Production process of negative electrode foil and negative electrode foil and polymer solid aluminum electrolytic capacitor

A production process and negative electrode technology, which is applied in the field of polymer solid aluminum electrolytic capacitors, can solve the problems of poor safety and economy, and cannot realize the miniaturization of capacitors, and achieve the effect of smaller volume and smaller ESR value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

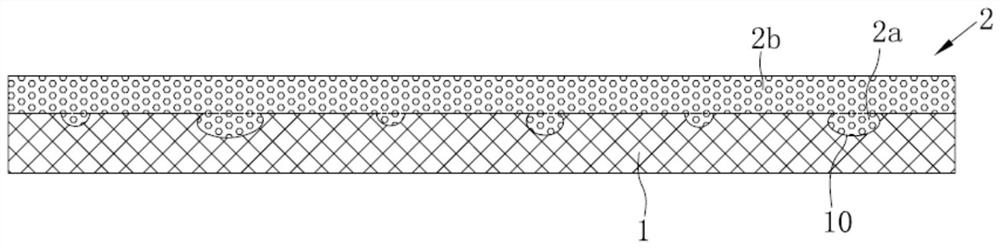

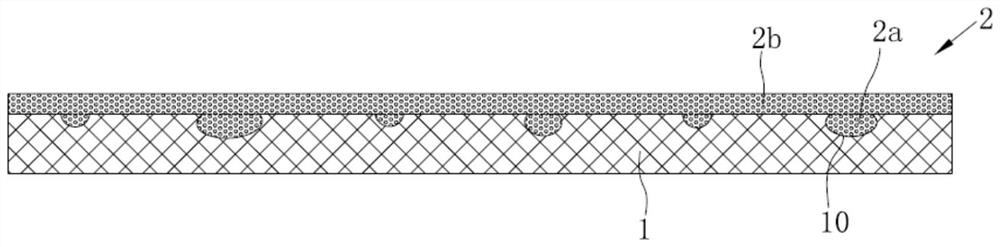

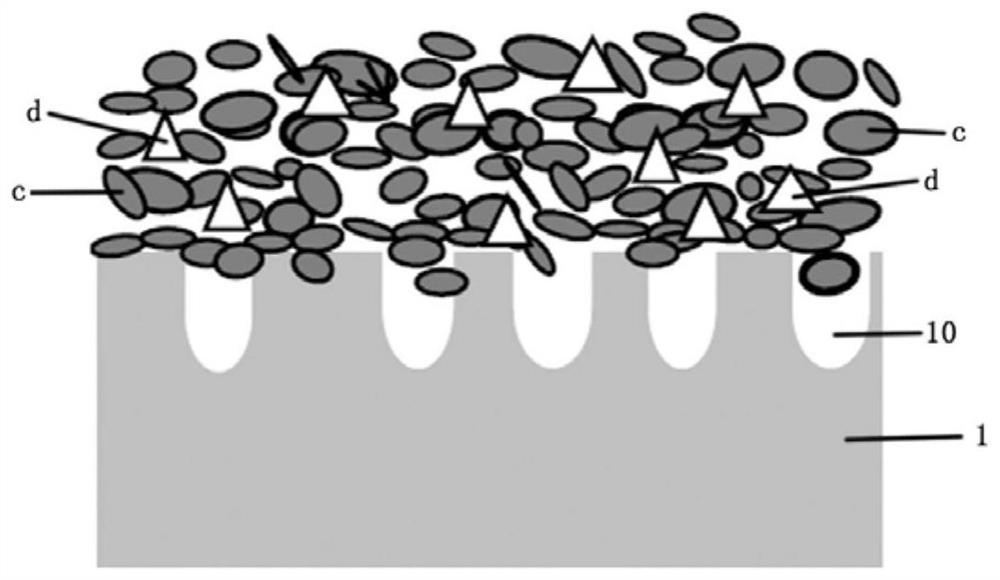

[0041]Seefigure 1 withfigure 2 As shown, the present embodiment provides an anode foil comprising an aluminum substrate 1, a dielectric layer 2 formed on the surface of the aluminum substrate 1.

[0042]Specifically, the negative electrode foil production process is as follows:

[0043]S1, select aluminum substrate, which is selected from 99.5%, and a aluminum foil having a thickness of 30 μm is an aluminum substrate.

[0044]S2, forming a dielectric layer step comprising the step of: a), a slurry; b), first etch the aluminum substrate surface to form a hole, then apply the slurry to the surface of the aluminum substrate having a hole, The surface is drying, followed by a rolling machine, press the coating into the hole and press the surface of the hole and the aluminum substrate; c), carbonization treatment.

[0045]In step a), the oxide dielectric particles of the valve metal, the metal particles, the organic resin, the dispersant, and the solvent are ingredient in mass ratio of 1: 0.15: 0.6:...

Embodiment 2

[0058]The negative electrode foil according to the present embodiment, its structure and processes are basically the same as those of Example 1, and different are:

[0059]1), the formation process of the holes in this example is to put the selected aluminum substrate into a concentration of 0.5 mol / L, the temperature of the hydrochloric acid solution of 80 ° C, and then washed with a 3 wt% nitric aqueous solution, and then again Wash the water and dry.

[0060]Specifically, the hole diameter of the hole 10 is 150 to 250 nm, the hole depth of the hole is 450 to 550 nm, and the distribution density of the surface of the hole in the surface of the aluminum substrate 1 is 1 × 104 / Cm2.

[0061]In this example, the titanium dioxide particles, silver particles, organic resins, dispersants and solvents are blended at a mass ratio of 1: 0.10: 0.6 :0.0002: 8, and mix well and mix well.

[0062]In this example, the surface slurry coating coated in an aluminum substrate is dried in a tunnel furnace of ...

Embodiment 3

[0067]The negative electrode foil according to the present embodiment, its structure and processes are basically the same as those of Example 1, and different are:

[0068]1), the formation process of the holes in this example is to put the selected aluminum substrate in a concentration of 1 mol / L, a temperature of 80 ° C, soaking 20s, followed by washing with a 3 wt% nitric aqueous solution, and then use water Rinse and dry.

[0069]Specifically, the aperture 10 has a hole diameter of 250 to 300 nm, the hole depth of the hole is 600 to 700 nm, and the distribution density of the surface of the hole in the aluminum substrate 1 is 4 × 105 / Cm2.

[0070]In this example, titanium dioxide particles, silver particles, organic resins, dispersants, and solvents are blended at a mass ratio of 1: 0.2: 0.6: 0.0002: 8, stir mix and mix, and are made into a slurry.

[0071]In this example, the surface slurry coating coated on the aluminum substrate is dried in a tunnel furnace of 110 ± 5 ° C, dried 240s,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com