Method for preparing composite conductive high molecular electrode material in use for super capacitor

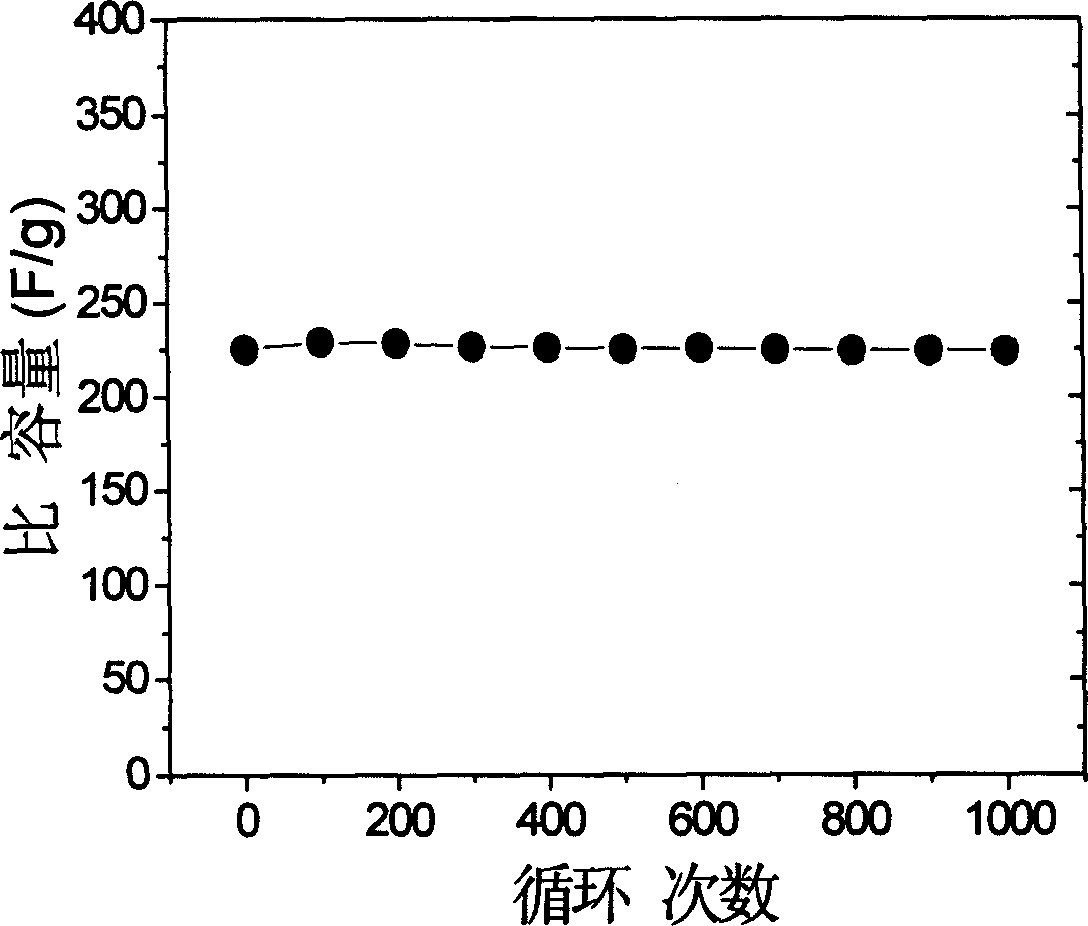

A polymer electrode and supercapacitor technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve problems such as poor cycle performance and lower specific capacity, and achieve high specific capacity, high specific capacity, and good cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

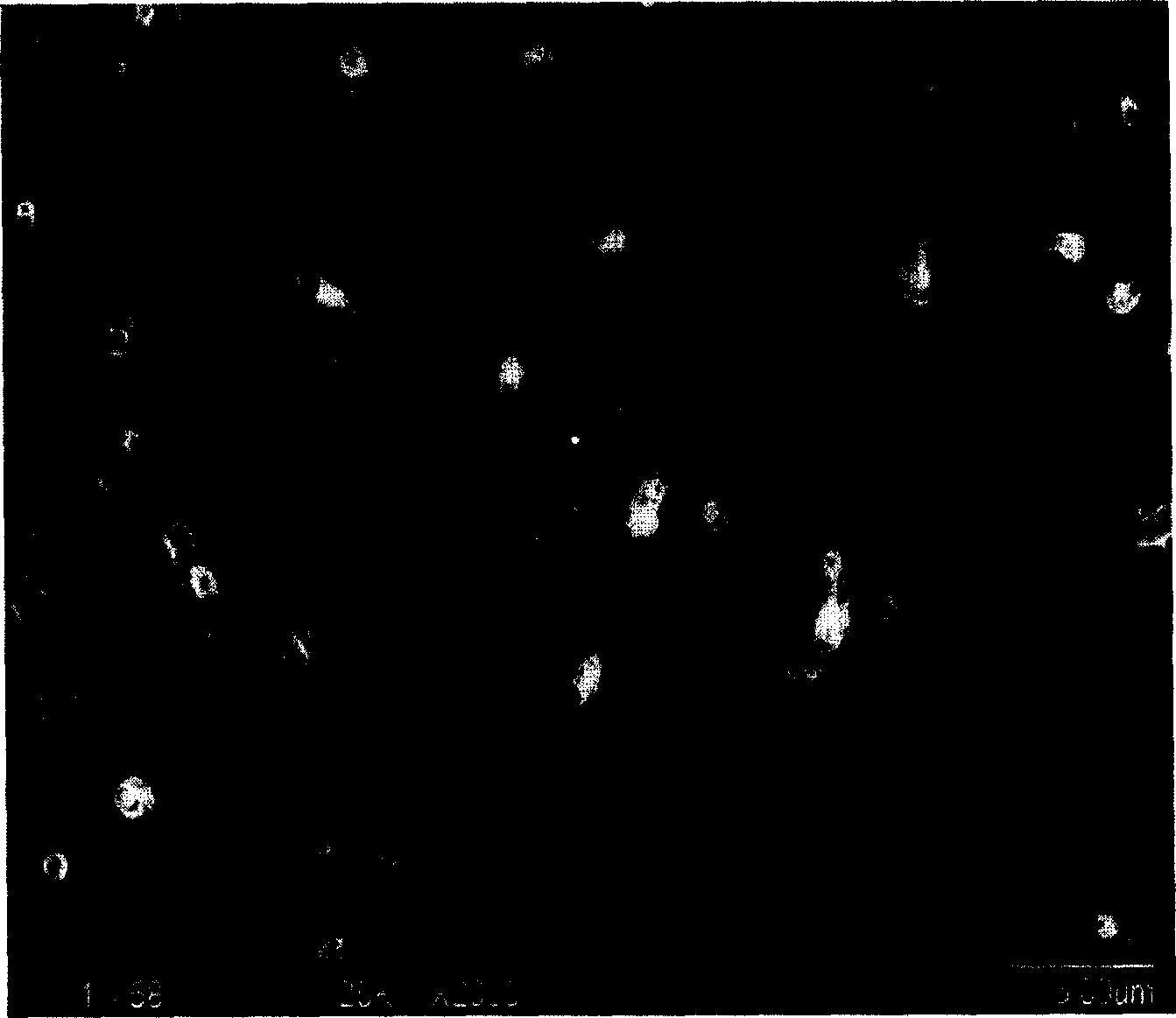

Image

Examples

Embodiment 1

[0014] Embodiment 1: 1) Preparation of A solution: first add lithium chloride to water and make the concentration of lithium chloride be the electrolytic solution of 0.1mol / l, then add hydrochloric acid in electrolytic solution and adjust the pH of electrolytic solution to be 3, obtain A solution;

[0015] 2) Preparation of solution B: add pyrrole monomer to solution A to prepare solution B with a concentration of pyrrole monomer of 0.1 mol / l;

[0016] 3) Insert a stainless steel mesh into the B solution as a working electrode and a stainless steel tank as a counter electrode to carry out electrochemical polymerization, and the polymerization current density is 20mA / cm 2 , the polymerization time is 1 minute; after the polymerization is completed, polypyrrole is formed on the surface of the working electrode, the working electrode and the counter electrode are taken out, washed, and dried at 60°C;

[0017] 4) Preparation of solution C: add aniline to solution A so that the co...

Embodiment 2

[0019] Embodiment 2: 1) Preparation of A solution: first add sodium chloride to the methanol solution so that the concentration of sodium chloride is an electrolyte solution of 0.6mol / l, then add hydrochloric acid corresponding to the electrolyte to adjust the electrolyte solution in the electrolyte solution The pH of is 4, obtains A solution;

[0020] 2) Preparation of solution B: add pyrrole monomer to solution A to prepare solution B with a concentration of pyrrole monomer of 0.9 mol / l;

[0021] 3) Then insert nickel mesh into the B solution as the working electrode and graphite plate as the counter electrode for electrochemical polymerization, and the polymerization current density is 15mA / cm 2 , the polymerization time is 20 minutes; after the polymerization is completed, polypyrrole is formed on the surface of the working electrode, the working electrode and the counter electrode are taken out, washed, and dried at 75°C;

[0022] 4) Preparation of solution C: adding eth...

Embodiment 3

[0024] Embodiment 3: 1) Preparation of A solution: first add potassium chloride to the propylene carbonate solution so that the concentration of potassium chloride is an electrolyte solution of 0.3mol / l, then add hydrochloric acid corresponding to the electrolyte in the electrolyte solution to adjust The pH of the electrolyte solution is 5, and A solution is obtained;

[0025] 2) Preparation of solution B: add pyrrole monomer to solution A to prepare solution B with a concentration of pyrrole monomer of 1 mol / l;

[0026] 3) Insert a stainless steel mesh into the B solution as a working electrode and a graphite plate as a counter electrode to carry out electrochemical polymerization, and the polymerization current density is 10mA / cm 2 , the polymerization time is 15 minutes; after the polymerization is completed, polypyrrole is formed on the surface of the working electrode, the working electrode and the counter electrode are taken out, washed, and dried at 80°C;

[0027] 4) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com