Patents

Literature

562results about "Capacitor dielectric layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid electrolytic capacitor containing a conductive polymer

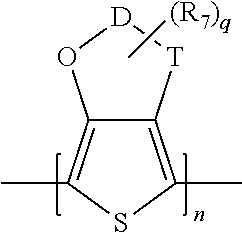

ActiveUS7515396B2Hybrid capacitor electrolytesSolid electrolytic capacitorsOligomerConductive polymer

A method for forming an electrolytic capacitor is disclosed. The method includes forming a conductive polymer coating by polymerizing a monomer in the presence of less than a stoichiometric amount of an oxidative polymerization catalyst. The present inventor has found that the use of less than the stoichiometric amount of the oxidative polymerization catalyst per mole of monomer can slow the polymerization of the monomer, creating oligomers that are shorter in length than if fully polymerized into a polymer. Without wishing to be bound by theory, it is believed that these shorter oligomers provide better penetration into the porous anode. Thus, the resulting conductive polymer layer can be more intimately positioned with respect to the anode. As a result, the formed capacitor can exhibit better performance.

Owner:KYOCERA AVX COMPONENTS CORP

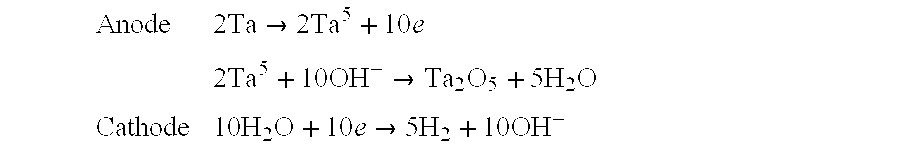

Process for the production of electrolyte capacitors of high nominal voltage

ActiveUS20070064376A1Lower equivalent series resistanceHigh nominal voltageSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisPhysical chemistry

The invention relates to a process for the production of electrolyte capacitors having a low equivalent series resistance and low residual current for high nominal voltages, electrolyte capacitors produced by this process and the use of such electrolyte capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

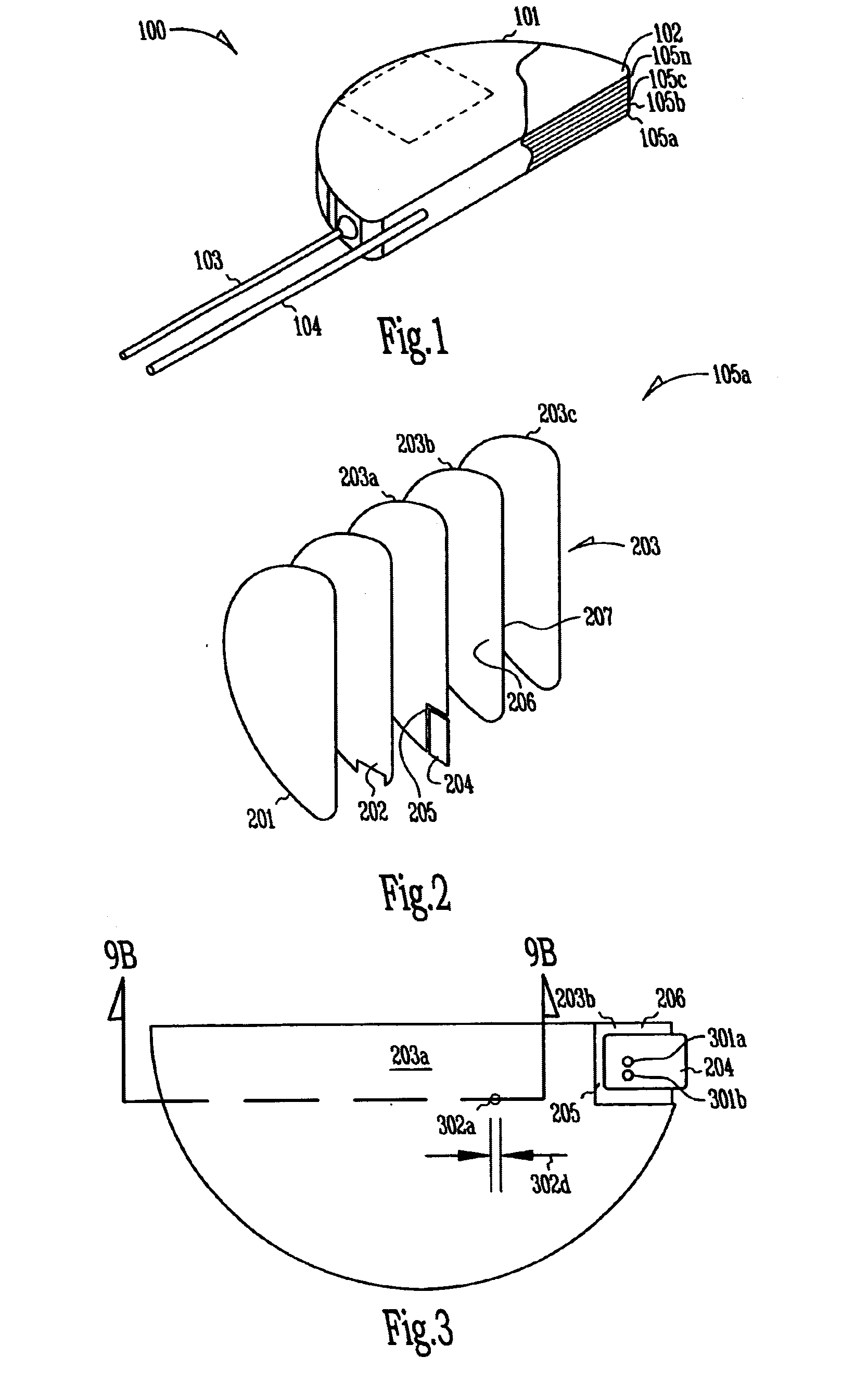

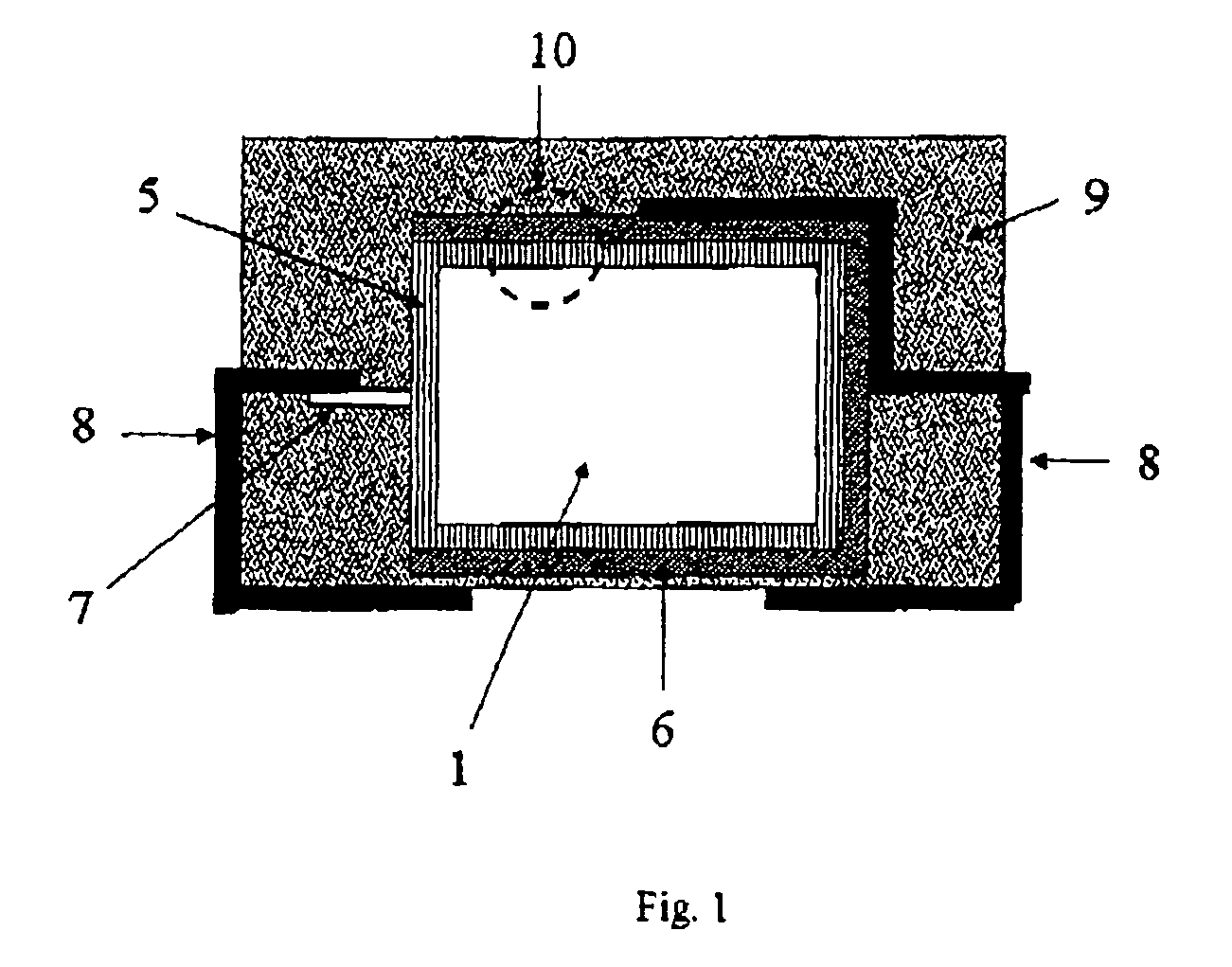

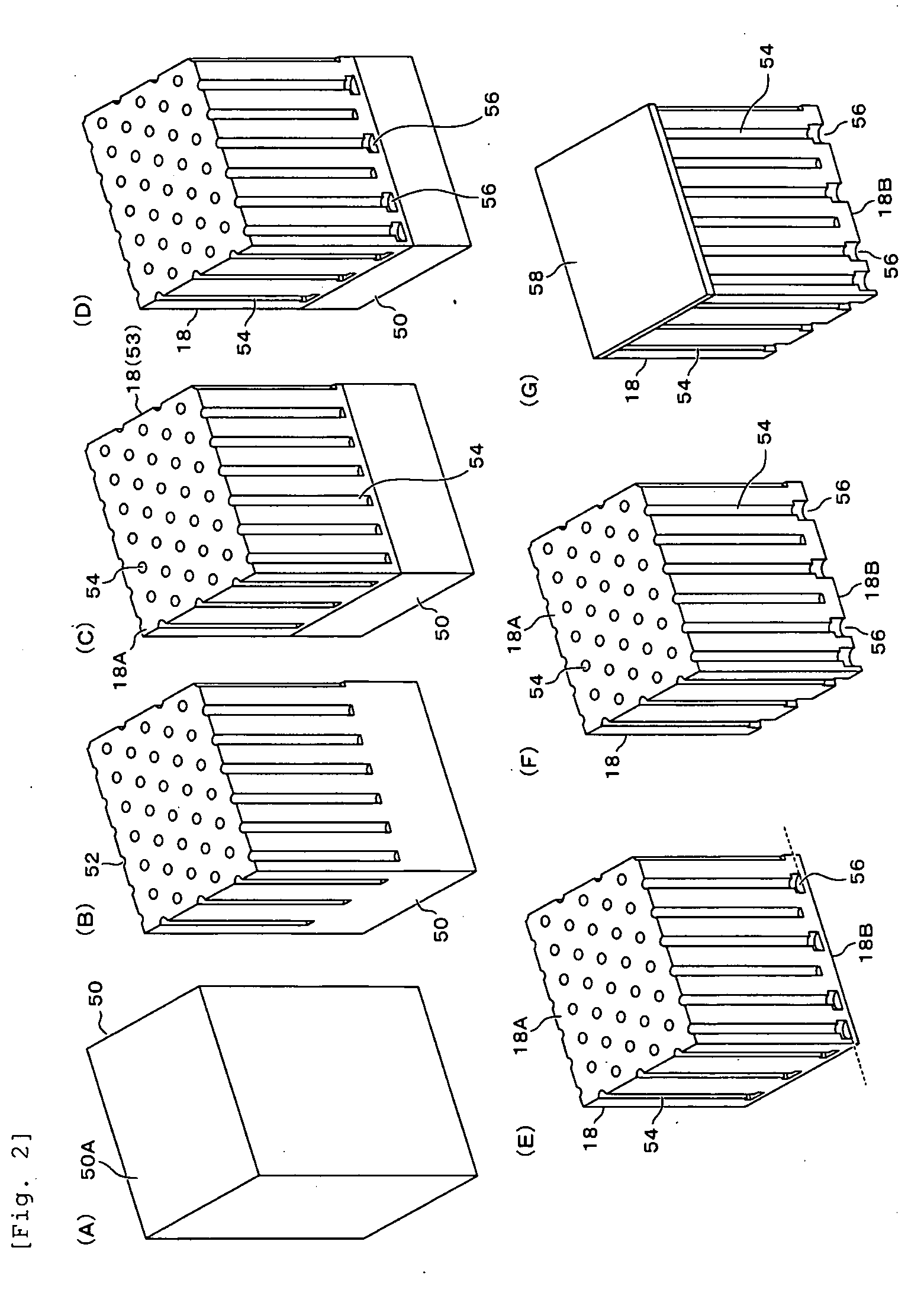

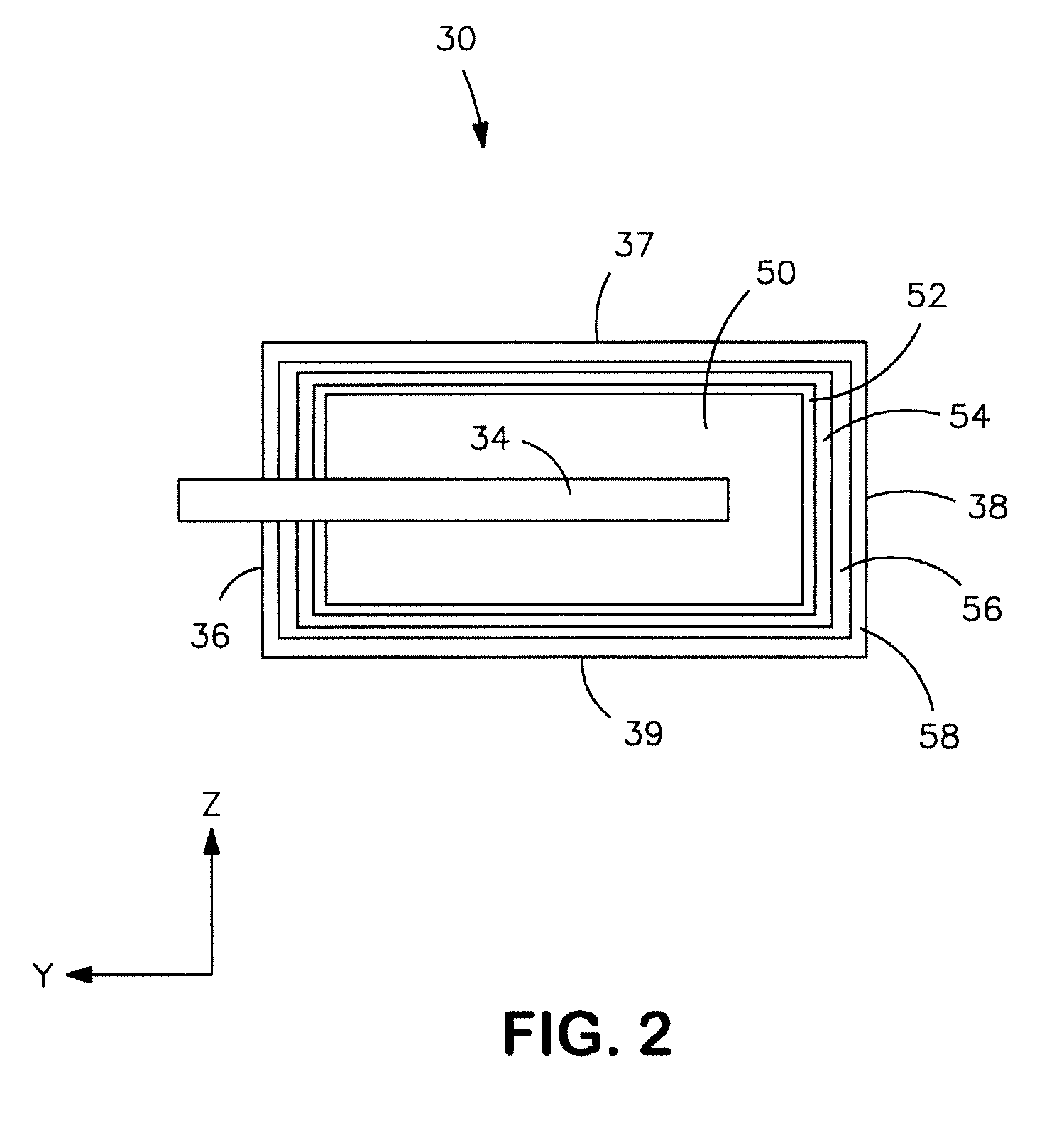

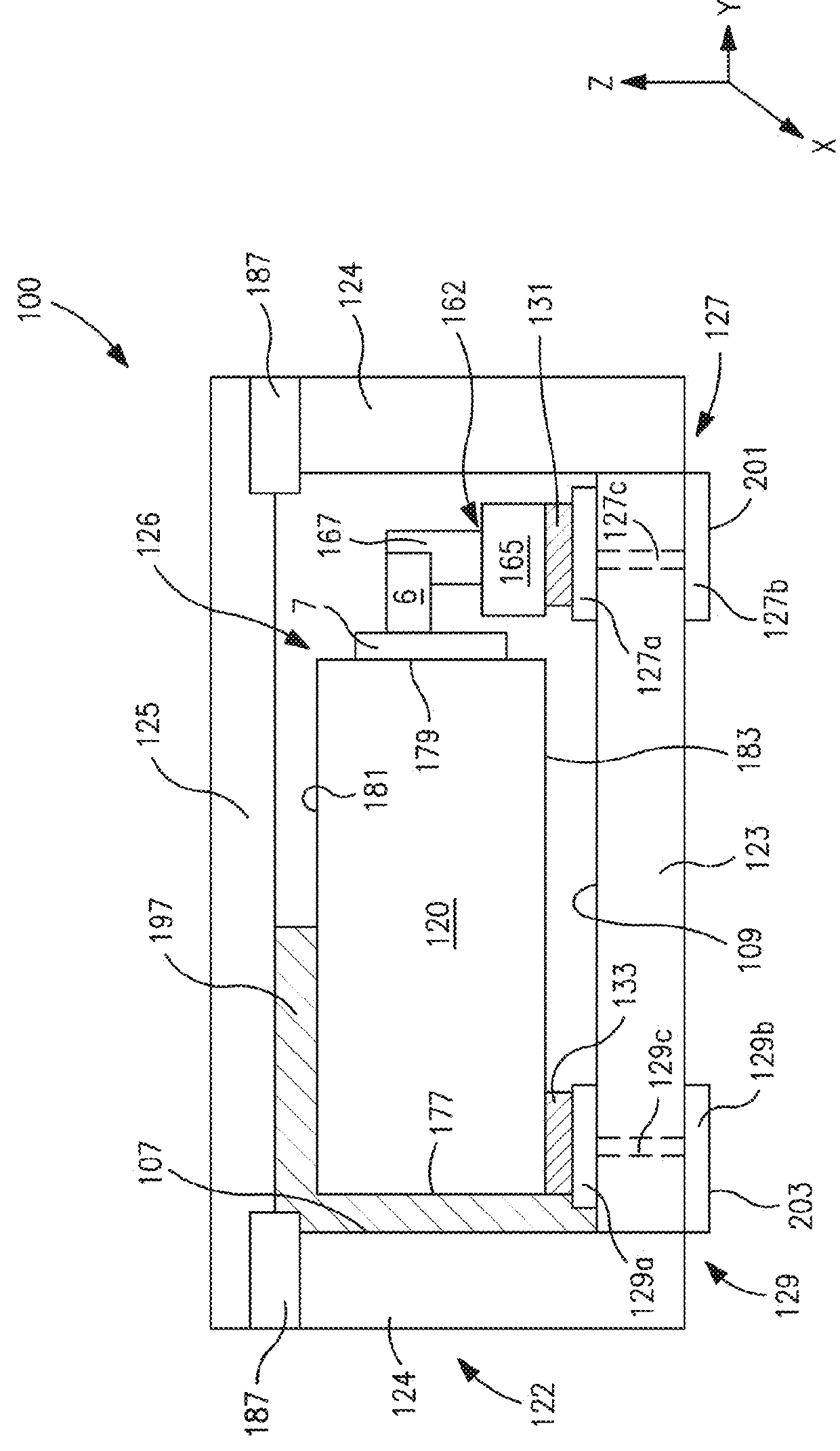

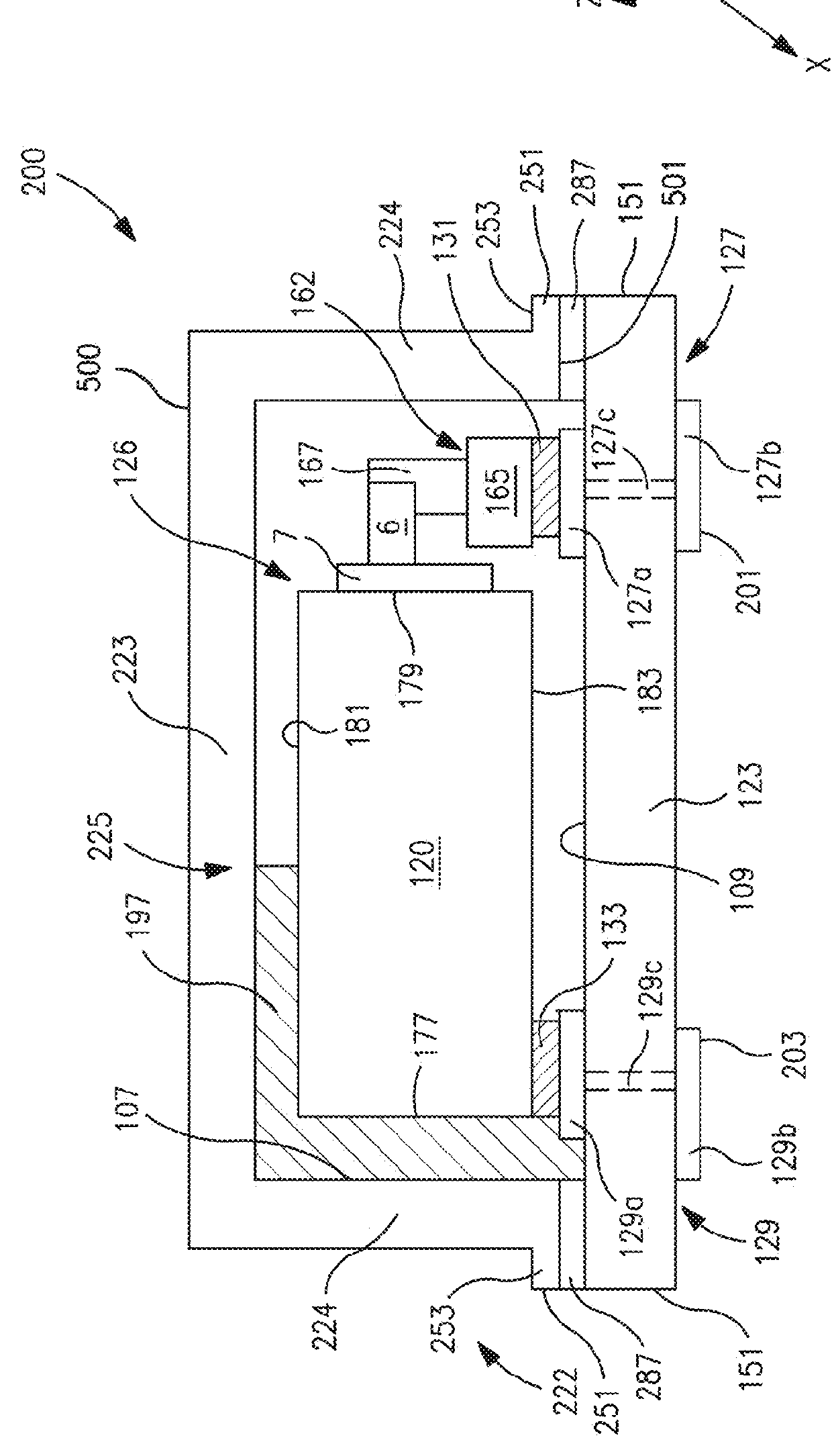

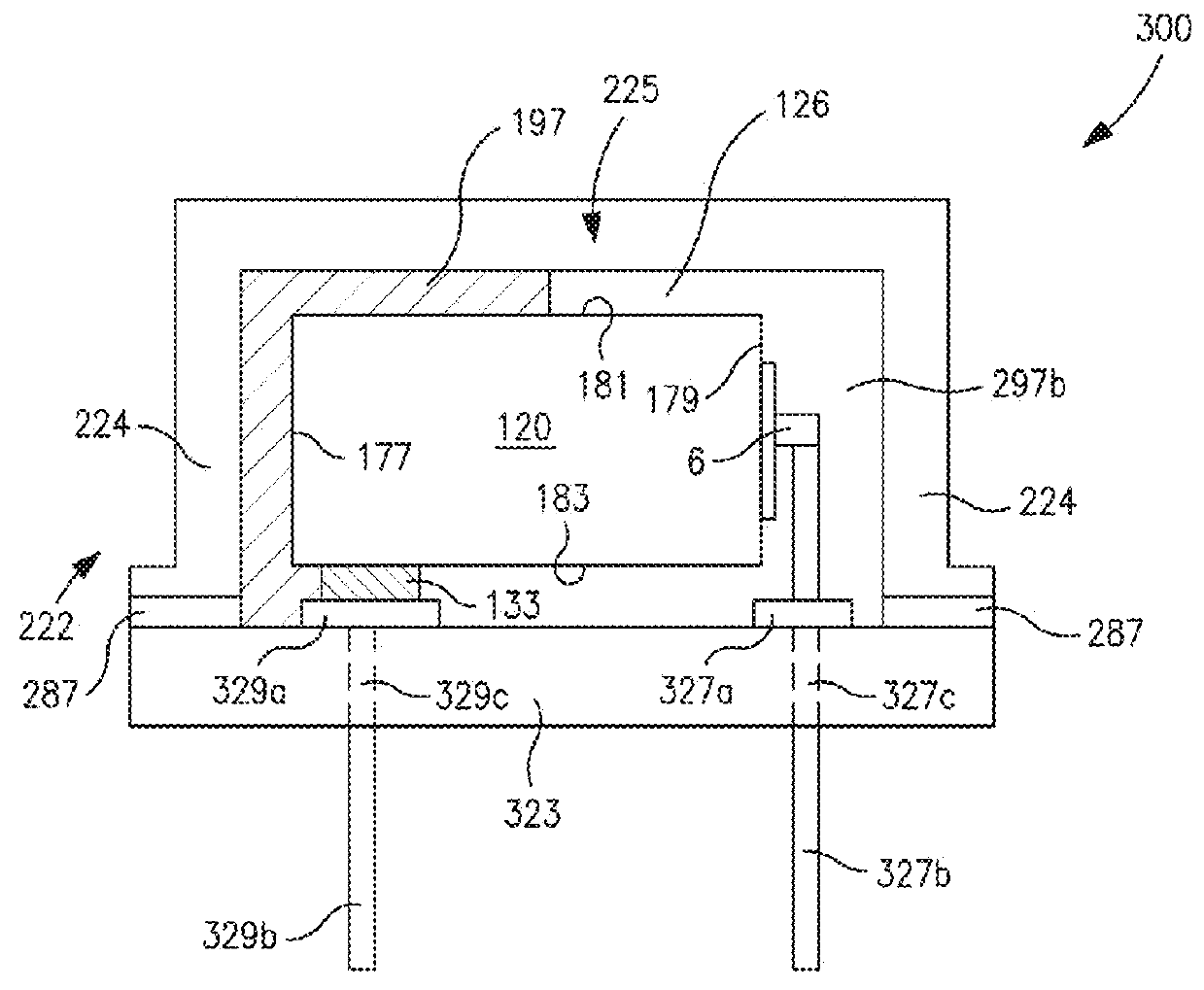

Flat capacitor for an implantable medical device

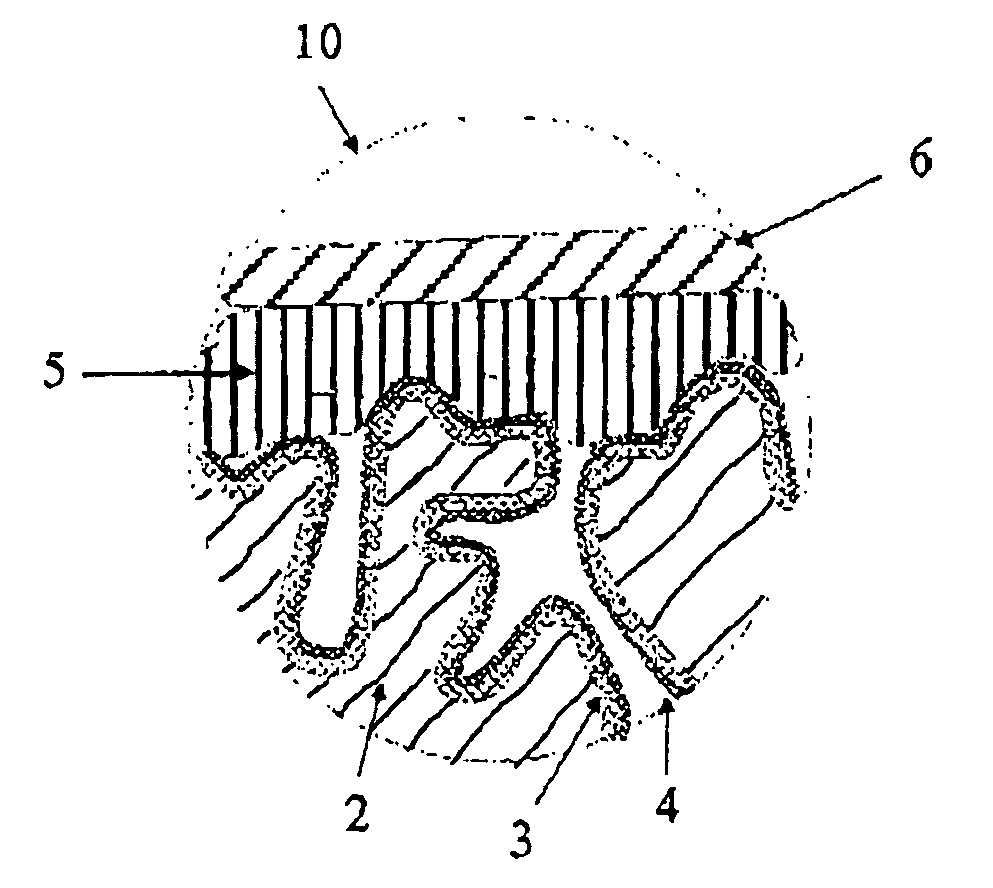

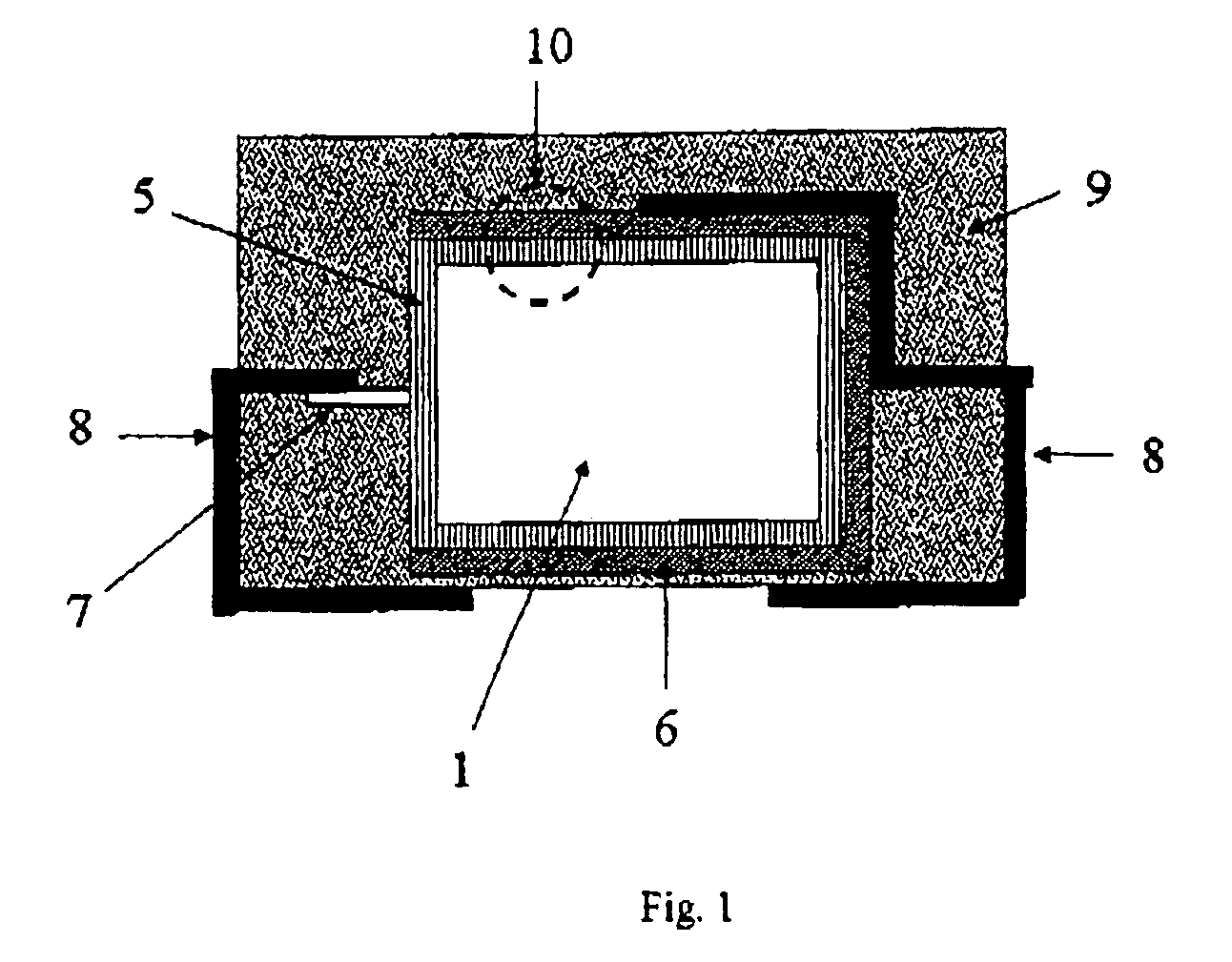

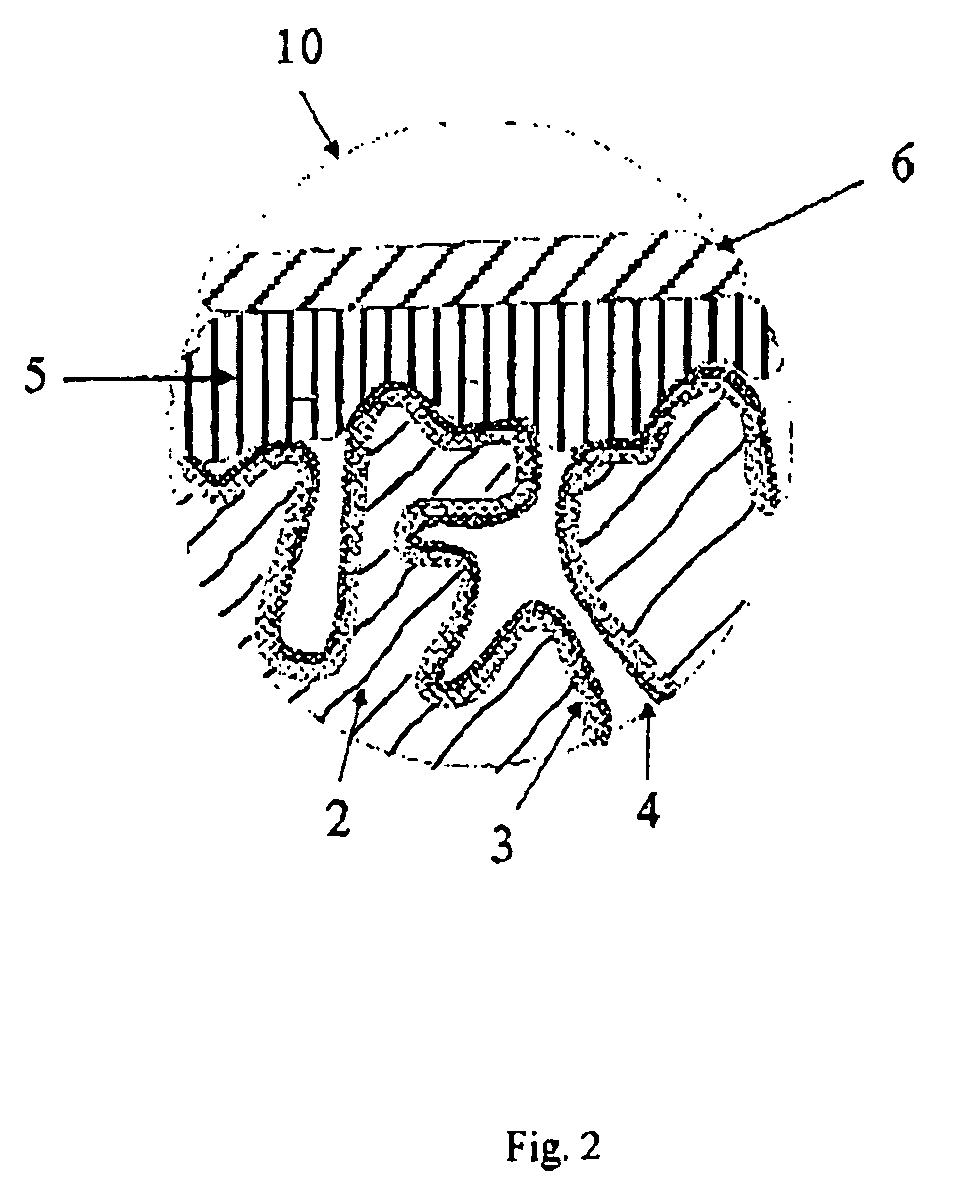

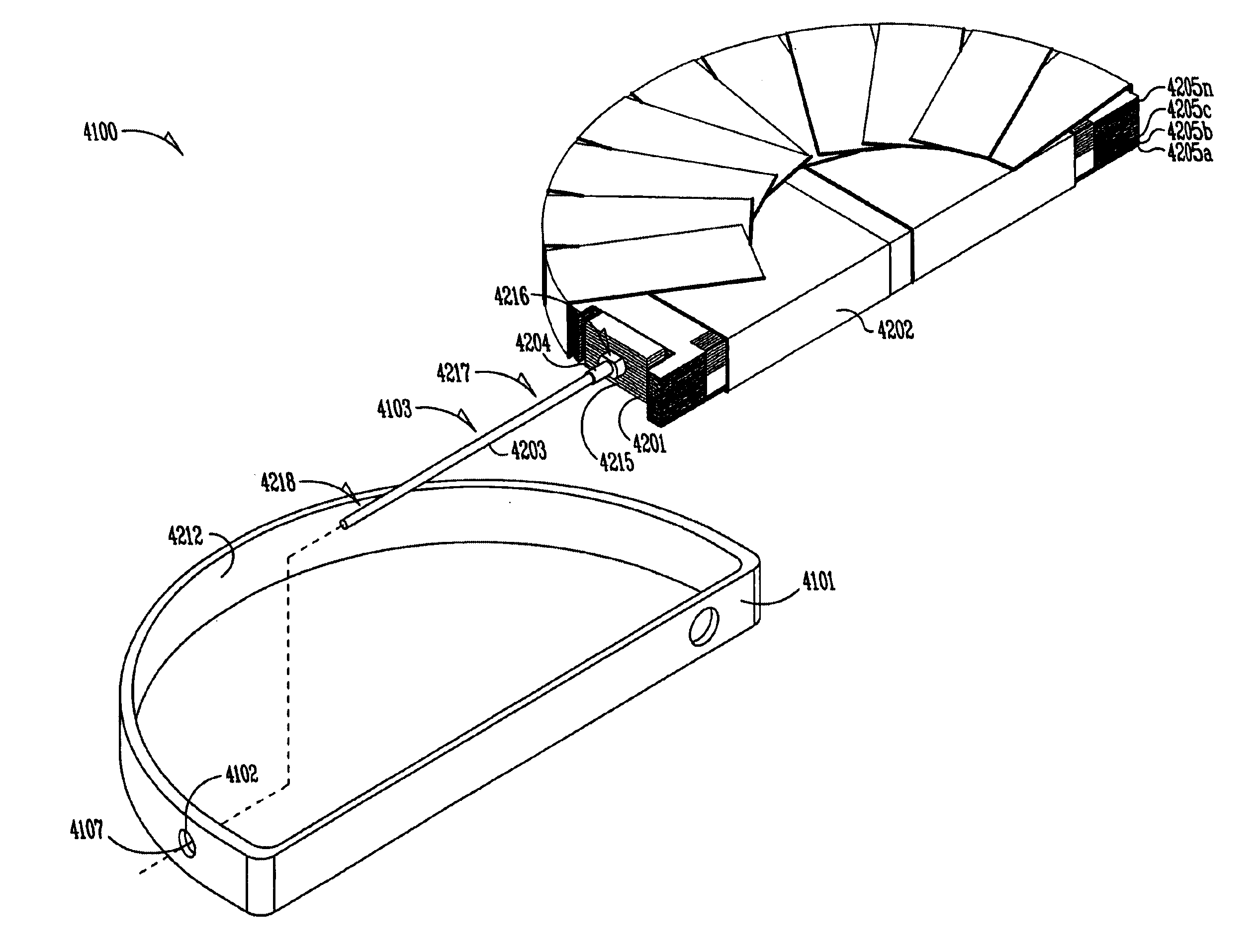

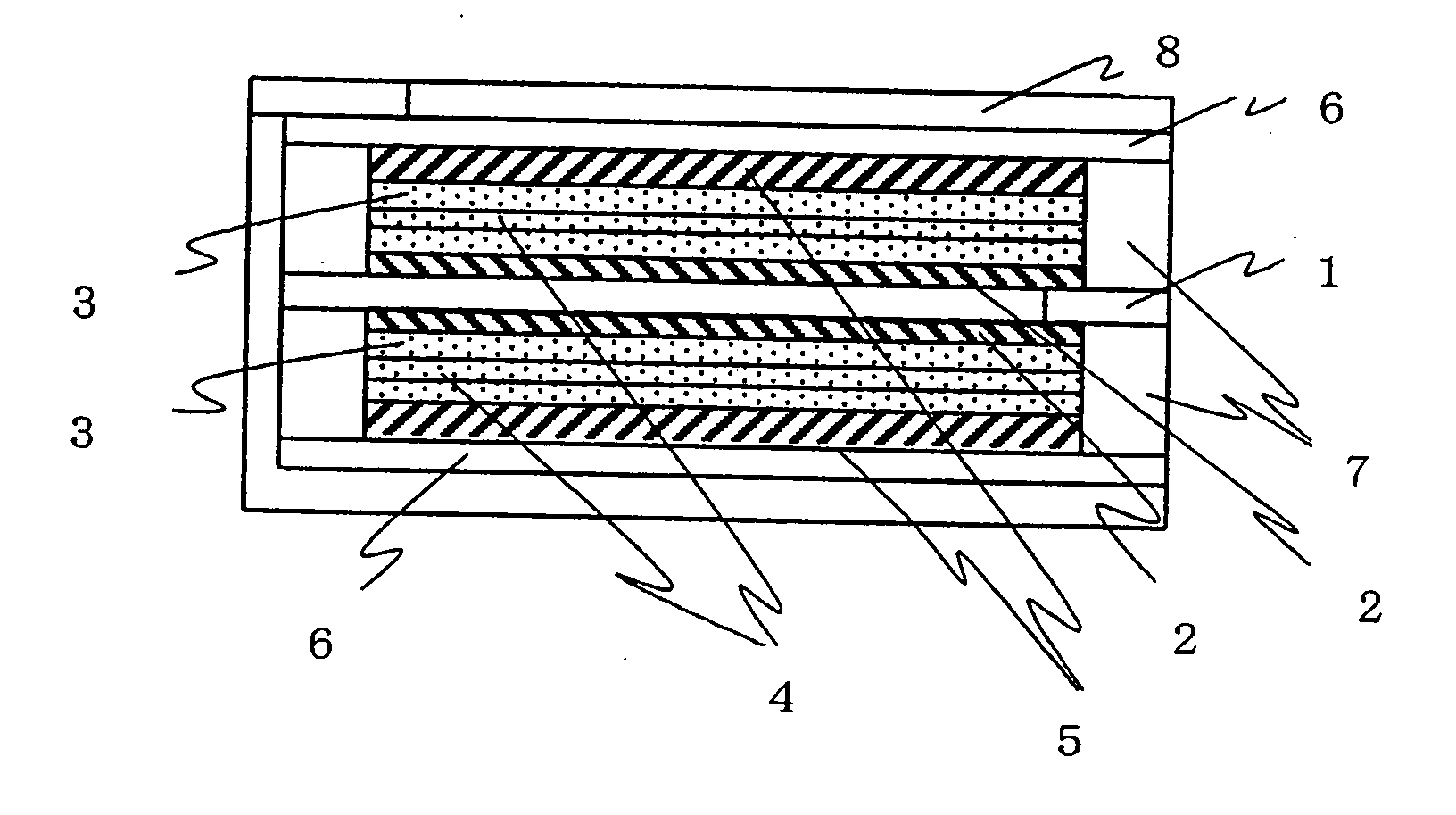

InactiveUS6699265B1Liquid electrolytic capacitorsCapacitor terminalsCapacitanceSemipermeable membrane

One embodiment includes a capacitor having a first anode stack having a first number of anode foils, a second anode stack having a second number of anode foils, where the first number of anode foils is different than the second number of anode foils. Another aspect provides a capacitor having a case having a curved interior surface, and first, second, and third capacitor modules that confront the curved interior surface of the case. One aspect provides a capacitor having one or more anodes and a cathode structure comprising a plurality of integrally connected cathode plates, the cathode structure having a serpentine shape, interweaving under and over each of the one or more anodes. One aspect provides a feedthrough assembly having an electrically conductive member dimensioned to extend at least partially through a feedthrough hole of a case of the capacitor, the conductive member having a passage therethrough. One aspect provides a capacitor having a first stack of capacitive elements a second stack of capacitive elements, wherein the first and second stacks are enclosed in separate compartments of a capacitor case that electrically isolate the electrolytes of each stack from one another. One aspect provides a capacitor case including a portion having opposing interior and exterior surfaces, with the portion having a hole; and a semi-permeable membrane adjacent the hole to regulate passage of fluids through the hole.

Owner:CARDIAC PACEMAKERS INC

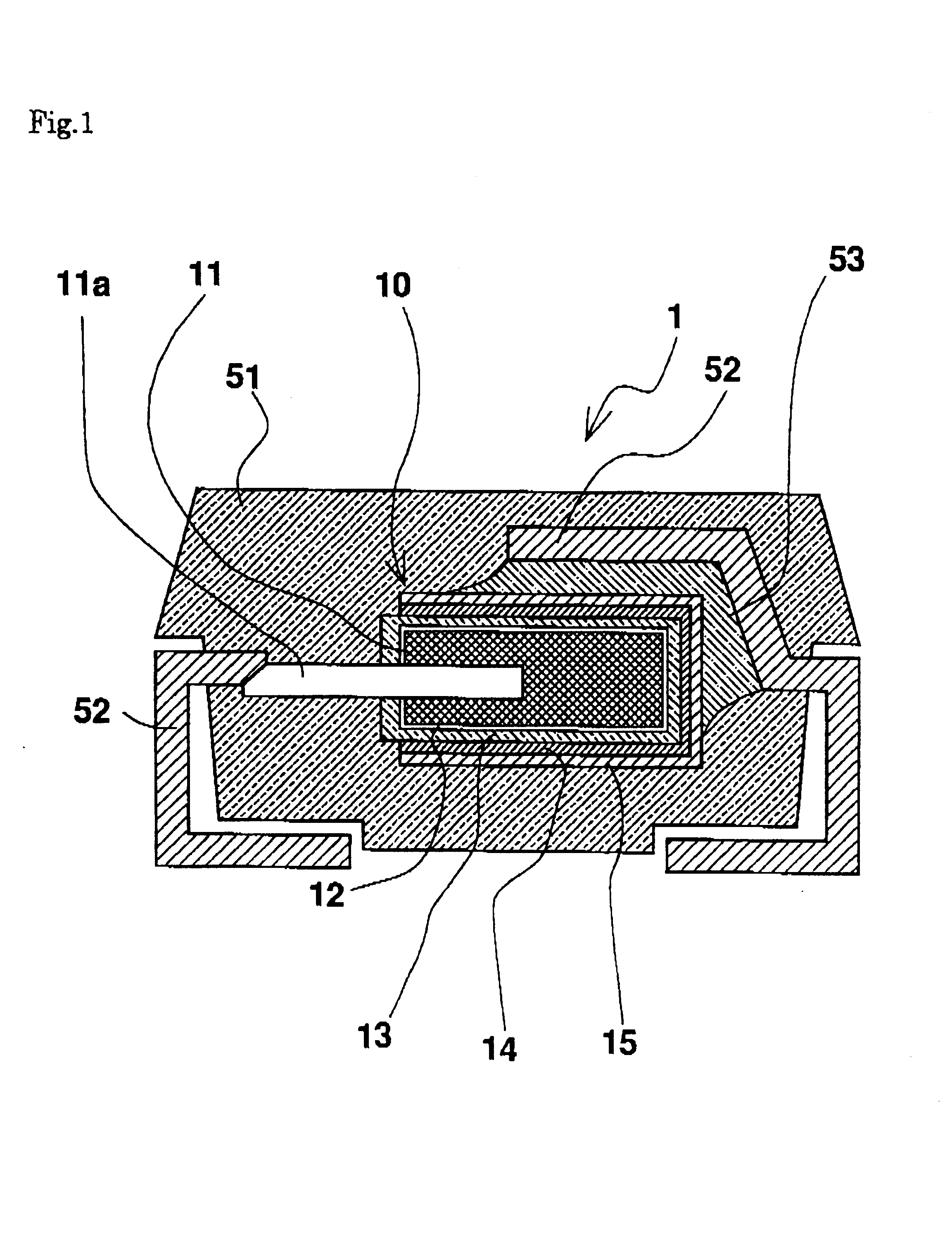

Capacitor

InactiveUS6115235AFixed capacitor electrodesLiquid electrolytic capacitorsOrganic semiconductorCapacitor

PCT No. PCT / JP98 / 00823 Sec. 371 Date Oct. 28, 1998 Sec. 102(e) Date Oct. 28, 1998 PCT Filed Feb. 27, 1998 PCT Pub. No. WO98 / 38660 PCT Pub. Date Sep. 3, 1998In a capacitor comprising a pair of electrodes and a dielectric substance intervening between the two electrodes, one of the electrodes is composed of sintered niobium nitride. Preferably, the dielectric substance is composed of niobium oxide and the electrode other than the electrode composed of sintered niobium nitride is composed of an ingredient selected from electrolytes, organic semiconductors and inorganic semiconductors. This capacitor has good environmental stability and good leak current characteristics.

Owner:SHOWA DENKO KK

Solid electrolytic capacitor containing a conductive polymer

ActiveUS20080232037A1Hybrid capacitor electrolytesSolid electrolytic capacitorsOligomerConductive polymer

A method for forming an electrolytic capacitor is disclosed. The method includes forming a conductive polymer coating by polymerizing a monomer in the presence of less than a stoichiometric amount of an oxidative polymerization catalyst. The present inventor has found that the use of less than the stoichiometric amount of the oxidative polymerization catalyst per mole of monomer can slow the polymerization of the monomer, creating oligomers that are shorter in length than if fully polymerized into a polymer. Without wishing to be bound by theory, it is believed that these shorter oligomers provide better penetration into the porous anode. Thus, the resulting conductive polymer layer can be more intimately positioned with respect to the anode. As a result, the formed capacitor can exhibit better performance.

Owner:KYOCERA AVX COMPONENTS CORP

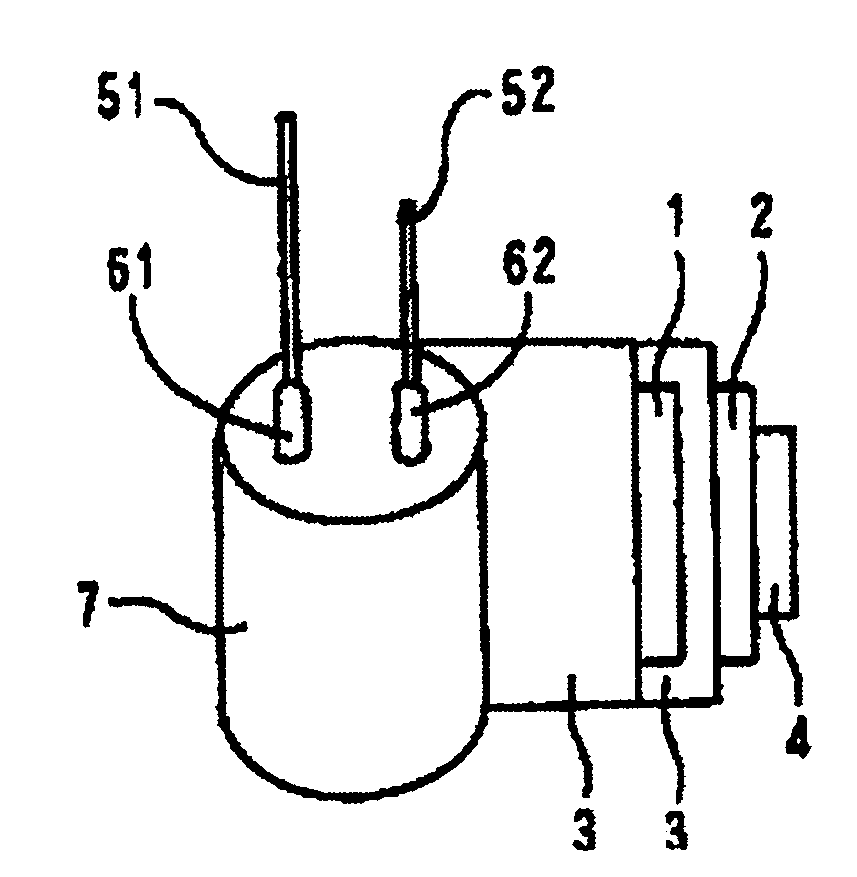

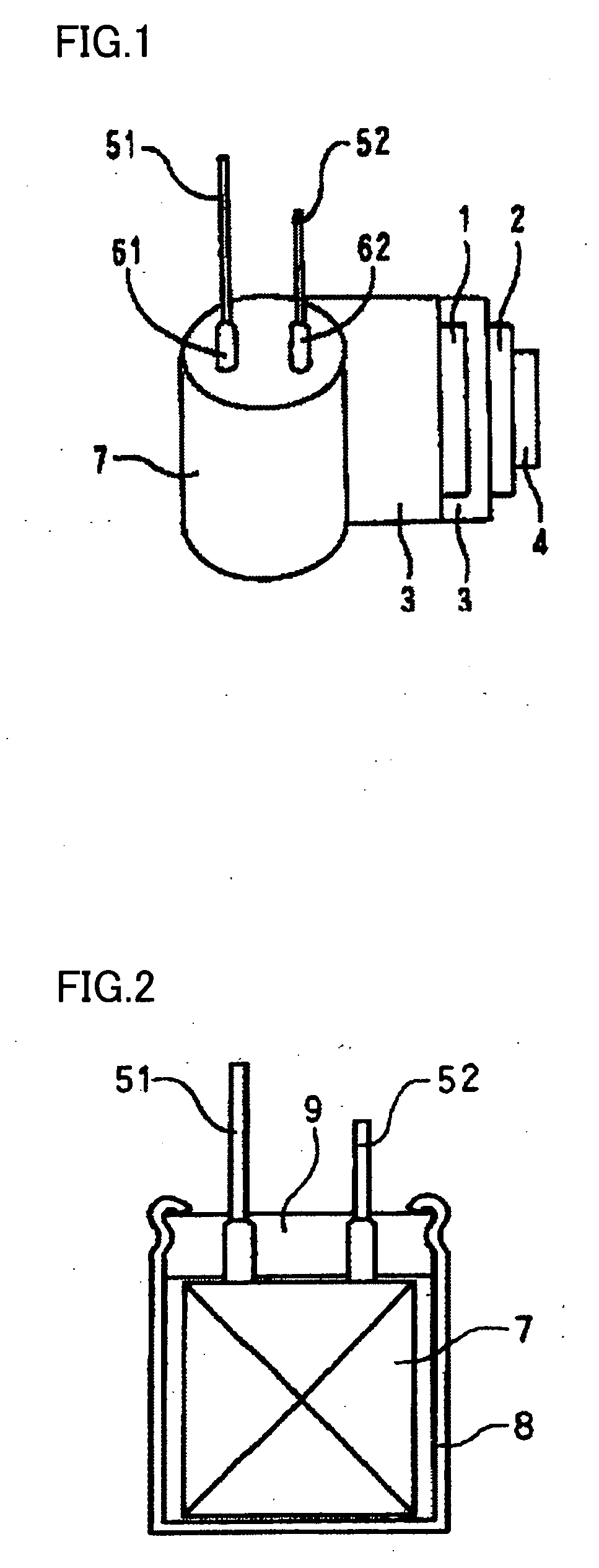

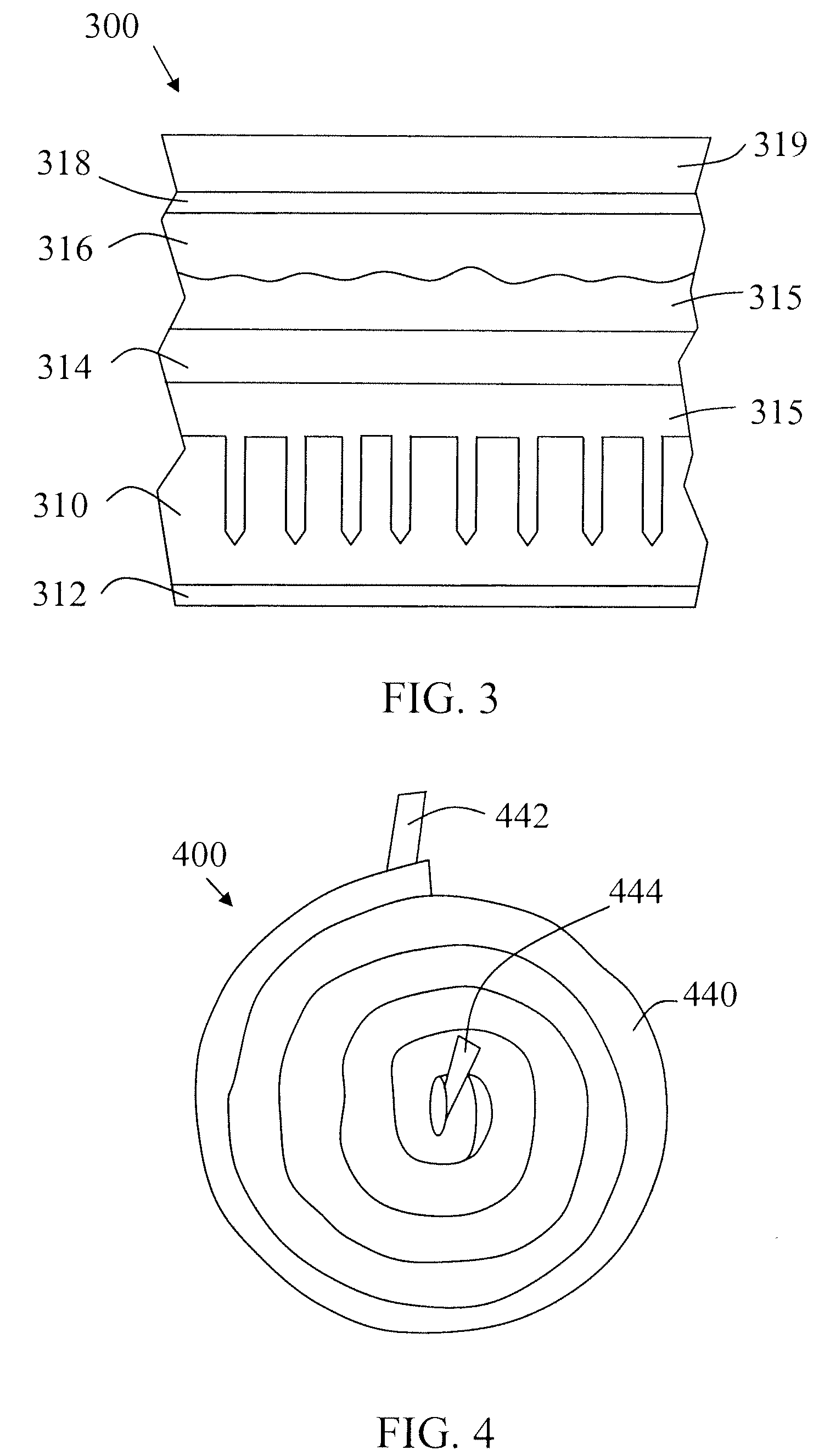

Method of manufacturing electrolytic capacitor and electrolytic capacitor

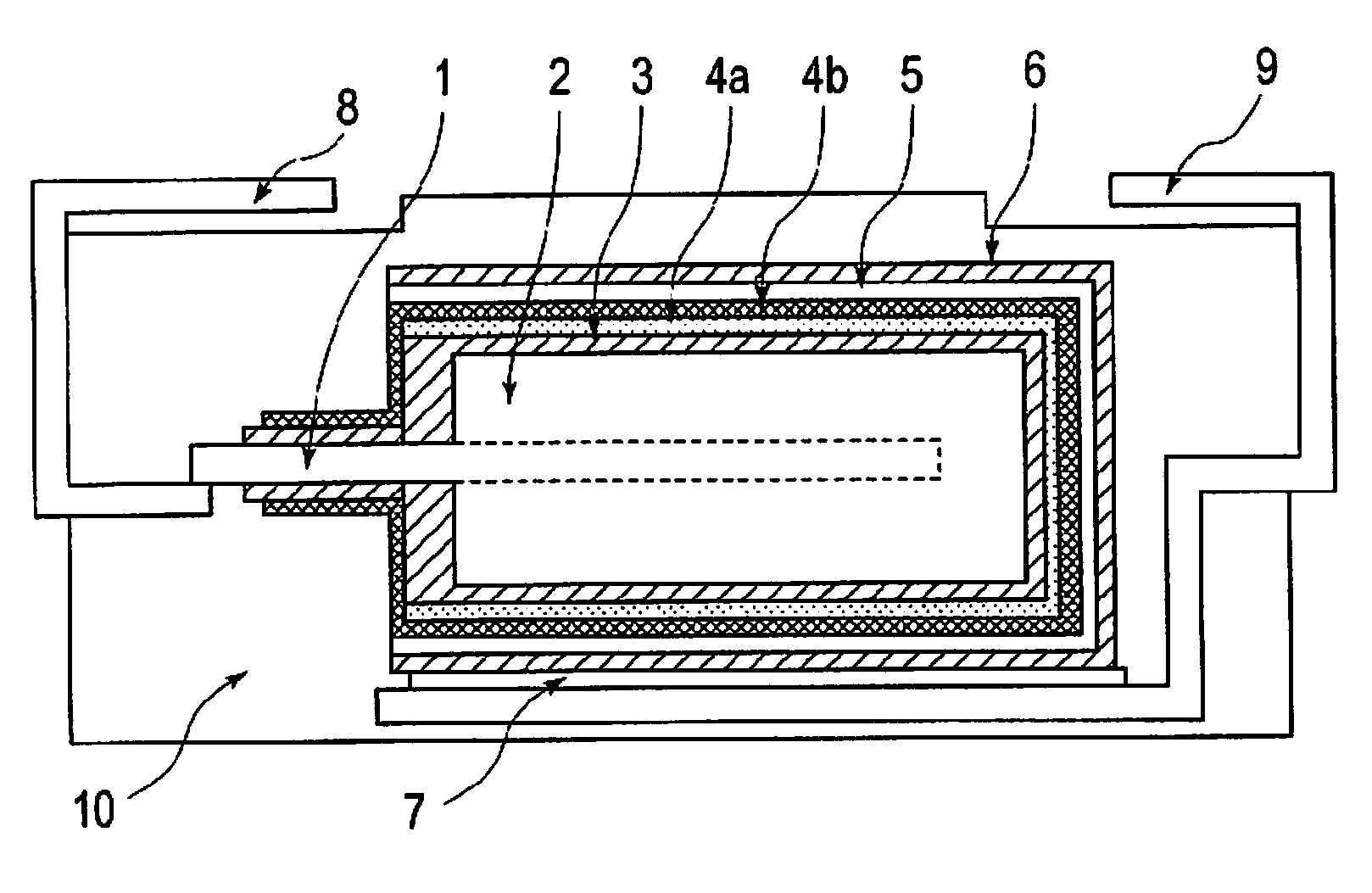

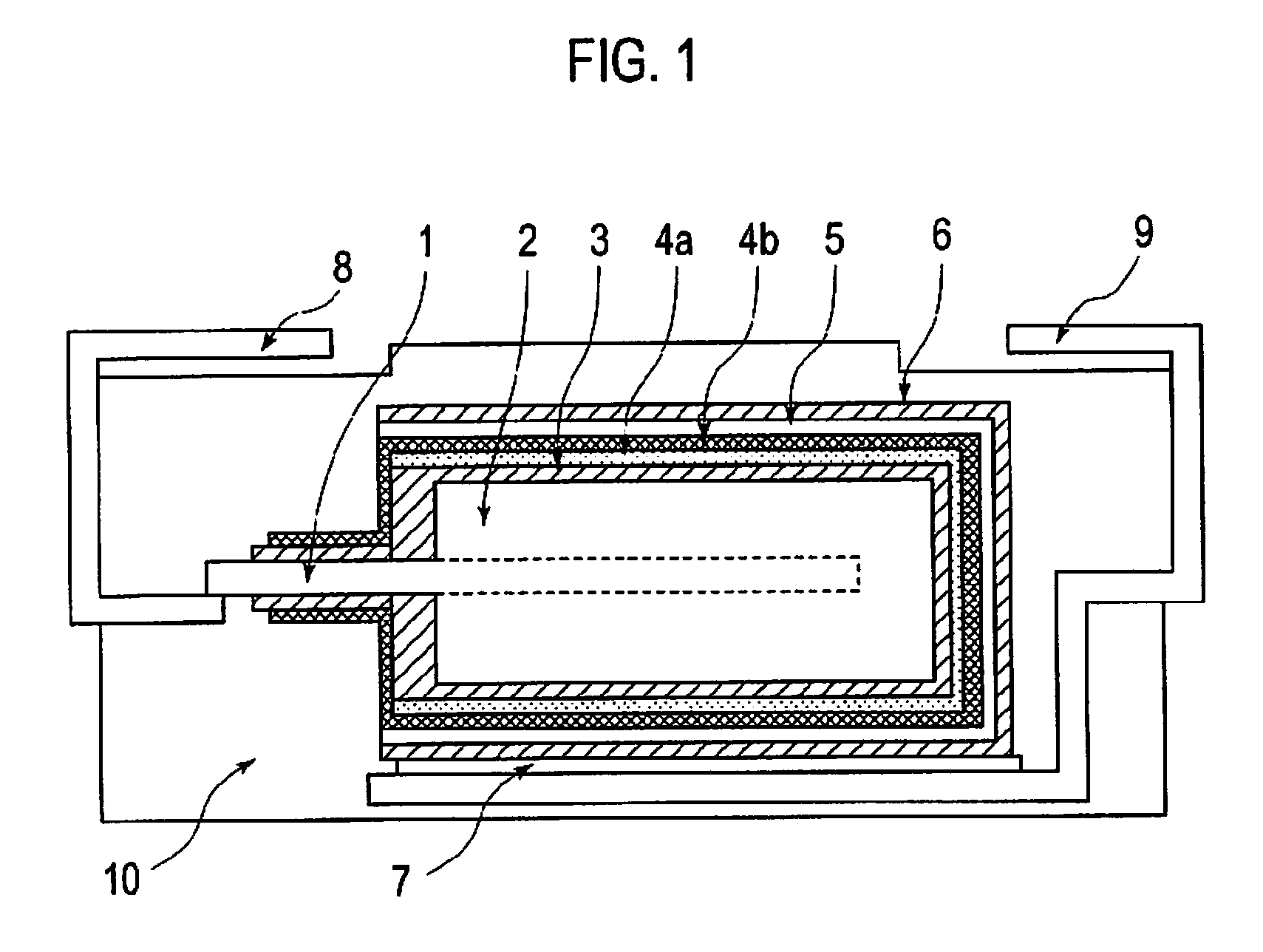

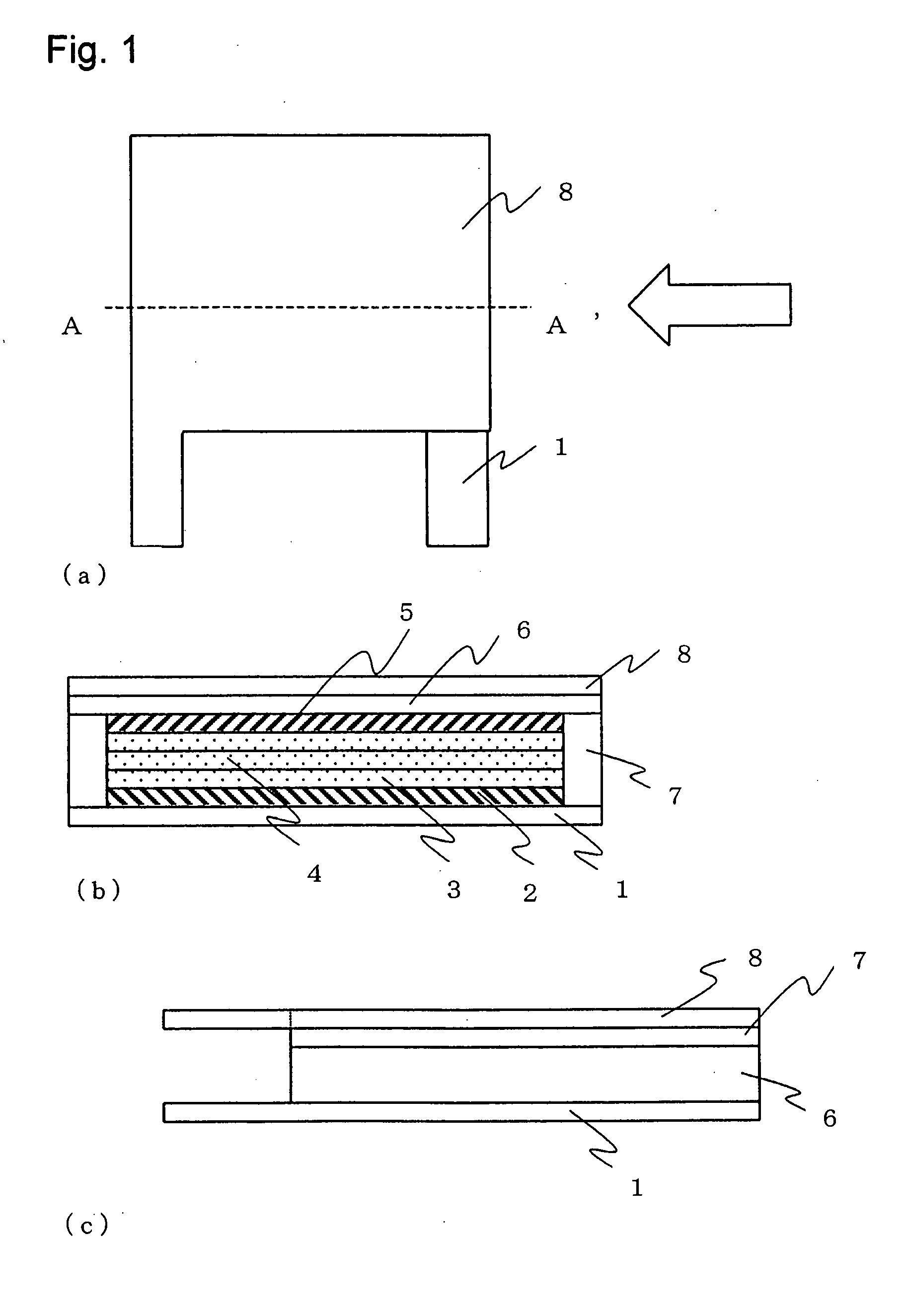

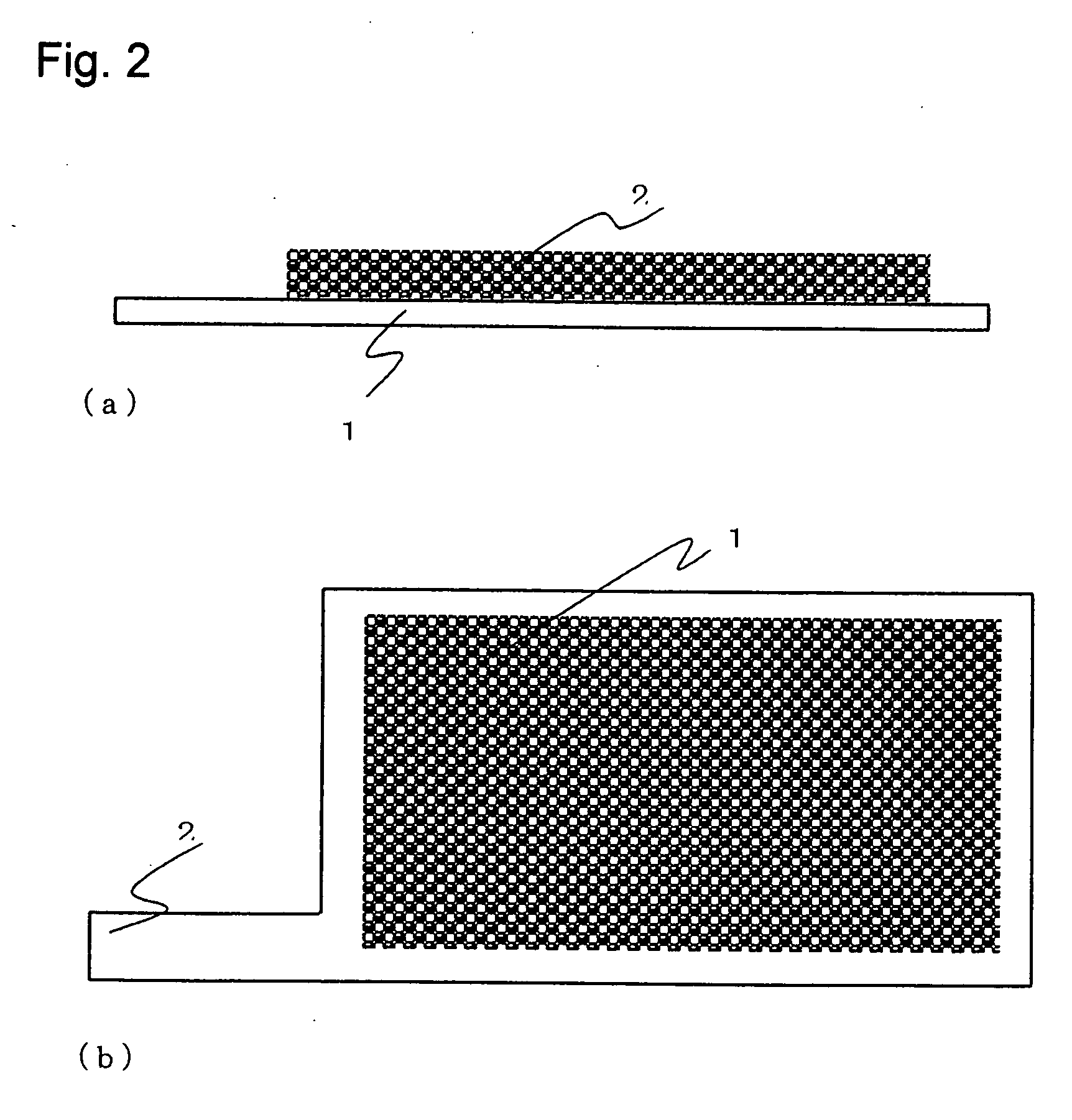

ActiveUS7497879B2Improve pressure resistanceSmall currentHybrid capacitor electrolytesSolid electrolytic capacitorsDielectricElectrolysis

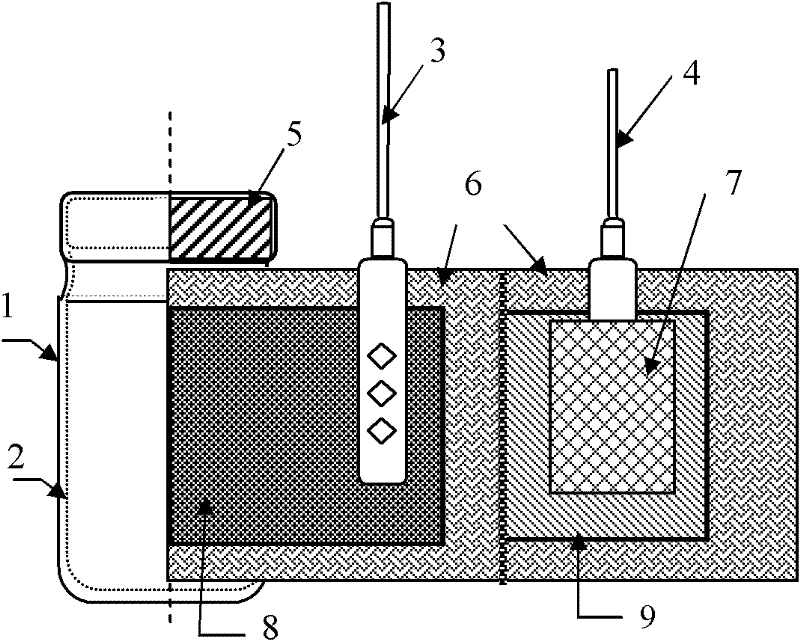

A method of manufacturing an electrolytic capacitor including the following steps as well as an electrolytic capacitor manufactured by the method are provided. The method includes: a dispersion impregnation step of impregnating, with a dispersion containing electrically conductive solid particles or powder and a solvent, a capacitor element having an anode foil with a dielectric coating film formed thereon and an opposite cathode foil that are wound with a separator interposed therebetween; a dry step of evaporating the solvent after the dispersion impregnation step to form an electrically conductive solid layer on a surface of the dielectric coating film; and an electrolytic solution impregnation step of impregnating a gap in the electrically conductive solid layer with an electrolytic solution. Accordingly, an electrolytic capacitor that can be manufactured more easily that is excellent in voltage proofing property and that has a lower ESR and a lower leakage current is provided.

Owner:SANYO ELECTRIC CO LTD +1

Process for the production of electrolyte capacitors of high nominal voltage

ActiveUS8313538B2Solid electrolytic capacitorsLiquid electrolytic capacitorsPhysical chemistryCapacitor

The invention relates to a process for the production of electrolyte capacitors having a low equivalent series resistance and low residual current for high nominal voltages, electrolyte capacitors produced by this process and the use of such electrolyte capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Protective coating for electrolytic capacitors

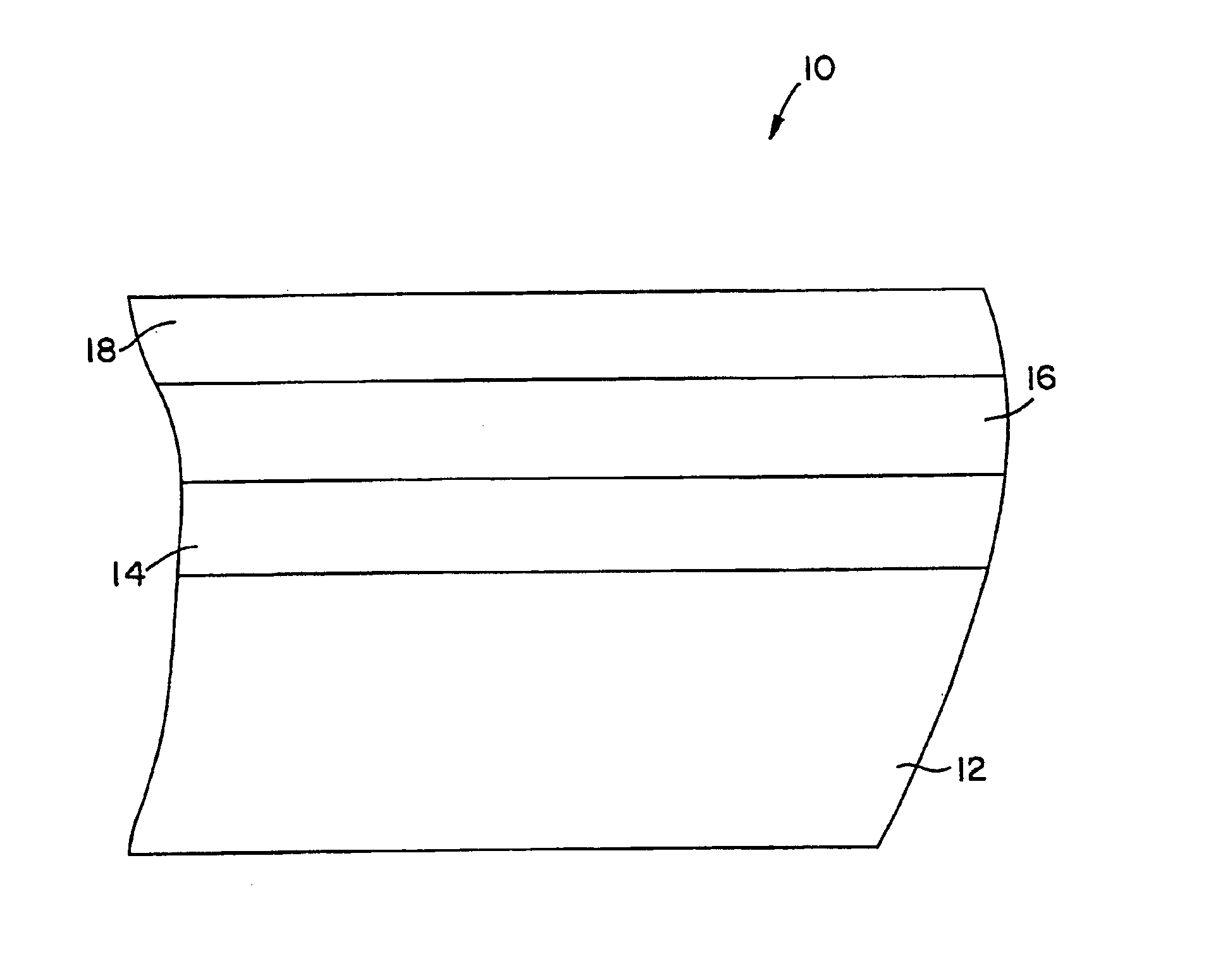

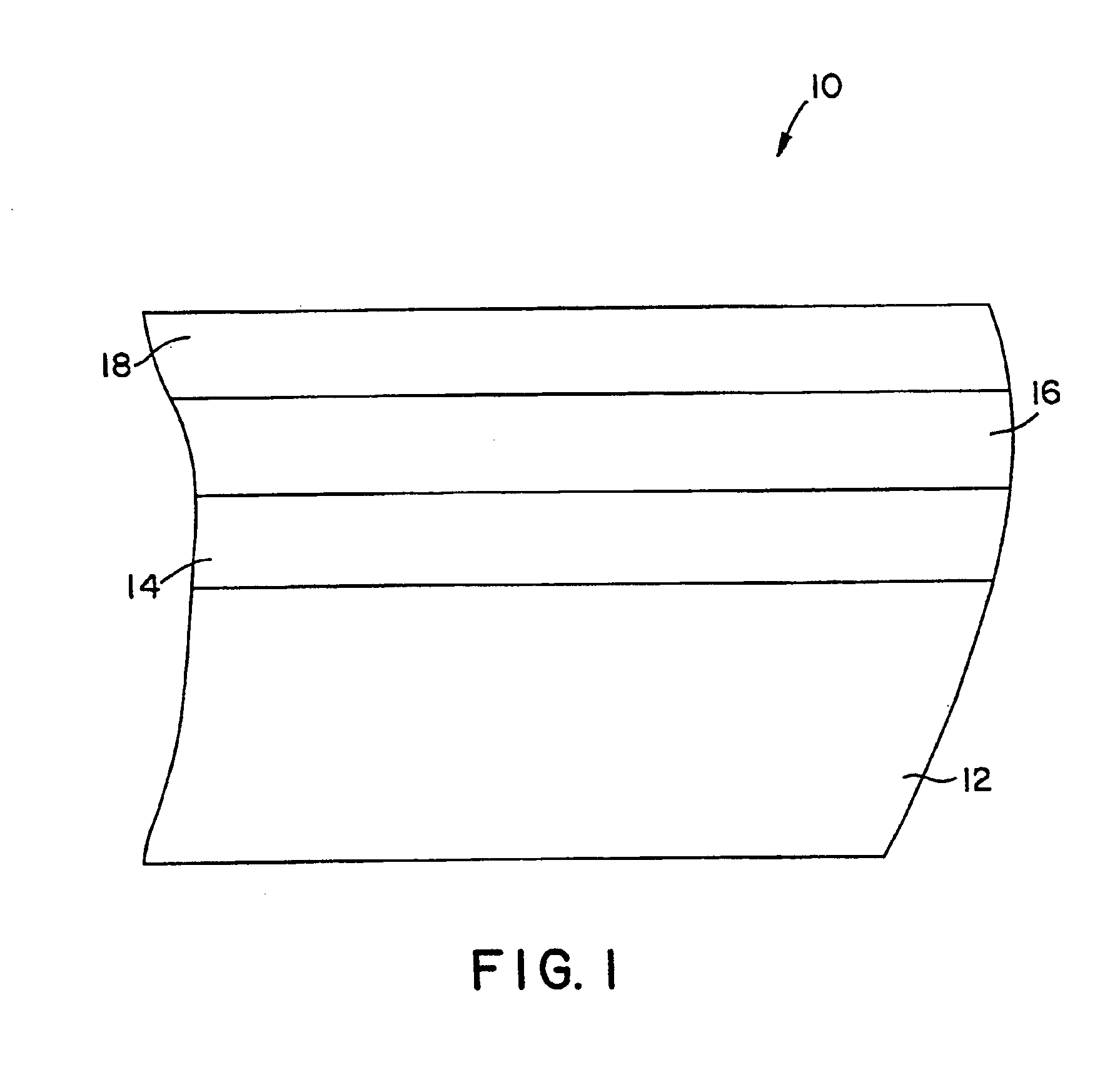

InactiveUS6864147B1Low dissipation factorLow leakage currentSolid electrolytic capacitorsSemiconductor/solid-state device manufacturingShellacElectrolysis

A solid electrolytic capacitor that comprises an anode that contains a valve-action metal (e.g., tantalum, niobium, and the like) and a dielectric film overlying the anode is provided. The capacitor also comprises a protective coating overlying the dielectric film, wherein the protective coating contains a relatively insulative, resinous material. For example, in one embodiment, the resinous material can be a drying oil, such as olive oil, linseed oil, tung oil, castor oil, soybean oil, shellac, and derivatives thereof. The capacitor also comprises a conductive polymer coating overlying the protective coating. As a result of the present invention, it has been discovered that a capacitor can be formed that can have a relatively low leakage current, dissipation factor, and equivalents series resistance.

Owner:KYOCERA AVX COMPONENTS CORP

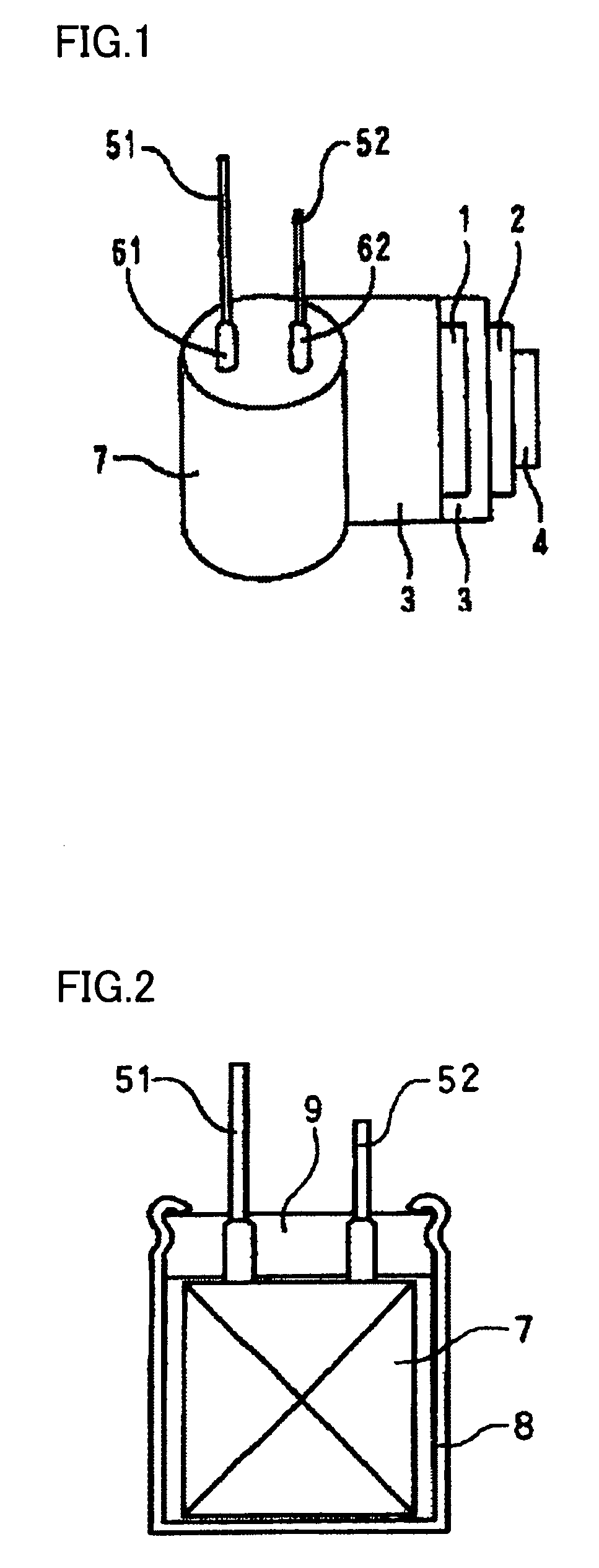

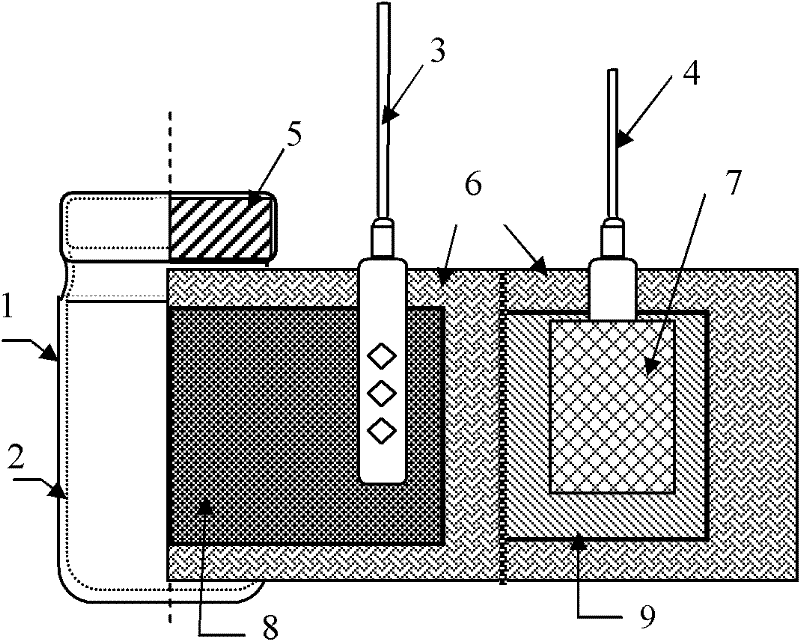

Electrolytic capacitor and a fabrication method therefor

InactiveUS6876083B2Avoid excessive leakage currentAvoid excessive currentTransistorSolid electrolytic capacitorsElectrolytic capacitorNiobium alloy

An electrolytic capacitor including one type of electrode selected from a group consisting of an electrode of at least one type of alloy selected from a group consisting of niobium alloy, titanium alloy, and tungsten alloy, an electrode of mixed sinter of niobium and aluminum, or a fluorine-doped electrode of niobium or niobium alloy and on a surface of each electrode a dielectric layer is formed by anodizing the electrode.

Owner:SANYO ELECTRIC CO LTD

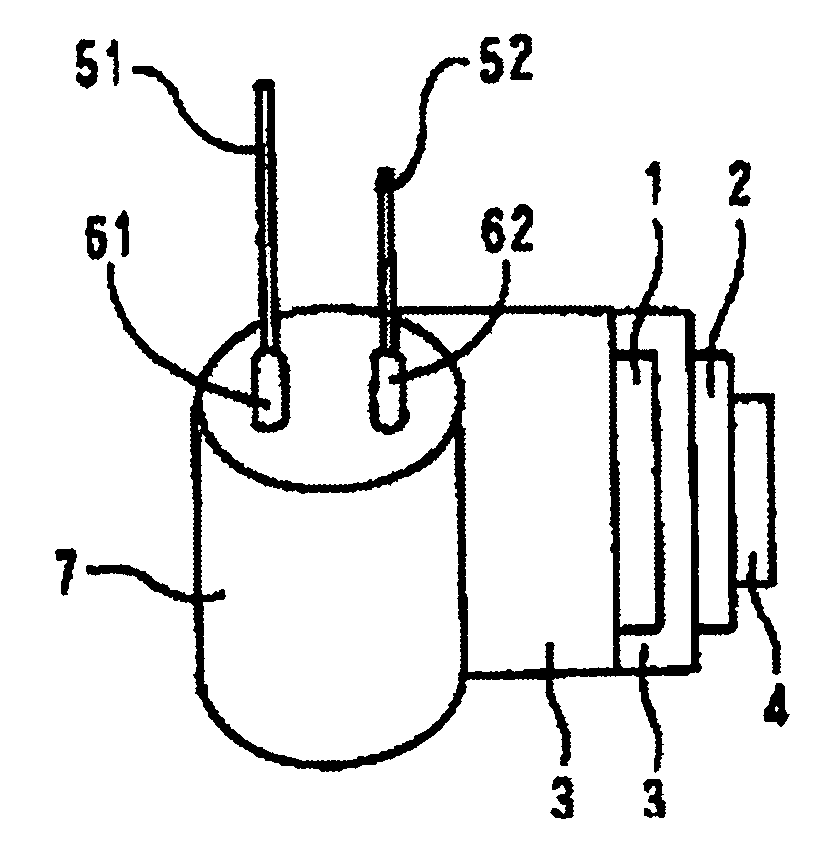

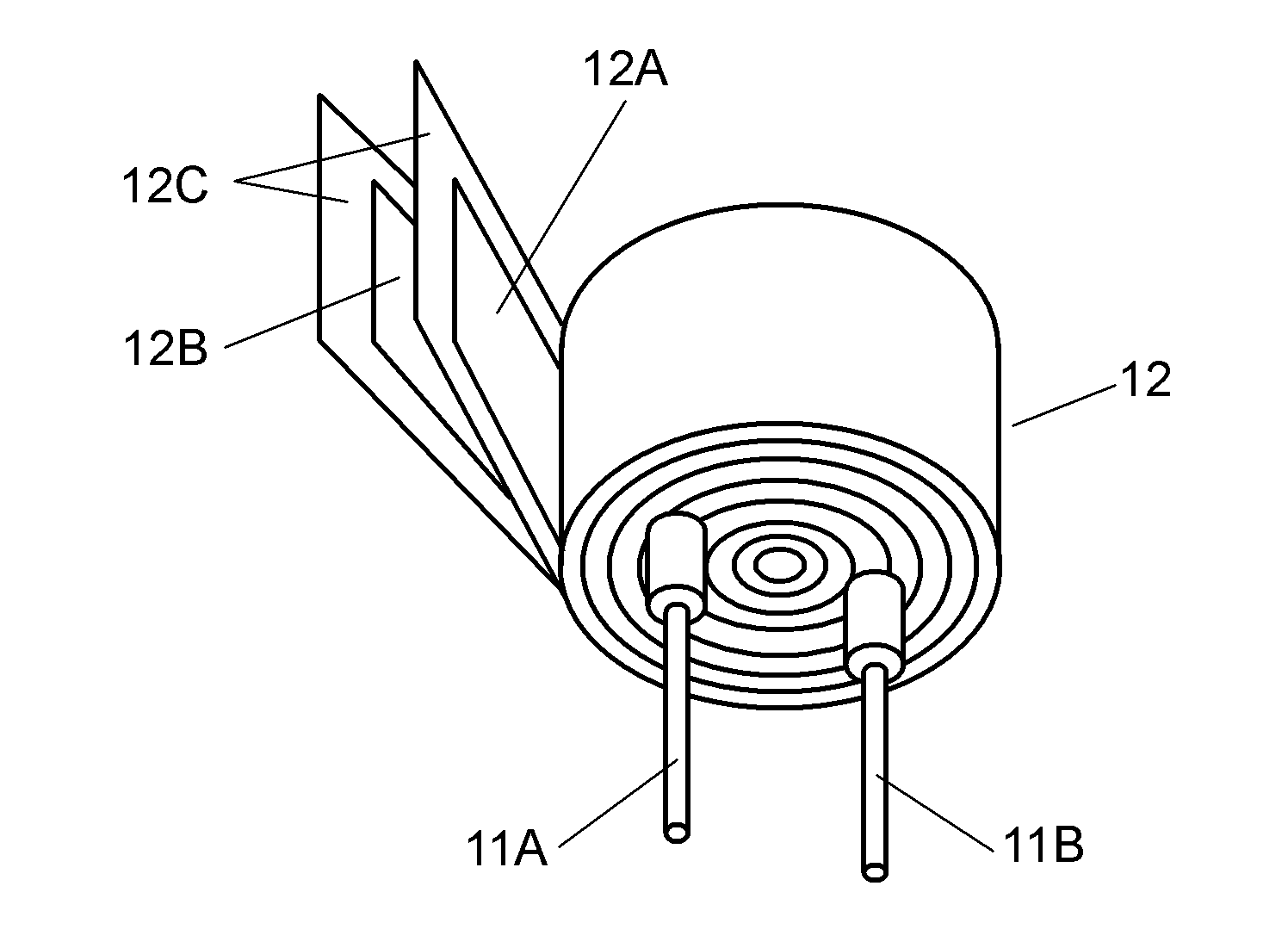

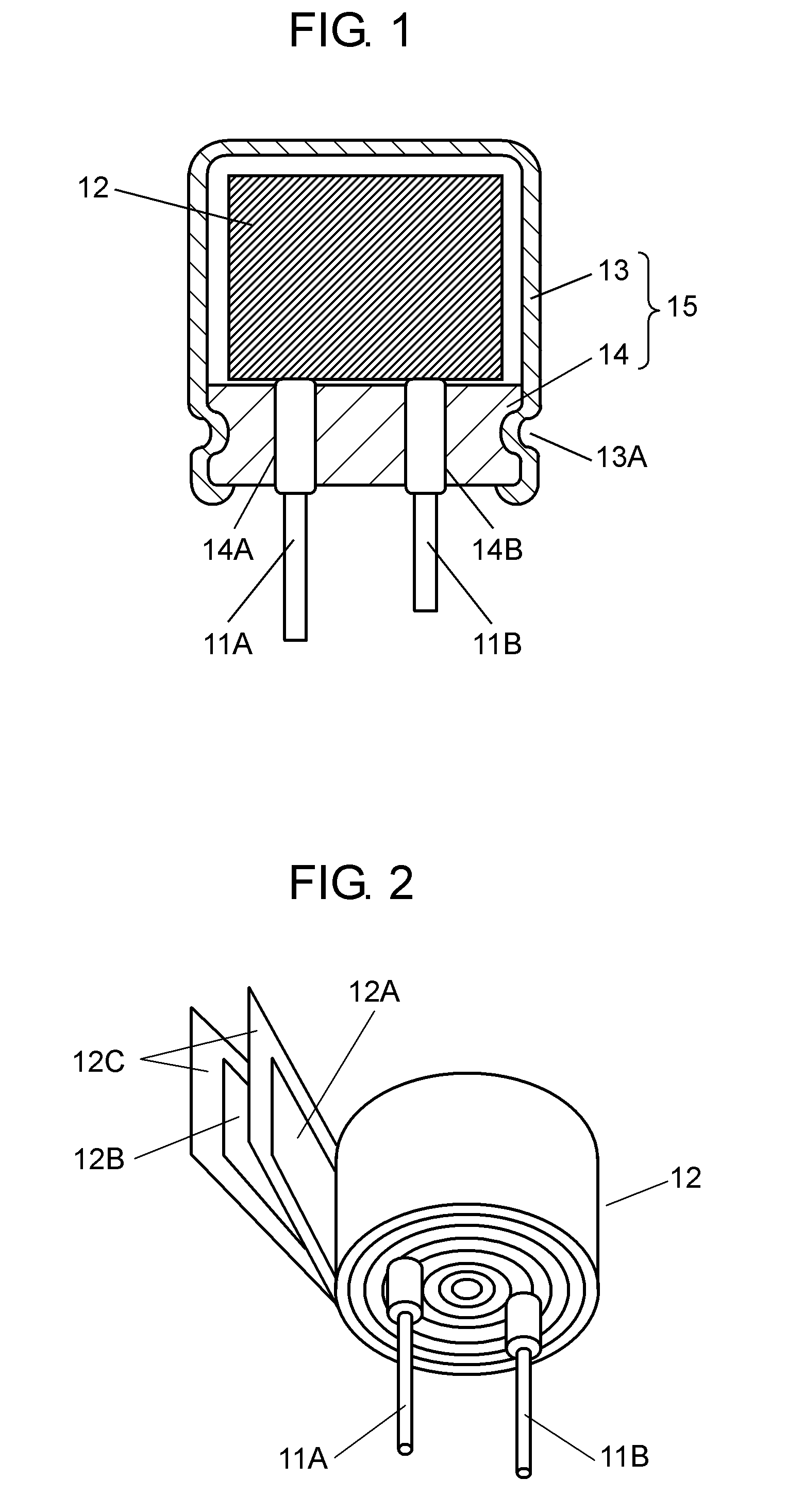

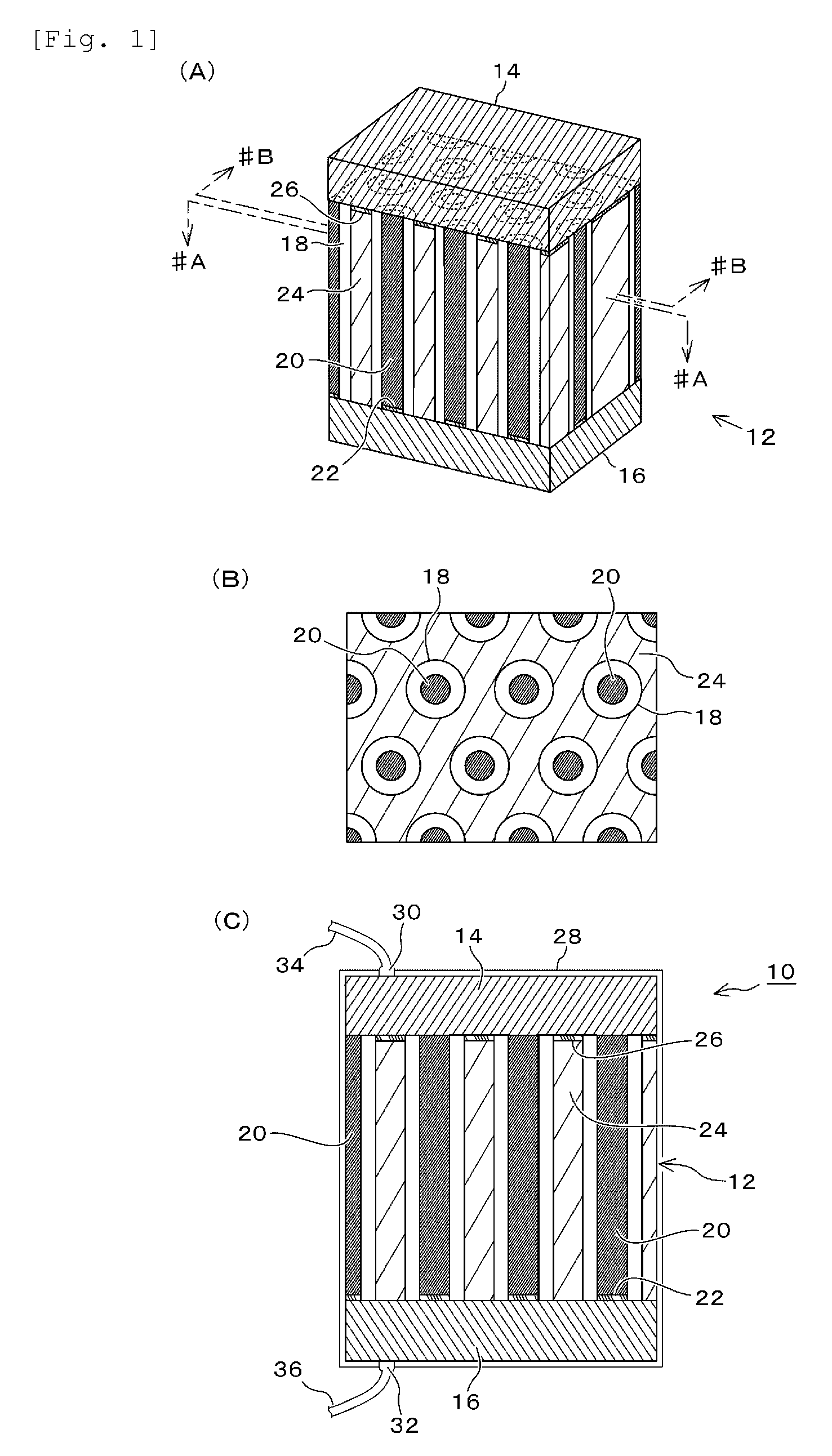

Electrolytic capacitor

ActiveUS20120300368A1Small sizeLarge capacitanceHybrid capacitor separatorsHybrid capacitor electrolytesElectrolysisDielectric layer

An electrolytic capacitor includes a capacitor element, an electrolyte solution with which the capacitor element is impregnated, and an outer package enclosing the capacitor element and the electrolyte solution. The capacitor element includes an anode foil having a dielectric layer on a surface thereof, a cathode foil, a separator disposed between the anode foil and the cathode foil, and a solid electrolyte layer in contact with the dielectric layer of the anode foil and the cathode foil. The electrolyte solution contains a low-volatile solvent that is at least one of polyalkylene glycol and a derivative of polyalkylene glycol.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

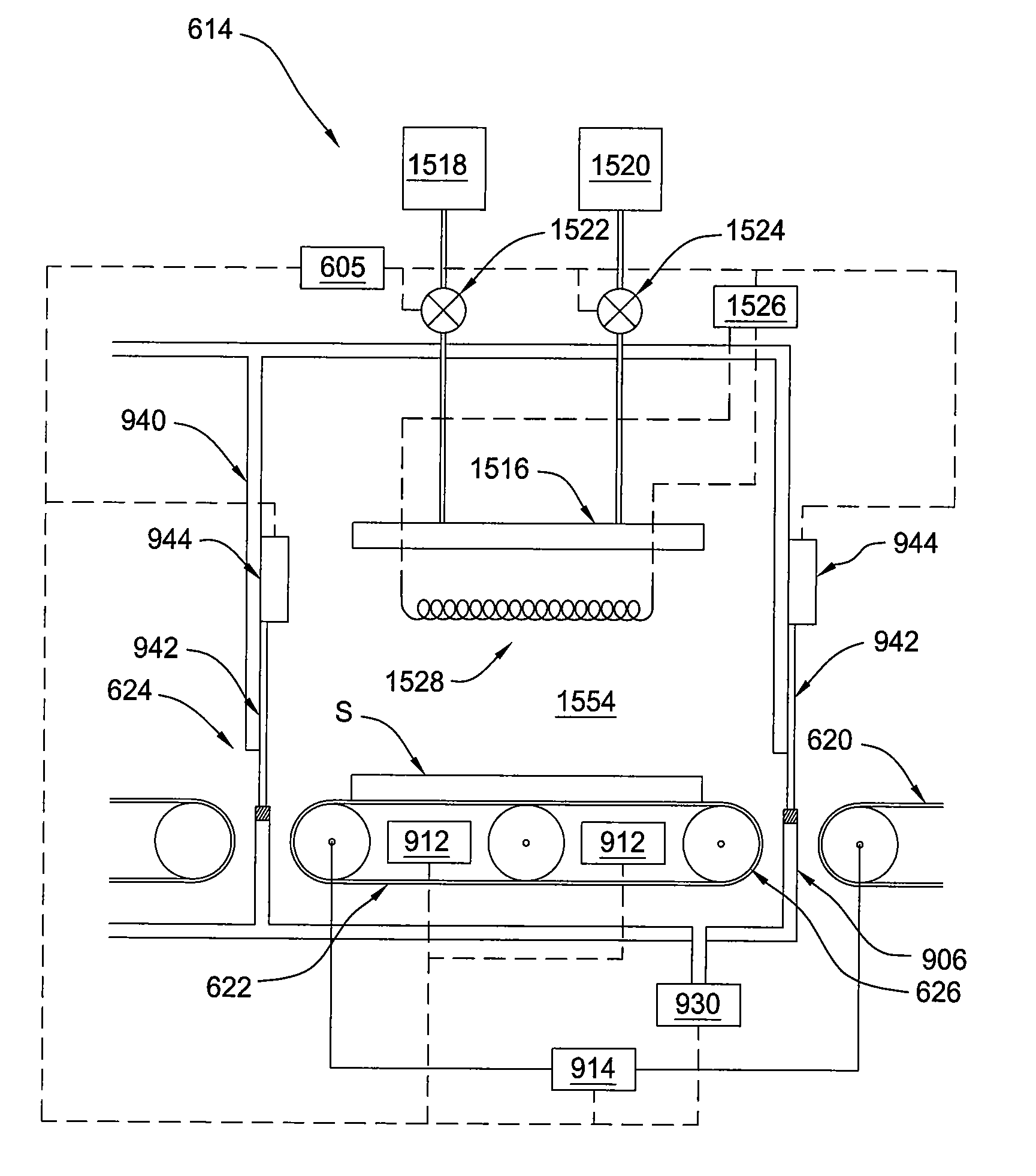

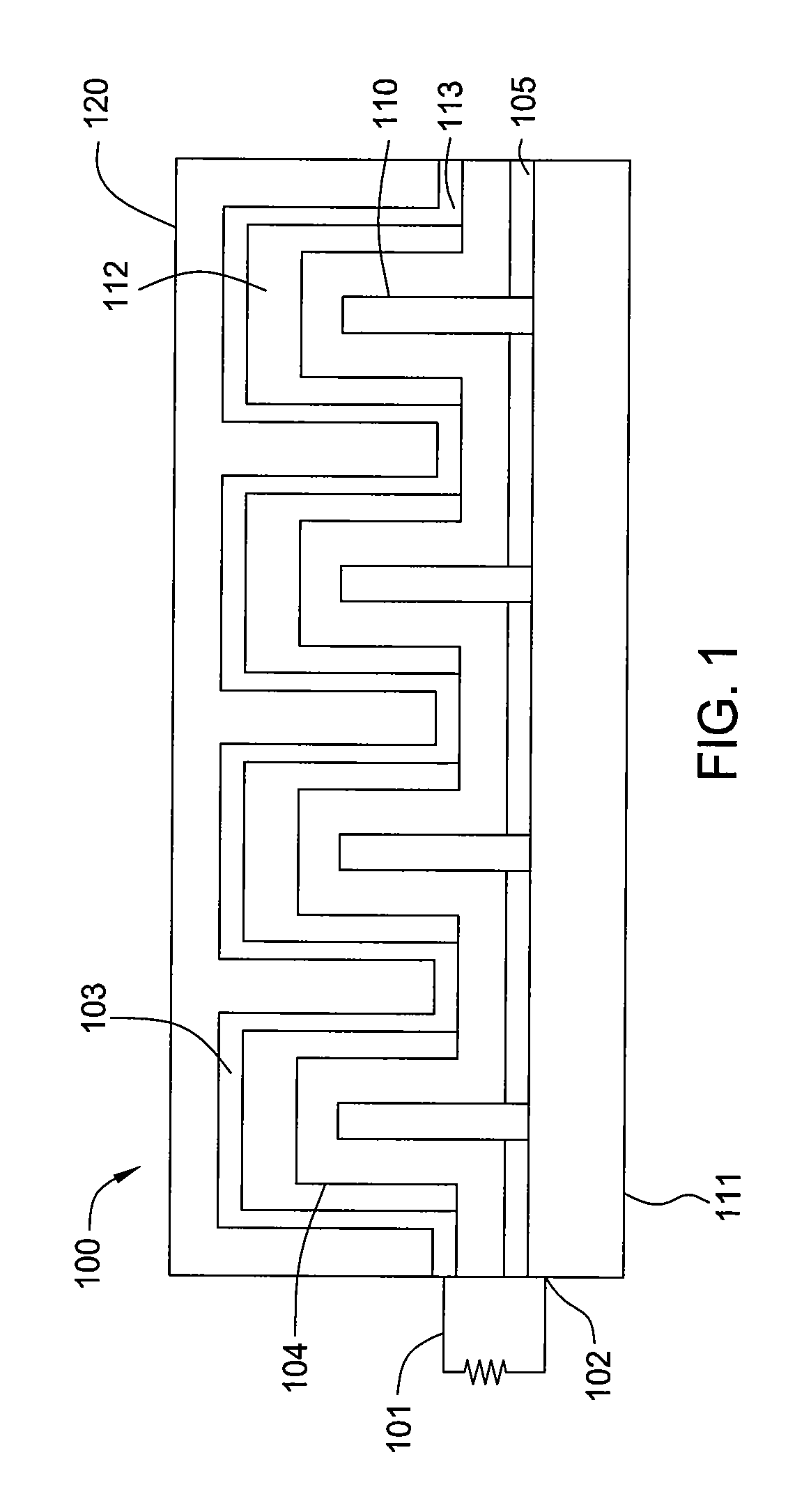

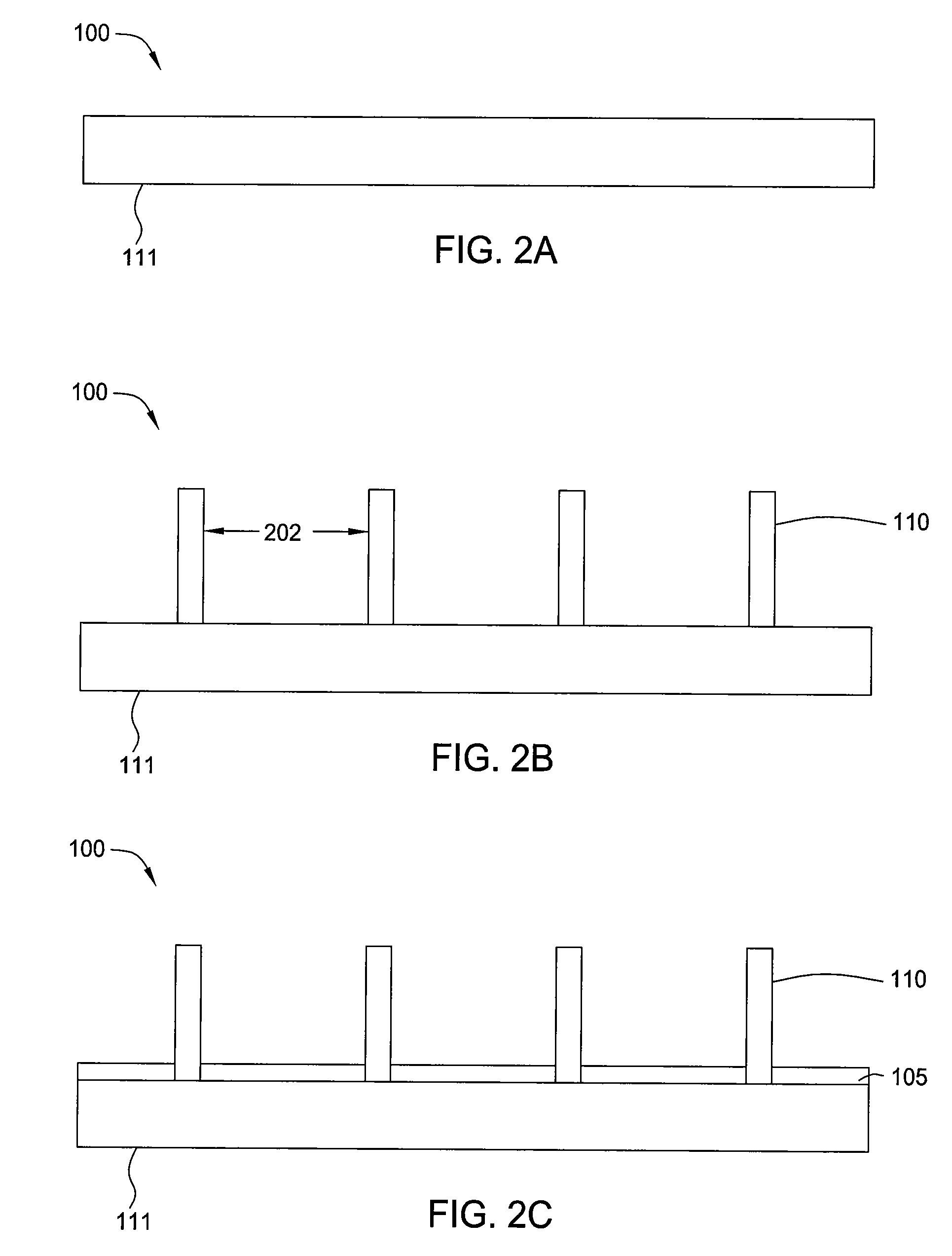

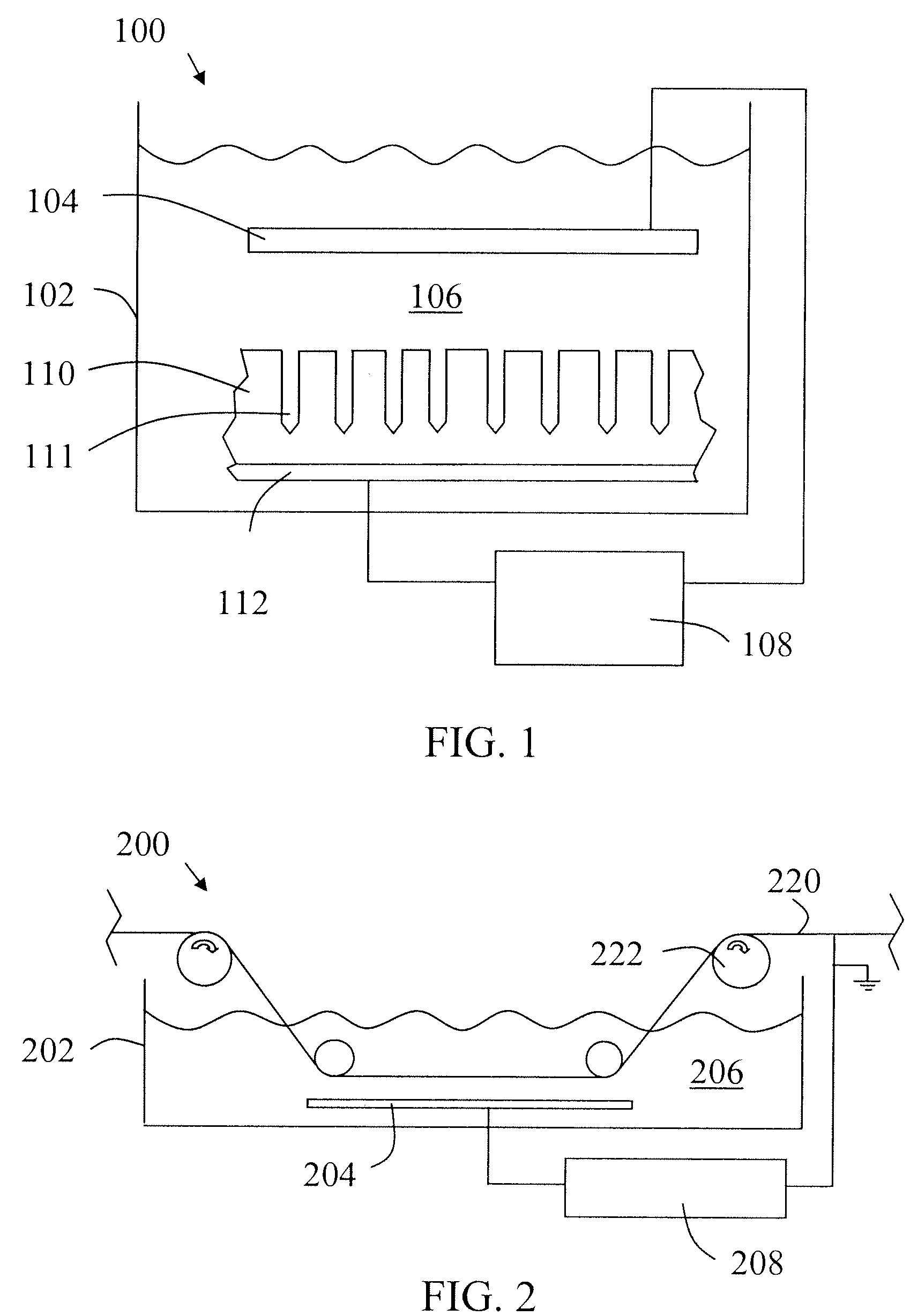

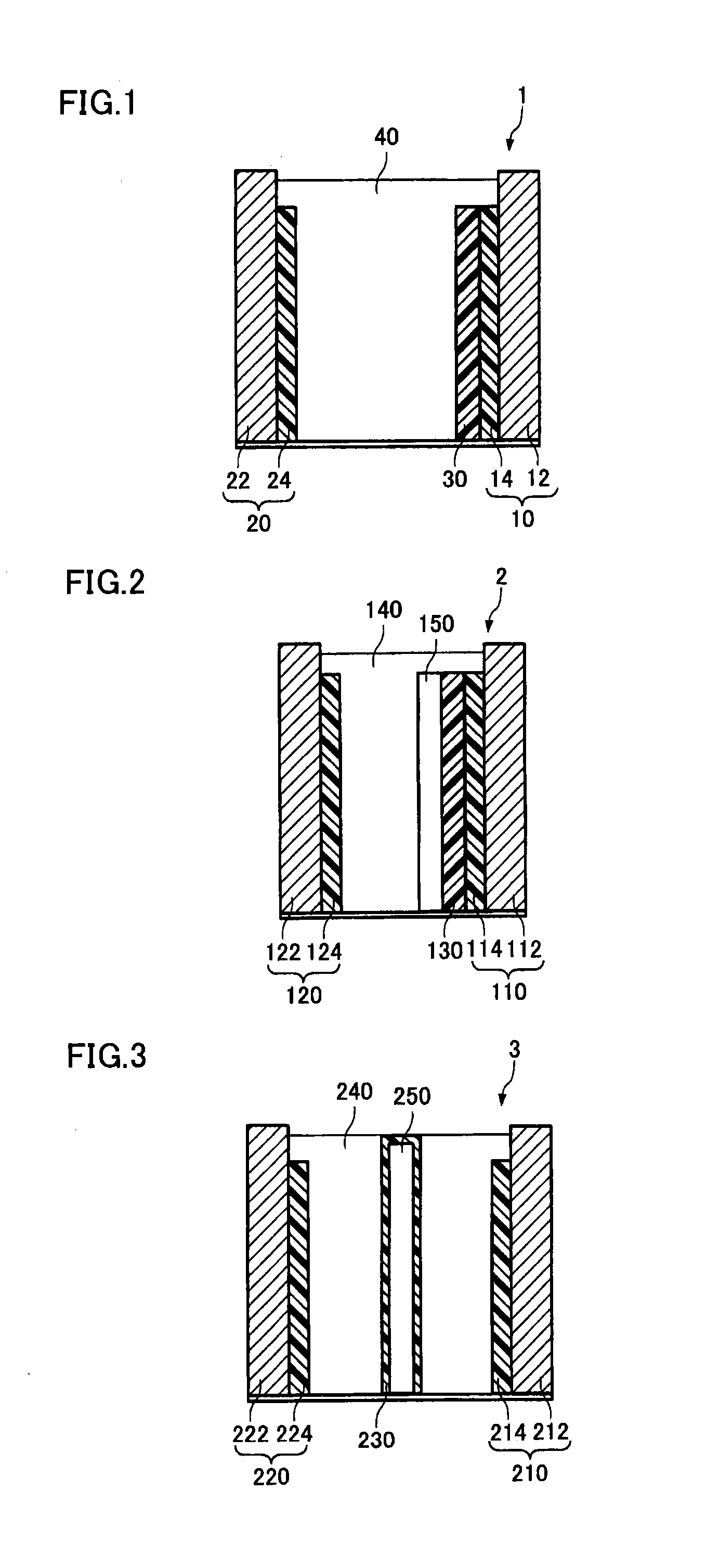

3D approach on battery and supercapacitor fabrication by initiation chemical vapor deposition techniques

Methods and apparatus for forming energy storage devices are provided. In one embodiment a method of producing an energy storage device is provided. The method comprises positioning an anodic current collector into a processing region, depositing one or more three-dimensional electrodes separated by a finite distance on a surface of the anodic current collector such that portions of the surface of the anodic current collector remain exposed, depositing a conformal polymeric layer over the anodic current collector and the one or more three-dimensional electrodes using iCVD techniques comprising flowing a gaseous monomer into the processing region, flowing a gaseous initiator into the processing region through a heated filament to form a reactive gas mixture of the gaseous monomer and the gaseous initiator, wherein the heated filament is heated to a temperature between about 300° C. and about 600° C., and depositing a conformal layer of cathodic material over the conformal polymeric layer.

Owner:APPLIED MATERIALS INC

Method of manufacturing electrolytic capacitor and electrolytic capacitor

ActiveUS20080002334A1Improve pressure resistanceSolve the large leakage currentHybrid capacitor electrolytesSolid electrolytic capacitorsDielectricElectrolysis

A method of manufacturing an electrolytic capacitor including the following steps as well as an electrolytic capacitor manufactured by the method are provided. The method includes: a dispersion impregnation step of impregnating, with a dispersion containing electrically conductive solid particles or powder and a solvent, a capacitor element having an anode foil with a dielectric coating film formed thereon and an opposite cathode foil that are wound with a separator interposed therebetween; a dry step of evaporating the solvent after the dispersion impregnation step to form an electrically conductive solid layer on a surface of the dielectric coating film; and an electrolytic solution impregnation step of impregnating a gap in the electrically conductive solid layer with an electrolytic solution. Accordingly, an electrolytic capacitor that can be manufactured more easily that is excellent in voltage proofing property and that has a lower ESR and a lower leakage current is provided.

Owner:SANYO ELECTRIC CO LTD +1

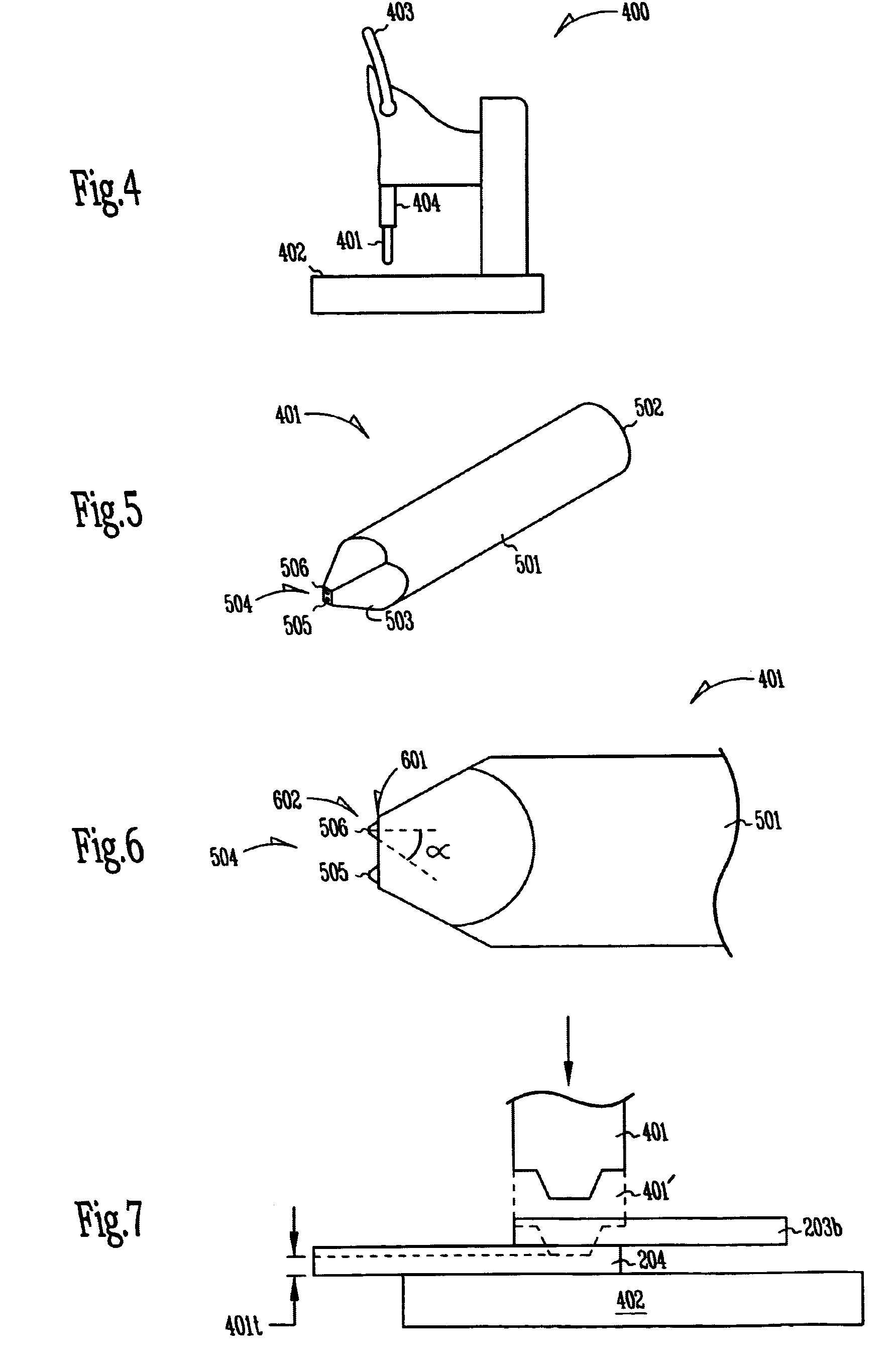

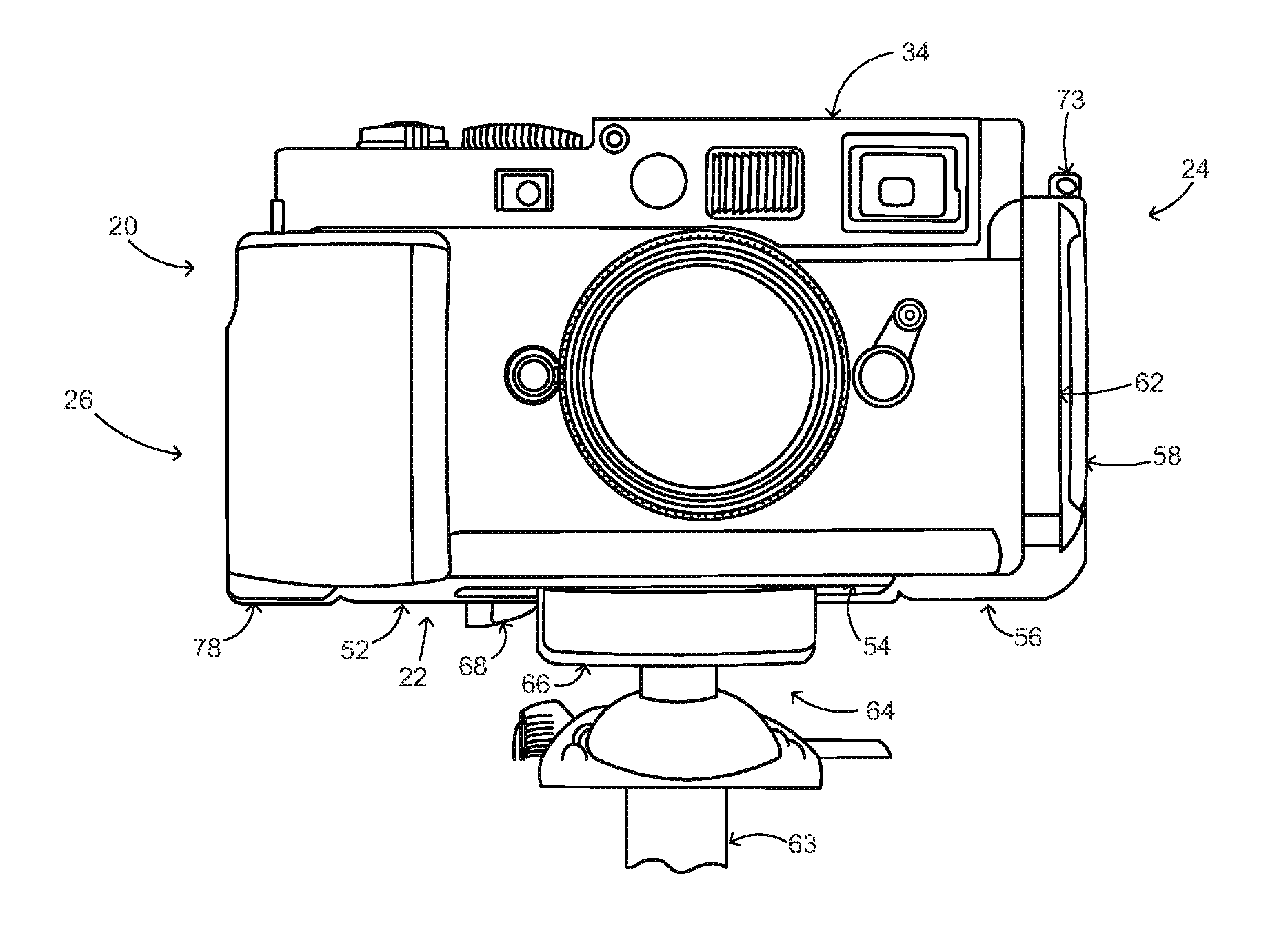

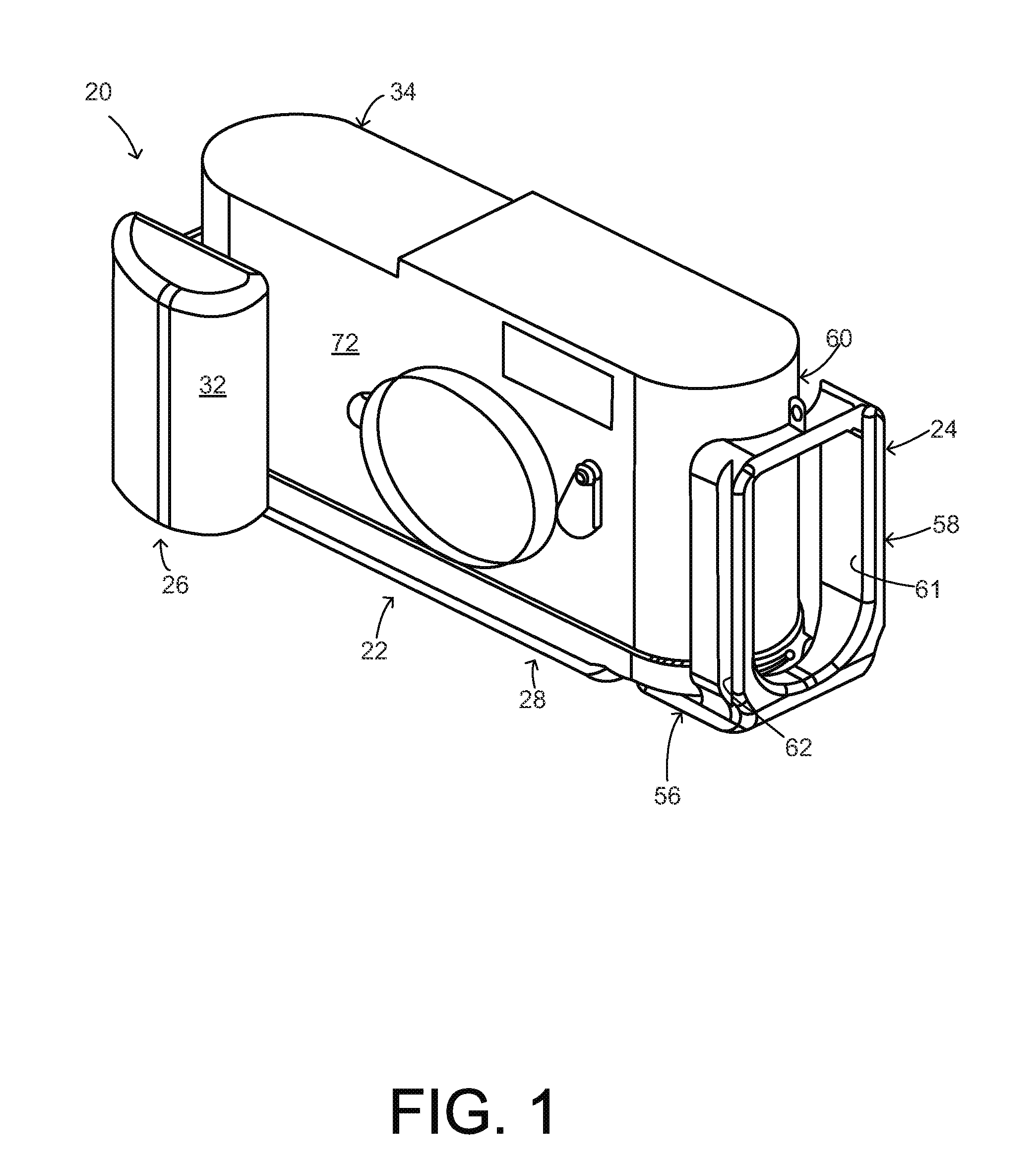

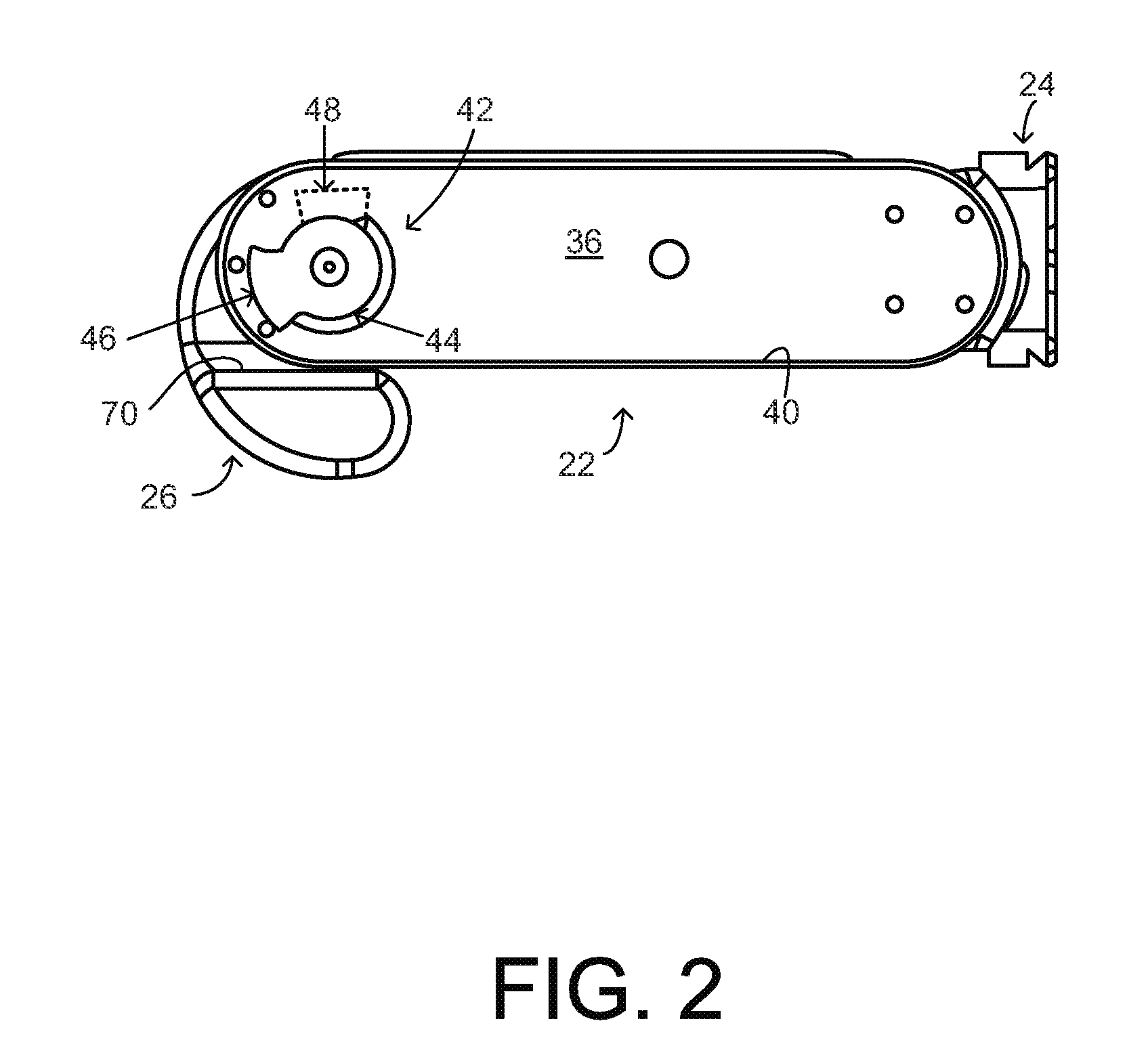

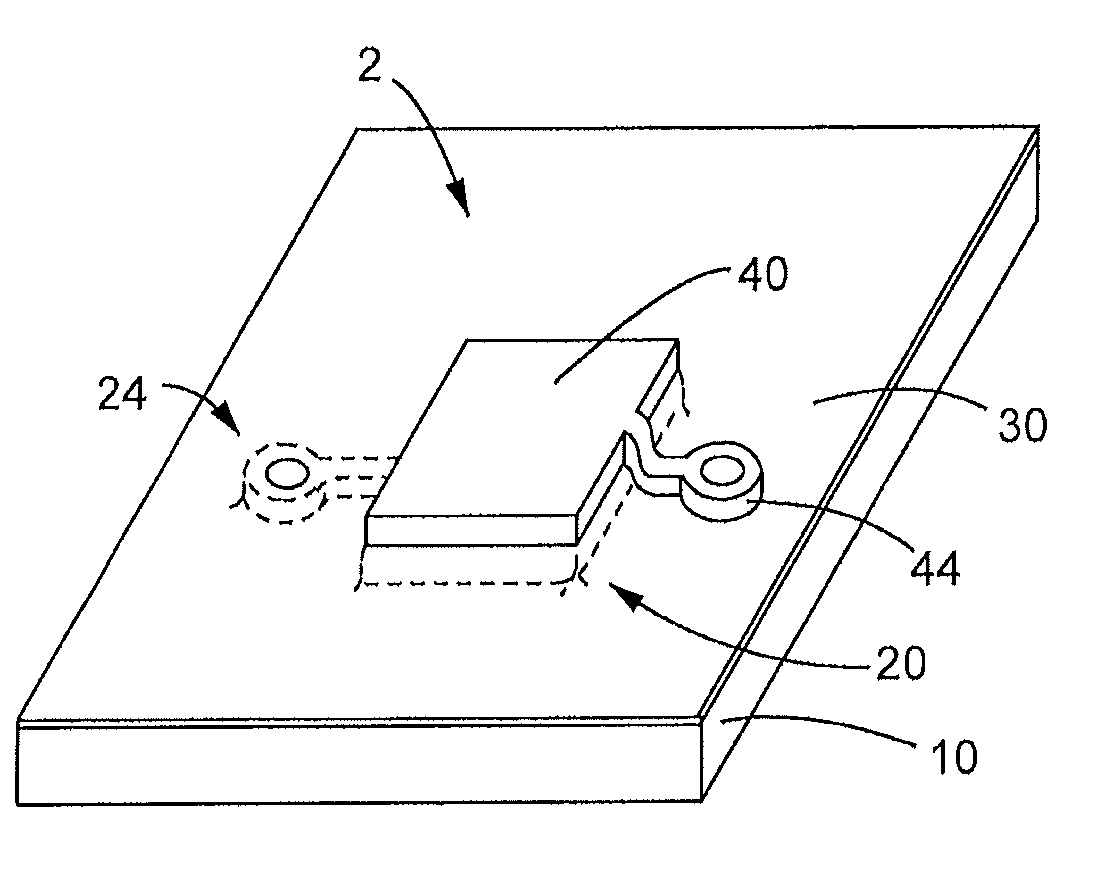

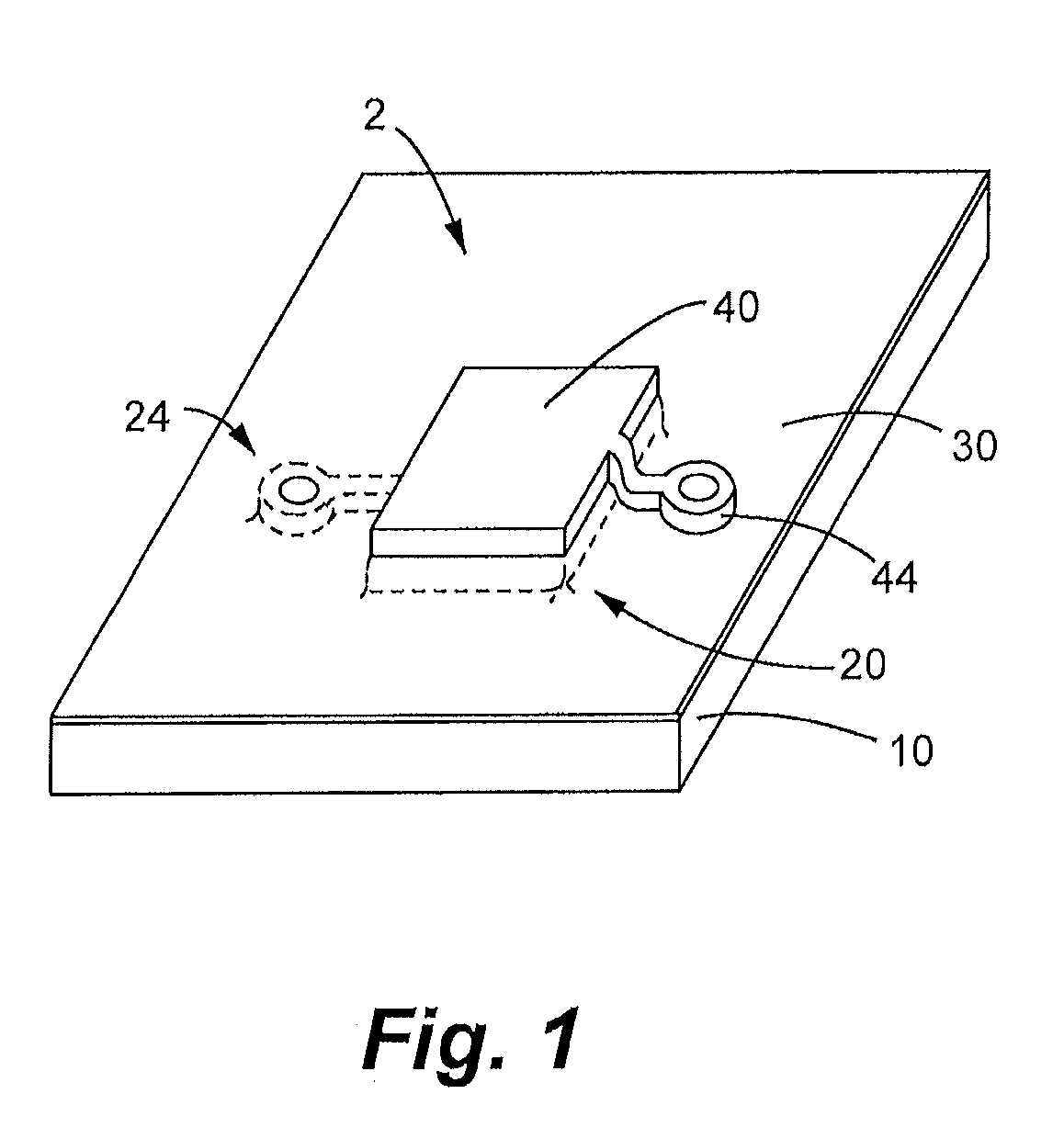

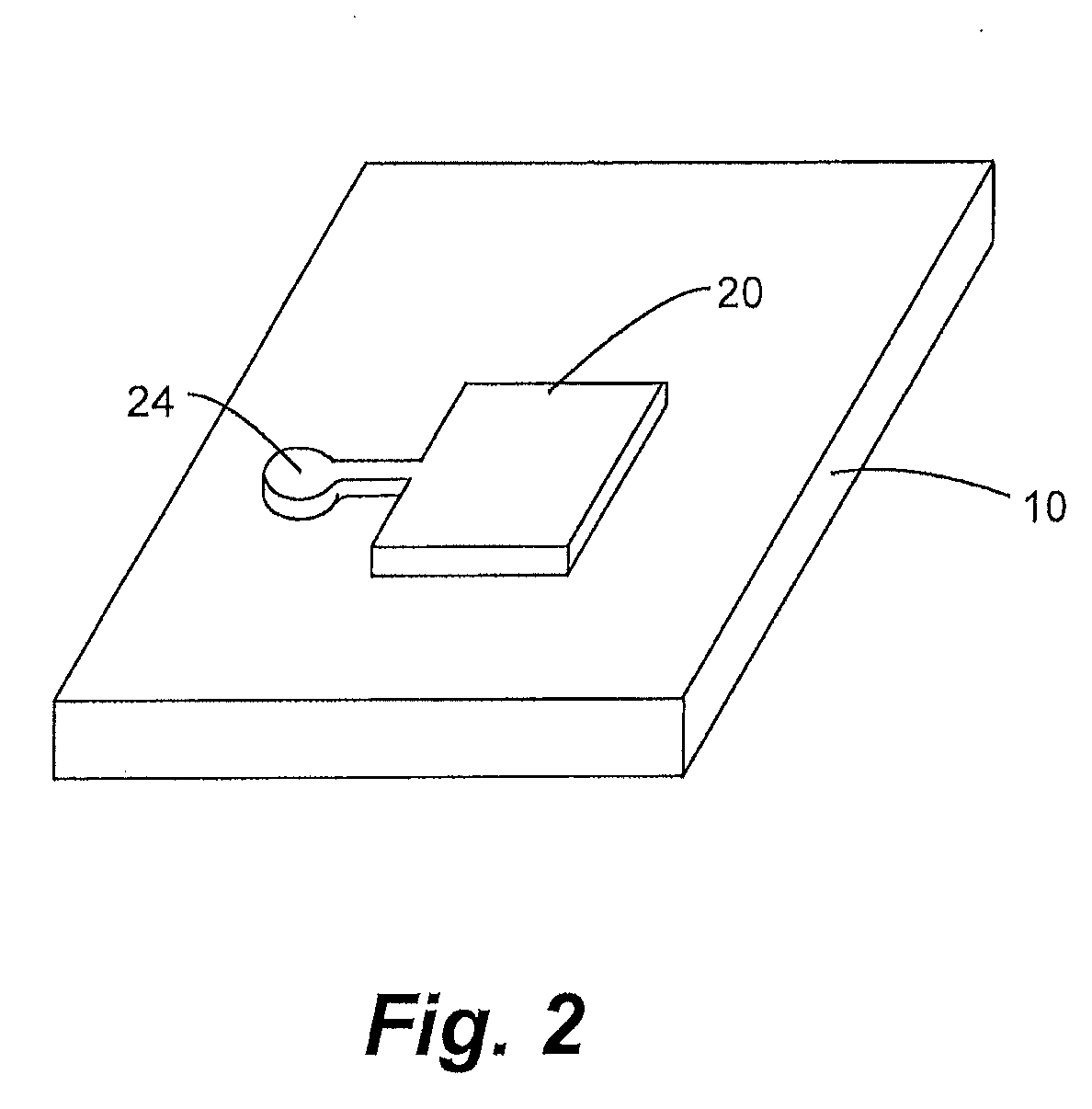

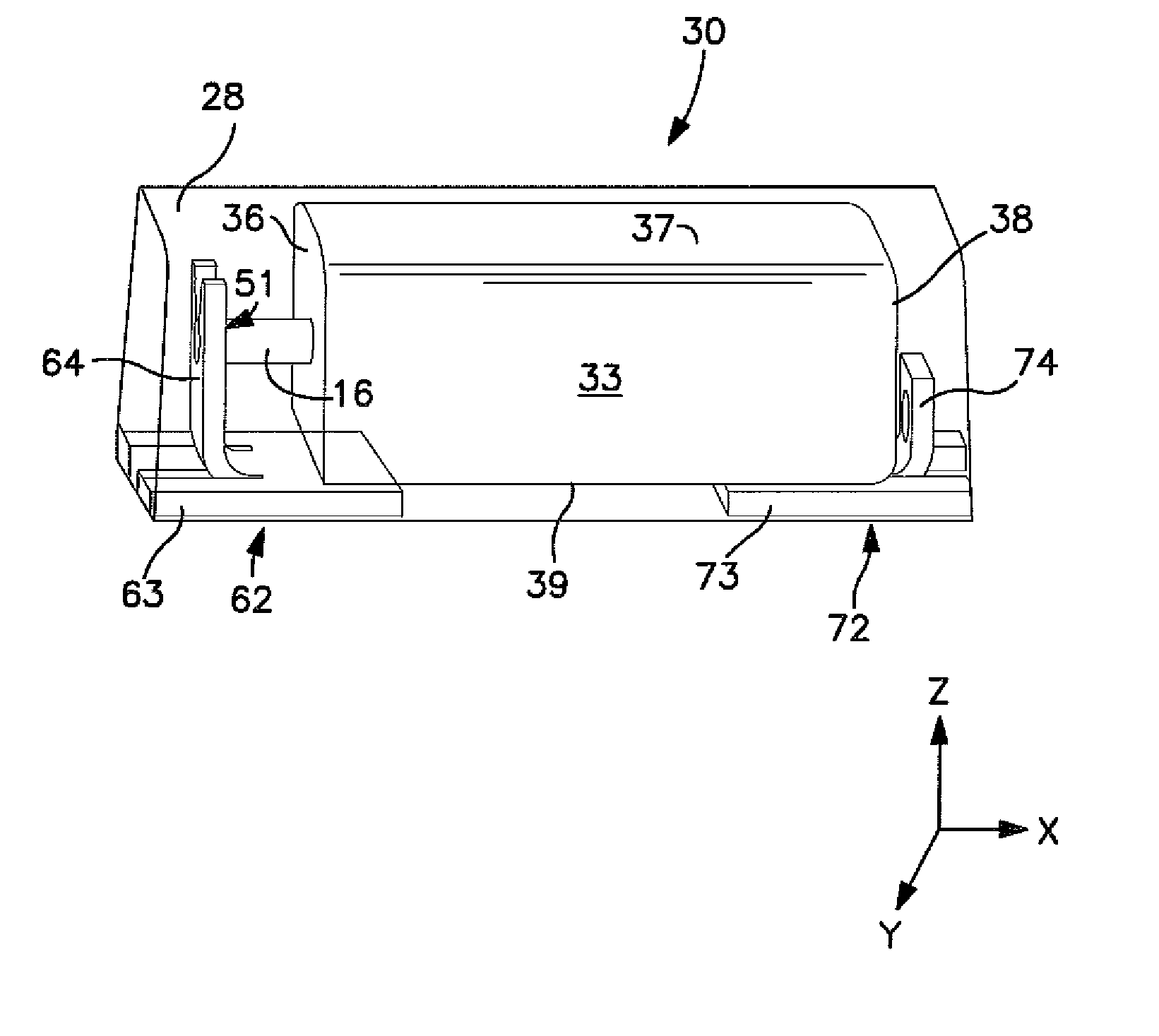

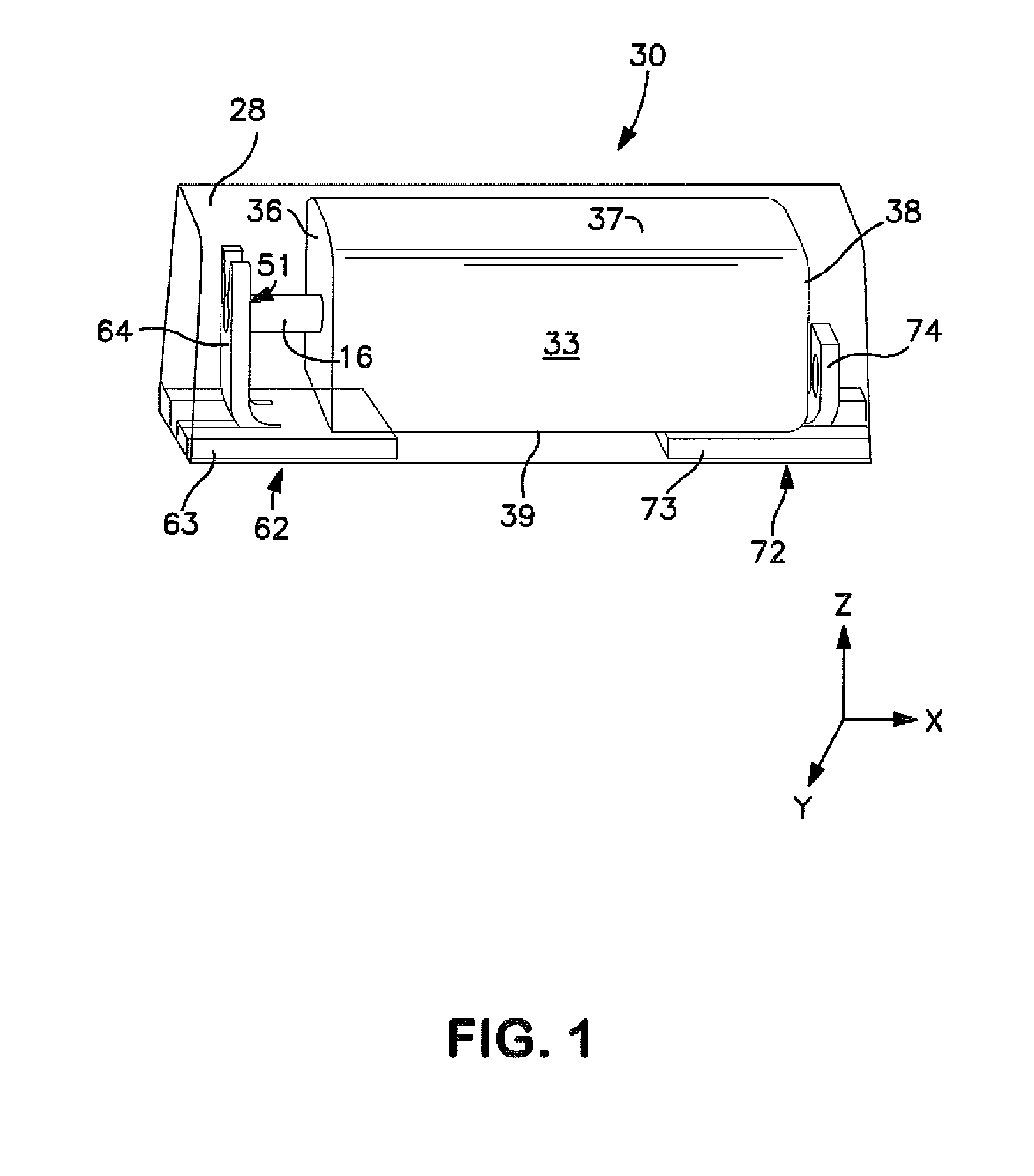

Camera mounting assembly

ActiveUS20120106944A1Improve balanceQuick installationSolid electrolytic capacitorsCapacitor electrolytes/absorbentsFast releaseMechanical engineering

A camera mounting assembly includes a base member or plate for holding a camera and a side member or plate. In an exemplary embodiment, lower slots on the base plate or side slots on the side plate are gripped by a vertical support's quick-release mechanism to mount the camera in a landscape or portrait orientation, respectively, the camera being generally centered and evenly balanced over the support in either case. The side member is detachably fastened to the base member, which modular construction permits separately timed purchase of the base member and side member as allowed by the user's budget and further permits breakdown of the assembly for ease of transport. The side member may be generally L-shaped with a lower arm length less than the side arm length, which also facilitates transport. Other components may be detachably added such as a hand grip facilitating freehand shooting with the camera.

Owner:REALLY RIGHT STUFF

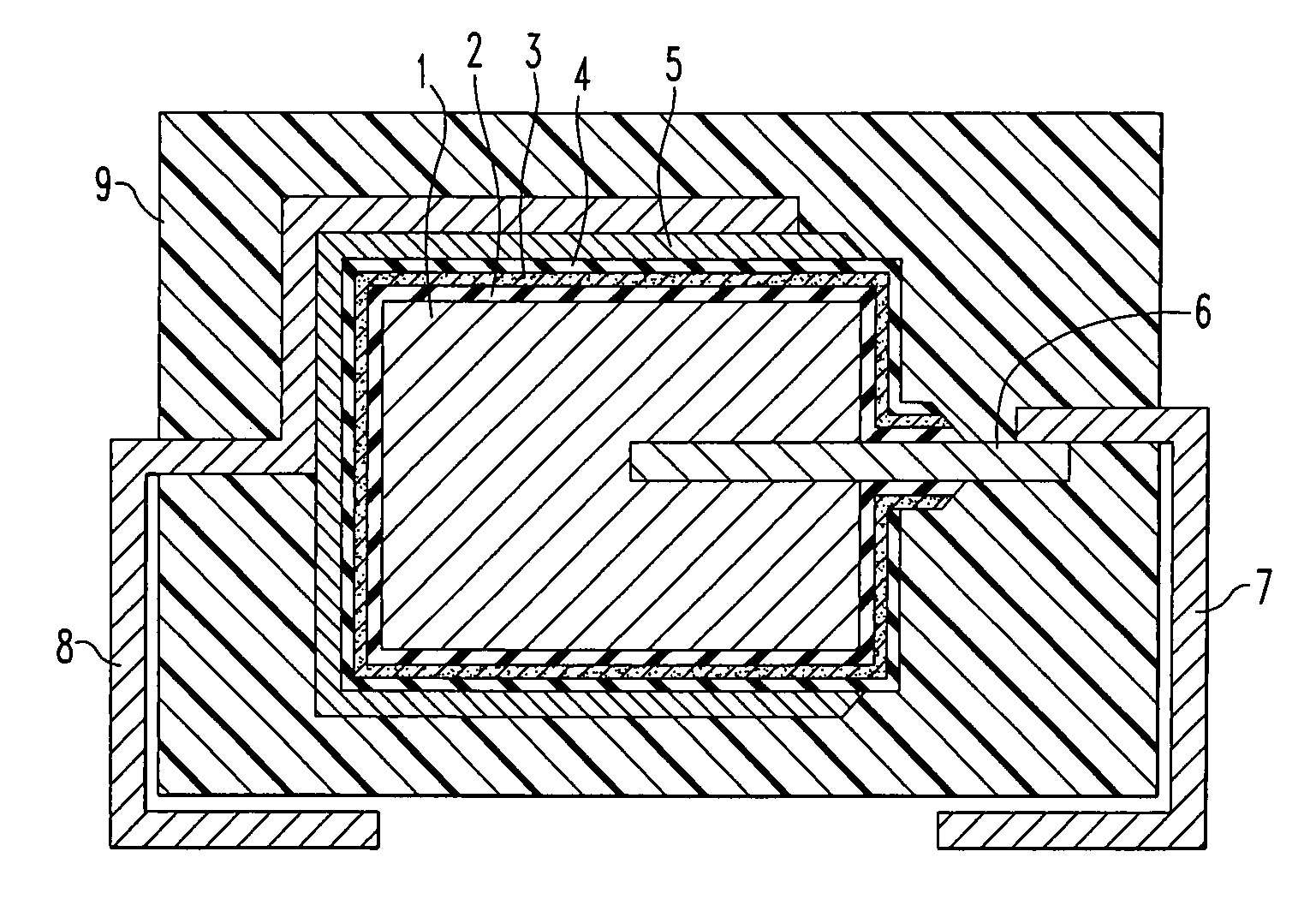

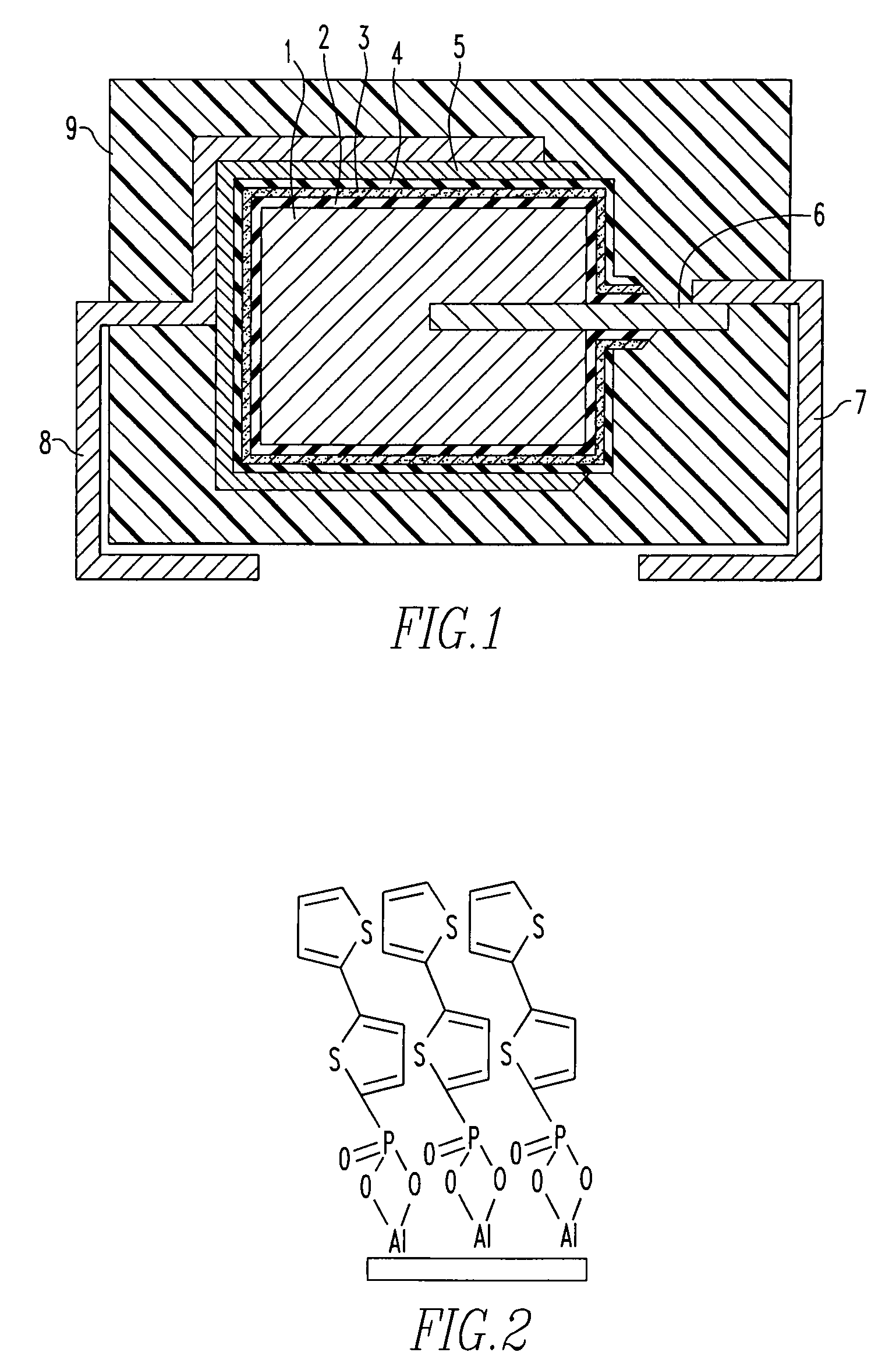

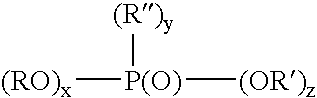

Solid electrolytic capacitors

InactiveUS7471503B2Hybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisOrganophosphorous compounds

A solid electrolytic capacitor is disclosed. The capacitor comprises an organophosphorus material positioned between the dielectric layer and the polymeric electrolyte layer. The organophosphorus compound improves the interlayer adhesion between the dielectric and electrolyte layers.

Owner:ACULON +1

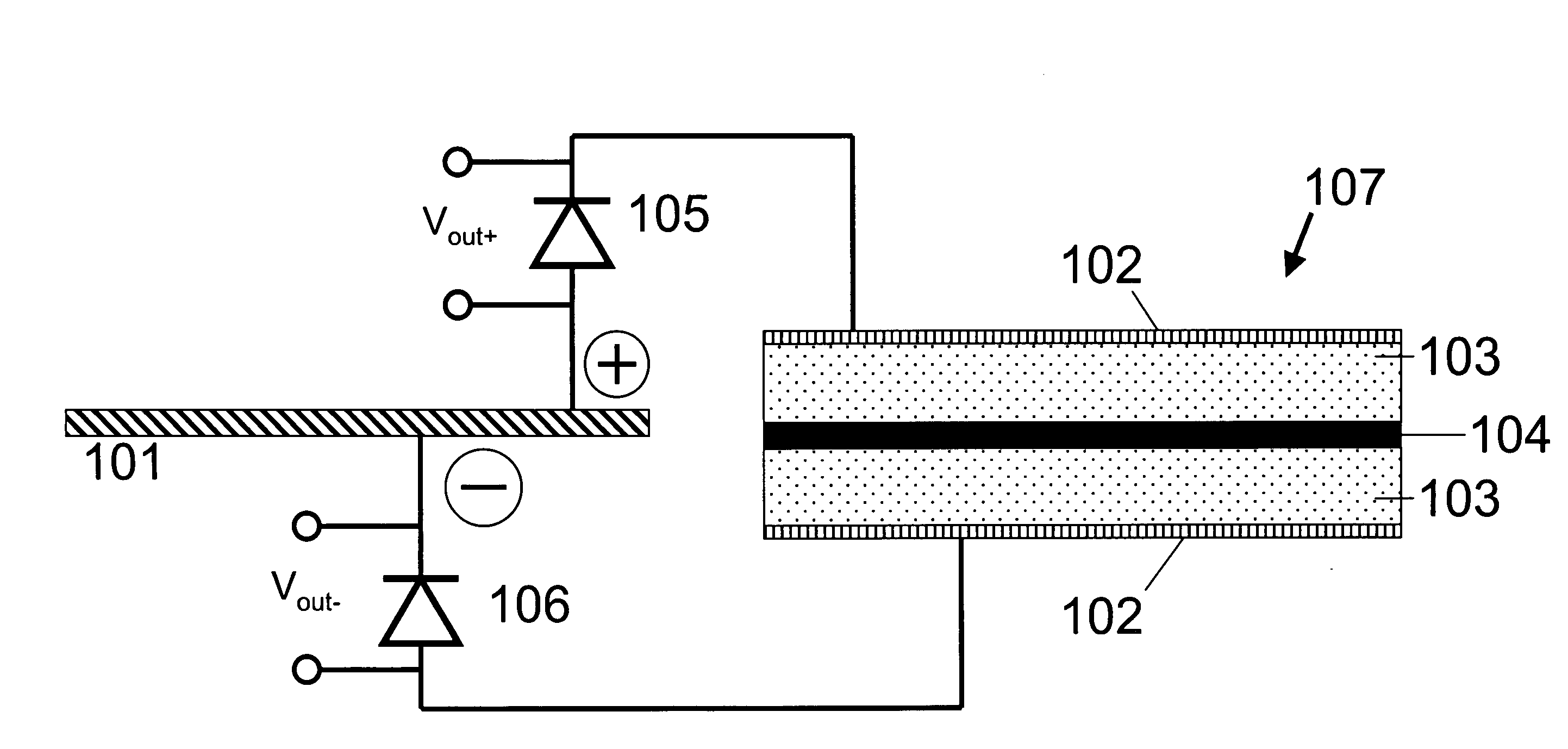

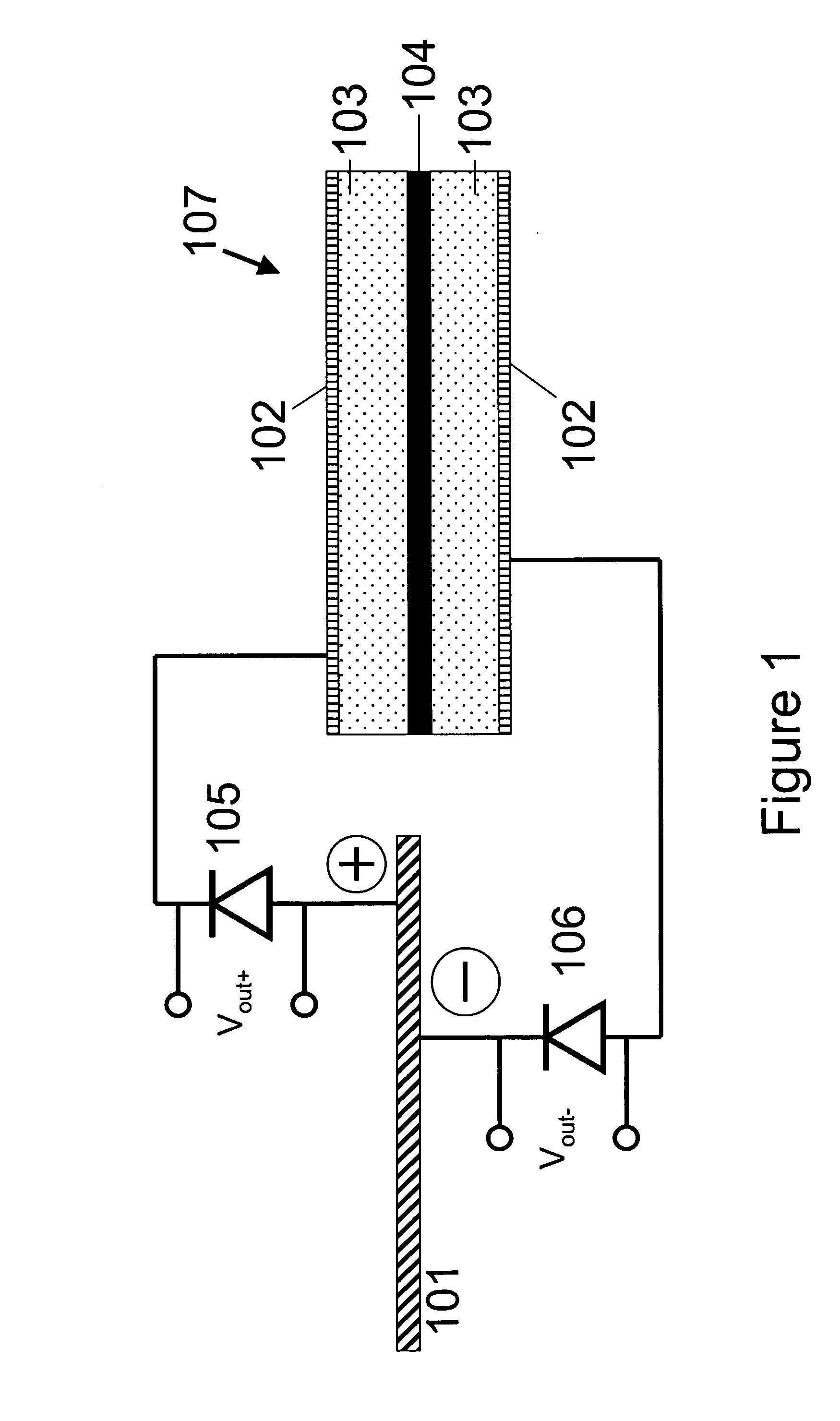

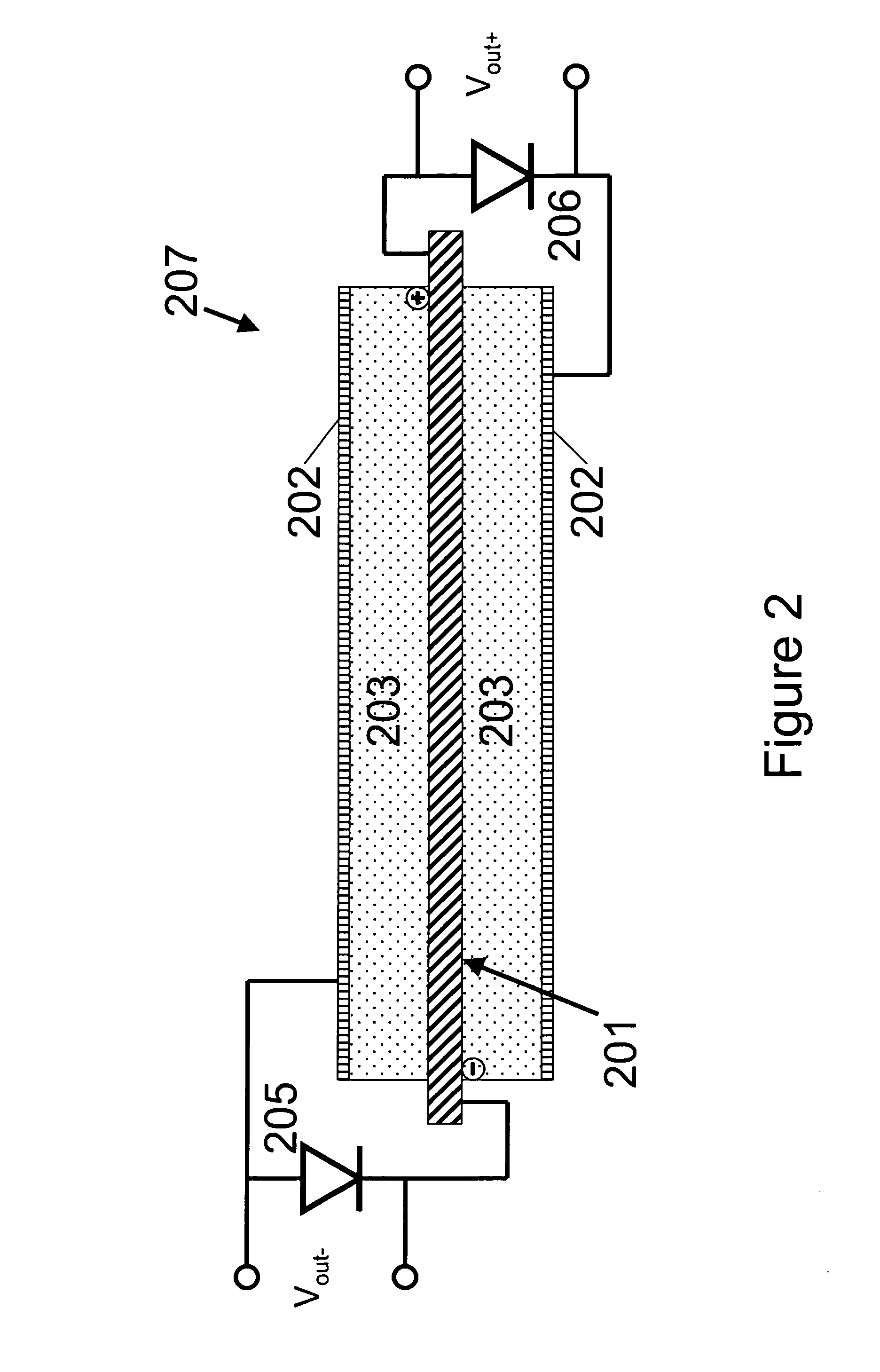

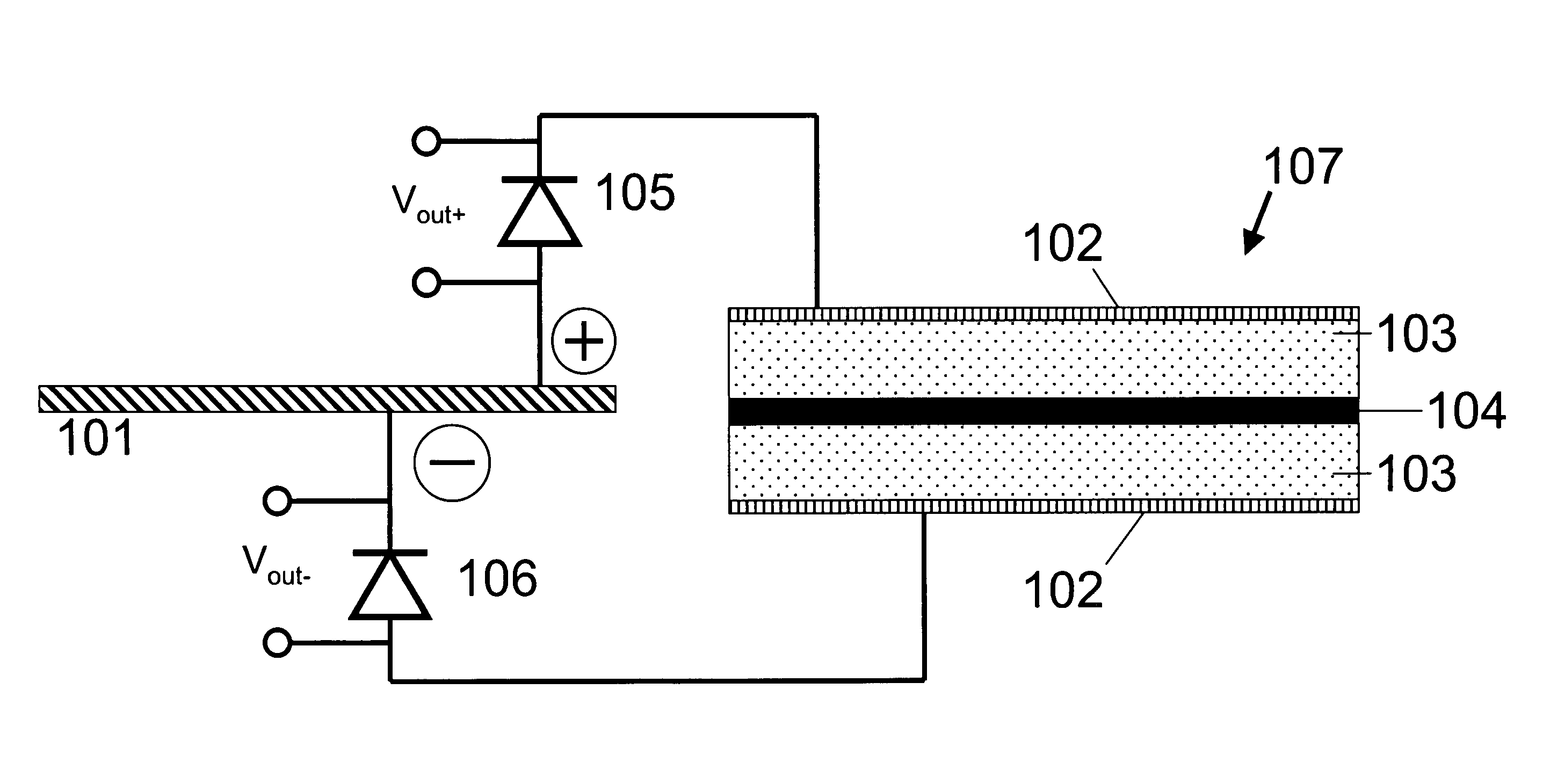

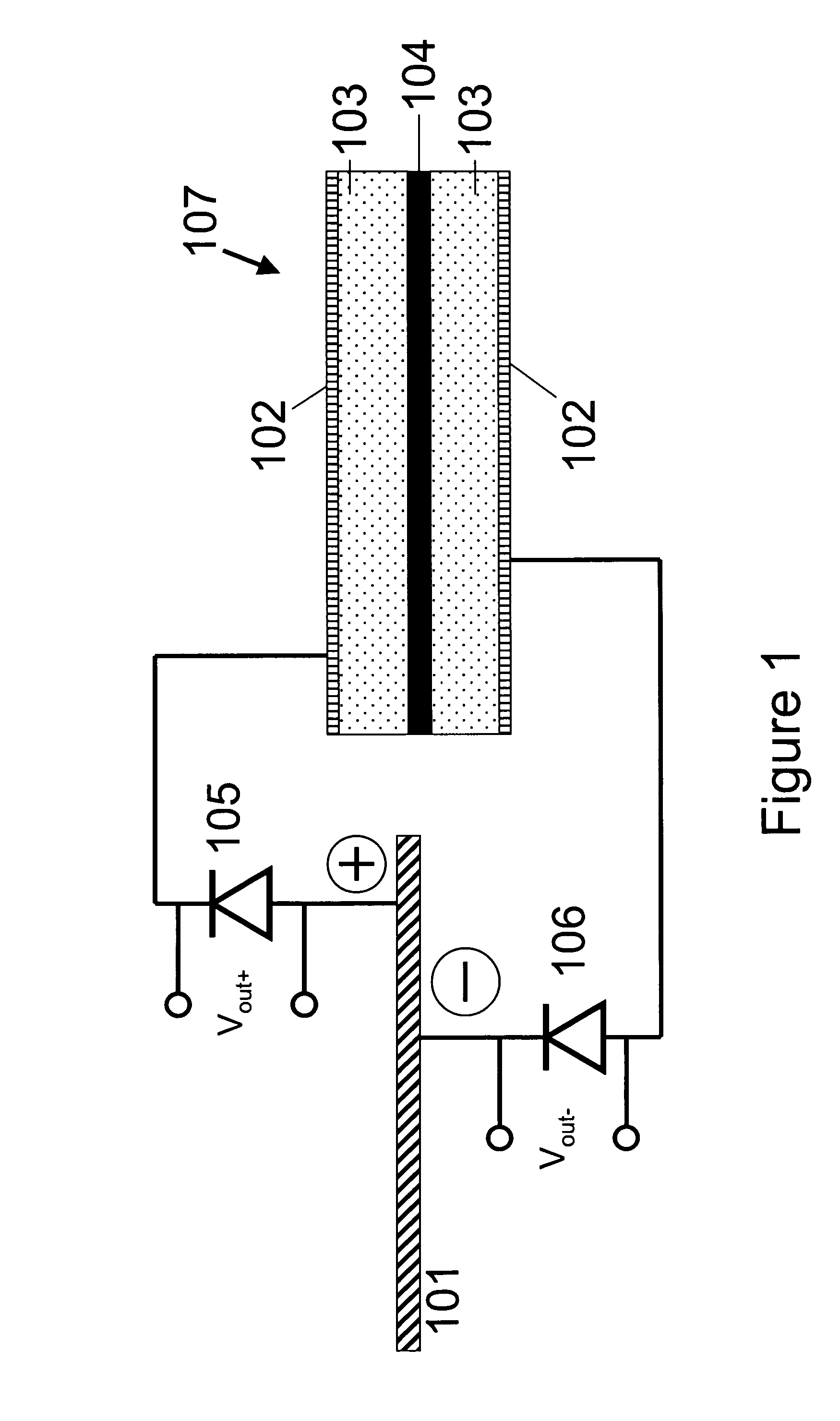

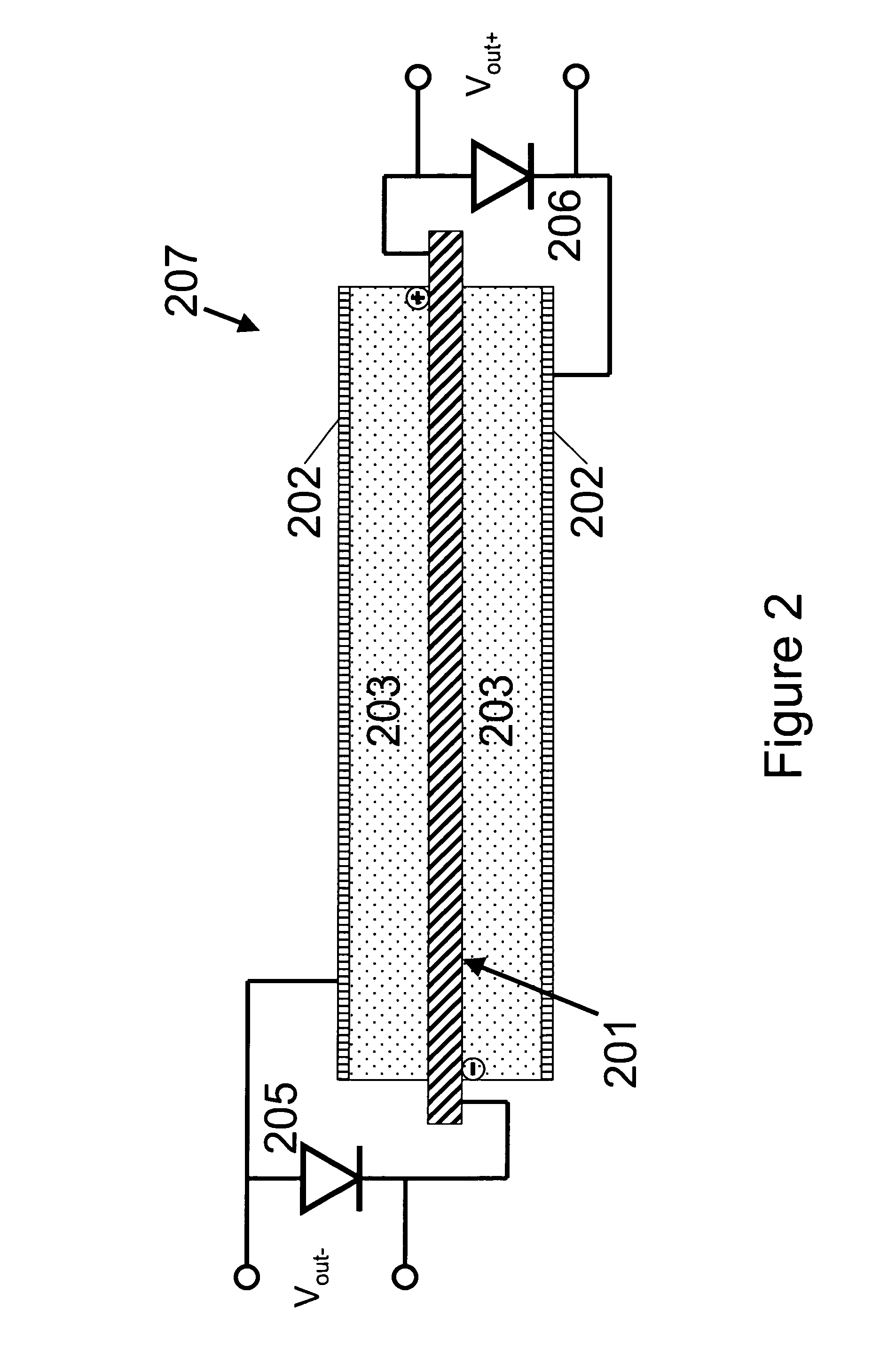

Piezoelectric Ultracapacitor

InactiveUS20080212262A1Efficient use ofImprove efficiencyTyre partsHybrid capacitor electrolytesElastomerElectricity

A piezoelectric ultracapacitor is disclosed capable of converting the kinetic energy of ordinary motion into an electrical potential. Multiple piezoelectric ultracapacitors may be configured together to provide an increased output voltage and various materials may advantageously be used. The piezoelectric ultracapacitor of the present invention may be used in various contexts, including power generation, switching and control and memory. An elastomeric piezoelectric ultracapacitor, along with methods of making and operating such a device, is also disclosed. The elastomeric piezoelectric ultracapacitor utilizes the voltage generation capabilities of a piezoelectric ultracapacitor and the generator mode operation of an elastomer actuator, combined and cooperating in novel ways, to provide improved energy generation capabilities.

Owner:MICALLEF JOSEPH A

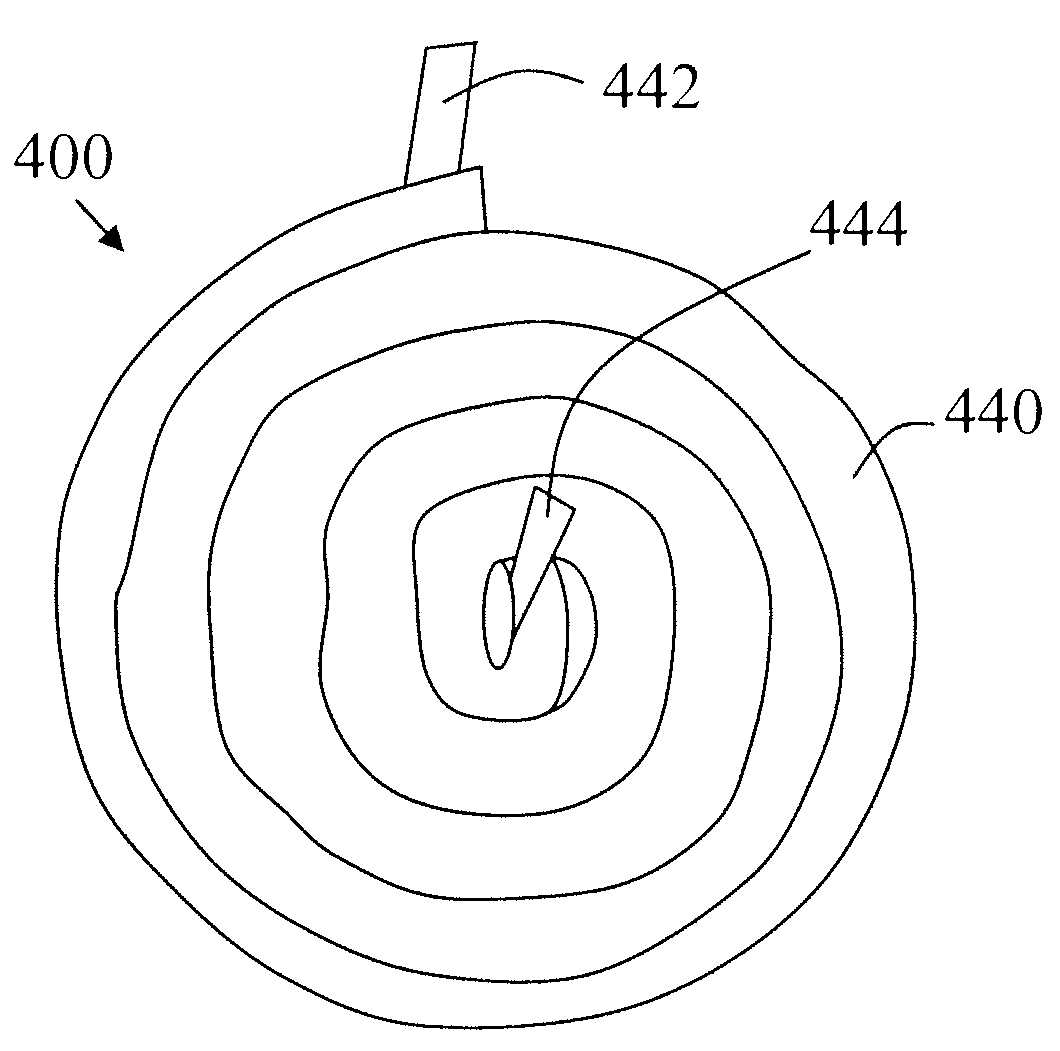

Energy storage device with porous electrode

A method of fabricating an energy storage device with a large surface area electrode comprises: providing an electrically conductive substrate; depositing a semiconductor layer on the electrically conductive substrate, the semiconductor layer being a first electrode; anodizing the semiconductor layer, wherein the anodization forms pores in the semiconductor layer, increasing the surface area of the first electrode; after the anodization, providing an electrolyte and a second electrode to form the energy storage device. The substrate may be a continuous film and the electrode of the energy storage device may be fabricated using linear processing tools. The semiconductor may be silicon and the deposition tool may be a thermal spray tool. Furthermore, the semiconductor layer may be amorphous. The energy storage device may be rolled into a cylindrical shape. The energy storage device may be a battery, a capacitor or an ultracapacitor.

Owner:APPLIED MATERIALS INC

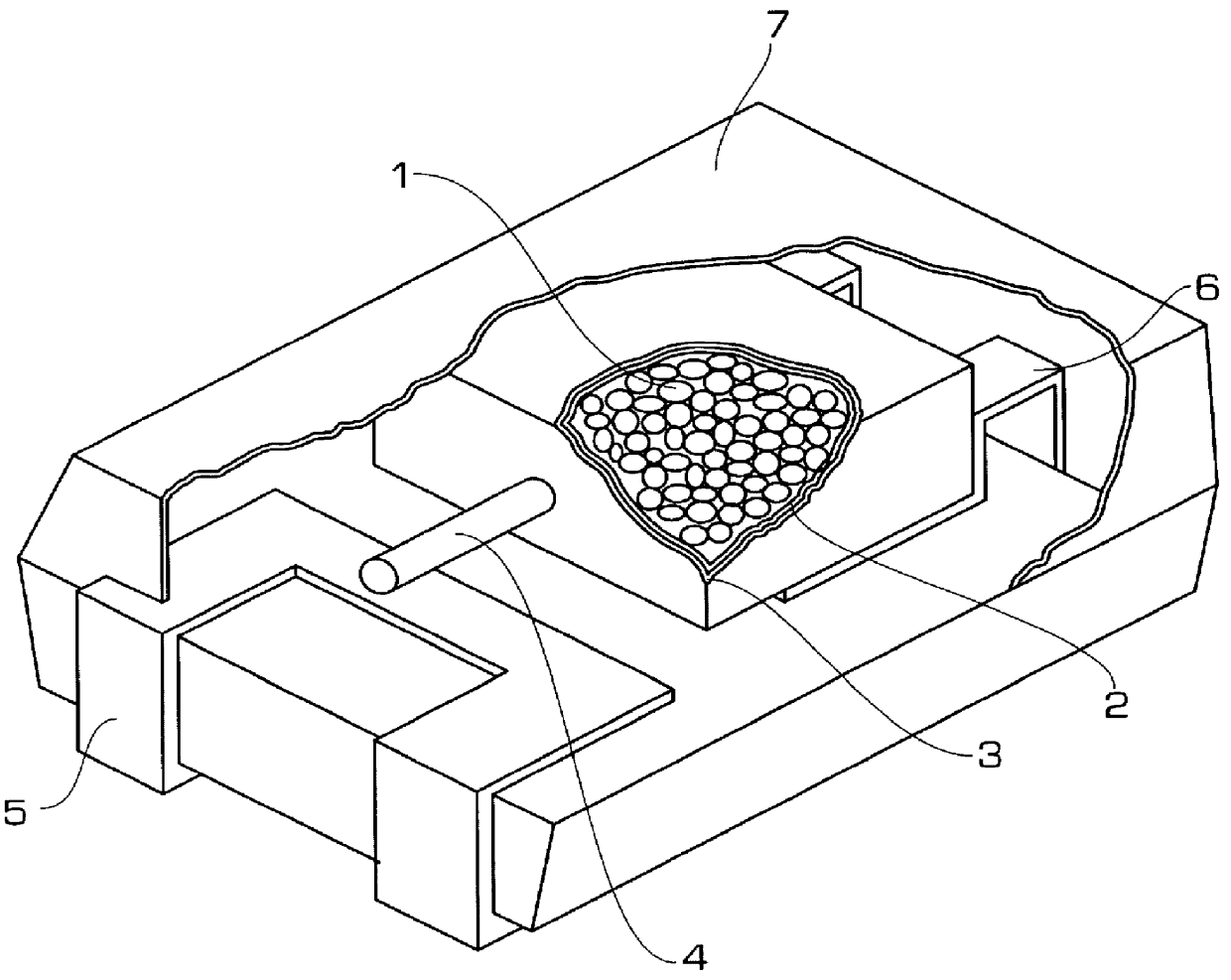

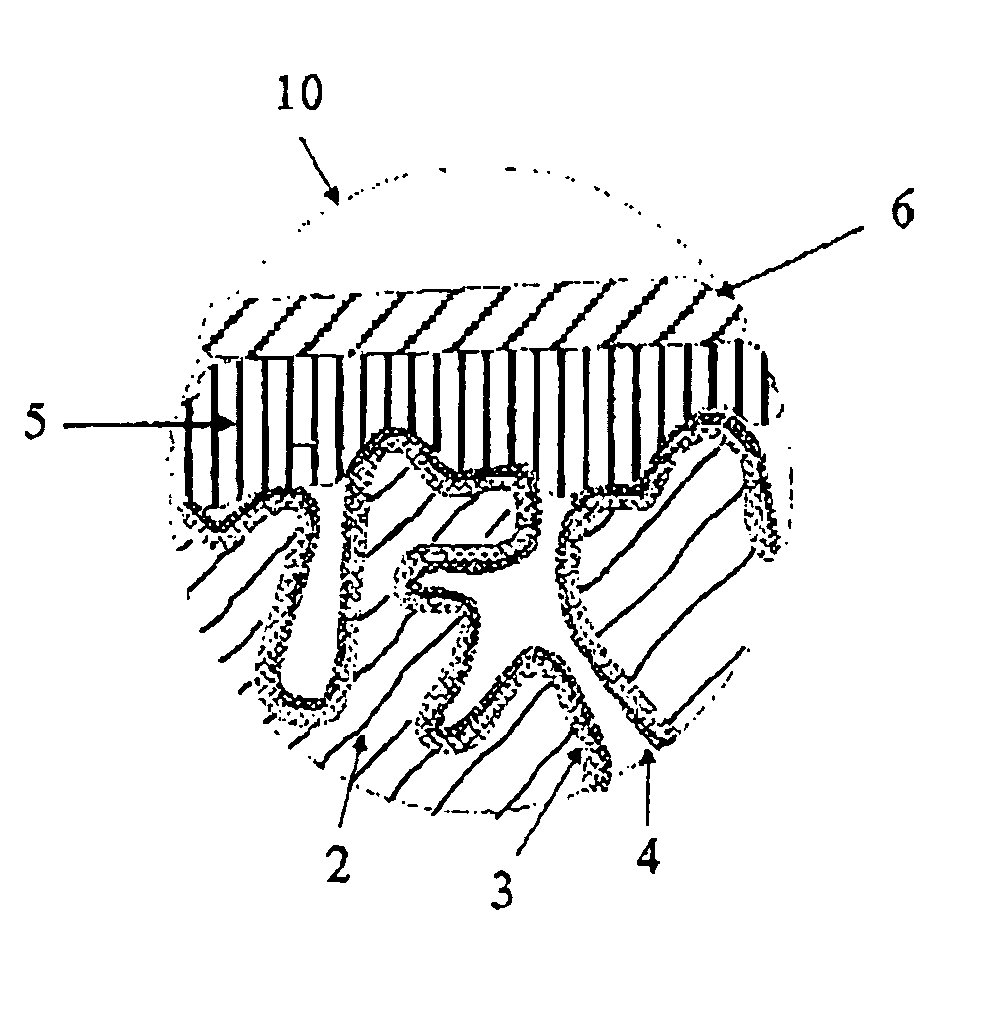

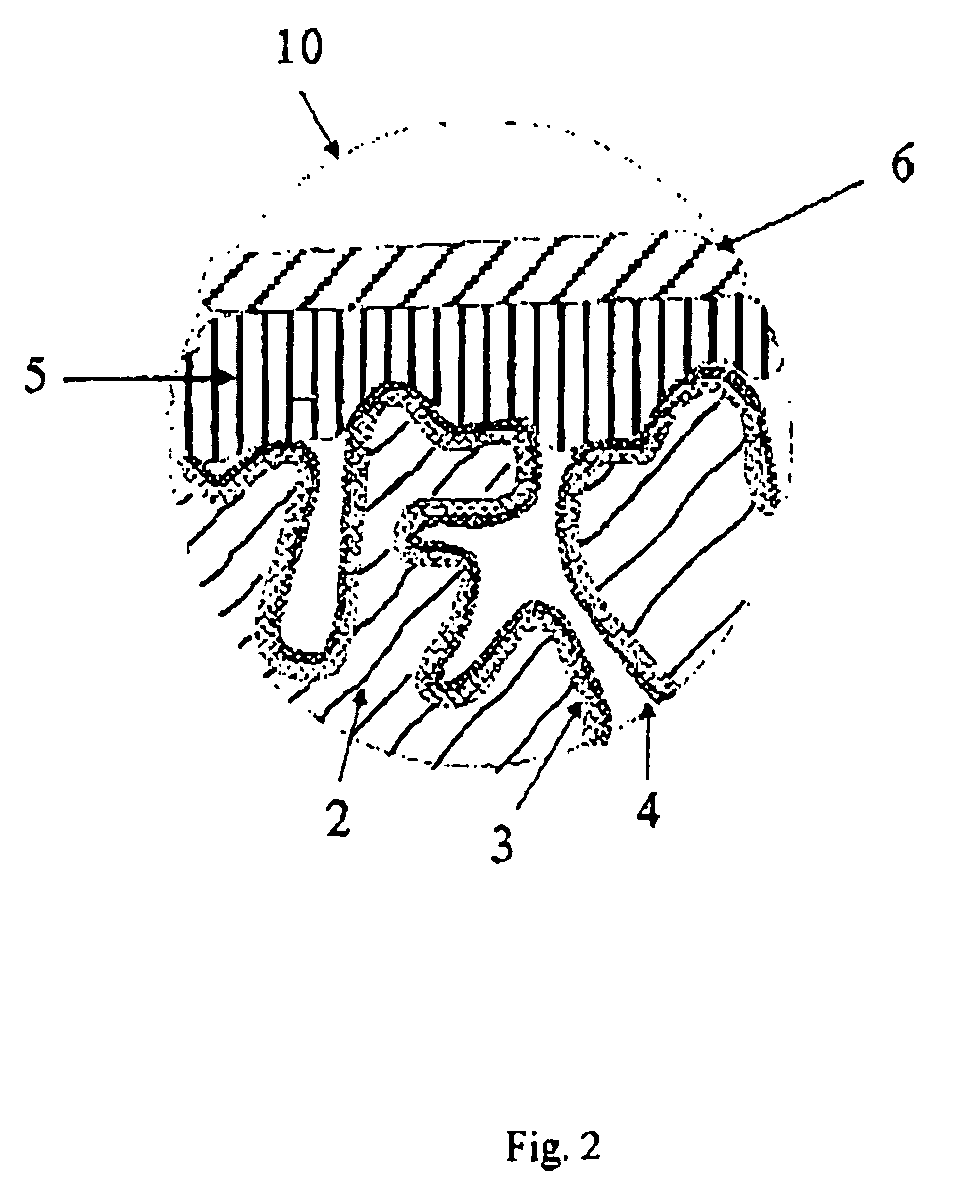

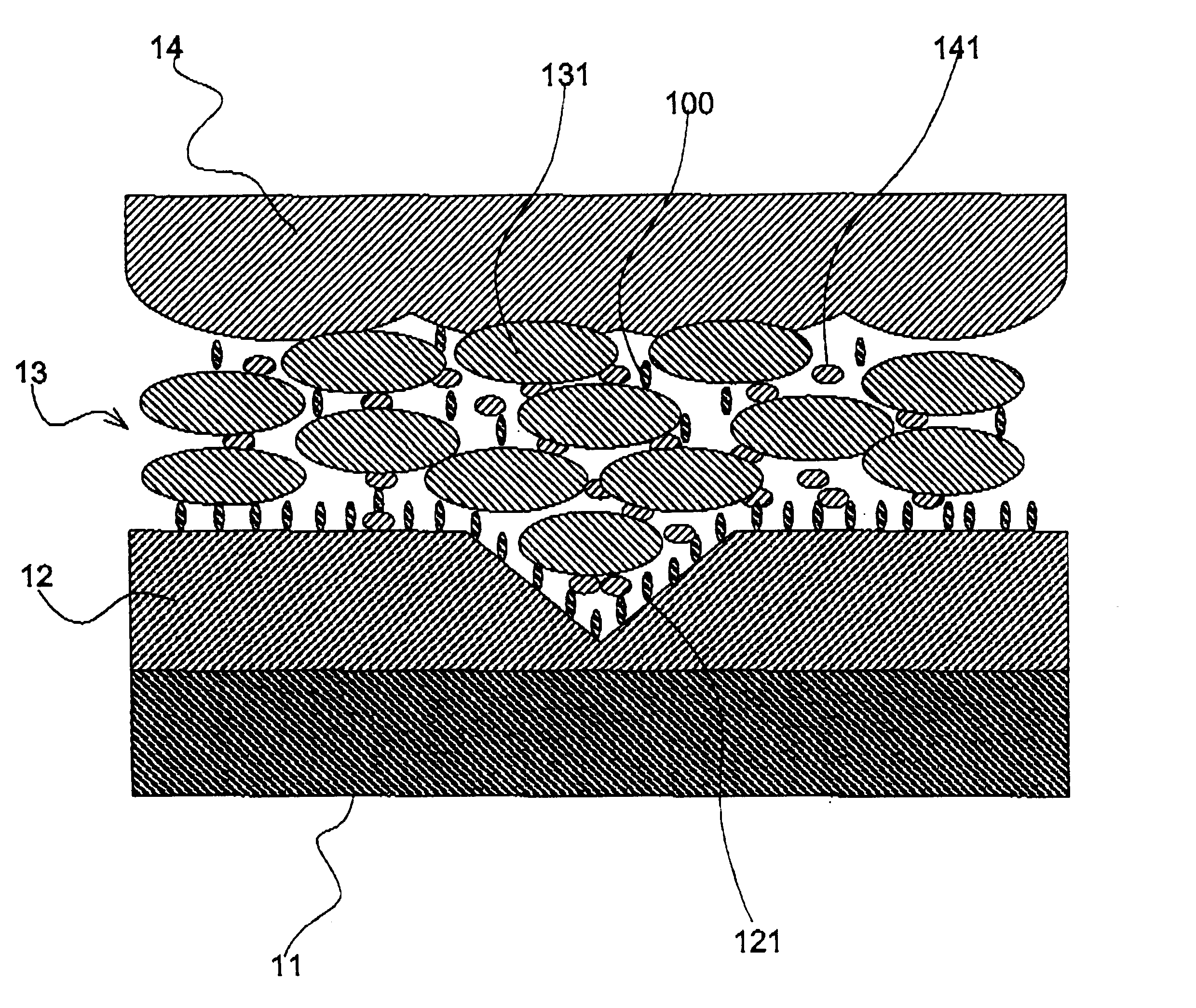

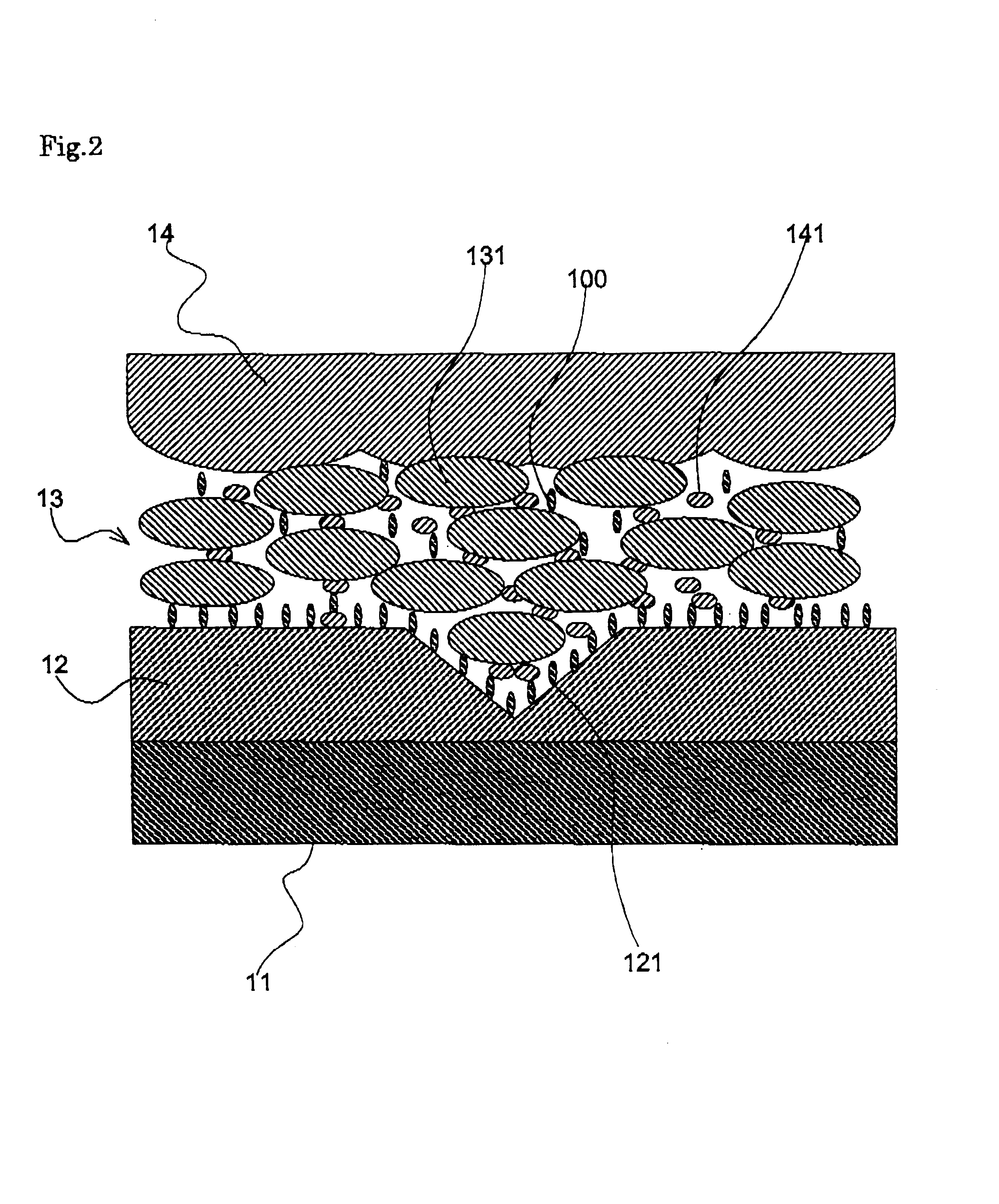

Solid electrolytic capacitor, and method for preparing the same

InactiveUS6671167B2Hybrid capacitor electrolytesHybrid capacitor electrodesElectrolysisElectrolytic capacitor

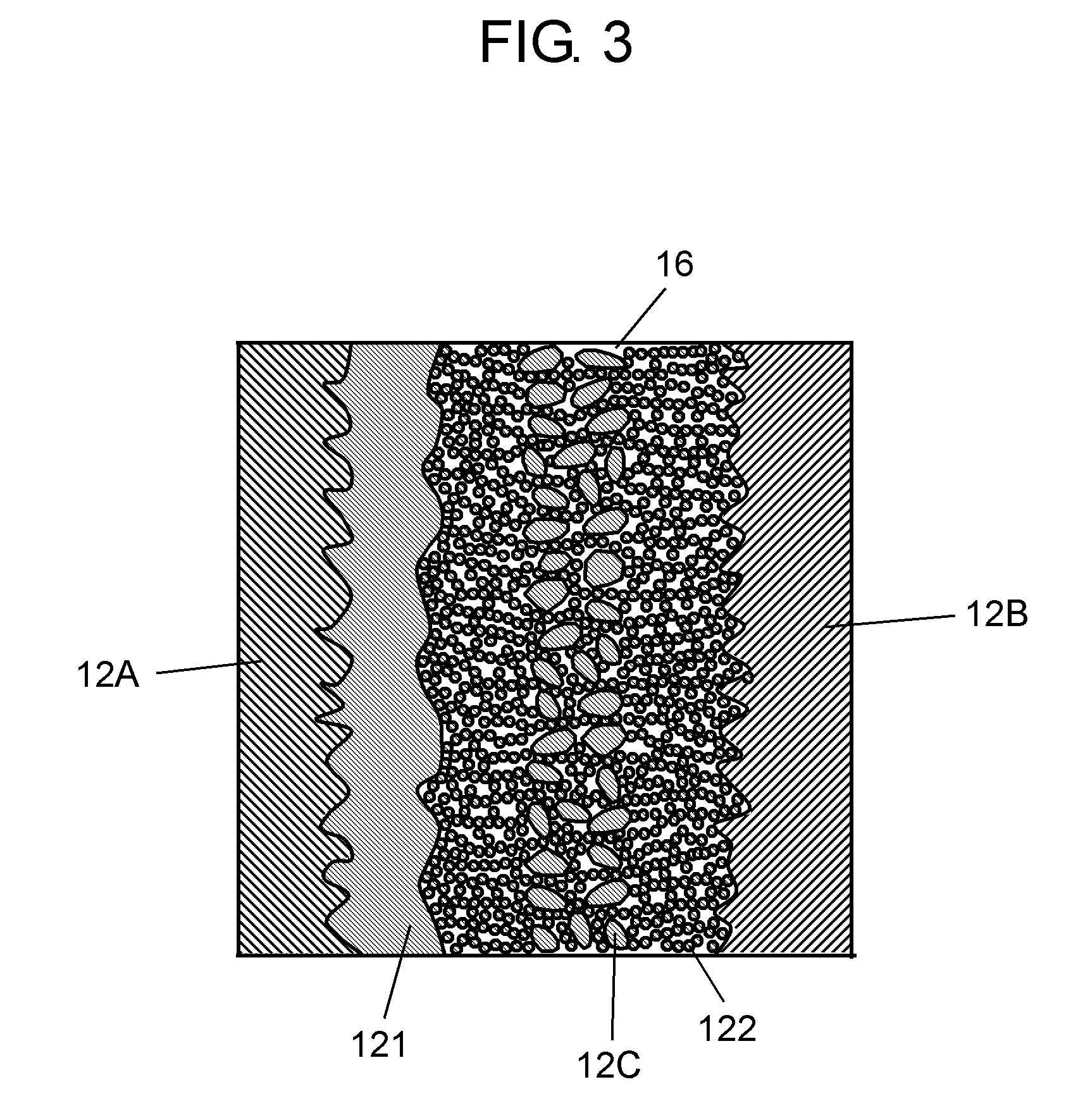

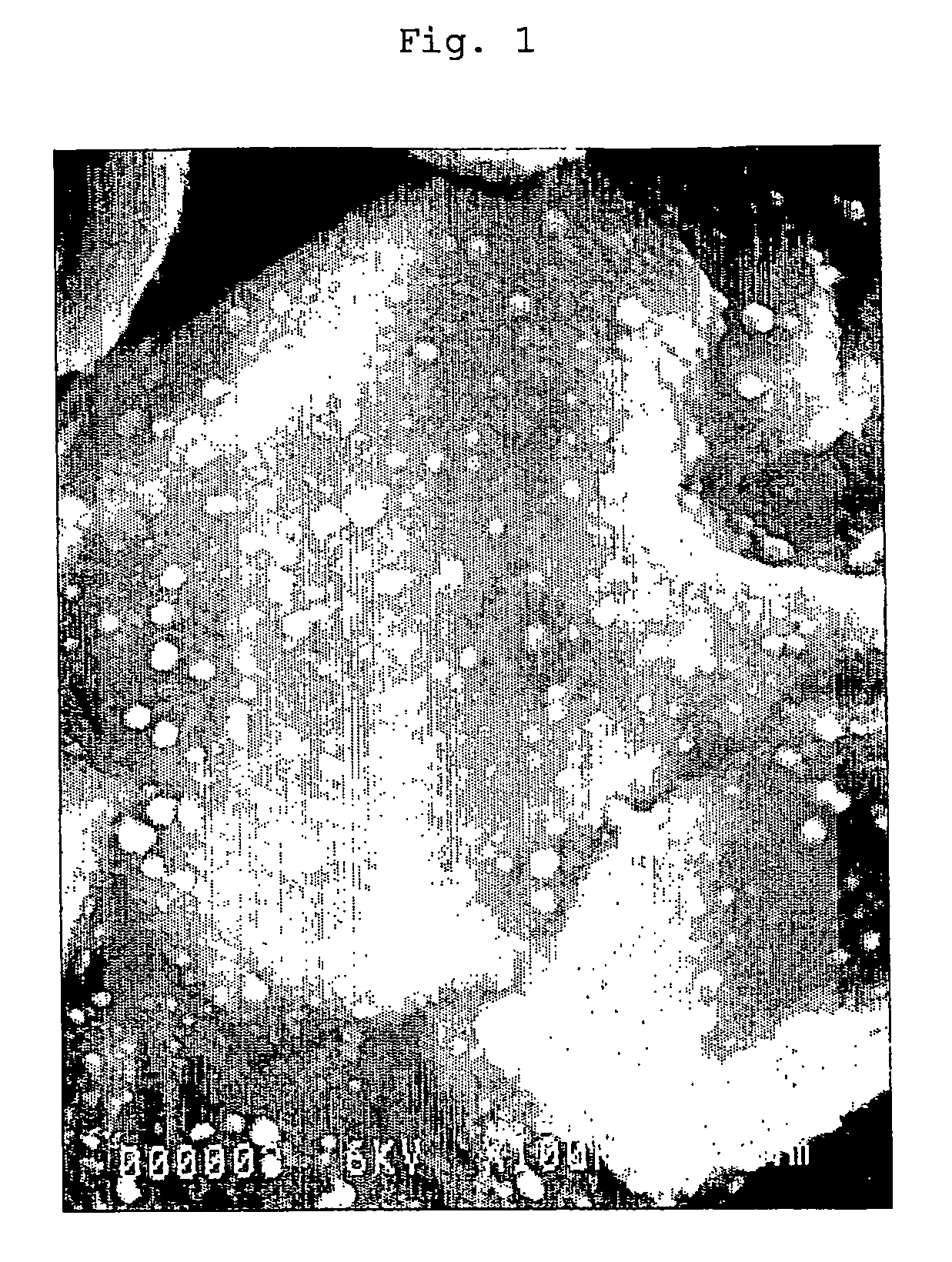

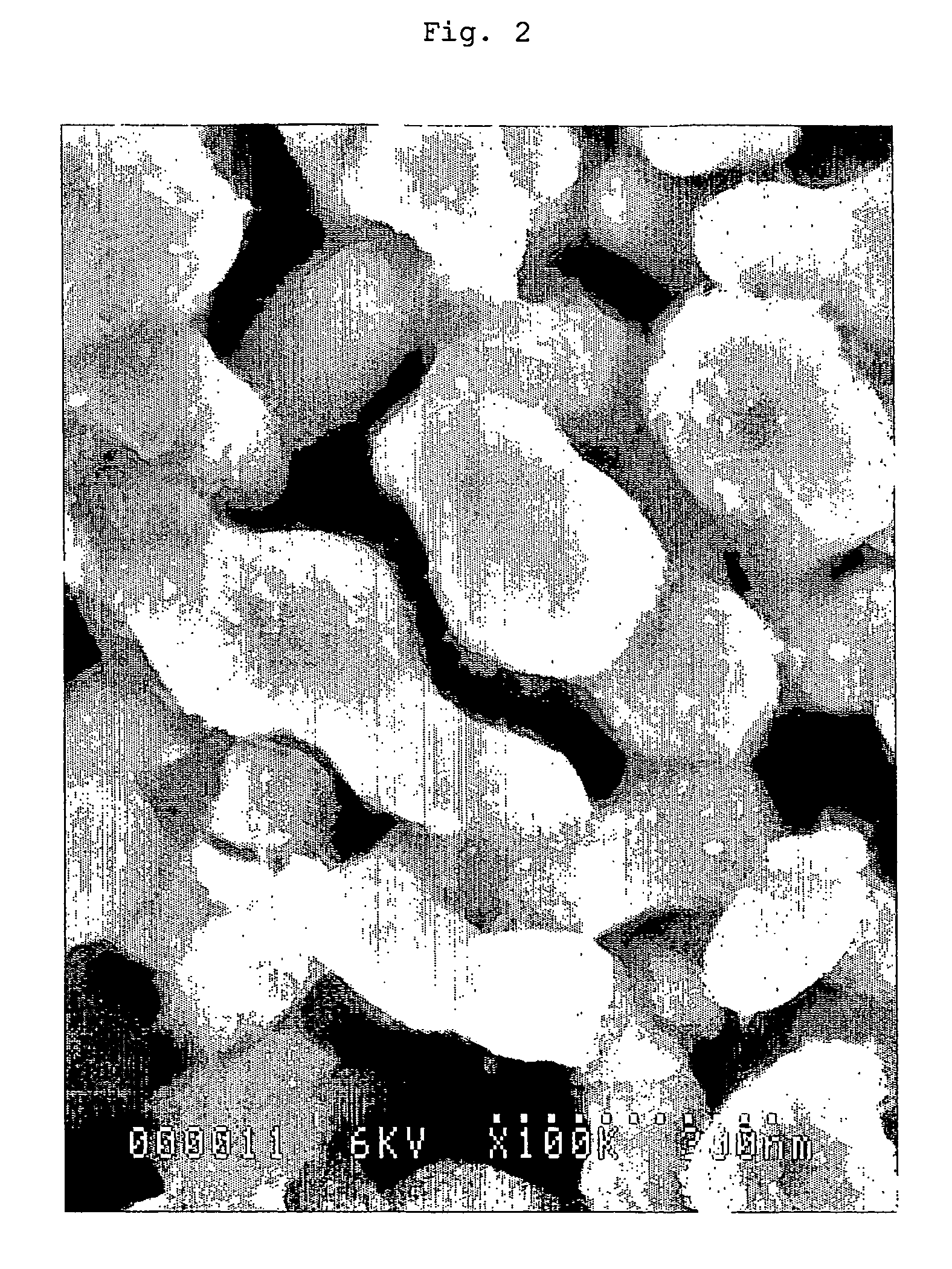

A solid electrolytic capacitor is disclosed which combines low LC with Low ESR and which has good characteristics even in a high frequency range, and a method for preparing the same is also disclosed. In the solid electrolytic capacitor whose electrolytic layer contains electrically conductive particles, non-conductive particles are present in at least a part of an interface between a dielectric layer and the electrolyte layer. By employing the structure, local intensifications of field strength in the dielectric layer are prevented to enable a problem of increase in LC to be overcome while keeping ESR low. By the method which comprised a step of applying a colloidal dispersion containing the non-conductive particles in the form of colloidal particles to the post-electrolytic layer formation step product, the solid electrolytic capacitor having the above-mentioned structure can be prepared efficiently.

Owner:TOKIN CORP

Atomic layer deposition process for manufacture of battery electrodes, capacitors, resistors, and catalyzers

InactiveUS20100123993A1No leaksReduced series resistancePorous dielectricsSolid electrolytic capacitorsMulti materialMacroscopic scale

The present disclosure relates generally to the field of sequential surface chemistry. More specifically, it relates to products and methods for manufacturing products using Atomic Layer Deposition (“ALD”) to depose one or more materials onto a surface. ALD is an emerging variant of Chemical Vapor Deposition (“CVD”) technology with capability for high-quality film deposition at low pressures and temperatures, which may produce defect-free films, on a macroscopic scale, at any given thickness. The present disclosure includes, in varying embodiments, methods of manufacturing microelectronic assemblies and components such as battery electrodes, capacitors, resistors, catalyzers and PCB assemblies by ALD, and the products manufactured by those methods.

Owner:LAOR CONSULTING +1

Solid electrolytic capacitor

ActiveUS20090128997A1Reduce capacitanceAdhesivenessAnodisationSolid electrolytic capacitorsElectrolysisConductive polymer

An aspect of the invention provides a solid electrolytic capacitor that comprises: an anode formed of a valve metal or an alloy mainly made of a valve metal; a dielectric layer formed on a surface of the anode; a first conducting polymer layer formed on the dielectric layer, the first conducting polymer layer containing a non-ionic surfactant; a second conducting polymer layer formed on the first conducting polymer layer; and a cathode layer formed on the second conducting polymer layer.

Owner:SANYO ELECTRIC CO LTD

Piezoelectric ultracapacitor

InactiveUS7859171B2Efficient use ofImprove efficiencyTyre partsHybrid capacitor electrolytesElastomerElectricity

A piezoelectric ultracapacitor is disclosed capable of converting the kinetic energy of ordinary motion into an electrical potential. Multiple piezoelectric ultracapacitors may be configured together to provide an increased output voltage and various materials may advantageously be used. The piezoelectric ultracapacitor of the present invention may be used in various contexts, including power generation, switching and control and memory. An elastomeric piezoelectric ultracapacitor, along with methods of making and operating such a device, is also disclosed. The elastomeric piezoelectric ultracapacitor utilizes the voltage generation capabilities of a piezoelectric ultracapacitor and the generator mode operation of an elastomer actuator, combined and cooperating in novel ways, to provide improved energy generation capabilities.

Owner:MICALLEF JOSEPH A

Electrolyte used for treating aluminium foil in aluminium electrolytic capacitor

InactiveCN101871115AImprove leakage currentImprove reliabilityAnodisationSolid electrolytic capacitorsElectrolysisSURFACTANT BLEND

The invention provides an electrolyte used for treating an aluminium foil in an aluminium electrolytic capacitor. A surfactant used for reducing surface tension of the electrolyte and improving infiltration of solution on the surface of the aluminium foil is added into the electrolyte, and is at least one of an anionic surfactant, a cationic surfactant, an ampholytic surfactant and a nonionic surfactant. The surfactant can obviously reduce the surface tension, improve the infiltration of the solution on the surface of the aluminium foil, and greatly improve the capacity of the electrolyte of reaching the surface of the aluminium foil to corrode hole walls and hole bottoms, so an oxidation film on the surface of the aluminium foil is fully repaired, and the leakage current and the reliability of the electrolytic capacitor are greatly improved. The electrolyte has the advantages of readily available raw materials and strong operability in the preparation process, and is suitable for large-scale technological improvement and promotion.

Owner:FUJIAN GUOGUANG ELECTRONICS SCI & TECHCO

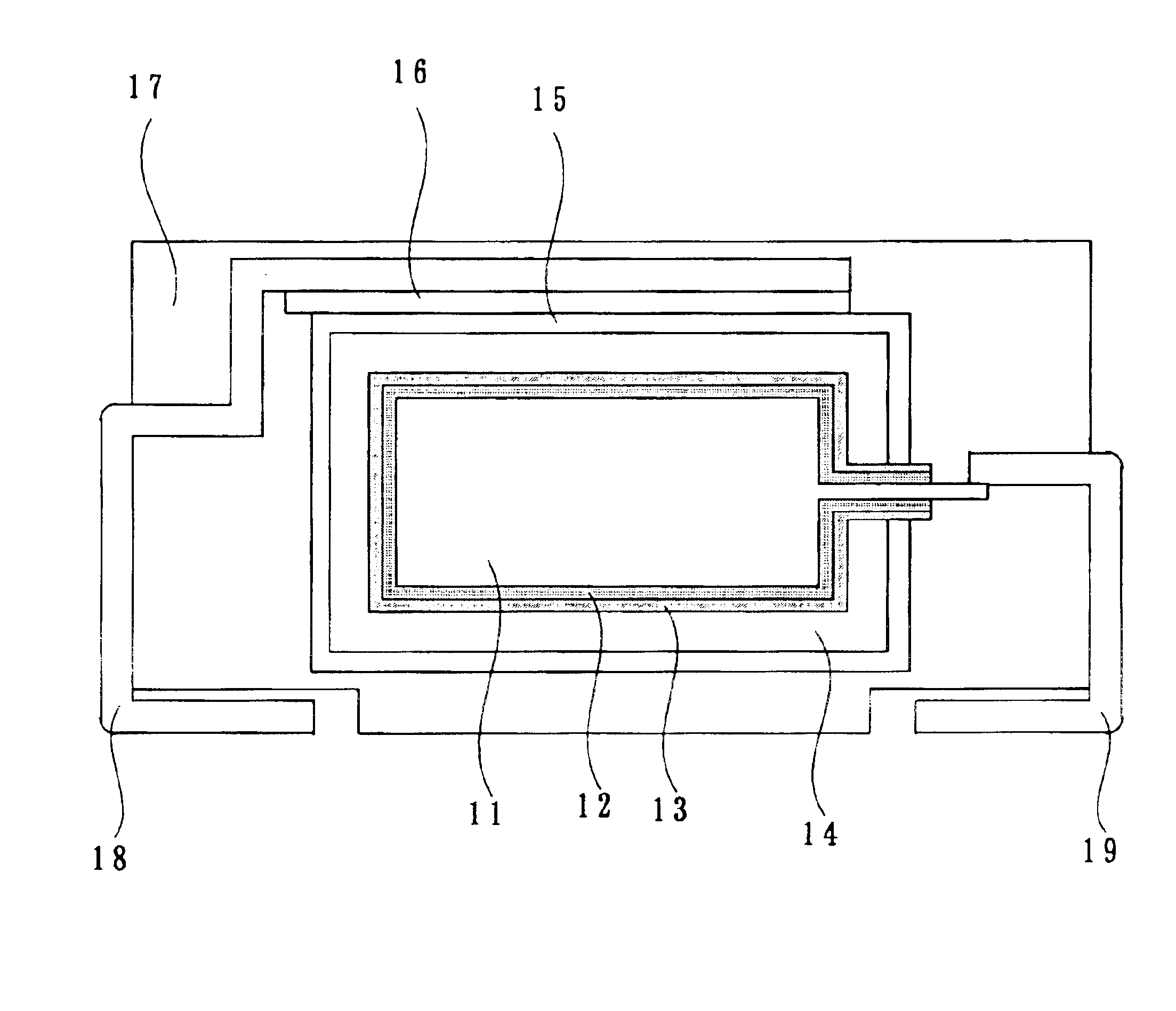

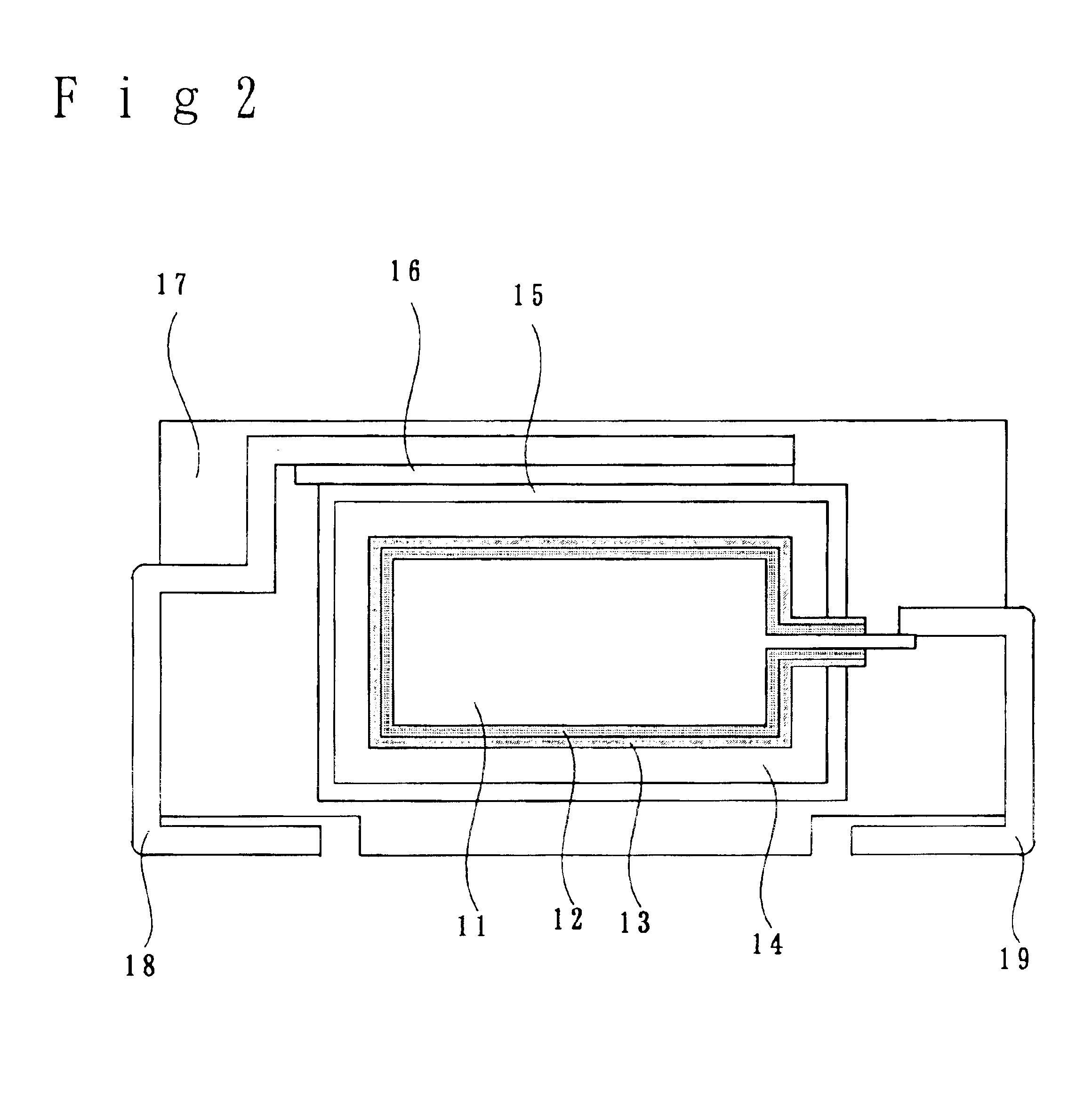

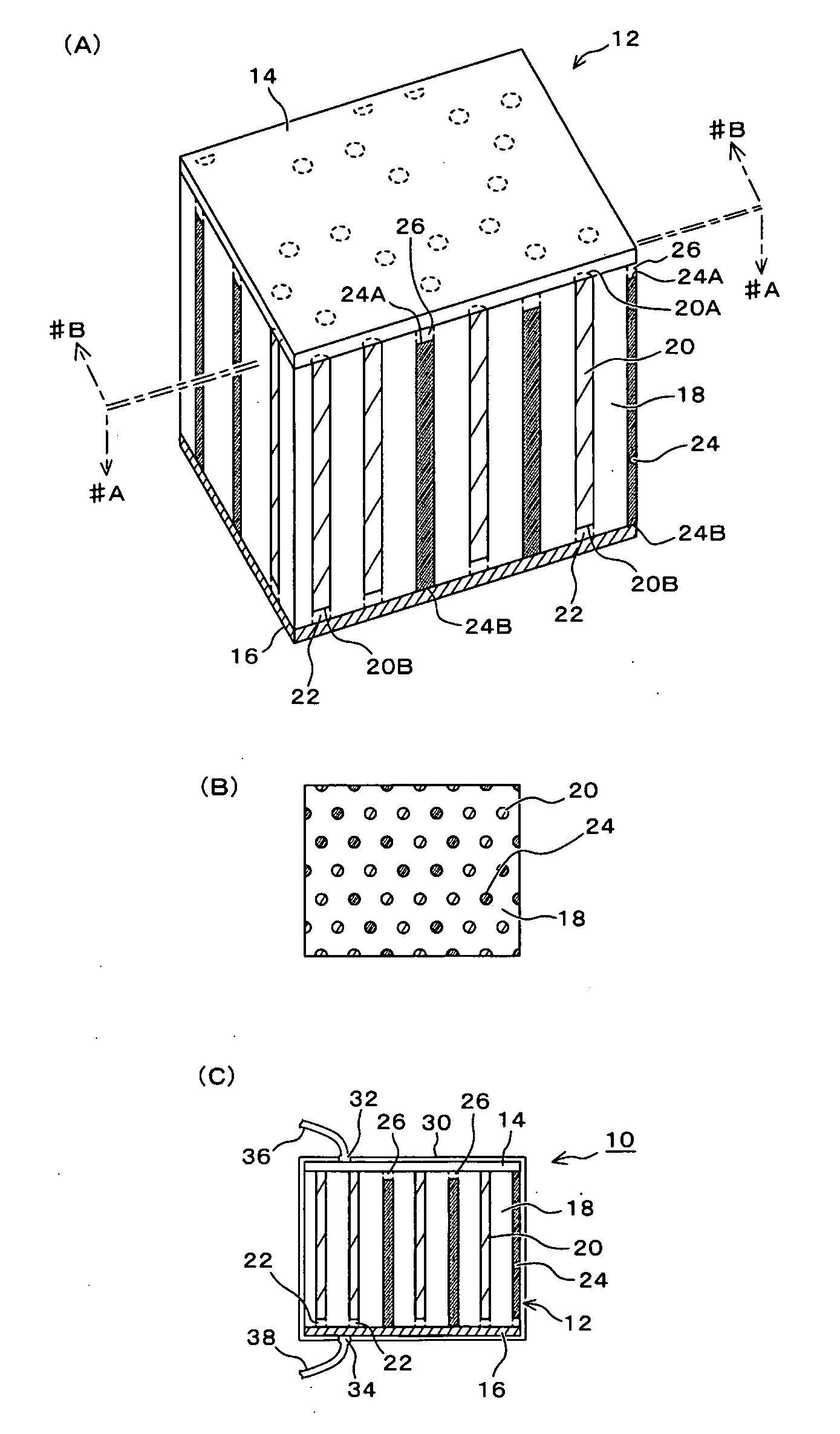

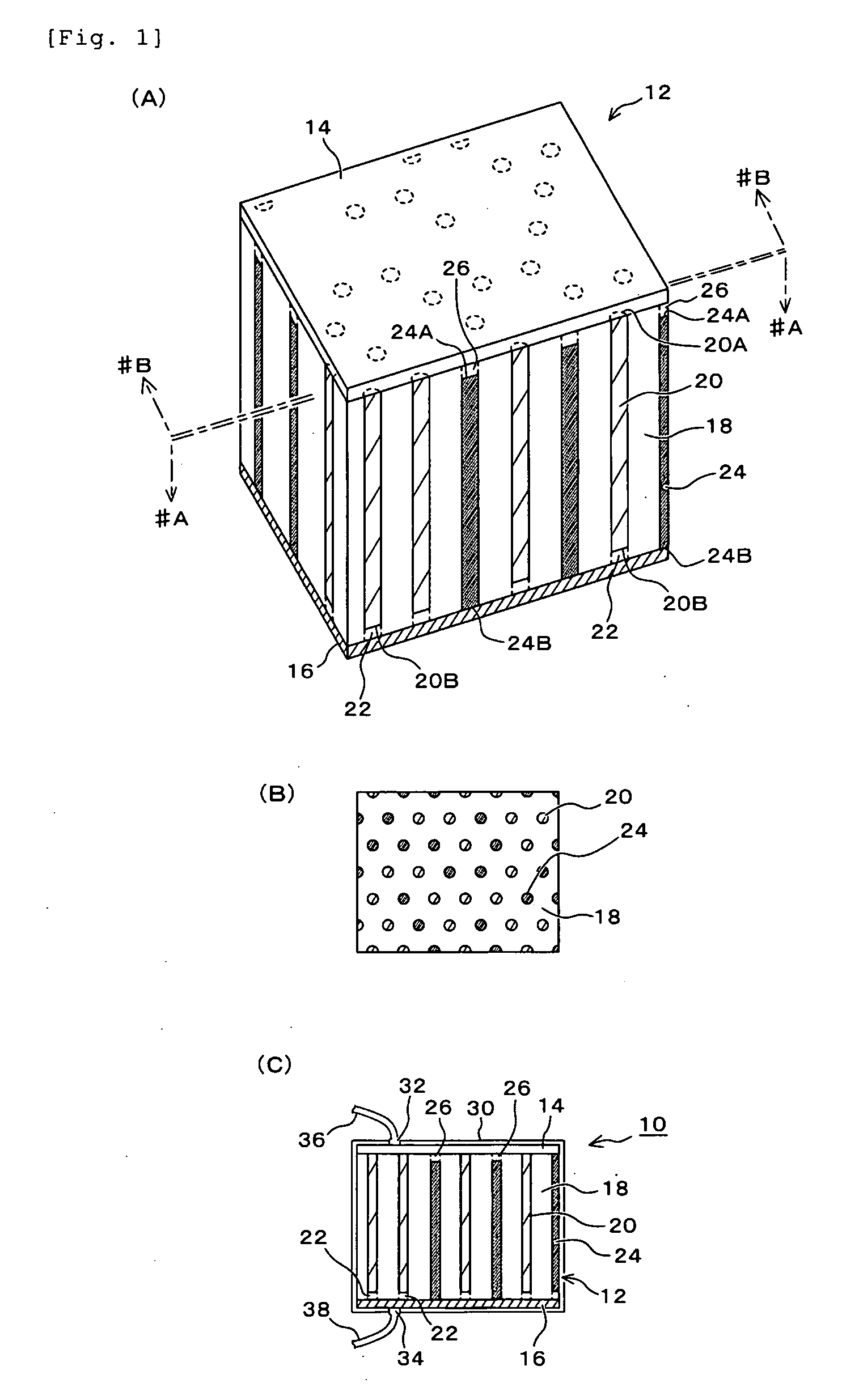

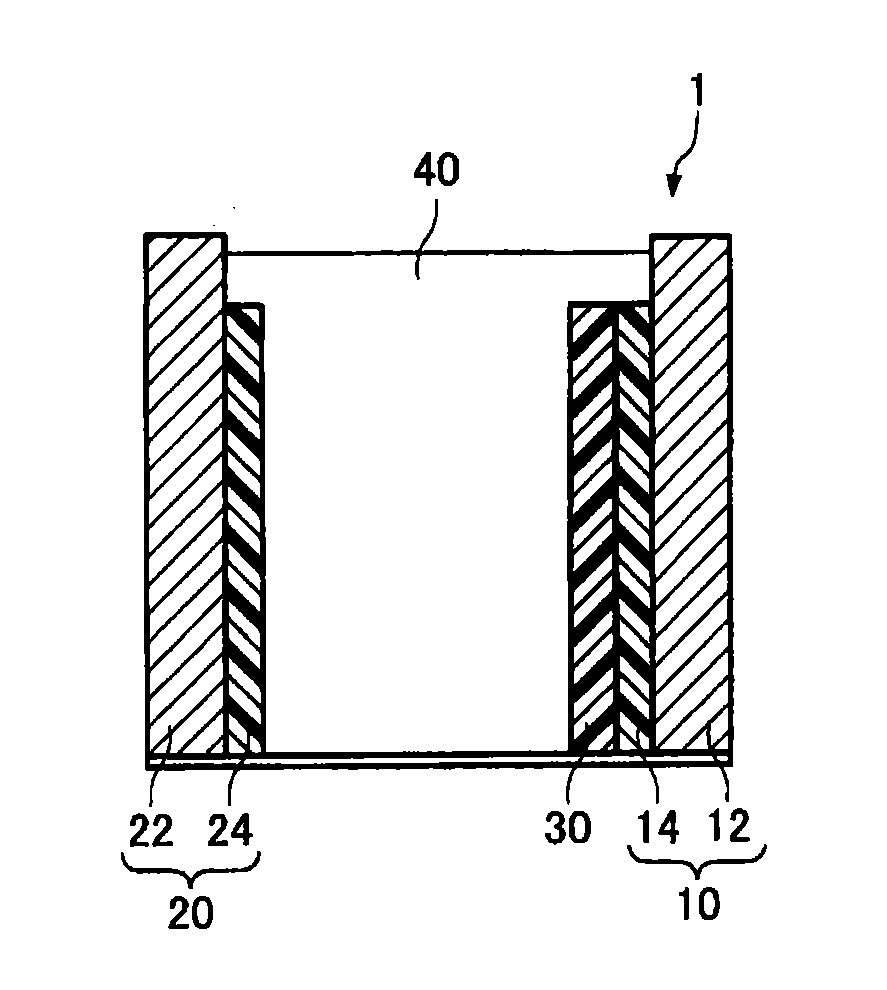

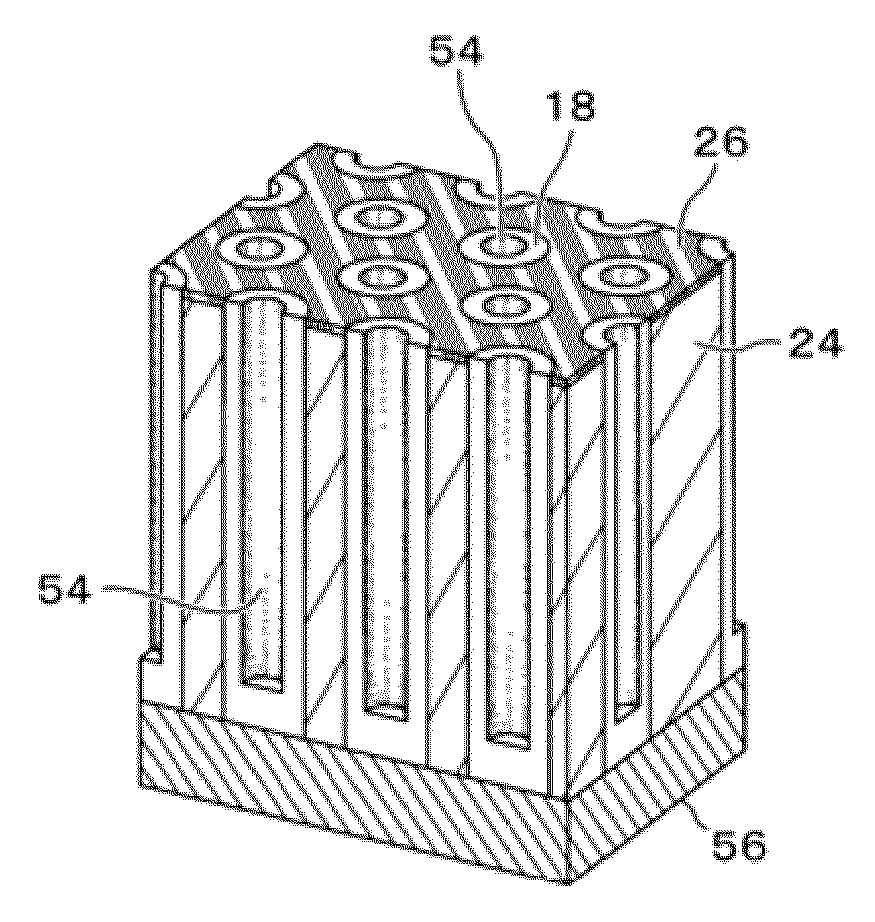

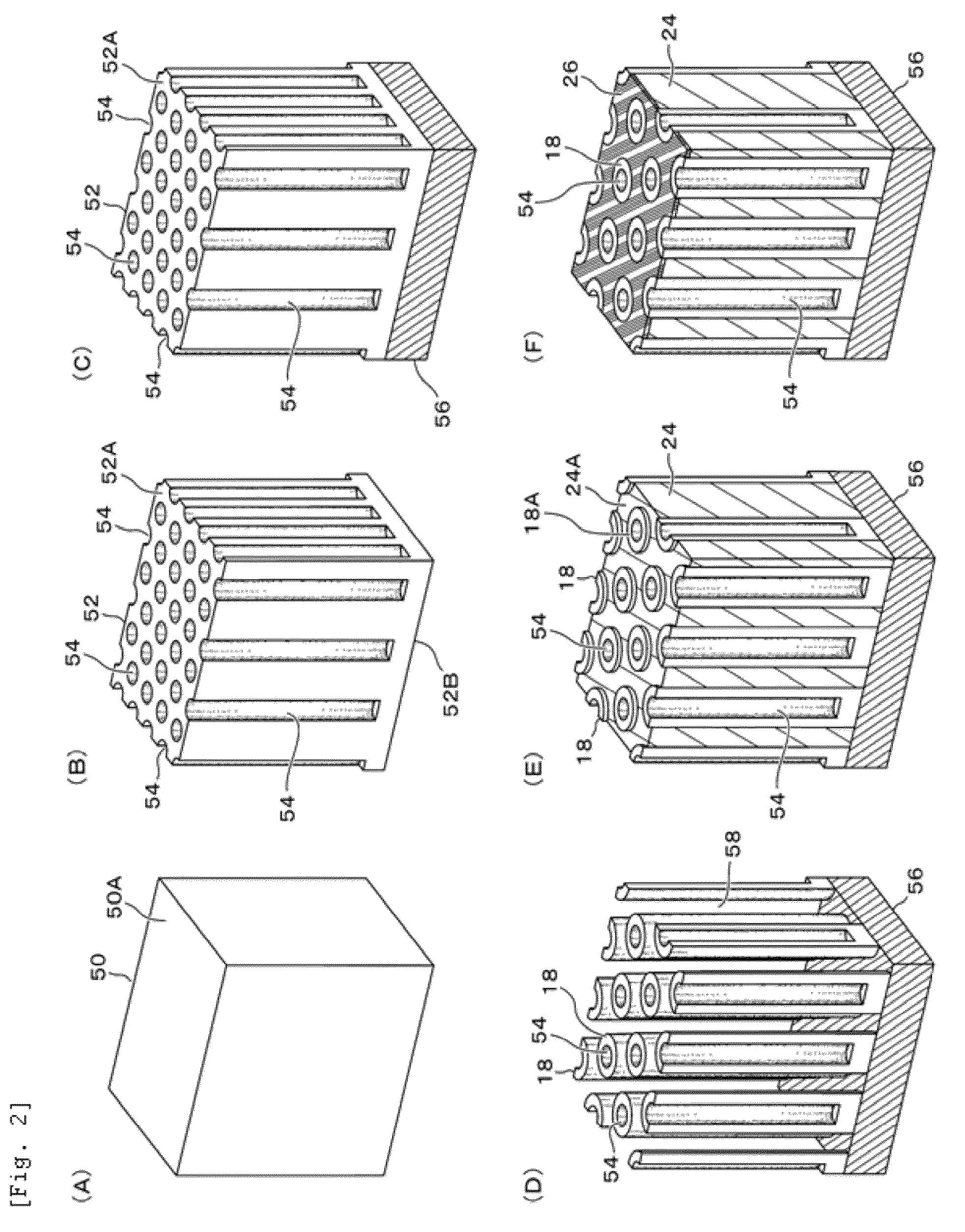

Capacitor and method of manufacturing the same

ActiveUS20090086404A1High selectivitySimple manufacturing processFixed capacitor electrodesFixed capacitor dielectricCapacitorMetal substrate

A capacitor element includes a pair of conductive layer, a plurality of first electrodes and second electrodes, and insulation caps for insulating these electrodes from the conductive layers. By anodizing a metal substrate in two stages, holes filled with the first electrodes and holes filled with the second electrodes are randomly distributed

Owner:TAIYO YUDEN KK

Sintered anode pellet treated with a surfactant for use in an electrolytic capacitor

InactiveUS7760488B2Solid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisElectrolytic capacitor

An electrolytic capacitor anode treated with a surfactant during anodic oxidation is provided. Without intending to be limited by theory, it is believed that the surfactant may lower the surface tension of an electrolyte, which inhibits the clustering of grown oxides and allows the dielectric layer to become more homogeneous and uniformly spread over the anode body. The resulting dielectric layer may thus have a substantially homogeneous thickness, smooth surface, and improved leakage current stability.

Owner:AVX CORP

Solid Electrolytic Capacitor with Improved Performance at High Voltages

ActiveUS20140022704A1Solid electrolytic capacitorsCapacitor electrolytes/absorbentsMetallurgyElectrolytic capacitor

A solid electrolytic capacitor that comprises a sintered porous anode, a dielectric layer that overlies the anode body, and a solid electrolyte overlying the dielectric layer is provided. The anode is formed from a finely divided powder (e.g., nodular or angular) having a relatively high specific charge. Despite the use of such high specific charge powders, high voltages can be achieved through a combination of features relating to the formation of the anode and solid electrolyte. For example, relatively high press densities and sintering temperatures may be employed to achieve “sinter necks” between adjacent agglomerated particles that are relatively large in size, which render the dielectric layer in the vicinity of the neck less susceptible to failure at high forming voltages.

Owner:KYOCERA AVX COMPONENTS CORP

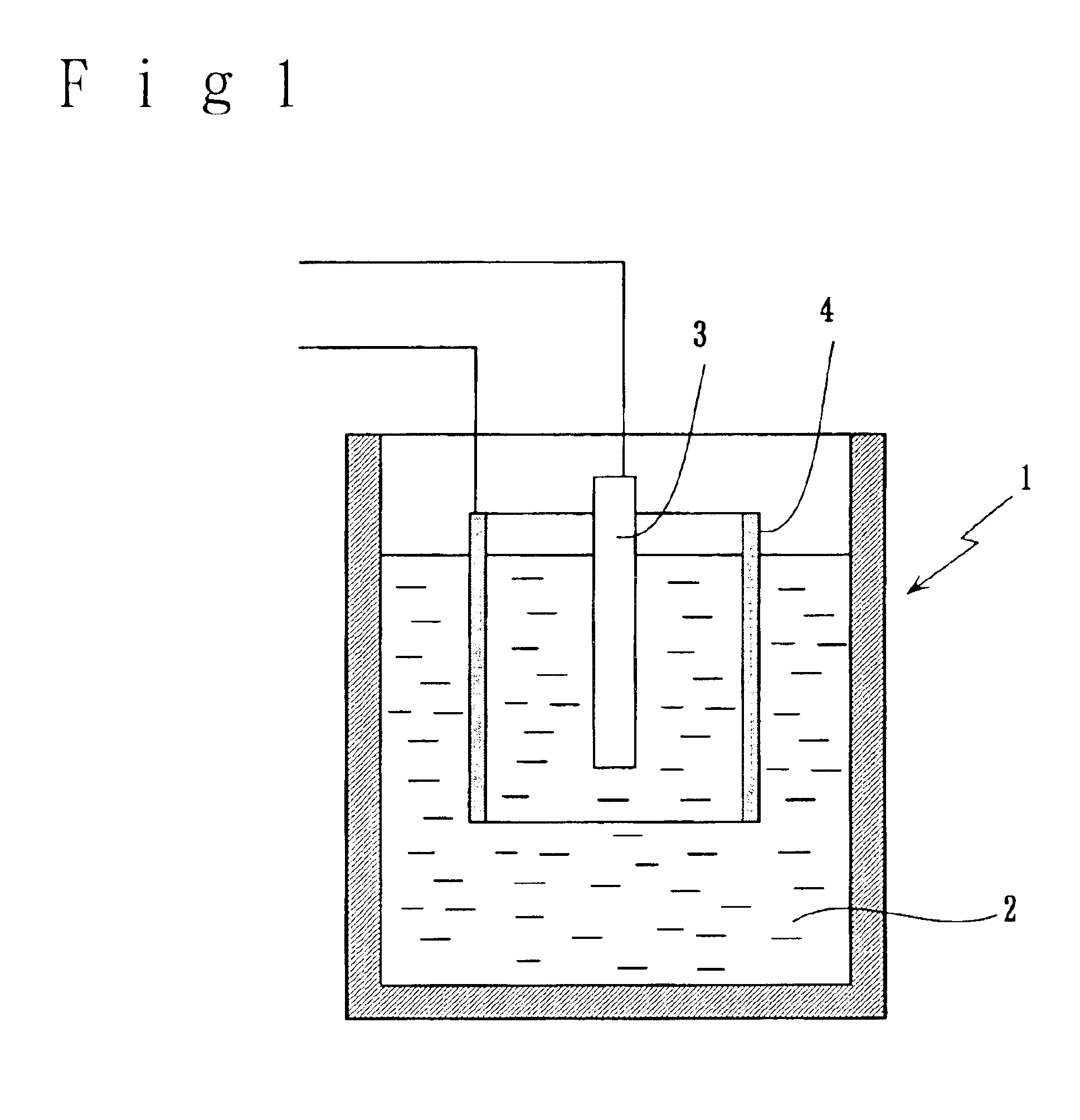

Wet electrolytic capacitor

InactiveUS20060028787A1Lower resistanceIncrease capacitanceHybrid capacitor electrolytesHybrid capacitor electrodesCapacitanceElectrolysis

The electrolytic capacitor and the electric double-layer capacitor both have difficulties to satisfy recent demands that the capacitor should have lower resistance, larger capacitance and moreover smaller size and thinner film thickness, altogether. The present invention provides a wet electrolytic capacitor which comprises a porous anode substance wherein at least a surface of a porous material made of a powder of a valve metal is an oxide film of the valve metal, a cathode formed of either an active carbon layer or a porous material made of a powder of a valve metal and an acid electrolytic solution contained between the porous anode substance and the cathode electrode.

Owner:TOKIN CORP

Production method of a capacitor

ActiveUS20070002526A1Excellent ESR performanceIncrease capacitanceHybrid capacitor electrolytesSolid electrolytic capacitorsCapacitanceDielectric layer

The present invention relates to a method for producing a capacitor comprising, as one electrode, an electric conductor having formed on the surface thereof a dielectric layer and, as the other electrode, a semiconductor layer formed on the electric conductor by energization using the electric conductor as the anode, wherein fine protrusions are formed on the dielectric layer before energization; a capacitor produced by the method thereof having a good capacitance appearance factor and a low ESR; and an electronic circuit and an electronic device using the capacitor.

Owner:SHOWA DENKO KK

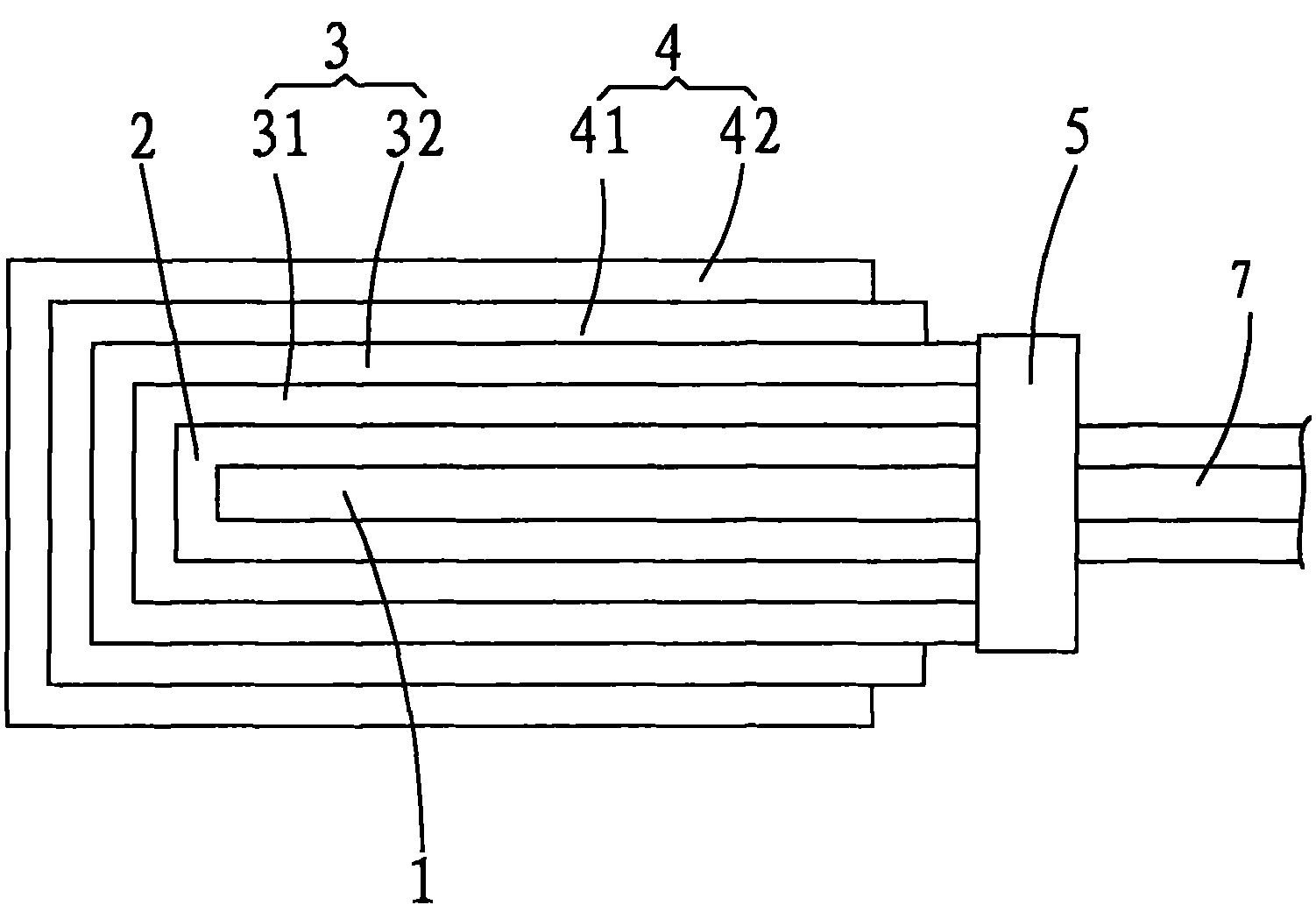

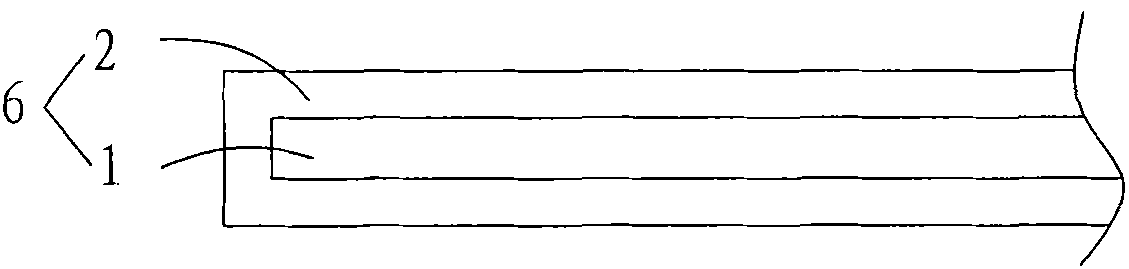

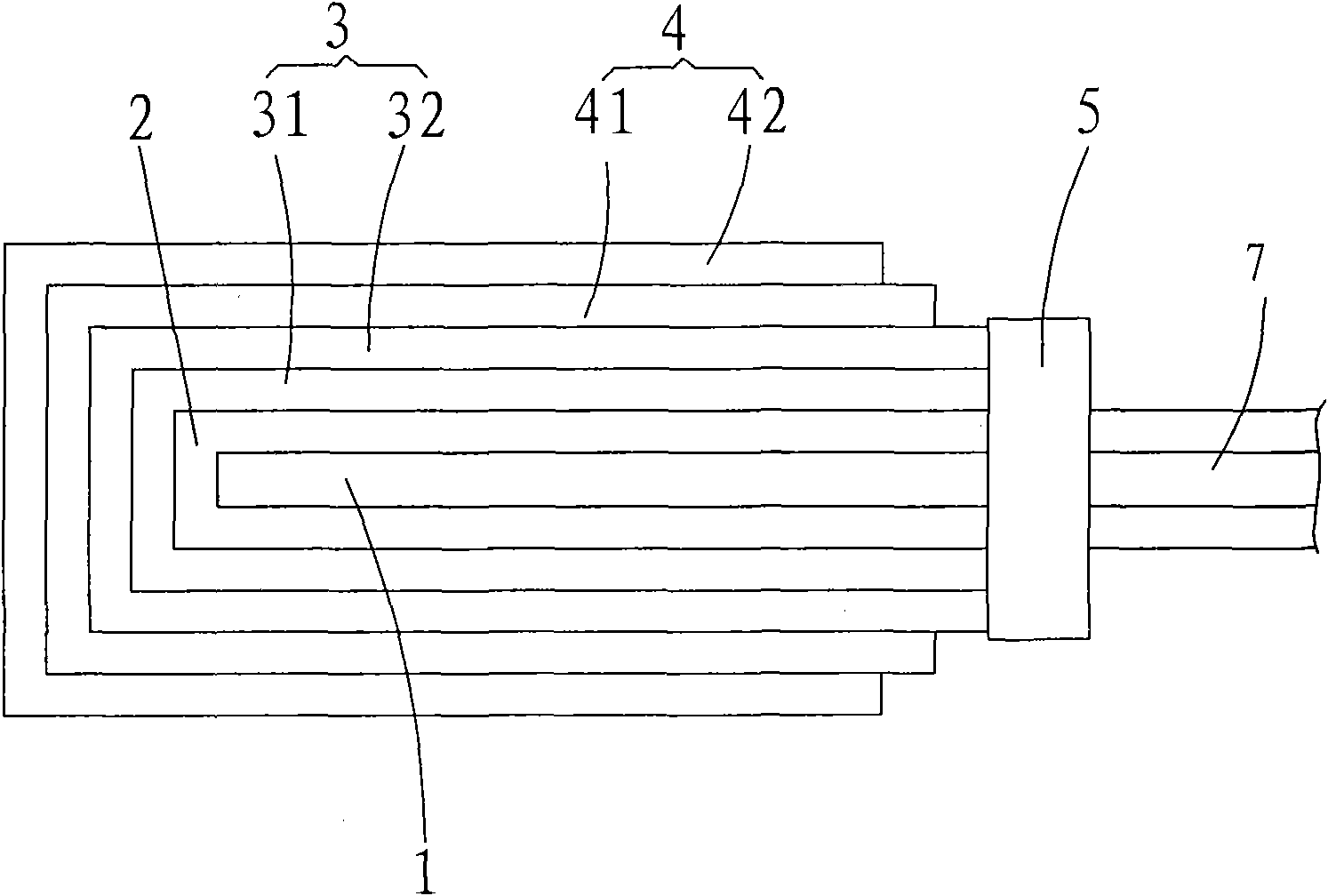

Aluminium electrolytic capacitor specially used in LED driving power supply and manufacturing method thereof

ActiveCN102222568AImprove high temperature resistanceExtended service lifeCapacitor terminalsCapacitor electrodesElectrolysisEngineering

The invention is directed to the technological field of electrolytic capacitor. The invention concretely discloses an aluminium electrolytic capacitor specially used in an LED driving power supply and a manufacturing method thereof. The aluminium electrolytic capacitor comprises an aluminium housing, a positive guide pin, an anode foil, a negative guide pin, a cathode foil and an electrolytic paper. The electrolytic paper is provided between the anode foil and the cathode foil and is reeled into a core bag with the anode foil and the cathode foil. A cover body is sleeved on the core bag and is arranged in the aluminium housing. A plaster foil is provided at the nailing position between the negative guide pin and the cathode foil. The paster foil covers the nailing hole of the cathode foil and the negative guide pin. The anode foil is highly overpressure resistant. The cathode foil is added with non-active metals. The electrolytic paper has a high tightness and a low thickness. The aluminium electrolytic capacitor is characterized by strong temperature resistance performance, long service life and miniaturized structure. The aluminium electrolytic capacitor uses a special-purpose high scintillation voltage electrolyte to ensure a long high temperature load life and a high temperature resistance wave current capability of the aluminium electrolytic capacitor.

Owner:ZHAOQING BERYL ELECTRONICS TECH

Solid Electrolytic Capacitor with Improved Performance at High Temperatures and Voltages

A capacitor assembly that is capable of exhibiting good electrical properties even under a variety of conditions is provided. More particularly, the capacitor contains a capacitor element that includes a porous anode body that contains a valve metal compound, a dielectric that overlies the anode body and includes an oxide of the valve metal compound, a solid electrolyte that overlies the dielectric, wherein the solid electrolyte includes at least one conductive polymer layer that contains a sulfonyl ion, and an organofunctional silane that is bonded to the oxide of the dielectric and is capable of bonding to the sulfonyl ion of the conductive polymer layer.

Owner:KYOCERA AVX COMPONENTS CORP

Protective film and composition for preparing the same, slurry, and electrical storage device

ActiveUS20140272523A1Lower internal resistanceImprove featuresHybrid capacitor separatorsElectrode manufacturing processesTectorial membraneSlurry

An electrical storage device includes a cathode, an anode, a protective film that is provided between the cathode and the anode, and an electrolyte solution, the protective film including a polymer that includes a repeating unit derived from a fluorine-containing monomer, and a repeating unit derived from an unsaturated carboxylic acid.

Owner:ENEOS MATERIALS CORP

Capacitor and method of manufacturing the same

ActiveUS20090195963A1Increase capacitance densityMetal material is greatly improvedFixed capacitor electrodesFixed capacitor dielectricCapacitorMaterials science

A capacitor includes a pair of electrically conductive layers; a plurality of substantially or nearly tubular dielectric materials disposed between the pair of electrically conductive layers formed of anodic oxide of metal; first electrodes which are filled in hollow portions of the dielectric materials and connected to one of the electrically conductive layers; and a second electrode that is filled in voids between the respective dielectric materials and connected to the other electrically conductive layer.

Owner:TAIYO YUDEN KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com