Microminiature rapid charging special-purpose aluminium electrolytic capacitor

A technology of aluminum electrolytic capacitors and fast charging, applied in capacitor parts, capacitor shells/packages, etc., can solve the problems of aluminum electrolytic capacitors failing to meet requirements, improve ripple resistance and lightning resistance, reduce size, The effect of reducing the ESR value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

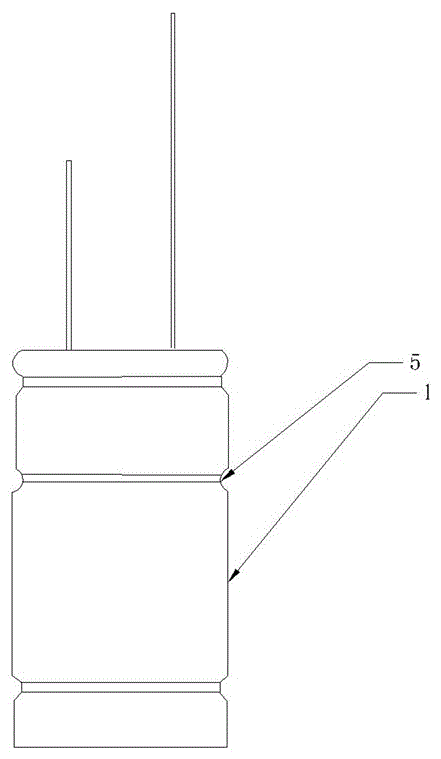

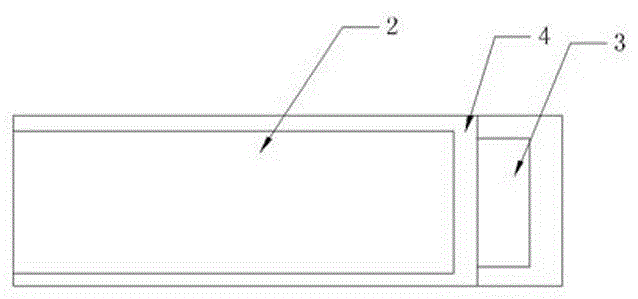

[0022] Such as figure 1 with figure 2 The shown ultra-small aluminum electrolytic capacitor for fast charging includes a shell, a core package and a rubber plug. The core package is sealed in the shell by a rubber plug. The rubber plug includes IIR butyl rubber, carbon black, clay and resin. The thickness is 1.8-4.0mm, and the hardness of the rubber plug is between 85-90. The rubber stopper is an anti-corrosion rubber stopper cleaned by a hydrophobic agent, and the hydrophobic agent includes silicone oil or PEG oil.

[0023] In this embodiment, the core package includes a positive electrode foil and a negative electrode foil, and the edges of the positive electrode foil and the negative electrode foil are staggered. The outer shell and the core pack are fixed by an inner recessed groove on the outer shell, and the outer layer of the core pack is wrapped by a multilayer adhesive tape.

[0024] In this embodiment, the electrolyte includes 64 parts ethylene glycol, 12 parts diethyl...

Embodiment 2

[0027] In this embodiment, the electrolyte includes 50 parts of ethylene glycol, 15 parts of γ-butyrolactone, 3 parts of water, 3 parts of ammonium dodecanoate, 4.5 parts of ammonium phthalate, 4 parts of ammonium pentaborate, 1.8 parts of decanoate Ammonium diacid, 1.5 parts of citric acid, 2.5 parts of ammonium hypophosphite, 6 parts of organic nano silicon solution, 6.5 parts of polyglycerol polyoxyethylene ether, 0.8 parts of p-nitrobenzyl alcohol. The conductivity of the electrolyte of this embodiment is 2400 μs / cm, the flash voltage is 595V, and the pH is 6.0. The other parts of this embodiment are the same as the first embodiment.

Embodiment 3

[0029] The electrolyte of this embodiment includes 50 parts of ethylene glycol, 20 parts of polyethylene glycol, 2.5 parts of water, 2.5 parts of diethylene glycol, 3 parts of ammonium dodecanoate, 5.5 parts of ammonium pentaborate, 0.8 parts of 2,5- Dihydroxybenzoic acid, 5.5 parts of organic nano silicon solution, 2 parts of ammonium hypophosphite, 8 parts of diglycerol polyoxyethylene ether, and 0.6 parts of p-nitrobenzyl alcohol. The conductivity of this embodiment is 2500 μs / cm, the flash voltage is 512V, and the PH is 6.2. The other parts of this embodiment are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com