Aluminium electrolytic capacitor specially used in LED driving power supply and manufacturing method thereof

An aluminum electrolytic capacitor, LED driving technology, applied in the direction of electrolytic capacitors, capacitors, capacitor terminals, etc., can solve the problems of LED driving power supply heating, poor product life characteristics, steam drum and other problems, to improve high temperature performance, long service life, Effect of high ripple current resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

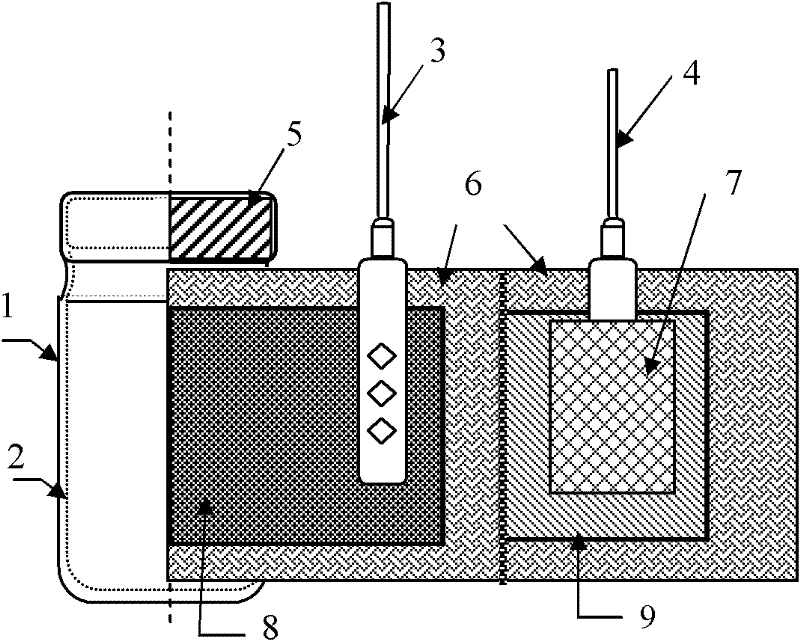

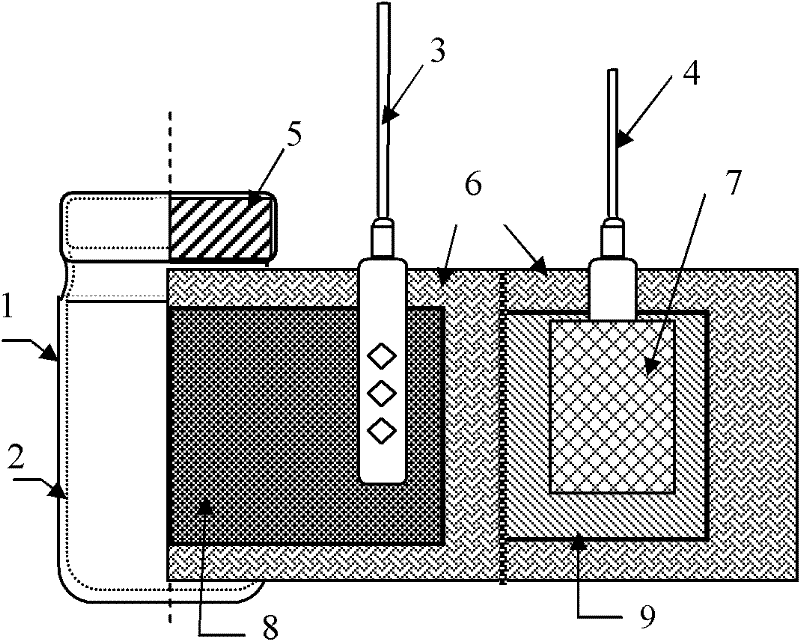

Image

Examples

Embodiment 1

[0031] LED驱动电源专用铝电解电容器的制作方法,具体步骤如下

[0032] (1)选材并裁切:选用高耐压的阳极箔,选用高紧度低厚度的电解纸,选用添加有非活性金属的阴极箔,并对阳极箔、阴极箔和电解纸进行裁切;

[0033] (2)钉绕:在阴极箔与负导针的钉接处加贴有一片贴箔覆盖住钉接孔处不平整的凸起部分;

[0034] (3)循环式抽真空、加压含浸:将芯包浸入电解液,周期性对其加载负压和正压,使电解液充分浸渍到电解纸上;

[0035] 电解液包括主溶剂、辅助溶剂、主溶质、辅助溶质、闪火电压提升剂及消氢剂,所述主溶剂为乙二醇、γ-丁内酯、N,N-二甲基酰胺、乙二醇甲醚中的一种或任意多种;所述辅助溶剂为去离子水;所述主溶质为癸二酸铵、癸烷二羧酸或乙醇胺的一种或两种;所述辅助溶质为甲酸铵;所述闪电压提升剂为次亚磷酸,甘露醇,磷酸二氢铵的一种或任意多种;所述消氢剂为对硝基苯酚或对硝基苯甲醇。

[0036] 上述各组分按重量百分比的配方如下表所示:

[0037] main solvent

61.1%

Auxiliary solvent

15%

main solute

17.3%

Auxiliary solute

0.5%

Flash voltage booster

1.0%

Hydrogen remover

5.1%

[0038] (Table I)

[0039] (4)组装,将浸渍好的芯包与铝壳和盖体组成裸品电容器;

[0040] (5)套管,将裸品电容器套上绝缘套管;

[0041] (6)老化;

[0042] (7)特性测试。

Embodiment 2

[0044] LED驱动电源专用铝电解电容器的制作方法,具体步骤如下

[0045] (1)选用高耐压的阳极箔,选用高紧度低厚度的电解纸,选用添加有非活性金属的阴极箔,并对阳极箔、阴极箔和电解纸进行裁切;

[0046] (2)钉绕,在阴极箔与负导针的钉接处加贴有一片贴箔覆盖住钉接孔处不平整的凸起部分;

[0047] (3)循环式抽真空、加压含浸,将芯包浸入电解液,周期性对其加载负压和正压,使电解液充分浸渍到电解纸上;

[0048] 电解液包括主溶剂、辅助溶剂、主溶质、辅助溶质、闪火电压提升剂及消氢剂,所述主溶剂为乙二醇、γ-丁内酯、N,N-二甲基酰胺、乙二醇甲醚中的一种或任意多种;所述辅助溶剂为去离子水;所述主溶质为癸二酸铵、癸烷二羧酸或乙醇胺的一种或两种;所述辅助溶质为甲酸铵;所述闪电压提升剂为次亚磷酸,甘露醇,磷酸二氢铵的一种或任意多种;所述消氢剂为对硝基苯酚或对硝基苯甲醇。

[0049] 上述各组分按重量百分比的配方如下表所示:

[0050] main solvent

70.9%

Auxiliary solvent

5%

main solute

8.5%

Auxiliary solute

10%

Flash voltage booster

3.6%

Hydrogen remover

2.0%

[0051] (Table II)

[0052] (4)组装,将浸渍好的芯包与铝壳和盖体组成裸品电容器;

[0053] (5)套管,将裸品电容器套上绝缘套管;

[0054] (6)老化;

[0055] (7)特性测试。

Embodiment 3

[0057] LED驱动电源专用铝电解电容器的制作方法,具体步骤如下

[0058] (1)选用高耐压的阳极箔,选用高紧度低厚度的电解纸,选用添加有非活性金属的阴极箔,并对阳极箔、阴极箔和电解纸进行裁切;

[0059] (2)钉绕,在阴极箔与负导针的钉接处加贴有一片贴箔覆盖住钉接孔处不平整的凸起部分;

[0060](3) Cyclic vacuuming, pressurized impregnation, immersing the core pack in the electrolyte, periodically applying negative pressure and positive pressure to it, so that the electrolyte is fully impregnated on the electrolytic paper;

[0061] The electrolytic solution includes a main solvent, an auxiliary solvent, a main solute, an auxiliary solute, a flash voltage booster and a hydrogen remover, and the main solvent is ethylene glycol, γ-butyrolactone, N, N-dimethylamide, ethyl alcohol One or more of glycol methyl ethers; the auxiliary solvent is deionized water; the main solute is one or both of ammonium sebacate, decane dicarboxylic acid or ethanolamine; the auxiliary solute It is ammonium formate; the flash voltage raising agent is one or more of hypophosphorous acid, mannitol, and ammonium dihydrogen phosphate;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com