Preparation method of carbon-coated lithium manganese borate cathode material for lithium ion battery

A carbon-coated technology for lithium manganese borate and lithium ion batteries, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor performance consistency of synthetic materials, and achieve low processing costs, uniform phase structure, and heavy weight. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a carbon-coated lithium manganese borate positive electrode material for a lithium ion battery, the preparation process comprising the following process steps:

[0032] 1. Mix 1.7956g lithium acetate dihydrate (0.0176 mol Li), 4.1895g manganese acetate tetrahydrate (0.0171 mol Mn), 1.0573g boric acid (0.0171 mol B) and 2.0171g citric acid (0.0105 mol), and then add an appropriate amount of Deionized water, dissolving lithium acetate dihydrate, manganese acetate tetrahydrate, boric acid and citric acid to form a solution, stirring continuously at 80°C to slowly evaporate the water until a sol is formed, and then drying the sol at 90°C;

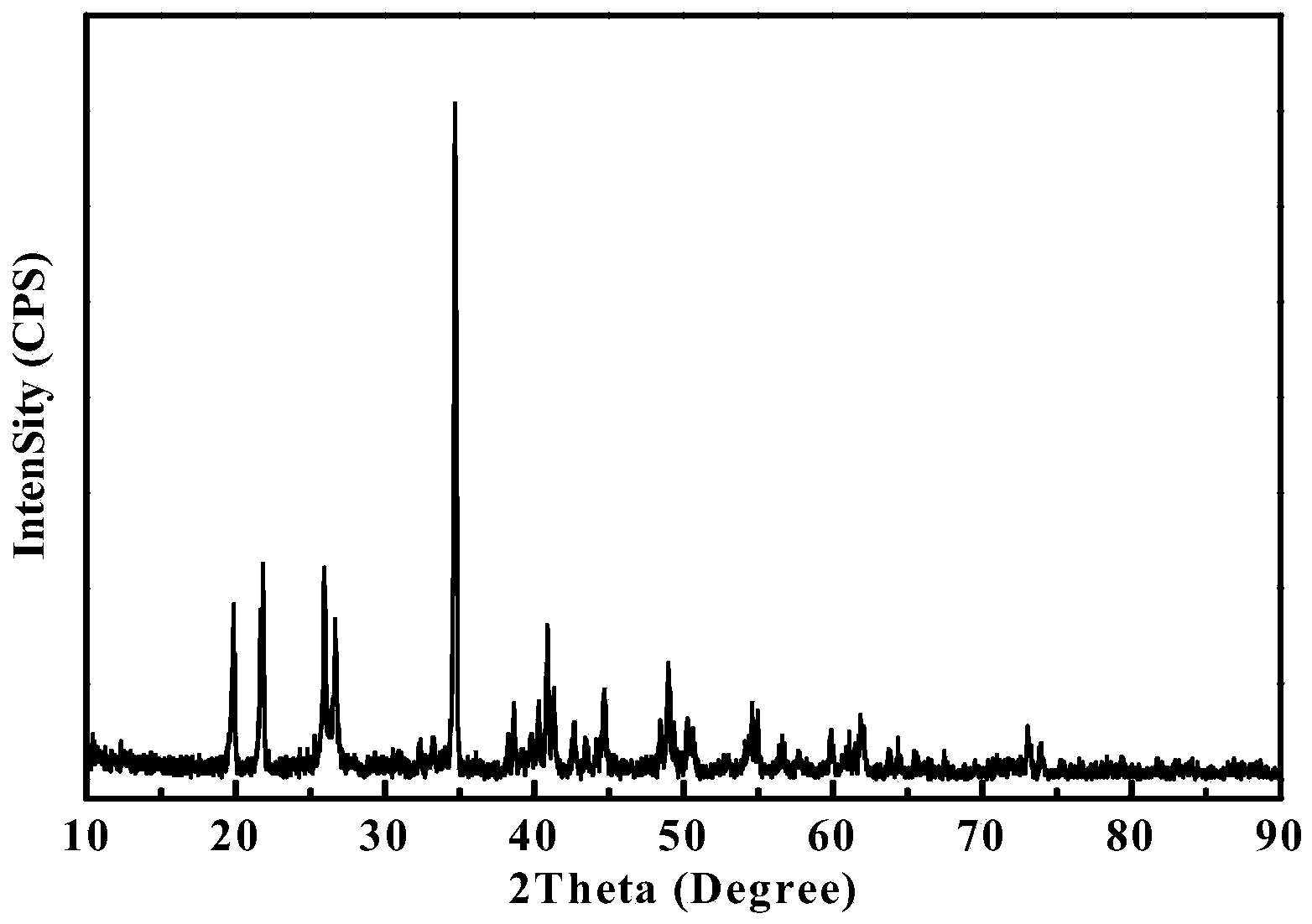

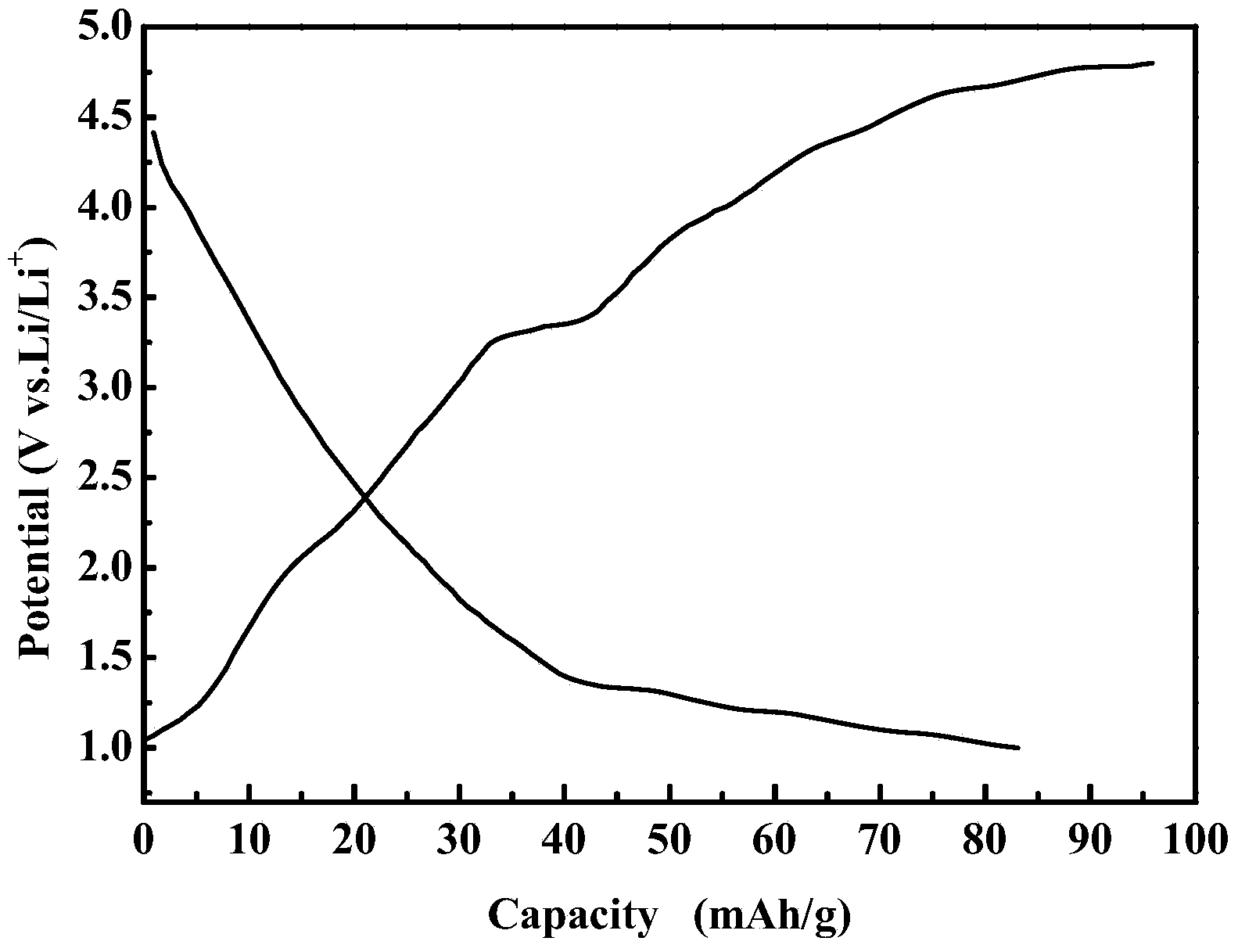

[0033] 2. Pre-fired at 350°C under the protection of argon for 3 hours, ground for 10 minutes after natural cooling, pressed into tablets under a pressure of 10 MPa, calcined at 850°C under the protection of argon for 12 hours, and ground after natural cooling to obtain a carbon-coated manganese lithium borate posit...

Embodiment 2

[0038] A method for preparing a carbon-coated lithium manganese borate positive electrode material for a lithium ion battery, the preparation process comprising the following process steps:

[0039] 1. Mix 0.7003g lithium oxalate (0.0137 mol Li), 1.9296g manganese oxalate (0.0135 mol Mn), 0.8889g ammonium borate tetrahydrate (0.0135 mol B) and 2.1081g glucose (0.0117 mol), then add an appropriate amount of deionized Water, dissolve lithium oxalate, manganese oxalate, ammonium borate tetrahydrate and glucose to form a solution, stir continuously at 60°C to slowly evaporate the water until a sol is formed, and then dry the sol at 100°C;

[0040] 2. Pre-fired at 300°C for 4 hours under the protection of nitrogen, and ground for 5 minutes after natural cooling, pressed into tablets under a pressure of 20 MPa, calcined at 800°C for 24 hours under the protection of a mixture of argon and hydrogen (the hydrogen content is 8%), and cooled naturally The carbon-coated lithium manganese ...

Embodiment 3

[0043] A method for preparing a carbon-coated lithium manganese borate positive electrode material for a lithium ion battery, the preparation process comprising the following process steps:

[0044] 1. Mix 0.6145g lithium carbonate (0.0166 mol Li), 1.8290g manganese carbonate (0.0159 mol Mn), 1.0469g ammonium borate tetrahydrate (0.0159 mol B) and 1.1846g sucrose (0.0035 mol), then add an appropriate amount of deionized Water, dissolve lithium carbonate, manganese carbonate, ammonium borate tetrahydrate and sucrose to form a solution, stir continuously at 90°C to slowly evaporate the water until a sol is formed, and then dry the sol at 80°C;

[0045] 2. Pre-calcined at 350°C for 5 hours under the protection of argon gas, ground for 10 minutes after natural cooling, pressed into tablets under a pressure of 15 MPa, and calcined for 24 hours under the protection of a mixture of nitrogen and hydrogen (hydrogen content is 5%) at 750°C, after natural cooling The carbon-coated lithiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com