Patents

Literature

185 results about "Ammonium borate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-phosphorus compound scale and corrosion inhibitor for treatment of circulating cooling water

ActiveCN1621362AEasy to useIncrease the concentration factorScale removal and water softeningPhosphateTungstate

The composite phosphate-free scale inhibiting corrosion inhibitor for treating circular cooling water consists of scale inhibitor and corrosion inhibitor. The scale inhibitor consists of one or several of PASP, PVA, oxidized starch, polyacrylic acid, acrylic acid / acrylate copolymer and acrylic acid / acrylate copolymer with sulfo radical. The corrosion inhibitor consists of one or several of sodium salt / potassium salt / ammonium salt of organic salt, sodium / potassium / ammonium borate, nitrous organic matter, soluble molybdenate, soluble tungstate, soluble nitrate, soluble nitrite and soluble zinc salt. The composite scale inhibiting corrosion inhibitor has excellent scale inhibiting and corrosion inhibiting performance, is environment friendly, and is especially the treatment of hard circulation water with high calcium and high alkali content.

Owner:BEIJING YANHUA XINGYE TECH DEV +1

Mixed solubility borate preservative

InactiveUS7449130B2Reduce solubilityImprove solubilityBiocideOther chemical processesCelluloseSolubility

Preservative composition for lignocellulosic-based composites providing rapid and long-lasting protection against insect and fungal attack, in both low and high moisture environments, through the use of a combination of higher solubility and lower solubility borates. Pesticidal amounts of a lower solubility borate and a higher solubility borate are combined before or during their incorporation into a lignocellulosic-based composite. Useful low solubility borates includes copper borate, zinc borate and barium metaborate. Useful high solubility borates includes boric acid, boric oxide, ammonium borate and alkali metal borates such as sodium borate. Some alkaline earth metal borates, including calcium borates, are of intermediate solubility and may be used effectively as either a low soluble or high soluble borate depending on the combination used.

Owner:U S BORAX INC

Ammonium borate containing compositions for stripping residues from semiconductor substrates

InactiveUS6875733B1Efficient removalExcellent peelabilityOrganic detergent compounding agentsDetergent mixture composition preparationHalogenOrganic solvent

The present invention comprises formulations for stripping wafer residues which originate from a halogen based plasma metal etching followed by oxygen plasma ashing. The formulations contain the following general components (percentages are by weight): an organic amine or mixture of amines 15-60 %, water 20-60 %, ammonium tetraborate or ammonium pentaborate 9-20 %, an optional polar organic solvent 0-15 %.

Owner:ENTEGRIS INC

Scaling powder for aluminium soldering tin wire core and preparation method thereof

InactiveCN101412168AImprove curing effectHigh activityWelding/cutting media/materialsSoldering mediaOrganic acidSolderability

The invention relates to a soldering flux for a soldering tin wire core through aluminium soldering and a preparation method thereof. The soldering flux is used for an inner core of a soldering tin wire through aluminium soldering or aluminium alloy soldering. The soldering flux comprises the following compositions in a formula in weight percentage: 14 to 28 percent of modified resin, 12 to 24 percent of ammonium borofluoride, 38 to 56 percent of organic amine, 4 to 10 percent of zinc source, 0.5 to 8 percent of tin salt and 0.1 to 2 percent of a fluorin surfactant. The zinc source is zinc salt, zinc powder or activated zinc oxide; the tin salt is inorganic tin salt or organic acid tin; and the fluorin surfactant is one or two of FC4430, FC4432, F5010, FSN-100, F501, F502 and FS-300. The soldering flux is in a solid state at normal temperature, has the characteristics of having good stiffness, high activity and simple preparation process, remarkably improving solderability of a soldering material and the cleanness of a weld spot and the like and is suitable for producing the soldering tin wire containing the soldering flux in the core and soldering aluminum and aluminum alloy.

Owner:SOUTH CHINA UNIV OF TECH

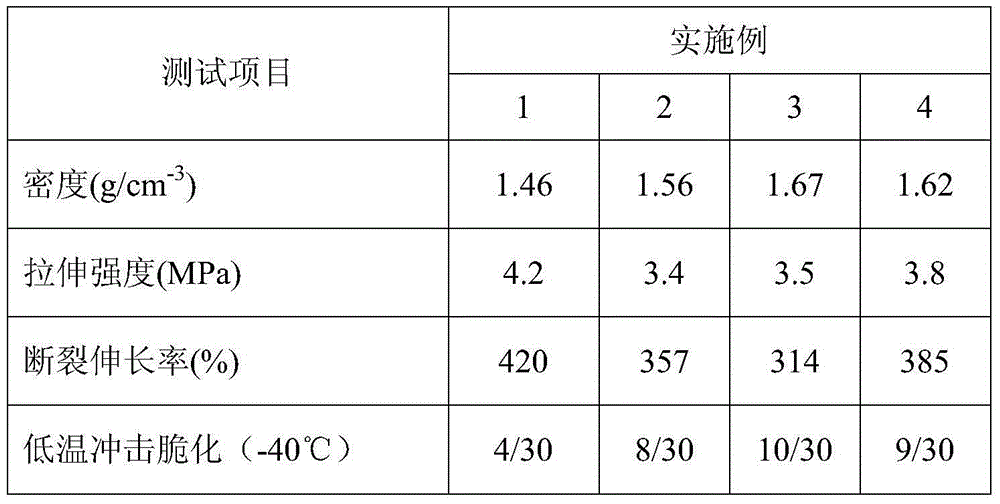

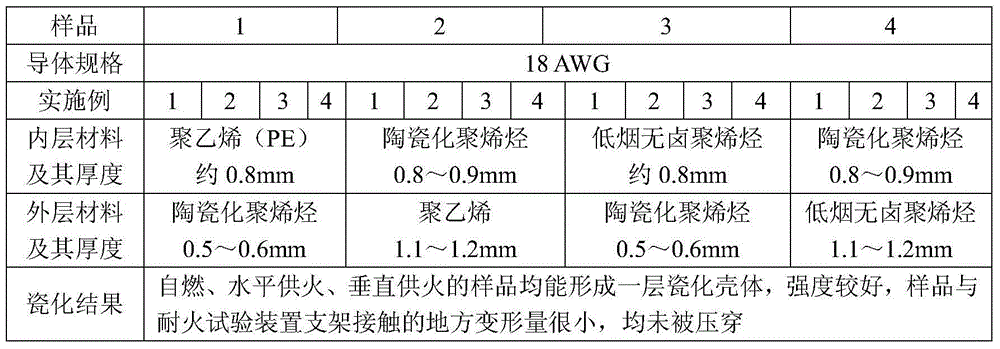

Ceramized polyolefin material and preparation method thereof

InactiveCN104558805AGood extrusion processing performanceGood porcelain performancePolyolefinAntioxidant

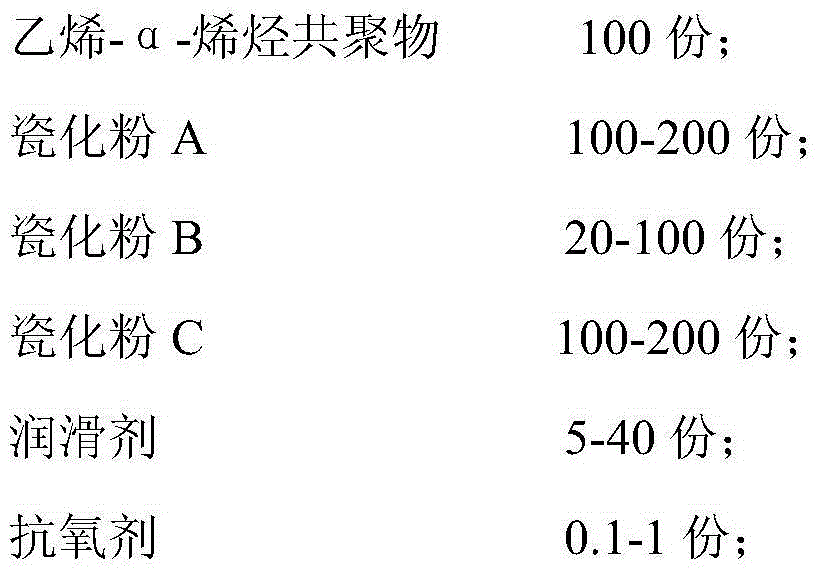

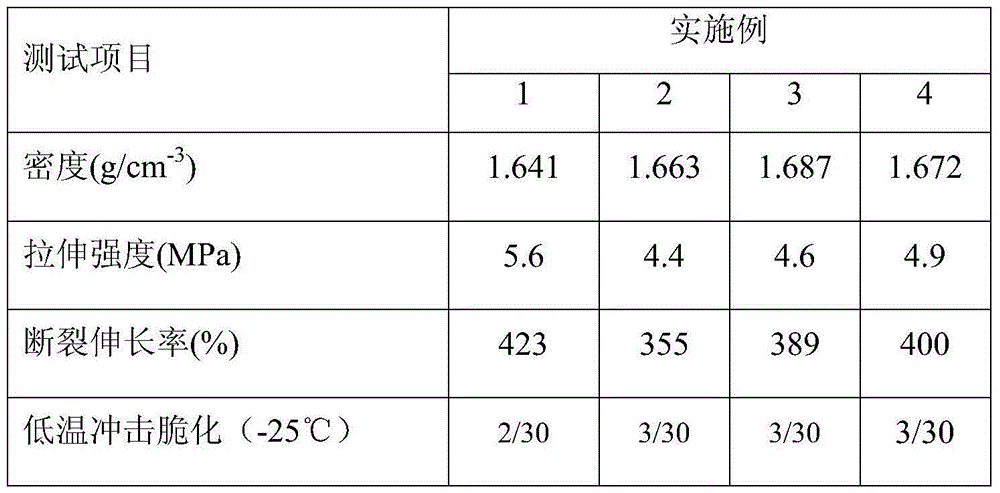

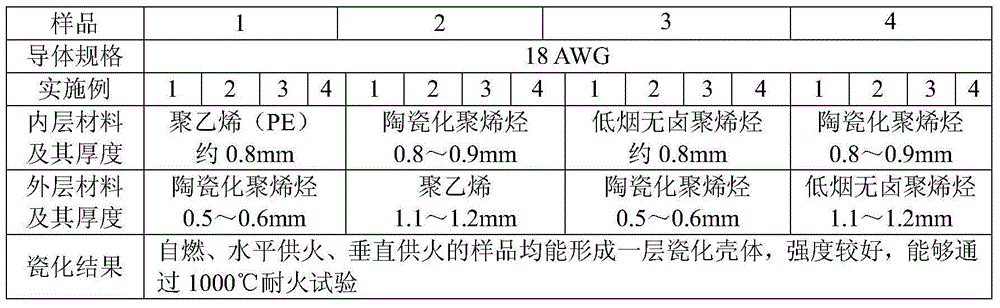

The invention discloses a ceramized polyolefin material and a preparation method thereof, belonging to the field of electric wire and cable materials. The ceramized polyolefin material comprises the following raw material components: 100 parts of an ethylene-alpha-olefin copolymer, 100-200 parts of ceramized powder A, 20-100 parts of ceramized powder B, 100-200 parts of ceramized powder C, 5-40 parts of a lubricating agent and 0.1-1 part of an antioxidant, wherein the ethylene-alpha-olefin copolymer is one or more selected from an ethylene and alpha-propylene copolymer, an ethylene and alpha-butylene copolymer, an ethylene and alpha-hexylene copolymer and an ethylene and alpha-octene copolymer; the ceramized powder A is one or a combination of more than one selected from layered inorganic powder, fibrous inorganic powder and needle-like inorganic powder; the ceramized powder B is at least one selected from borax, ammonium borate, a zinc borate and boron frit, phosphate glass powder with a low melting point, borate glass powder with a low melting point and silicate glass powder with a low melting point; the ceramized powder C is granular powder with excellent high-temperature insulativity; and the antioxidant is at least one selected from 1010, 1076, 168, 626, 300 and DSTDP.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

Ceramized polyolefin material and preparation method thereof

InactiveCN104558804AHigh strengthReduce the temperaturePlastic/resin/waxes insulatorsPolyolefinAntioxidant

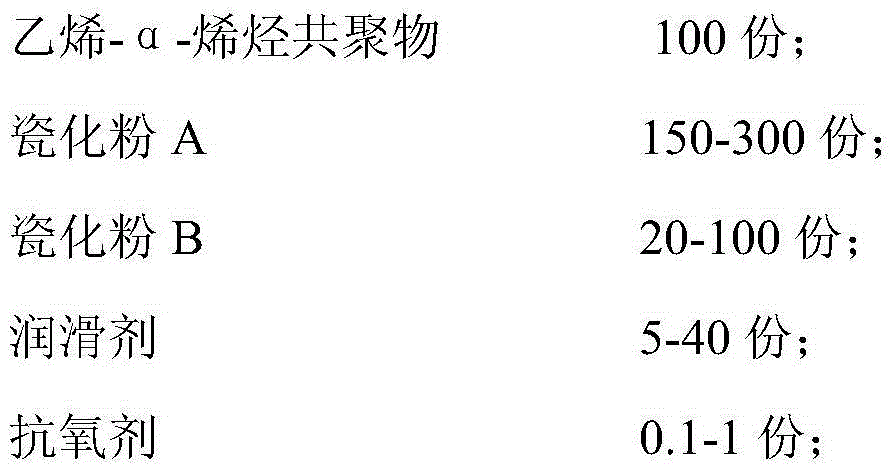

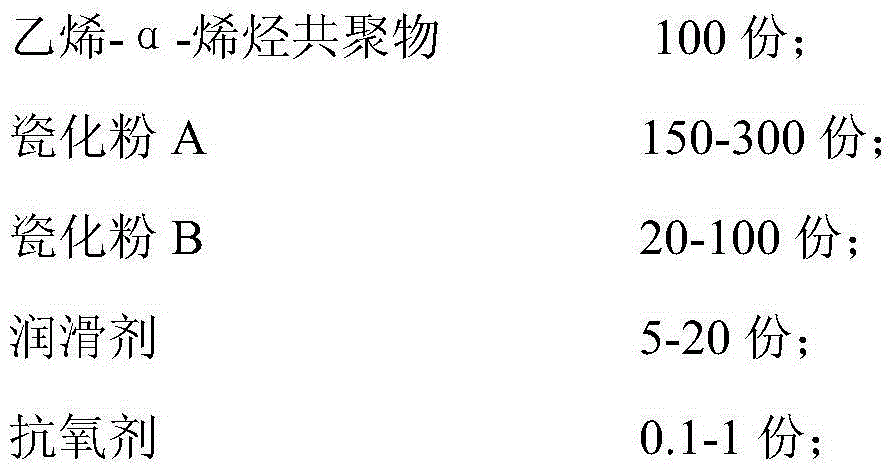

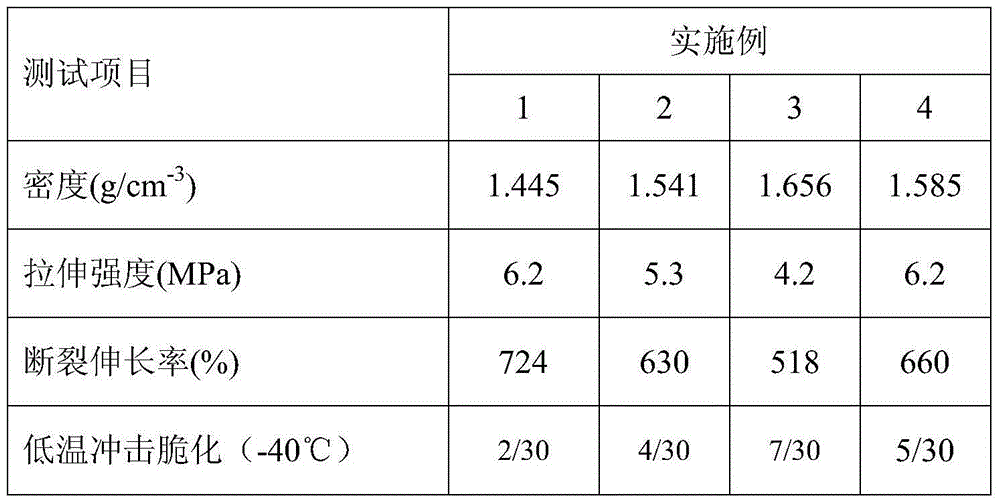

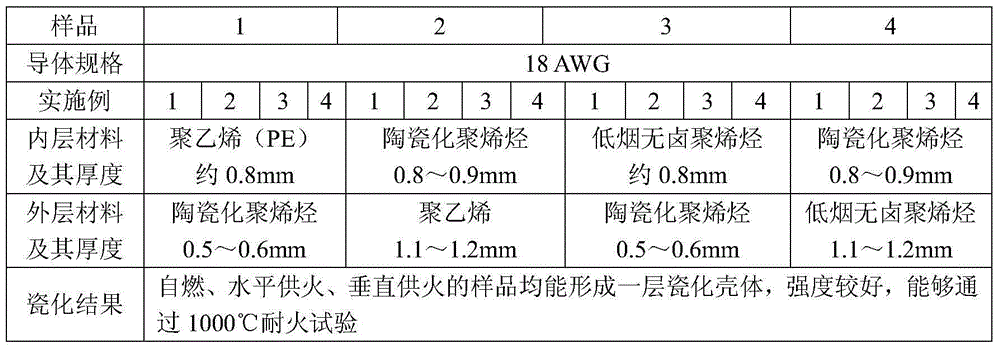

The invention discloses a ceramized polyolefin material and a preparation method thereof, belonging to the field of electric wire and cable materials. The ceramized polyolefin material comprises the following raw material components: 100 parts of an ethylene-alpha-olefin copolymer, 150-300 parts of ceramized powder A, 20-100 parts of ceramized powder B, 5-40 parts of a lubricating agent and 0.1-1 part of an antioxidant, wherein the ethylene-alpha-olefin copolymer is one or more selected from an ethylene and alpha-propylene copolymer, an ethylene and alpha-butylene copolymer, an ethylene and alpha-hexylene copolymer and an ethylene and alpha-octene copolymer; the ceramized powder A is one or a combination of more than one selected from layered inorganic powder, fibrous inorganic powder and needle-like inorganic powder; the ceramized powder B is at least one selected from borax, ammonium borate, a zinc borate and boron frit, phosphate glass powder with a low melting point, borate glass powder with a low melting point and silicate glass powder with a low melting point; and the antioxidant is at least one selected from 1010, 1076, 168, 626, 300 and DSTDP. The ceramized polyolefin material is reasonable in raw material and proportion, capable of ensuring normal operation of a route, good in flexibility, simple in process and low in cost.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

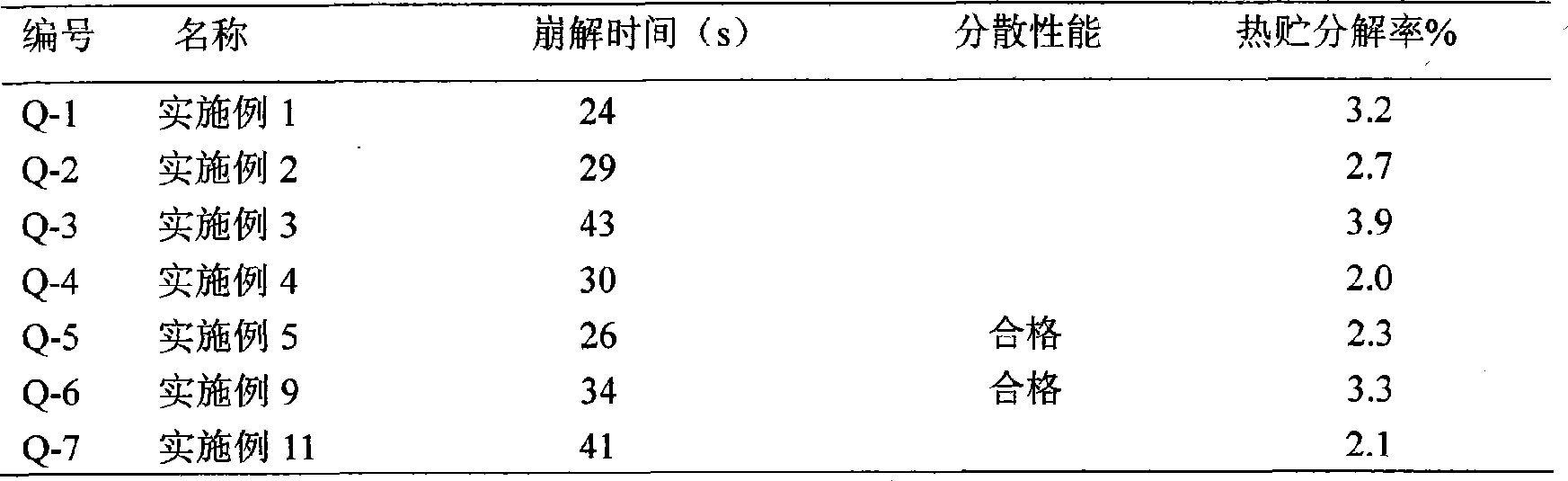

Boric fertilizer water dispersing granule and preparing method thereof

InactiveCN101531550AFast disintegrationDissolve (disperse) completelyFertiliser formsFertilizer mixturesMagnesium phosphatePotassium

The invention belongs to a new boric fertilizer, referring to a boric fertilizer water dispersing granule and preparing method thereof. The invention comprises one or more than one boric fertilizers and at least one surfactant; the materials are processed as the regular or irregular granules water dispersing granule; the weight part of the boric fertilizer is 5-95 parts; the rest is the assistant. The preferable solution of the invention is following: the boric fertilizer comprises one of the boric acid, boron oxide, boric acid ammonium, sodium tetraborate, calcium borate side, partial sodium borate, sodium borate tetrahydrate, magnesium diboride, sodium perborate, zinc borate, boric acid manganese, high-sodium borate, partial acid potassium, boron and magnesium fertilizer, boron and magnesium phosphate and boron mud or the mixture of the two or more than two of the above. The preparing method of the invention is scaling the prescription, mixing, crushing, and granule and drying to obtain the product. The boric fertilizer water dispersing granule of the invention has a fast disintegration, dissolving (dispersing) completely, not plugging the nozzle and the dropping pipe lines, no heating while using, easy to absorb moisture, packaging, storage and transportation, measurement, the use of low cost, widely used in food crops, cash crops, horticulture, lawns and urban greening; the market prospect is very broad.

Owner:SHENZHEN LANGTAI BIOTECH

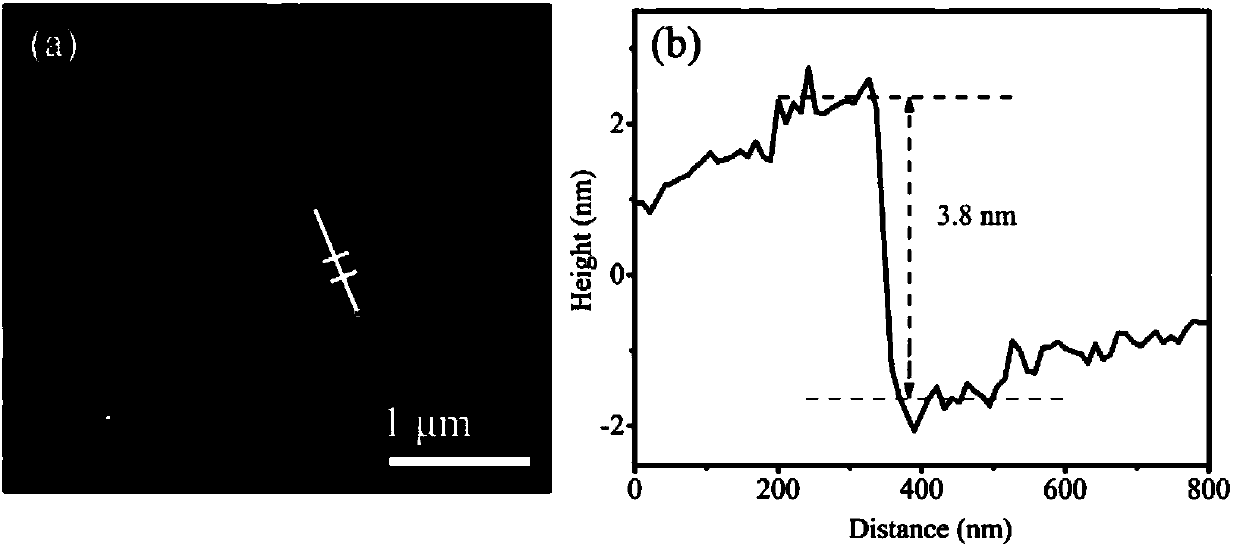

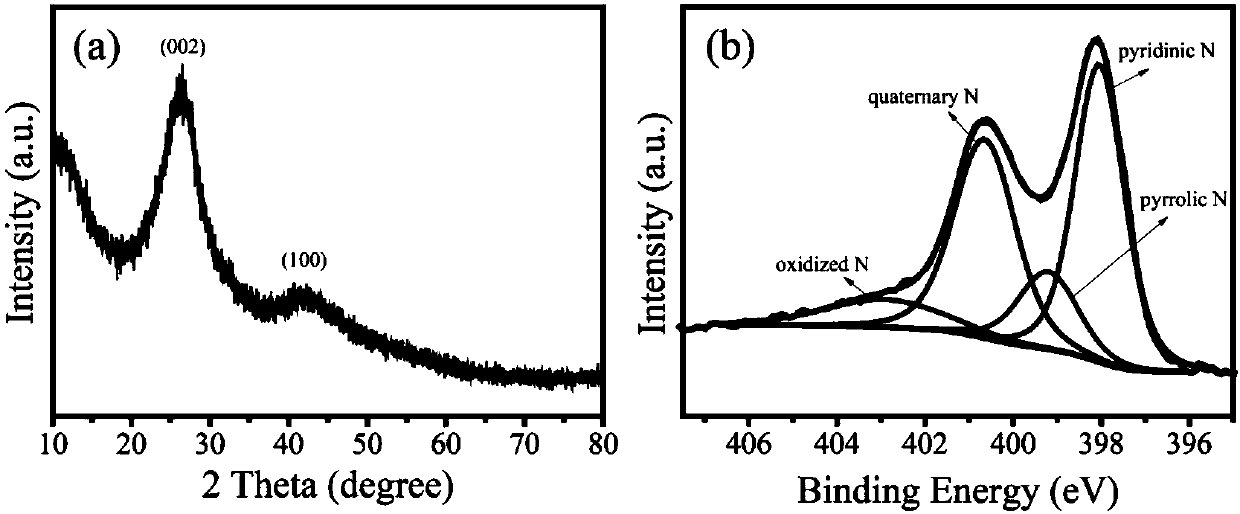

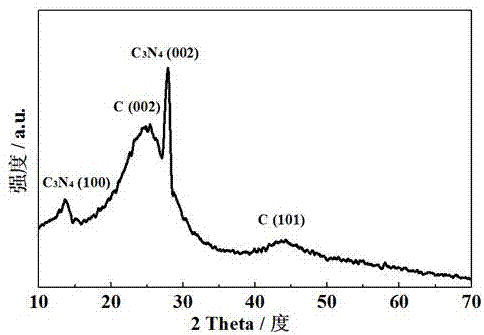

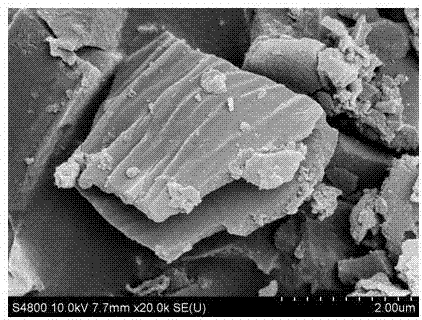

Preparation method of heteroatom-doped graphene

The invention discloses a preparation method of heteroatom-doped graphene. The method comprises the steps of dissolving a nitrogen source and a carbon source into a solvent in a ratio, stirring in a water bath to obtain a sol gel, drying the sol gel to obtain a precursor and sintering the precursor at a high temperature to obtain nitrogen-doped graphene. Nitrogen sulfur, nitrogen boron or nitrogenphosphorus can be doped by adding a material containing other doping element such as thiourea, sulfuric acid, boric acid, ammonium borate, phosphoric acid or ammonium phosphate to the raw materials.Multi-element co-doped graphene is obtained by adjusting the ratio of the nitrogen source to the carbon source, controlling the pyrolysis temperature and time, and adding controllable doping content and type of other non-metal element compounds. The prepared doped graphene has high specific surface area, excellent electrical conductivity and rich active sites, and can be used as an electrode material in the field of electrochemical energy storage / conversion.

Owner:NANJING UNIV OF SCI & TECH

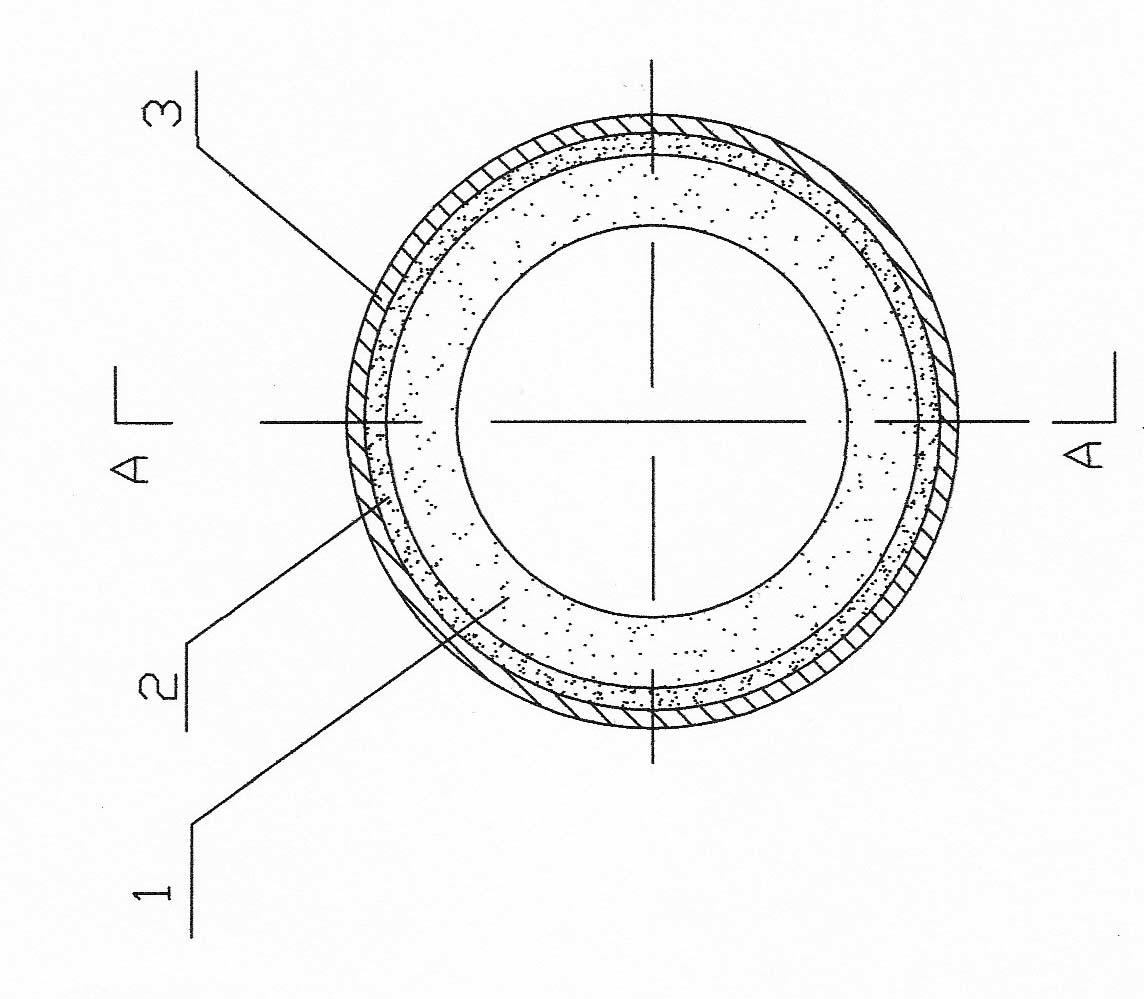

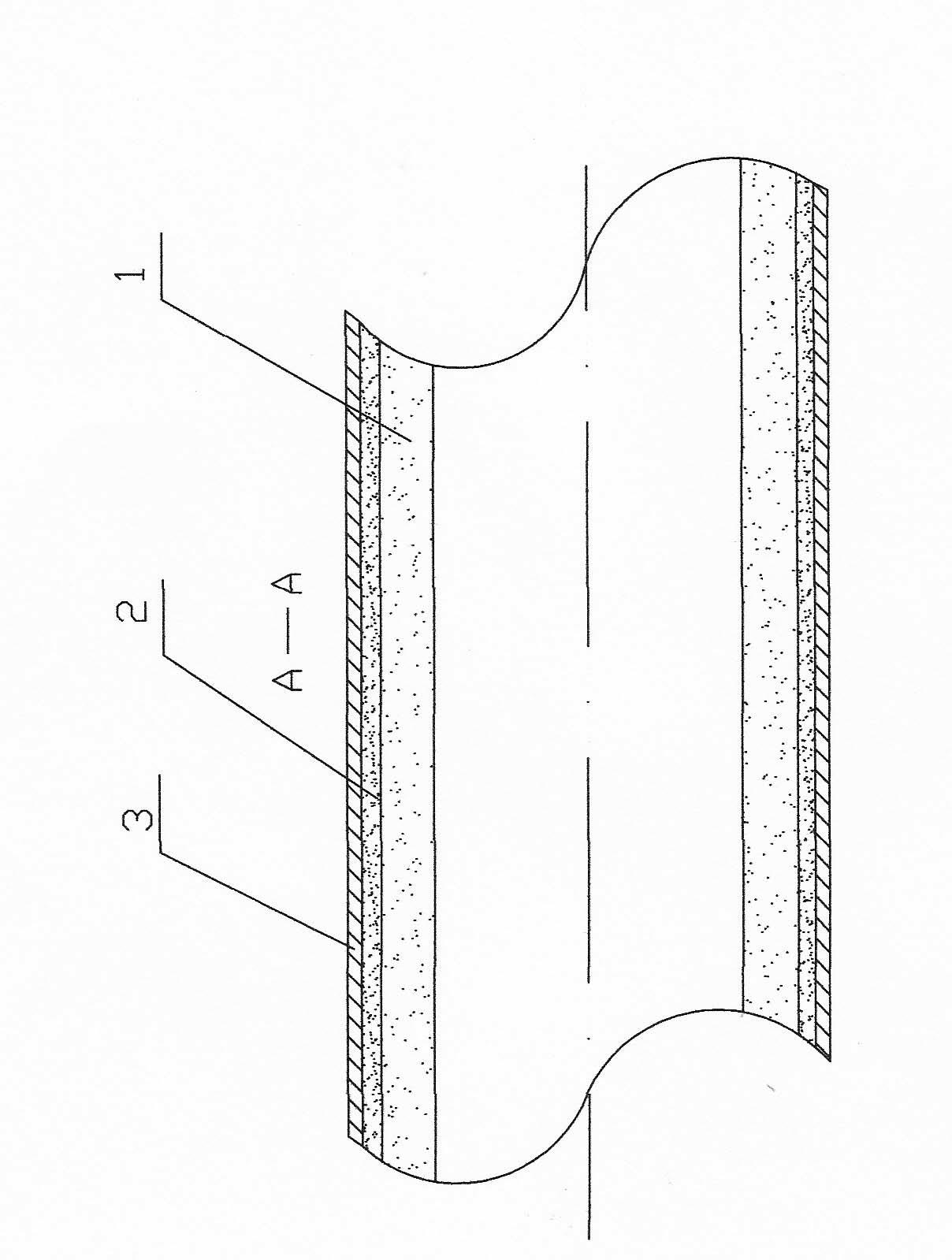

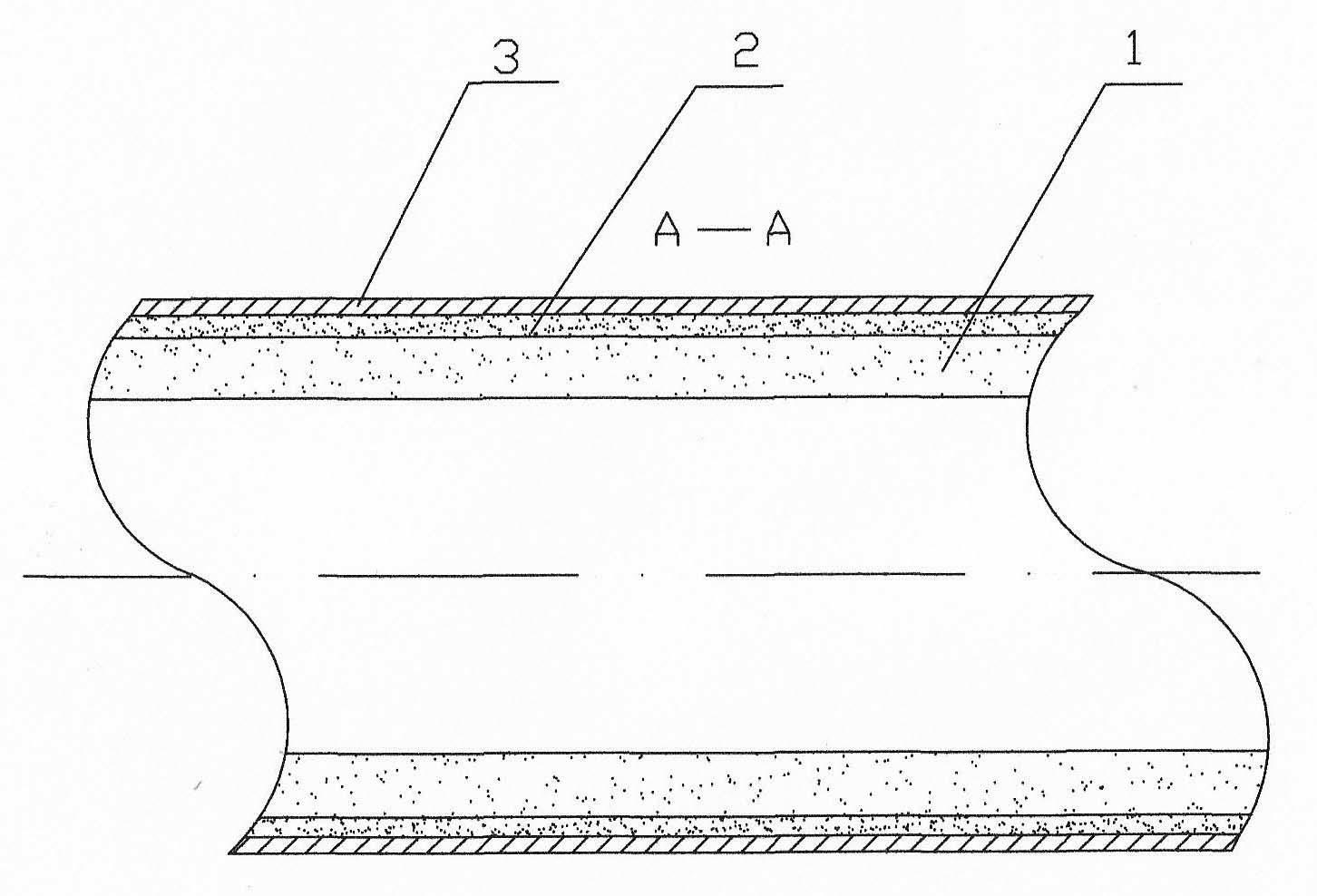

Radiation-proof, high-temperature-resistant and heat-insulating composite sleeve and preparation method thereof

ActiveCN102278569AGood anti-radiation performanceImprove heat insulation and flame retardant effectThermal insulationStarch coatingsCyclohexanoneAlkali free

The invention provides an anti-radiation high temperature resistant heat insulating composite bushing and a preparation method. The anti-radiation high temperature resistant heat insulating composite bushing comprises a lining bushing, a high temperature resistant heat insulating coating layer coated on the lining bushing, and a thin type aluminum film winding band winded on the high temperature resistant heat insulating coating layer. The thickness of the high temperature resistant heat insulating coating layer is 1-2mm, the high temperature resistant heat insulating coating layer is made from raw materials in component parts as follows, the parts are weight parts, wherein: adipic acid: 25-35 parts; trimethylolpropane: 16-20 parts; dechlorane plus: 20-30 parts; diantimony trioxide: 3-10 parts; ammonium borate: 5-12 parts; starch: 8-15 parts; zinc oxide: 5-12 parts; ammonium polyphosphate: 10-20 parts; and cyclohexanone or xylene 100-200 parts. The thin type aluminum film winding band is formed via cutting after synthesis of alkali-free glass fiber cloth and an aluminum plated film via a high temperature resistant flame retardant adhesive, and is winded on the high temperature resistant heat insulating coating layer in a mode of 1 / 2 hasp.

Owner:衡阳凌云特种材料有限公司

Water-based long-acting antirust agent

The invention discloses a water-based long-effective antirust agent, which comprises the following parts: 5.0-30.0% C8-C10 carboxylate (sodium, potassium or ammonium salt), 5.0-15.0% ethanolamine (monoethanolamine, diethanolamine or triethanolamine), 3.0-8.0% boric acid (boric acid or ammonium borate) and 0.0-5.0% polyethylene glycol (8-10 polymerization degrees). The product displays light yellow transparent viscous liquid to dissolve in the water under normal temperature or heating condition, which possesses excellent protective effect for common carbon steel and cast iron.

Owner:DALIAN SANDAAOKE CHEM

Water-retention nutrient soil for drought-enduring lawn

InactiveCN105330414AReduce releaseImprove water absorption and retention capacityFertilizer mixturesBiologyPlant soil

The invention discloses water-retention nutrient soil for a drought-enduring lawn. The water-retention nutrient soil is prepared from, by weight, 50-60 parts of planting soil, 30-50 parts of humus, 15-25 parts of turfy soil, 6-8 parts of wormcast, 5-7 parts of plant ash, 10-12 parts of bean pulp, 6-10 parts of urea, 6-12 parts of calcium magnesium phosphate, 2-4 parts of ammonium chloride, 0.005-0.01 part of ferric chloride, 8-12 parts of potassium sulfate, 0.02-0.03 part of manganese sulfate, 0.01-0.03 part of sodium molybdate, 0.5-1.5 parts of sodium silicate, 0.01-0.03 part of ammonium borate and 10-20 parts of composite water-retaining agent. The composite water-retaining agent is prepared from kieselguhr, maize straw powder, attapulgite, humic acid and a modified water-retaining agent. The water-retention nutrient soil has rich nutrients and high water and fertilizer retention performance.

Owner:宁国市汉唐盛世农林开发有限公司

Anodizing Electrolytes Using A Dual Acid System For High Voltage Electrolytic Capacitor Anodes

InactiveUS20070221507A1Improve breakdown voltageImproved dielectric oxide qualityAnodisationElectrotherapyElectrolytic agentO-Phosphoric Acid

An improved formation electrolyte and method for anodizing valve metal anodes used in electrolytic capacitors, particularly for high voltage sintered tantalum powder anode, is described. The anodizing electrolyte composition is comprised of 1) a phosphorus oxyacid and / or its salt, such as phosphoric acid and ammonium phosphate; 2) a weak inorganic acid / salt (such as boric acid, ammonium borate) or a weak carboxylic acid / salt; 3) water; and 4) a protic solvent or a mixture of two or more protic solvents. The weak mono-carboxylic acid / salt has 2 to 7 carbon atoms and the weak di- or poly-carboxylic acid / salt has 3 to 13 carbon atoms. The present electrolytes have high anodizing breakdown voltage capability and the formed dielectric oxides have improved oxide quality including good oxide hydration resistant ability, and result in more stable capacitor performance. These properties are particularly important for critical applications such as implantable cardioverter defibrillators (ICDs). Significantly, this means that fewer capacitors are needed to meet an ICD's operating voltage.

Owner:WILSON GREATBATCH LTD

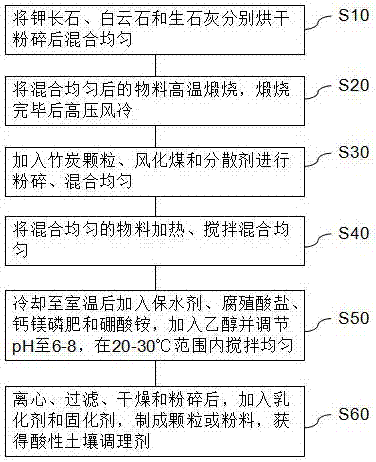

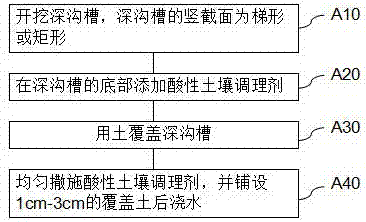

Acid soil conditioner, preparation method and soil improvement method

InactiveCN108003887APromote growthReduce demandOrganic fertilisersSoil-working methodsPotassium feldsparSoil conditioner

The invention provides an acid soil conditioner, a preparation method and a soil improvement method of the acid soil conditioner. The acid soil conditioner comprises, by weight, 20-30 parts of potassium feldspar, 10-15 parts of dolomite, 5-20 parts of quicklime, 5-10 parts of weathered coal, 5-10 parts of bamboo charcoal particles, 5-10 parts of humate, 1-2 parts of calcium-magnesium-phosphate fertilizer, 1-2 parts of ammonium borate, 2-5 parts of dispersing agent, 3-5 parts of water-retaining agent, 5-10 parts of emulsifier and 3-5 parts of curing agent. By means of the acid soil conditioner,the acid soil can be adjusted, heavy metal is adsorbed, the gas permeability and water-retaining property of soil are improved, and resources are saved.

Owner:GUANGDONG RES INSTITITUTE OF PETROCHEM & FINE CHEM ENG

Formation foil, preparation method and application thereof

ActiveCN109609991AAcid controlReduce corrosionAnodisationElectrolytic capacitorsOXALIC ACID DIHYDRATEPhysical chemistry

The embodiment of the invention discloses a method for preparing a formation foil. The method comprises the following steps that the corrosion foil is placed in the treatment liquid for constant-current oxidation treatment; the treatment liquid comprises oxalic acid with the mass concentration of 1-5% and boric acid with the mass concentration of 0.5%-2%; and the second sub-formation comprises thefollowing steps that the aluminum foil subjected to the first phosphating treatment is placed in a mixed solution of boric acid and ammonium borate, and a direct-current superposition pulse power source is used for processing. The corrosion foil is subjected to anodic oxidation treatment by using a mixed solution of the oxalic acid and the boric acid, on one hand, the acidity of the solution is better controlled due to the introduction of boric acid, and the corrosion resistance of the solution to the corrosion foil is reduced; on the other hand, the oxidation film formed in the anodic oxidation process is more compact, so that the formed porous oxide film is more stable in subsequent formation; the direct-current superposition pulse power supply is used for processing, so that the defectis exposed and repaired, the number of defects of the formation foil oxidation film is reduced, and the quality of the formation foil is further improved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD +1

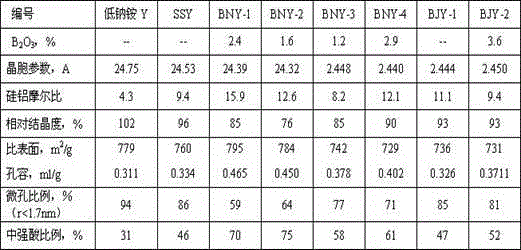

Ammonium fluoroborate modified Y-type molecular sieve and preparation method thereof

ActiveCN104556124AMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sievePhysical chemistry

The invention discloses a preparation method for a modified Y-type molecular sieve. The preparation method comprises the following steps: preparing an ammonium fluoroborate solution; (2) putting an industrially produced Y molecular sieve in the ammonium fluoroborate solution in the step (1), carrying out an aluminization removal and boron supplement reaction in the slurry system: NH4BF4+Al<3+>+Na<+>=NaAlF4 (a large-particle precipitate)+B<3+>+NH4<+>, and carrying out solid-liquid separation and drying after the reaction; (3) adding the molecular sieve dried in the step (2) into an alkaline solution to be pulped, and separating, washing and drying after the pulping to prepare the modified Y-type molecular sieve. The invention provides a modification method for carrying out aluminization removal and boron supplement on the Y-type molecular sieve by a combination of a boron-containing compound and the alkaline solution, so that a boron-containing modified Y-type molecular sieve which is medium / high in strong acid content is prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

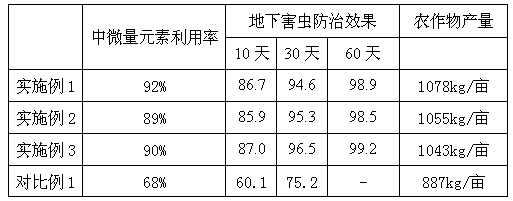

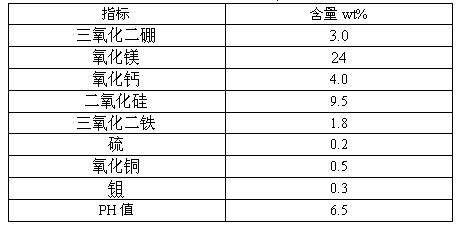

Humic acid chelated boron, magnesium, zinc and iron fertilizer and preparation method thereof

The invention provides a humic acid chelated boron, magnesium, zinc and iron fertilizer and a preparation method thereof. The fertilizer is composed of the following components in parts by weight: 20 to 30 parts of urea, 10 to 15 parts of diammonium hydrogen phosphate, 10 to 15 parts of potassium sulfate, 30 to 40 parts of boron magnesium slag, 10 to 15 parts of humic acid, 12 to 15 parts of citric acid, 1 to 2 parts of ammonia borate, 6.5 to 8 parts of magnesium sulfate, 7 to 7.5 parts of zinc sulfate, 5 to 6.5 parts of ferrous sulfate, 1 to 2 parts of avermectin, and 0.3 to 0.4 part of diazinon. The preparation method comprises the following steps: preparing medium trace element chelated fertilizer from citric acid, ammonium borate, magnesium sulfate, zinc sulfate, ferrous sulphate and humic acid, then adding urea, diammonium hydrogen phosphate, potassium sulfate, and boron magnesium slag into the fertilizer, grinding, and carrying out a spraying granulation process by using a mixed solution of avermectin and diazinon so as to obtain the finished product. The fertilizer has the advantages of high utilization rate of trace elements, reduction on soil hardening and water pollution, sustain-released effect, and longer lasting drug effect and fertilizing effect.

Owner:锦州硕丰农药集团有限公司

Ceramic polyolefin cable material and preparation method thereof

InactiveCN104558806AHigh strengthReduce the temperaturePlastic/resin/waxes insulatorsPolyolefinAntioxidant

The invention discloses a ceramic polyolefin cable material and a preparation method thereof, and belongs to the technical field of a wire / cable material. The ceramic polyolefin cable material consists of the following raw material components in parts by weight: 100 parts of an ethylene-alpha-olefine copolymer, 150-300 parts of ceramic powder A, 20-100 parts of ceramic powder B, 5-20 parts of a lubricant and 0.1-1 part of an antioxidant, wherein the ethylene-alpha-olefine copolymer is a mixture of ethylene and any one or more of alpha-propylene, alpha-butylene, alpha-hexylene and alpha-octylene copolymers according to any proportions by weight; the ceramic powder A is any one or any combinations of lamellar inorganic powder, fibrous inorganic powder and acicular inorganic powder; the ceramic powder B is at least one of borax, ammonium borate, zinc borate, boron frit, low-melting-point phosphate glass powder, low-melting-point borate glass powder and low-melting-point silicate glass powder; and the antioxidant is at least one of 1010, 1076, 168, 626, 300 and DSTDP.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

Novel tunnel fireproof paint

InactiveCN103992670ALight weightGood fire resistance and heat insulationFireproof paintsAlkali metal silicate coatingsFiberRailway tunnel

The invention discloses a novel tunnel fireproof paint, belonging to the technical field of chemical engineering. The fireproof paint is prepared from the following components in parts by weight: 22-30 parts of water glass, 10-15 parts of silicate, 15-20 parts of styrene-acrylic emulsion, 3-5 parts of aluminum silicate fiber, 30-40 parts of magnesium hydroxide, 5-7 parts of tin oxide, 2-4 parts of ammonium borate, 10-12 parts of meerschaum, 25-27 parts of light calcium carbonate, 12-14 parts of expanded perlite, 10-11 parts of melamine, 3-5 parts of pentaerythritol, 3-4 parts of vermiculite, 1-3 parts of ammonium dichromate and 0.8-2 parts of dispersing agent. The tunnel fireproof paint has the advantages of light volume weight, favorable fire resistance, favorable heat insulation property, favorable water / acid / alkali resistance and the like, prevents the steel concrete in the tunnel from temperature drop due to quick temperature rise in a fire hazard, and prevents the concrete from bursting up. The tunnel fireproof paint is suitable for fireproof protection of highway tunnels and railway tunnels.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

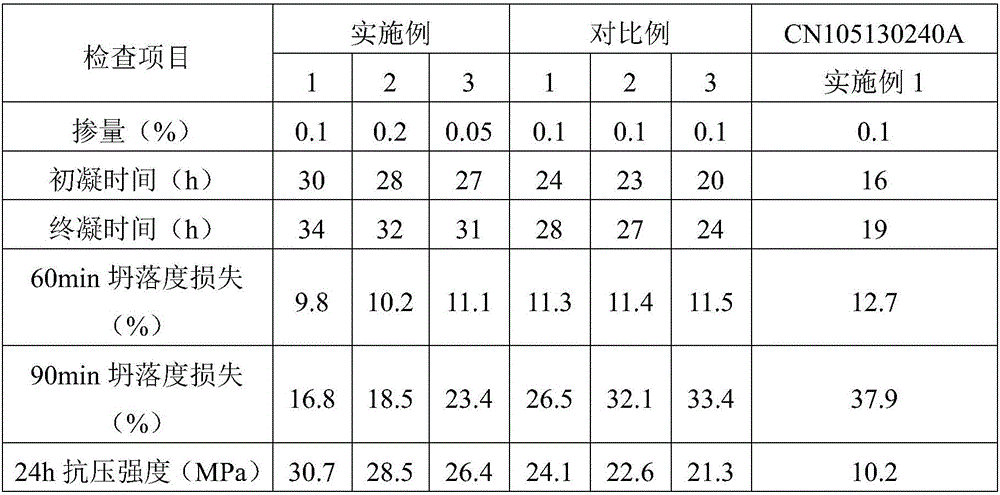

Novel concrete retarder

The invention disclsoes a novel concrete retarder. The novel concrete retarder is prepared from the following components in parts by weight: 2 to 5 parts of ammonium borate, 3 to 8 parts of sodium pyrophosphate, 4 to 9 parts of magnesium sulfate, 6 to 9 parts of diethylenetriaminepenta(methylenephosphonic) acid, 3 to 6 parts of sodium carboxymethyl cellulose, 1 to 4 parts of maltodextrin, 1 to 3 parts of sodium tartrate, 15 to 20 parts of palygorskite powder, 4 to 7 parts of a water reducing agent, 1 to 3 parts of a dispersant and 0.5 to 0.8 part of a surfactant. The novel concrete retarder provided by the invention has the advantages of excellent retarding effect, high strength, no pollution and the like, and is a concrete additive which has a very good development future.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

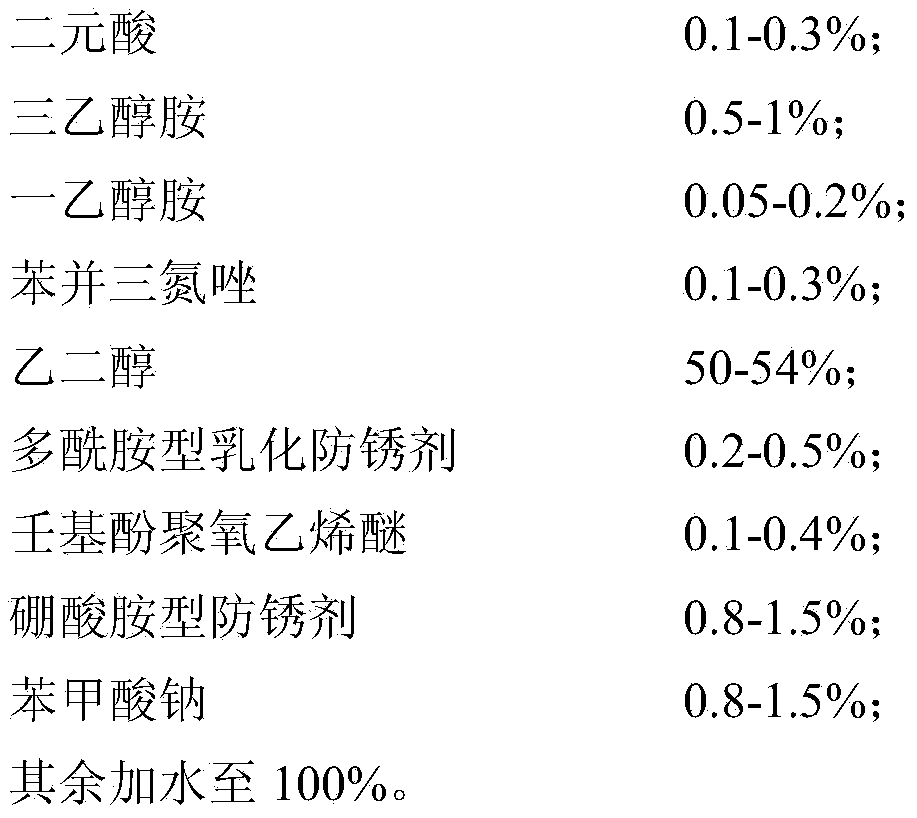

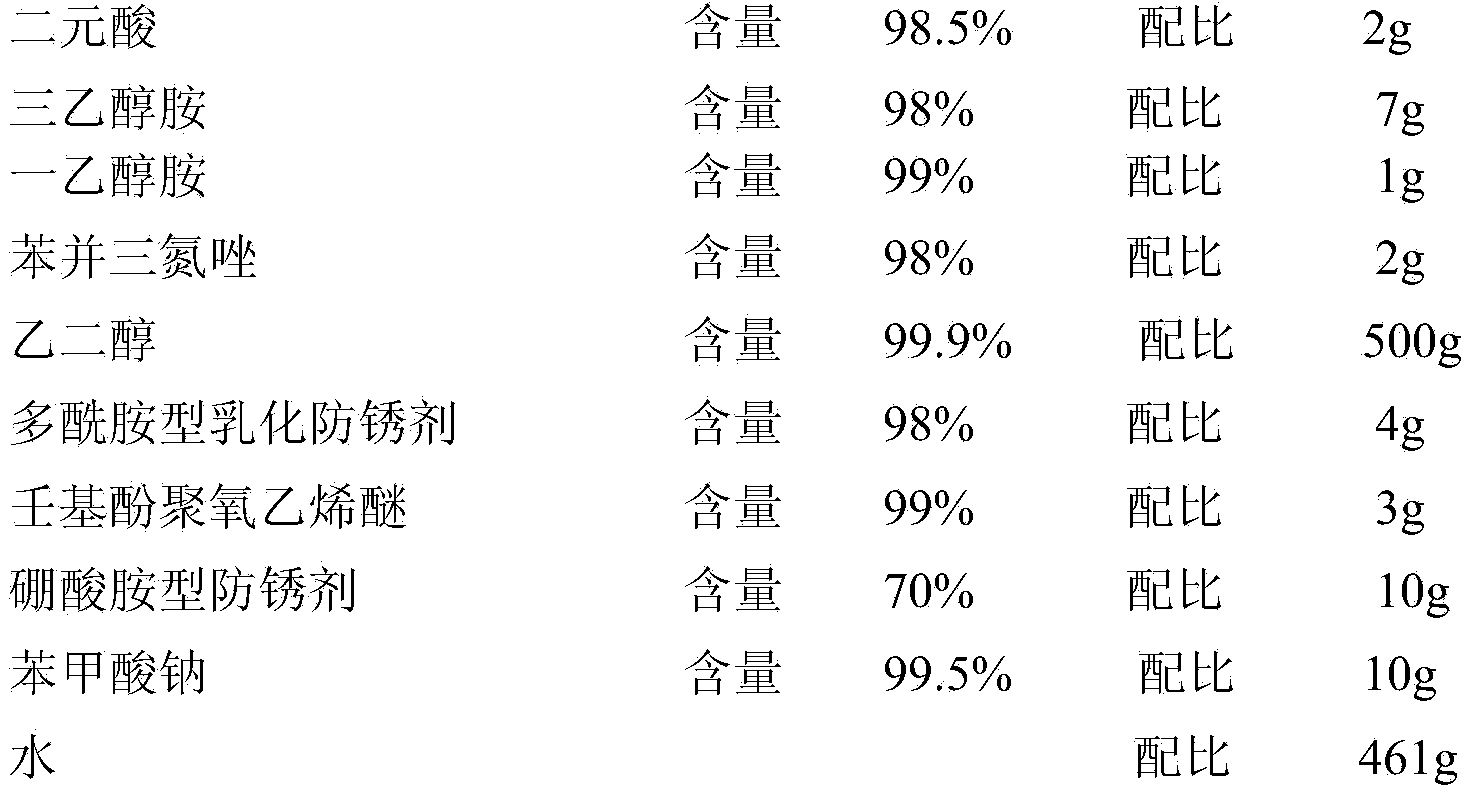

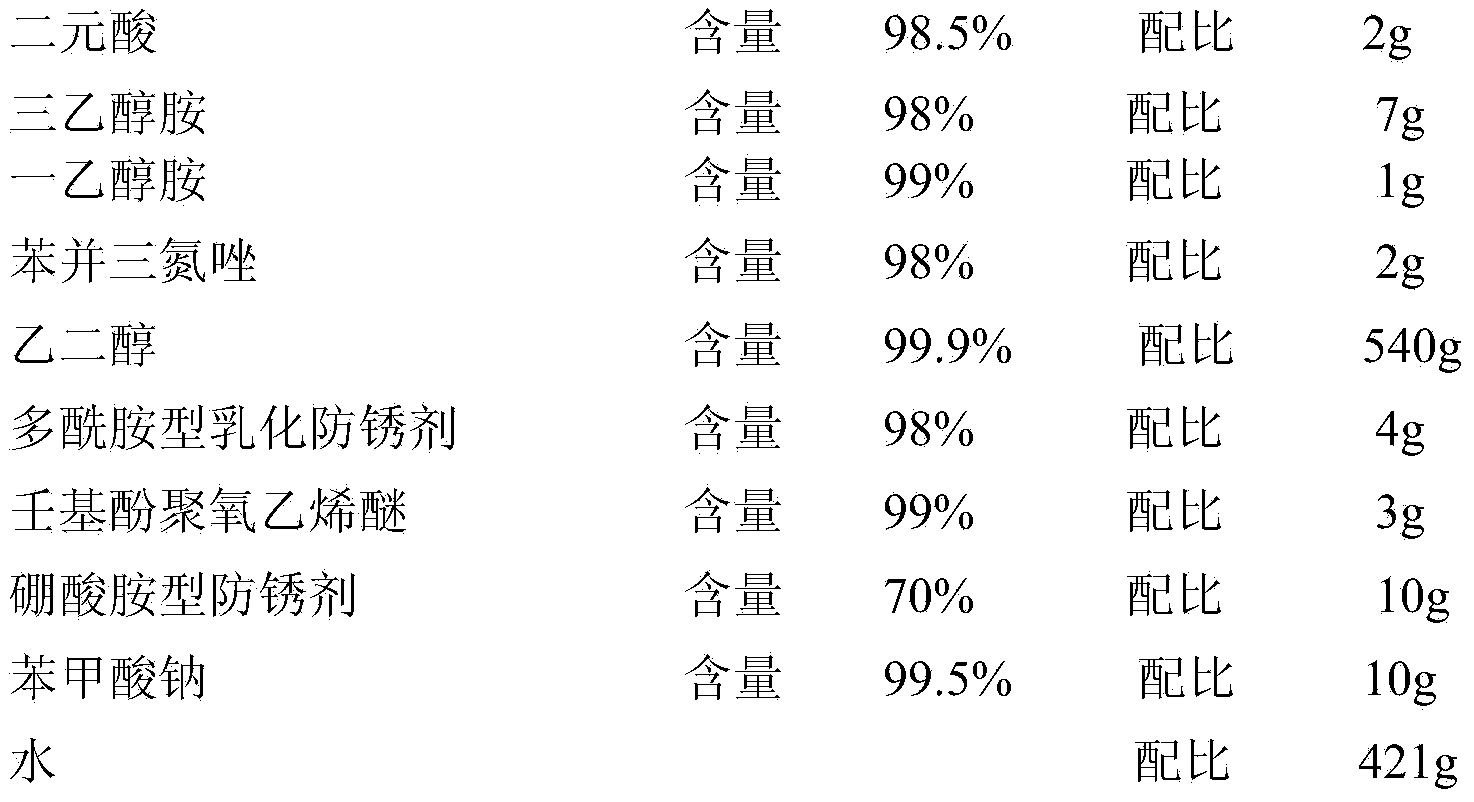

Environment-friendly hydraulic support antifreeze fluid and preparation method thereof

ActiveCN103666738AAnti-rust for a long timeExcellent anti-rustLubricant compositionEmulsionPhenyl Ethers

The invention relates to an environment-friendly hydraulic support antifreeze fluid and a preparation method thereof. The fluid is composed of the following components in percentage by weight: 0.1 to 0.3% of diacid, 0.5 to 1% of triethanolamine, 0.05 to 0.2% of ethanolamine, 0.1 to 0.3% of benzotriazol, 50 to 54% of glycol, 0.2 to 0.5% of polyamide type emulsion antirust agent, 0.1 to 0.4% of polyoxyethylene nonyl phenyl ether, 0.8 to 1.5% of ammonium borate type antirust agent, 0.8 to 1.5% of sodium benzoate, and the balance being water. The action mechanism of the antifreeze fluid is simple and scientific. Through the synergetic effect between each component, optimum antirust, lubricating and antifreeze effects are abtained. The ammonium borate type antirust agent and the sodium benzoate both have an antiseptic function, and thus can effectively prevent the hydraulic support from corrosion during the storage or work process. The ratio of glycol to water can be adjusted so as to obtain various antifreeze liquids applied in different low temperatures.

Owner:华阳新兴科技(天津)集团有限公司

Weather-proof and corrosion-resistant anti-rust oil and preparation method thereof

InactiveCN106479627AGood weather resistanceAccelerated corrosionLubricant compositionSodium BentoniteAntioxidant

The invention discloses weather-proof and corrosion-resistant anti-rust oil and a preparation method thereof. The anti-rust oil is prepared from main ingredients including organic silicone oil, 46# machine oil, asphalt and pentaerythritol mixed with sodium cetostearyl sulphate, ammonium borate, zinc naphthenate, microcrystalline cellulose, nano ceramic powder, organic bentonite, dibutyl succinate, polyoxyethylene rosin ester, 2,2,4-trimethyl-1,3-pentanediolmono(2-methylpropanoate), sorbitol anhydride monooleate, silicon dioxide particles and an antioxidant by ball milling, sintering, heating and stirring, ultrasonic oscillation, microwave vacuum drying, high-speed shearing and the like. The anti-rust oil has excellent weather resistance and corrosion resistance and good low-temperature adhesion, can meet requirements of the industry and has better application prospect.

Owner:WUJIANG HUAWEI SPECIAL OIL

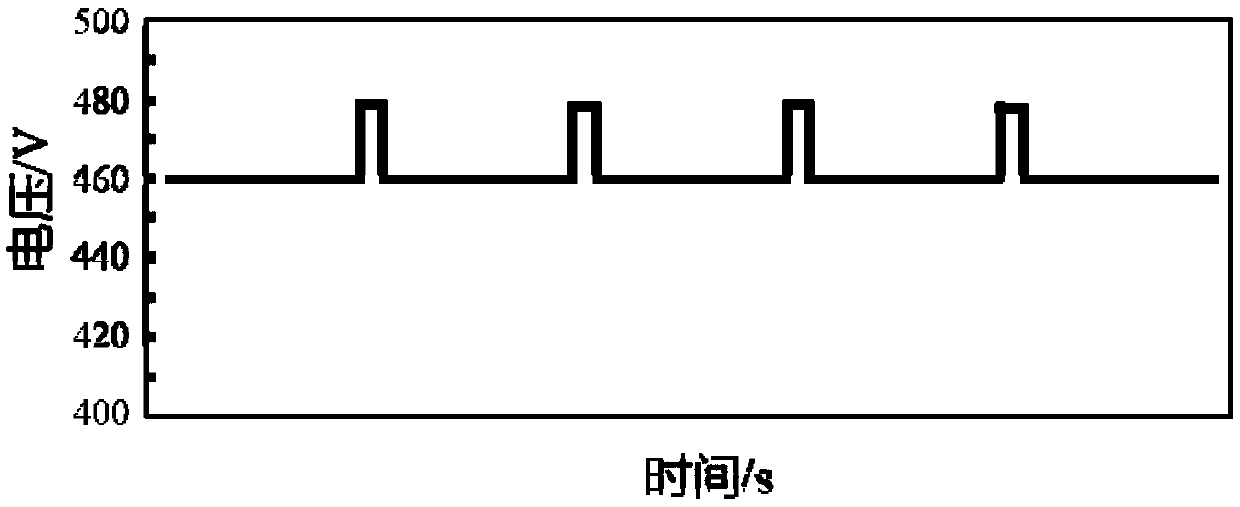

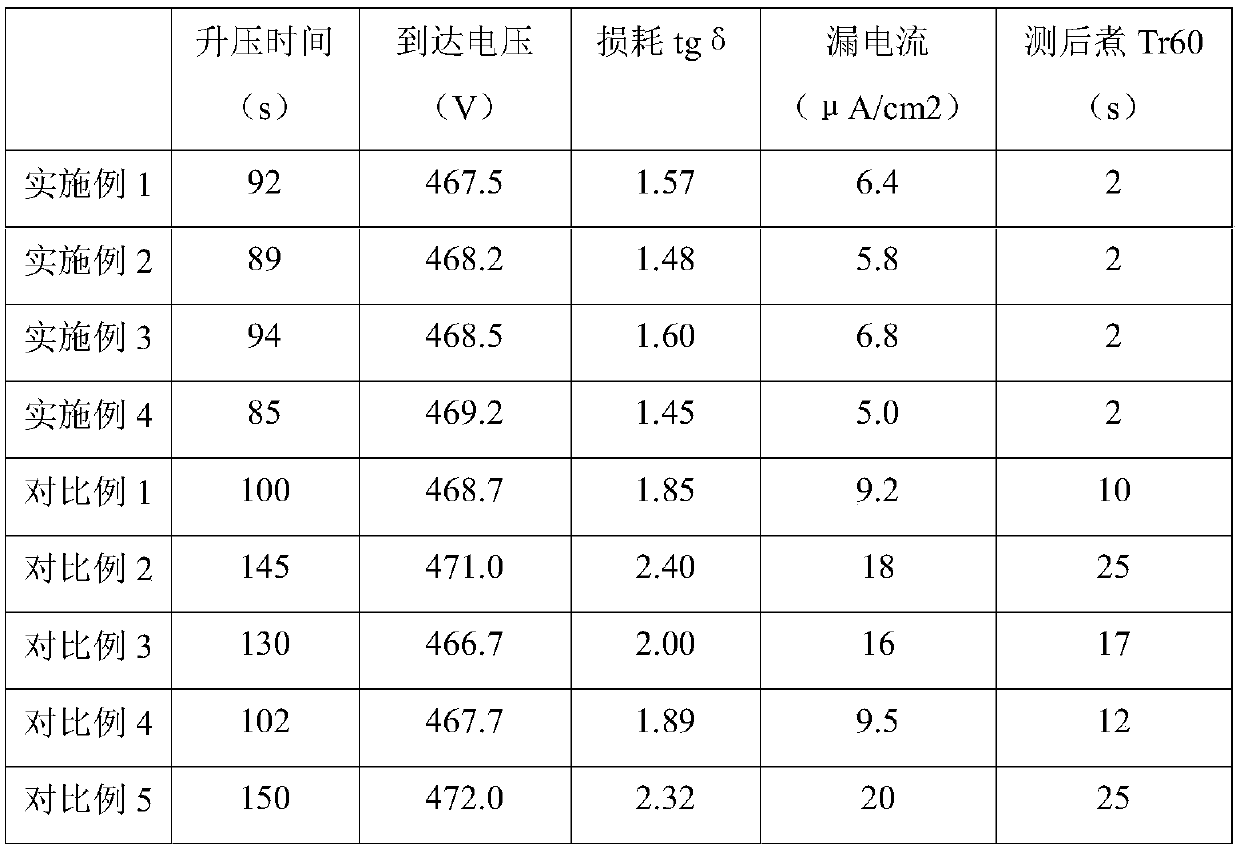

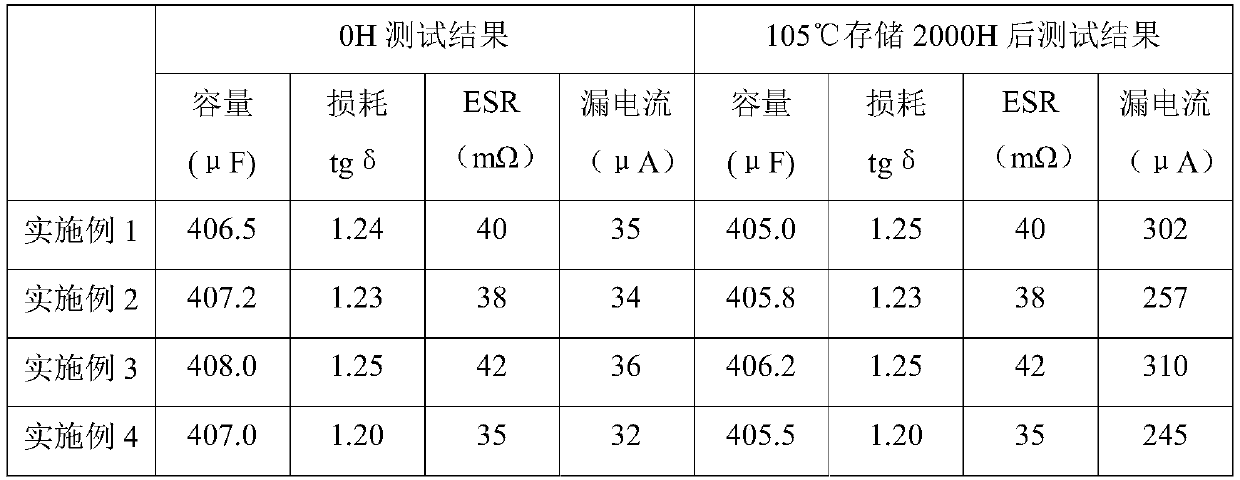

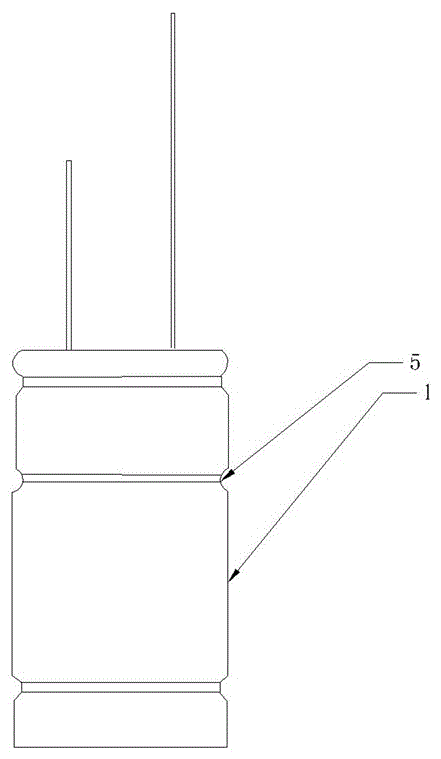

Microminiature rapid charging special-purpose aluminium electrolytic capacitor

InactiveCN106252083AGuaranteed capacityGuaranteed high withstand voltage performanceCapacitor housing/encapsulationP-nitroanisoleLightning strike

The invention provides a microminiature rapid charging special-purpose aluminium electrolytic capacitor which comprises a shell, a core bag and a rubber plug. The core bag is sealed in the shell through the rubber plug. The core bag contains electrolyte which comprises a solvent, an inorganic acid ammonium salt, an organic acid ammonium salt, and a hydrogen elimination agent. The inorganic acid ammonium salt is ammonium borate or ammonium pentaborate or the mixture of the ammonium borate or the ammonium pentaborate. The organic acid ammonium salt comprises one or more of ammonium sebacate, ammonium azelate, diammonium phthalate, and dodecyl ammonium carboxylate. The hydrogen elimination agent comprises one or more of a p-Nitrobenzyl alcohol, a p nitroanisole and p-nitrobenzoic acid. The conductivity of the electrolyte in the invention is between 2.4 ms / cm to 2.8ms / cm, the ESR value of a product can be effectively reduced, thus the ripple resistance and lightning strike resistance ability of the product are improved greatly, the flash fire voltage is above 490V, in a condition of high voltage, the breakdown of electrolytic paper caused by flash fire of the electrolyte does not appears, and thus the voltageproof performance of the product is ensured.

Owner:HUNAN AIHUA GRP

Bentonite composite super absorbent material and preparation method thereof

InactiveCN109399654AImprove water absorptionStrong anti-penetrationSilicon compoundsSodium BentoniteAbsorbent material

The invention discloses a bentonite composite super absorbent material and a preparation method thereof, and relates to the field of bentonite material preparation. The bentonite composite super absorbent material is prepared from the following raw materials in parts by weight: 70-90 parts of sodium bentonite particles, 20-30 parts of a polymer crosslinking agent, 10-15 parts of oligomeric resin,1-5 parts of microcrystalline cellulose, 1-5 parts of sodium salt modified silica gel, 1-5 parts of expanded vermiculite, 0.1-1 part of ammonium borate, 0.1-1 part of magnesium hydroxide, 0.1-1 part of polyacrylamide, 0.01-0.1 parts of a redox initiator, 0.1-1 part of an oxidant and 0.1-1 part of a reducing agent. The sodium bentonite particles are activated into secondary sodium bentonite particles to replace common sodium bentonite particles, and oligomeric resin is added. Compared with common bentonite absorbent materials, the bentonite composite super absorbent material has the advantagesof high water absorption rate, large water absorption amount and high permeation resistance. Besides, the preparation method is simple, the raw materials are easily available, and requirements on equipment are low.

Owner:句容康泰膨润土有限公司

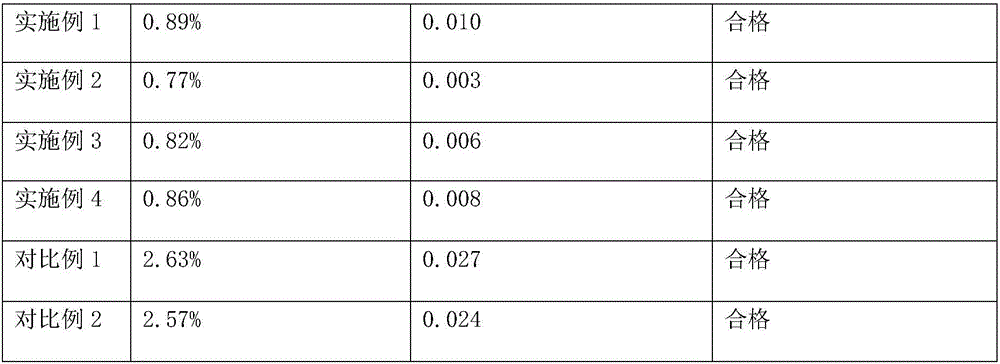

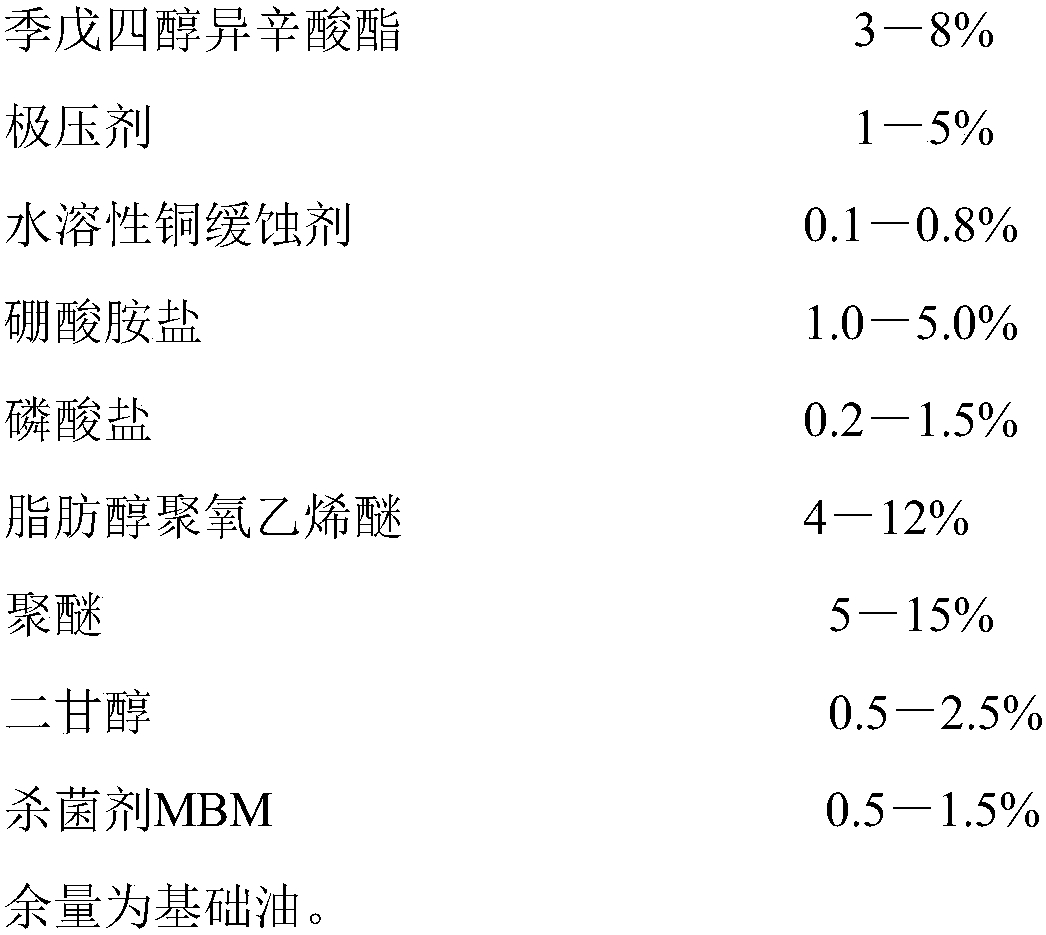

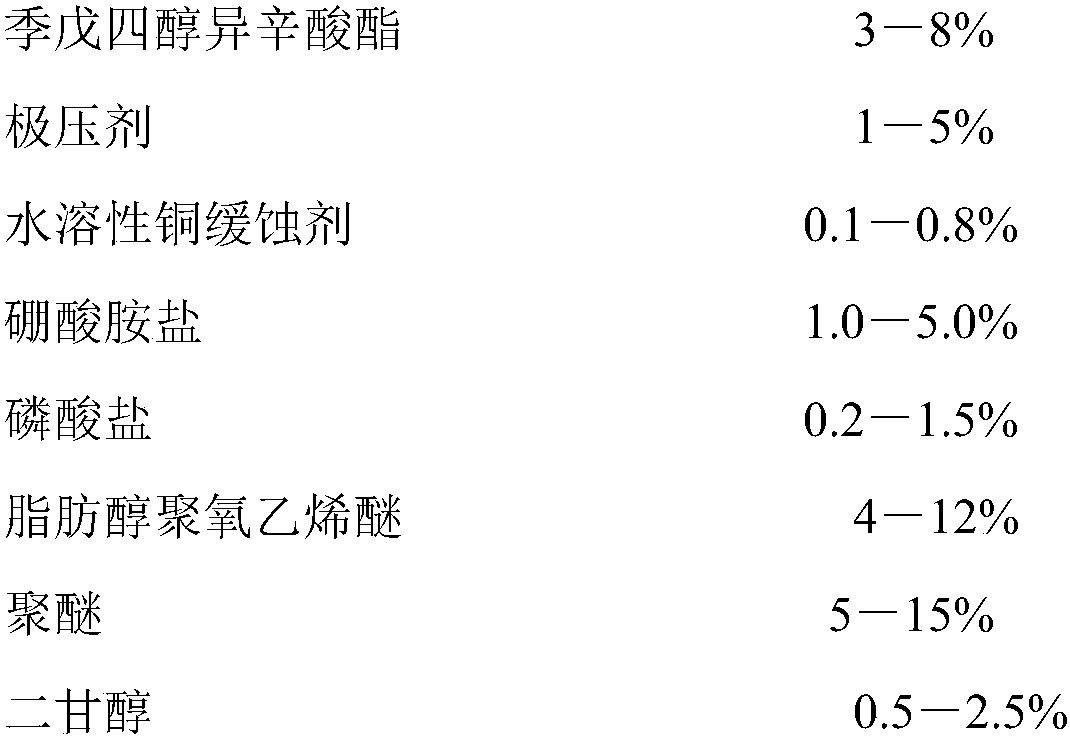

Copper wire drawing liquid

InactiveCN107629842AMeet the requirements of fast drawingNot easy to generateLubricant compositionPhosphateCopper wire

The invention relates to a copper wire drawing liquid, which comprises the following raw materials by weight: 3-8% of pentaerythritol isooctanoate, 1-5% of an extreme pressure agent, 0.1-0.8% of a water-soluble copper corrosion inhibitor, 1.0-5.0% of ammonium borate, 0.2-1.5% of phosphate, 4-12% of fatty alcohol polyoxyethylene ether, 5-15% of polyether, 0.5-2.5% of diethylene glycol, 0.5-1.5% ofa sterilization agent MBM, and the balance of base oil. According to the present invention, the copper wire drawing liquid can meet the rapid copper wire drawing requirement, is the micro-emulsification liquid containing a small amount of mineral oil, uses the synthetic polyol fatty acid ester as the oily agent, uses the water-soluble phosphorus-containing compound as the extreme pressure agent, uses the polyether-based nonionic surfactant as the main emulsifier, has effects of good lubrication, good cooling and good cleaning, does not easily generate copper soap, has characteristics of long service life and good oxidation resistance, and can completely meet the rapid copper wire drawing requirement.

Owner:TIANJIN AOLUPU LUBRICATION TECH CO LTD

Method for preparing organic titanium-containing ammonium borate fertilizer with recrystallization technology

The invention relates to a method for preparing an organic titanium-containing ammonium borate fertilizer with a recrystallization technology. The method is characterized by: using alkali to neutralize the ice water solution of a titanium salt so as to prepare a new precipitate metatitanic acid; using the new precipitate metatitanic acid to substitute a chloride of titanium and a sulfate to serve as the raw material for synthesizing titanium citrate; taking the new precipitate metatitanic acid as a titanium source, and citric acid as a solvent and a chelating agent, employing a micro wave hot melting and chelating process to synthesize a saturated titanium citrate solution; conducting neutralization and salting-out on the saturated titanium citrate solution with powdered ammonium carbonate for preparing a composite salt of organic titanium-organic ammonium, mixing the powder of the organic titanium-organic ammonium composite salt with crystal water-containing ammonium tetraborate and carrying out eutectic melting so as to manufacturing the titanium-containing ammonium borate fertilizer. Due to the characteristic of titanium element to powerfully promote the absorption and running of nitrogen, phosphorus, potassium as well as other secondary elements and trace elements in plants, water soluble titanium citrate with superior stability obtained from micro wave hot melting and sufficient chelating can be used as a synergist for promoting ammonium borate fertilizer absorption and a crop growth accelerator.

Owner:FUJIAN CHAODA GROUP

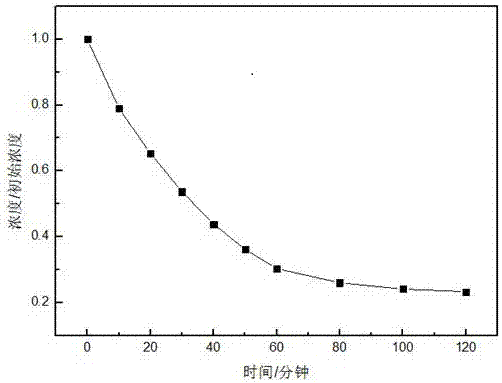

Preparation method and applications of porous carbon environment restoration material

InactiveCN107349903AEasy accessEasy to fireOther chemical processesContaminated soil reclamationPorous carbonThiourea

Owner:YANGZHOU UNIV

Mixed solubility borate preservative

InactiveUS20090053509A1Rapid, yet long-lasting, resistance against insectReduce solubilityBiocideInorganic boron active ingredientsSolubilityCellulose

Preservative composition for lignocellulosic-based composites providing rapid and long-lasting protection against insect and fungal attack, in both low and high moisture environments, through the use of a combination of higher solubility and lower solubility borates. Pesticidal amounts of a lower solubility borate and a higher solubility borate are combined before or during their incorporation into a lignocellulosic-based composite. Useful low solubility borates include copper borate, zinc borate and barium metaborate. Useful high solubility borates include boric acid, boric oxide, ammonium borate and alkali metal borates such as sodium borate. Some alkaline earth metal borates, including calcium borates, calcium magnesium borates, magnesium borates and calcium sodium borates, are of intermediate solubility and may be used effectively as either a low soluble or high soluble borate depending on the combination used.

Owner:U S BORAX INC

Leaf surface fertilizer of polymerized neodymium borate, and preparation method

InactiveCN101050133AAvoid residual contaminationImprove boron nutrient deficiencyAmmonium salt fertilisersBoratesCrystallinityAmmonia

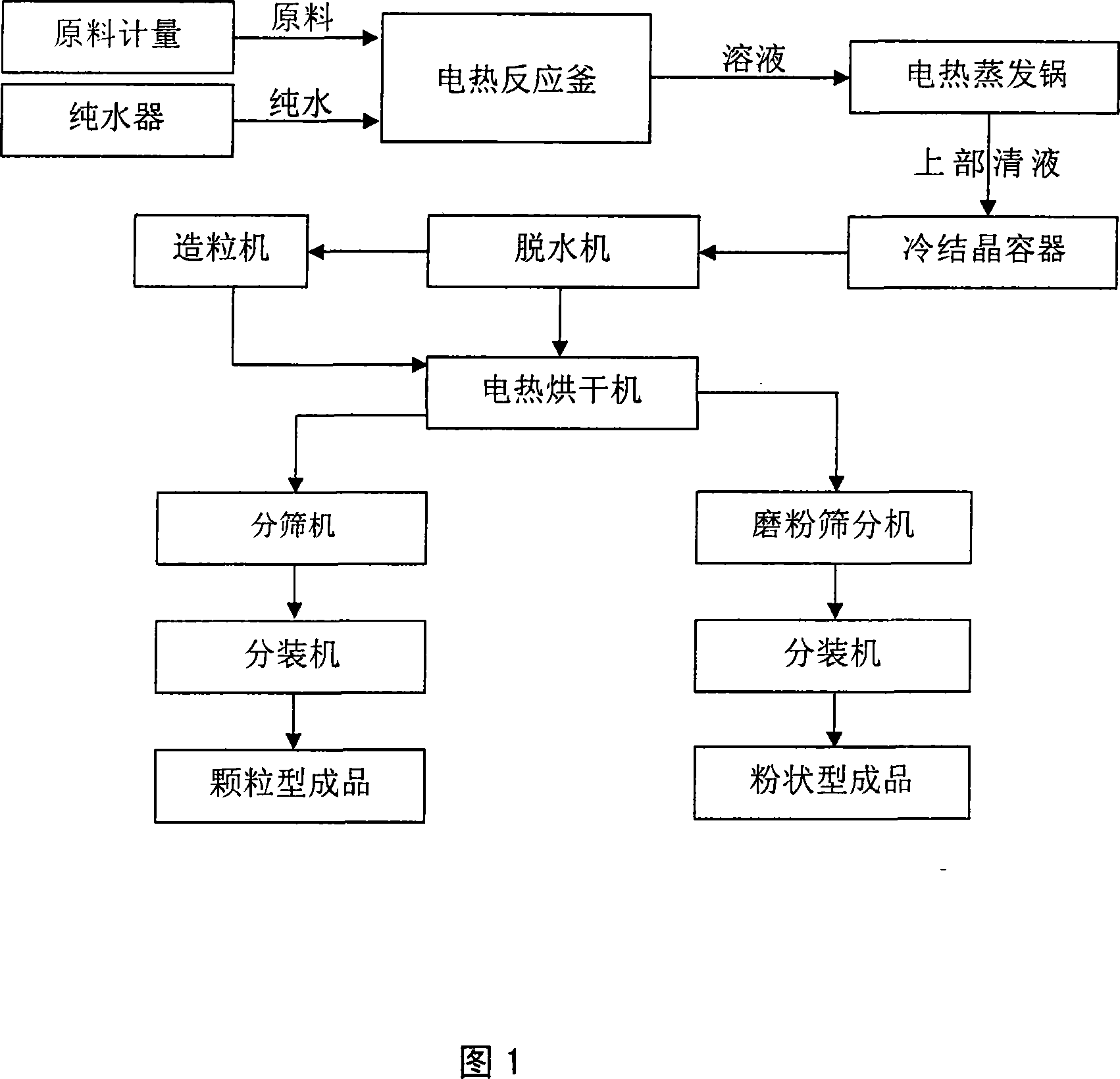

This invention discloses a method for preparing leaf fertilizer of poly (ammonium borate). The method comprises: (1) heating 60 kg water in the reaction kettle to 60 deg.C, and adding 50 kg boric acid and 50 kg ammonia under stirring until no air bubbles; (2) evaporating and concentrating the solution in an electric evaporator at less than or equal to 100 deg.C to 50%, filtering the supernatant, cooling to normal temperature, and crystallizing; (3) dehydrating the crystal, and drying in a drier at 100-105 deg.C for 8 h to obtain the leaf fertilizer of poly(ammonium borate). The leaf fertilizer of poly (ammonium borate) has such advantages as high boron content, easy absorption, and low crystallinity.

Owner:武汉富强科技发展有限责任公司

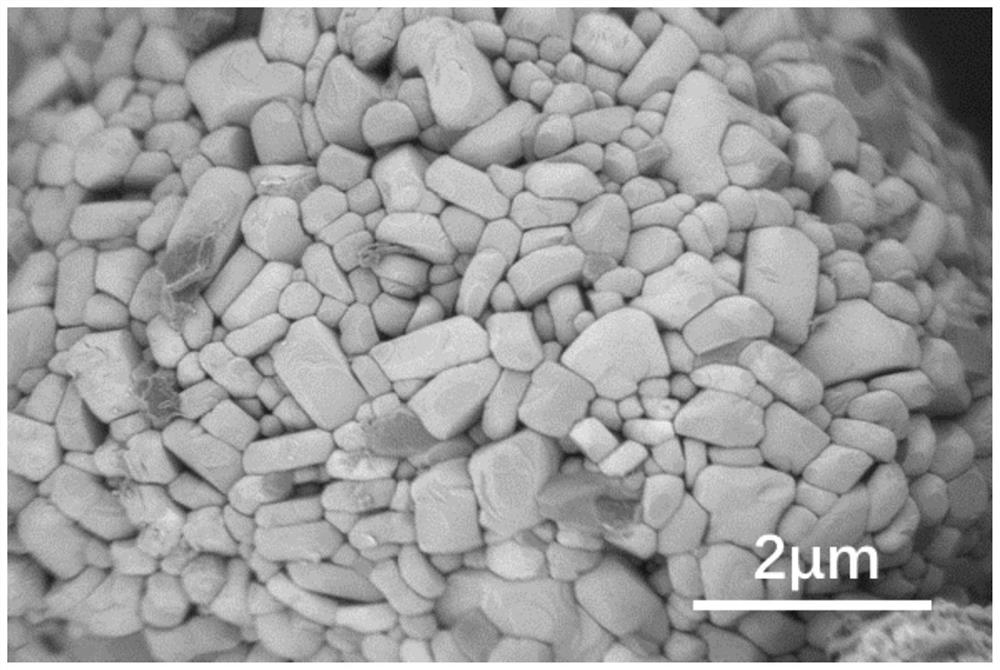

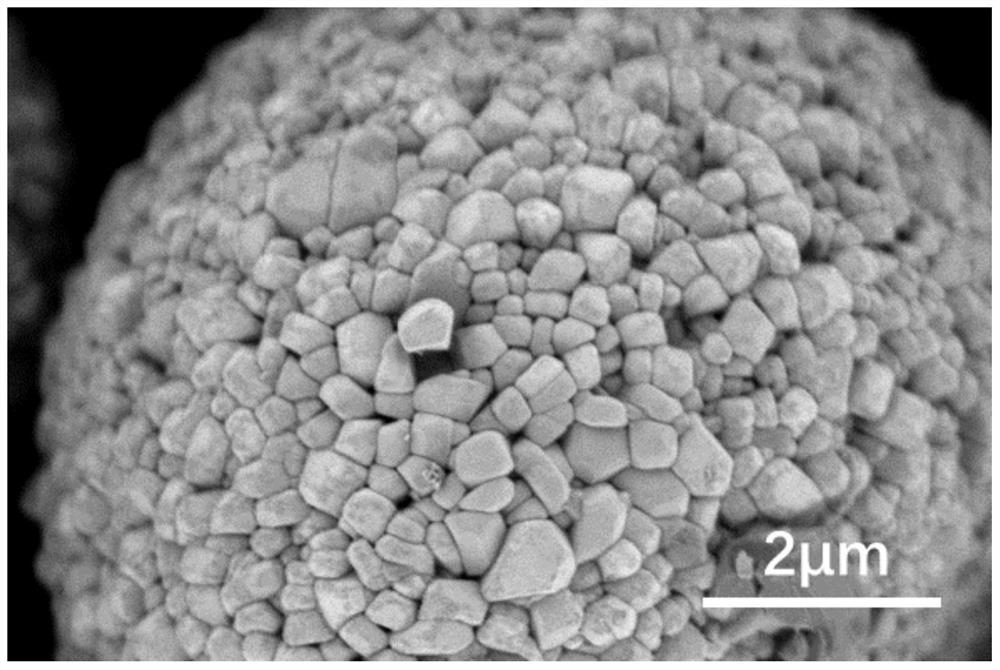

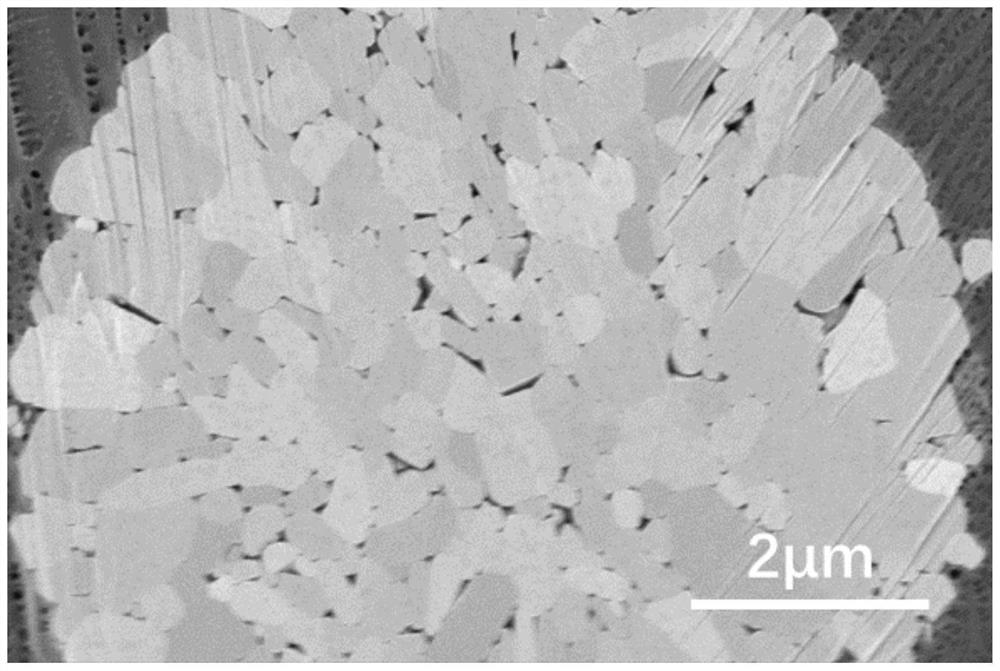

High-nickel ternary positive electrode material as well as preparation method and application thereof

InactiveCN112614991AImprove cycle stabilityReduce stressPositive electrodesLi-accumulatorsElectrical batteryManganese

The invention belongs to the technical field of lithium ion batteries, and provides a high-nickel ternary cathode material and a preparation method and application thereof, the chemical formula of the high-nickel ternary cathode material is LiNixCoyMnzBiO2, B is at least one of diboron trioxide, boric acid, lithium tetraborate, ammonium pentaborate, ammonium fluoborate or boron carbide, x > / = 0.9, y>0, z>0, i is not smaller than 0.001 and is not greater than 0.1, and x+y+z+i=1. The preparation method comprises the following steps of ball-milling and mixing a nickel-cobalt-manganese hydroxide precursor, a lithium source and a boron source, sintering and sieving to obtain the high-nickel ternary positive electrode material. Primary particles of the high-nickel ternary positive electrode material of the lithium battery are slender, interiors of secondary particles are looser, the high-nickel ternary positive electrode material of the lithium battery has higher first-circle capacity and better cycling stability, and the loose internal structure can reduce stress in the material in the cycling process, inhibit generation of microcracks, enhance the structural stability of the material and prolong the service life of the material; thus, a material having excellent cycle stability is obtained.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

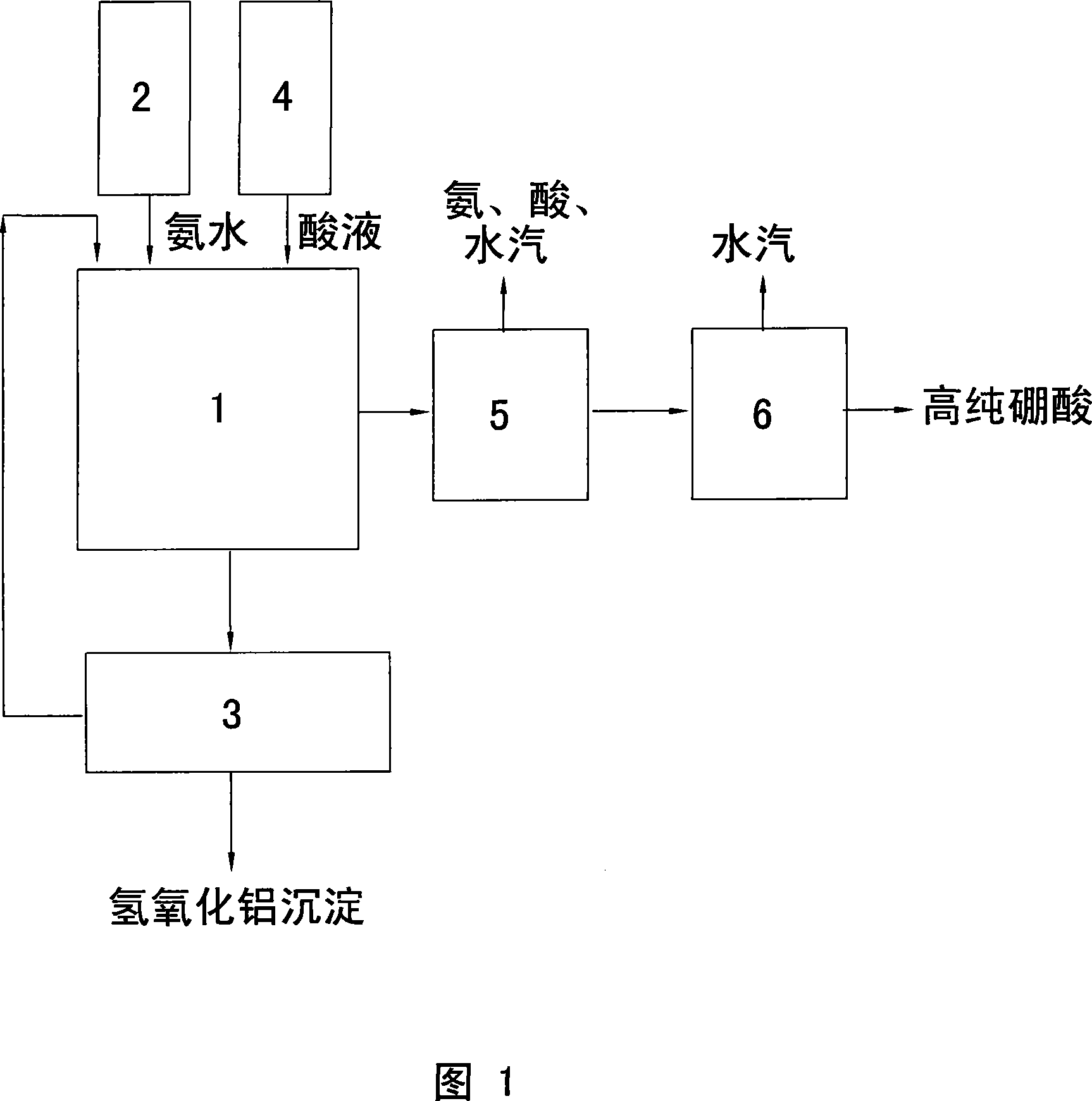

Boric acid formed in waste liquor recovery processing method and processing system thereof

InactiveCN101139097AEfficient separationImprove protectionMultistage water/sewage treatmentWater/sewage treatment by heatingLiquid wasteBoiling point

The invention relates to a recycling processing method and a processing system of forming boric acid in waste liquid. The method includes the following steps of that ammonia is added in the waste liquid to promote the waste liquid to precipitate aluminum hydroxide deposition, separate precipitate aluminum hydroxide deposition from the waste liquid and get primary separating liquid; acidizing fluid with low boiling point is added in the primary separating liquid to promote ammonium borate pentaborate in the primary separating liquid to hydrolyze into boric acid and acquire acidizing fluid; the acidizing fluid is decompressed and distilled to braize out the water in ammonium group and acidizing fluid until solid boric acid is precipitated; the solid boric acid precipitated is dried in vacuum or normal pressure and recycled. The processing method and system of the invention can high effectively precipitate aluminum and ammonium group and transfer the ammonium borate pentaborate into boric acid so as to high effectively recycle and utilize. The invention can not only better protect environment, but also guarantee the purity of recycling boric acid product and recycling application in the foil forming industry. The invention can improve production efficiency and reduce recycling cost as well.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com