Patents

Literature

31results about How to "Lower ESR value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

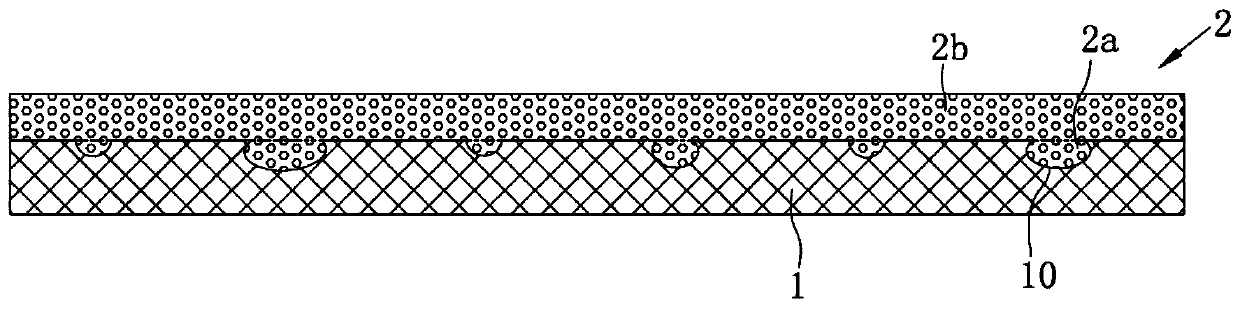

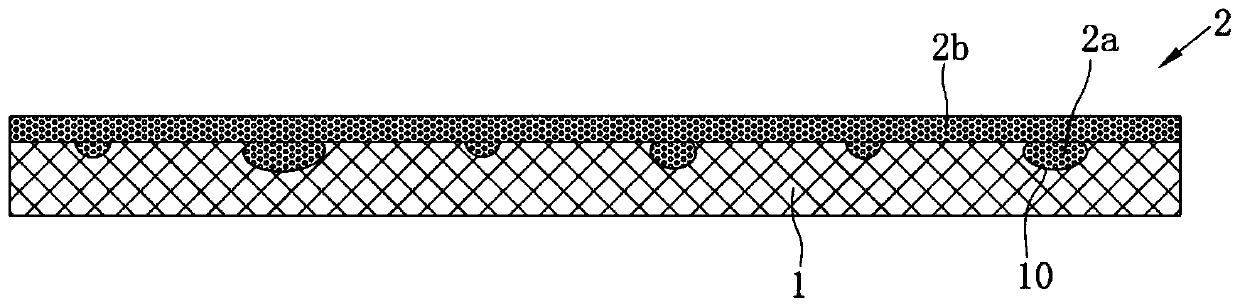

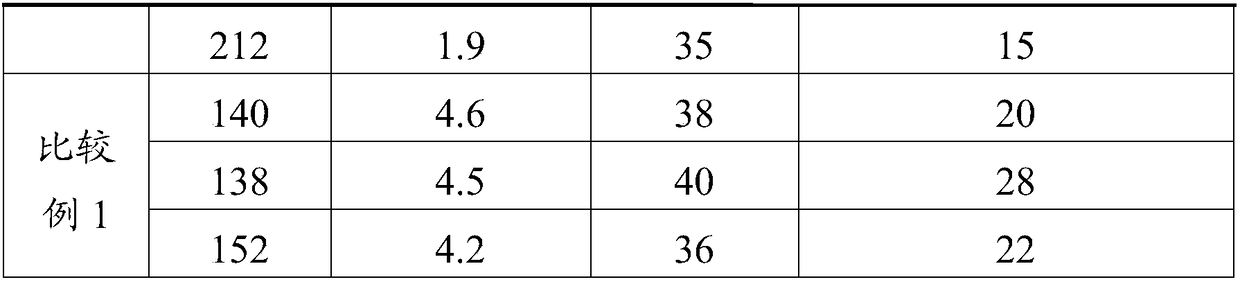

Production process of negative electrode foil, negative electrode foil and polymer solid aluminum electrolytic capacitor

ActiveCN109830374AIncrease specific volumeReduce volumeSolid electrolytic capacitorsCapacitor dielectric layersElectrolysisCarbonization

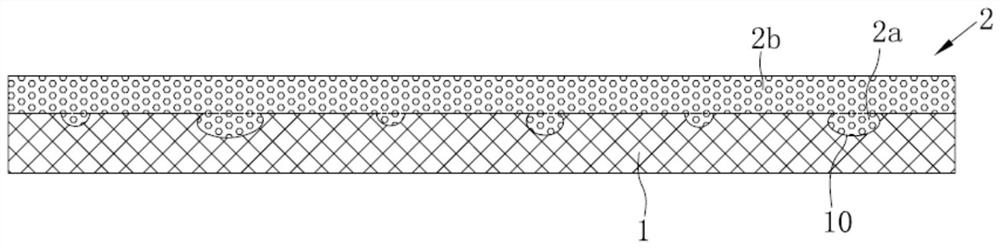

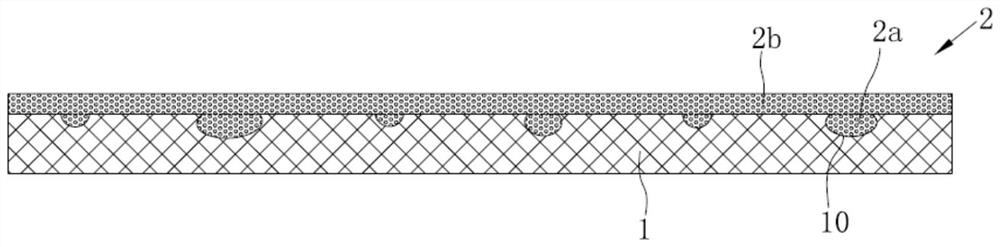

The invention relates to a production process of a negative electrode foil, a negative electrode foil and a polymer solid aluminum electrolytic capacitor. The production process of the negative electrode foil comprises the following steps of S1, selecting an aluminum substrate; and S2, a process of forming a dielectric layer, comprising the following steps of a) preparing a paste; b) etching the surface of the aluminum substrate to form a hole, coating the surface of the aluminum substrate having the hole with the paste, drying the surface, feeding aluminum substrate to a rolling mill, pressing a coating into the hole and compacting the coating on the surface of the hole and the aluminum substrate; and c), performing a carbonization treatment. On the premise of increasing the specific volume, the negative electrode foil having the same specific volume is significantly thinner. The polymer solid aluminum electrolytic capacitor produced by the negative electrode foil is significantly smaller in size and lower in ESR value among the products having the same capacity. The negative electrode foil contributes to the miniaturization and the current withstanding capability of the polymer solid aluminum electrolytic capacitor.

Owner:安徽纳诺箔材有限公司

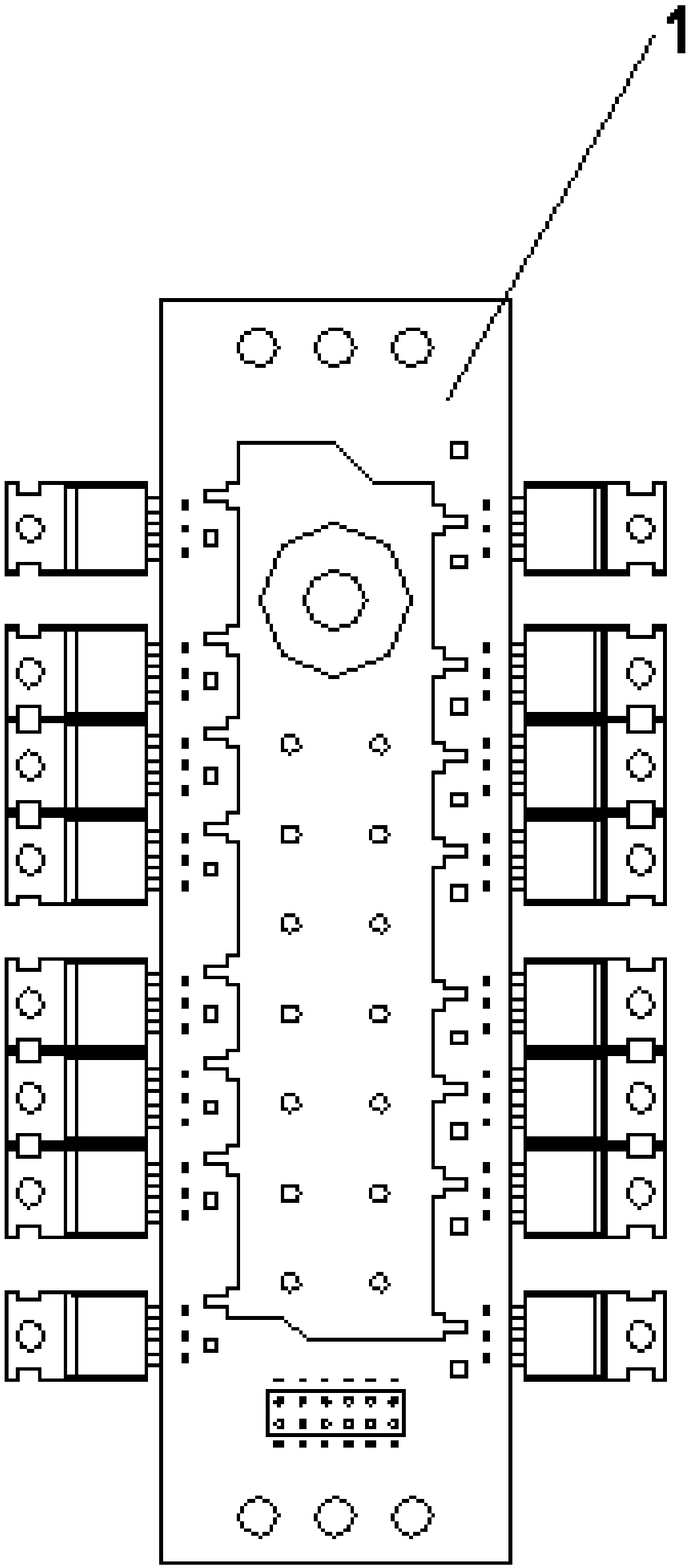

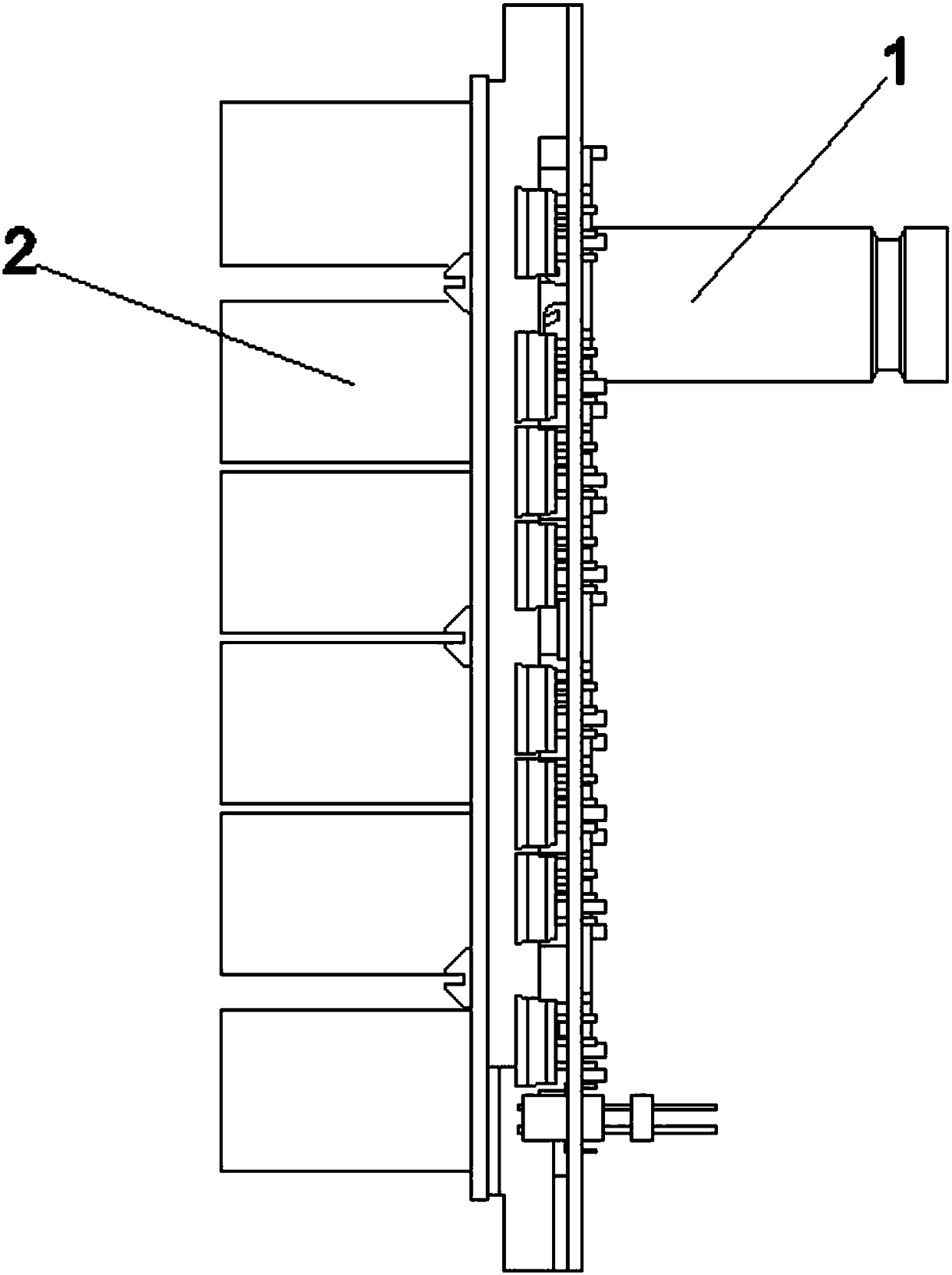

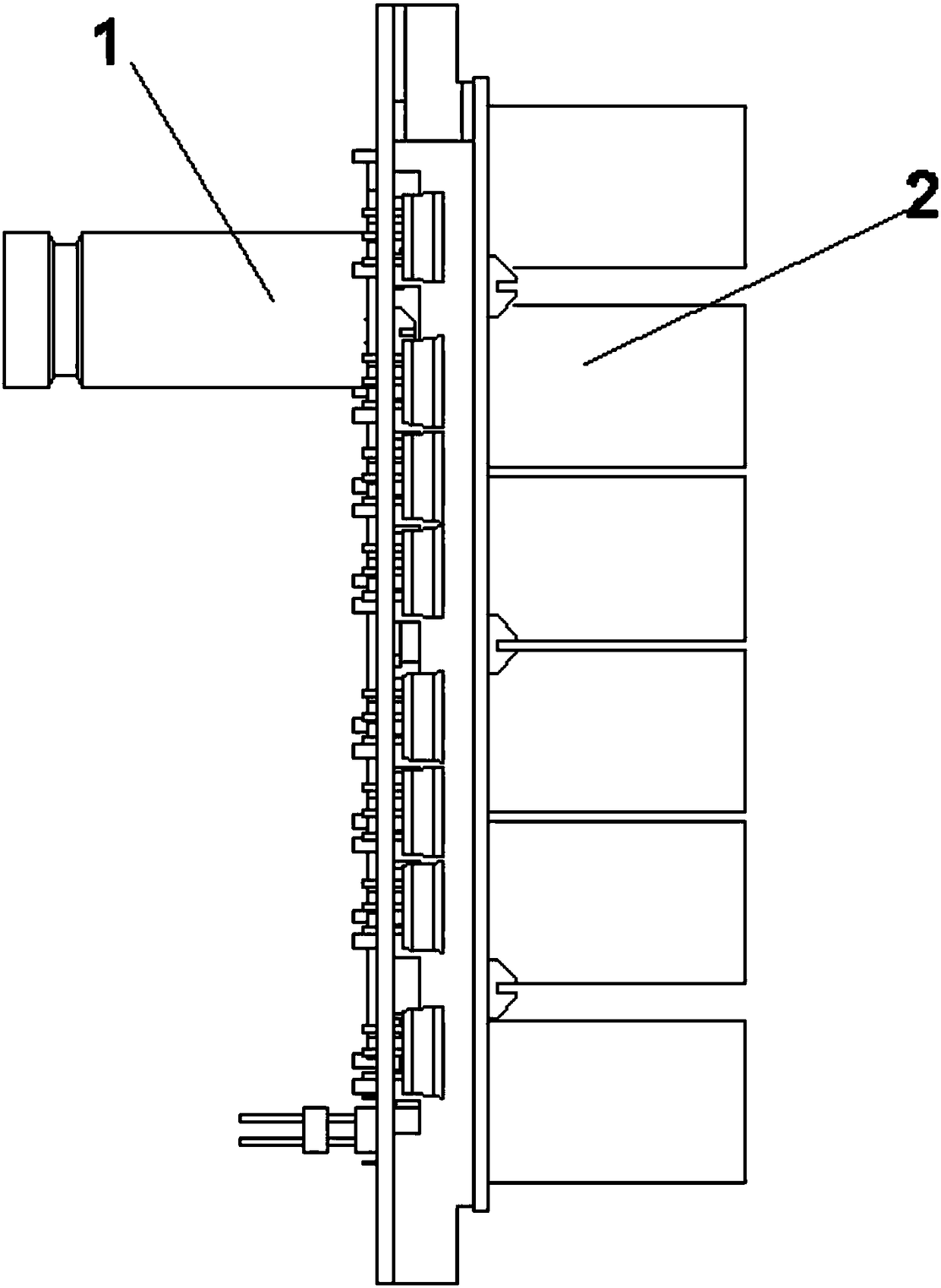

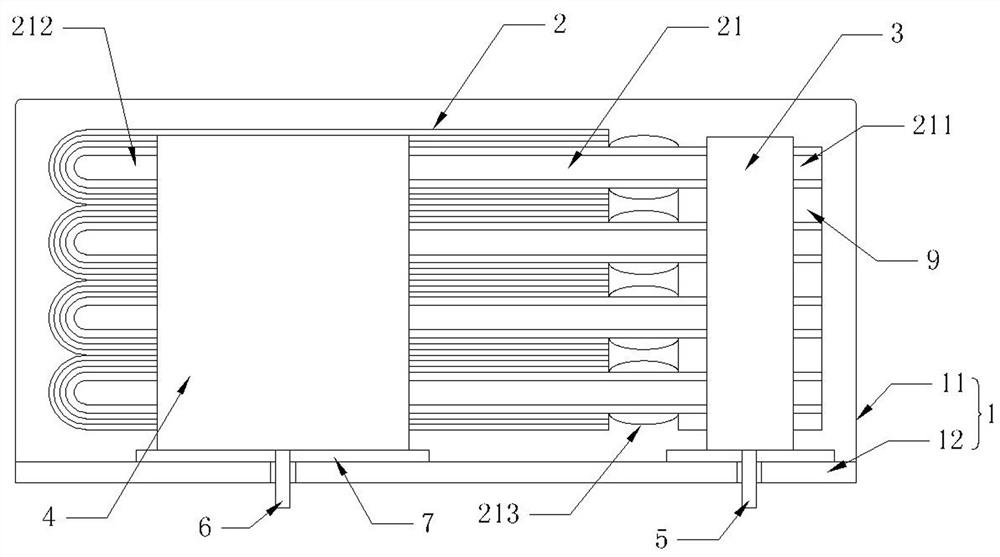

Novel structured half-bridge module

PendingCN108288919ALower ESR valueUniform current distributionConversion constructional detailsCapacitanceEngineering

The invention discloses a novel structured half-bridge module. A capacitor module part comprises compensating and filtering capacitors which are uniformly distributed on a capacitor PCB in a horizontal line shape, and the capacitors are embedded in an aluminum shell; a power driving module part comprises a power module PCB; a power module current confluence copper sheet is welded on the power module PCB; power tubes are uniformly arranged on the two sides of the power module PCB in columns; the power module PCB is also provided with an output copper column, a board-to-board connecting pin base, a power module negative electrode copper strip and a power module positive electrode copper strip; the capacitor module part is connected with the power module negative electrode copper strip and the power module positive electrode copper strip on the power module PCB through screws; and the capacitor module part and the power driving module part are integrated into an integral module. The novelstructured half-bridge module is more optimized and reasonable, so that the capacitors can make full advantages of the current compensating characteristics to the maximum degree, thereby lowering module heating of the power module part and improving the heat dissipation condition.

Owner:林锋

Low-ESR cathode of tantalum electrolytic capacitor and preparation method for cathode

ActiveCN109300695ALower ESR valueImprove electrical performanceSolid electrolytic capacitorsSpecific gravityDecomposition

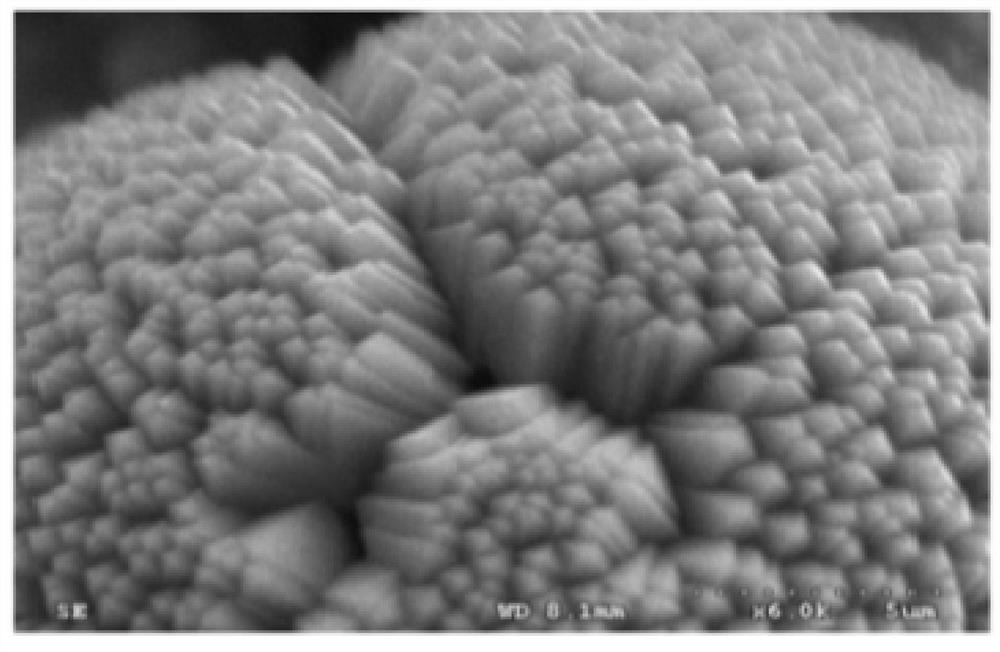

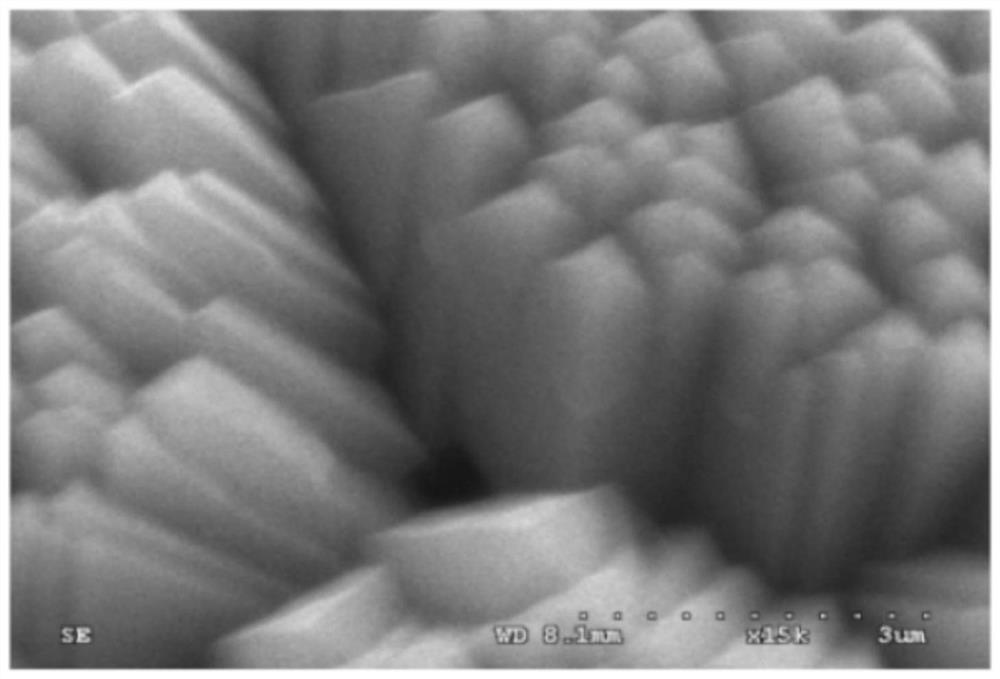

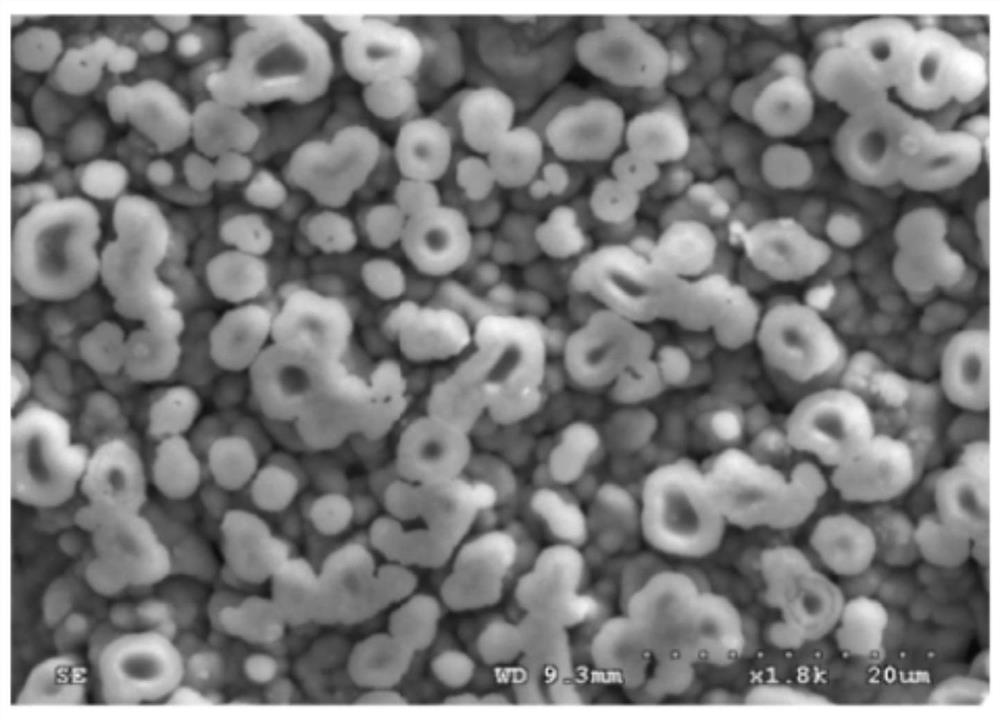

The invention relates to a low-ESR cathode of a low-ESR tantalum electrolytic capacitor and a preparation method for the cathode, and relates to the technical field of tantalum capacitor manufacturing. The preparation method comprises the steps: preparing a manganese dioxide layer on the surface of a tantalum block with a dielectric oxidation film, wherein the manganese dioxide layer is prepared through a method which comprises the steps: performing the dipping of the tantalum block in manganese nitrate solution with different specific gravities for many times, performing the thermal decomposition to obtain a first cathode, performing the dipping of the first cathode in outer mixed solution, performing the decomposition for many times under the temperature from 250 DEG C to 280 DEG C, performing the reinforcement processing, and performing the dipping and thermal decomposition in the outer mixed solution to obtain the electrode, wherein the outer mixed solution is prepared through adding a dispersing agent and a viscosity reducer to the manganese nitrate solution. The method enables the surface of the tantalum block to form compact manganese dioxide shaped like popcorn, thereby completing the manufacturing of the low-ESR electrode, and improving the high-frequency electrical performance of the tantalum electrolytic capacitor.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

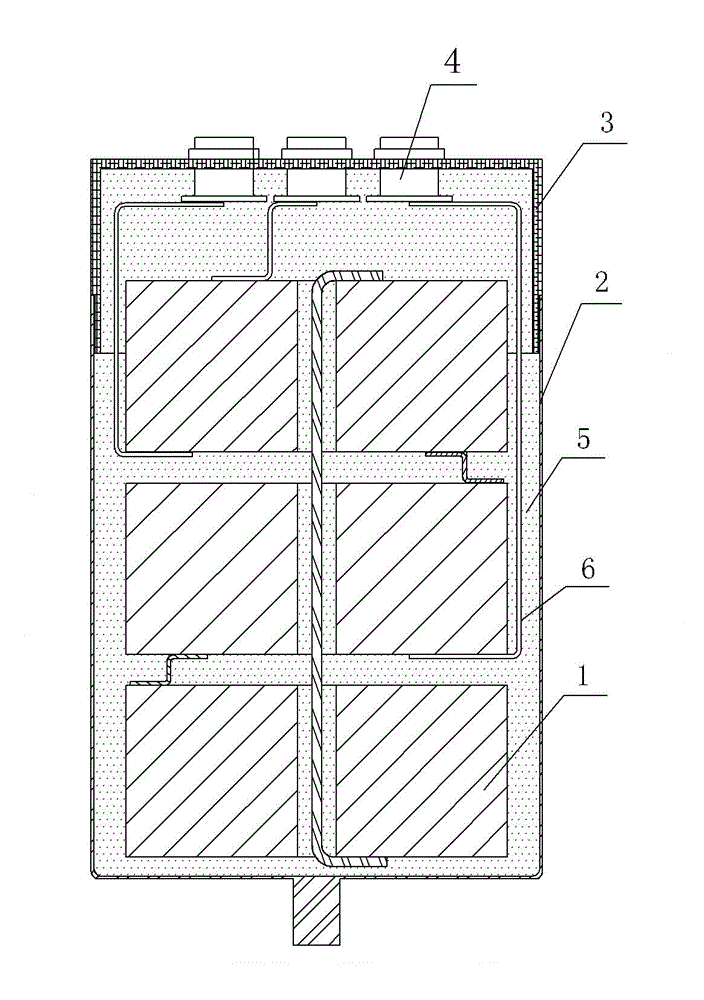

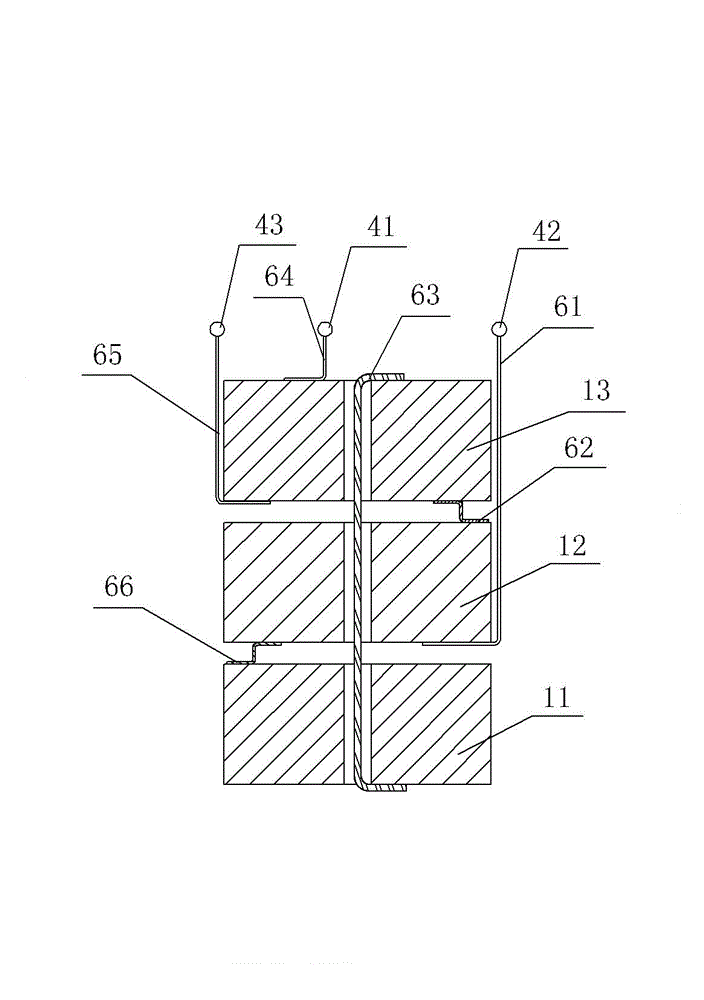

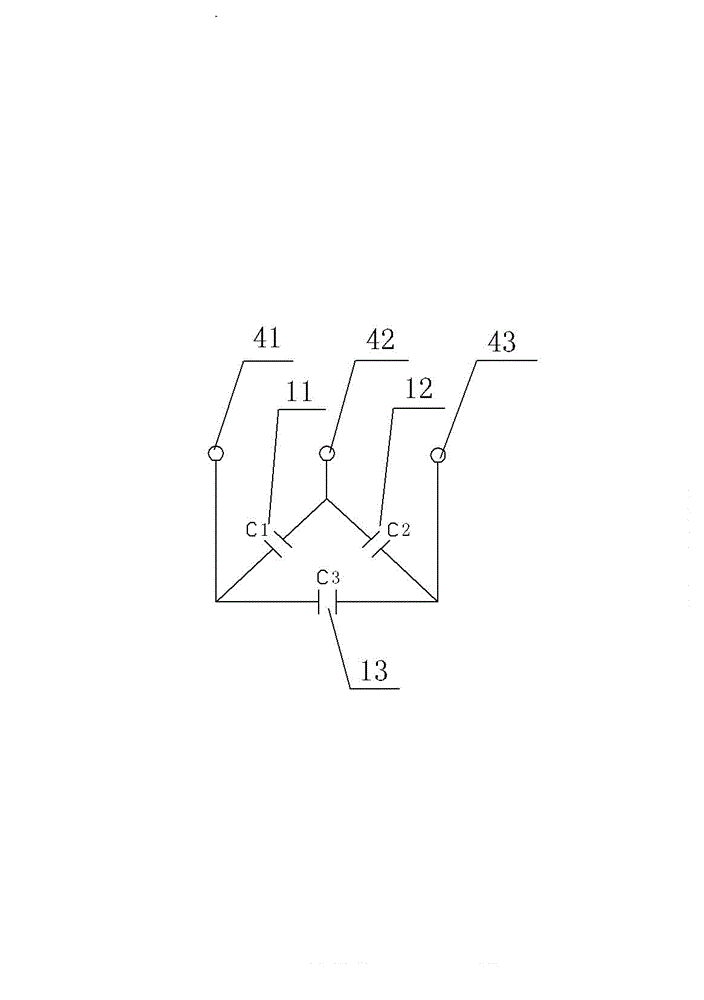

Thin film capacitor for high power three-phase alternating-current filtering occasion

InactiveCN103151170AReduce feverUniform flowMultiple fixed capacitorsThin/thick film capacitorCapacitanceEngineering

The invention relates to the technical field of a power electronic capacitor, in particular to a thin film capacitor for a high power three-phase alternating-current filtering occasion. The thin film capacitor has the advantages that the structure is reasonable, the repeated wiring of multiple capacitors is avoided, the size is small, and the application is safer and more reliable. The thin film capacitor comprises capacitor cores, a connecting copper strip, leading-out terminals, an enclosure, a potting compound and a plastic positioning cover, and is characterized in that the number of the capacitor cores is three, the number of the leading-out terminals is three, the three capacitor cores are connected in pairs to form a triangular connection mode through the connecting copper strip, and the connecting ends of the three capacitor cores are respectively and correspondingly connected with the three leading-out terminals through the connecting copper strip.

Owner:WUXI CHENRUI NEW ENERGY TECH

Ultra-low impedance aluminum electrolytic capacitor for switching power supply

ActiveCN110993346ALower impedanceMeet miniaturizationLiquid electrolytic capacitorsCapacitor housing/encapsulationBenzoic acidElectrolytic agent

The invention discloses an ultra-low impedance aluminum electrolytic capacitor for a switching power supply. The ultra-low impedance aluminum electrolytic capacitor comprises a shell with an opening,a core arranged in the shell and a rubber plug connected with the opening of the shell in a sealed mode. The core is soaked with an electrolyte, the electrolyte comprises the following components in percentage by weight of 5%-25% of solute, 1%-10% of additive and the balance of solvent, wherein the solute is ethylene glycol ammonium, ammonium formate, ammonium maleate and o-benzoic acid, the additive is a passivator, ammonium dihydrogen phosphate and nitrobenzoic acid, and the solvent is ethylene glycol, gamma-butyrolactone, glycerol and water. In the present invention, by developing the high-performance electrolyte, selecting the proper electrode foil and controlling sealing, the prepared aluminum electrolytic capacitor is low in impedance, can bear larger ripple current, and can meet therequirements of miniaturization, large capacity, ripple current resistance, high-frequency low impedance, high temperature, long service life and better adaptability to high-density assembly of an existing switching power supply.

Owner:ZHAOQING BERYL ELECTRONICS TECH

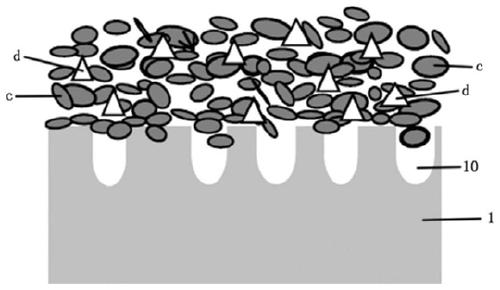

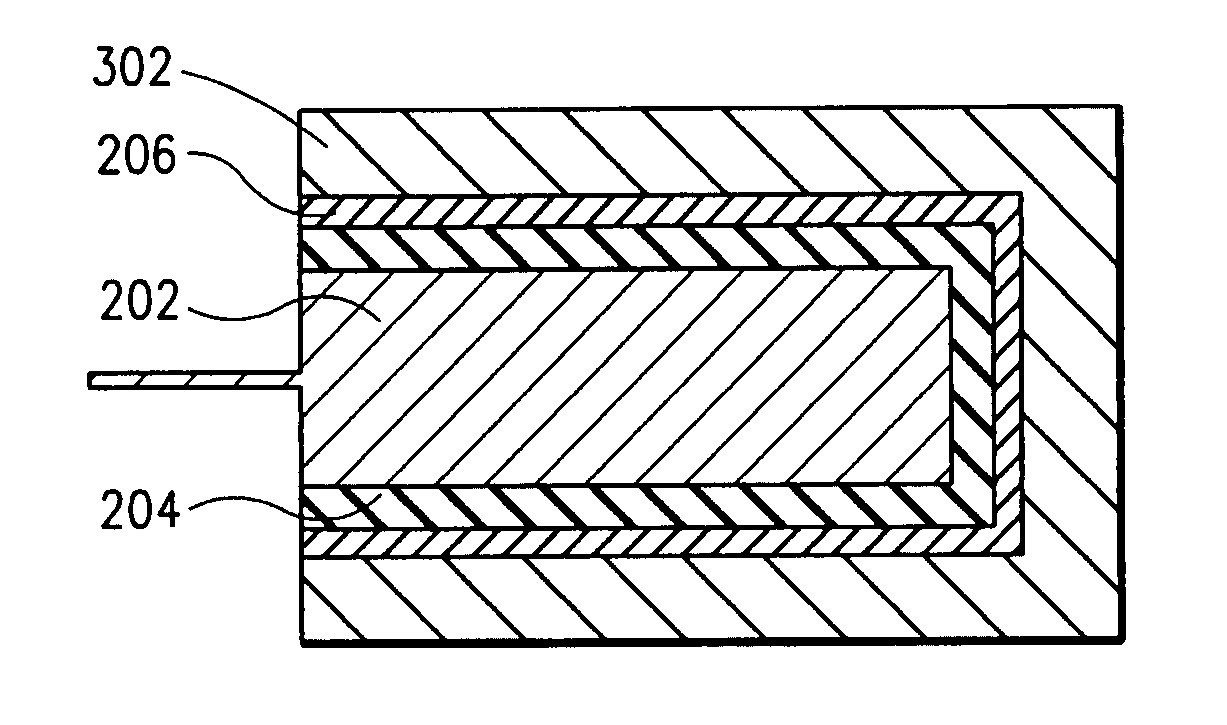

Conductive paste for solid electrolytic capacitor electrode and process for producing solid electrolytic capacitor electrode using the same

ActiveUS7697266B2Reduce adverse effectsLower ESR valueClosuresLiquid electrolytic capacitorsConductive pasteElectrolysis

A conductive paste for a solid electrolytic capacitor electrode contains an electroconductive powder having a mean particle size of no more than 1 μm and at least 90% thereof having a particle size of at least 0.3 μm; an organic binder; and a solvent.

Owner:DU PONT CHINA LTD

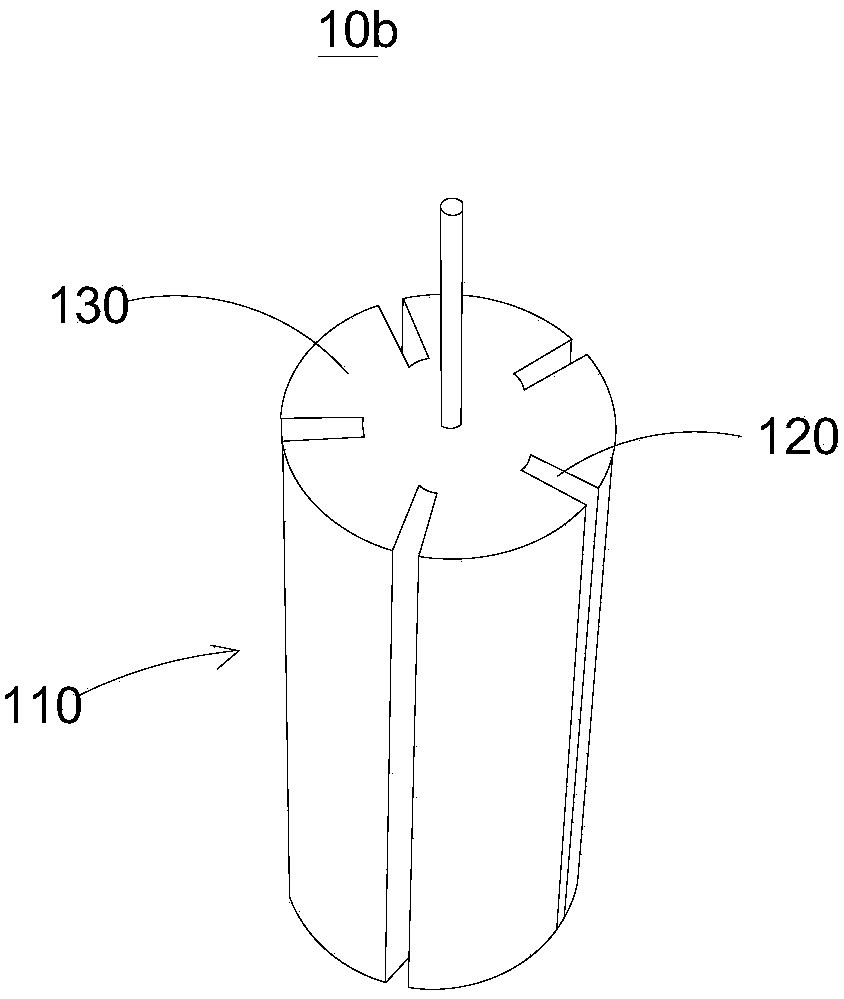

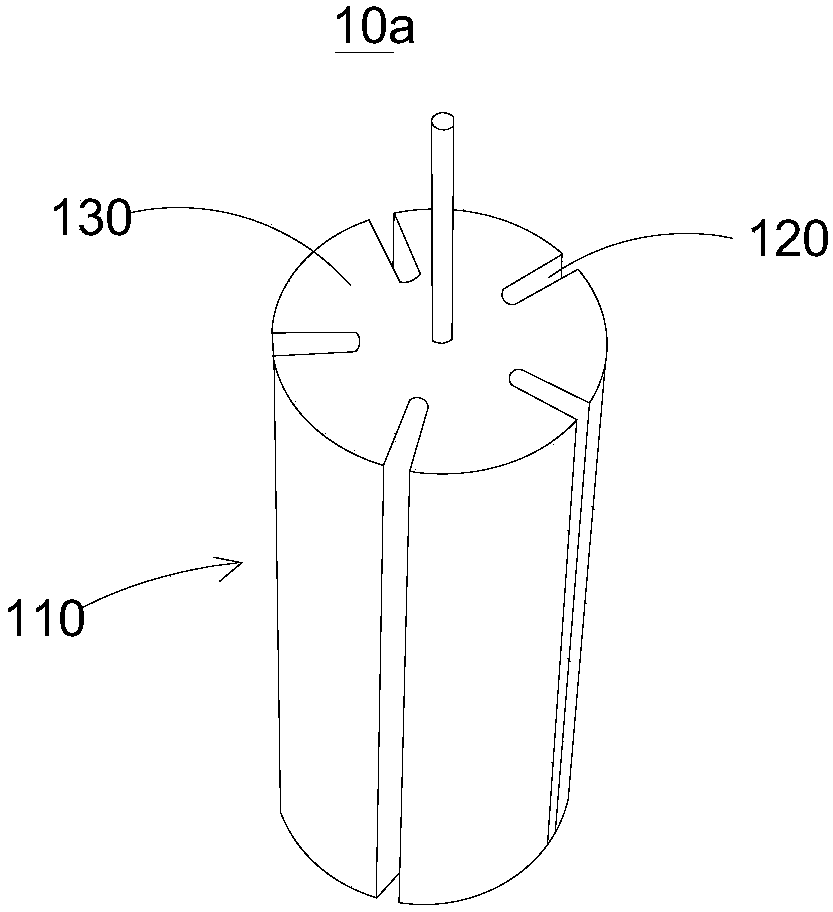

Anode tantalum block and preparation method thereof

InactiveCN108091490ALower ESR valueAlleviate the problem of large ESR value and high heat generationLiquid electrolytic capacitorsCapacitor electrodesTantalum capacitorTantalum

The invention relates to an anode tantalum block and a preparation method thereof. The anode tantalum block comprises a column-shaped tantalum block body. A side wall of the column-shaped tantalum block body is provided with multiple grooves with equal intervals along a radial direction, each groove passes through two ends of the tantalum block body along an axial direction, the depth of each of the grooves is 5% to 80% of the radius of the tantalum block body, and the ESR value of a non-solid electrolyte tantalum capacitor is reduced. The preparation method of the anode tantalum block comprises the steps of pressing tantalum powder to form a green body of the anode tantalum block and carrying out vacuum sintering. The anode tantalum block which effectively reduces the ESR value of the non-solid electrolyte tantalum capacitor is prepared, and the industrial production is facilitated at the same time.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

Conductive paste for solid electorlytic capacitor electrode and process for producing solid electolytic capacitor electrode using the same

ActiveUS20080297984A1Lower ESR valueReduce adverse effectsClosuresLiquid electrolytic capacitorsConductive pasteElectrolytic capacitor

A conductive paste for a solid electrolytic capacitor electrode contains an electroconductive powder having a mean particle size of no more than 1 μm and at least 90% thereof having a particle size of at least 0.3 μm; an organic binder; and a solvent.

Owner:DU PONT CHINA LTD

Ultra-low ESR low-temperature curing silver paste and preparation method thereof

The invention discloses ultra-low ESR low-temperature curing silver paste and a preparation method thereof. The ultra-low ESR low-temperature curing silver paste comprises silver powder, an organic carrier and an additive, wherein the silver powder is mixed flake silver powder of flake silver powder with different particle sizes, the organic carrier comprises a resin, an organic solvent, a curing agent and an accelerant, the resin is ethyl cellulose resin or one or more of epoxy resin and phenolic resin, the organic solvent is composed of one or more of DBE, diethylene glycol butyl ether acetate, dimethyl glutarate and butyl carbitol, the curing agent is blocked isocyanate or dicyandiamide or imidazole, and the additive is one or a mixture of more of triglycerol acetate and fumed silica. According to the invention, the problem that existing organic tantalum capacitor leading-out end silver paste is large in ESR and unstable is solved, and the ultra-low ESR low-temperature curing silver paste is widely applied to the electrode material of the organic tantalum capacitor leading-out end.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

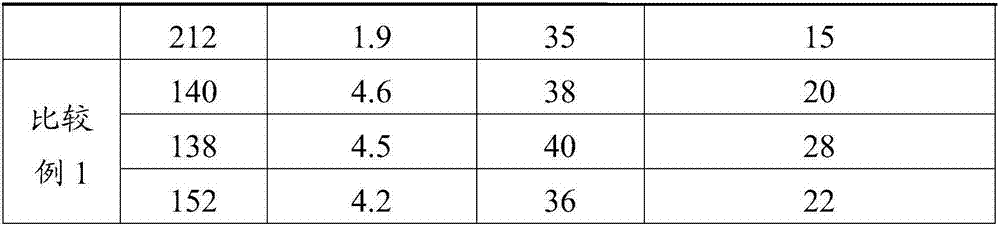

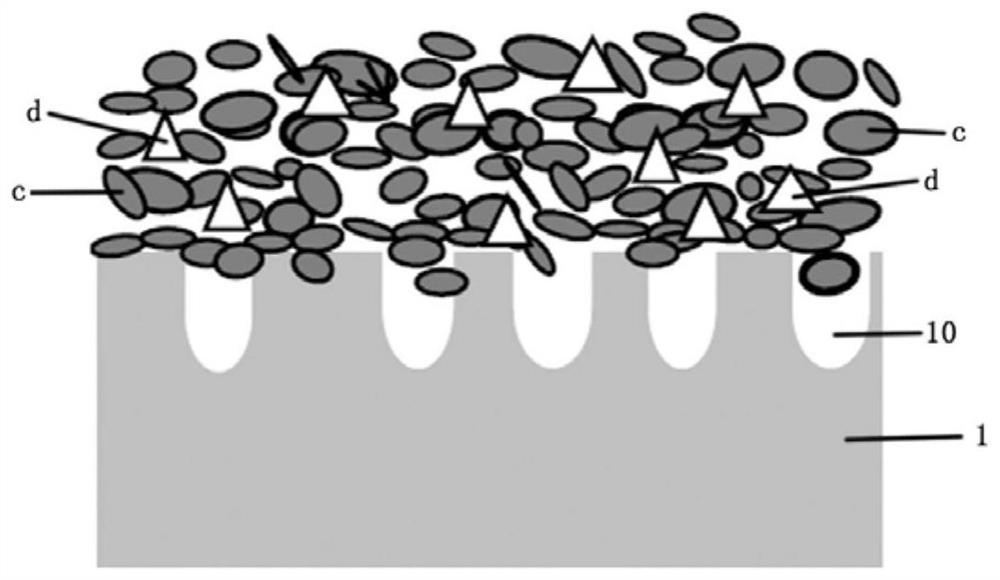

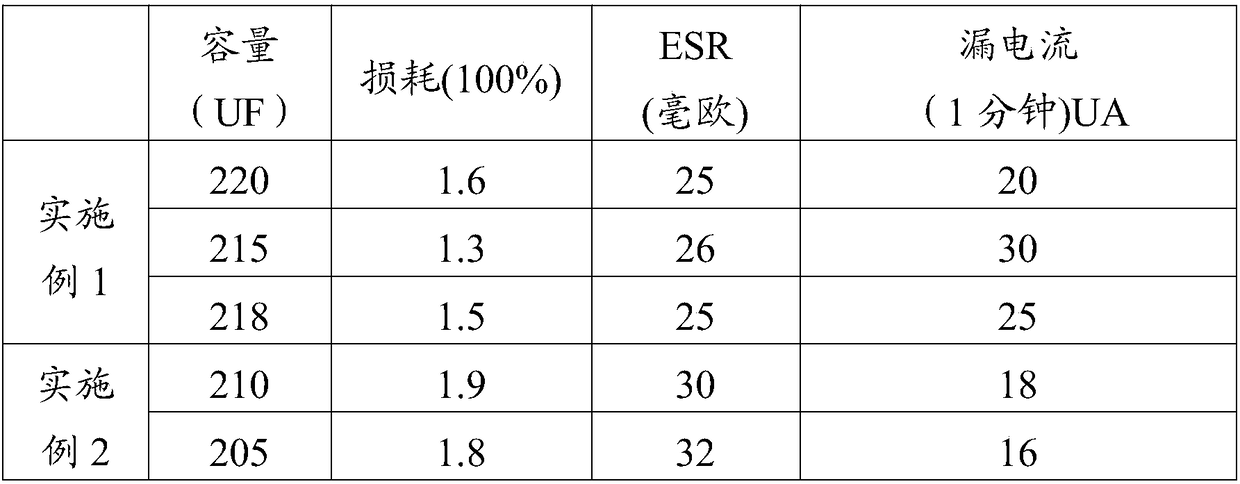

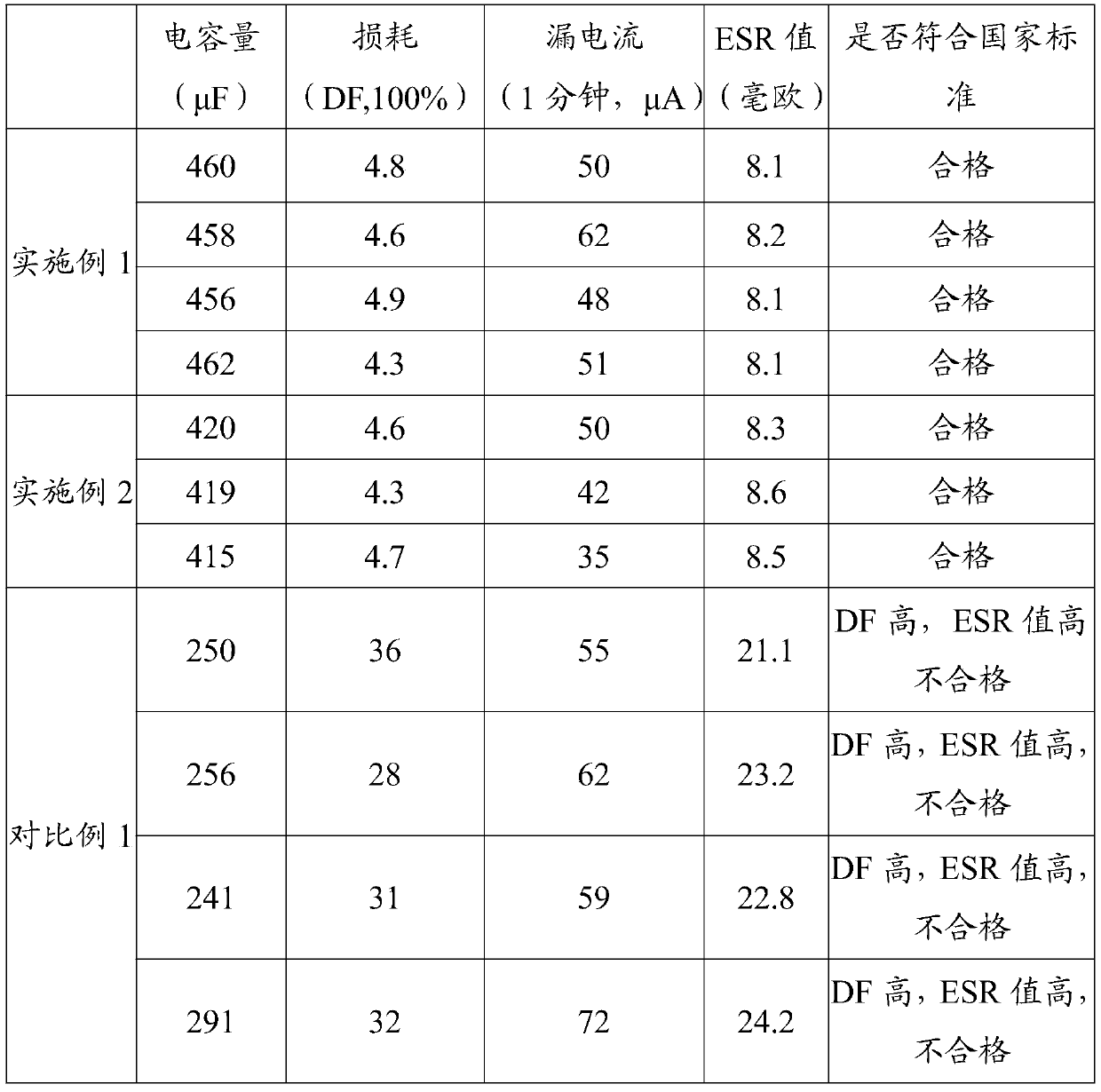

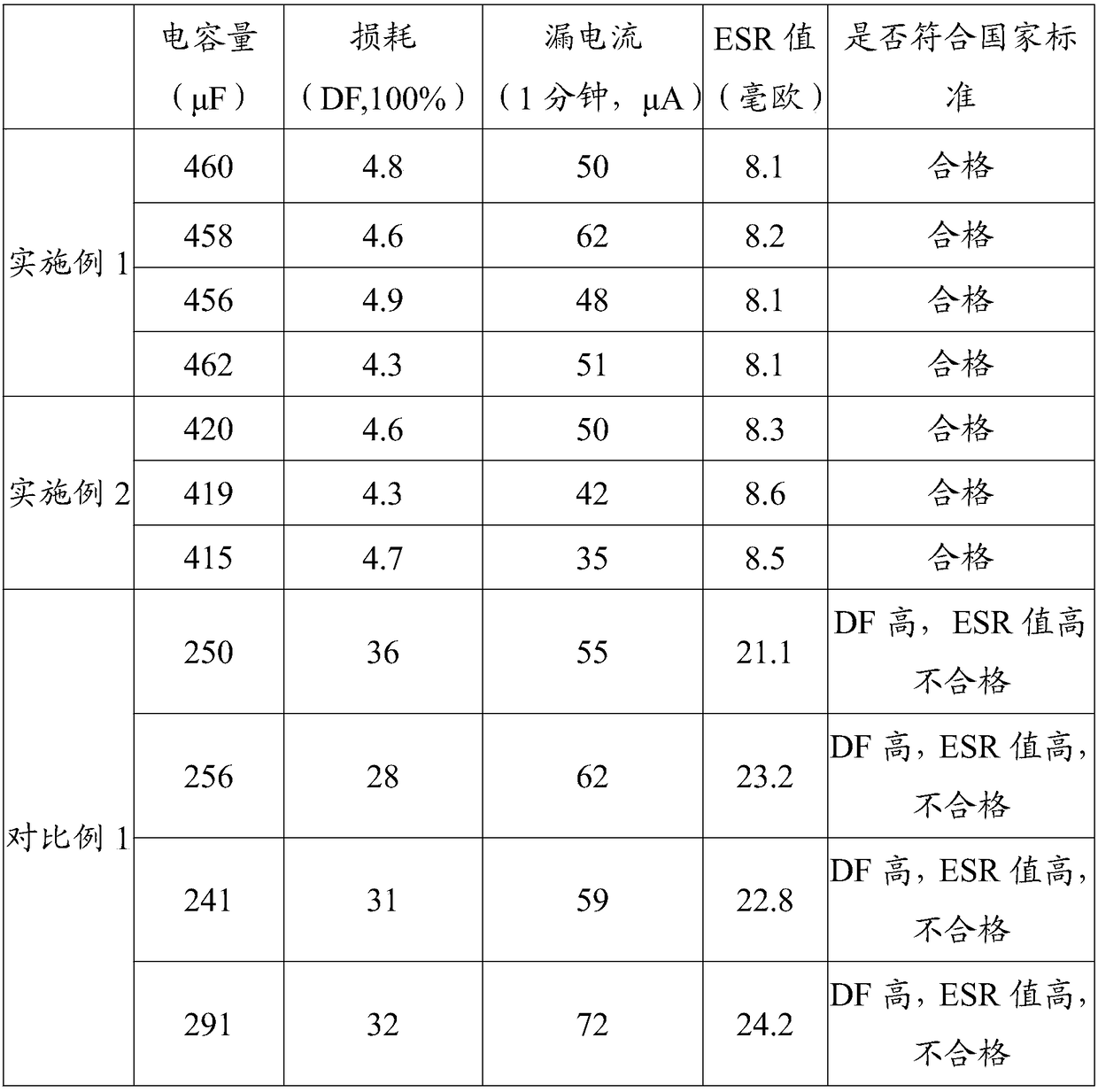

Capacitor core cladding, preparation method thereof and solid aluminum electrolytic capacitor

The invention provides a capacitor core cladding, a preparation method thereof and a solid aluminum electrolytic capacitor. The preparation method of the capacitor core cladding provided by the invention is simple to operate, high-temperature carbonization is not required to be performed, and the energy is saved. In addition, the capacitor acquired according to the invention has the characteristics of high capacitance, low loss rate and low ESR value. According to the result of an embodiment, the capacitance of the capacitor acquired in the embodiment is 205-220UF which is far higher than the capacitance 138-152UF of a comparison sample; the loss rate of the acquired capacitor is only 1.3-1.9% which is far lower than the loss rate 4.2-4.6% of the comparison sample; the ESR value of the acquired capacitor is 25-35 milliohms which his far lower than the ESR value 36-40 milliohms of the comparison sample; and the leakage current per minute is 15-30UA.

Owner:深圳市金富康电子有限公司 +1

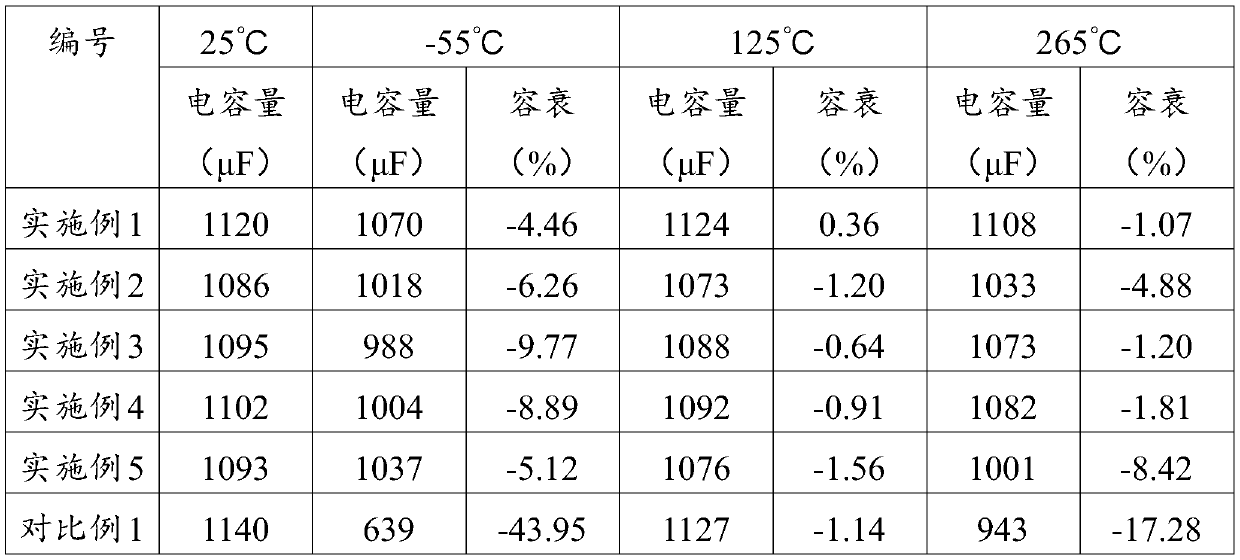

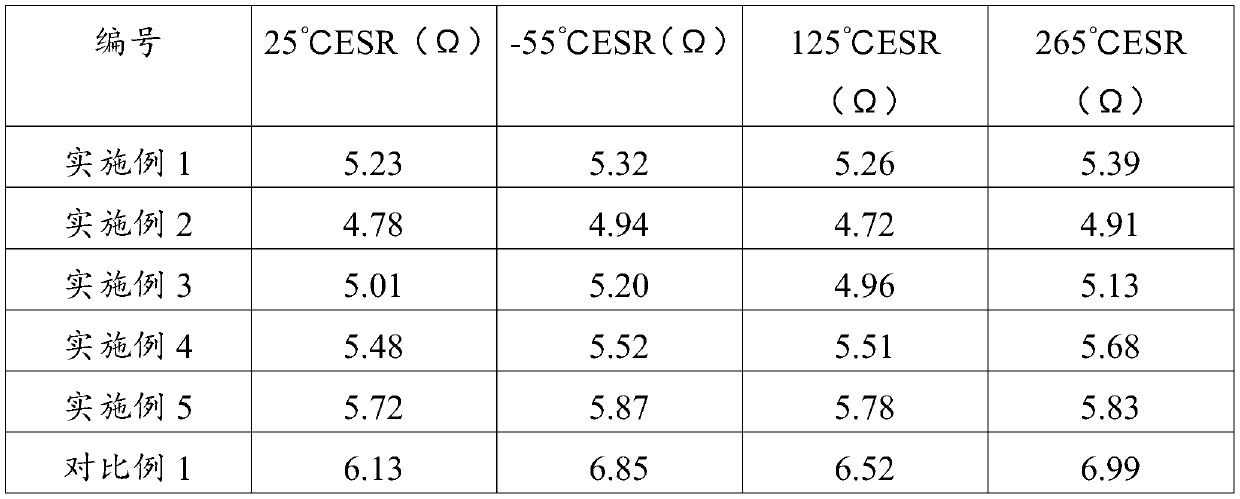

Novel dispersion liquid for solid capacitor, capacitor and preparation method thereof

ActiveCN110310832ALower equivalent series resistanceImprove breakdown voltageSolid electrolytic capacitorsCapacitor electrodesPolymer scienceIn situ polymerization

The invention discloses a novel dispersion liquid for a solid capacitor, a capacitor and a preparation method thereof. The method is characterized in that the polystyrolsulfon acid is replaced with polyanions such as sulfonated polystyrene block copolymer, acidified polystyrene block copolymer or sulfonated polystyrene graft copolymer, the rigid structure of PSS is improved through modification, the PEDOT structure is granted with a certain flexibility, so performance of a PEDOT / PSS film is improved, a problem that high-temperature resistance, low-temperature resistance and repeated charge anddischarge resistance of the capacitor due to the PSS structure are inferior to the in-situ polymerization method is solved, the polyanions such as the sulfonated polystyrene block copolymer, the acidified polystyrene block copolymer or the sulfonated polystyrene graft copolymer are added simultaneously, the emulsification effect is better, formed milk droplets are smaller, the prepared PEDOT dispersion has a smaller particle size and higher electrical conductivity, triggering the capacitor capacity is made to be easier, and an ESR value of the prepared capacitor is smaller.

Owner:广东华鸿科技有限公司

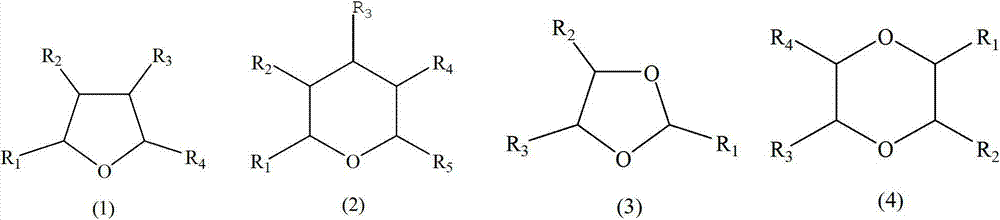

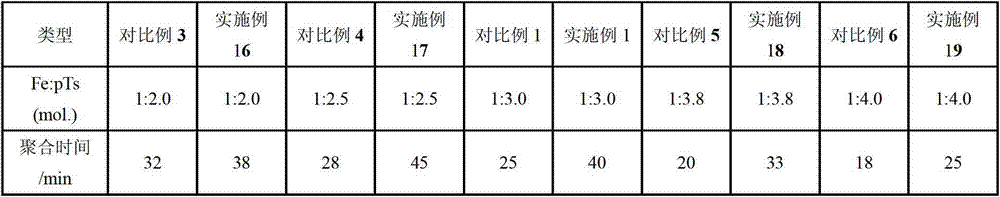

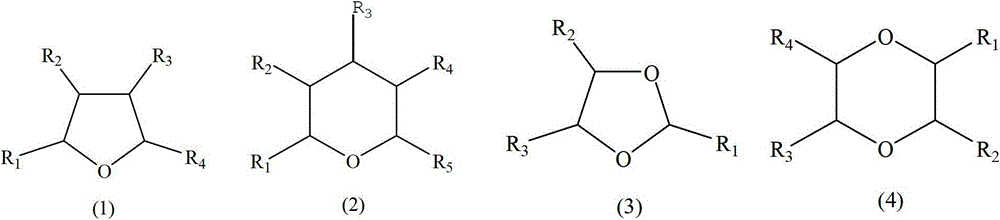

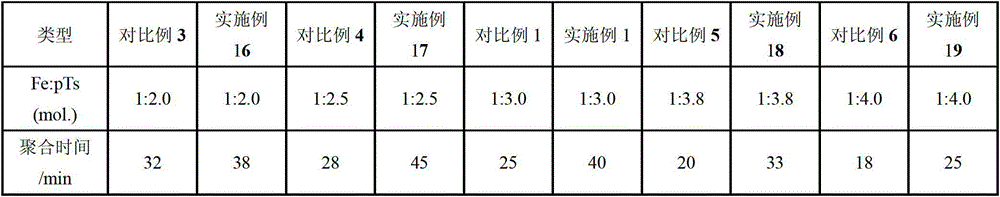

Conductive high polymer, oxidizer for synthesis thereof and solid capacitor

ActiveCN103113559AImprove electrochemical performanceImprove conductivitySolid electrolytic capacitorsCapacitor electrolytes/absorbentsElectrolysisPolymer science

The invention provides an oxidizer solution for conductive high polymer synthesis. The oxidizer solution for conductive high polymer synthesis can be mixed with a polymerized monomer and is used for impregnating a capacitor core package to generate a conductive high polymer through reaction so as to be used for producing a high-performance solid electrolytic capacitor. The oxidizer solution for conductive high polymer synthesis comprises iron sulfonate and solvent, wherein the solvent is lower alcohol and cyclic ether, and the lower alcohol is selected from one or some of monobasic alcohol of which the carbon atom number is 1-4; and the number of oxygen groups of an ether bond in the cyclic ether is 1 or 2, and the ring containing the ether bond is a five-membered one or six-membered one. By using the oxidizer to synthesize a conductive high molecular polymer, the conductivity of the conductive polymer can be improved, thereby reducing the ESR (equivalent series resistance) value of a capacitor.

Owner:SHENZHEN CAPCHEM TECH

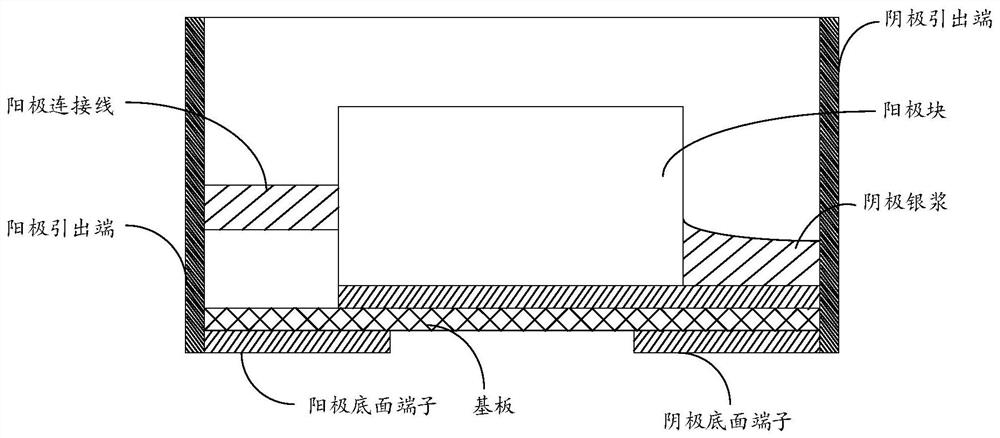

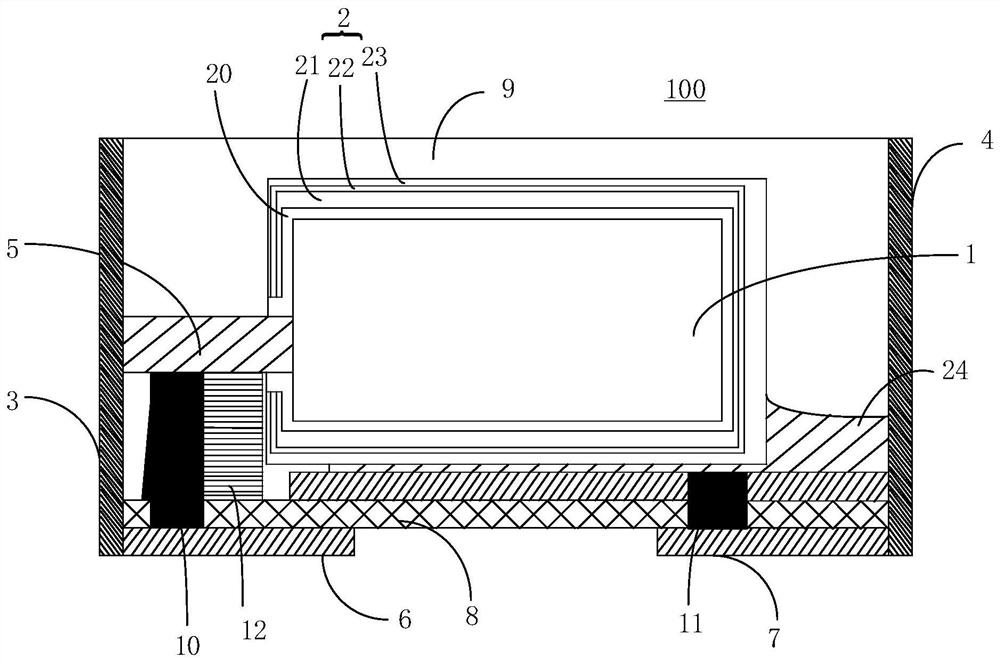

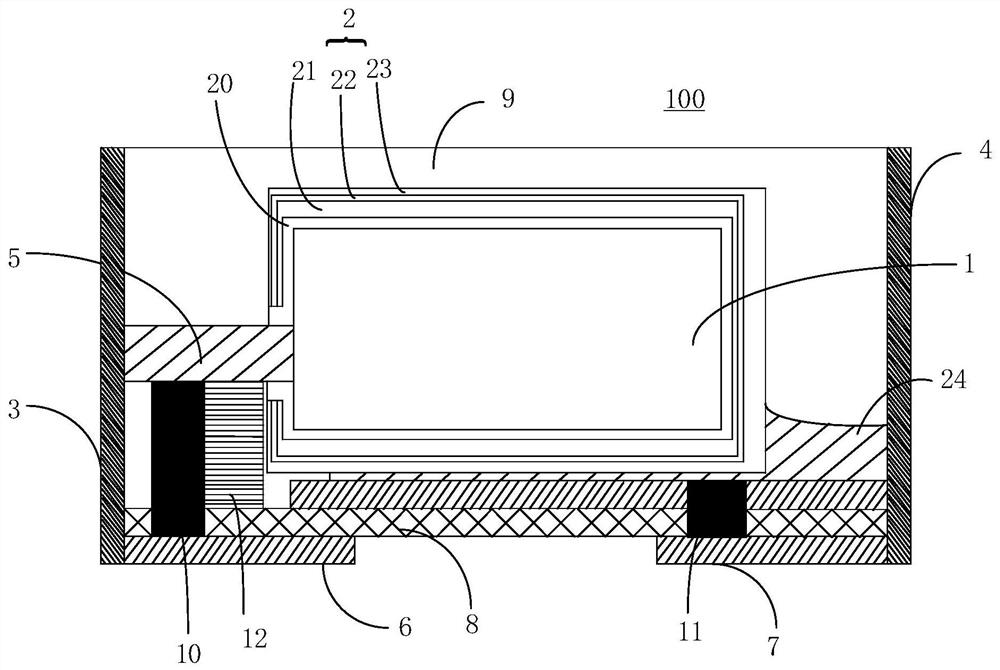

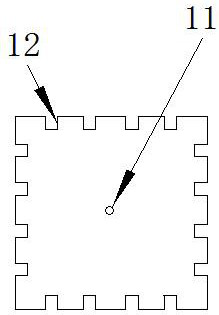

Surface-packaged capacitor and manufacturing method of surface-packaged capacitor

PendingCN112435853ALower ESR valueImprove reliabilityFixed capacitor housing/encapsulationFixed capacitor terminalsEngineeringCapacitor

The invention provides a surface-packaged capacitor and a manufacturing method of the surface-packaged capacitor. The surface-packaged capacitor comprises an anode element and a cathode element whichare isolated from each other, an anode outgoing line; a substrate, wherein an anode connecting groove and a cathode connecting groove are formed in the substrate, and conductors are arranged in the anode connecting groove and the cathode connecting groove; an anode bottom surface terminal which is connected with a notch in one side of the anode connecting groove, wherein one end of the electric conductor arranged in the anode connecting groove is connected with the anode leading-out wire, and the other end of the electric conductor arranged in the anode connecting groove is connected with theupper surface of the anode bottom surface terminal; a cathode bottom surface terminal which is connected with a notch in one side of the cathode connecting groove, wherein one end of the electric conductor arranged in the cathode connecting groove is connected with the cathode element, and the other end of the electric conductor arranged in the cathode connecting groove is connected with the uppersurface of the cathode bottom surface terminal. Through the above structure arrangement, the ESR value of the surface-packaged capacitor is reduced, and the reliability of the surface-packaged capacitor is improved.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

A kind of cathode of low ESR tantalum electrolytic capacitor and preparation method thereof

ActiveCN109300695BLower ESR valueImprove electrical performanceSolid electrolytic capacitorsElectrolysisTantalum capacitor

The invention relates to a low-ESR cathode of a low-ESR tantalum electrolytic capacitor and a preparation method for the cathode, and relates to the technical field of tantalum capacitor manufacturing. The preparation method comprises the steps: preparing a manganese dioxide layer on the surface of a tantalum block with a dielectric oxidation film, wherein the manganese dioxide layer is prepared through a method which comprises the steps: performing the dipping of the tantalum block in manganese nitrate solution with different specific gravities for many times, performing the thermal decomposition to obtain a first cathode, performing the dipping of the first cathode in outer mixed solution, performing the decomposition for many times under the temperature from 250 DEG C to 280 DEG C, performing the reinforcement processing, and performing the dipping and thermal decomposition in the outer mixed solution to obtain the electrode, wherein the outer mixed solution is prepared through adding a dispersing agent and a viscosity reducer to the manganese nitrate solution. The method enables the surface of the tantalum block to form compact manganese dioxide shaped like popcorn, thereby completing the manufacturing of the low-ESR electrode, and improving the high-frequency electrical performance of the tantalum electrolytic capacitor.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

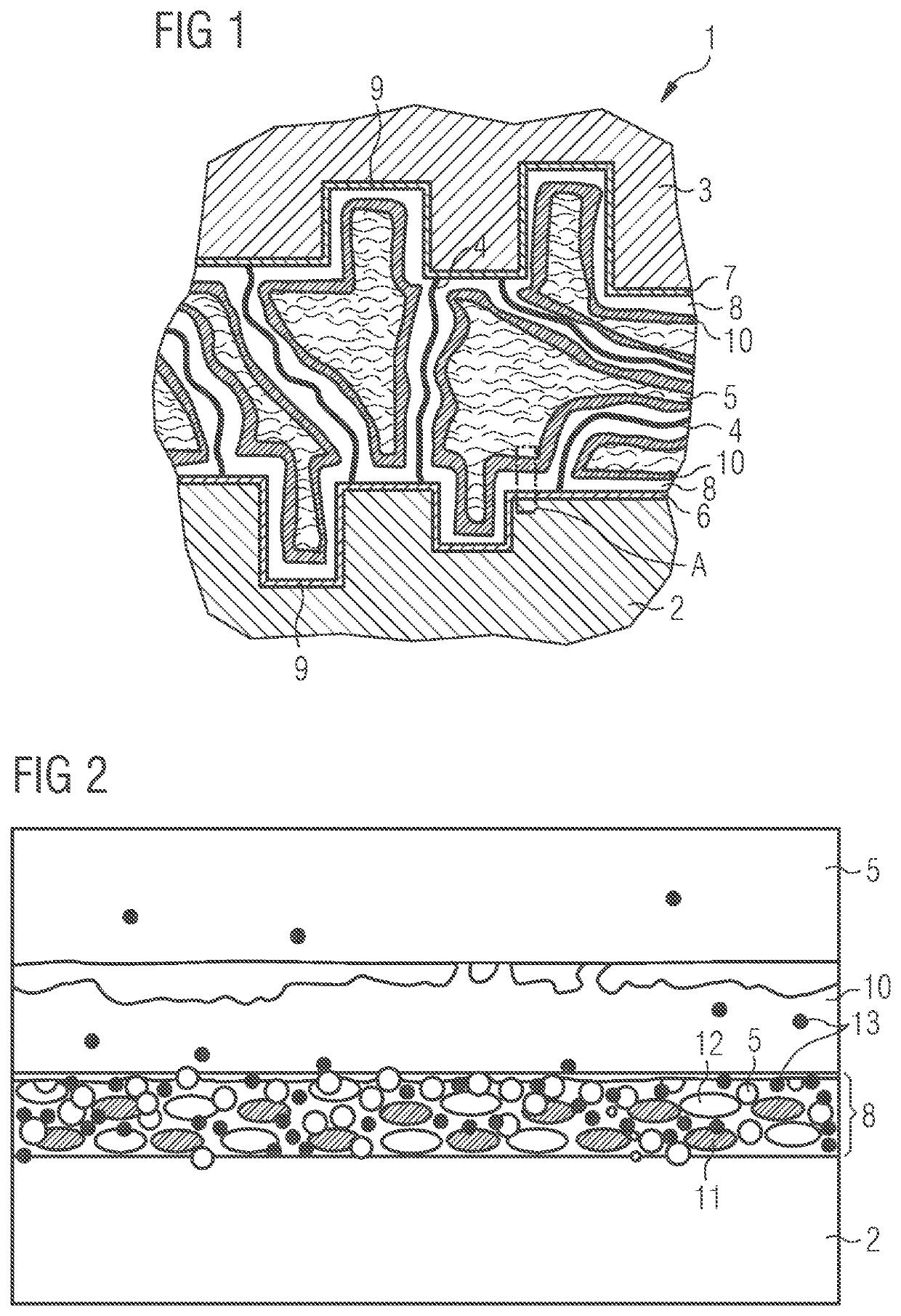

Electrolytic capacitor

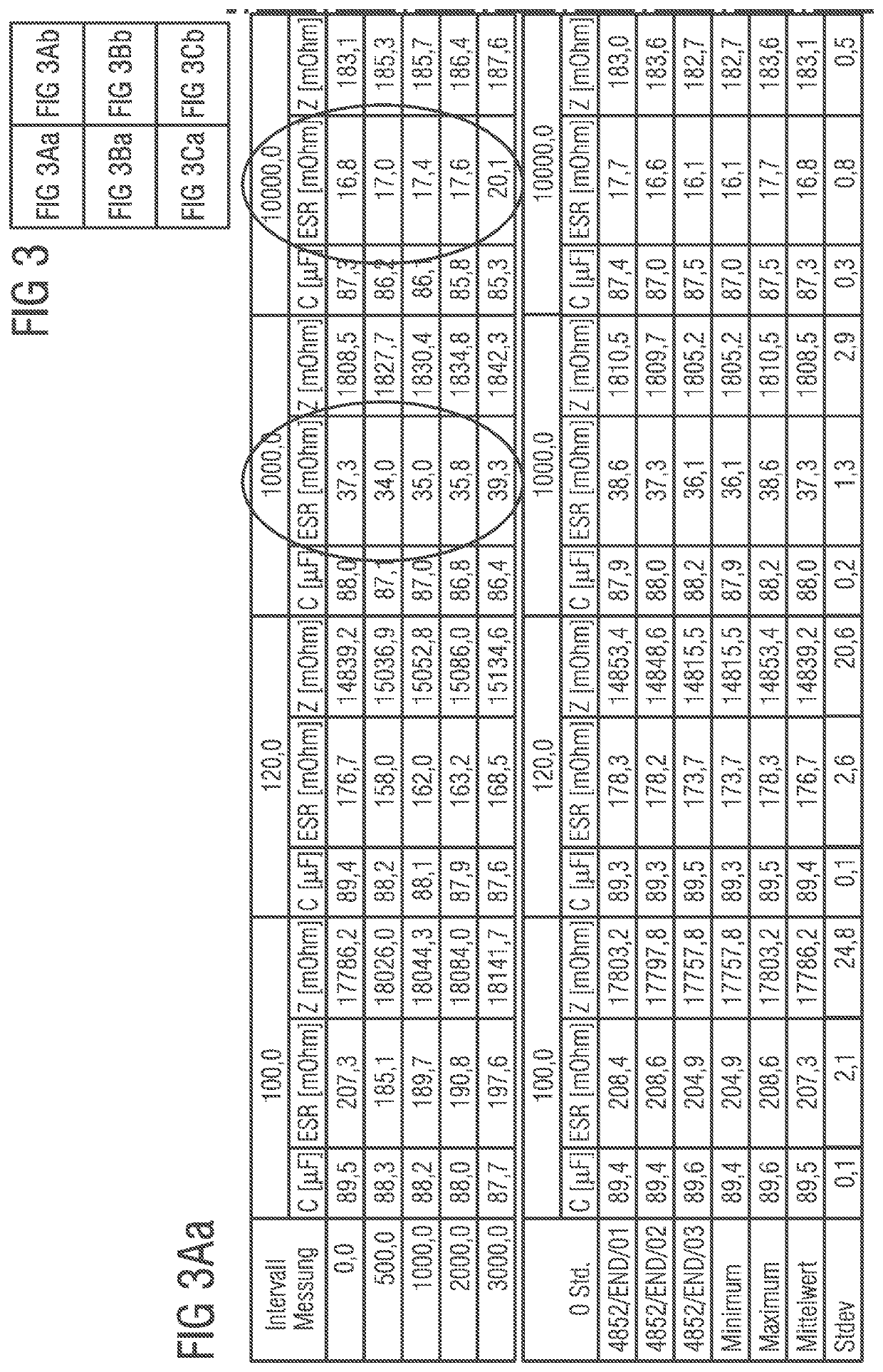

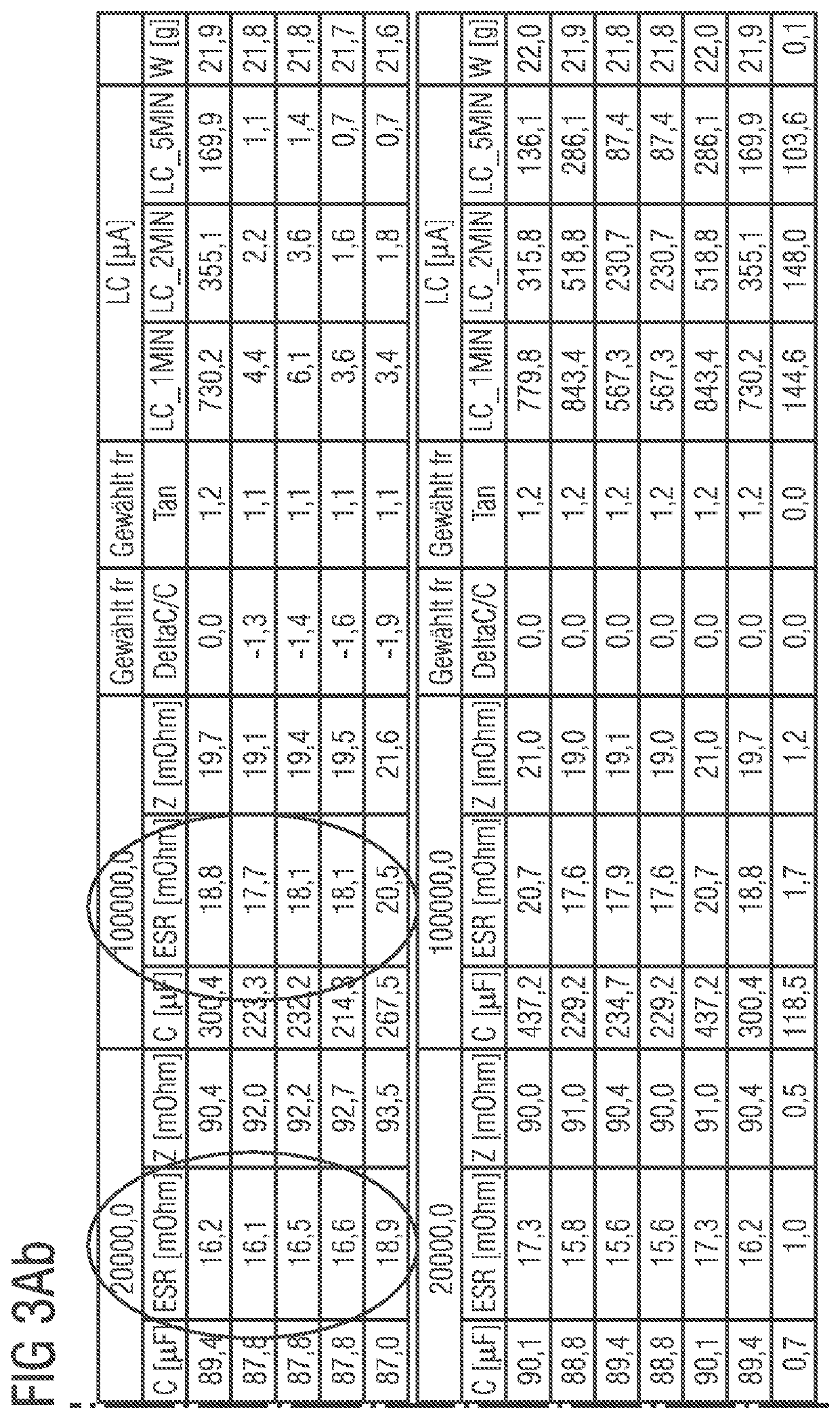

ActiveUS11049662B2Increase working voltageReduce conductivityHybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisEngineering

Owner:EPCOS AG

Production process of negative electrode foil and negative electrode foil and polymer solid aluminum electrolytic capacitor

ActiveCN109830374BIncrease specific volumeReduce volumeSolid electrolytic capacitorsCapacitor dielectric layersMetal foilMiniaturization

The present invention relates to a production process of negative electrode foil and a negative electrode foil and a polymer solid aluminum electrolytic capacitor. The production process of the negative electrode foil includes the following steps: S1, selecting an aluminum substrate; S2, forming a dielectric layer process, which includes the following steps: a) Preparation of slurry; b) Etching the surface of the aluminum substrate to form holes, then coating the slurry on the surface of the aluminum substrate with holes, drying the surface, and then sending it into the rolling machine, Press the coating into the hole and compact it on the surface of the hole and the aluminum substrate; c), carbonization treatment. Under the premise of increasing the specific capacity, the negative electrode foil of the present invention is obviously thinner than the negative electrode foil used in the same capacity, and at the same time, the polymer solid aluminum electrolytic capacitor produced by the negative electrode foil has a significantly smaller volume among products with the same capacity. The ESR value has also become smaller, while contributing to the miniaturization and current withstand capability of polymer solid aluminum electrolytic capacitors.

Owner:安徽纳诺箔材有限公司

Capacitor core pack, preparation method thereof, and solid aluminum electrolytic capacitor

ActiveCN107093518BReduce loss rateLower ESR valueSolid electrolytic capacitorsPhysical chemistryEngineering

The invention provides a capacitor core cladding, a preparation method thereof and a solid aluminum electrolytic capacitor. The preparation method of the capacitor core cladding provided by the invention is simple to operate, high-temperature carbonization is not required to be performed, and the energy is saved. In addition, the capacitor acquired according to the invention has the characteristics of high capacitance, low loss rate and low ESR value. According to the result of an embodiment, the capacitance of the capacitor acquired in the embodiment is 205-220UF which is far higher than the capacitance 138-152UF of a comparison sample; the loss rate of the acquired capacitor is only 1.3-1.9% which is far lower than the loss rate 4.2-4.6% of the comparison sample; the ESR value of the acquired capacitor is 25-35 milliohms which his far lower than the ESR value 36-40 milliohms of the comparison sample; and the leakage current per minute is 15-30UA.

Owner:深圳市金富康电子有限公司 +1

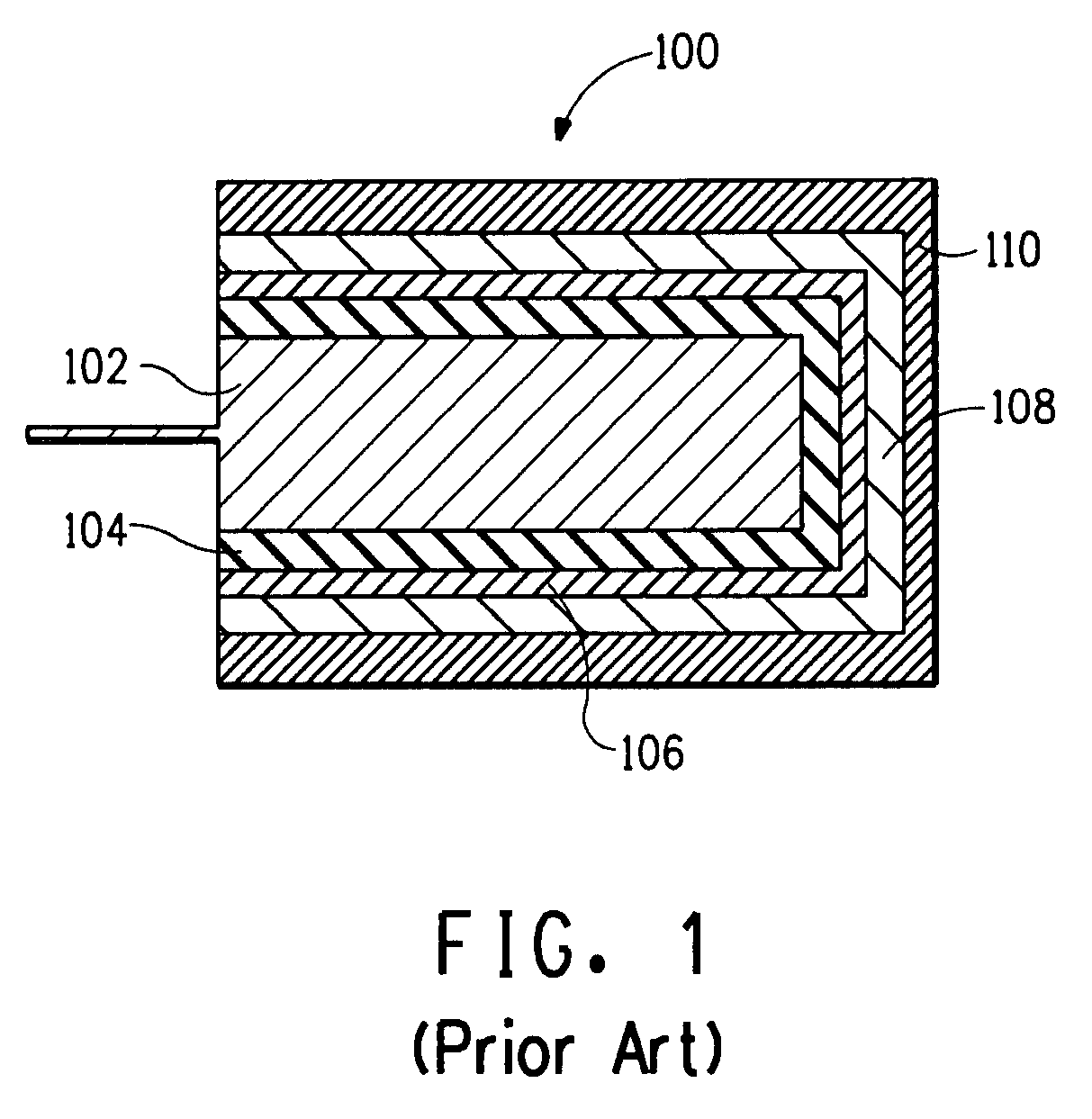

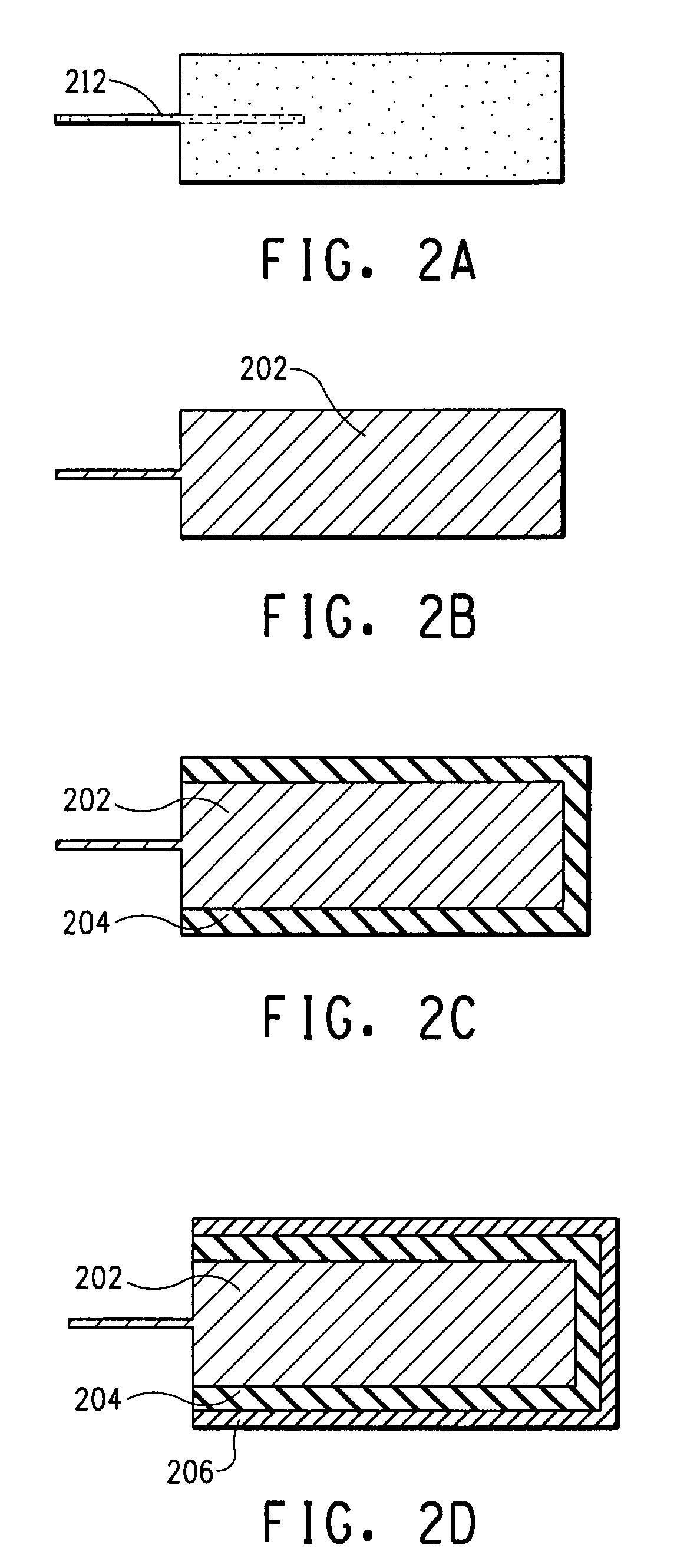

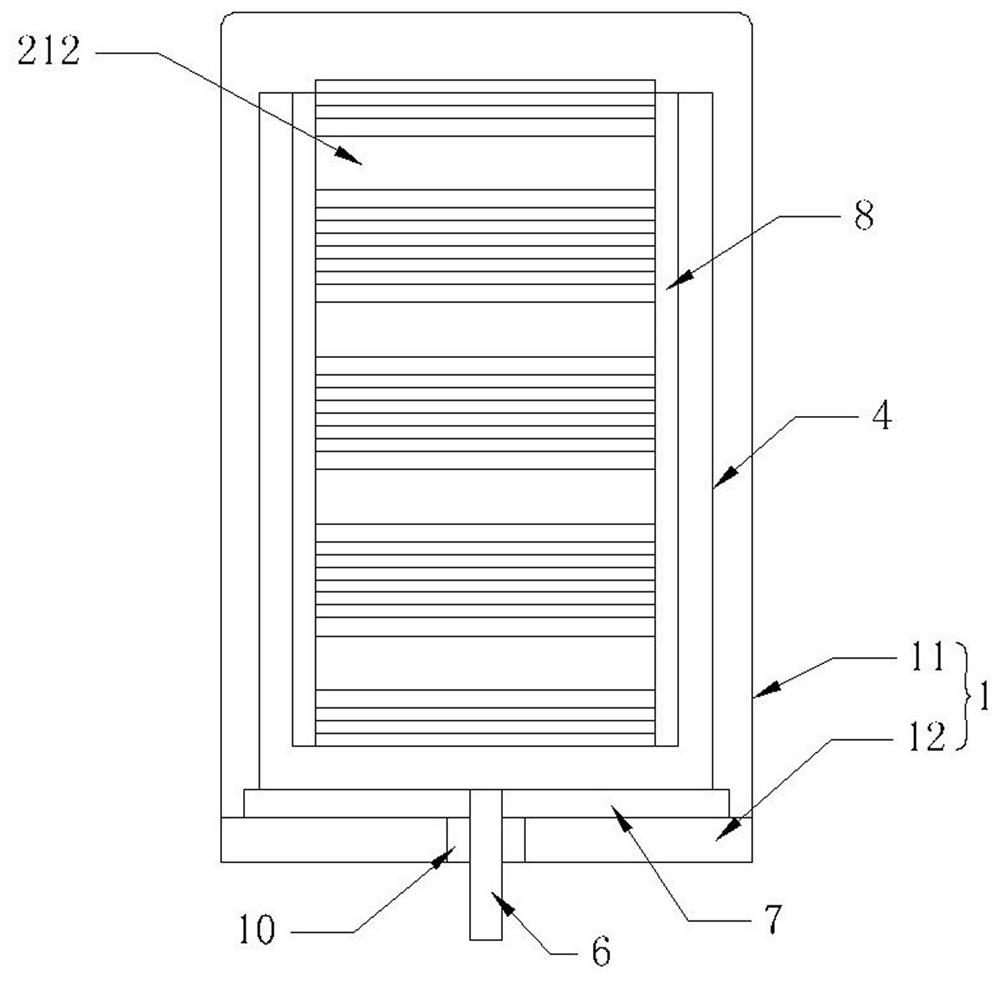

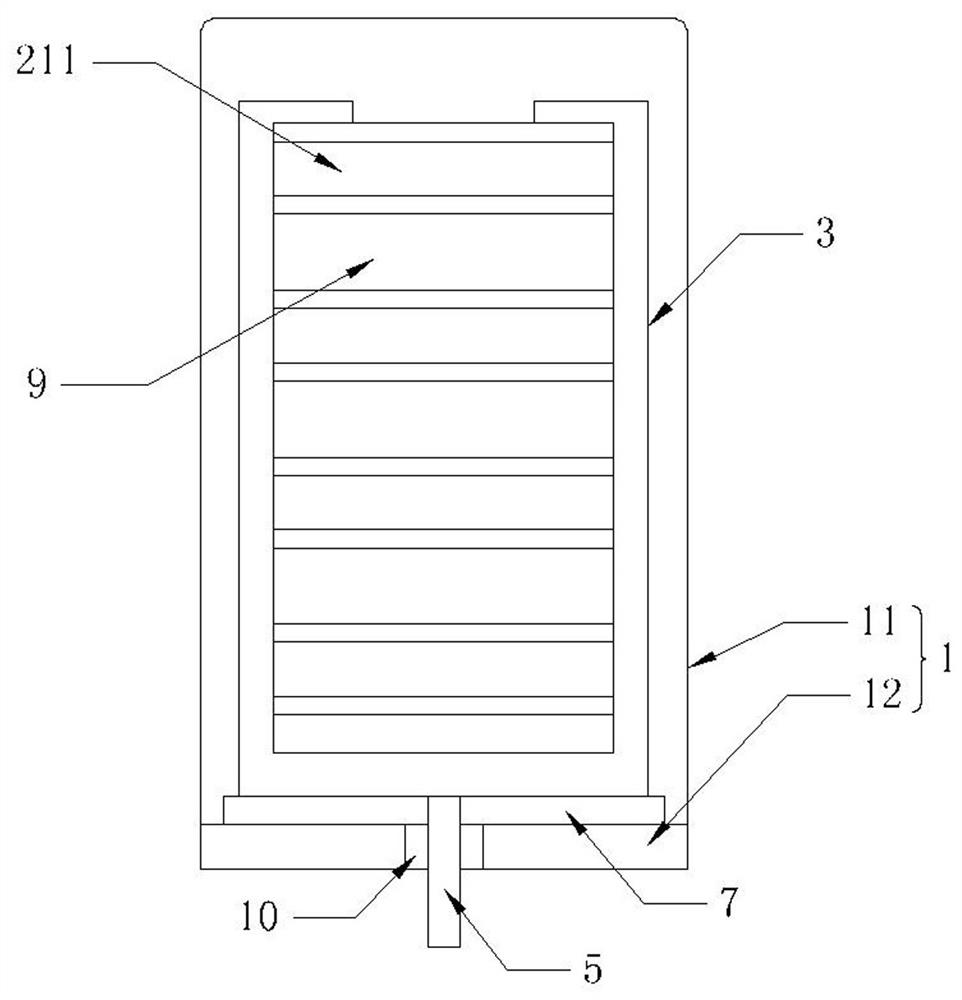

Manufacturing method of laminated sheet type solid aluminum electrolytic capacitor

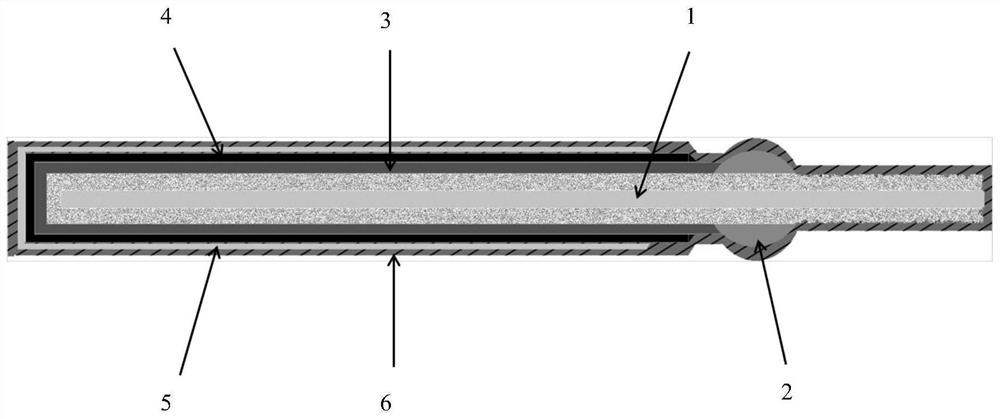

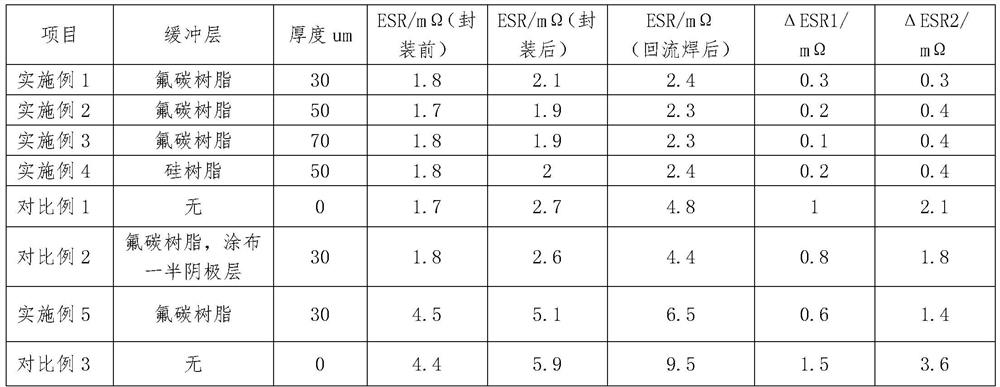

PendingCN114334467AImprove pass rateRelieve pressureSolid electrolytic capacitorsCapacitor housing/encapsulationSilver pasteConductive polymer

The invention discloses a method for manufacturing a laminated sheet type solid aluminum electrolytic capacitor, which comprises the following steps of: cutting an aluminum foil, arranging barrier glue, forming a conductive polymer solid electrolyte layer, a conductive graphite layer and a conductive silver paste layer in a cathode region, and sequentially carrying out lamination, buffer layer formation, injection molding packaging, moisture absorption aging, reflow soldering treatment and the like. The buffer layer is formed on the surface of the aluminum foil, the thickness of the buffer layer is about 10-70 microns, and the coverage height of the buffer layer is that the whole aluminum foil area comprises a positive electrode area and a negative electrode area. Through the technical scheme, the ESR of the laminated solid aluminum electrolytic capacitor can be reduced, and the leakage current qualification rate can be improved, so that the total qualification rate of the laminated solid aluminum electrolytic capacitor is obviously improved, and the laminated solid aluminum electrolytic capacitor has remarkable economic benefits and social benefits.

Owner:赣州市柏瑞凯电子科技有限公司

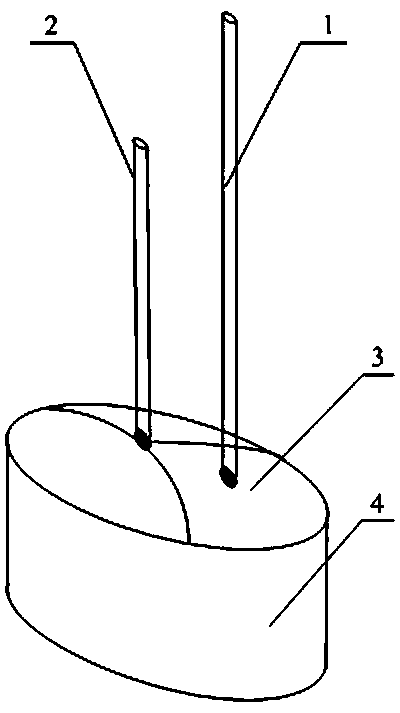

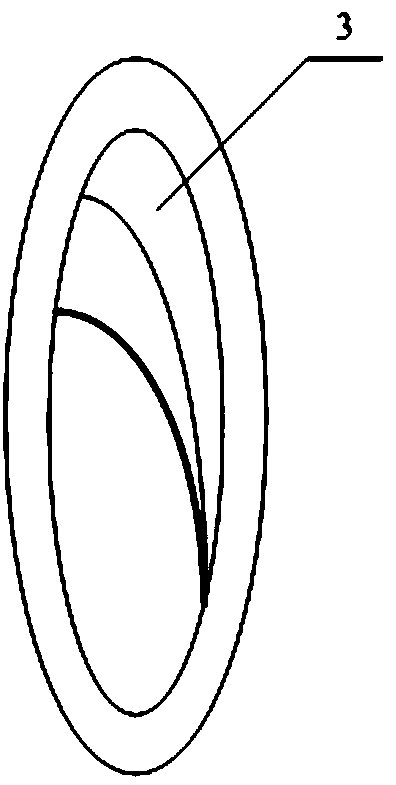

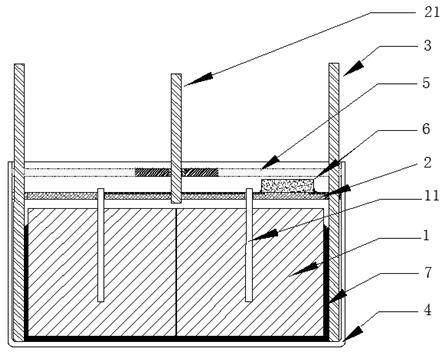

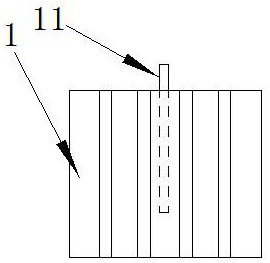

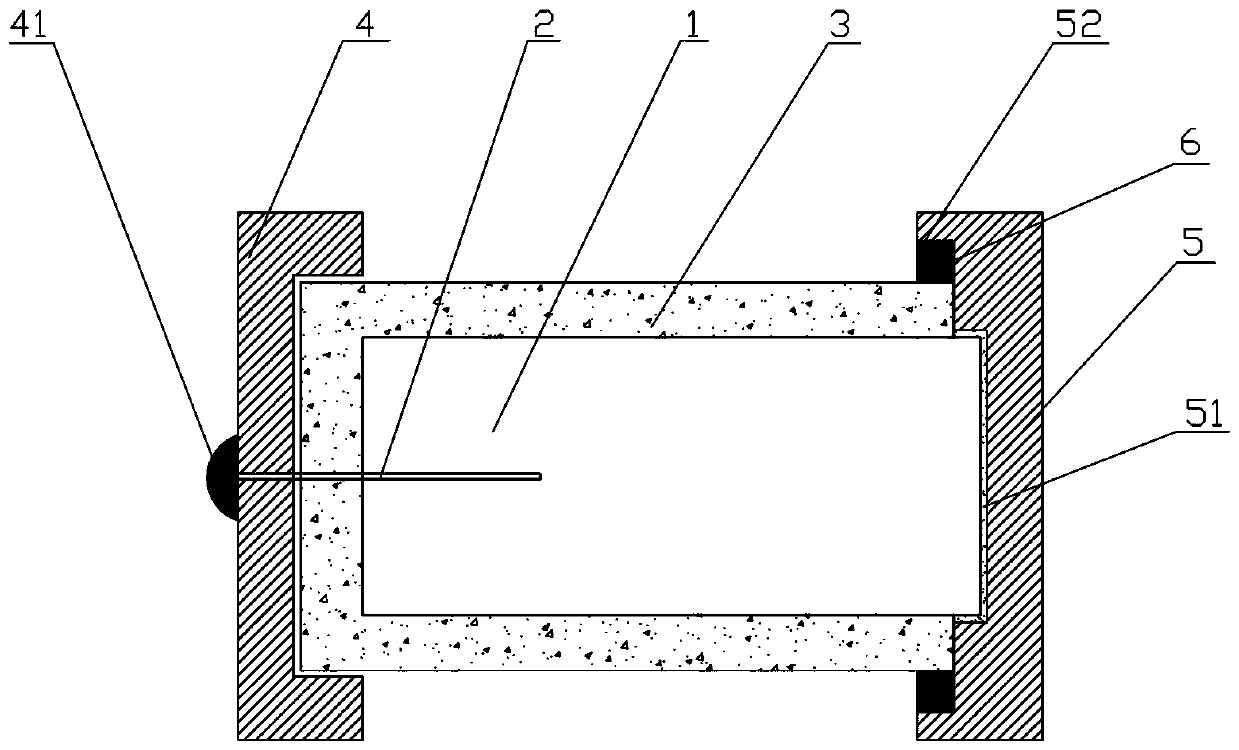

Low-loss square capacitor

InactiveCN108257787AImprove impregnation efficiencyCompact structureCapacitor housing/encapsulationCapacitorMaterials science

The invention discloses a low-loss square capacitor, which comprises a core cladding, an aluminum shell and an aluminum cover used for sealing the core cladding in the aluminum shell. The core cladding comprises positive electrode foil, negative electrode foil, electrolytic paper arranged between the positive electrode foil and the negative electrode foil, a positive electrode lead wire connectedwith the positive electrode foil, and a negative electrode lead wire connected with the negative electrode foil. The positive electrode lead wire and the negative electrode lead wire penetrate the aluminum cover and extend out of the aluminum cover. The core cladding is a laminated core cladding. The positive electrode foil and the negative electrode foil are sintered foil, a plurality of laminated positive electrode tabs are arranged on the positive electrode foil, and a plurality of laminated negative electrode tabs are arranged on the negative electrode foil. A positive electrode welding region used for welding the plurality of positive electrode tabs with the positive electrode lead wire is reserved on the outer surface of each positive electrode tab. A negative electrode welding region used for welding the plurality of negative electrode tabs with the negative electrode lead wire is reserved on the outer surface of each negative electrode tab. The low-loss square capacitor disclosed by the invention has the advantages of compact structure, high impregnation efficiency, small ESR value, and fully utilized internal space.

Owner:HUNAN AIHUA GRP

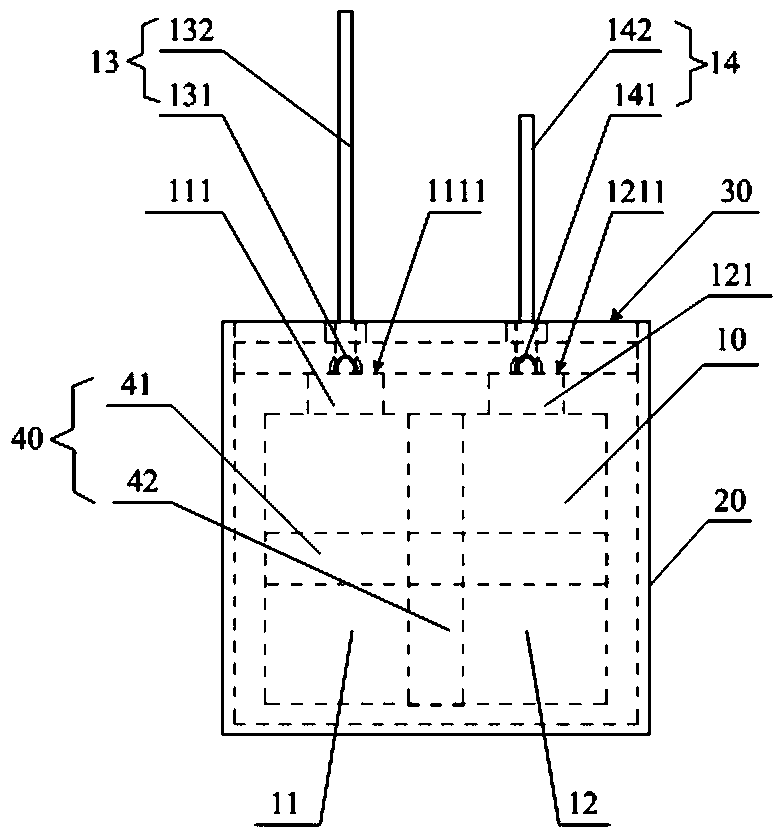

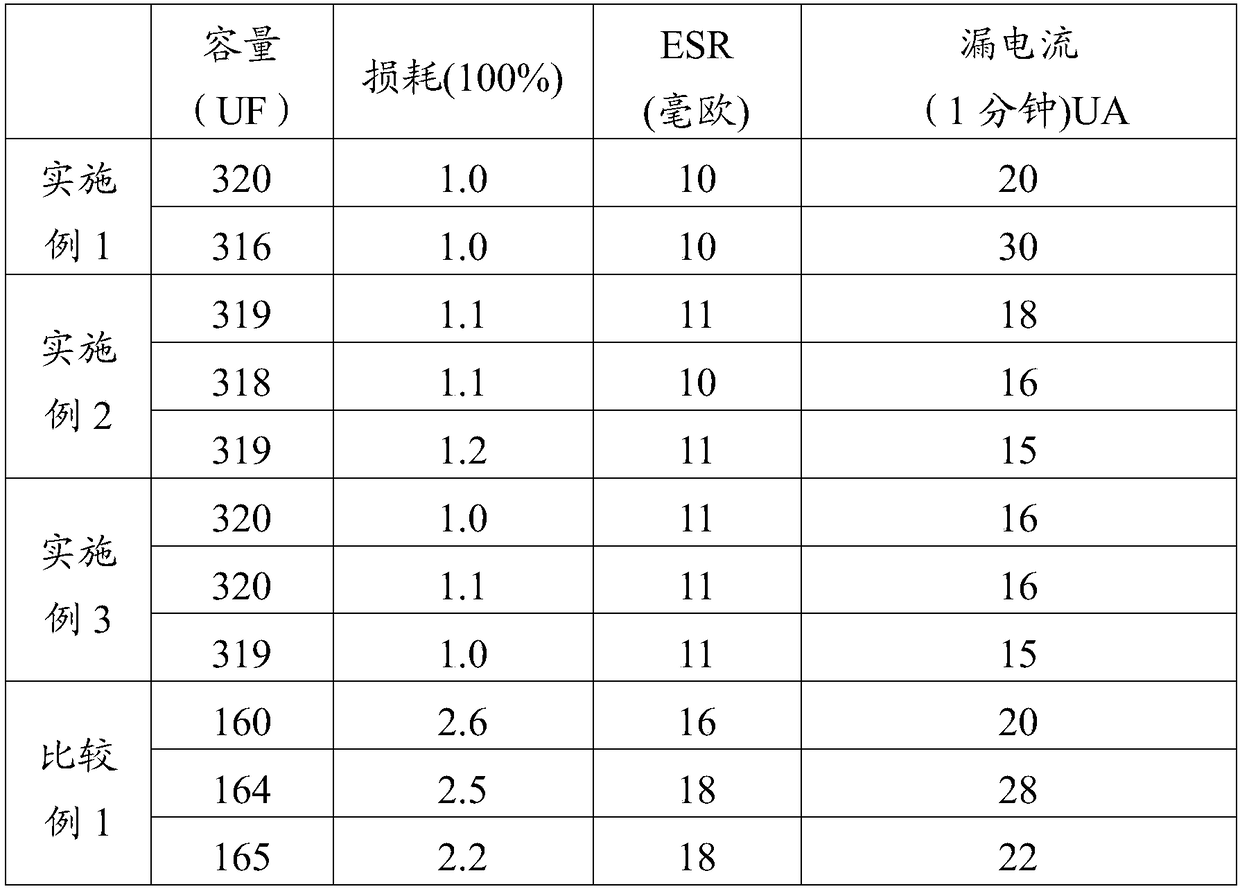

Capacitor core package and preparation method thereof, and solid aluminum electrolytic capacitor

ActiveCN107275092BReduce loss rateLower ESR valueSolid electrolytic capacitorsElectrolytic capacitor manufactureCapacitanceTO-18

The invention provides a capacitor core cladding, a preparation method thereof, and a solid aluminum electrolytic capacitor. The preparation method of the capacitor core cladding provided by the invention is simple in operation, does not need to carry out high-temperature carbonization and saves energy. In addition, the capacitor obtained by the invention has the characteristics of high capacitance, low loss rate and low ESR value. According to the results of an embodiment, the capacitance of the capacitor obtained in this embodiment is 316 to 320 UF, which is much higher than the capacitance of 160 to 165 UF in a comparative embodiment; the loss rate is only 1.0 to 1.2%, much lower than 2.2 to 2.6% in the comparative embodiment; the ESR value is 10 to 11 milliohms, far lower than 16 to 18 milliohms in the comparative embodiment; and the 1-minute leakage current is 15 to 30UA.

Owner:深圳市金富康电子有限公司 +1

A kind of preparation method of solid aluminum electrolytic capacitor with high electrostatic capacity

ActiveCN112420390BLower ESR valueImprove conductivitySolid electrolytic capacitorsPolymer dissolutionSolid state electrolyte

A preparation method of a solid aluminum electrolytic capacitor with high electrostatic capacity, comprising the following steps: 1) winding an anode foil, an electrolytic paper and a cathode foil into a core package; 2) dissolving a conductive high molecular polymer in a first solvent or dispersing After being in the first dispersion liquid, the core pack is impregnated in the first solvent or the first dispersion liquid; 3) the upper part of the core pack is removed in step 2) the impregnated first solvent or the first dispersion liquid; 4) the core contains Immersion in a second solvent compatible with the first solvent or the first dispersion; 5) drying. In the present invention, by impregnating the core pack in the second solvent, the conductive polymer formed on the core pack is more uniform, thereby improving the conductivity of the solid electrolyte and reducing the ESR value of the core pack; When the two solvents are used, the conductive polymer can further penetrate into the core package, thereby increasing the electrostatic capacity of the solid aluminum electrolytic capacitor.

Owner:YIYANG WANJINGYUAN ELECTRONICS

Solid tantalum capacitor and its manufacturing process

ActiveCN110853920BIncrease energy densityLarge capacityFixed capacitor electrodesFixed capacitor dielectricSilver pasteMetallic enclosure

Solid tantalum capacitor and its manufacturing process, including tantalum capacitor body, tantalum capacitor body including tantalum core, anode lead-out plate, cathode lead, metal shell and glass powder insulator, multiple tantalum cores are sequentially fixed on the metal shell by tin solder or conductive silver paste Among them, the metal shell is encapsulated by a glass powder insulator, the anode lead-out plate is installed in the metal shell and is located between the glass powder insulator and the tantalum core, the anode wire of the anode lead-out plate passes through the glass powder insulator as the anode lead of the capacitor, and the cathode lead is inserted into the metal In the shell and welded with the glass powder insulator and the metal shell, the tantalum core is a porous matrix formed by pressing a cuboid made of high-volume tantalum powder and sintered under high-temperature vacuum, and the tantalum core is covered by electroplating, coating or impregnation. There is a conductive polymer layer, and the tantalum core has jagged sides with alternating convex and concave. The invention greatly reduces the ESR value of the capacitor while the capacitor provides a large capacitance, and the reliability of the capacitor is higher.

Owner:ZHUZHOU HONGDA ELECTRONICS

Conductive high polymer, oxidizer for synthesis thereof and solid capacitor

ActiveCN103113559BImprove electrochemical performanceImprove conductivitySolid electrolytic capacitorsCapacitor electrolytes/absorbentsPolymer scienceElectrolysis

The invention provides an oxidizer solution for conductive high polymer synthesis. The oxidizer solution for conductive high polymer synthesis can be mixed with a polymerized monomer and is used for impregnating a capacitor core package to generate a conductive high polymer through reaction so as to be used for producing a high-performance solid electrolytic capacitor. The oxidizer solution for conductive high polymer synthesis comprises iron sulfonate and solvent, wherein the solvent is lower alcohol and cyclic ether, and the lower alcohol is selected from one or some of monobasic alcohol of which the carbon atom number is 1-4; and the number of oxygen groups of an ether bond in the cyclic ether is 1 or 2, and the ring containing the ether bond is a five-membered one or six-membered one. By using the oxidizer to synthesize a conductive high molecular polymer, the conductivity of the conductive polymer can be improved, thereby reducing the ESR (equivalent series resistance) value of a capacitor.

Owner:SHENZHEN CAPCHEM TECH CO LTD

Anti-vibration laminated solid aluminum electrolytic capacitor and manufacturing method thereof

PendingCN113658804AAvoid looseImprove electrical performanceSolid electrolytic capacitorsCapacitor housing/encapsulationEngineeringStructural engineering

An anti-vibration laminated solid aluminum electrolytic capacitor comprises a sealing assembly and a core fixedly arranged in the sealing assembly, the core is electrically connected with a positive guide pin and a negative guide pin, and the positive guide pin and the negative guide pin penetrate out of the sealing assembly; the core is composed of a plurality of stacked single sheets, and each single sheet comprises a positive electrode end, a negative electrode end and a shielding glue wire located between the positive electrode end and the negative electrode end; the positive electrode end of the single sheet is provided with a positive electrode fixing terminal, the positive electrode guide pin is connected with the positive electrode fixing terminal, the negative electrode end of the single sheet is provided with a negative electrode fixing terminal, and the negative electrode guide pin is connected with the negative electrode fixing terminal. The positive electrode fixing terminal and the negative electrode fixing terminal are adopted to fix the positive electrode ends and the negative electrode ends of the stacked single sheets respectively, the stacked single sheets can be effectively prevented from loosening due to the influence of the external environment in the assembling process of the capacitor and the using process of the capacitor, and therefore the electrical performance of the capacitor is stable.

Owner:HUNAN AIHUA GRP

A kind of ultra-low impedance aluminum electrolytic capacitor for switching power supply

ActiveCN110993346BLower impedanceMeet miniaturizationLiquid electrolytic capacitorsCapacitor housing/encapsulationCapacitanceElectrolytic agent

The invention discloses an ultra-low impedance aluminum electrolytic capacitor for a switching power supply, which comprises a shell provided with an opening, a core arranged inside the shell and a rubber plug sealed and connected to the opening of the shell; the core is impregnated with electrolytic liquid; the electrolyte includes the following components in percentage by weight: solute: 5%-25%, additive 1%-10%, and the balance is solvent; the solute is ammonium glycolate, ammonium formate, horse Ammonium formate and phthalic acid, described additive is deactivator, ammonium dihydrogen phosphate and nitrobenzoic acid, and described solvent is ethylene glycol, γ-butyrolactone, glycerol and water. In the present invention, by developing a high-performance electrolyte, selecting a suitable electrode foil and controlling the sealing, the aluminum electrolytic capacitor produced has low impedance, can withstand larger ripple currents, and can meet the miniaturization of the current switching power supply. Capacity, ripple current resistance, high frequency and low impedance, high temperature and long life, and more suitable for high-density assembly requirements.

Owner:ZHAOQING BERYL ELECTRONICS TECH

A kind of solid capacitor negative electrode carbon foil and its preparation method and a solid capacitor and its preparation method

ActiveCN108492988BIncrease capacityReduce lossSolid electrolytic capacitorsDrying/impregnating machinesAluminum foilCapacitor

Owner:深圳市金富康电子有限公司 +1

Solid tantalum capacitor with extremely low ESR value and leading-out welding sheet at gold plating end

InactiveCN108054016ALower ESR valueReduce contact resistanceSolid electrolytic capacitorsCapacitor housing/encapsulationEpoxyTantalum capacitor

The invention discloses a solid tantalum capacitor with an extremely low ESR value and a leading-out welding sheet at a gold plating end. The solid tantalum capacitor comprises a tantalum core and a tantalum wire, wherein an epoxy resin encapsulation layer wraps the tantalum core, a positive electrode gold plating cap and a negative electrode gold plating cap are respectively arranged at two endsof the encapsulation layer, the negative electrode gold plating cap is arranged at an opening end of the encapsulation layer, and the negative electrode gold plating cap and the tantalum core are connected by a surface welding mode. Spot welding between an existing wire and the tantalum wire is changed to contact surface welding, and the ESR value of the tantalum capacitor can be effectively reduced by large-area welding; and moreover, existing positive / negative pole plate tin plating is changed to gold plating cap leading out, the conductivity of a welding position can be greatly improved, and the contact resistance of the tantalum capacitor on a circuit board also can be greatly reduced.

Owner:株洲中电电容器有限公司

A processing method of tantalum anode blocks for reducing the high-frequency equivalent series resistance of tantalum capacitors

ActiveCN103093964BLower ESR valueLow resistivityElectrolytic capacitorsElectrolysisContact resistance

The invention discloses a method for processing a tantalum anode block for reducing the high-frequency equivalent series resistance of a tantalum capacitor. The method comprises immersing the tantalum anode block into a suspension of the semiconductor layer outside the cathode to process the semiconductor layer outside the cathode, and immersing the tantalum anode block into a graphite solution. Processing of cathode transition layer and coating of graphite and silver paste. This method eliminates the interlayer contact resistance by adding a transition layer between the semiconductor layer and the conductive layer on the surface of the tantalum anode block, and reduces the ESR value of the tantalum electrolytic capacitor by more than 30%. High efficiency, suitable for industrial mass production.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

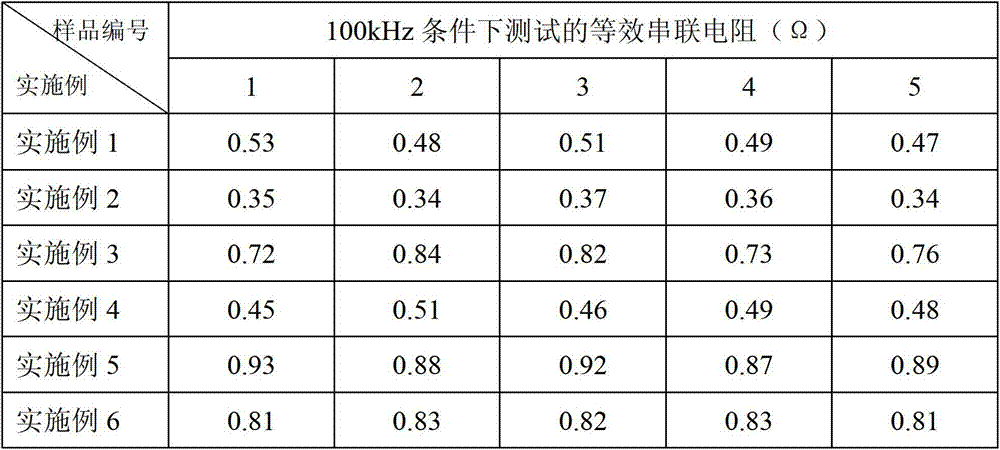

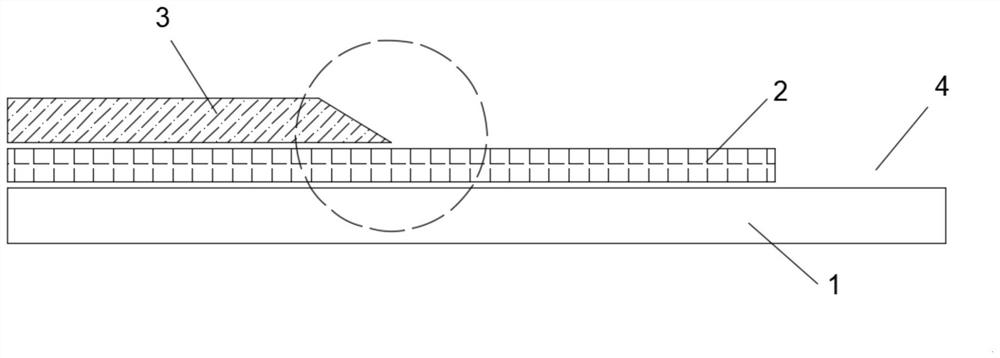

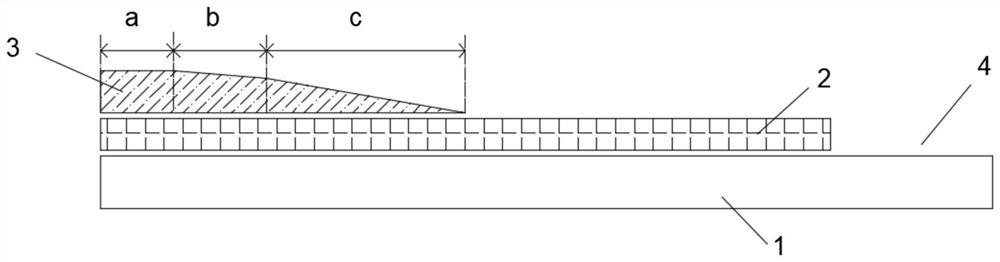

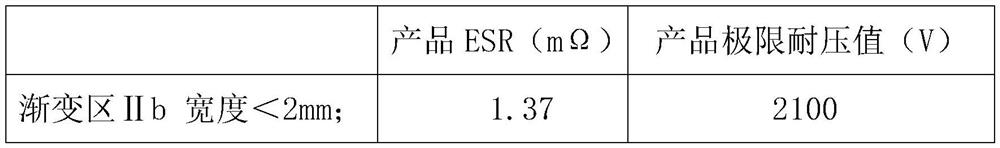

Metallized film with gradual change type sheet resistance structure

ActiveCN113690054AThe trend of increasing thicknessIncrease contact areaThin/thick film capacitorStacked capacitorsCapacitanceThin membrane

The invention discloses a metalized film with a gradual change type sheet resistance structure, and belongs to the technical field of electronic components. The metalized film with a gradual change type sheet resistance structure comprises a base film, a metal layer and a blank margin, a thickening layer aligned with the side edge of the metal layer is arranged on the metal spraying side, away from the blank margin, of the metal layer, and the thickening layer is composed of three continuous gradual change areas with the thickness gradually changed. The gradual change area comprises a base layer I, a gradual change area II connected with the base layer I and a gradual change area III extending to the blank margin. Compared with a traditional two-section gradual change type sheet resistance structure, the three-section gradual change type thickened structure is adopted, and the change trend of the coating thickness of the gradual change area IIb is mainly increased. According to the metallized film, the lodging of the metal edge, namely the base layer Ia, caused by an overlarge sheet resistance gradual change trend during metal spraying after the metallized film is coiled is greatly relieved, the contact area of sprayed metal and a metallized film plating layer is increased, the overcurrent capability of a capacitor product is ensured, the ESR value of the capacitor product is reduced, and thus the use temperature of the capacitor is increased.

Owner:NANTONG XINJIANGHAI POWER ELECTRONICS

Solid-state capacitor negative carbon foil and preparation method thereof and solid-state capacitor and preparation method thereof

ActiveCN108492988AIncrease capacityReduce lossSolid electrolytic capacitorsDrying/impregnating machinesAluminum foilCapacitor

The invention provides a solid-state capacitor negative carbon foil comprising a corrosion aluminum foil and a conductive layer. The conductive layer wraps the surface of the corrosion aluminum foil.The conductive layer comprises a conductive high-molecular polymer layer and a carbon conductive layer. The conductive high-molecular polymer layer wraps the surface of the corrosion aluminum foil orthe surface of the corrosion aluminum foil coated with the carbon conductive layer. One conductive high-molecular polymer layer and one carbon conductive layer wrap the conventional corrosion aluminumfoil and the solid-state capacitor negative carbon foil having the simple structure is obtained, the solid-state capacitor negative carbon foil can be prepared by only using the conventional coatingmethod, and the solid-state capacitor prepared by using the negative foil has the advantages of high capacity, low loss and low ESR value.

Owner:深圳市金富康电子有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com