Premixed powder for preparing whole coarse cereal steamed bun

A technology of premixed flour and miscellaneous grains, which is applied in the field of food steamed bread, can solve the problems of single quantity of miscellaneous grains and unbalanced nutrition of products, and achieve the effects of extending shelf life, improving taste, and increasing product specific volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the embodiment of the present invention, 30 parts of corn flour, 10 parts of red bean flour, 5 parts of black bean flour, 5 parts of kidney bean flour, 5 parts of mung bean flour, 5 parts of soybean flour, 10 parts of black rice flour, 10 parts of small yellow rice flour, and 10 parts of sorghum flour 5 parts of rice flour, 5 parts of barley rice flour, 5 parts of buckwheat flour, 5 parts of sesame powder, 0.5 part of polyglycerol fatty acid ester, 0.005 part of cellulase, 0.01 part of xylanase, 0.5 part of sorbitol, 0.5 part of active dry yeast 0.5 part of baking powder, 0.002 part of tricalcium phosphate, 2 parts of cross-linked pregelatinized carboxymethyl starch. Modified starches can be derived from corn, potato or tapioca.

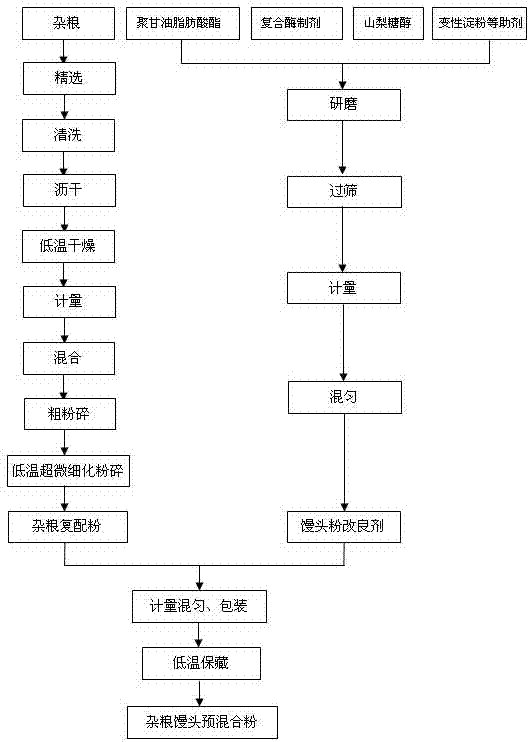

[0024] Such as figure 1 Shown, the production method of this whole multigrain steamed bread premix powder is:

[0025] First, the miscellaneous grains are pretreated

[0026] (1) Select, wash and drain the miscellaneous grain raw materia...

Embodiment 2

[0035] In the embodiment of the present invention, 20 parts of corn flour, 5 parts of red bean flour, 5 parts of black bean flour, 5 parts of chickpea flour, 10 parts of mung bean flour, 5 parts of soybean flour, 10 parts of black rice flour, and 10 parts of small yellow rice flour , 10 parts of sorghum rice flour, 10 parts of barley rice flour, 9 parts of buckwheat flour, 1 part of sesame powder, 0.5 part of polyglycerol fatty acid ester, 0.001 part of cellulase, 0.002 part of xylanase, 1 part of sorbitol, active dry 1 part of yeast, 0.1 part of baking powder, 0.003 part of tricalcium phosphate, 1 part of cross-linked pregelatinized carboxymethyl starch.

[0036] The production method of this whole multigrain steamed bread premix powder is:

[0037] First, the miscellaneous grains are pretreated

[0038] (1) Select, wash and drain the miscellaneous grain raw materials;

[0039] (2) Dry the drained miscellaneous grains at a drying temperature of 45°C until the water content ...

Embodiment 3

[0047] In the embodiment of the present invention, 40 parts of corn flour, 5 parts of red bean flour, 10 parts of black bean flour, 2 parts of pea flour, 2 parts of broad bean flour, 2 parts of lentil flour, 2 parts of green bean flour, 2 parts of chickpea flour, 5 parts of mung bean flour, 5 parts of soybean flour, 5 parts of black rice flour, 5 parts of small yellow rice flour, 5 parts of sorghum rice flour, 4 parts of barley rice flour, 2 parts of oat flour, 2 parts of barley flour, 1 part of rye flour, 1 part of sesame flour , 0.5 part of polyglycerol fatty acid ester, 0.003 part of cellulase, 0.006 part of xylanase, 0.2 part of sorbitol, 0.7 part of active dry yeast, 0.3 part of baking powder, 0.001 part of tricalcium phosphate, cross-linked pregelatinization 0.5 parts of carboxymethyl starch.

[0048] The production method of this whole multigrain steamed bread premix powder is:

[0049] First, the miscellaneous grains are pretreated

[0050] (1) Select, wash and drain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com