Solid tantalum capacitor and its manufacturing process

A tantalum capacitor, solid-state technology, applied in the field of solid-state tantalum capacitors and their manufacturing processes, can solve the problems of high ESR, unsatisfactory use reliability, and low capacity, etc. The effect of large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

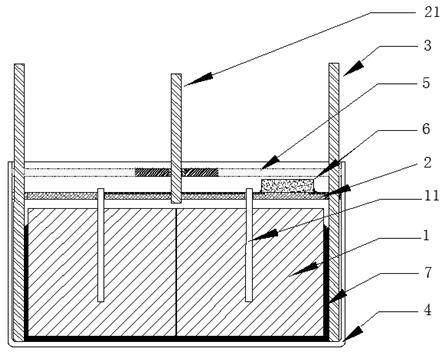

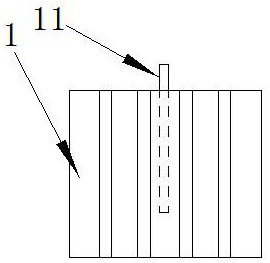

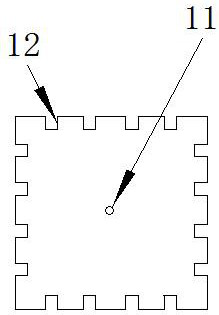

[0041] Combine below Figure 1 to Figure 4 The embodiments of the present invention are described in detail.

[0042]A solid tantalum capacitor, including a tantalum capacitor body, a tantalum capacitor body including a tantalum core 1, an anode lead-out plate 2 connected to a tantalum wire 11 embedded in the tantalum core 1, a cathode lead 3, a metal shell 4 and a glass powder insulator 5, a plurality of The tantalum core 1 is sequentially fixed in the metal shell 4 by tin solder or conductive silver paste, and the metal shell 4 is encapsulated by the glass powder insulator 5, and the characteristic is that the anode lead-out plate 2 is installed in the metal shell 4 and is located between the glass powder insulator 5 and the tantalum core. 1, the anode wire 21 of the anode lead-out plate 2 passes through the glass powder insulator 5 as the anode lead of the capacitor, the cathode lead 3 is inserted into the metal shell 4 and welded with the glass powder insulator 5 and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com