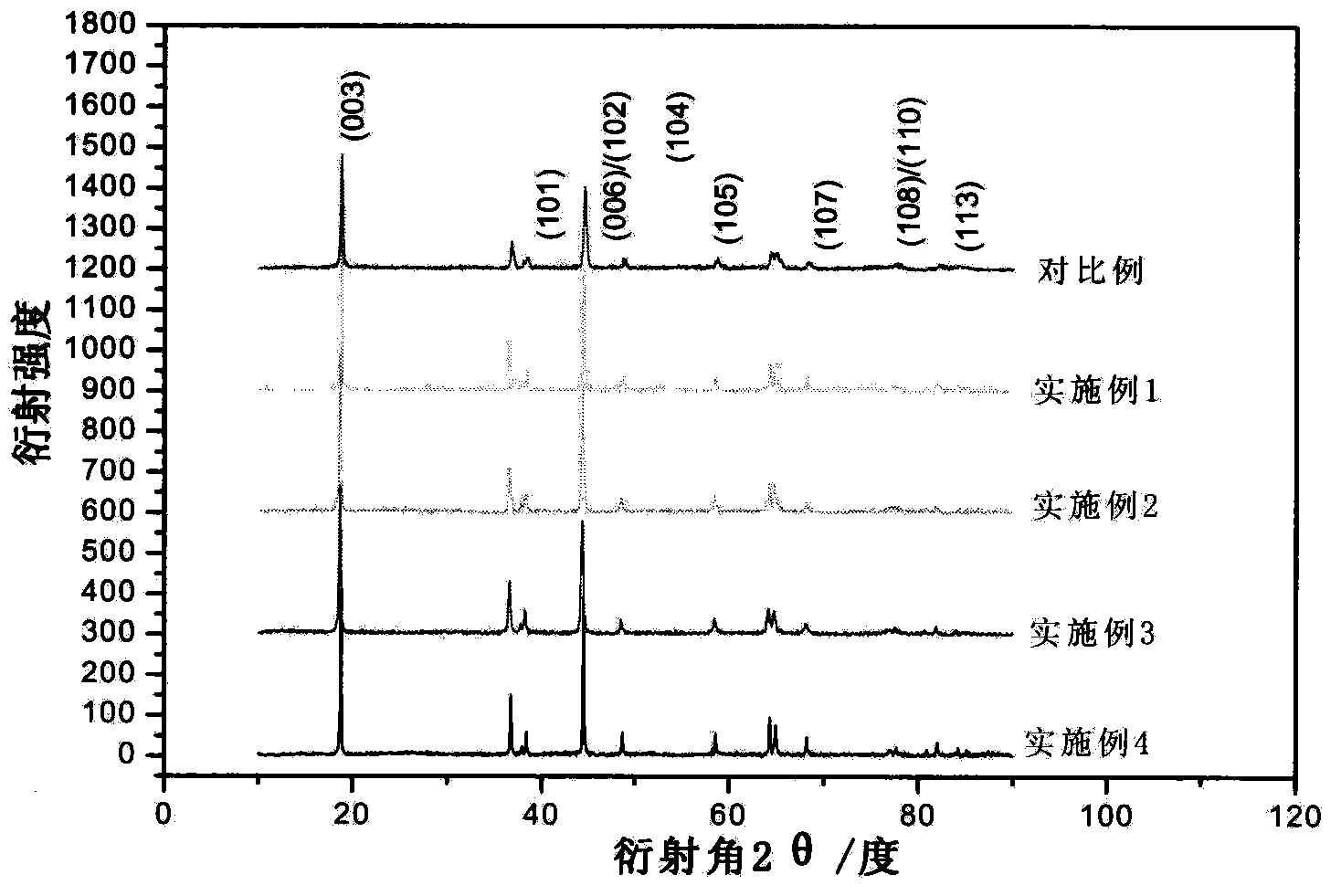

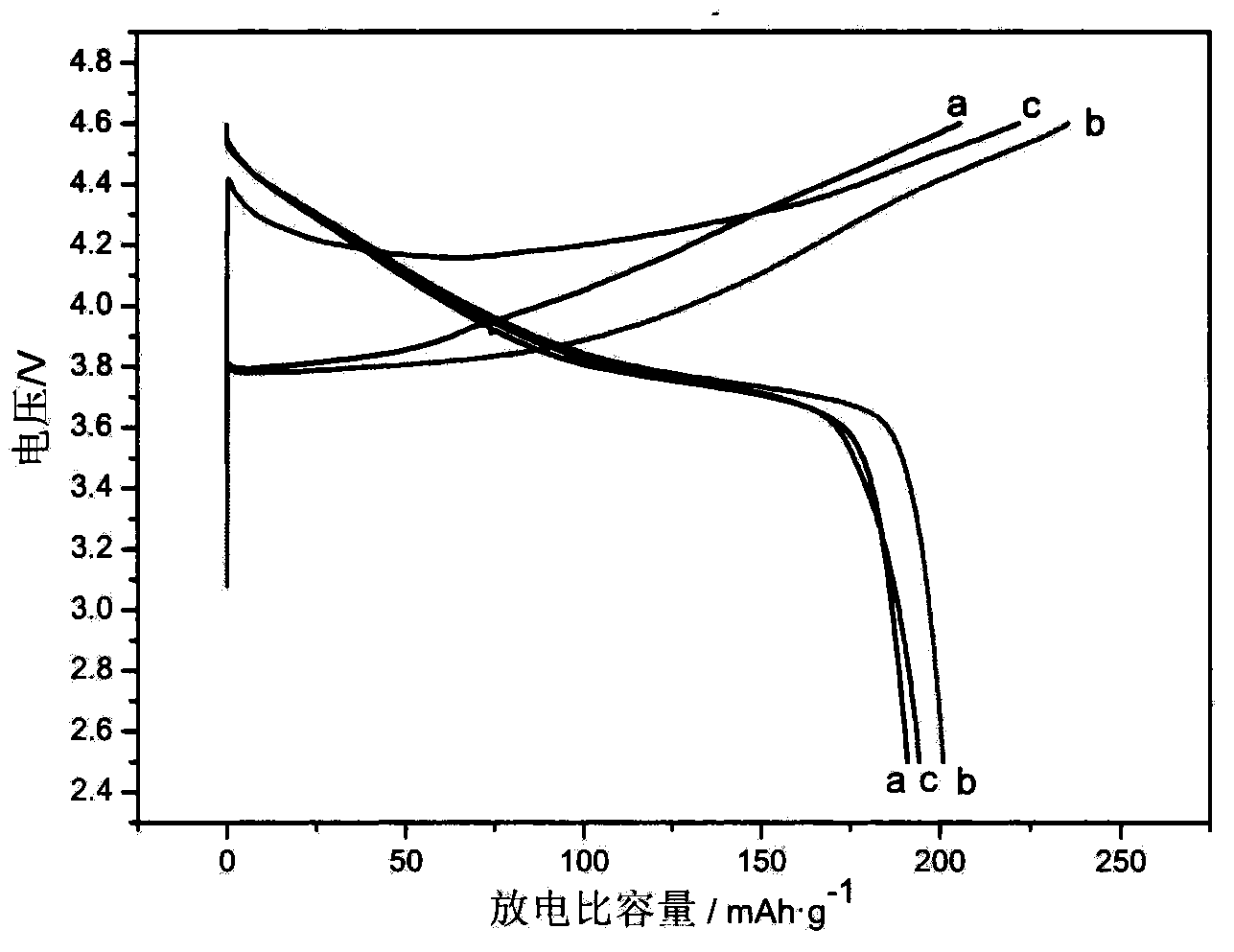

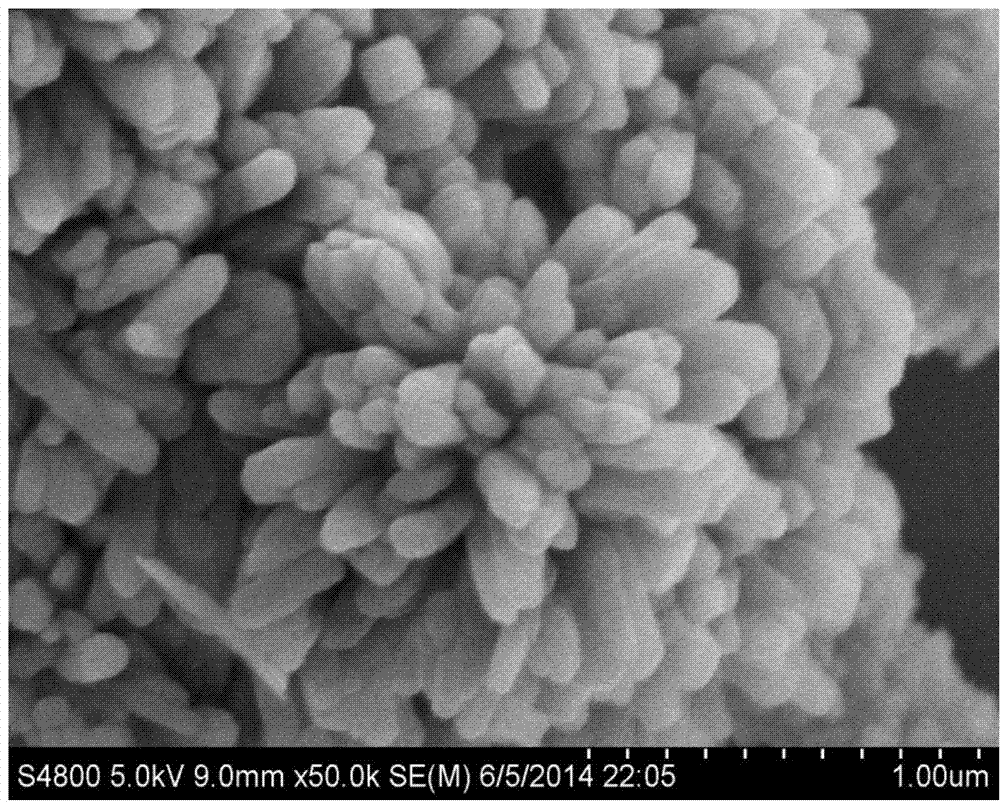

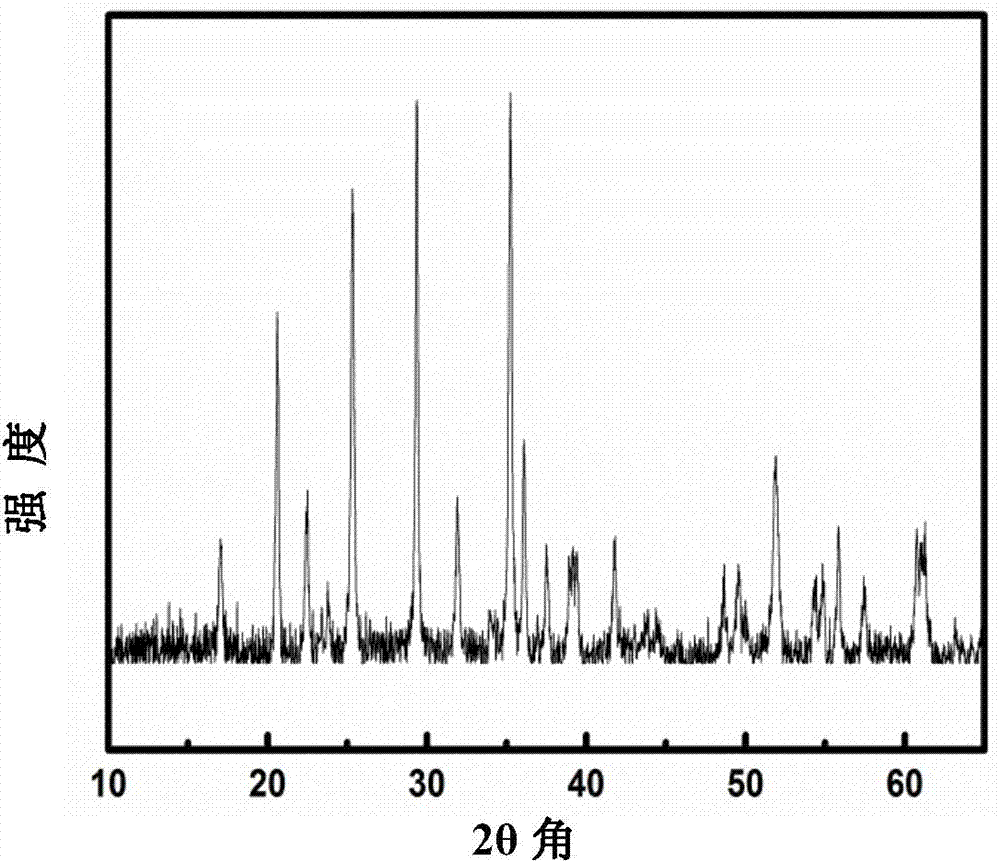

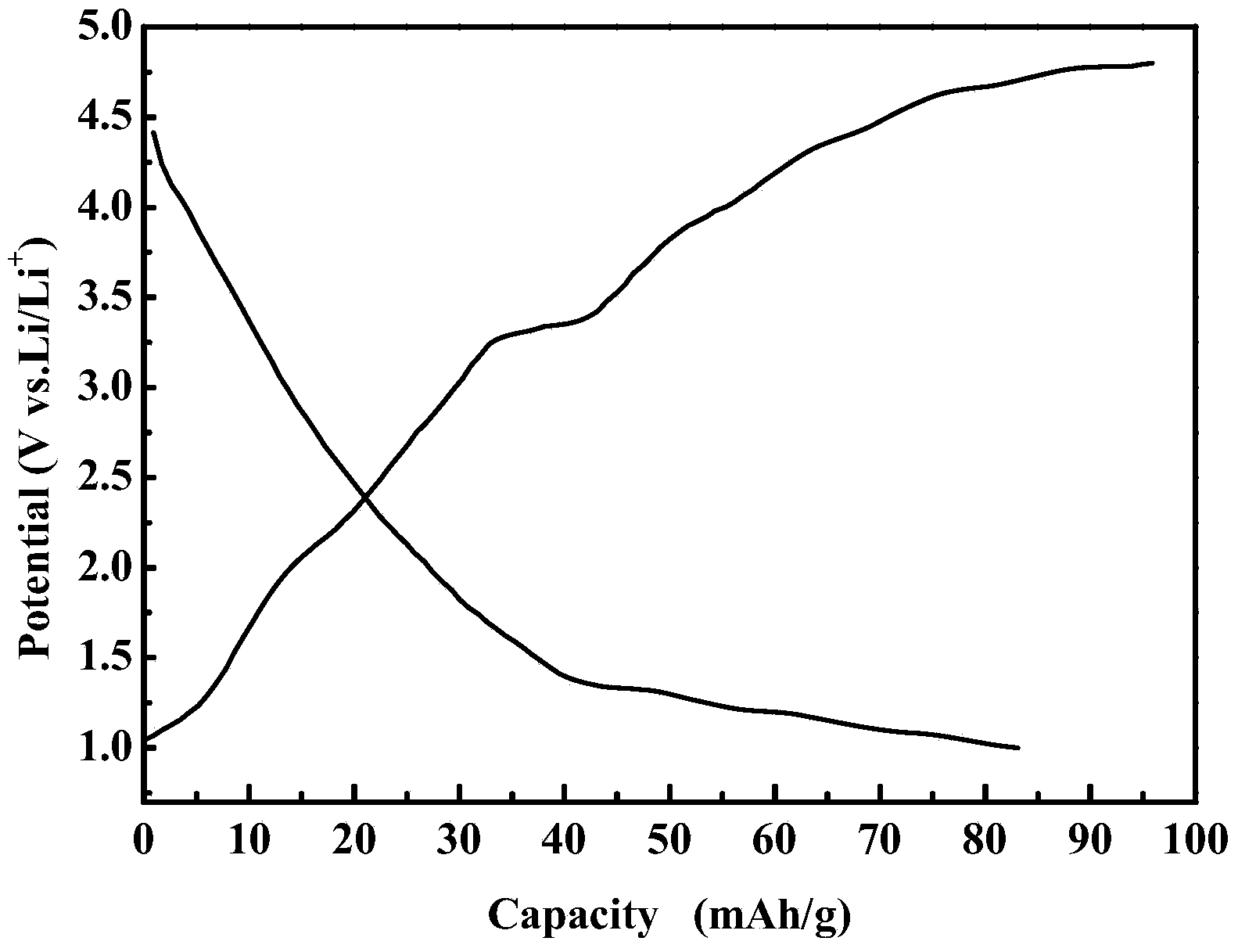

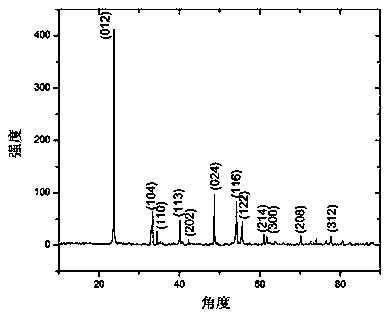

Lithium-rich positive electrode modified material of lithium ion battery and preparation method of lithium-rich positive electrode modified material

InactiveCN106602009AHigh puritySmall particle sizeCell electrodesSecondary cellsWater bathsSodium-ion battery

The invention relates to a lithium-rich positive electrode modified material of a lithium ion battery and a preparation method of the lithium-rich positive electrode modified material, and belongs to the technical field of a positive electrode material of the lithium ion battery. The lithium-rich positive electrode modified material comprises a positive electrode material and a three-class metal oxide cladding material, wherein the cladding material is TiO2, MnO2 or Al2O3. The preparation method comprises the steps of performing water bath stirring and heating to obtain gel by a sol-gel method, performing drying to obtain dried gel, respectively performing low-temperature pre-sintering and high-temperature calcination, obtaining the positive electrode material after cooling and grinding, dispersing the prepared positive electrode material and TiO2 and MnO2 cladding materials in deionized water, performing constant-temperature stirring, and performing standing, filtering, washing, drying and calcination to obtain the lithium-rich positive electrode modified material of the lithium ion battery. While for Al2O3, a liquid phase cladding method is adopted, the positive electrode material is dispersed in an aluminum nitrate nonahydrate solution, and the required modified material is obtained after constant-temperature stirring, standing, filtering, washing, drying and calcination. The preparation method is simple and easy to operate, the lithium-rich positive electrode modified material obtained through preparation is uniform in particle grain distribution and high in crystallinity, and the rate performance and the cycle performance of the material after cladding both are obviously improved.

Owner:JIANGNAN UNIV

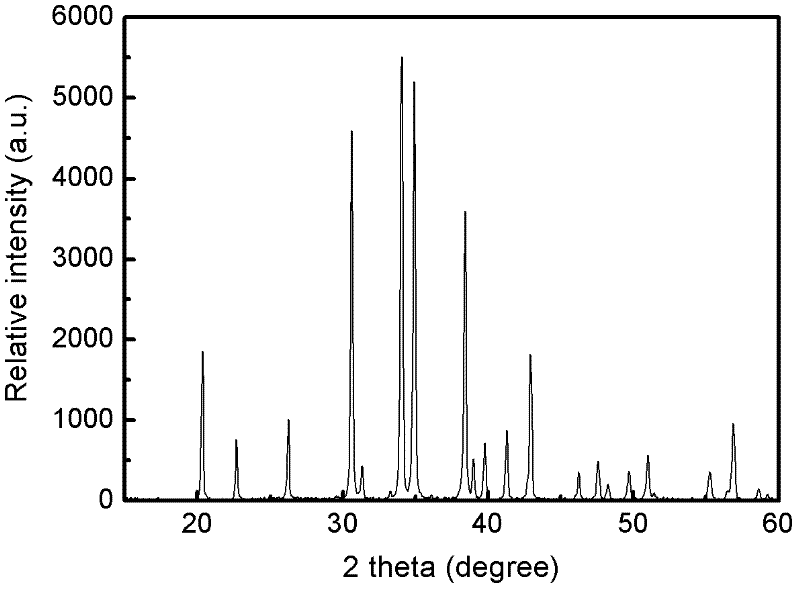

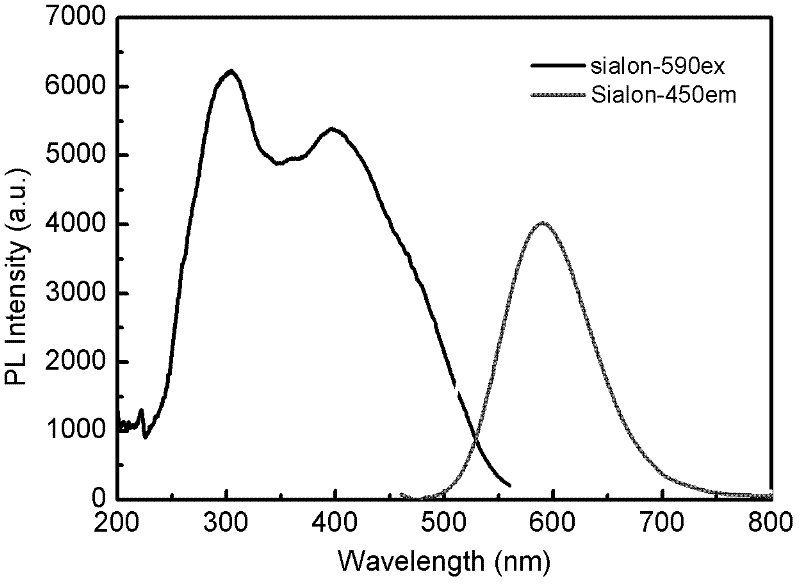

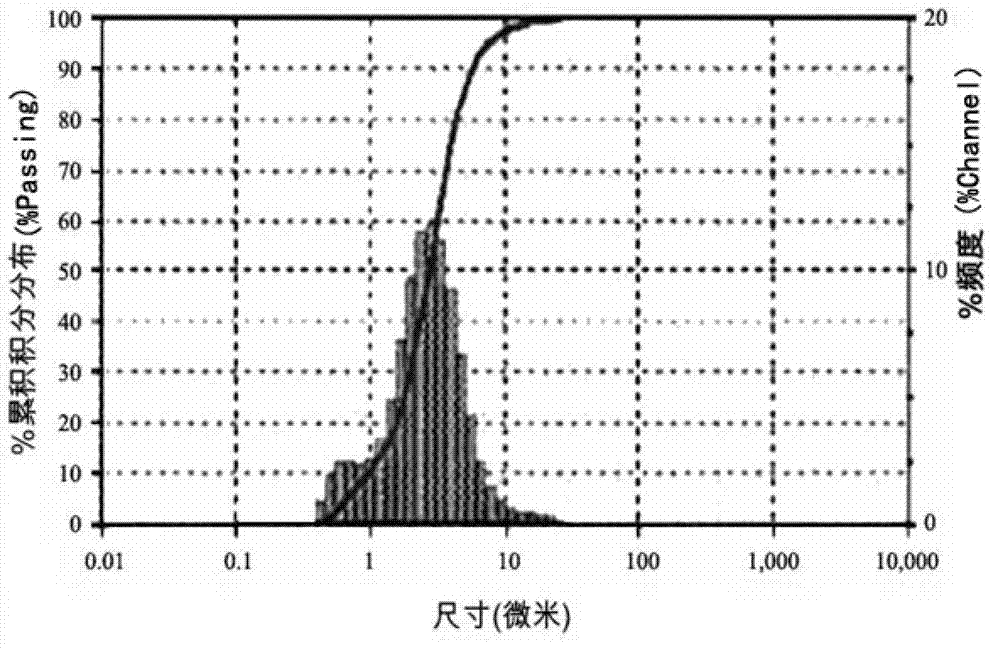

A kind of preparation method of nitride/oxynitride fluorescent powder for white light LED

InactiveCN102260500AUniform distribution of temperature fieldReduce temperature gradientElectroluminescent light sourcesGas discharge lamp usagePolymer scienceHigh pressure

Provided is a method for preparing a nitride / oxynitride fluorescent powder used by a white LED. The raw material is weighted according to the chemometry of each element in the chemical formula of a nitride / oxynitride fluorescent powder and loaded into a sagger made of a wave-transparent material after being mixed uniformly, then the sagger is placed into a professional microwave oven, in a fixed gas atmosphere, and the fluorescent powder is obtained by adjusting the microwave power to control the warming rate, heating to the resultant temperature, and finally cooling and grinding. As compared to methods in the prior art, the method is performed under normal pressure, reducing the resultant temperature, shortening the production period, and greatly reducing the production costs; and the fluorescent powder obtained has good crystallinity, fine grain size, a narrow granularity distribution range, good grain dispersibility, and a regular shape.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

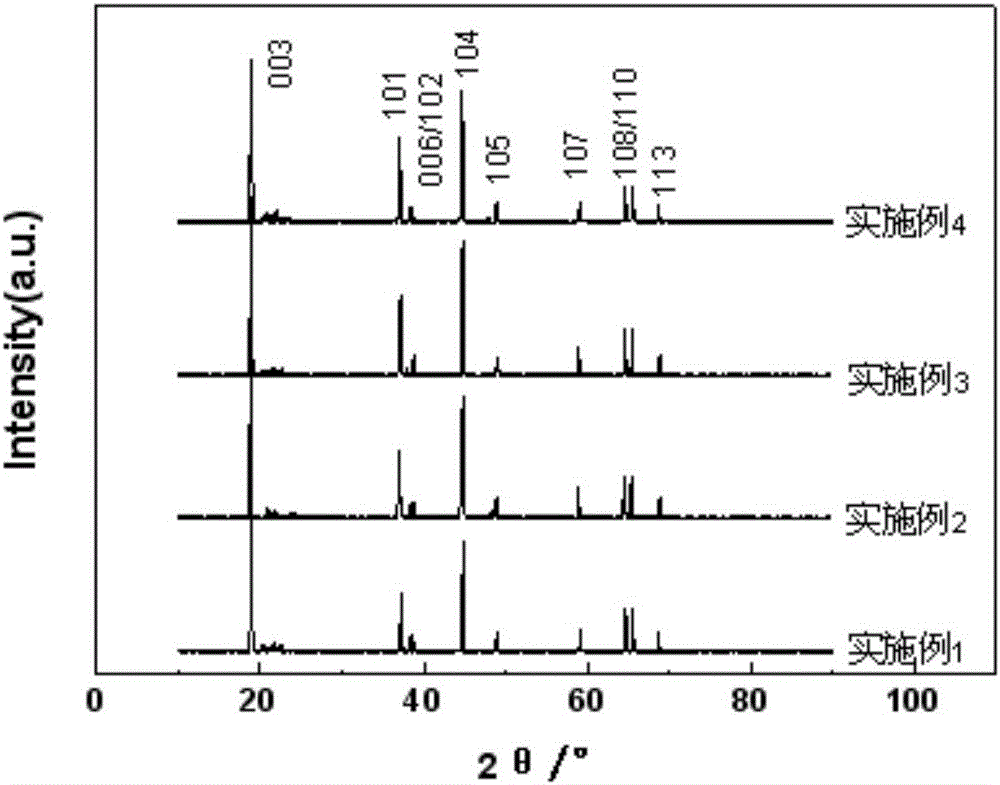

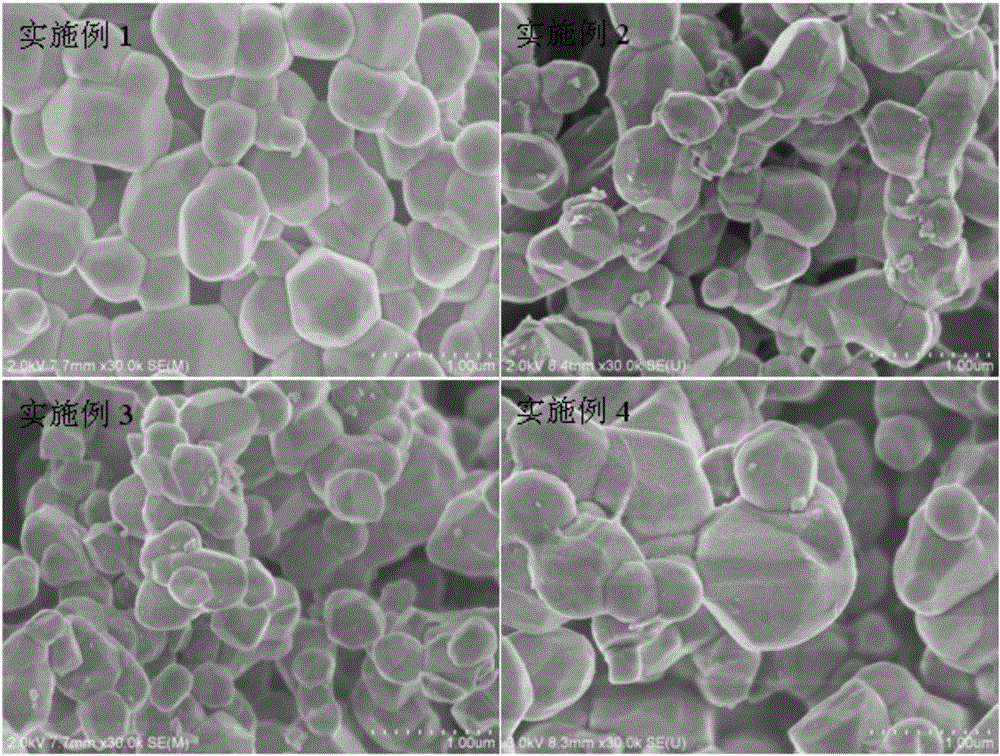

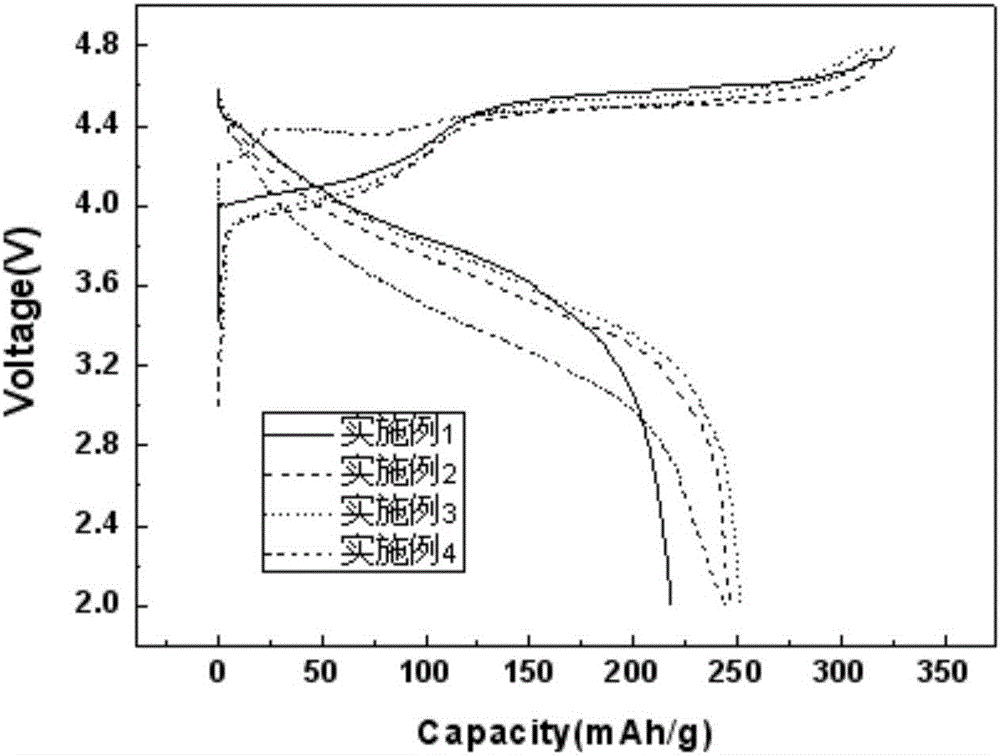

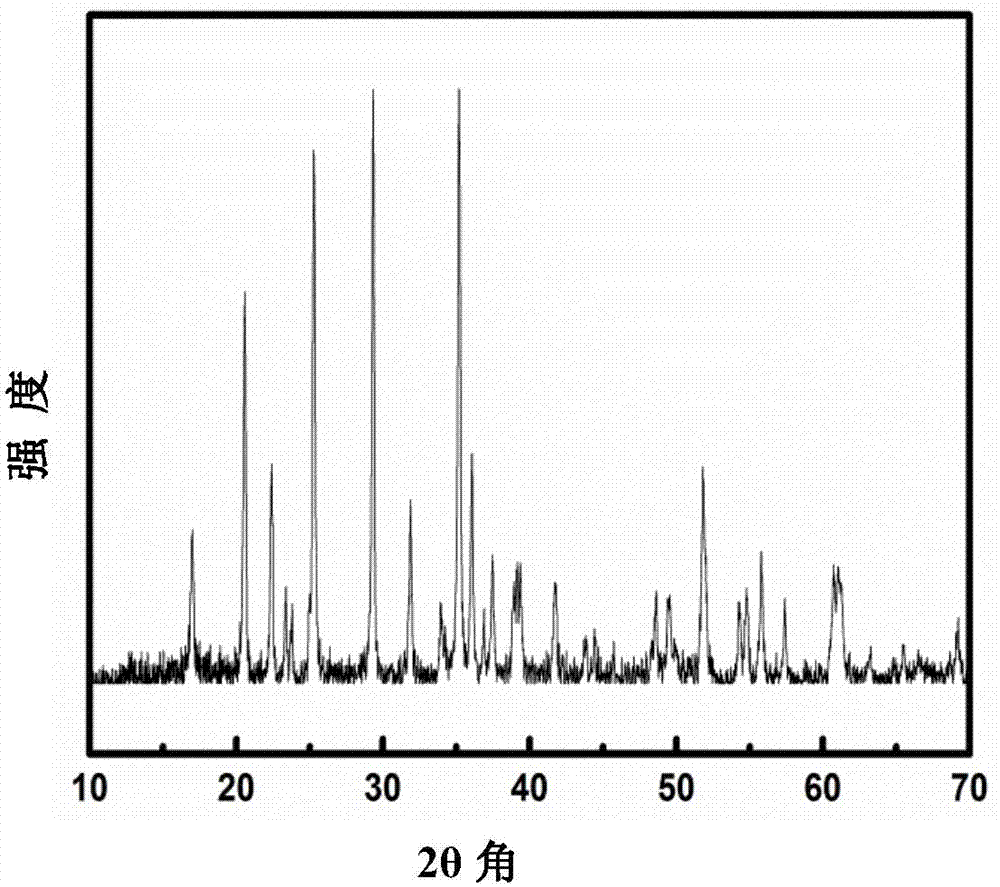

Anion/cation-doped and modified lithium ion battery (4:4:2)type ternary cathode material and preparation method thereof

InactiveCN104253273AUniform particle size distributionHigh crystallinityCell electrodesSecondary cellsSodium-ion batteryCobalt

The invention relates to an anion / cation-doped and modified lithium ion battery (4:4:2)type ternary cathode material and a preparation method thereof, which belong to the lithium ion battery field. A general chemical formula of the cathode material is Li(Ni0.4Co0.2Mn0.4)1-xMxO2-yNy, M is Ti, Mg, Al or Cu; N is F, Cl or Br; x is greater than 0 and less than or equal to 0.15; and y is greater than 0 and less than or equal to 0.15. The preparation method comprises the following steps: weighing soluble lithium source, nickel source, manganese source, cobalt source and metal M salt and N salt according to mol ratio, respectively using deionized water for dissolving, adding a citric acid solution for uniformly mixing and stirring, using concentrated ammonia liquor to adjust pH value, and heating and evaporating to obtain gel, heating and drying the gel, performing twice calcination and grinding to obtain the anion / cation-doped and modified lithium ion battery (4:4:2)type ternary cathode material. The cathode material has the advantages of uniform particles, smooth surface, good crystallization performance, high specific capacity and cycle performance. The material is suitable for large scale production, and can be used for lithium ion batteries cathode material.

Owner:JIANGNAN UNIV

Preparation method and product of flowerlike lithium manganese phosphate nano-particles

InactiveCN104326467ASimple processEasy to controlMaterial nanotechnologyPhosphorus compoundsLithium sulphateNanoparticle

The invention discloses a preparation method of flowerlike lithium manganese phosphate nano-particles. The preparation method comprises the following steps: mixing ethylene glycol with water in a volume ratio of 1 to (1-2) to obtain an ethylene glycol / water mixed solvent; taking one part of the ethylene glycol / water mixed solvent to mix with manganese sulfate to obtain a mixed solution I with concentration of 0.1-0.2mol / L; then, taking one part of the ethylene glycol / water mixed solvent to mix with lithium sulfate, ammonium dihydrogen phosphate and sodium hydroxide to obtain a mixed solution II, wherein the concentration of the lithium sulfate in the mixed solution II is 0.15-0.3mol / L; adding the mixed solution I into the mixed solution II, uniformly stirring to obtain a precursor solution, performing hydrothermal reaction for 8-24 hours at 160-240 DEG C, and then, performing post-treatment to obtain the flowerlike lithium manganese phosphate nano-particles. According to the preparation method disclosed by the invention, by precisely controlling the charging sequences and the reaction conditions, a method of preparing the flowerlike lithium manganese phosphate nano-particles is obtained, wherein the method is simple in process and easy to control.

Owner:ZHEJIANG UNIV

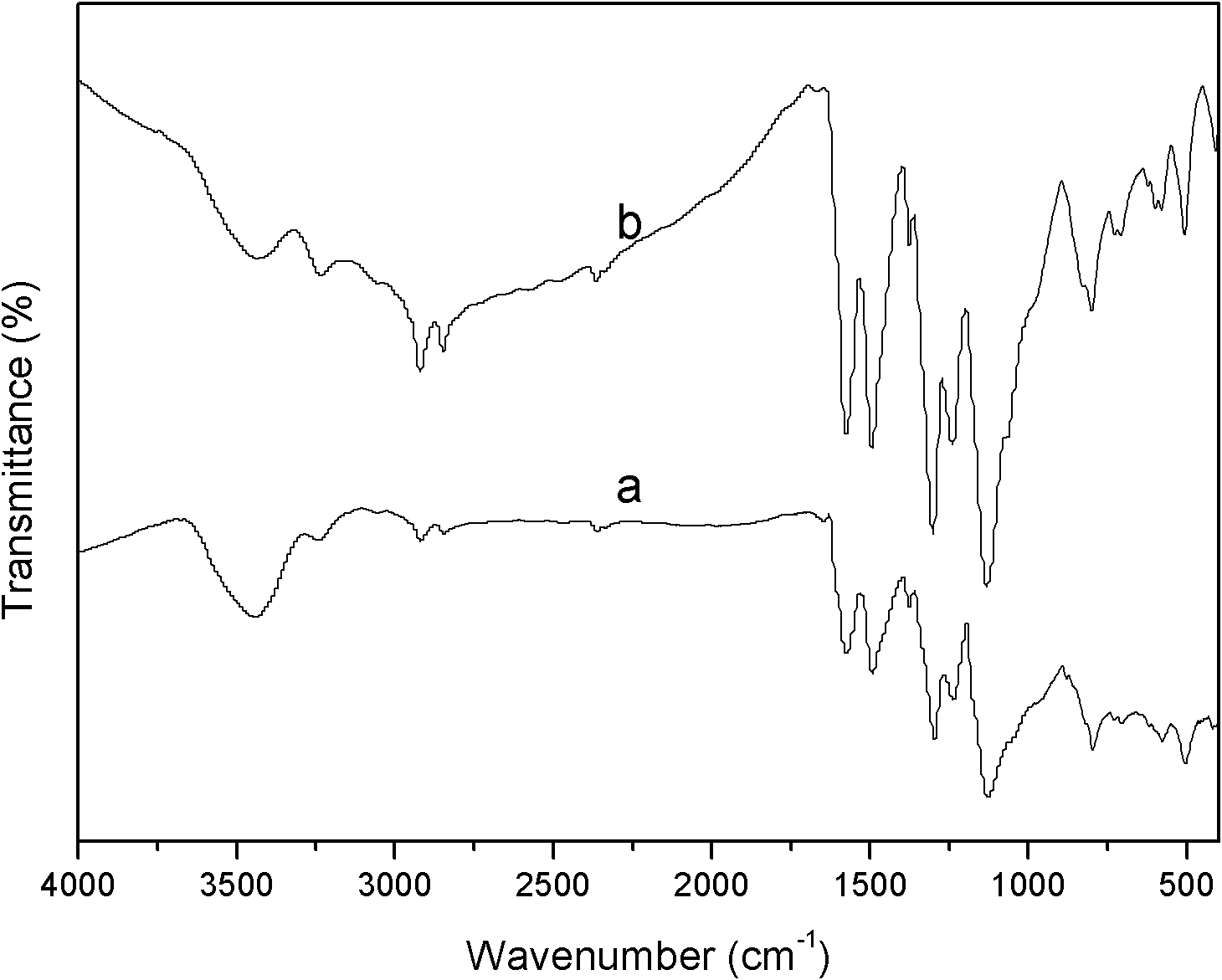

Polyaniline/silver conductive nanocomposite material and preparation method thereof

The invention relates to a polyaniline / silver conductive nanocomposite material and a preparation method thereof, which belong to the technical field of composite materials. In the method, aniline is polymerized to form polyaniline and silver ions are reduced in situ at the same time by adopting an opposite phase microemulsion polymerization method without the addition of an oxidizer or a reducer and by effectively utilizing UV irradiation technology; and silver particles are uniformly dispersed in the polyaniline to form a nano-core-shell structure of which silver particles are coated by the polyaniline. By using the method, the problem of system incompatibility in a process of compounding a metal with the polyaniline in situ is solved, and the problem of agglomeration when nano-silver particles and the polyaniline are polymerized is solved, so that the generated nano-silver particles are dispersed in the polyaniline uniformly to form the nano-core-shell structure. Therefore, the conductivity, the thermodynamic stability and the processability of the polyaniline are improved effectively.

Owner:CENT SOUTH UNIV

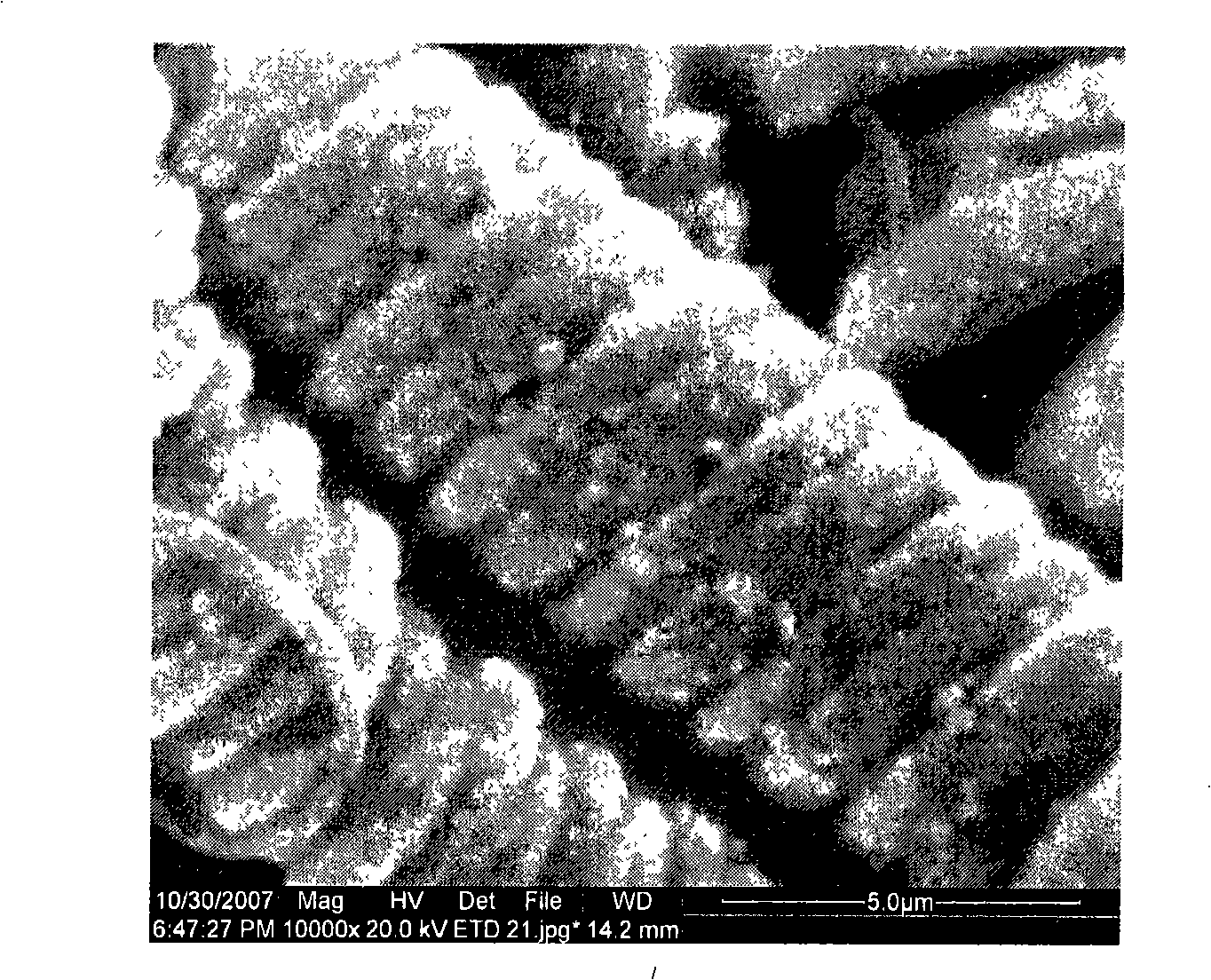

Process for preparing micro-coiled carbon fiber/Ni composite material by chemical nickel plating

InactiveCN101285180AGood particle dispersionThickness is easy to controlLiquid/solution decomposition chemical coatingFiberNickel salt

The invention relates to a method for preparing a micro-coiled carbon fiber / Ni composite material by utilization of chemical nickel plating. The method is characterized in that: firstly, surface roughenine treatment for micro-coiled carbon fiber particles is performed; sensibilization is performed in SnCl2 hydrochloric acid solution; activation is performed in PdCl2 hydrochloric acid solution; secondly, chemical nickel plating is performed. Plating solution for chemical nickel plating is prepared by nickel salt, sodium citrate, ammonium chloride, sodium hypophosphate, thiourea and sodium dodecyl benzene sulfonate. The technological parameters of the plating solution are pH: 8.0 to 9.0; temperature: 50 to 90 DEG C; time: 10 to 60 minutes. Afterward, the micro-coiled carbon fiber / Ni composite material is prepared by sintering under the function of shielding gas. The method has the advantages that: the micro-coiled carbon fiber surface chemical nickel plating formula and technique are simple and convenient and easy to operate; the plating solution is stable and difficult to go bad; a micro-coiled carbon fiber surface cladding obtained is compact and uniform; the particle dispersibility is good; and the thickness of a micro-coiled carbon fiber / Ni composite material cladding prepared is easy to control.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

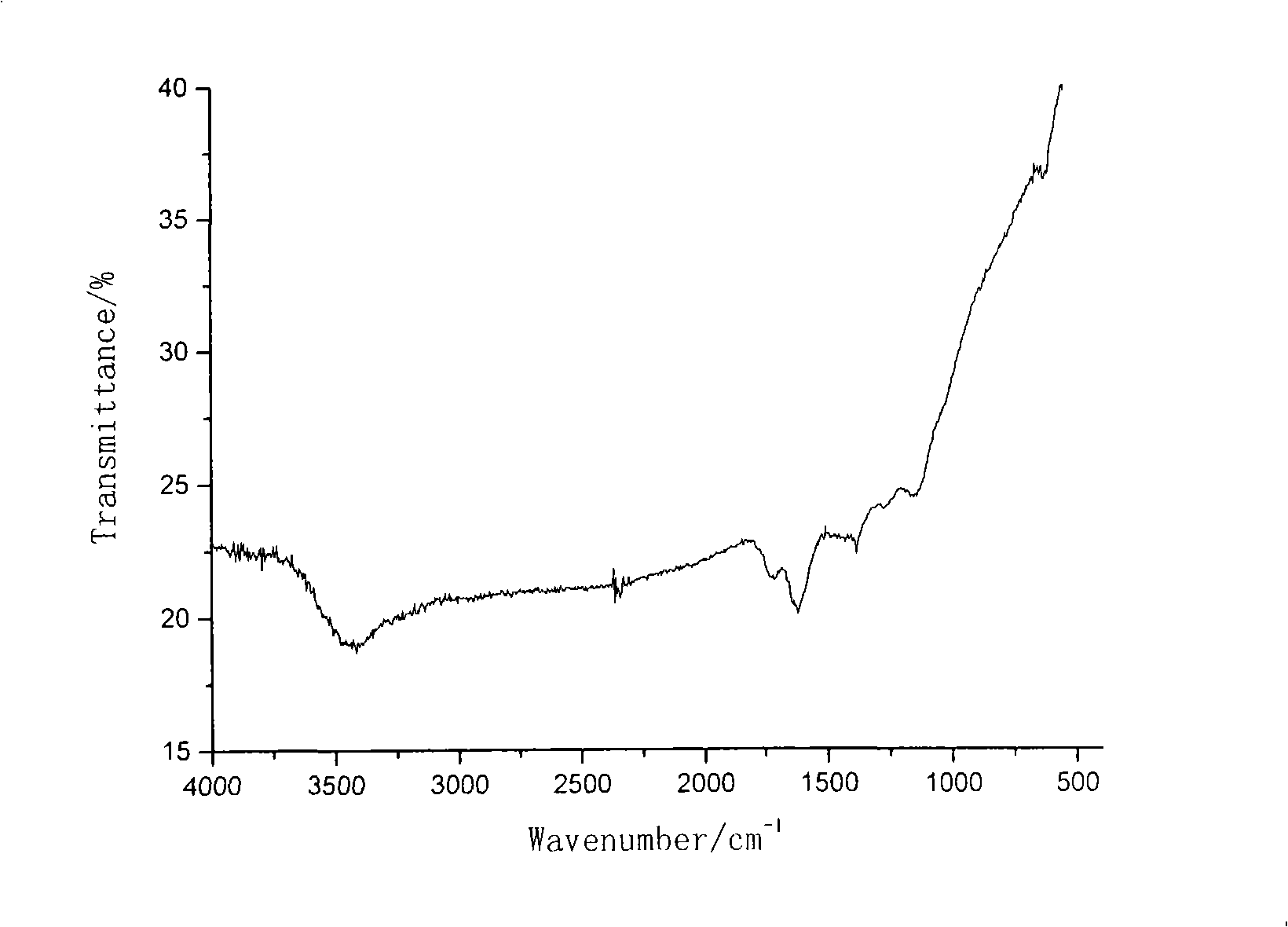

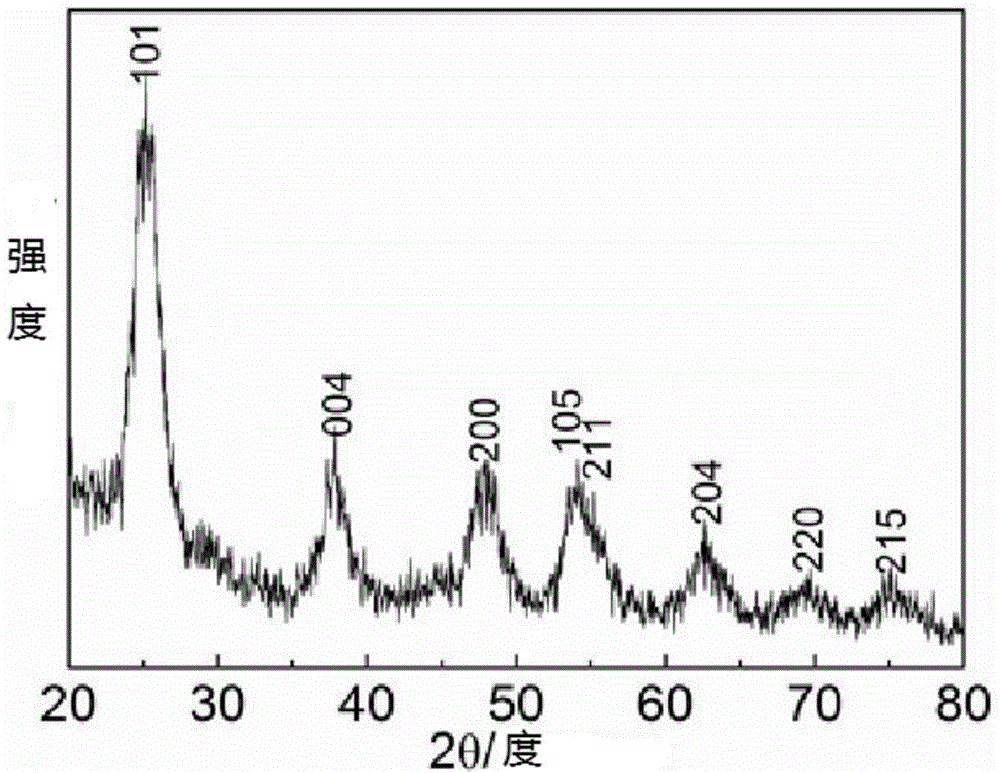

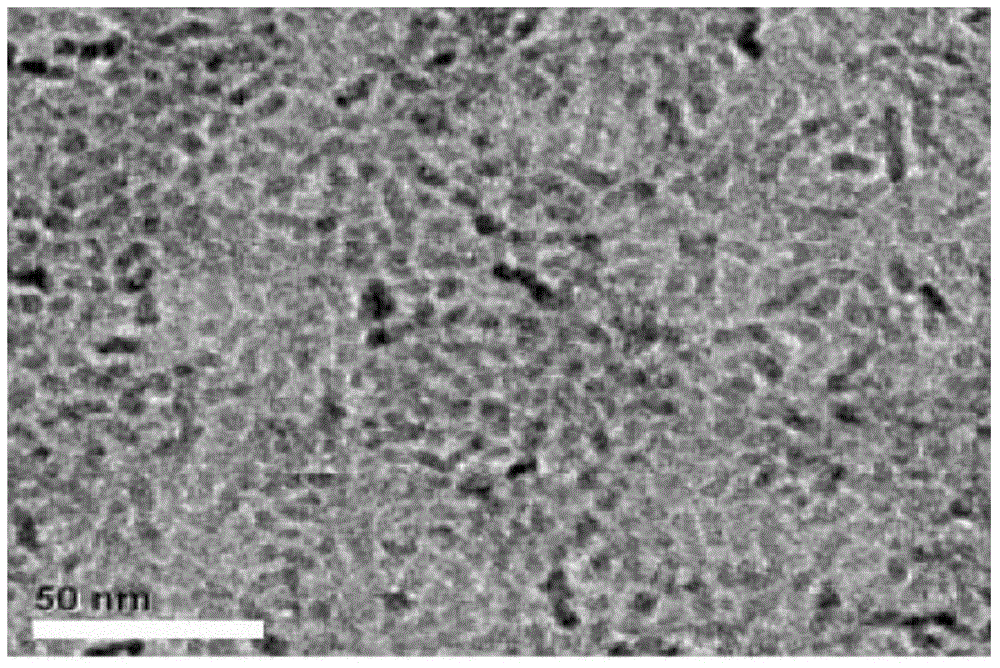

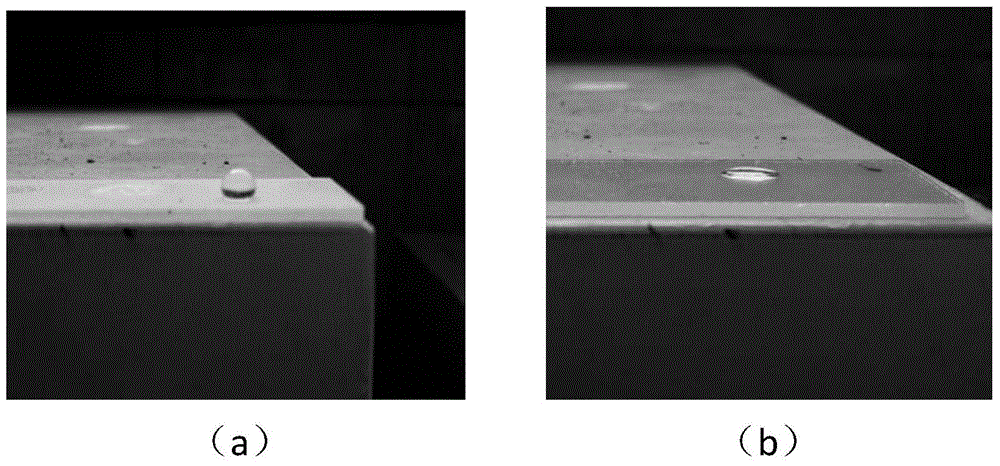

Method for preparing nanometer titanium dioxide super-hydrophobic film

Disclosed is a method for preparing a nanometer titanium dioxide super-hydrophobic film. Nanometer titanium dioxide is prepared by a hydrothermal method, on basis of hydrolysis reaction, titanium n-propoxide with hydrolysis reaction under natural conditions is selected as a titanium source, nanometer titanium dioxide with good crystal form is obtained through controlling of reaction conditions and used for preparing a composite material, anatase-type crystal form is used for preparing a super-hydrophobic thin film, and then the super-hydrophobic thin film is formed after modification by low surface energy substance stearic acid. The method for preparing the nanometer titanium dioxide super-hydrophobic film has the advantages that the method is low in preparation costs, simple and rapid, a contact angle of the prepared super-hydrophobic film is water contact angle of hydrophobic nanometer titanium dioxide, which is 95.3 degrees, rolling angle is 0-4 degrees, grain size of nanometer titanium dioxide is about 7nm, grain dispersibility and stability are good, effects are still good though the nanometer titanium dioxide super-hydrophobic film is put in air for a period of time, acidic and alkali resistance is good, and the nanometer titanium dioxide super-hydrophobic film can be used for resisting water, freezing and metallic corrosion.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

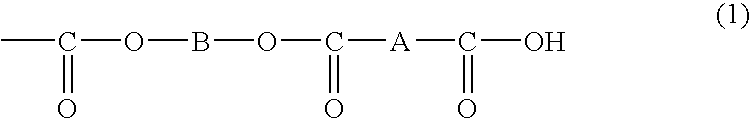

Organic polymer particles and process for producing same

ActiveUS20080078974A1Reduction factorGood particle dispersionSynthetic resin layered productsCellulosic plastic layered productsPolymer sciencePhenyl group

Organic polymer particles having a structure shown by the following formula (1) are disclosed.wherein A represents an alkylidene group, an alkylene group, a cyclohexylene group, or a phenylene group, and B represents a linear or branched alkylene group or an alkylidene group having 1 to 6 carbon atoms.

Owner:JSR CORPORATIOON

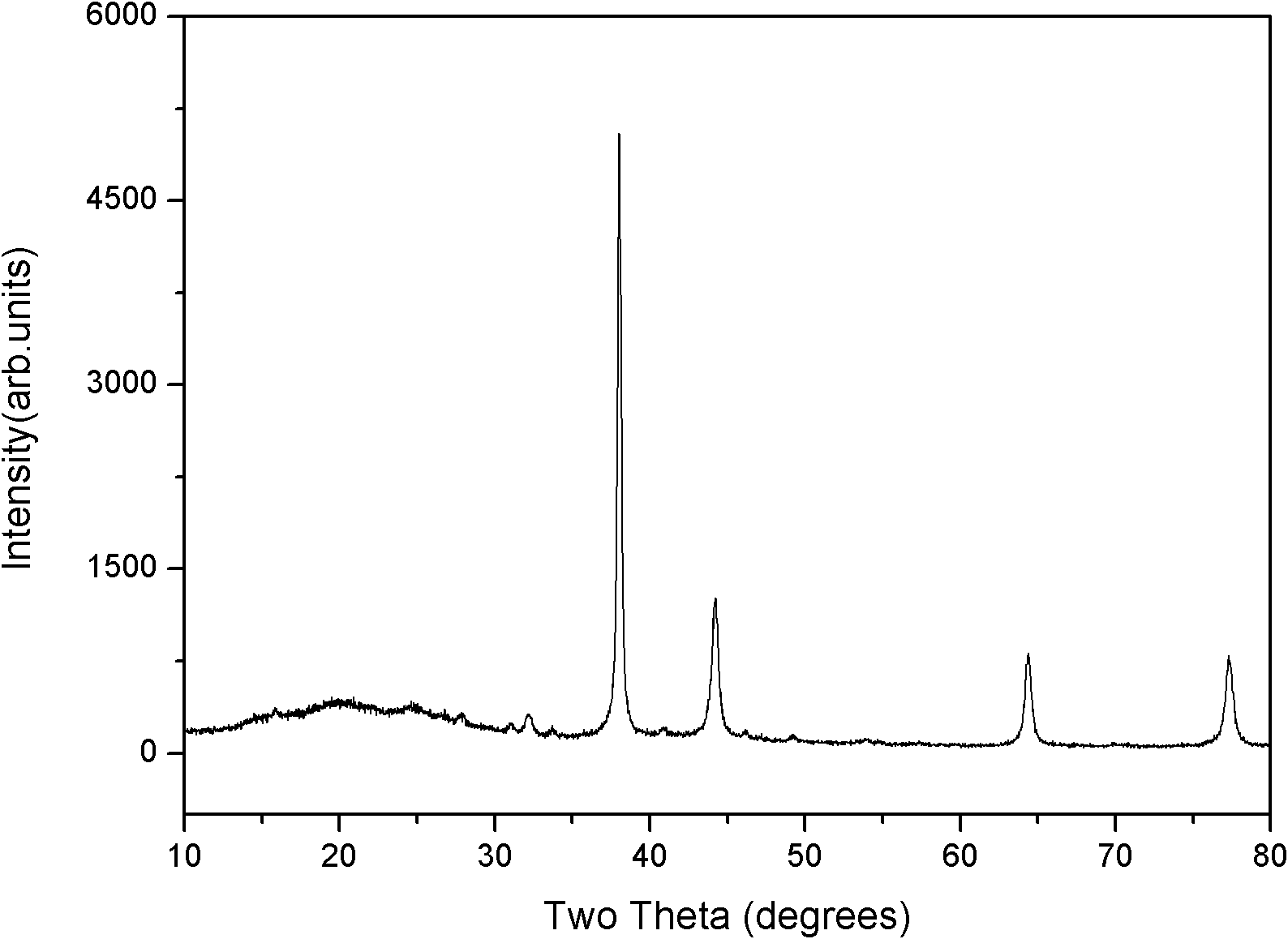

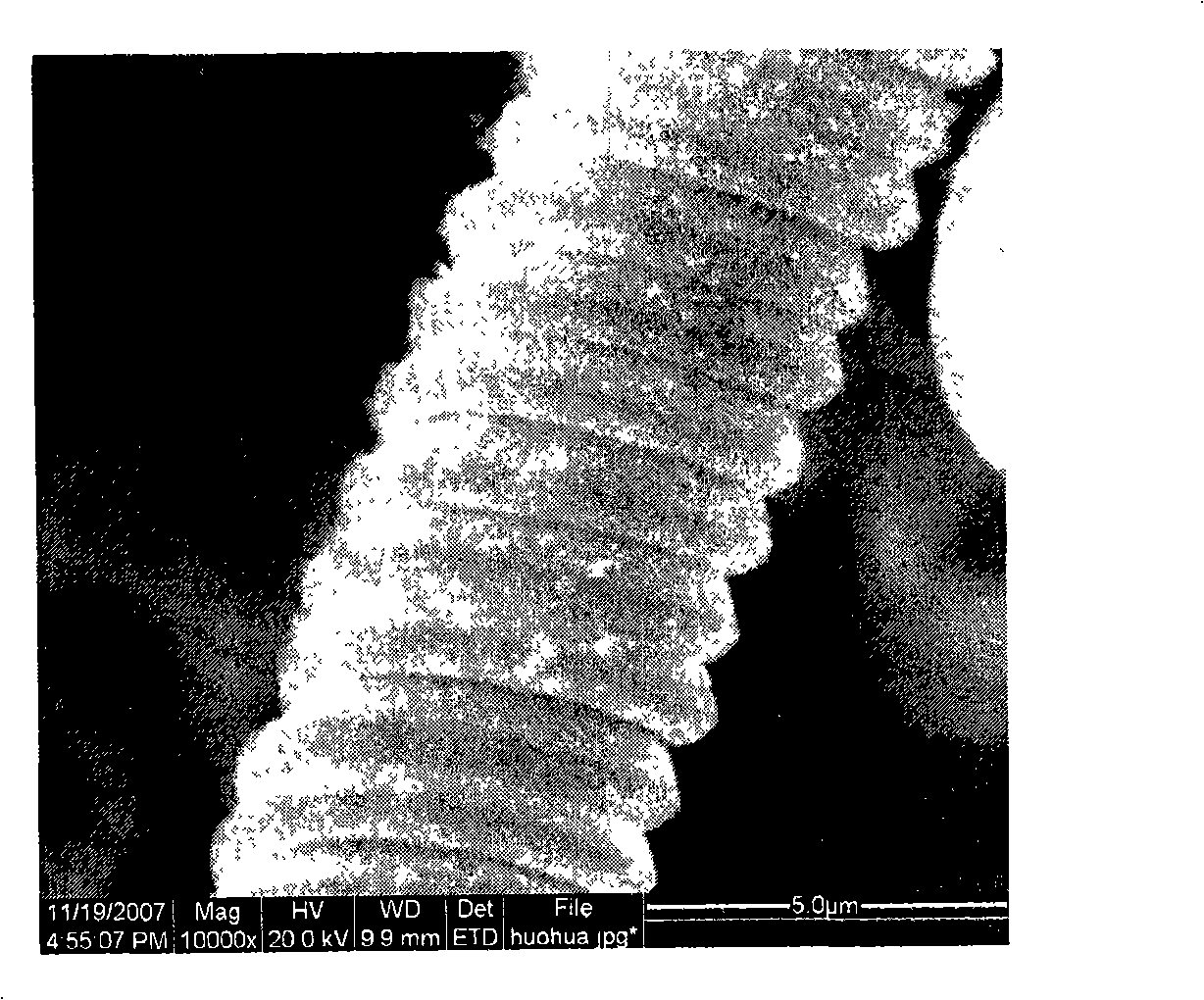

Method for preparing helical carbon fiber

InactiveCN101451278AHigh purityIncrease productionInorganic material artificial filamentsLiquid/solution decomposition chemical coatingFiberChemical plating

The invention relates to a method for preparing a spiral carbon fiber. The method is characterized in that graphite is used as a basal body and is subjected to deoiling, sensitizing, activation treatment to form an even nickel-phosphorus alloy layer on the surface of the graphite through a chemical plating process, and the nickel-phosphorus alloy layer is used as a catalyst; under the action of a compound containing S, N2 is used as carrier gas; the flow of reaction gas C2H2 / H2 is controlled to be between 1 / 2 and 1 / 6; the reaction temperature is between 600 and 800 DEG C; the reaction time is between 1 and 3 hours; and the carbon fiber with two spiral structures is prepared, namely a single spiral carbon fiber and a double spiral carbon fiber. The diameter of a spiral tube is between 0.5 and 9 mu m; the thread pitch is between 0.1 and 3 mu m; and the length reaches the spiral carbon fiber of millimeter level. The method is simple, convenient and easy to operate, has an even and dense plating layer, good particle dis paster persity and high catalytic activation; the manufactured spiral carbon fiber has high purity and yield and can control the spiral shape of the spiral carbon fiber through changing the reaction condition.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

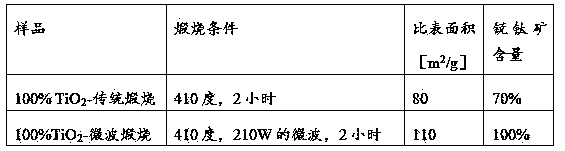

Nanometer titanium dioxide powder for flue gas deodorization/denitration catalyst and preparation method and application thereof

ActiveCN104437469AStable specific surface areaSmall particlesDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAdditive ingredientAmmonium paratungstate

The invention discloses nanometer titanium dioxide powder for a flue gas deodorization / denitration catalyst and a preparation method thereof. The nanometer titanium dioxide powder is prepared from the following ingredients in mass percentage: 50-100% of TiO2, 0-50% of SiO2, 0-15% of WO3 and 0-10% of V2O5; the preparation method of the nanometer titanium dioxide powder comprises the following steps: carrying out hydrolysis on titanyl sulfate or titanium sulfate used as a raw material in a microwave heating manner to obtain titanic hydroxide, filtering, washing, adding with deionized water, pulping to form 20-80% metatitanic acid slurry, adding with SiO2 sol, a V2O5 precursor-ammonium metavanadate and / or a WO3 precursor-ammonium paratungstate, adjusting the pH value to be within a range of 8-11, carrying out atmospheric-pressure microwave hydro-thermal treatment, performing filter pressing, microwave sintering and crushing to obtain the nanometer titanium dioxide powder. The invention also relates to an application of the nanometer titanium dioxide powder used as the flue gas deodorization / denitration catalyst.

Owner:河北林格环保科技有限公司

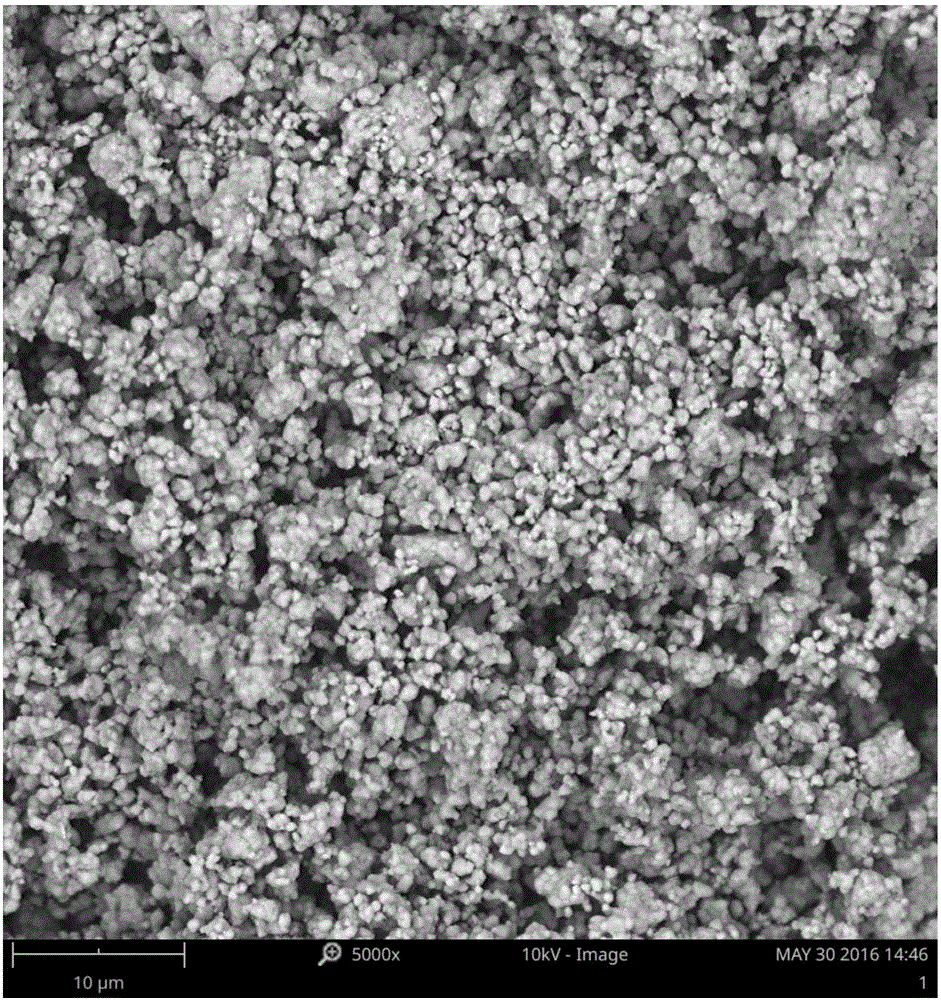

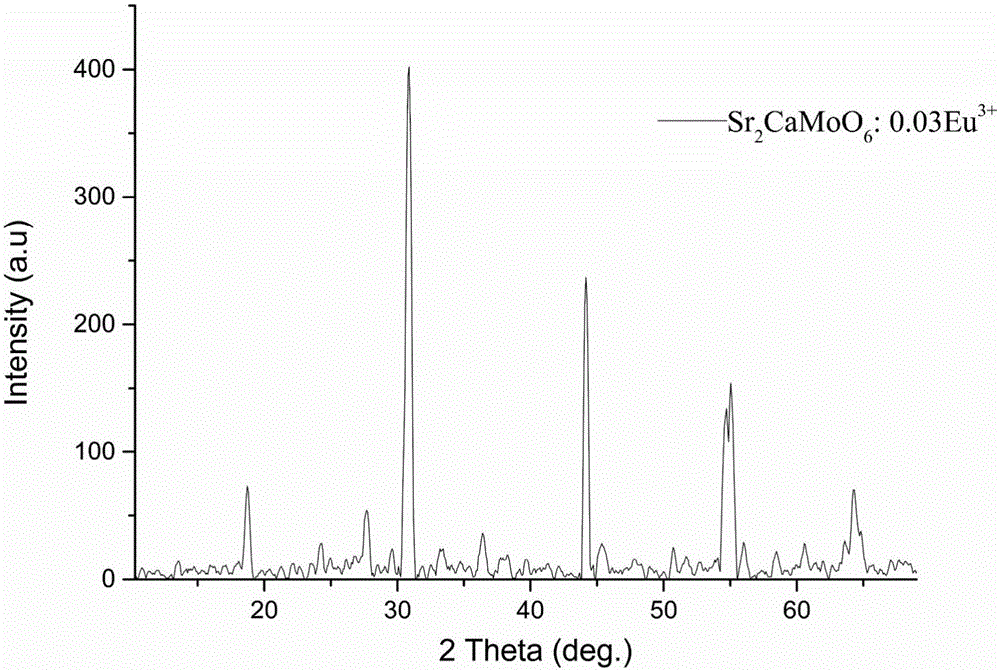

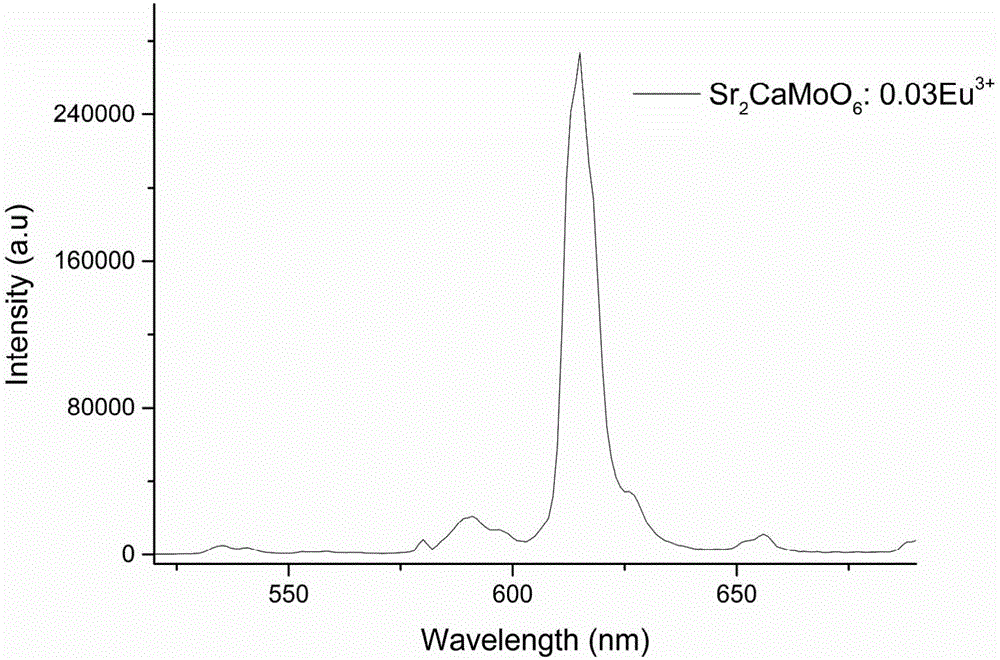

Preparation method of Eu<3+> doped molybdate red fluorescent powder used for white light LED (Light Emitting Diode)

InactiveCN106190119AReduced sinteringShort sintering timeEnergy efficient lightingLuminescent compositionsMolybdateMicrowave

The invention discloses a preparation method of Eu<3+> doped molybdate red fluorescent powder used for a white light LED (Light Emitting Diode). A chemical formula of the red fluorescent powder is Sr2CaMoO6:xEu<3+>, wherein x is greater than or equal to 0.01 and less than or equal to 0.15. Raw materials are weighed according to a stoichiometric ratio, the raw materials and a fluxing agent are fully and evenly mixed, and a mixture is added into double crucibles made of corundum, wave absorbent is arranged between the double crucibles, the double crucibles are loaded into a microvan, temperature is quickly raised to 750 to 950DEG C, the mixture is sintered in an oxidation environment, and heat preservation time is 0.5 to 4h; finally, cooling, grinding, washing and drying are carried out to obtain the red fluorescent powder used for the white light LED. During microvan sintering, the fluxing agent is added to accelerate the formation and growth of molybdate polycrystal, the sintering degree of the fluorescent powder is obviously lowered, sintering time is obviously shortened, a powder body is loose and does not need to be mechanically smashed, in addition, the shapes of aluminate fluorescent powder particles are effectively controlled, and the particles with a small particle diameter and even distribution are obtained, wherein the appearance of the particles is similar to a sphere.

Owner:SHANGHAI INST OF TECH

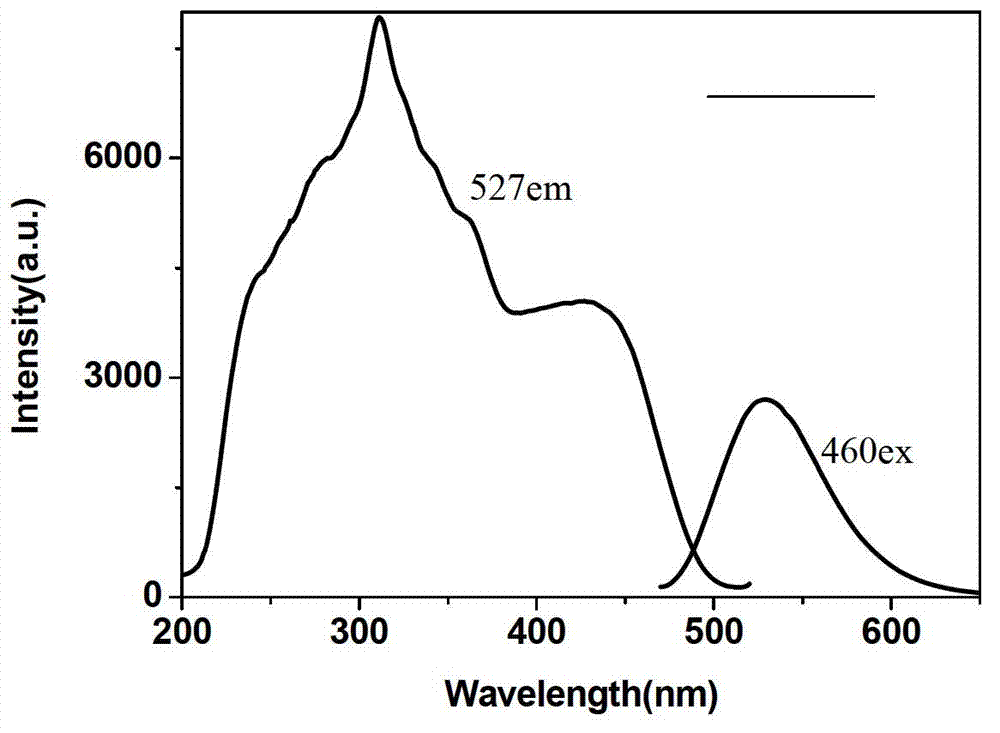

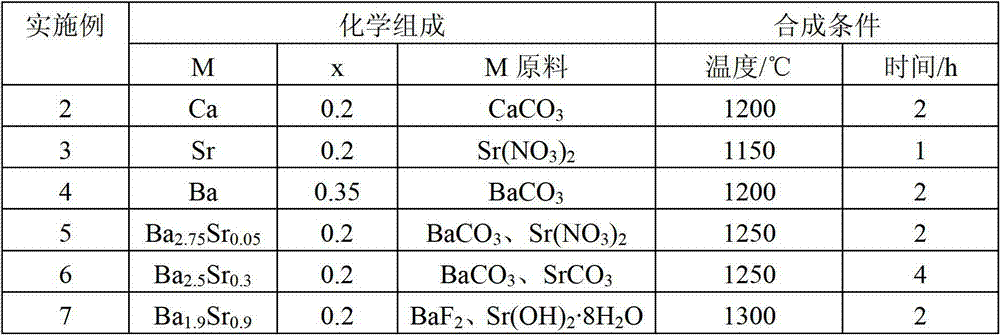

Preparation method of M3Si6O12N2: xRe system green fluorescent powder

InactiveCN102888218AHigh activityFacilitated DiffusionGas discharge lamp usageLuminescent compositionsRare-earth elementLight-emitting diode

The invention discloses a preparation method of M3Si6O12N2: xRe system green fluorescent powder. According to the preparation method, M is one or the mixture of more than two of Ca, Sr and Ba; Re means a rare-earth element; and x is more than or equal to 0.2 mol% and less than or equal to 20mol%. The method comprises the steps as follows: weighing raw materials based on the stoichiometric ratio of various elements in the chemical formula of fluorescent powder; fully and uniformly mixing the raw materials; then placing the mixture into a sagger manufactured by a wave-transmitting material; positioning the sagger into a special microwave oven; adjusting the microwave power to control the temperature raise rate under a certain gas atmosphere; heating to reach the synthesizing temperature; and finally, cooling and simply grinding to obtain the system green fluorescent powder. Compared with traditional high-temperature solid phase method, the preparation method disclosed by the invention adopts microwave heating, therefore, the synthesizing temperature is reduced to 1000 to 1500 DEG C, moreover, the reaction time is reduced, and the production efficiency is improved; and the prepared green fluorescent powder has the advantages of fine grain size, high crystallizing performance, narrow range of size distribution, regular appearance and shape, high particle dispersing performance, and the like, and is specifically applied to white light and backlight LEDs (Light Emitting Diodes).

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

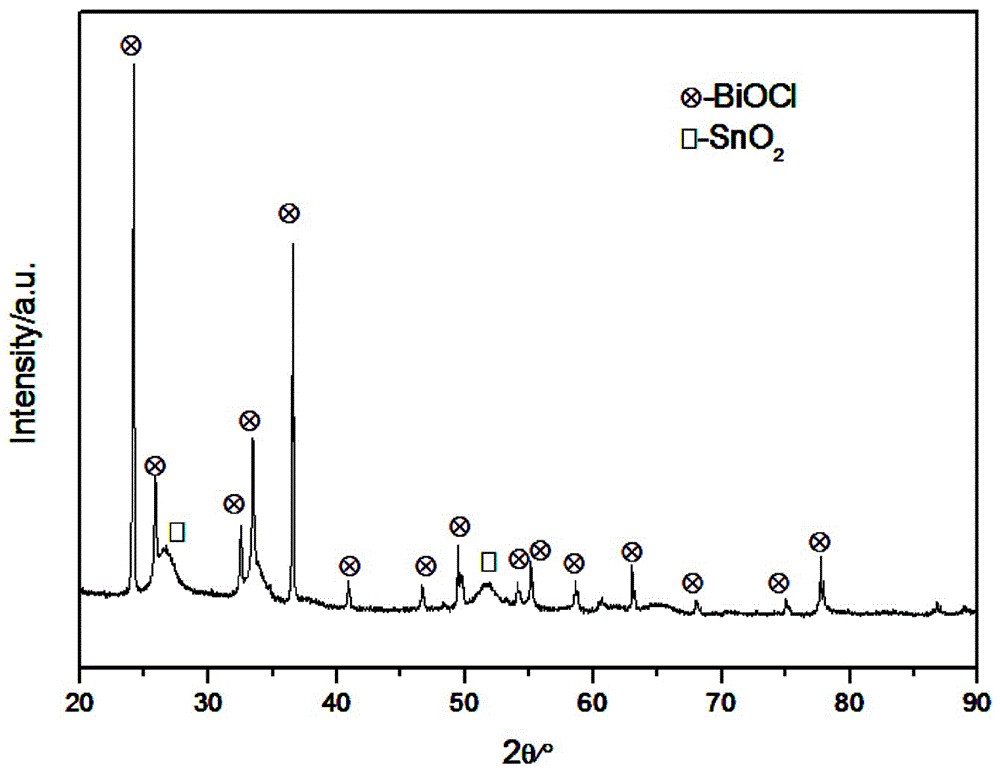

High-performance BiOCl/SnO2 heterojunction material and preparing method thereof

InactiveCN105728004AImprove physical performanceGood physical propertiesPhysical/chemical process catalystsWater/sewage treatment by irradiationHeterojunctionSingle crystal

The invention relates to a high-performance BiOCl / SnO2 heterojunction material and a preparing method and application thereof.The heterojunction material is prepared in the mode that SnO2 nanometer particles are attached to the surfaces of BiOCl single crystal nanometer sheets, the size of the SnO2 nanometer particles ranges from 5 nm to 30 nm, the width of the BiOCl single crystal nanometer sheets ranges from 20 nm to 500 nm, and the thickness of the BiOCl single crystal nanometer sheets ranges from 10 nm to 50 nm.The preparing method includes the steps that inorganic tin salt and inorganic bismuth salt serve as raw materials and are subjected to an one-step precipitation reaction and solid-liquid separation, dried, calcined and the like to obtain the BiOCl / SnO2 heterojunction material.By means of the BiOCl / SnO2 heterojunction material, the performance of single constituent elements can be developed, and the novel characteristic can be shown through the synergistic effect of heterojunctions.According to the preparing method, the one-step precipitation reaction method is adopted, the preparing method has the advantages that the process is simple, the growth condition is easy to control, energy consumption and cost are low, the preparation cycle is short, and the environment is friendly, the performance of the SnO2 materials can be improved, the obtained BiOCl / SnO2 heterojunction material can be used for degrading organic compounds in water, and particularly treatment of a trace of toxic, harmful and refractory organic compounds in water is achieved.

Owner:CHINA THREE GORGES UNIV

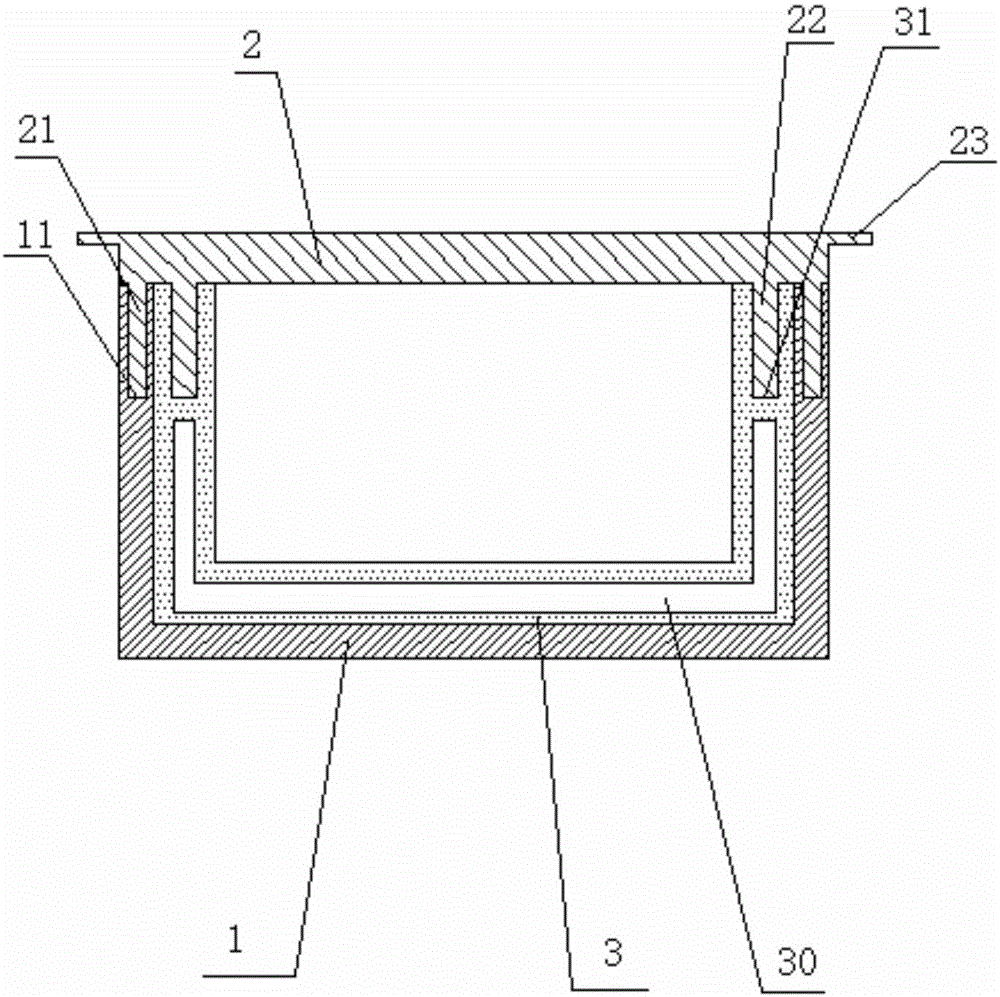

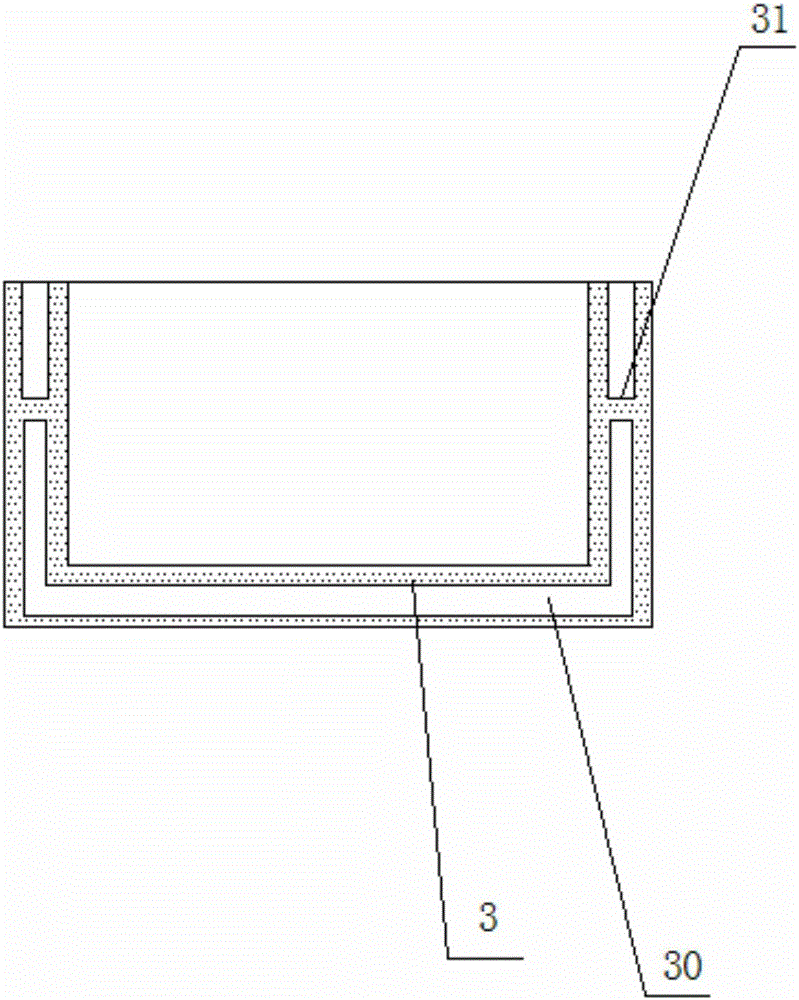

Energy-saving heat preservation box

InactiveCN106241069AImprove insulation effectSimple structureDomestic cooling apparatusLighting and heating apparatusEngineering

Owner:合肥海宝节能科技有限公司

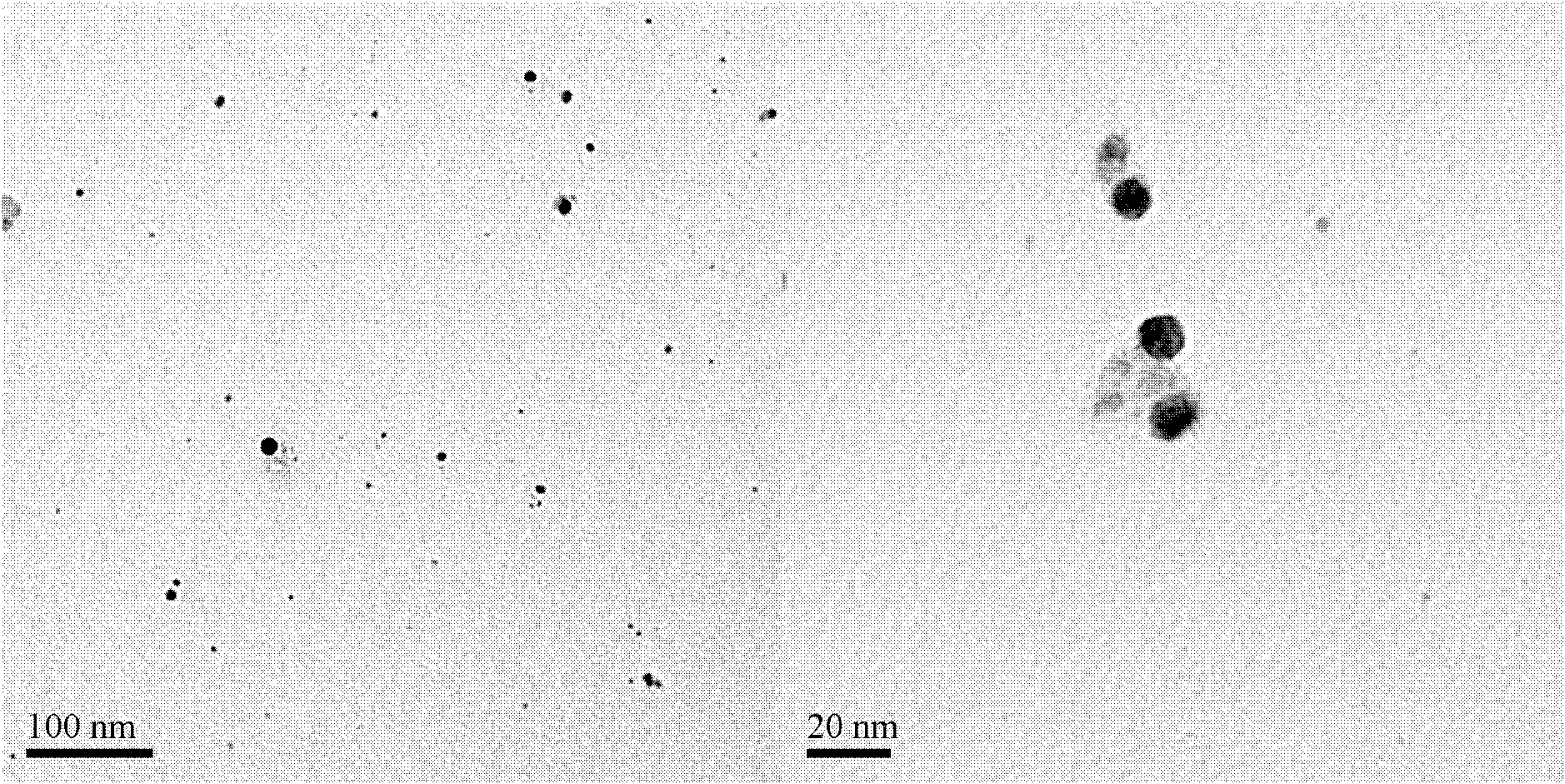

Method for producing nickel particle, nickel particle obtained by the production method, and electroconductive paste using the nickel particle

InactiveUS20090014694A1Improve adhesionIncrease capacitanceMaterial nanotechnologyTransportation and packagingNickel saltPolyol

The present invention is directed at providing fine nickel particles with a sharp particle size distribution, and providing an electroconductive paste using the nickel particles. In order to obtain the nickel particles capable of achieving the purpose, a method for producing the nickel particle by elevating a temperature of the reactive solution containing a nickel salt and a polyol to a reduction temperature, and reducing the nickel salt in the reactive solution which is characterized in that the reactive solution is prepared to contain a carboxylic acid or an amine having a carboxyl functional group and / or an amino functional group, and a precious metal catalyst before the solution temperature is elevated to the reduction temperature. Nickel particles obtained with the production method have an average image analytical particle diameter of 1 nm to 300 nm.

Owner:MITSUI MINING & SMELTING CO LTD

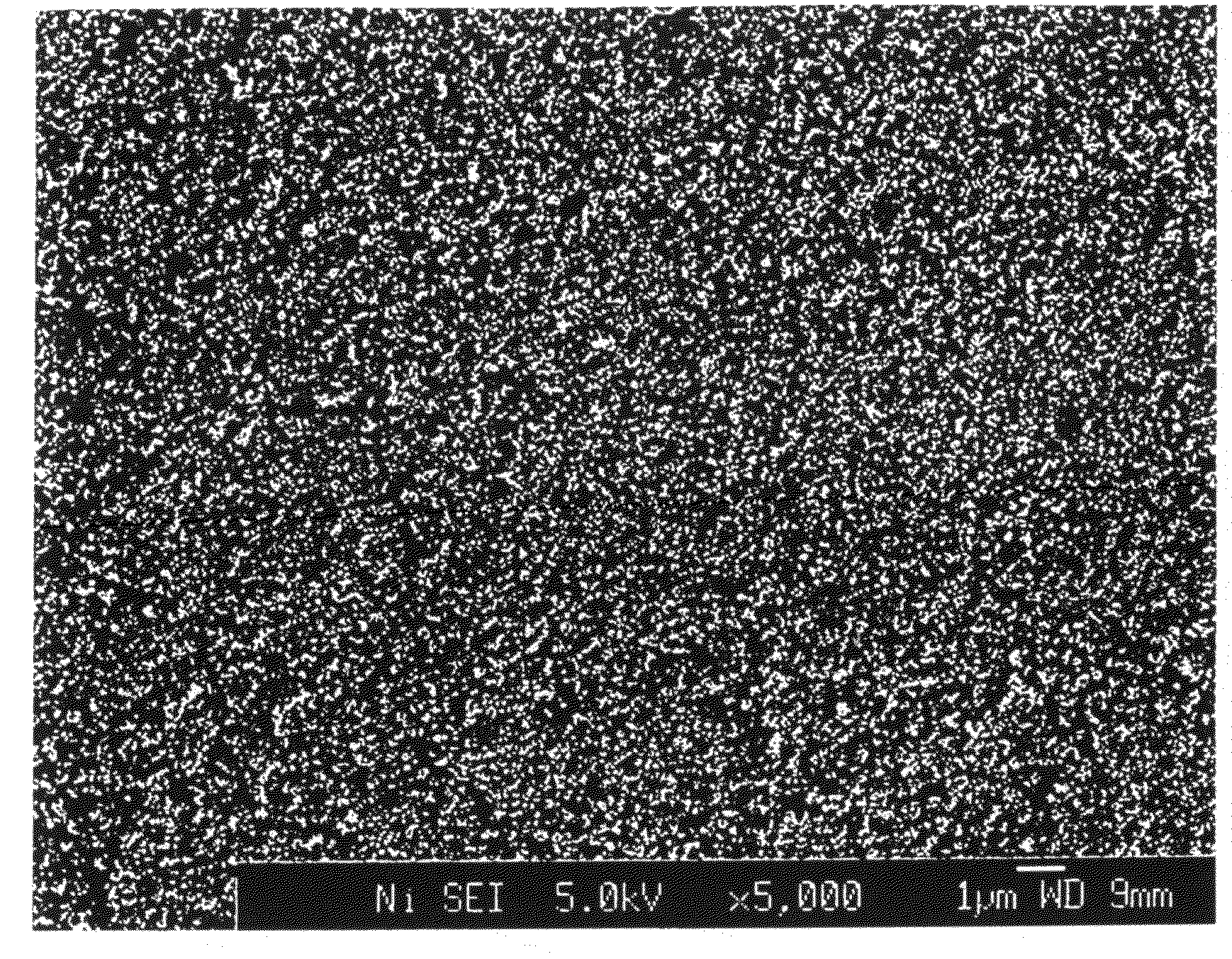

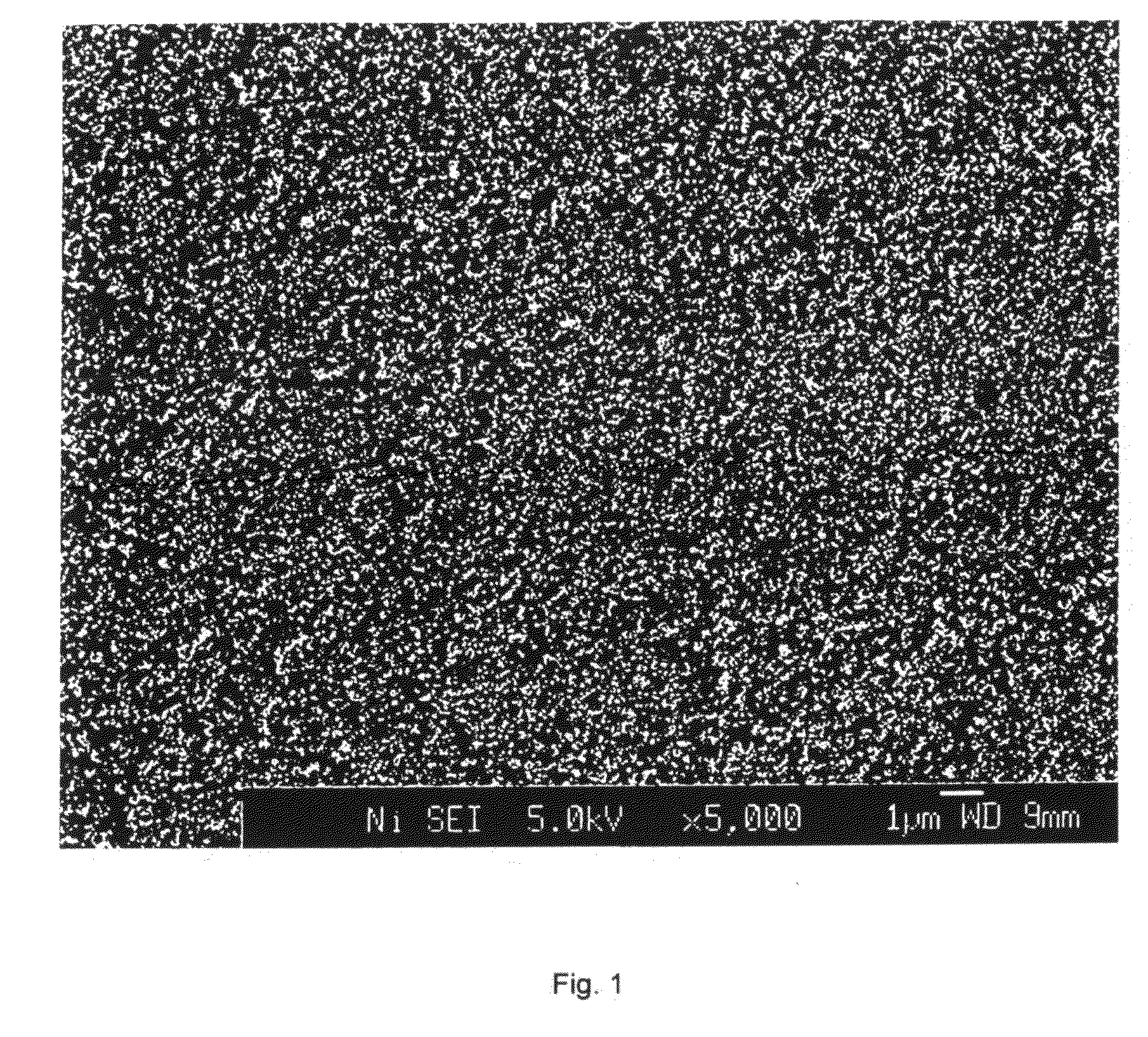

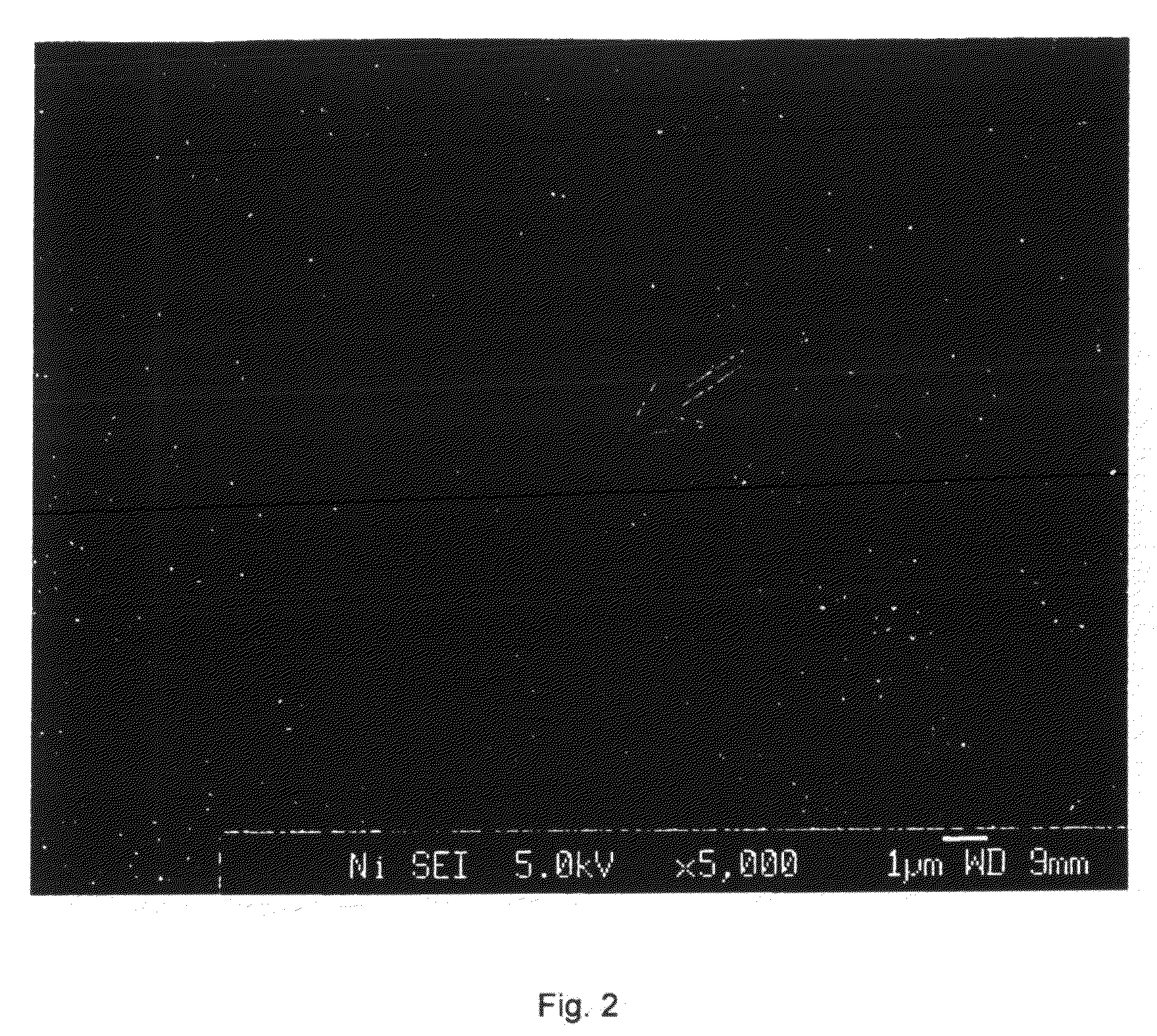

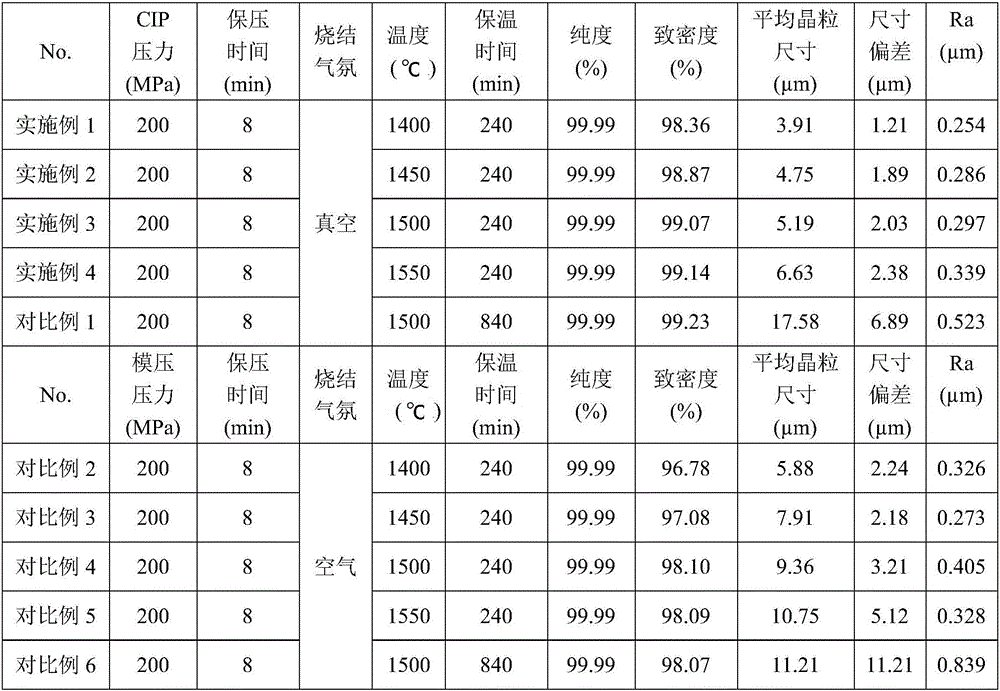

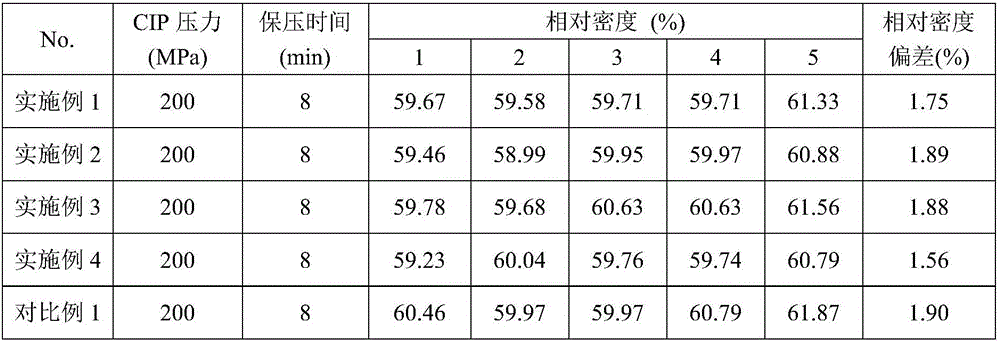

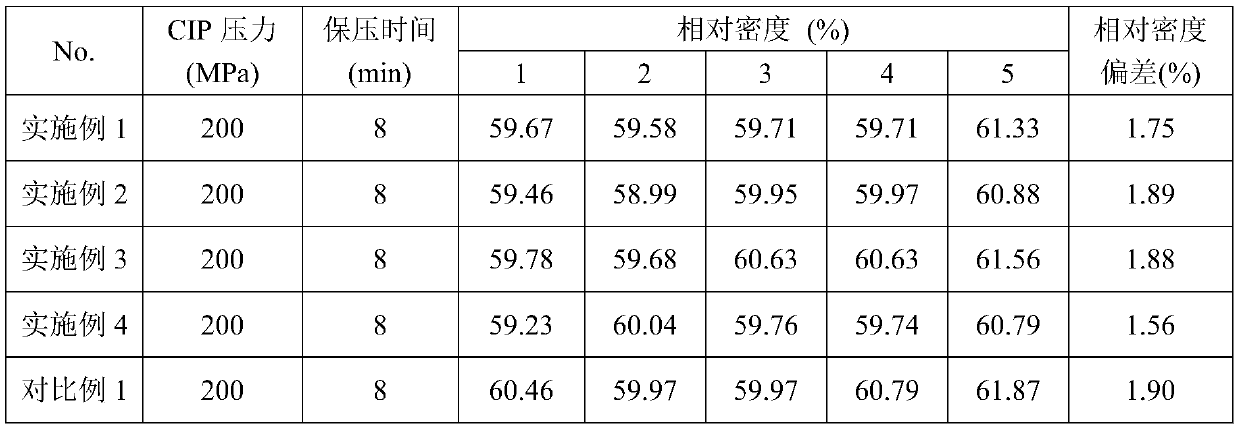

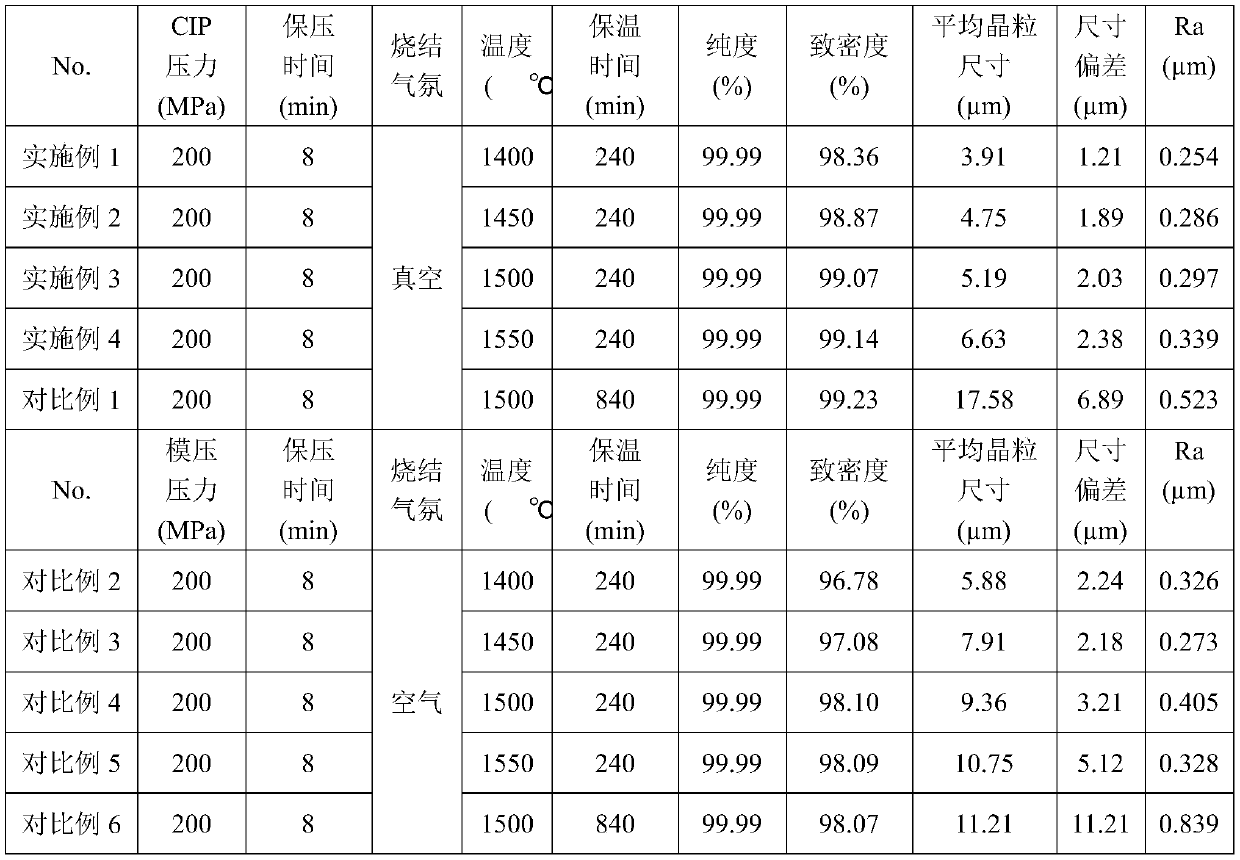

High-purity compact magnesium oxide target material and preparation method thereof

ActiveCN106587940AImprove particle size distributionGood particle dispersionVacuum evaporation coatingSputtering coatingSurface roughnessImpurity

The invention belongs to the technical field of novel material manufacturing and application and particularly relates to a high-purity compact magnesium oxide target material and a preparation method thereof. Magnesium oxide powder subjected to planetary ball milling are further subjected to isostatic cool pressing and vacuum sintering to obtain the near-net formed high-purity compact magnesium oxide target material, wherein a vacuum sintering temperature is 1400-1550 DEG C, heat preservation time is 2-10h, and a vacuum degree is 0.1-1.0Pa. The high-purity compact magnesium oxide target material prepared according to the method is 98.36% or above in compactness, 100ppm or below in total impurity element content, 7micron or blow in average grain size, 3.0micron or below in size deviation and 0.4micron or below in surface roughness Ra. The magnesium oxide target material prepared according to the method is high in purity and compactness and fine and uniform in grain size. The preparation method has advantages of short production cycle, low production cost, high production efficiency and availability for batch production.

Owner:GRIKIN ADVANCED MATERIALS

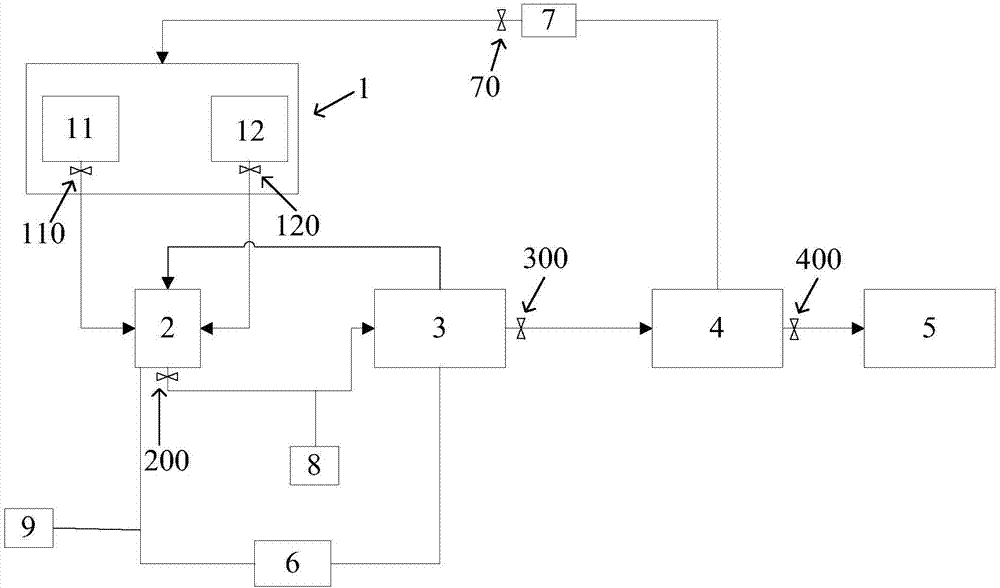

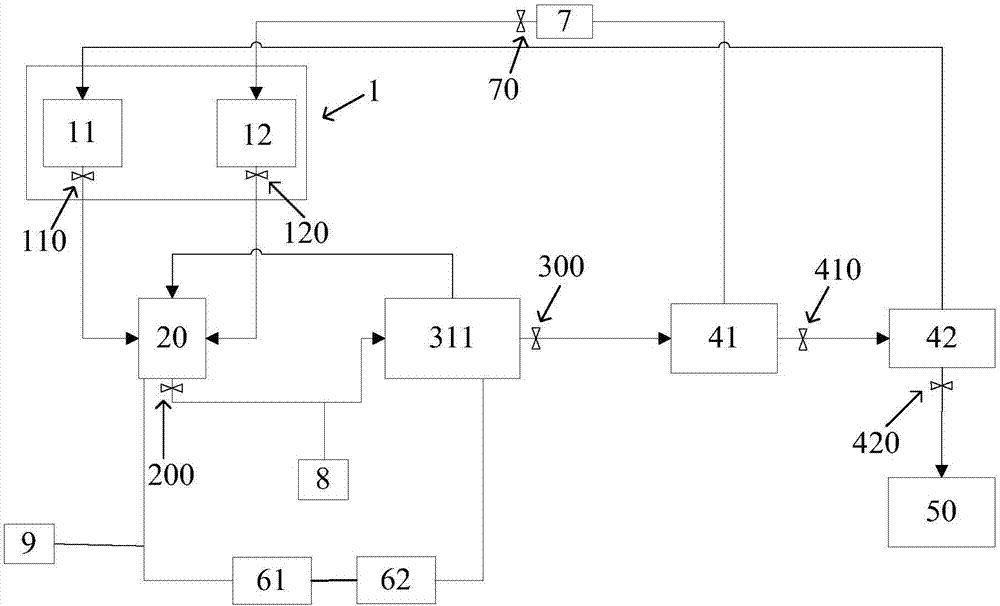

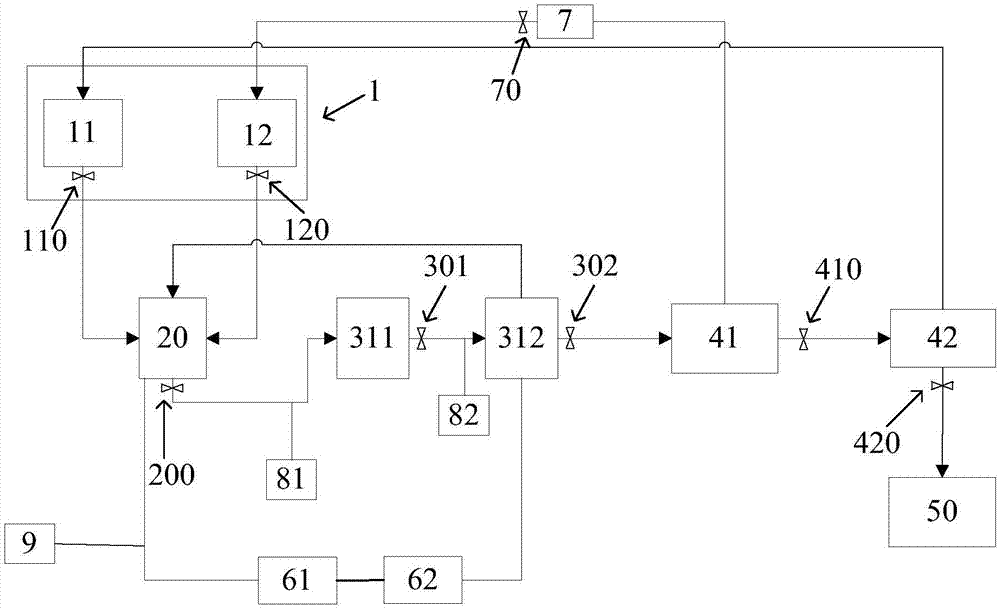

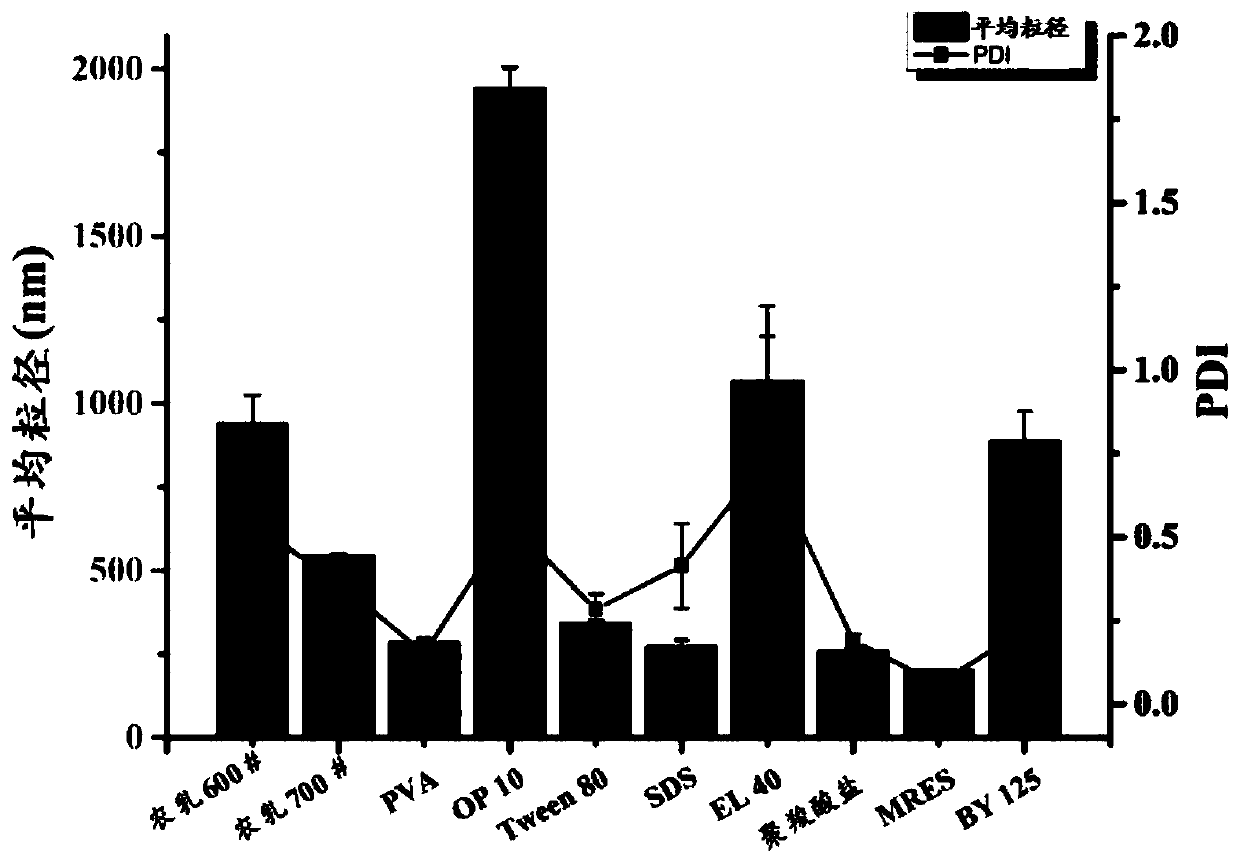

Automatic continuous production device for nanocapsules and method for preparing nanocapsules

PendingCN107961746ASmall particle sizeGood particle dispersionTransportation and packagingMixersMaterials preparationEmulsion

The invention relates to the field of nano material preparation, and in particular, relates to an automatic continuous production device for nanocapsules and a method for preparing the nanocapsules byusing the device. The device includes a storage tank, a shearing device, an emulsifying homogenizing device and a solvent recovery device which are connected in series in sequence through a pipeline,wherein the storage tank includes a dispersed phase storage tank for storing a dispersed phase material and a continuous phase storage tank for storing a continuous phase material; the emulsifying homogenizing device preferably includes a multistage emulsifier, a membrane emulsifier or a high pressure homogenizer or a combination thereof. The method for preparing the nanocapsules by using the device includes the steps: preparing the dispersed phase material and the continuous phase material respectively, mixing, carrying out high-speed shearing, emulsifying and homogenizing to obtain a fine emulsion, and then recovering to obtain the nanocapsules by a solvent. The device can prepare the nanocapsules with uniform and controllable particle size, the process is simple, the energy consumptionof the preparation process is low, and the large-scale automatic continuous production of the nanocapsules can be realized.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Preparation method of carbon-coated lithium manganese borate cathode material for lithium ion battery

InactiveCN104064773AShorten the diffusion pathUniform structureCell electrodesSecondary cellsManganeseLithium-ion battery

The invention relates to a preparation method of a carbon-coated lithium manganese borate cathode material for a lithium ion battery, belonging to the technical field of lithium ion batteries. The preparation method of the carbon-coated lithium manganese borate cathode material for the lithium ion battery comprises the following process steps of (1) mixing a lithium source compound, a manganese source compound, a boron source compound and a carbon source compound according to the molar ratio that Li to Mn to B to a carbon source is equal to (1-1.05) to 1 to 1 to (0.1-1.0), then, adding deionized water to form a solution, next, continuing to stir at the temperature of 50-90 DEG C to slowly evaporate water to form sol, and then, drying the sol at the temperature of 70-110 DEG C; (2) presintering under the protection of inert gases and at the temperature of 300-400 DEG C for 3-5h, grinding for 5-10min after naturally cooling, flaking at the pressure of 5-20MPa, calcining under the protection of inert gases and at the temperature of 700-850 DEG C for 12-24h, and grinding after naturally cooling to obtain the carbon-coated lithium manganese borate cathode material. The preparation method has the advantages of simple process route, good repeatability, suitability for industrial production and low manufacturing cost; in addition, the prepared material is uniform in particle size distribution, favorable in electrochemical property and the like.

Owner:盐城市新能源化学储能与动力电源研究中心

Double-loaded nano pesticide sustained-release capsule for preventing and curing rice sheath blight disease and preparation method of double-loaded nano pesticide sustained-release capsule

ActiveCN110786324AReduce volatilityReduce decompositionBiocideDisinfectantsAdjuvantSustained Release Capsule

The invention provides a double-loaded nano pesticide sustained-release capsule for preventing and curing rice sheath blight disease and a preparation method of the double-loaded nano pesticide sustained-release capsule. The double-loaded nano pesticide sustained-release capsule is prepared from the following components by weight: 2.1-2.5 parts of validamycin, 0.3-0.5 part of thifluzamide, 2.4-4 parts of capsule wall materials, 45-70 parts of organic solvent, 3-5 parts of an emulsifier, 225-350 parts of water, 15-150 parts of excipient and 0-10 parts of adjuvant; and the weight ratio of the validamycin to the thifluzamide is (5 to 1)-(7 to 1). The double-loaded nano pesticide sustained-release capsule is small in particle size, good in particle dispersibility, excellent in sustained-release performance, high in effective utilization rate, good in prevention and control effect on the rice sheath blight disease and simple in preparation process, and industrialization is facilitated.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Method for preparing high-efficiency catalyst for chemically reducing nitrates in wastewater

ActiveCN109317198AImprove bindingEvenly combinedOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsPolystyreneBiological activation

The method for preparing high-efficiency catalyst for chemically reducing nitrates in wastewater, and belongs to the field of wastewater treatment. The preparation steps comprise pre-treating macroporous polystyrene resin carrier by activation to prepare a precursor A of the catalyst, immersing the precursor A of the catalyst in an immersion liquid of PdCl2h and Ce(NO3)3; immersing the catalyst precursor in a saturated solution of EDTA (Ethylenediaminetetraacetic Acid), drying; and then immersing in a copper sulfate immersion liquid. By multi-step pretreatment of the carrier, the binding forceof the carrier to the EDTA and active components is increased, so that a large amount of metal ions are bonded and uniformly dispersed on the inner surface of exchange resin micropores, and the metalions are reduced to form metal clusters and deeply embedded in the three-dimensional network structure of resins, so that the activity is evenly dispersed on the resin and firmly bonded.

Owner:CHINA PETROLEUM & CHEM CORP

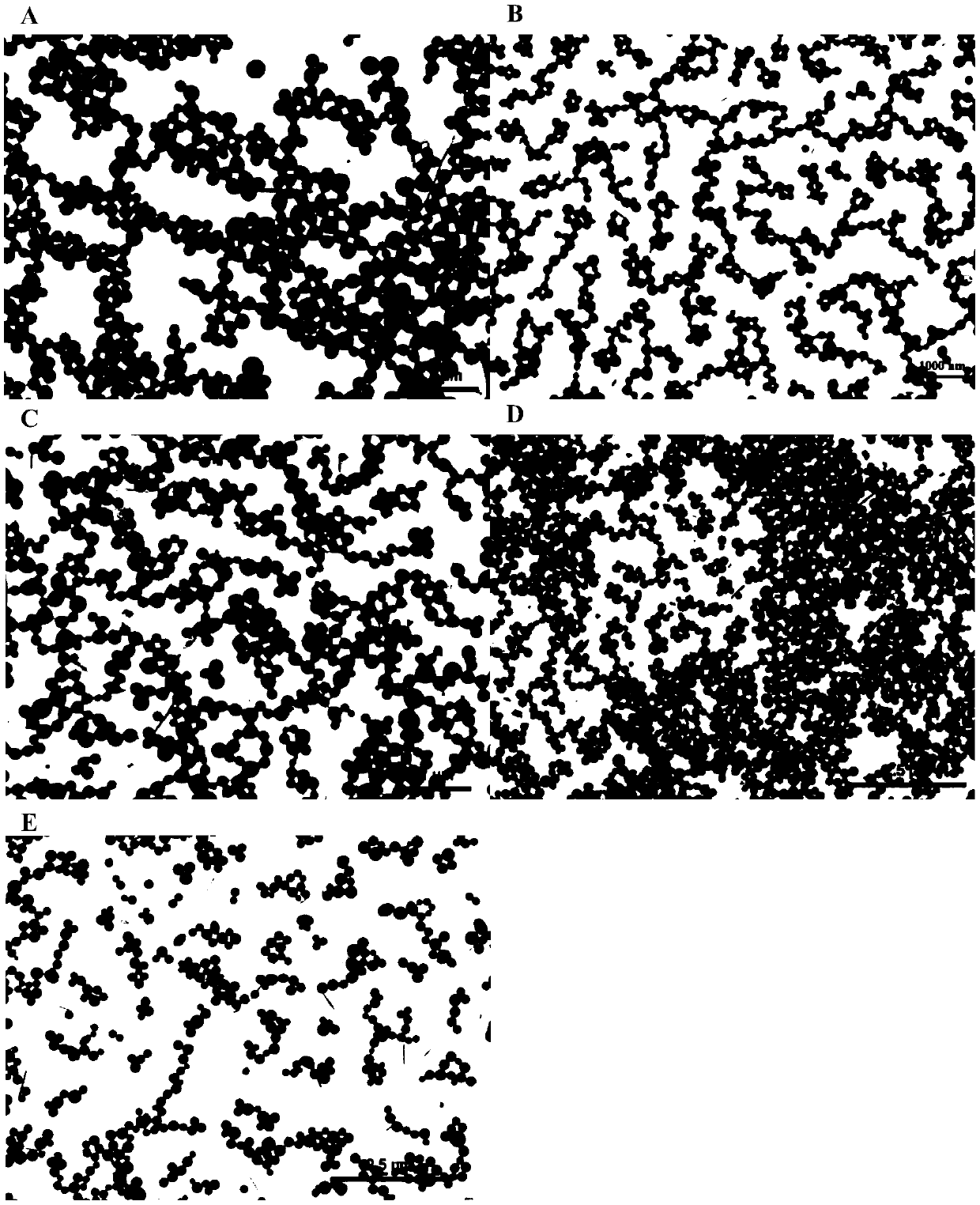

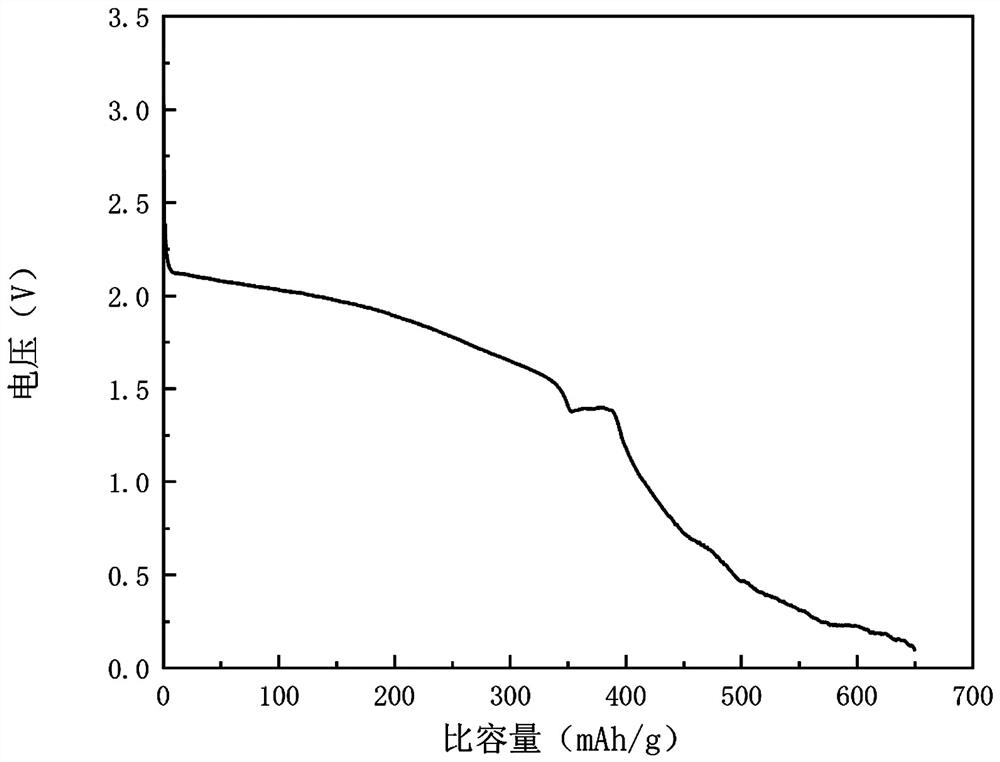

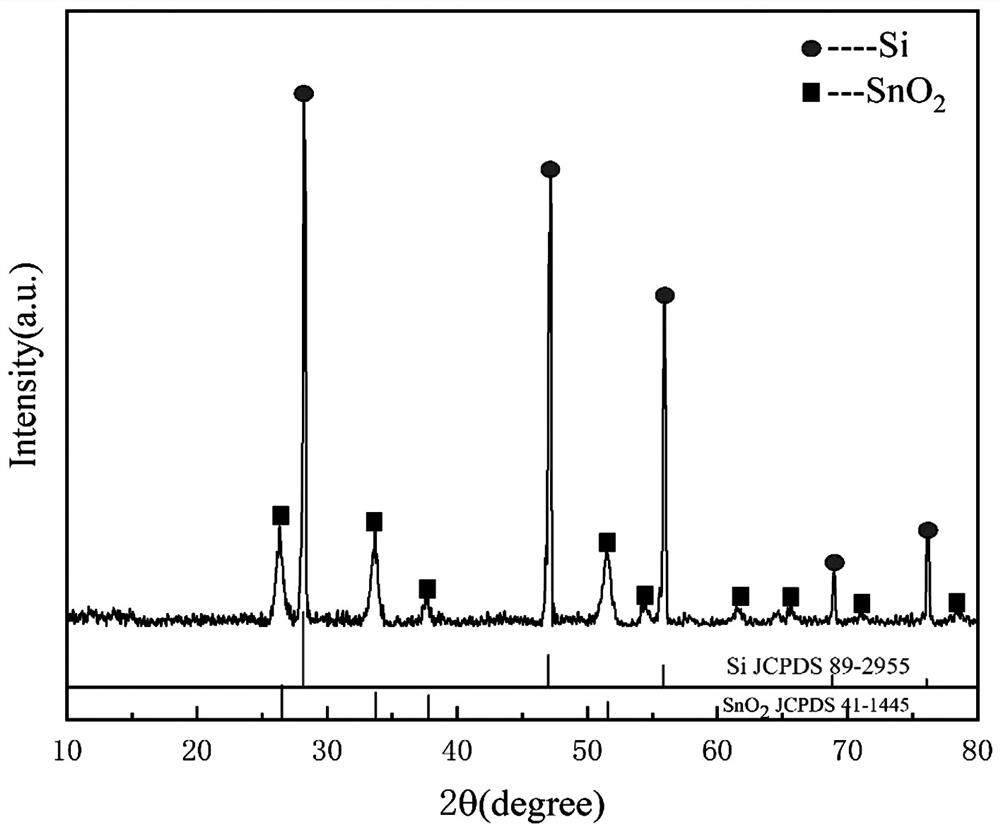

Preparation method of Si@SnO2@C microspheres used as positive electrode material of high-temperature lithium battery

InactiveCN111987299AUniform particle sizeGood particle dispersionPositive electrodesLi-accumulatorsElectrically conductivePTFE - Polytetrafluoroethylene

The invention relates to a high-temperature lithium battery, in particular to a preparation method of Si@SnO2@C microspheres serving as a positive electrode material of a high-temperature lithium battery, and solves the problems that the capacity of the high-temperature lithium battery is easily and quickly attenuated and the conductivity of the high-temperature lithium battery is weaker when monatomic silicon is used as a positive electrode material of the high-temperature lithium battery. The invention relates to the preparation method of the Si@SnO2@C microspheres used as the positive electrode material of the high-temperature lithium battery. The method is realized by adopting the following steps: (1) carrying out surface activation treatment on silicon powder; 2) adding the activatedsilicon powder into 80mL of deionized water; 3) adding glucose into a solution A; (4) adding 0.28-0.5 g of stannous chloride and 0.04-0.09 g of ammonium fluoride into a solution B, (5) transferring aprecursor suspension into a 100mL polytetrafluoroethylene reaction kettle; and (6) cleaning and drying a collected precipitate, and putting the precipitate into a tubular furnace.

Owner:ZHONGBEI UNIV

Method for synthesizing FeF3/CNTs positive electrode material by liquid phase method

InactiveCN108270003ASmall granularityGood particle dispersionCell electrodesHigh rateCarbon nanotube

The invention discloses a method for synthesizing a FeF3 / CNTs positive electrode material by a liquid phase method and belongs to the technical field of lithium ion batteries. The method comprises dispersing carbon nanotubes in a mixed solution of nitric acid and sulfuric acid through magnetic stirring to obtain a mixed solution A, adding hydrofluoric acid into the mixed solution A to obtain a mixed solution B, dissolving a surfactant and ferric acetylacetonate in an aqueous solution of ethanol to obtain a mixed solution C, adding the mixed solution C into the mixed solution B drop by drop, carrying out magnetic stirring for a reaction, after dropwise addition, carrying out stirring for 15-24h, filtering and washing the reaction product, carrying out drying through a vacuum drying oven, and carrying out calcination in an inert atmosphere at a temperature of 300 to 500 DEG C to obtain the FeF3 / CNTs positive electrode material. The FeF3 / CNTs positive electrode material has the characteristics of small particle size, good particle dispersibility and good electrical conductivity, can be used for preparation of a lithium ion battery, and has a high charge-discharge ratio capacity, goodcirculation stability and high rate performance.

Owner:KUNMING UNIV OF SCI & TECH

Modified aluminum powder as well as preparation method and application thereof

ActiveCN113953520AIncrease coverageThe interface is firmly bondedTransportation and packagingMetal-working apparatusAluminium powderCopper oxide

The invention relates to modified aluminum powder as well as a preparation method and application thereof. The modified aluminum powder is obtained through bidirectional airflow mixing to obtain composite aluminum powder with a microporous structure on the surface, and then the composite aluminum powder is coated with a polytetrafluoroethylene-copper oxide-thinned graphite flake ternary composite material. According to the modified aluminum powder as well as the preparation method and application thereof, when the modified aluminum powder is used as an energetic material, the problems that traditional aluminum powder is low in enthalpy value and long in specific impulse signal can be solved, the coating rate of the aluminum powder is high, interface bonding is firm, the particle dispersity is good, the enthalpy value of a product is high, the performance is excellent, and the modified aluminum powder can be used in chemical power enterprises, civil blasting and other industries with the high enthalpy value requirement and the short specific impulse signal requirement.

Owner:CENT SOUTH UNIV +1

A kind of high-purity dense magnesium oxide target material and preparation method thereof

ActiveCN106587940BImprove particle size distributionGood particle dispersionVacuum evaporation coatingSputtering coatingSurface roughnessHeat conservation

The invention belongs to the technical field of novel material manufacturing and application and particularly relates to a high-purity compact magnesium oxide target material and a preparation method thereof. Magnesium oxide powder subjected to planetary ball milling are further subjected to isostatic cool pressing and vacuum sintering to obtain the near-net formed high-purity compact magnesium oxide target material, wherein a vacuum sintering temperature is 1400-1550 DEG C, heat preservation time is 2-10h, and a vacuum degree is 0.1-1.0Pa. The high-purity compact magnesium oxide target material prepared according to the method is 98.36% or above in compactness, 100ppm or below in total impurity element content, 7micron or blow in average grain size, 3.0micron or below in size deviation and 0.4micron or below in surface roughness Ra. The magnesium oxide target material prepared according to the method is high in purity and compactness and fine and uniform in grain size. The preparation method has advantages of short production cycle, low production cost, high production efficiency and availability for batch production.

Owner:GRIKIN ADVANCED MATERIALS

Preparing method of magnetostriciton material

The invention relates to a preparing method of a magnetostriciton material, and belongs to the technical field of preparation of magnetostriciton materials. Aimed at the problem that in the current prepared resin matrix magnetostriciton material, interface bonding is bad and usability performance of the materials is reduced due to the fact that magnetostriciton particles have low wetting with resin, and the particles are prone to clustering and segregation when being mixed together, the magnetostriciton material is provided. According to the preparing method of the magnetostriciton material, magnetic ceramic powder is prepared, and the magnetic ceramic powder is then combined with epoxy resin; under the action of a coupling agent, magnetic ceramic is uniformly recombined to the inner part of the resin; under a magnetic action of an external permanent magnet, bonding strength between modified resin matrix and magnetic-induced particles is strengthened, sedimentation speed of particles among the resin is lowered; under the action of a magnetic field system, a controllable oriented magnetic field is determined, and a stable compound system is formed. The magnetostriciton material has a high combination degree, particles have good dispersity, and magnetostriction coefficient improved by 5-8% compared with similar products; meanwhile, the preparing method is simple, the raw material is green and safe, and the prepared magnetostriciton material does not cause environment pollution.

Owner:ZHEJIANG JIAYUDA MACHINERY CO LTD

Hydrothermal synthesis method for positive pole material lithium manganese phosphate nanoparticles of lithium-ion batteries

InactiveCN104183844AGood dispersionFacilitated DiffusionCell electrodesSecondary cellsArgon atmospherePotassium hydroxide

The invention discloses a hydrothermal synthesis method for positive pole material lithium manganese phosphate nanoparticles of lithium-ion batteries. According to the hydrothermal synthesis method, deionized water serves as a solvent, a manganese source, a lithium source and phosphoric acid are taken as reacting materials, a block copolymer is taken as a template agent, potassium hydroxide is taken as a mineralizer, so as to promote nucleation and growth of lithium manganese phosphate, heat treatment is carried out at high temperature and high pressure, then, calcining treatment is carried out at the temperature of 550-650 DEG C under the protection of a nitrogen or argon atmosphere while carrying out heat preservation, and then, the lithium manganese phosphate nanoparticles are obtained. The hydrothermal synthesis method has the advantages that the product is stable in quality, high in purity and good in particle dispersibility and is beneficial to the diffusion of lithium ions and the improvement of the electrochemical properties of a lithium-ion battery, and the preparation process is simple in process, easy to control and low in cost and is pollution-free, so that the large-scale production is facilitated.

Owner:ZHEJIANG UNIV

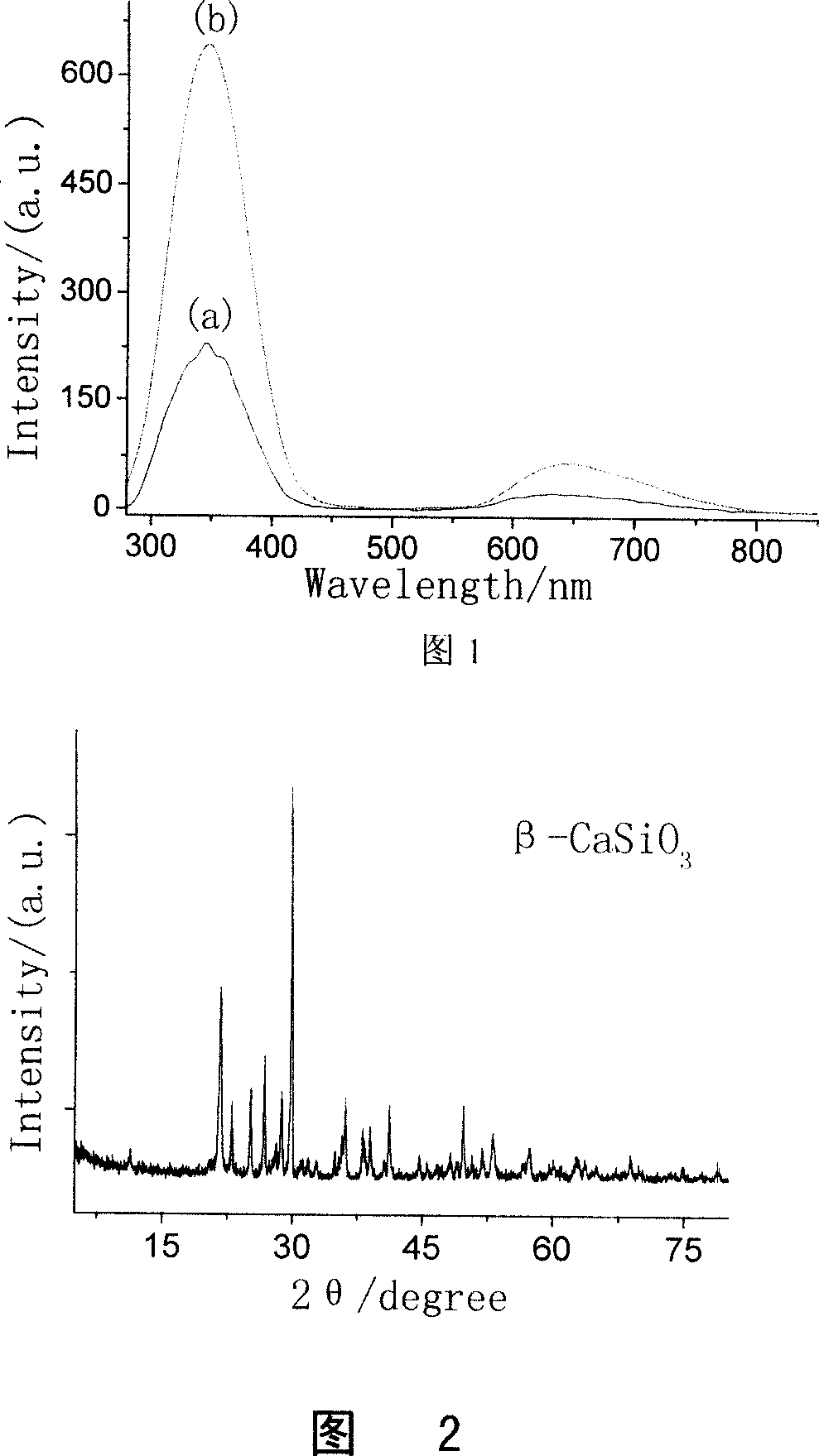

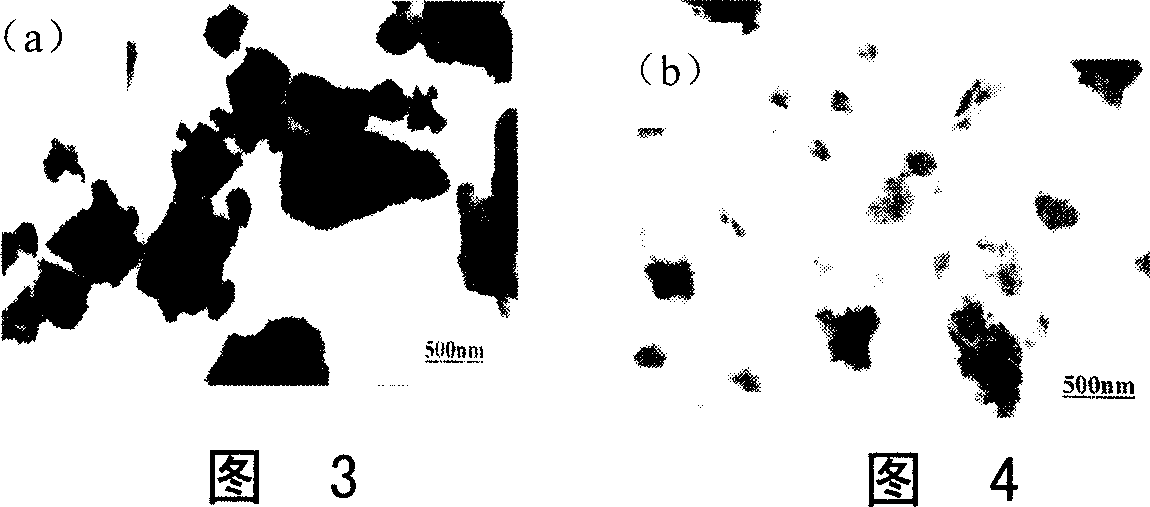

Nano red CaSiO3:Pb, Mn fluorescent material and its preparing method

InactiveCN1986728AHigh luminous intensityGood particle dispersionLuminescent compositionsNitrateLead nitrate

The present invention relates to a kind of nanometer red CaSiO3:PbMn fluorescent material and its preparation process. The fluorescent material features its chemical expression of 0.7CaO.0.025PbO.0.033MnO.1.3SiO2, and includes matrix material calcium nitrate and silica aerosol, fluorescent sensitizer lead nitrate, fluorescent activator manganese nitrate and non-ionic surfactant ON7O, XL80 or TO8, with the weight ratio of calcium nitrate, lead nitrate, manganese nitrate and silica aerosol being 3.2971 to 0.1656 to 0.2706 to 1.5622. The fluorescent material has high fluorescent strength, high particle dispersivity, average nanometer crystal particle size of 150 nm and excellent application performance.

Owner:SHANGHAI NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com