Patents

Literature

382 results about "Tantalum capacitor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tantalum electrolytic capacitor is an electrolytic capacitor, a passive component of electronic circuits. It consists of a pellet of porous tantalum metal as an anode, covered by an insulating oxide layer that forms the dielectric, surrounded by liquid or solid electrolyte as a cathode. Because of its very thin and relatively high permittivity dielectric layer, the tantalum capacitor distinguishes itself from other conventional and electrolytic capacitors in having high capacitance per volume (high volumetric efficiency) and lower weight.

Tantalum powder for capacitors

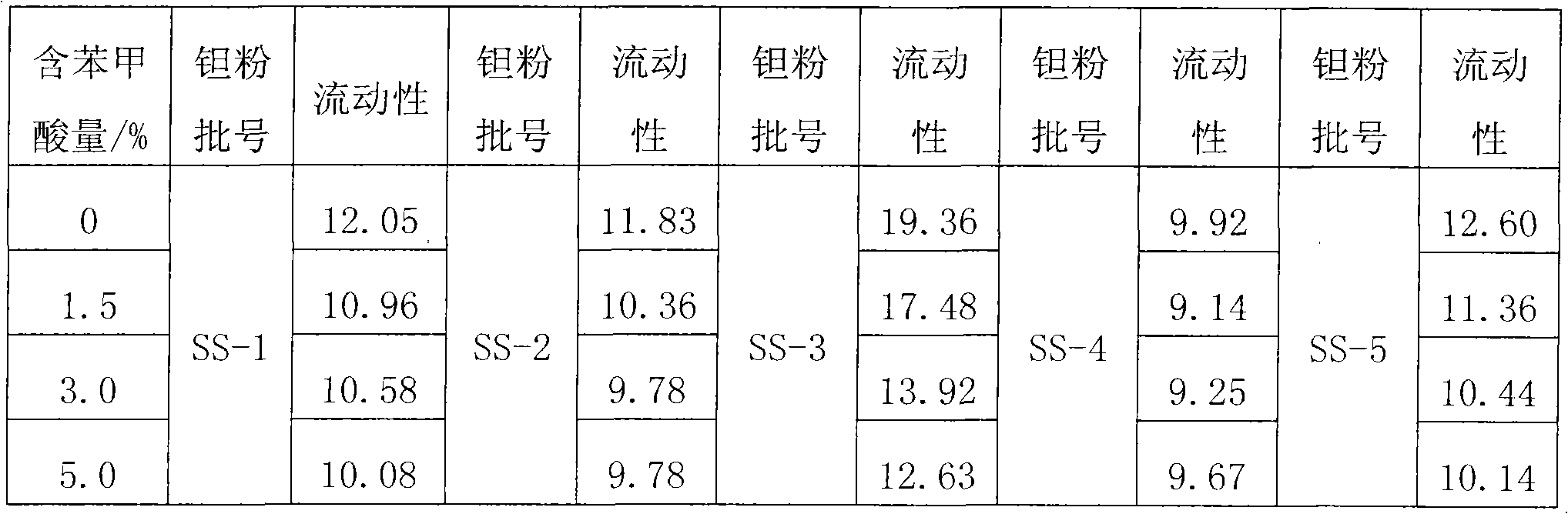

InactiveUS6689187B2Suitable cohesive strengthUniform porosityElectrolytic capacitorsTransportation and packagingPorosityCapacitance

The tantalum powder for capacitors of the present invention has a specific surface area SB as determined by the BET method of 1.3 m<2> / g or more, and an SB / SF ratio between the specific surface area SB as determined by the BET method and the specific surface area SF determined by the FSS method of 4 to 10. This tantalum powder not only has a large specific surface area SB, but also has suitable cohesive strength and uniform porosity.Consequently, a solid state electrolytic capacitor having high capacitance and low ESR can be obtained by providing with a capacitor anode formed from a sintered body of this tantalum powder. In addition, whether or not this tantalum powder is suitable for the production of a tantalum capacitor having high capacitance and low ESR can be determined easily and reliably by evaluating the tantalum powder using the specific surface area SB as determined by the BET method and the SB / SF ratio between SB and the specific surface area SF determined by the FSS method.

Owner:GLOBAL ADVANCED METALS JAPAN

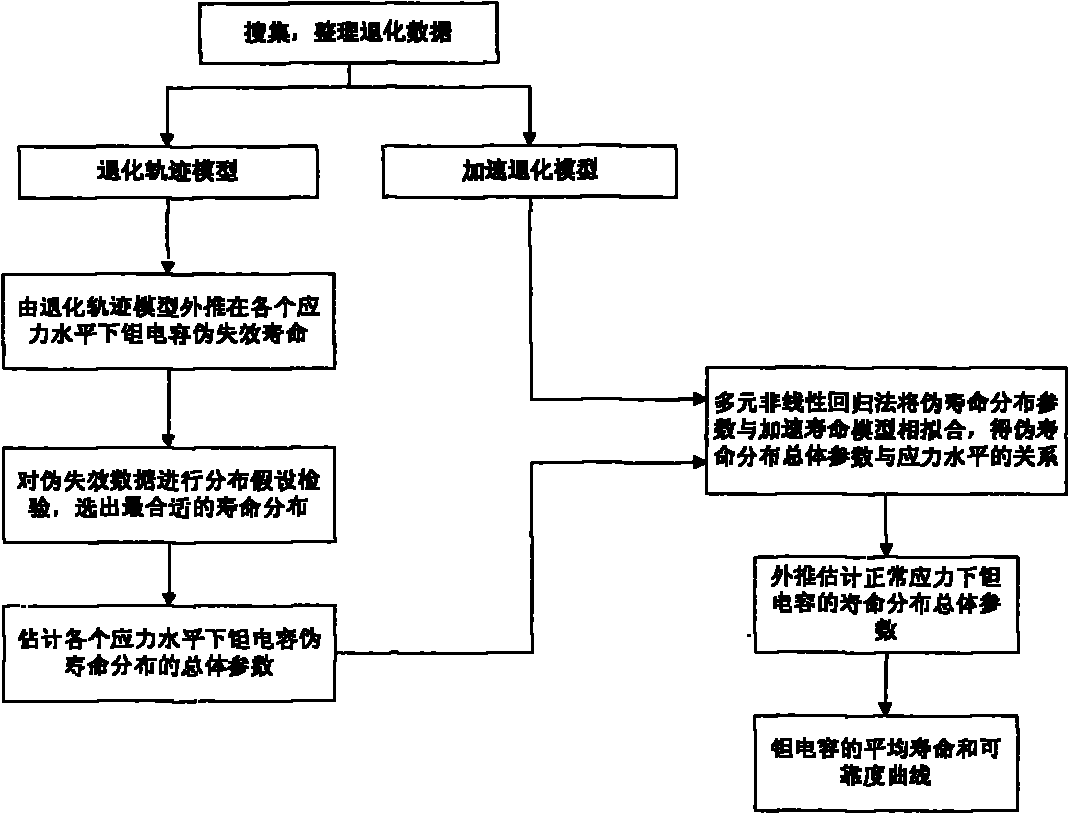

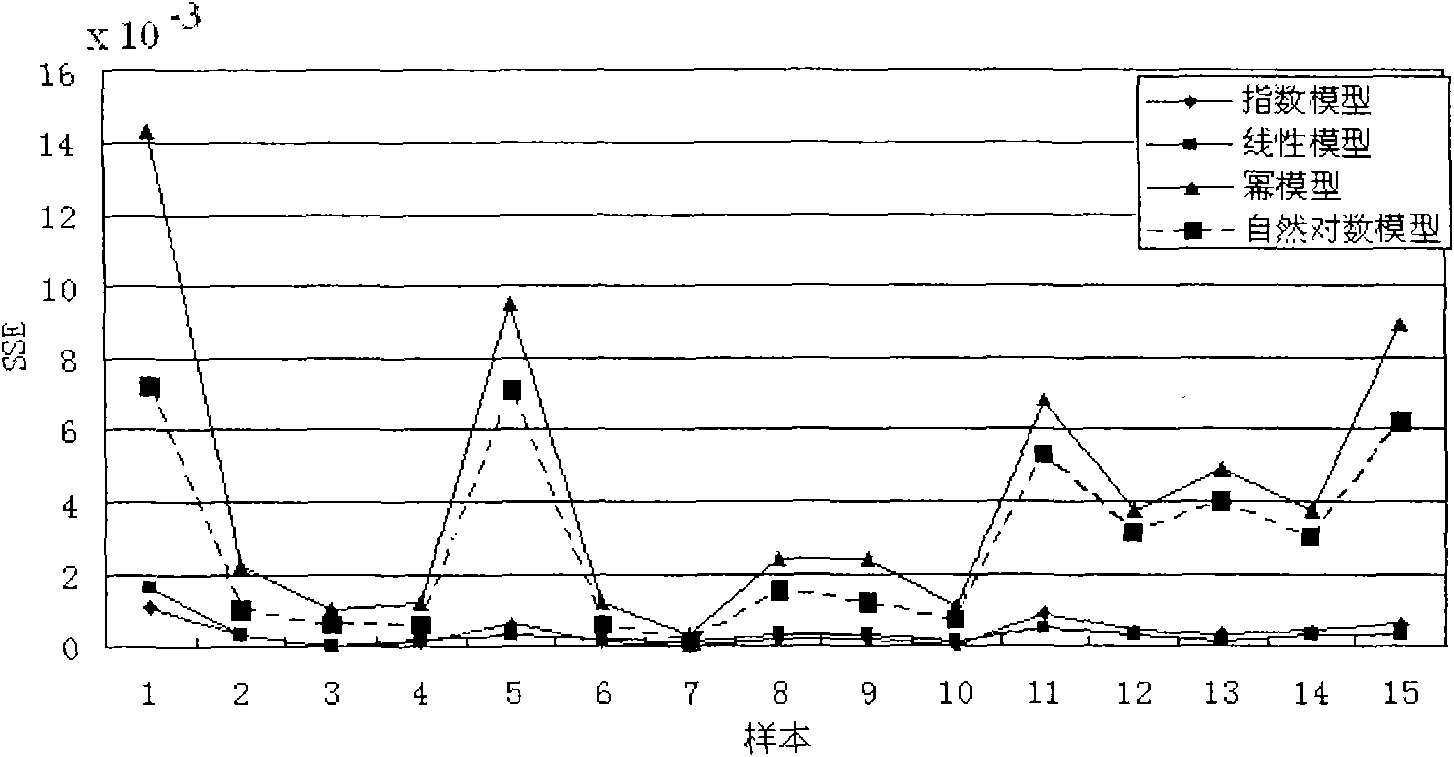

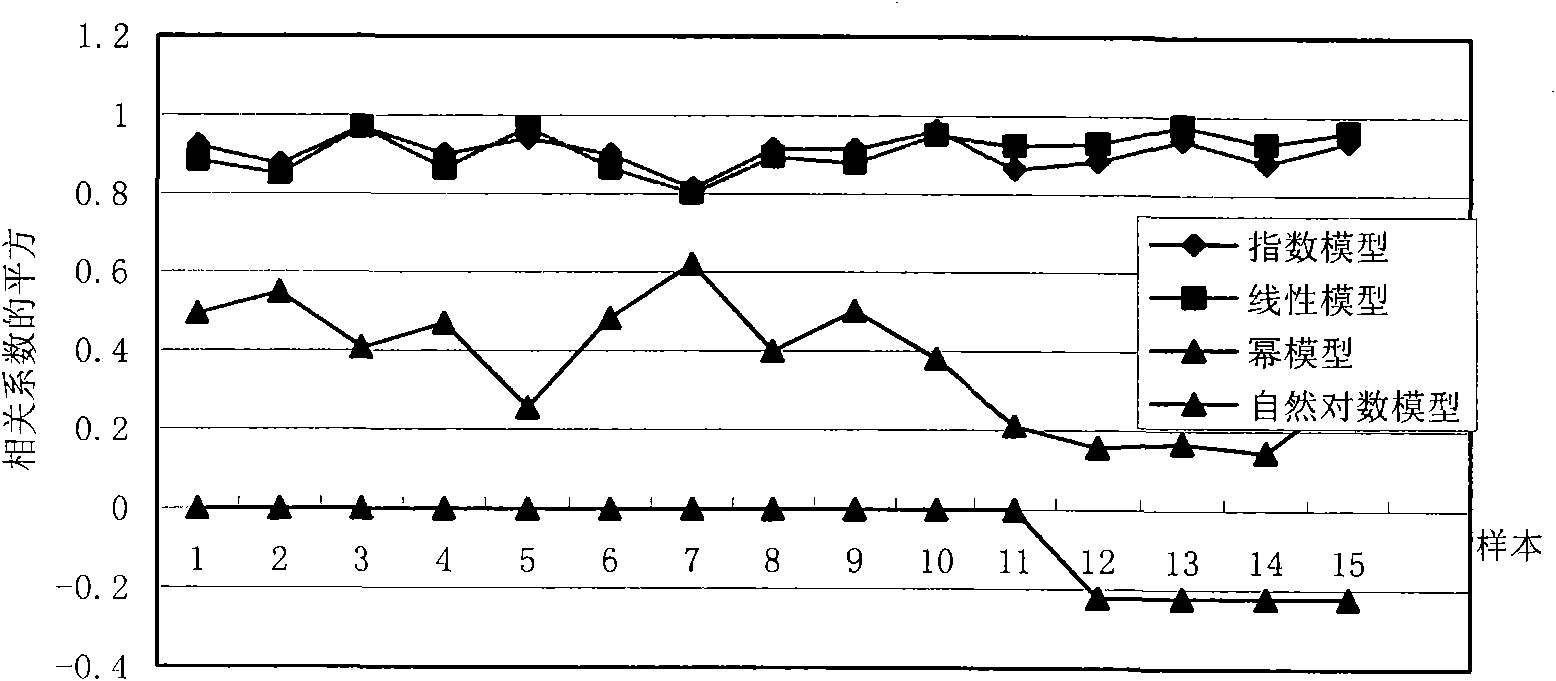

Method for predicting life of solid tantalum electrolytic capacitor

InactiveCN102033182ASolve the problem of longevityAddressing Adaptive IssuesElectrical testingCapacitanceHypothesis

The invention relates to a method for predicting the life of a solid tantalum electrolytic capacitor, which comprises the following steps of: 1, collecting current degradation data; 2, determining a degradation track model and a degradation accelerating model; 3, extrapolating the degradation track model to obtain the pseudo-failure life of each sample; 4, performing hypothesis test of pseudo-life distribution and the estimation of unknown parameters; 5, determining the relation of population parameters of the pseudo-life distribution and a stress level; 6 estimating the population parameters of the life distribution of a tantalum capacitor under the normal stress by extrapolating; and 7, determining the average life and reliability curve of the tantalum capacitor. The method has novel concept and simple programs and does not need life tests, the test time can be shorted, the test cost can be saved, and the problem of disharmony between the prediction of the conventional life and engineering is solved, so the method has wide application prospect in the technical field of life prediction.

Owner:BEIHANG UNIV

Tantalum powder for capacitors

InactiveUS20020050185A1Suitable cohesive strengthUniform porosityElectrolytic capacitorsTransportation and packagingPorosityCapacitance

The tantalum powder for capacitors of the present invention has a specific surface area SB as determined by the BET method of 1.3 m2 / g or more, and an SB / SF ratio between the specific surface area SB as determined by the BET method and the specific surface area SF determined by the FSS method of 4 to 10. This tantalum powder not only has a large specific surface area SB, but also has suitable cohesive strength and uniform porosity. Consequently, a solid state electrolytic capacitor having high capacitance and low ESR can be obtained by providing with a capacitor anode formed from a sintered body of this tantalum powder. In addition, whether or not this tantalum powder is suitable for the production of a tantalum capacitor having high capacitance and low ESR can be determined easily and reliably by evaluating the tantalum powder using the specific surface area SB as determined by the BET method and the SB / SF ratio between SB and the specific surface area SF determined by the FSS method.

Owner:GLOBAL ADVANCED METALS JAPAN

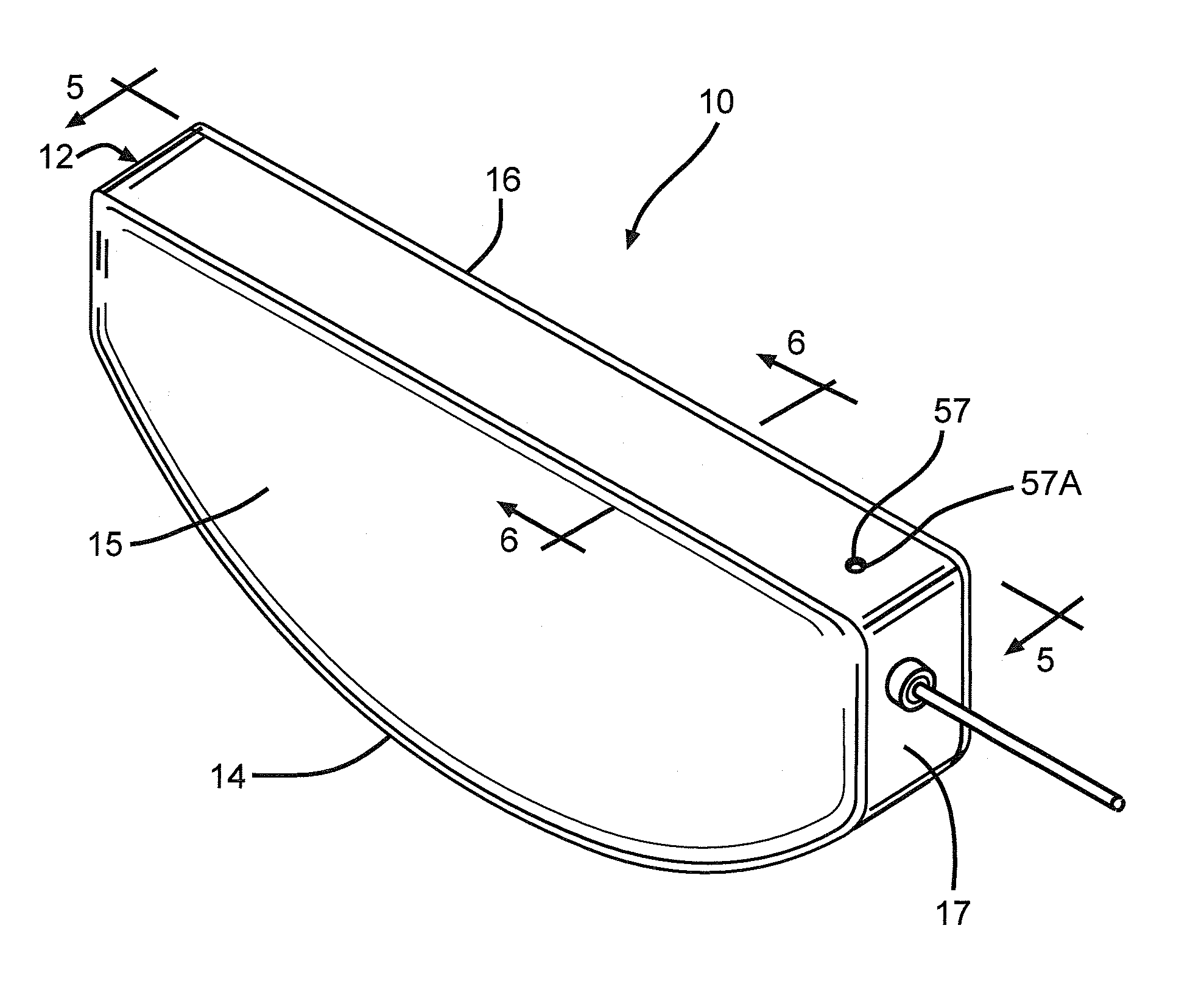

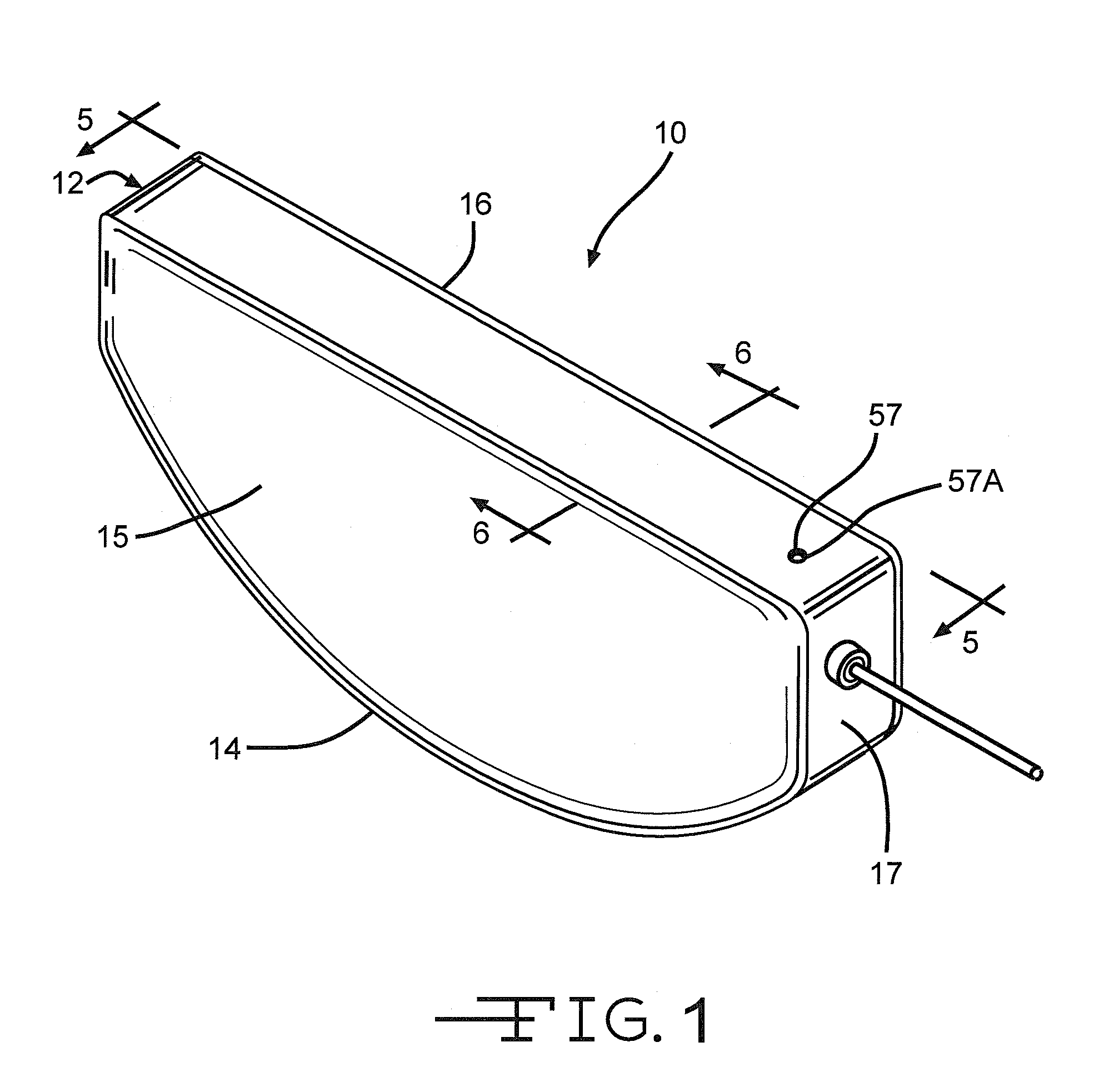

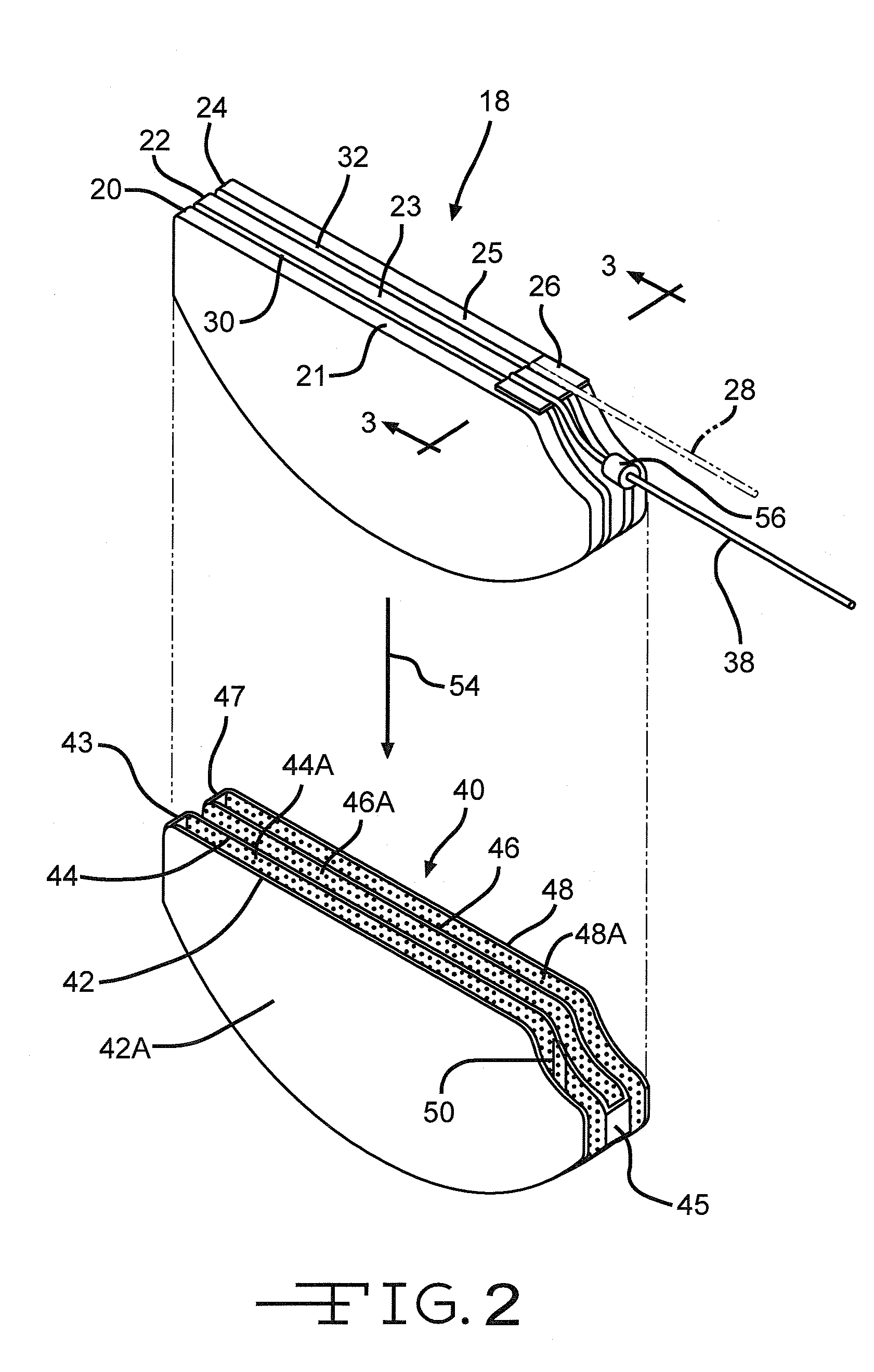

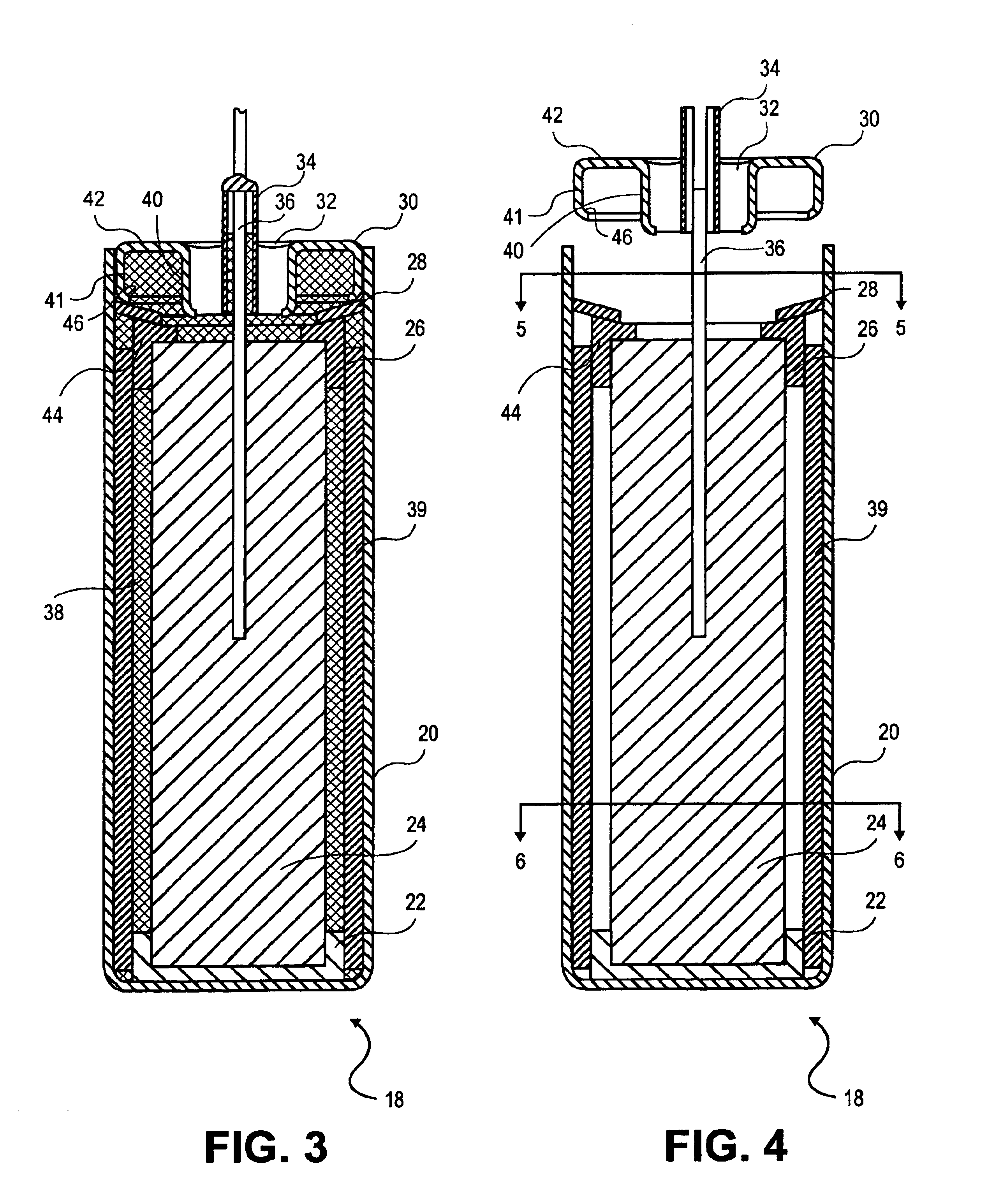

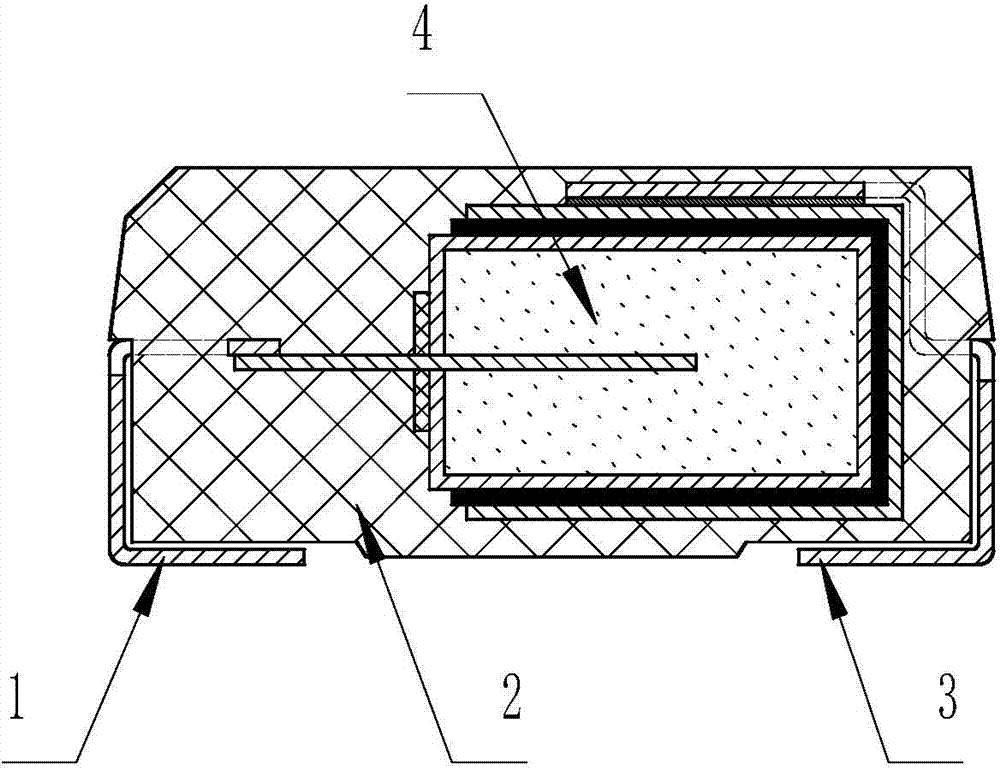

Wet tantalum capacitor with multiple anode connections

A capacitor assembly comprising a casing, an anode pack housed within the casing and comprising two or more anode pellets of anode active material electrically connected to each other by a bridge, and a cathode comprised of cathode current collectors including major faces with cathode active material provided thereupon is described. The bridge, which spans between sidewalls of the anode pellets, helps maintain them in a parallel alignment. The bridge is also a convenient location to connect the feedthrough wire that exits the casing through a glass-to-metal seal. The cathode current collectors are disposed between adjacent anode pellets and are electrically connected to each other and to the casing. A feedthrough wire electrically connected to the anode pack extends outside the casing in electrical isolation there from. An electrolyte is provided to activate the anode and the cathode.

Owner:WILSON GREATBATCH LTD

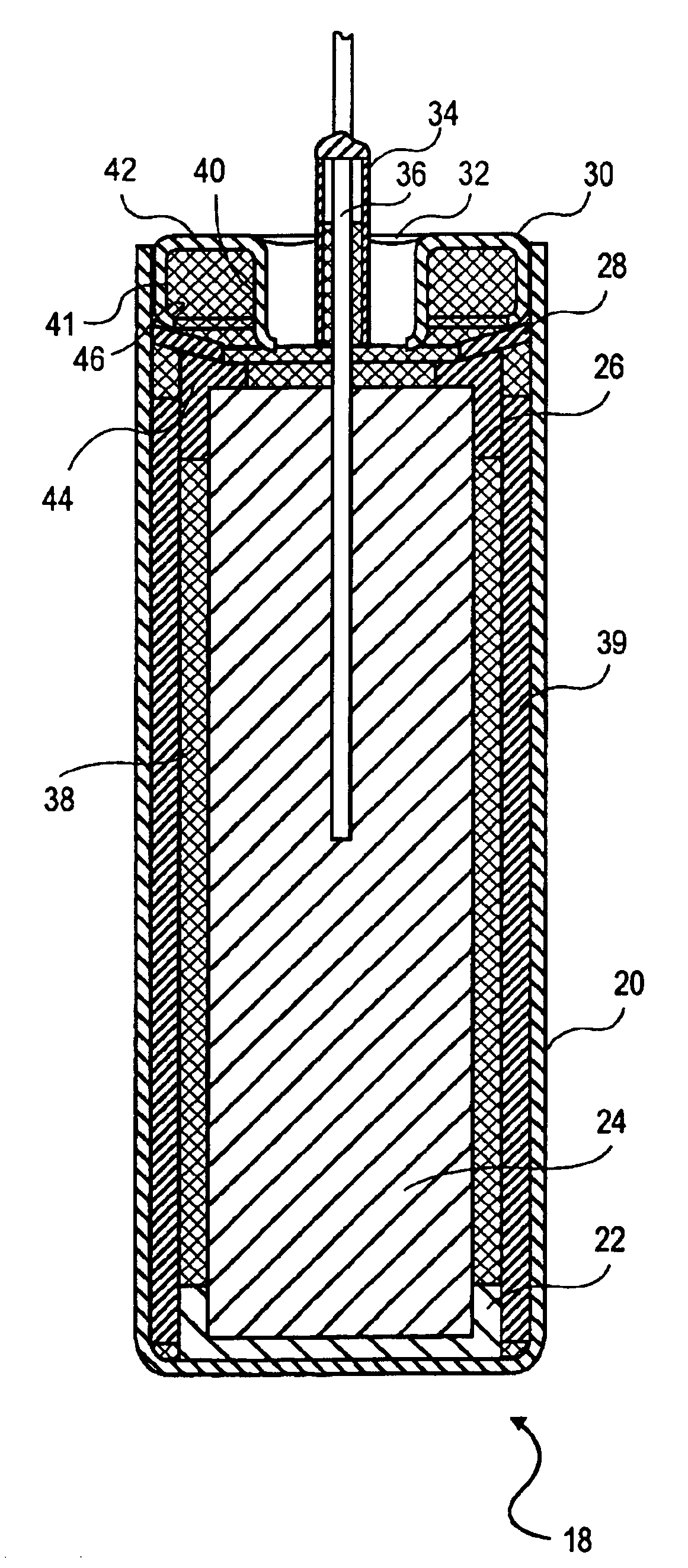

Tantalum capacitor case with increased volumetric efficiency

ActiveUS6952339B1Easy to manufactureEasy to adaptClosuresLiquid electrolytic capacitorsTantalum capacitorElectrolyte

A capacitor and a method for assembling a capacitor. A capacitor is assembled from a case, which contains an anode that is electrically insulated from the case by isolators. A washer is placed above the anode. This washer transfers force from a capacitor cap to the isolators and anode, securing the anode in place. A cap is placed on the case. The cap may be shaped as a toroid with an outer and an inner annular wall. The annular walls may meet at the top and have an opening at the bottom creating a cap cavity in order to store electrolyte or other materials in the cap. The cap also supports a glass seal that insulates the lead tube and lead wire coming from the anode. Once assembled, the capacitor is filled with electrolyte. A weld extends around the cap to secure the cap to the case. The weld may be administered from the top of the capacitor.

Owner:TANTALUM PELLET CO LLC

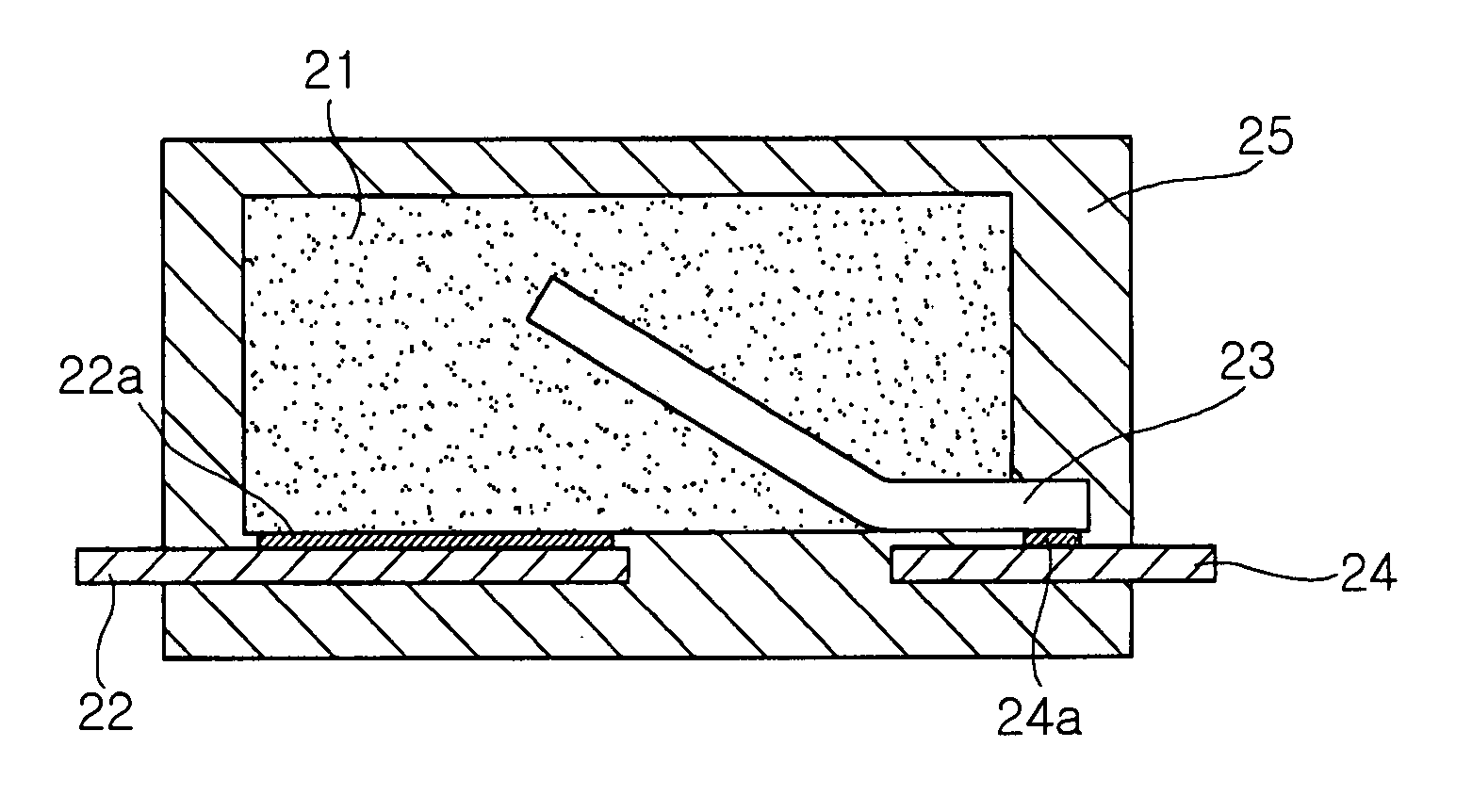

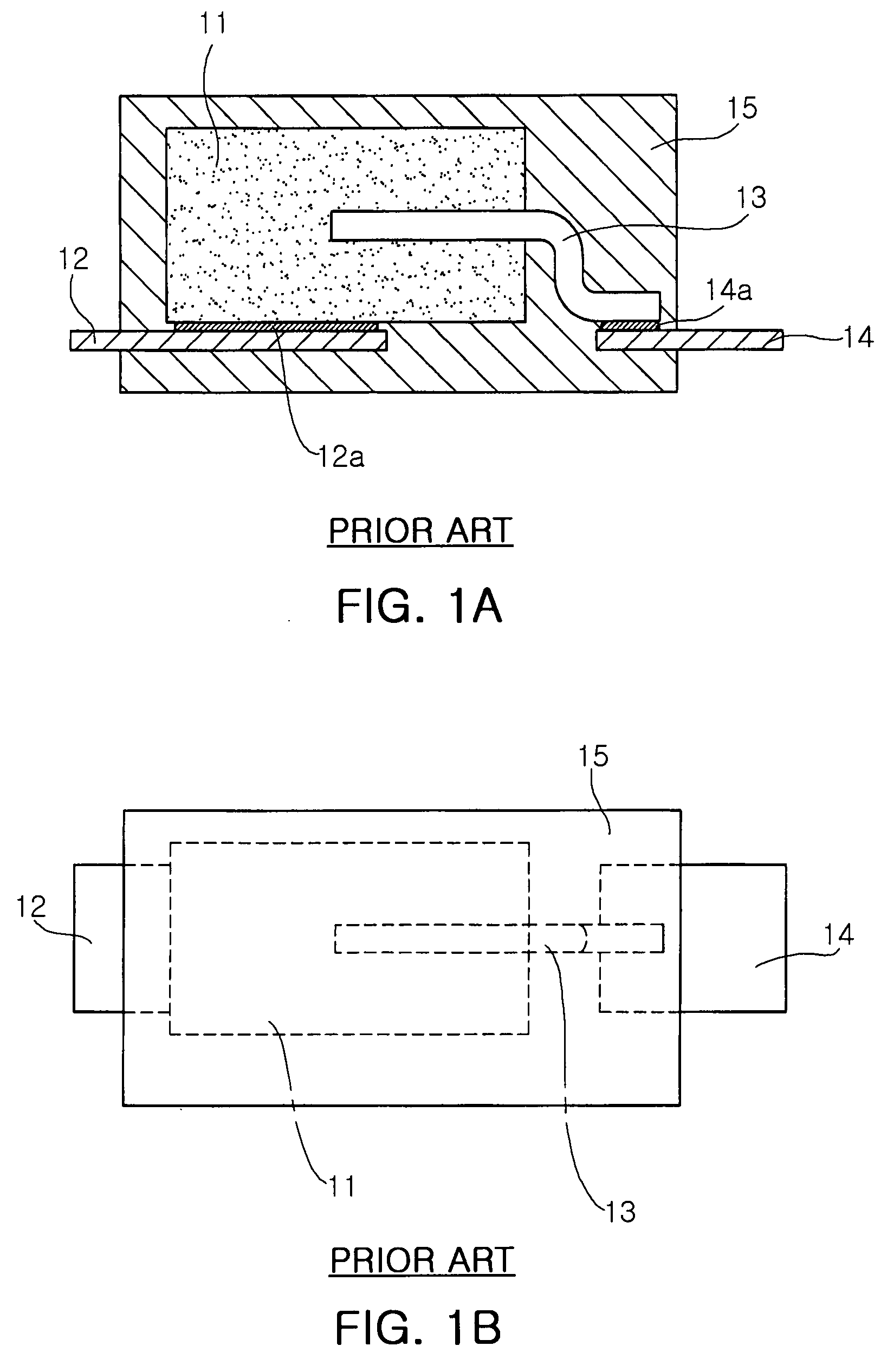

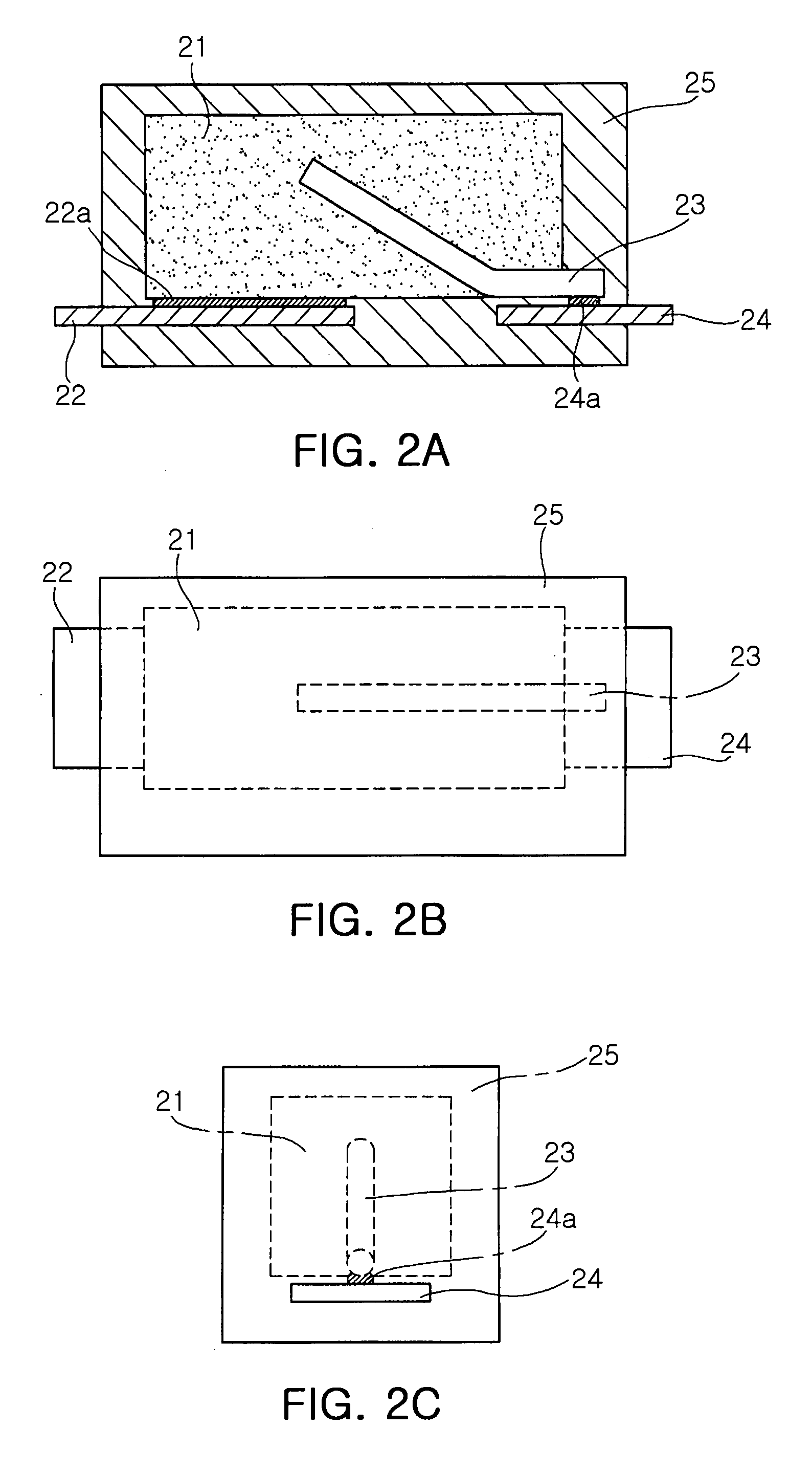

Tantalum capacitor

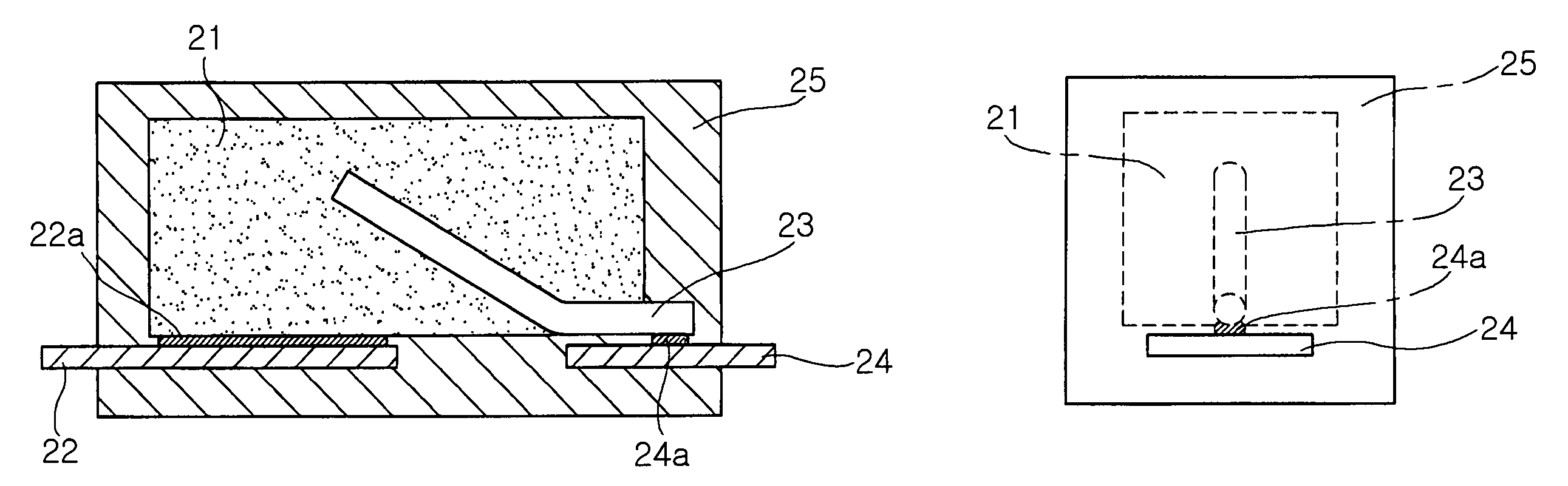

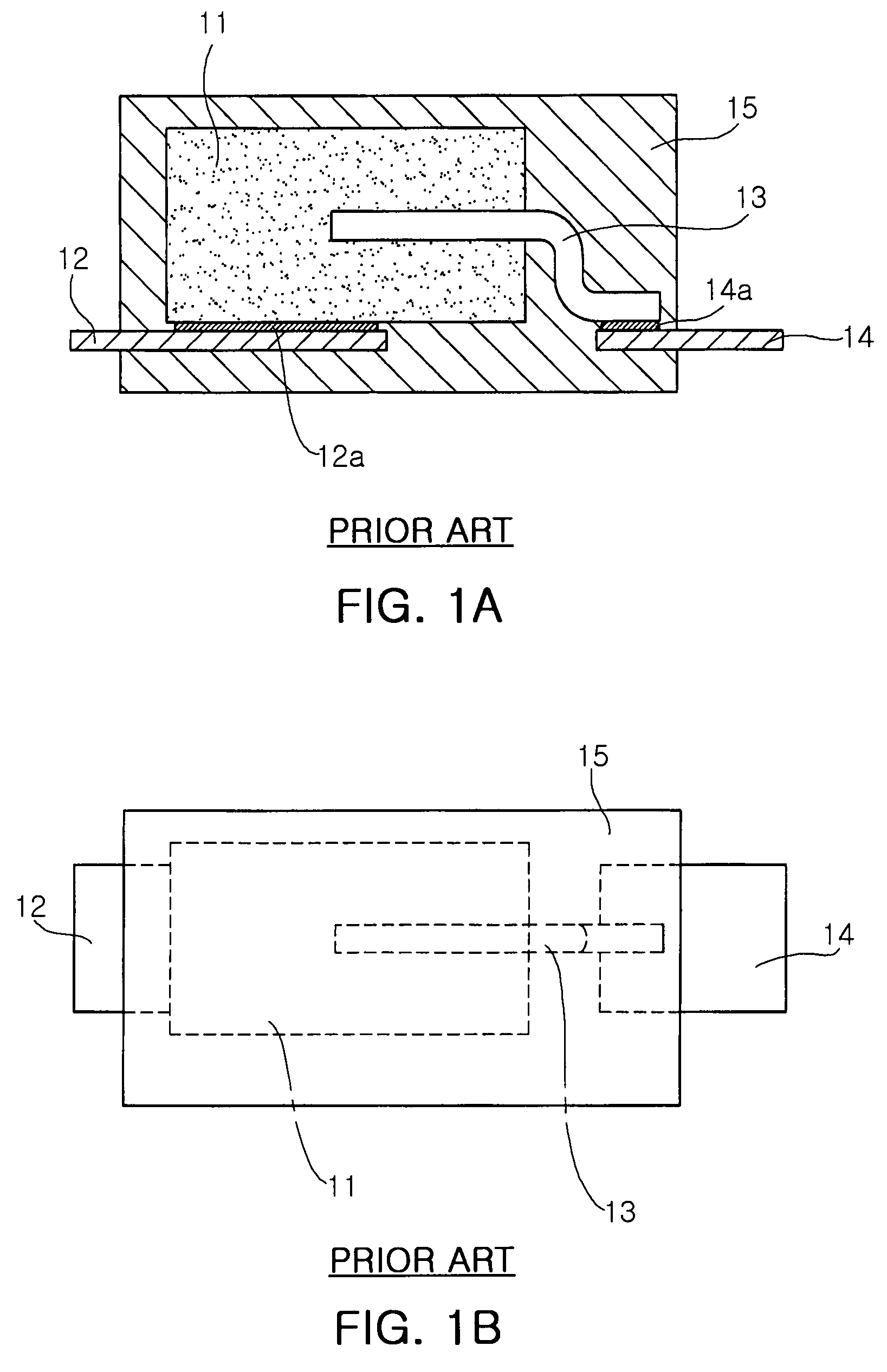

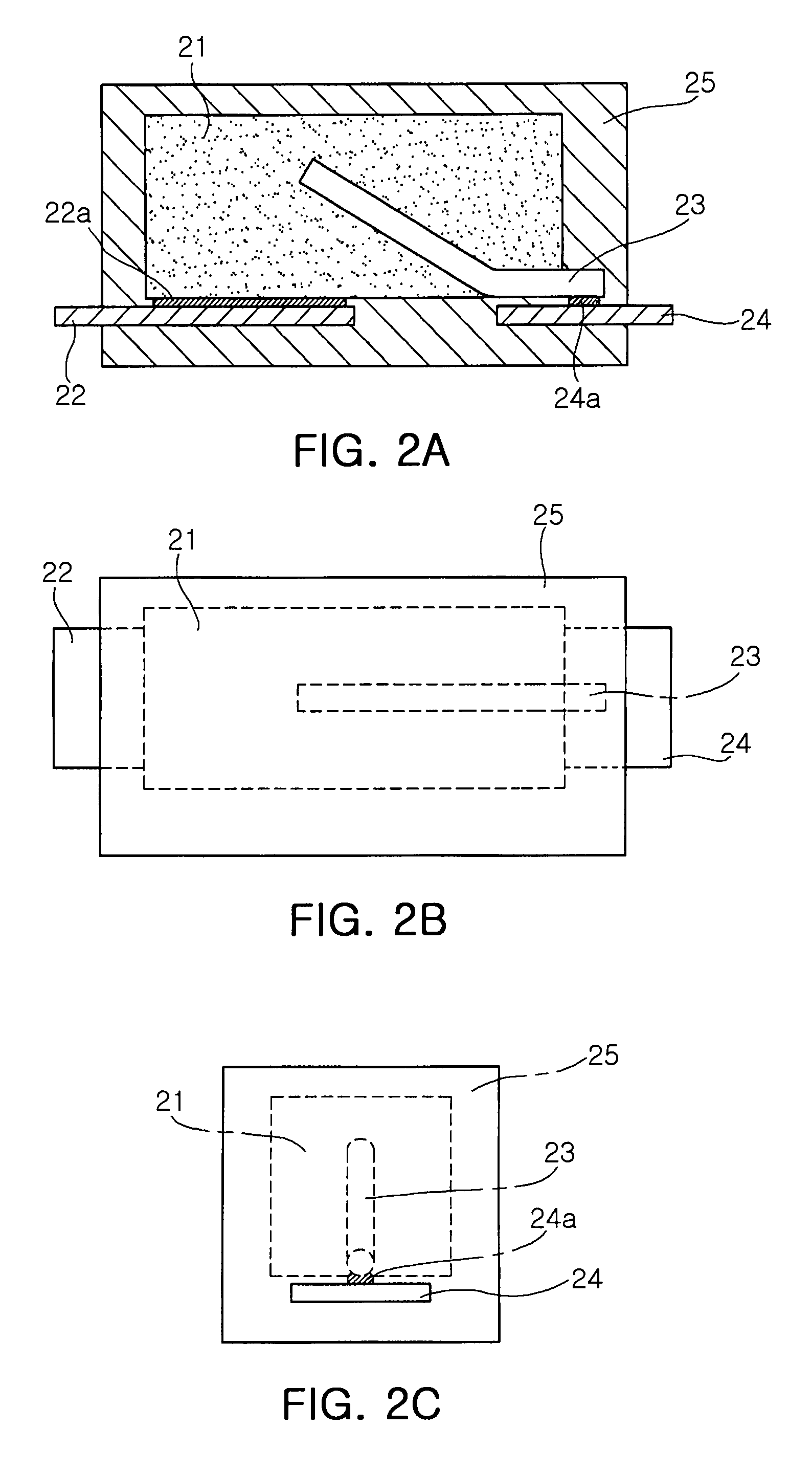

ActiveUS20080080124A1Increase the usable areaIncrease volumeSolid electrolytic capacitorsFixed capacitor terminalsTantalum capacitorLead frame

A tantalum capacitor including: a capacitor body containing a tantalum powder and having a mounting surface; a cathode lead frame having the capacitor body mounted thereon; a tantalum wire having an insertion portion located inside the capacitor body and a non-insertion portion located outside the capacitor body; an anode lead frame connected to the non-insertion portion of the tantalum wire; and a resin mold surrounding the capacitor body and the tantalum wire, wherein the insertion portion of the tantalum wire has at least one bending.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Tantalum capacitor

ActiveUS7570480B2Increase the usable areaIncrease volumeSolid electrolytic capacitorsFixed capacitor terminalsTantalum capacitorLead frame

A tantalum capacitor including: a capacitor body containing a tantalum powder and having a mounting surface; a cathode lead frame having the capacitor body mounted thereon; a tantalum wire having an insertion portion located inside the capacitor body and a non-insertion portion located outside the capacitor body; an anode lead frame connected to the non-insertion portion of the tantalum wire; and a resin mold surrounding the capacitor body and the tantalum wire, wherein the insertion portion of the tantalum wire has at least one bending.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

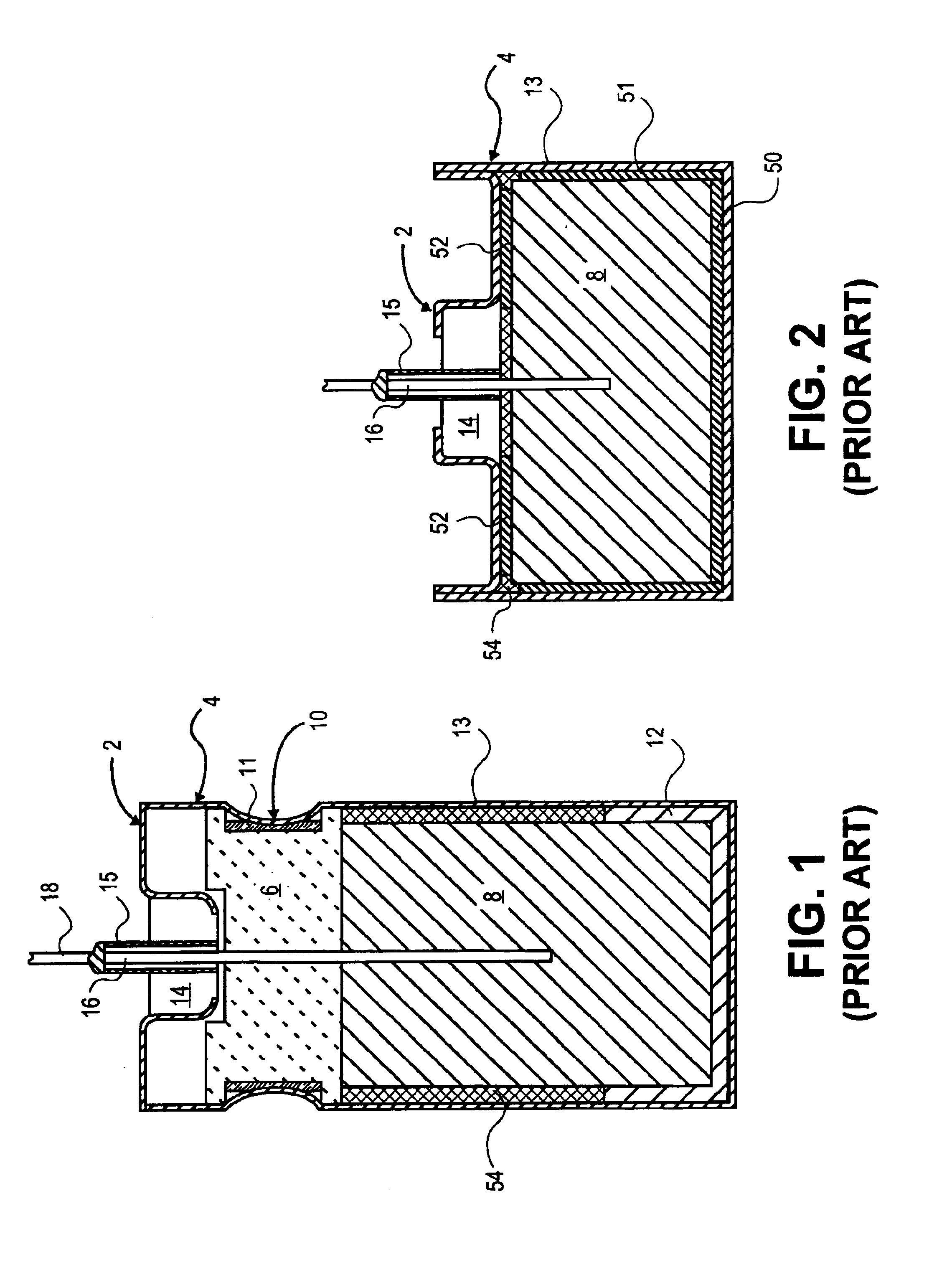

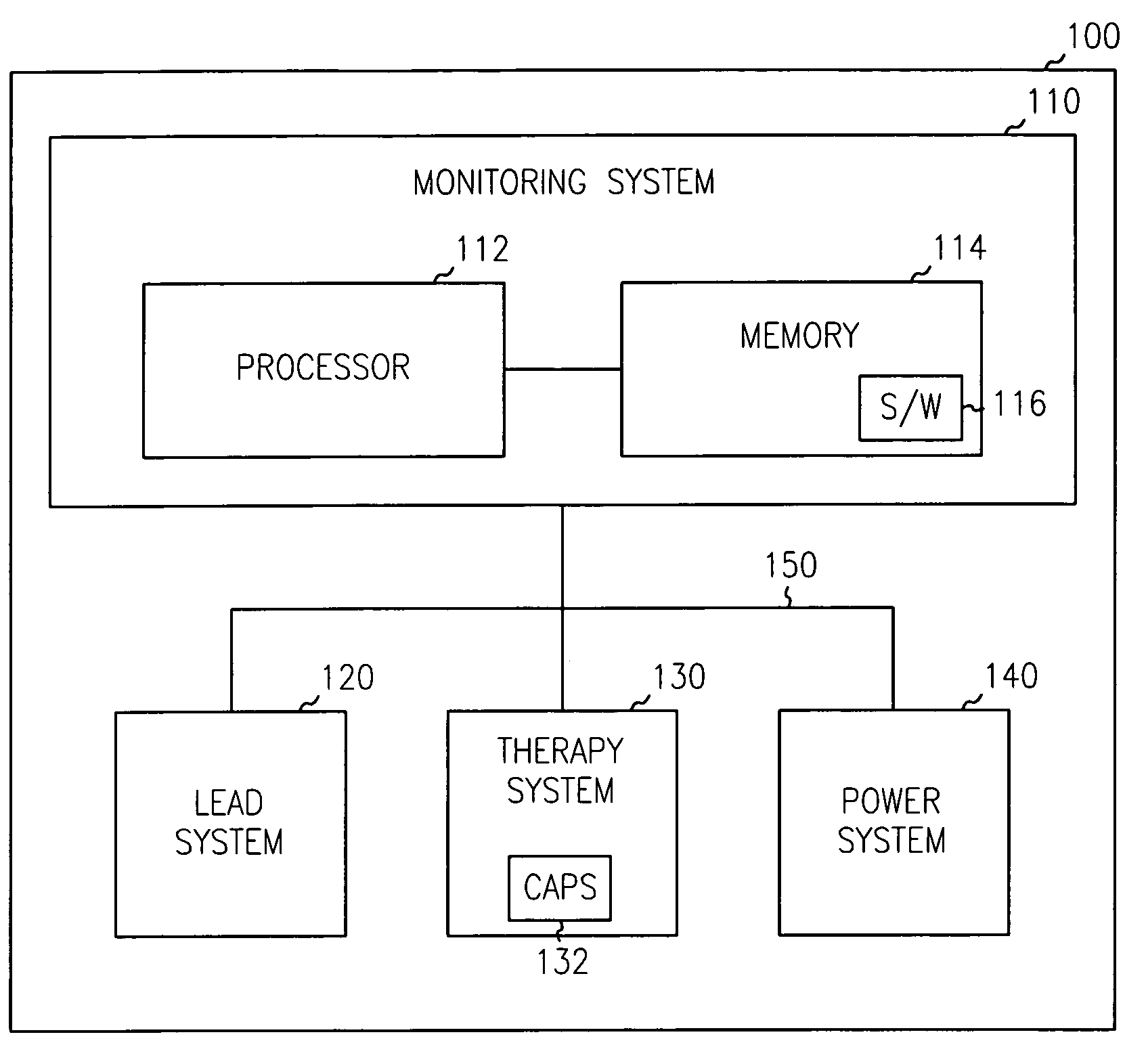

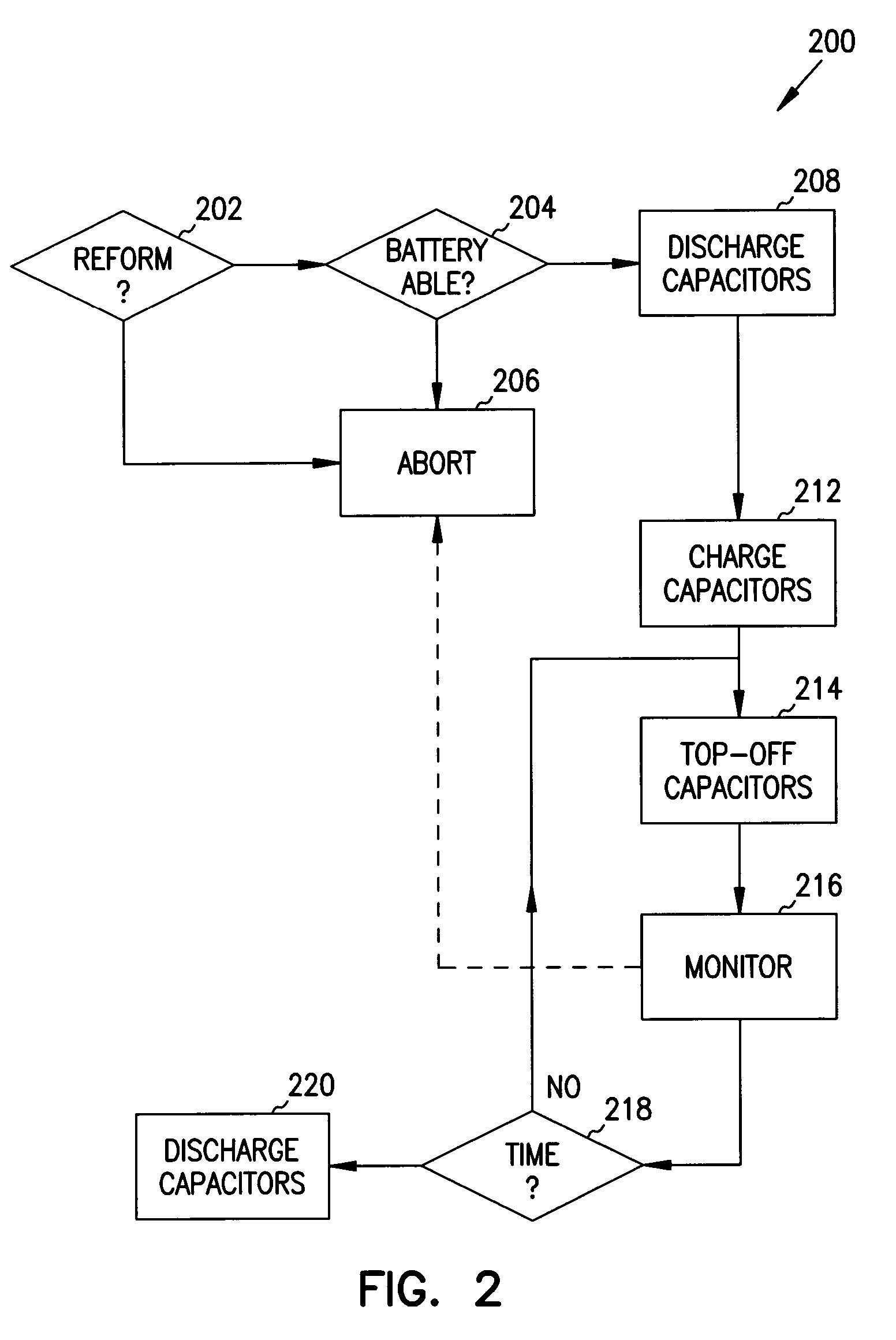

Reforming wet-tantalum capacitors in implantable medical devices

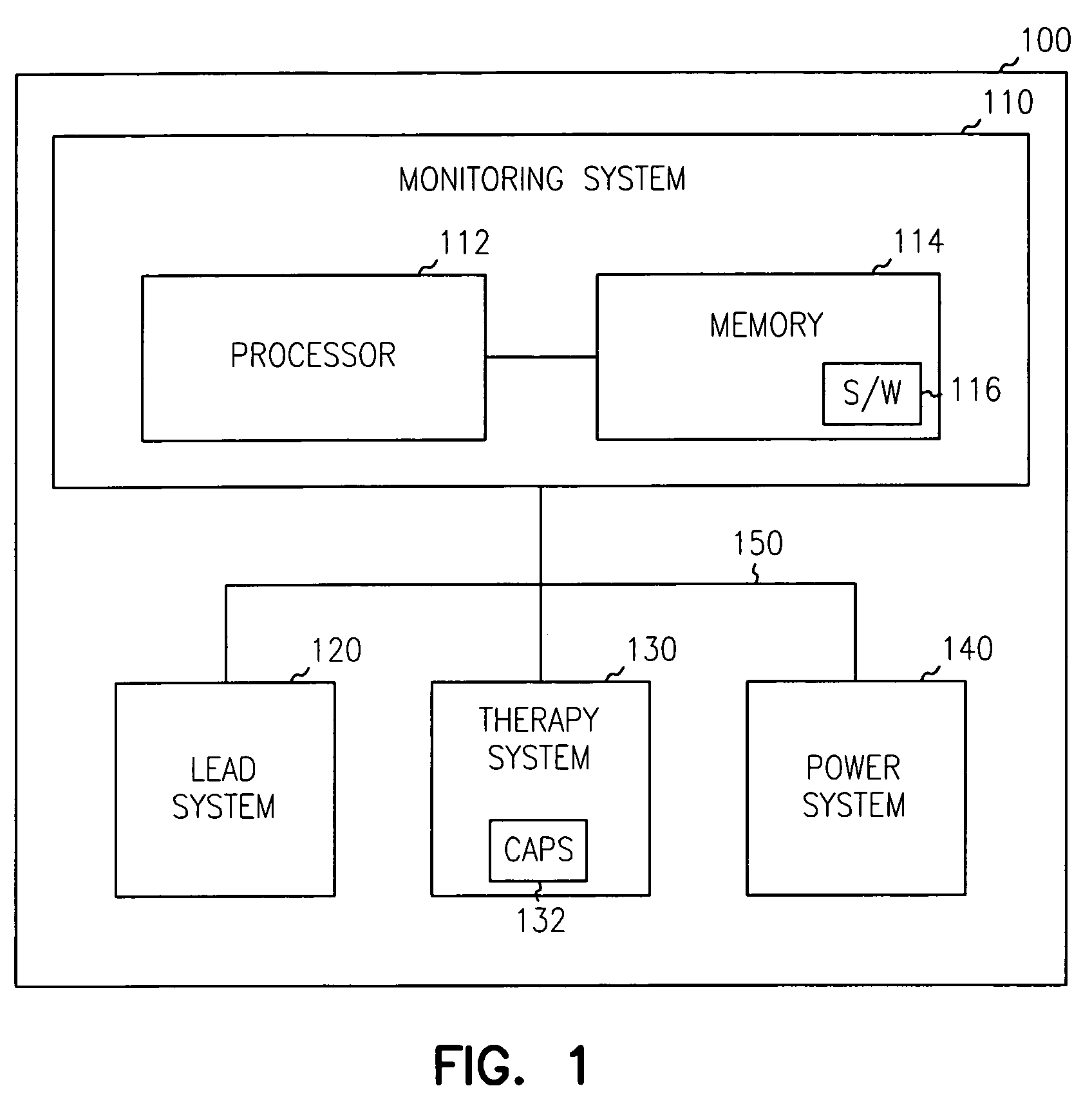

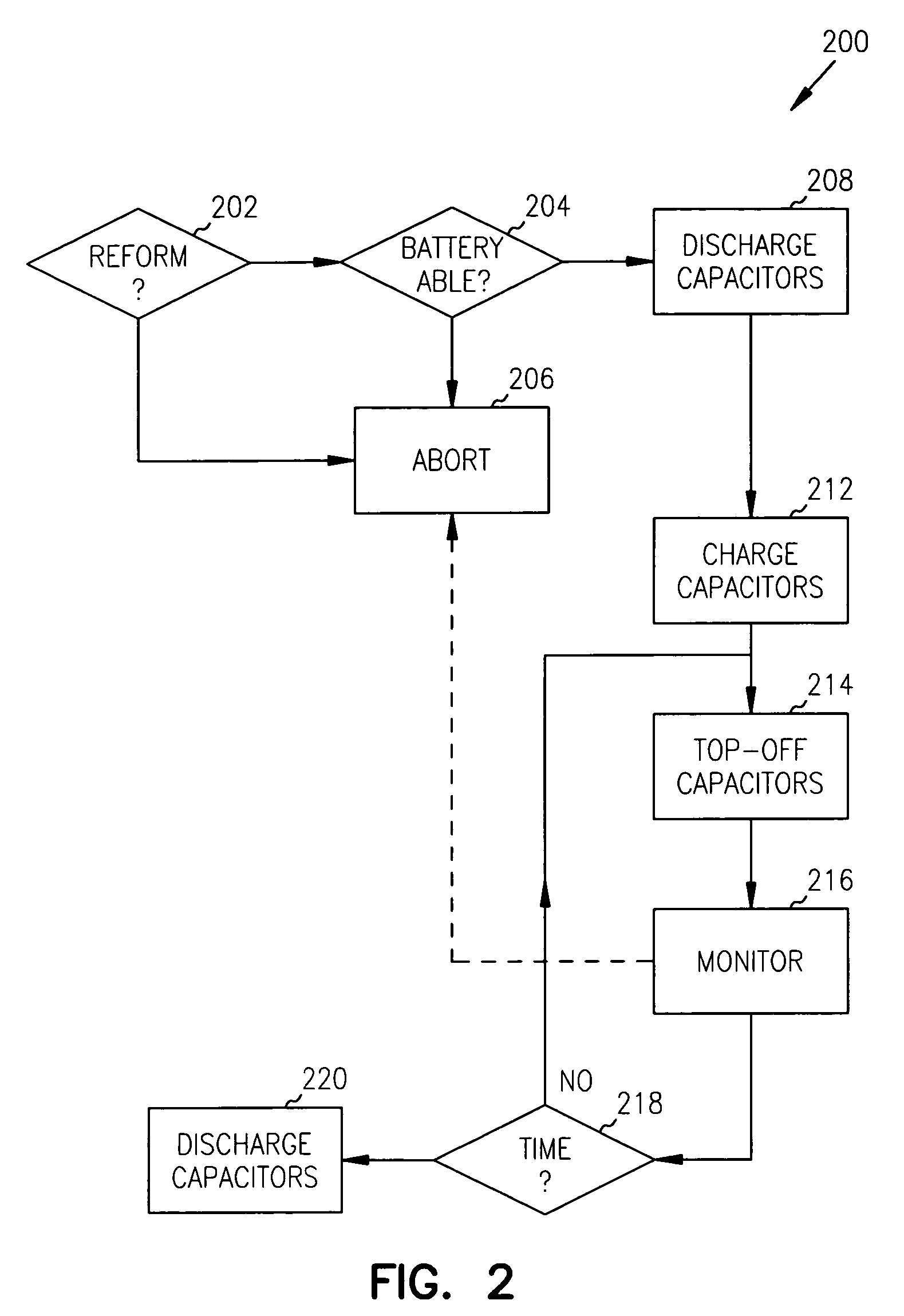

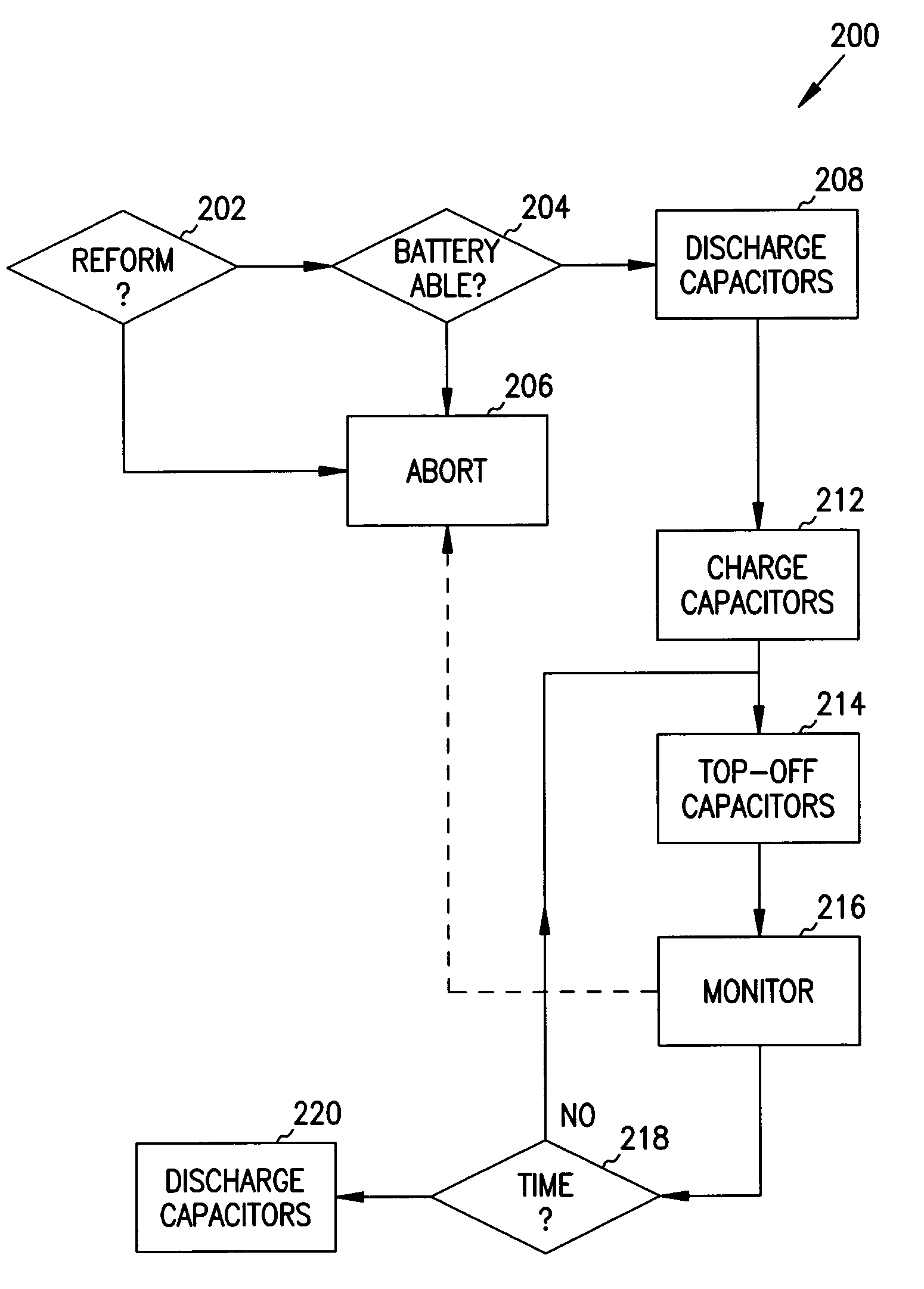

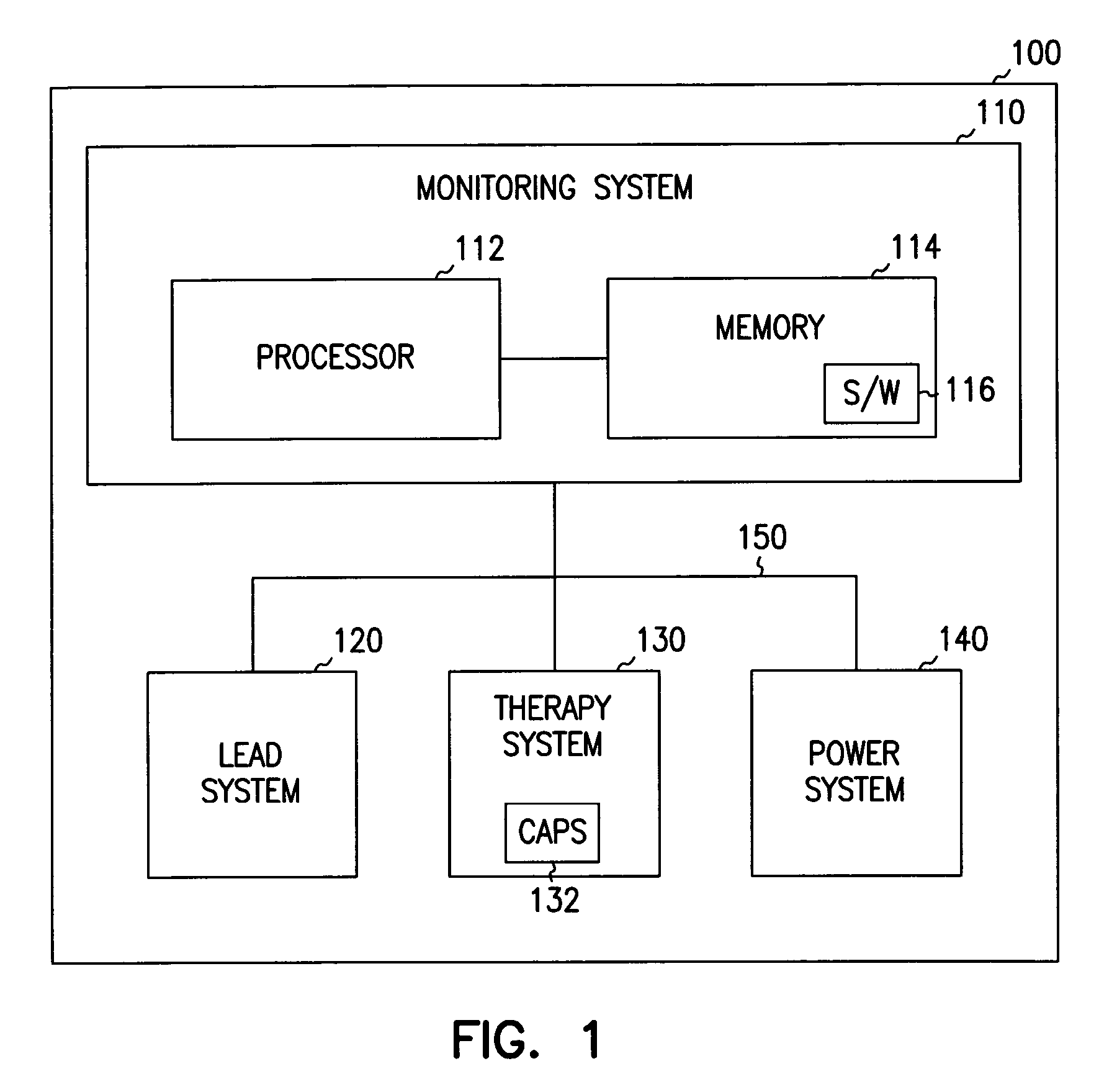

InactiveUS7131988B2Efficient chargingElectrolytic capacitorsHeart defibrillatorsElectrolysisEngineering

Miniature defibrillators and cardioverters detect abnormal heart rhythms and automatically apply electrical therapy to restore normal heart function. Critical to this function, aluminum-electrolytic capacitors store and deliver life-saving bursts of electric charge to the heart. This type of capacitor requires regular “reform” to preserve its charging efficiency over time. Because reform expends valuable battery energy, manufacturers developed wet-tantalum capacitors, which are generally understood not to require reform. Yet, the present inventors discovered through extensive study that wet-tantalum capacitors exhibit progressively worse charging efficiency over time. Accordingly, to address this problem, the inventors devised unique reform techniques for wet-tantalum capacitors. One exemplary technique entails charging wet-tantalum capacitors to a voltage equal to about 90% of their rated voltage and allowing the charge to dissipate through system leakage for a period of time, before discharging through a non-therapeutic load.

Owner:WILSON GREATBATCH LTD

Reforming wet-tantalum capacitors in implantable defibrillators and other medical devices

Miniature defibrillators and cardioverters detect abnormal heart rhythms and automatically apply electrical therapy to restore normal heart function. Critical components in these devices are aluminum electrolytic capacitors, which store and deliver one or more life-saving bursts of electric charge to a heart of a patient. This type of capacitor requires regular “reform” to preserve its charging efficiency over time. Because reform expends valuable battery life, manufacturers developed wet-tantalum capacitors, which are generally understood not to require reform. Yet, the present inventors discovered through extensive study that wet-tantalum capacitors exhibit progressively worse charging efficiency over time. Accordingly, to address this problem, the inventors devised unique reform techniques for wet-tantalum capacitors. One exemplary technique entails charging wet-tantalum capacitors to a voltage equal to about 90% of their rated voltage and maintaining this voltage for about five minutes before discharging them.

Owner:WILSON GREATBATCH LTD

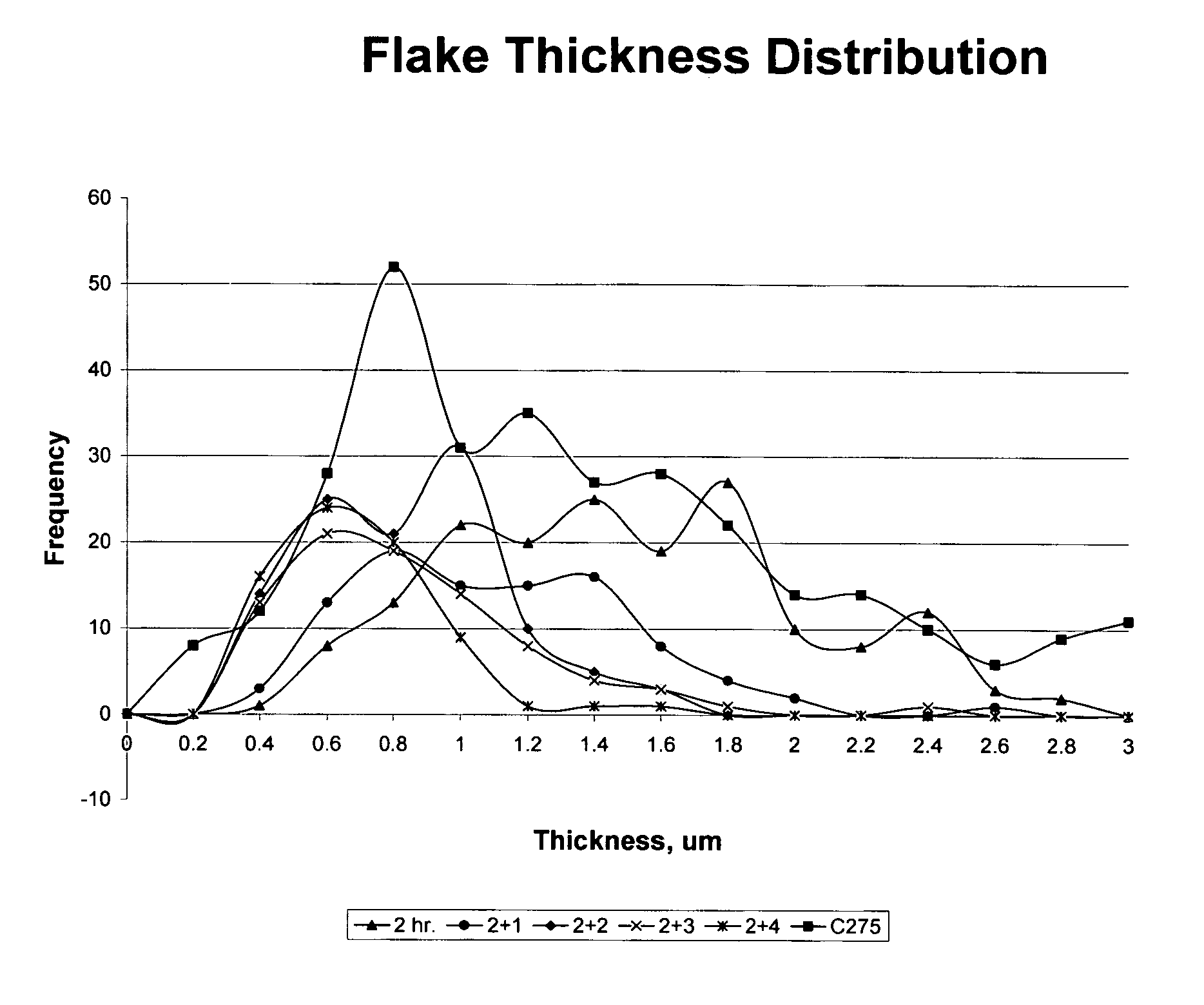

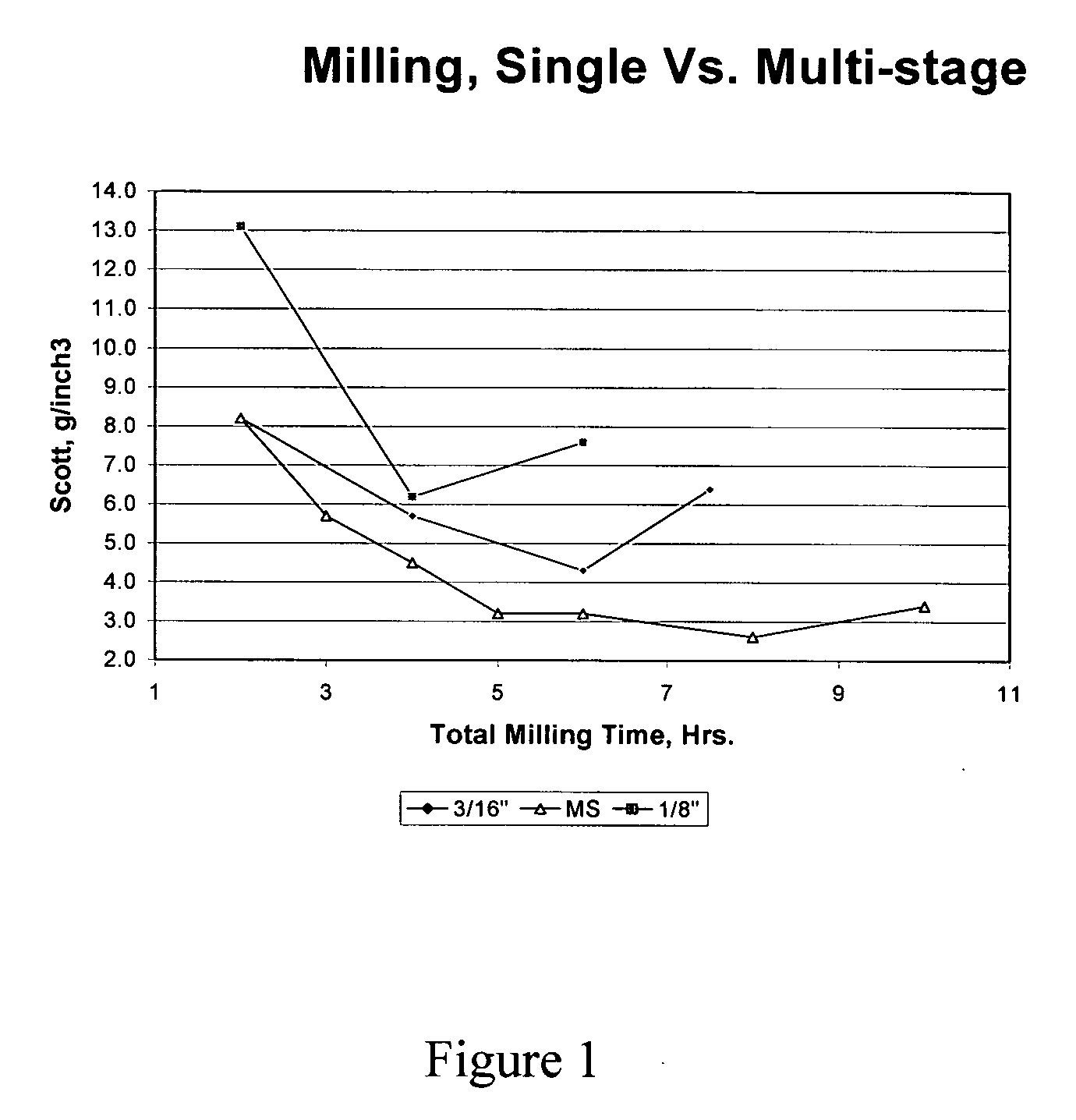

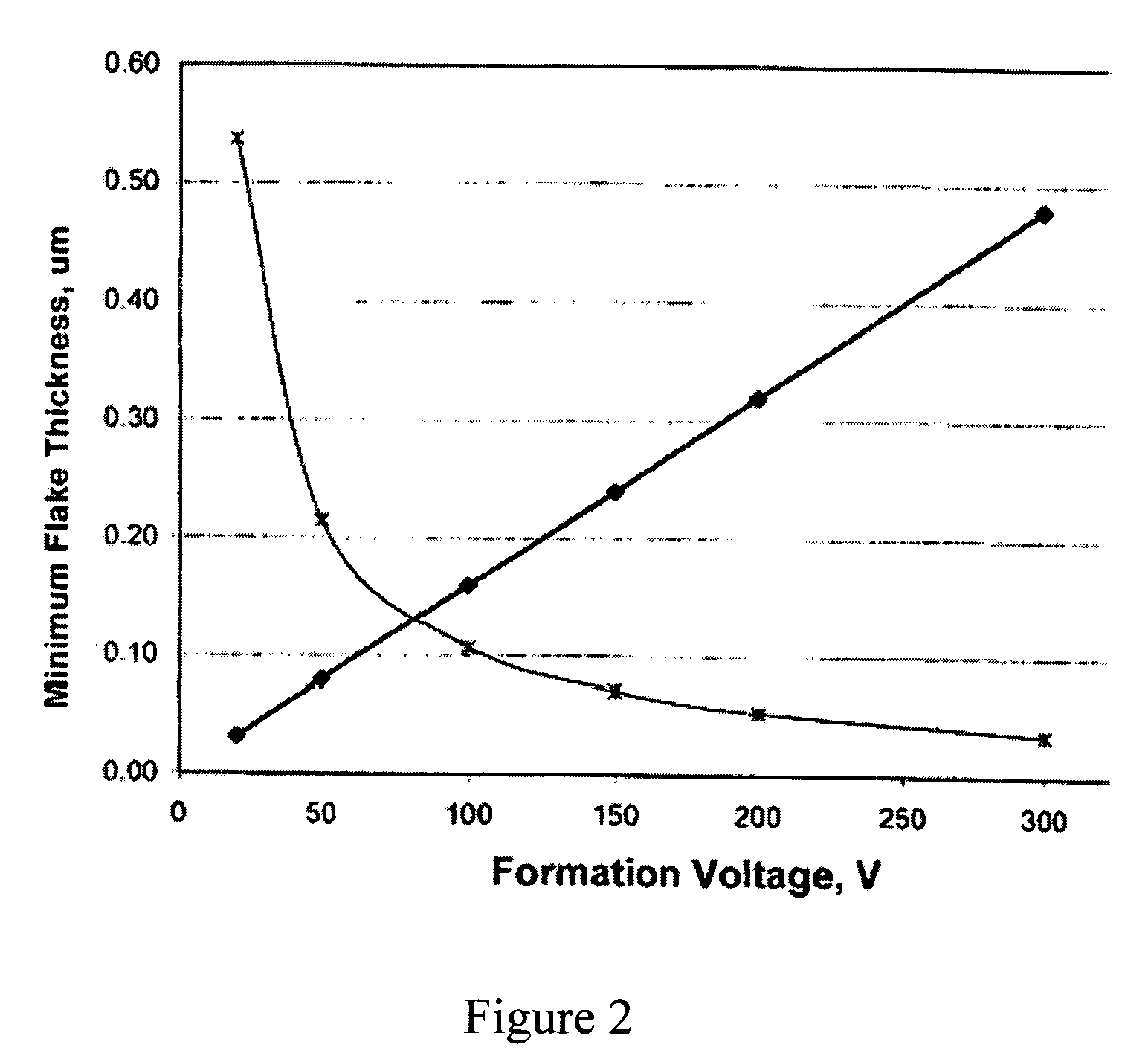

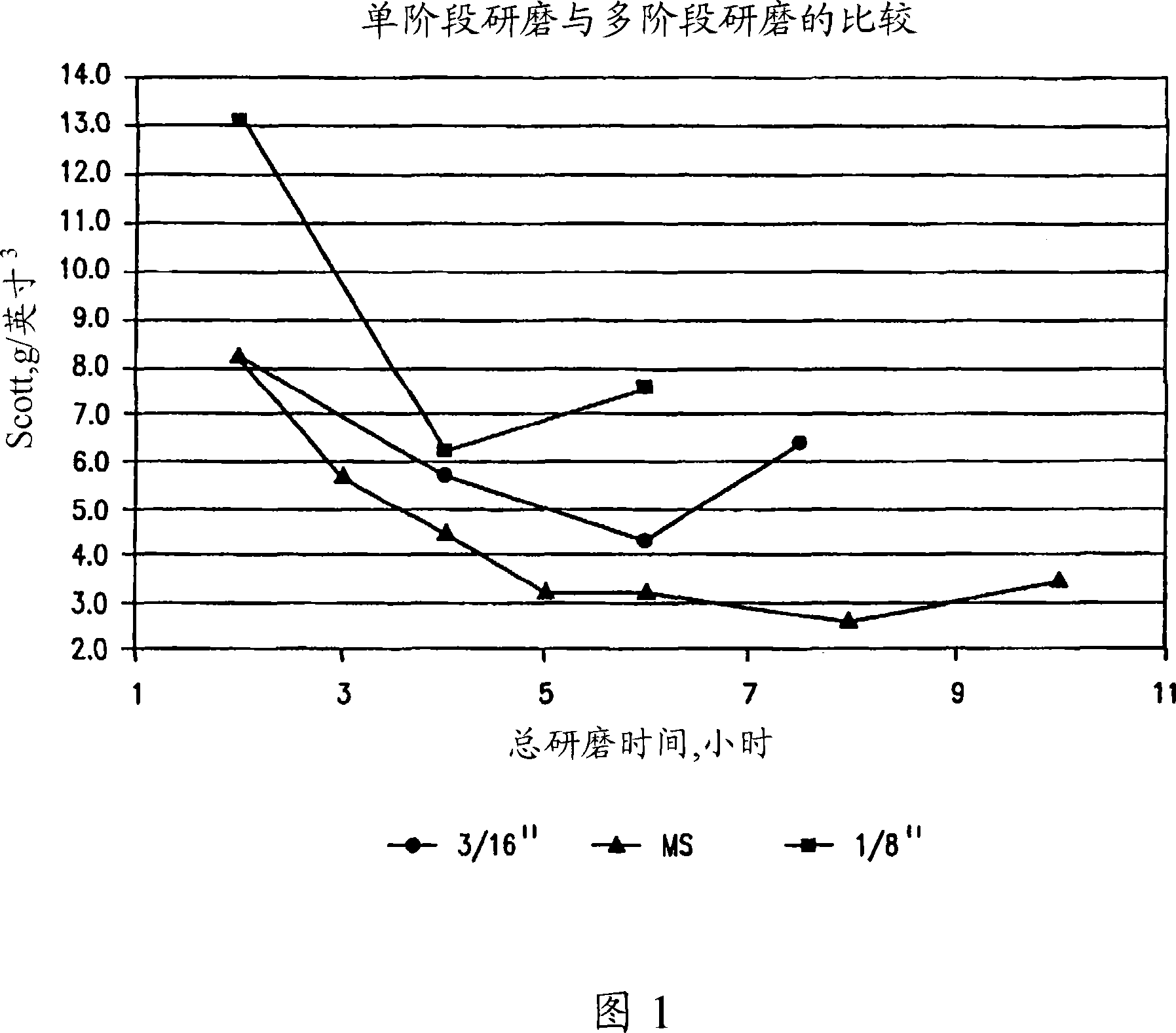

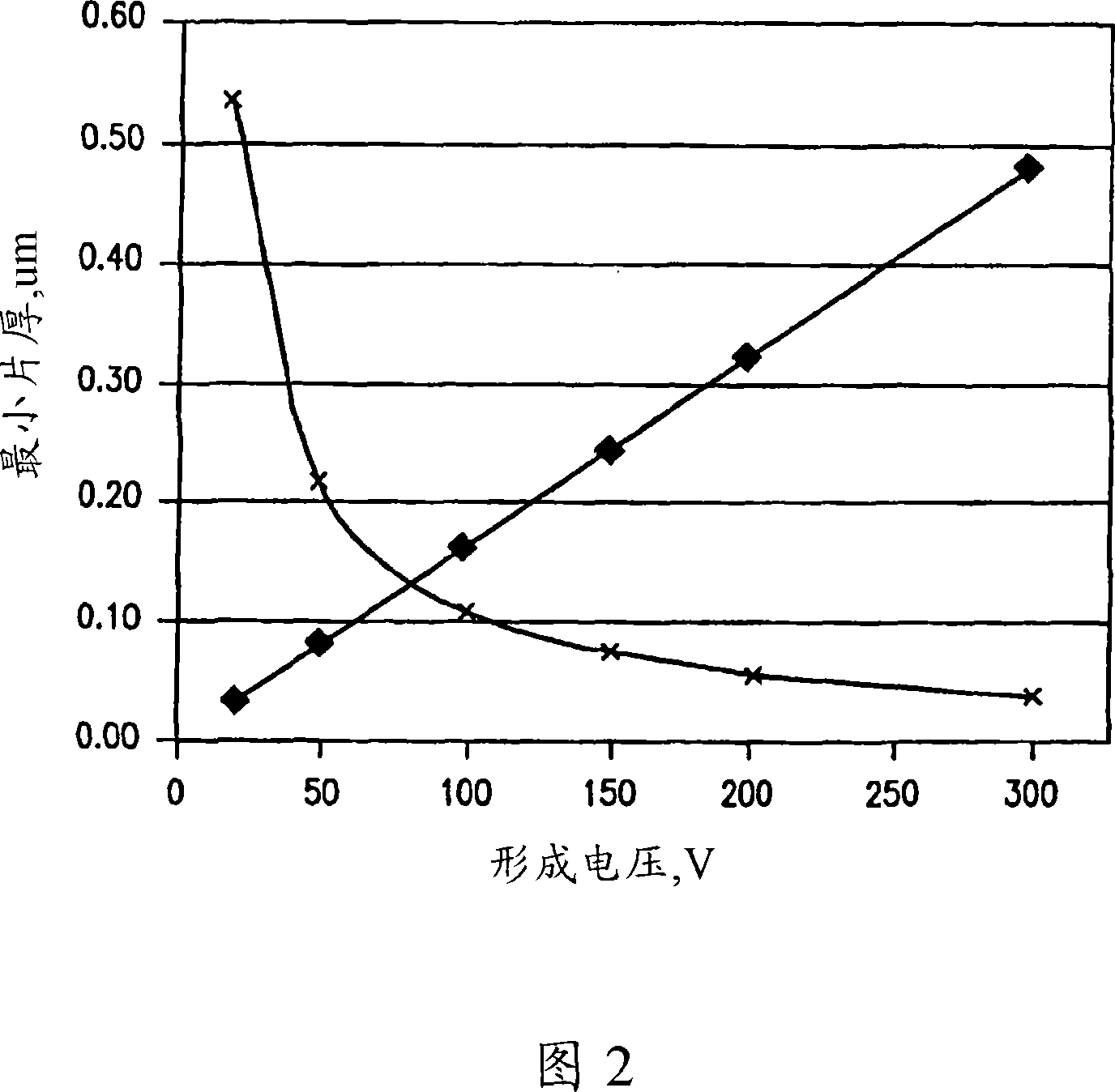

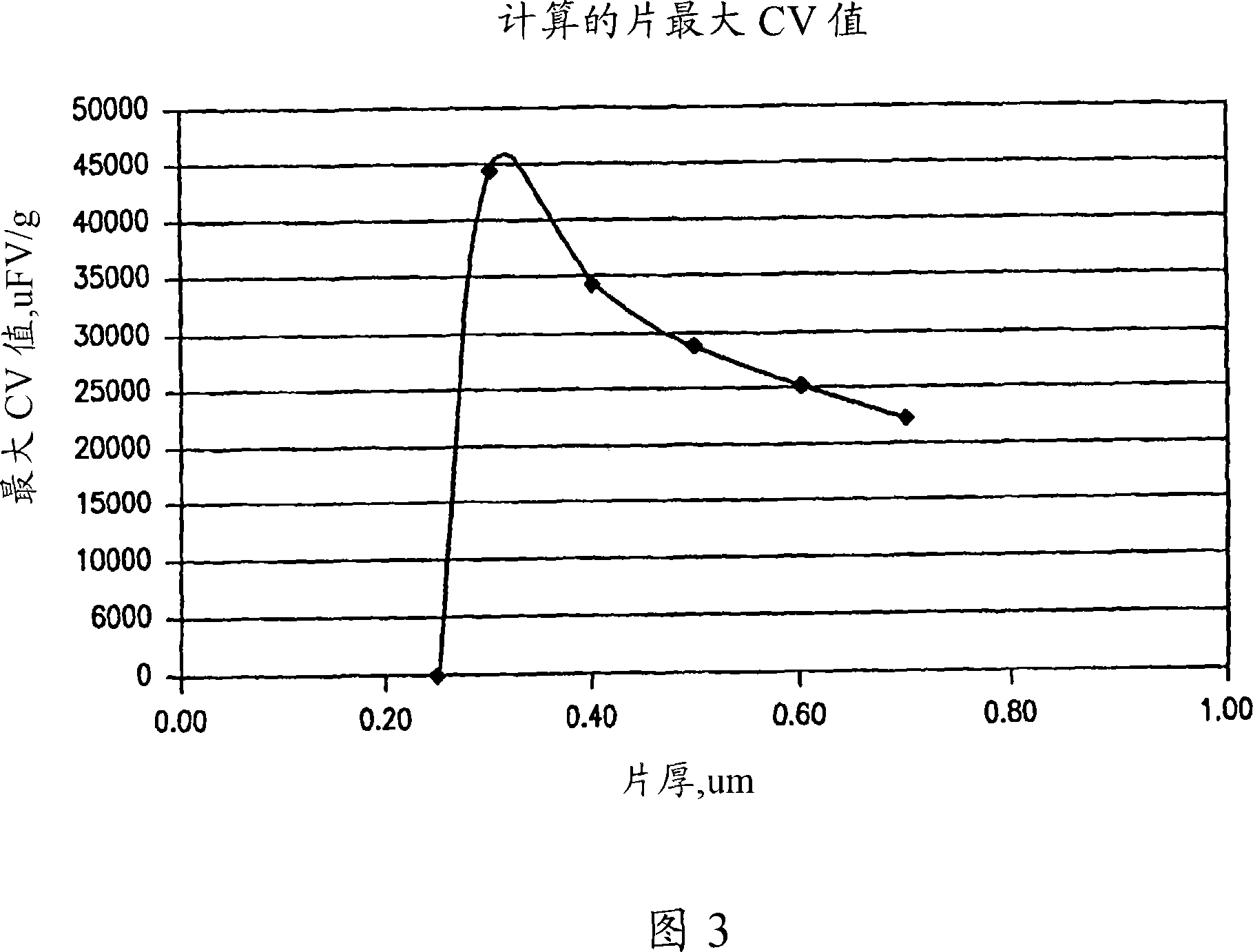

High capacitance tantalum flakes and methods of producing the same

InactiveUS20060070492A1Maximized capacitance capabilityElectrolytic capacitorsTransportation and packagingCapacitanceTantalum capacitor

Methods of maximizing a tantalum capacitor's capacitance are disclosed, as well as tantalum flake powder and anodes. A two step milling process can be used to mill tantalum particles into tantalum flake powder having flakes of the desired thickness. This flake powder can then be pressed and sintered thereby forming an anode. Other flake capacitance methods and products are also described.

Owner:CABOT CORP

Molding compound for sheet tantalum capacitor

InactiveCN1546566AMeet the requirements of production molding process parametersImprove product qualityCapacitorsEpoxyCombustion

The invention discloses a molded plastic compound for sheet tantalum capacitor, which is an epoxy resin compound and belongs to the field of special-purpose plastic encapsulating material in electronic industry. The molded plastic uses epoxy resin as the main block resin and phenolic resins as curing agent, prepared by adding solidification accelerating agent, filling material, releasing agent, combustion inhibitor, coloring agent, coupling agent, toughening agent and modifier though the steps of disintegrating, mixing, pugging, cooling down, disintegrating, batch mixing, pre-forming and packaging.

Owner:WUXI RES & DESIGN INST OF CHEM IND

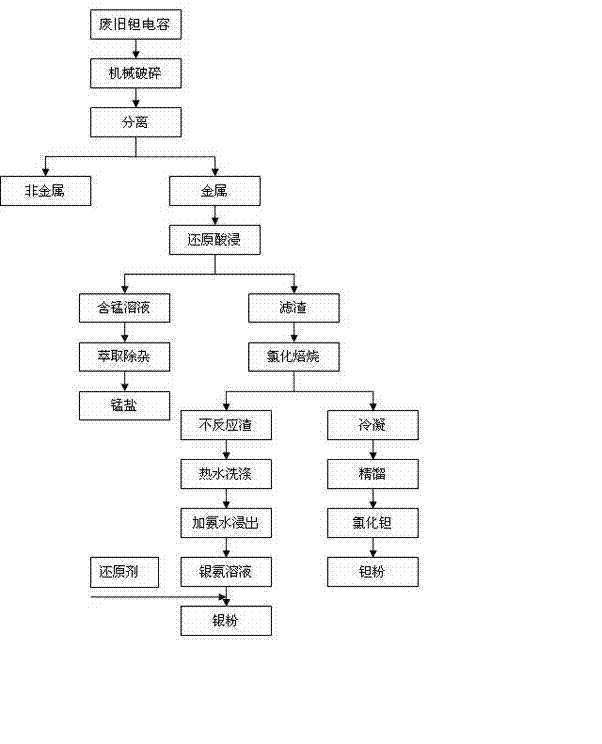

Method for recovering tantalum, silver and manganese in waste and old tantalum capacitor

ActiveCN103194604AImprove protectionThe process steps are simpleProcess efficiency improvementManganeseWater chlorination

The invention provides a method for comprehensively recovering a plurality of metals in a tantalum capacitor. The method comprises the following steps: mechanically crushing the waste and old tantalum capacitor, separating metals from nonmetals to obtain metal materials, carrying out reduction acid dipping of the metal materials, filtering to obtain a manganese-containing solution, and carrying out extraction and impurity removal to obtain a manganese salt; and mixing filter residues obtained after the reduction acid dipping and filtration with carbon black and a chlorine salt, carrying out high temperature roasting in a chlorinator for reacting to generate tantalum chloride, arranging a condensation system at the upper portion of the chlorinator to condensate and recover tantalum chloride, rectifying the obtained tantalum chloride solid to obtain high-purity tantalum chloride, reducing the tantalum chloride to obtain high-purity tantalum powder, washing unreacted residues obtained after the roasting with hot water, adding ammonia water, filtering to obtain a silver-ammonia solution, and adding a reducing agent for reducing to obtain silver powder. The method has simple and practical steps, and is helpful for the resource recovery and the environmental protection.

Owner:JIANGXI GREEN ECO MFG RESOURCE CYCLE

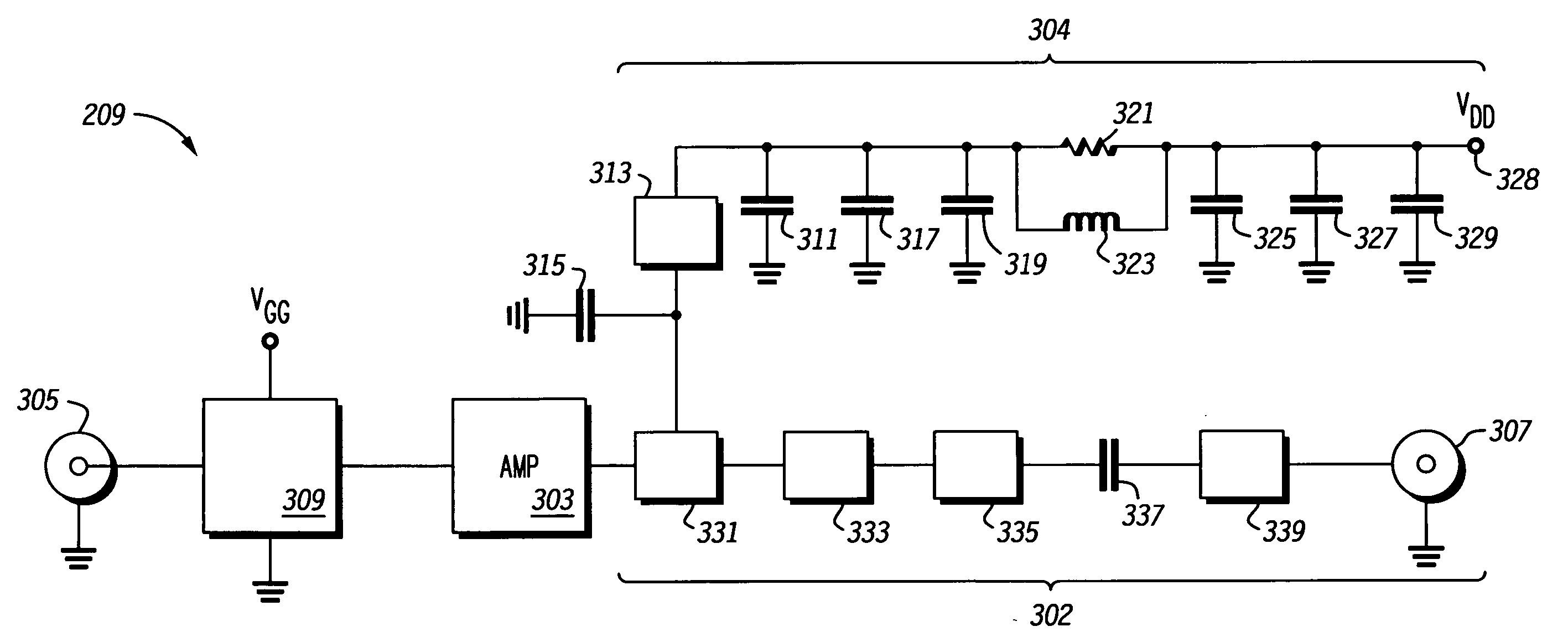

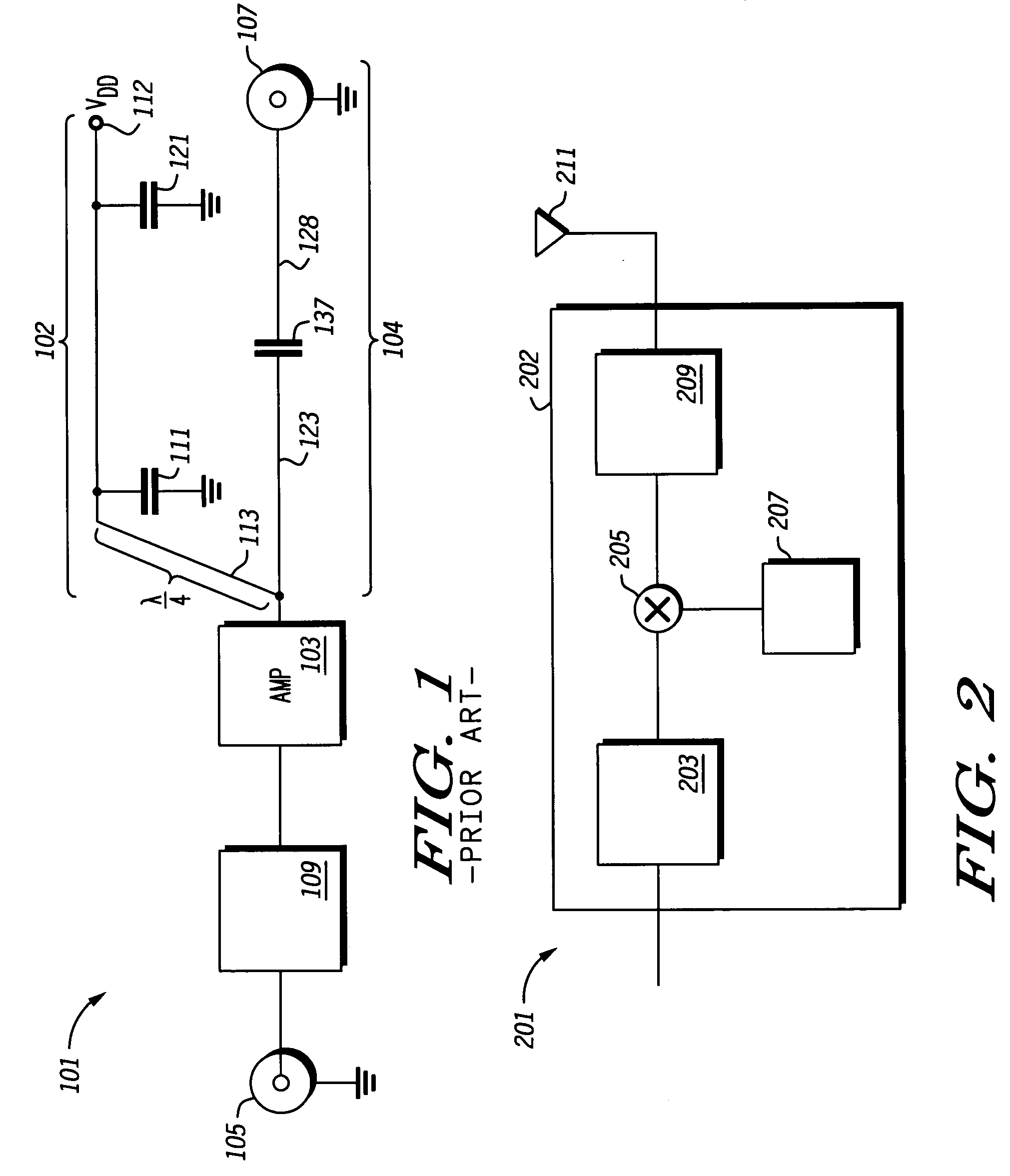

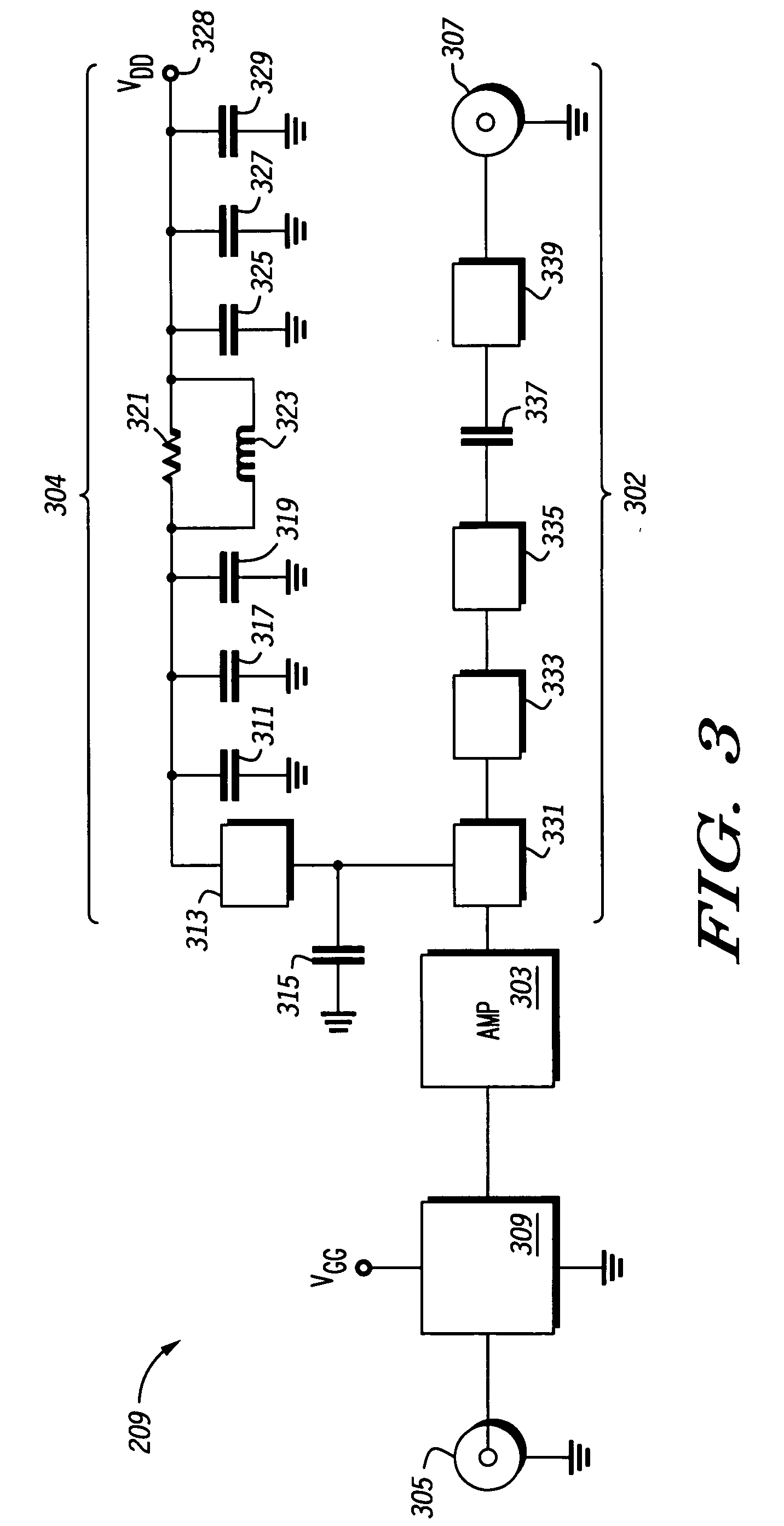

Amplifier circuit

ActiveUS20050083134A1High frequency amplifiersAmplifier modifications to reduce temperature/voltage variationCapacitanceAudio power amplifier

An amplifier circuit has an amplifier, a D.C. bias circuit, and an output signal path. The amplifier amplifies a modulated signal that has a carrier frequency. The D.C. bias circuit has a decoupling capacitor that is coupled to a transmission line having a length equal to N times the wavelength of the carrier frequency divided by four, where N is an odd integer. A low frequency decoupling capacitor is located between the decoupling capacitor and the output of the amplifier to reduce intermodulation distortion products. In one embodiment, the low frequency decoupling capacitor is a tantalum capacitor.

Owner:NXP USA INC

Hermetically-sealed solid electrolyte tantalum capacitor packaged through ceramic

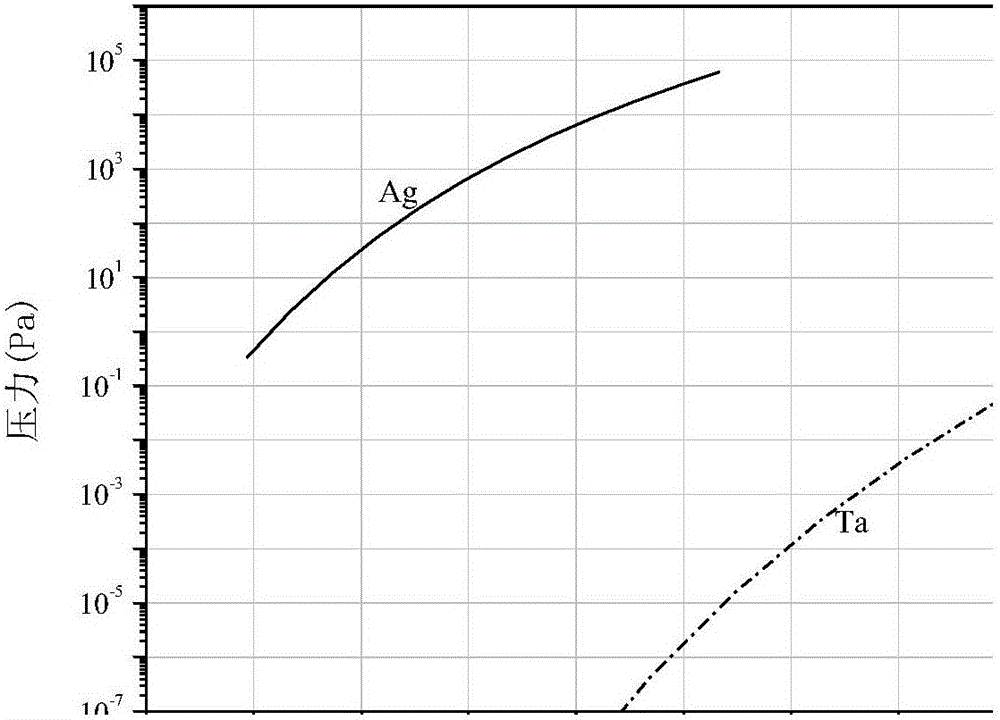

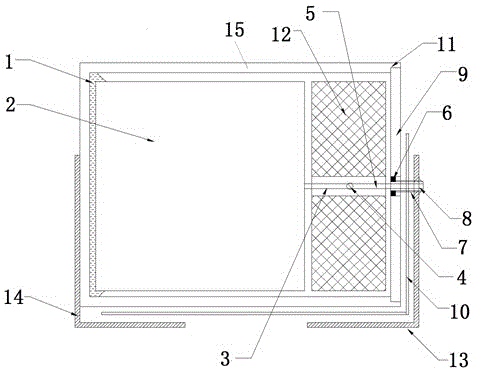

ActiveCN105826080AImprove high temperature resistanceSolve the problem of not being able to meet the high temperature working environmentCapacitor housing/encapsulationTemperature stressTantalum capacitor

The invention provides a hermetically-sealed solid electrolyte tantalum capacitor packaged through ceramic. A lower side of an anode tantalum core is fixedly welded with a Ni strip and is then bounded in a ceramic casing through bonding silver slurry, the anode tantalum core is connected with a cathode leading-out end fixed on the ceramic casing, an anode tantalum wire on the anode tantalum core is connected through a connection leading wire with an anode leading-out end fixedly arranged on the ceramic casing, and a cover board is sealed at a top end of the ceramic casing and is in fixed sealing connection with the ceramic casing. According to the capacitor, the Ni strip is added between the anode tantalum core and the bonding silver slurry, the anode tantalum core is connected with the casing by utilizing the soft Ni strip to release temperature stress generated by the anode tantalum core, influence on electrical performance parameters of products can be avoided, high temperature resistance capability of the capacitor is improved, a problem that a capacitor in the prior art can not operate in the high temperature work environment is solved, by utilizing ceramic parallel seam welding, the chip tantalum electrolytic capacitor is sealed, and the hermetically-sealed solid electrolyte tantalum capacitor can normally operate even in the environment with temperature of 180 DEG C.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

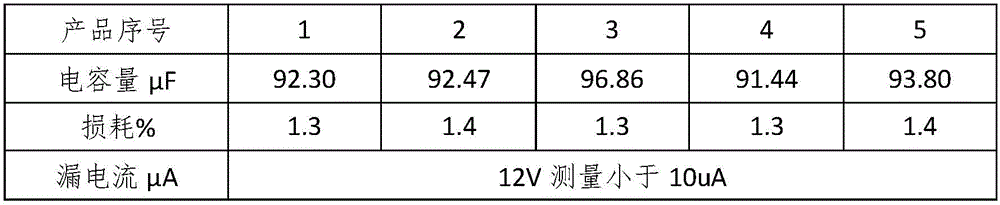

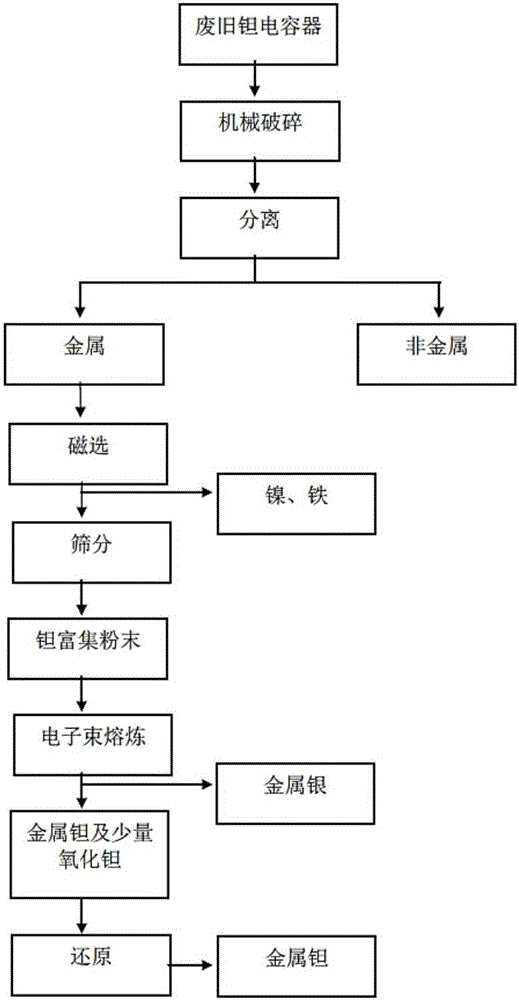

Method for recovering tantalum, silver, nickel and iron from waste tantalum capacitor

ActiveCN106048231AAvoid pollutionRealize resource utilizationMagnetic separationTantalum capacitorResource utilization

The invention relates to a method for recovering tantalum, silver, nickel and iron from a waste tantalum capacitor. The method comprises the following steps: firstly, the waste tantalum capacitor is mechanically crushed, and metal and nonmetal are separated to obtain a metal material; then, the metal material is magnetically separated to separate out a nickel-iron magnetic material; then, a residue is screened to obtain silver-contained tantalum-enriched powder; then, the electronic beam smelting is performed for the tantalum-enriched powder, and metal silver is separated out through evaporation-condensation; and finally, a residual metal tantalum material (containing less tantalum oxide) is reduced to obtain high-purity metal tantalum. The method is simple, generates no poisonous gas and waste liquid in the whole process, prevents the environmental pollution caused by traditional thermometallurgy and hydrometallurgy, and realizes the resource utilization of the waste tantalum capacitor under environment-friendly condition.

Owner:SHANGHAI JIAO TONG UNIV

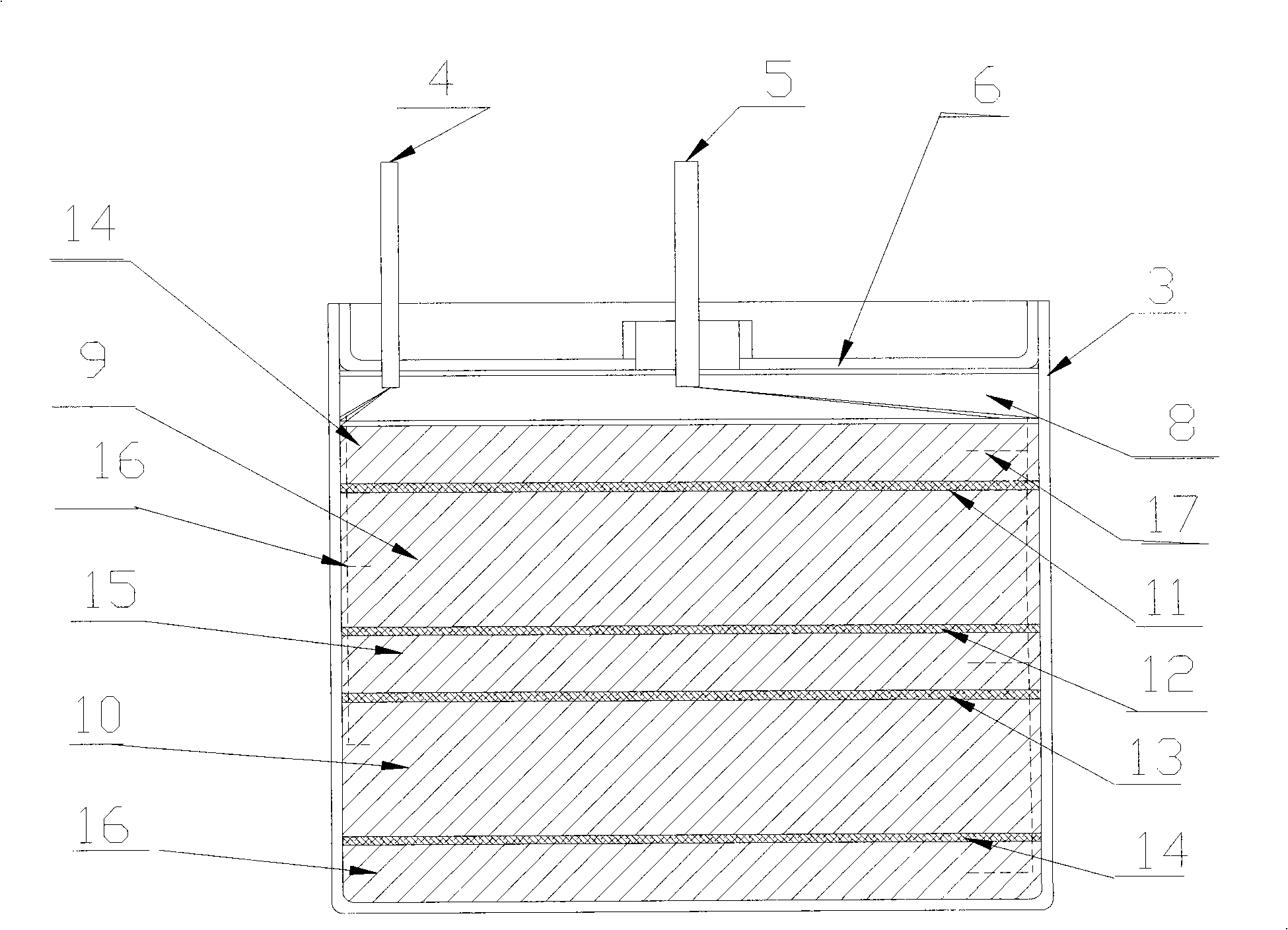

Square high-energy tantalum hybrid capacitor and manufacturing technology thereof

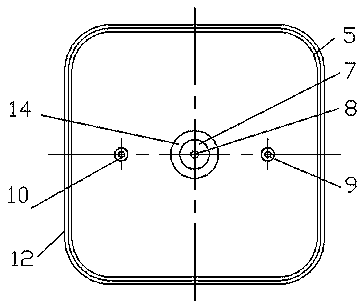

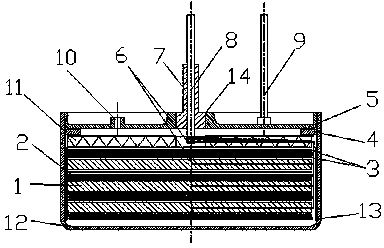

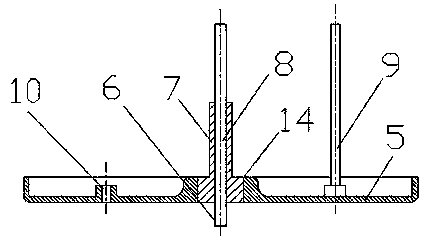

ActiveCN103366968AIncreased capacitor capacityUse efficientlyCapacitor terminalsCapacitor electrodesSpecific volumeHigh energy

The invention discloses a square high-energy tantalum hybrid capacitor and a manufacturing technology of the square high-energy tantalum hybrid capacitor. The square high-energy tantalum hybrid capacitor comprises a capacitor cavity which is composed of a square tantalum outer shell and a square insulating tantalum sub-cover, wherein the capacitor cavity is filled with anode tantalum cores which are made of high-specific-volume tantalum powder in a pressed mode, cathode layers coated by RuO2, and a plurality of isolating layers in sequence. According to the square high-energy tantalum hybrid capacitor and the manufacturing technology of the square high-energy tantalum hybrid capacitor, the capacity of the square high-energy tantalum hybrid capacitor is improved, material cost is reduced, and manufacturing is convenient.

Owner:湖南华冉科技有限公司

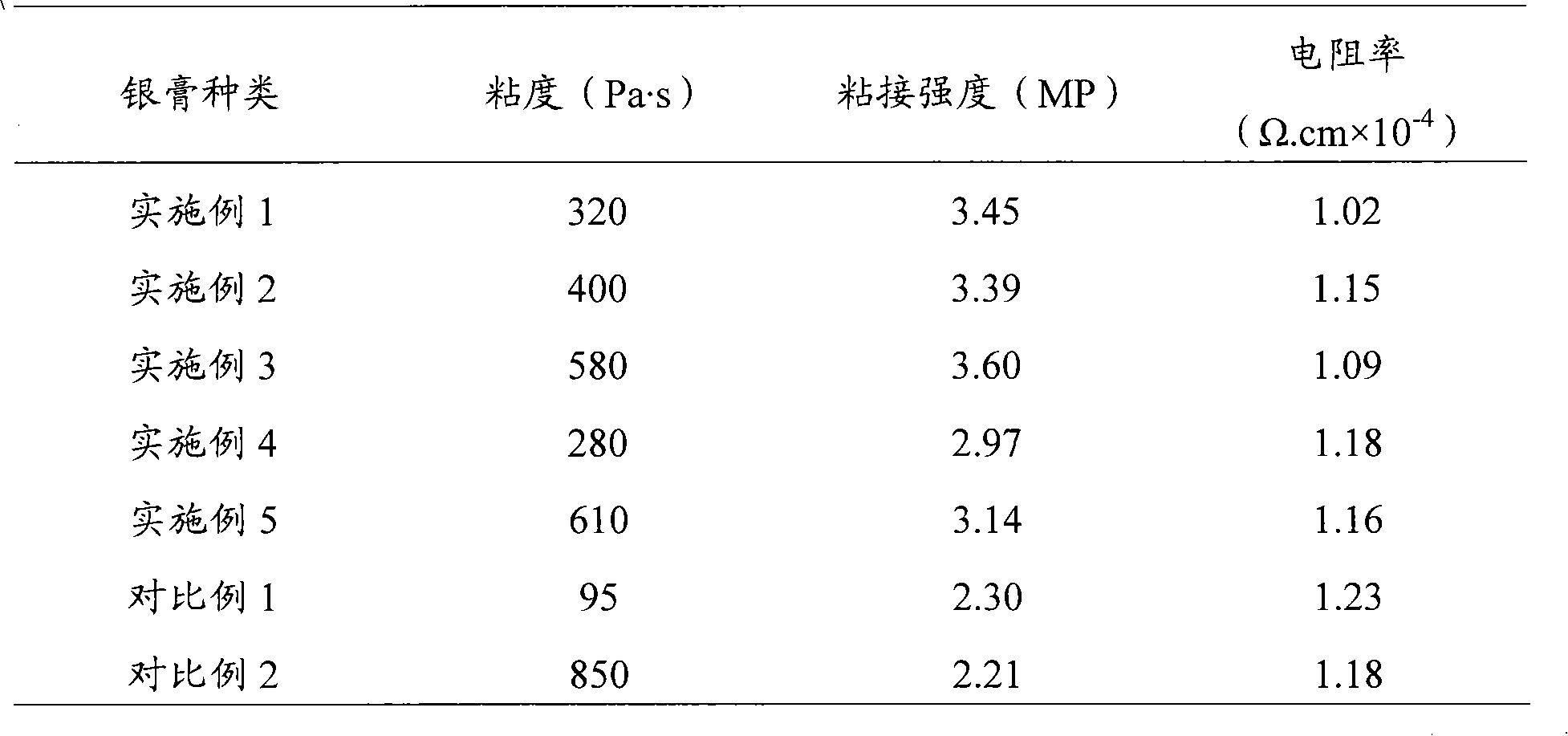

Silver paste for gluing tantalum capacitor and preparation method thereof

ActiveCN101562061AImprove conductivityGood adhesionCapacitor electrolytes/absorbentsNon-conductive material with dispersed conductive materialSilver pasteEpoxy

The invention provides a silver paste for gluing a tantalum capacitor, which comprises the following components according to weight percentage: 60-80 percent of silver powder; 5-18 percent of epoxy resin; 4-15 percent of solidifying agent; 0.1-2 percent of accelerant; 0.5-3 percent of anti-settling agent; and 2-10 percent of solvent. The invention also provides a preparation method of the tantalum capacitor as follows: 1) the epoxy resin, the solidifying agent, the accelerant, the anti-settling agent, the dissolvent and the silver powder are mixed according to proportion; and 2) the evenly mixed silver paste is rolled. The gluing silver paste provided by the invention has good dispersiveness and anti-settling performance as well as good electric conductivity and high gluing strength. Test results show that the silver paste provided by the invention has the gluing strength of more than or equal to 3MP and good overall performance, and can meet the current requirements for highly automatic production of the tantalum capacitor.

Owner:CNMC NINGXIA ORIENT GRP

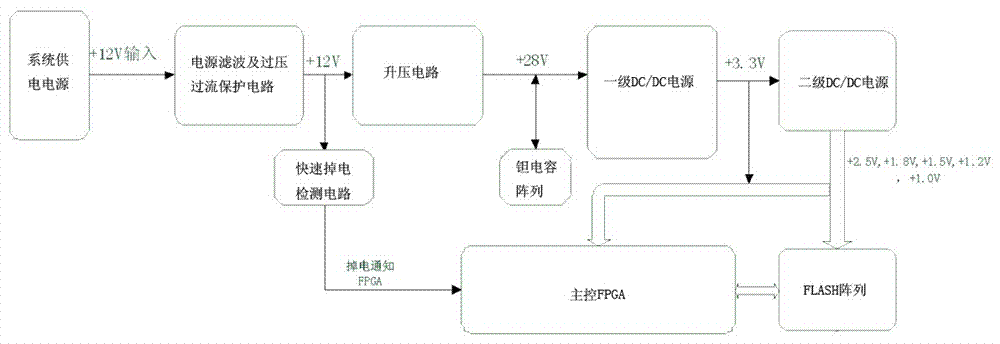

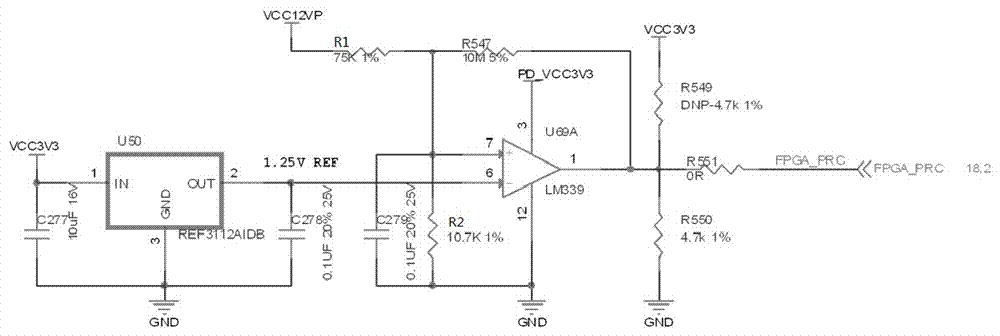

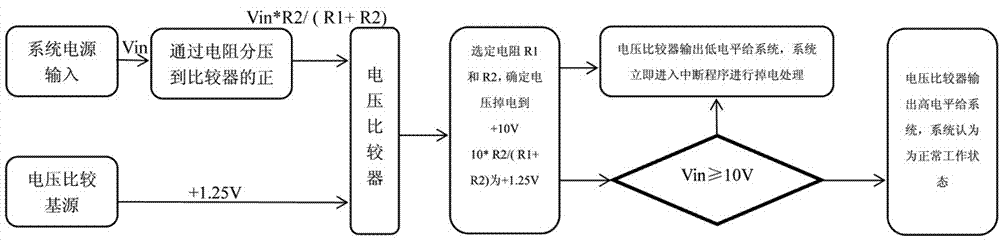

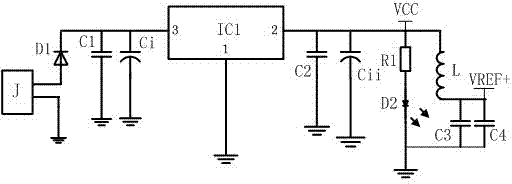

Mass storage end-to-end data protection system based on power down protection

PendingCN107885631AReduce in quantitySmall sizeDetecting faulty hardware by power-on testMemory loss protectionMass storageElectricity

The invention in particular relates to a mass storage end-to-end data protection system based on power down protection. The mass storage end-to-end data protection system based on power down protection comprises a power module, wherein the power module comprises a system power supply, a boosted circuit, a primary DC / DC power module and a secondary DC / DC power module connected in sequence; the power module boosts the system power supply from +12V to +28V; and the primary DC / DC power module outputs the voltage of +28V to be +3.3V. The mass storage end-to-end data protection system further comprises a master control FPGA (Field Programmable Gate Array) and a FLASH array, wherein a rapid power failure detection circuit is arranged between the system power supply and the master control FPGA; the rapid power failure detection circuit, the master control FPGA and the FLASH array are connected in sequence; the secondary DC / DC power module is respectively connected with the master control FPGAand the FLASH array; and a tantalum capacitor array is arranged between the boosted circuit and the primary DC / DC power module. With the adoption of the rapid power failure detection circuit, the master control FPGA has more time to process the power failure interrupt program, and the safety of the end-to-end data protection is improved.

Owner:XIAN KEYWAY TECH

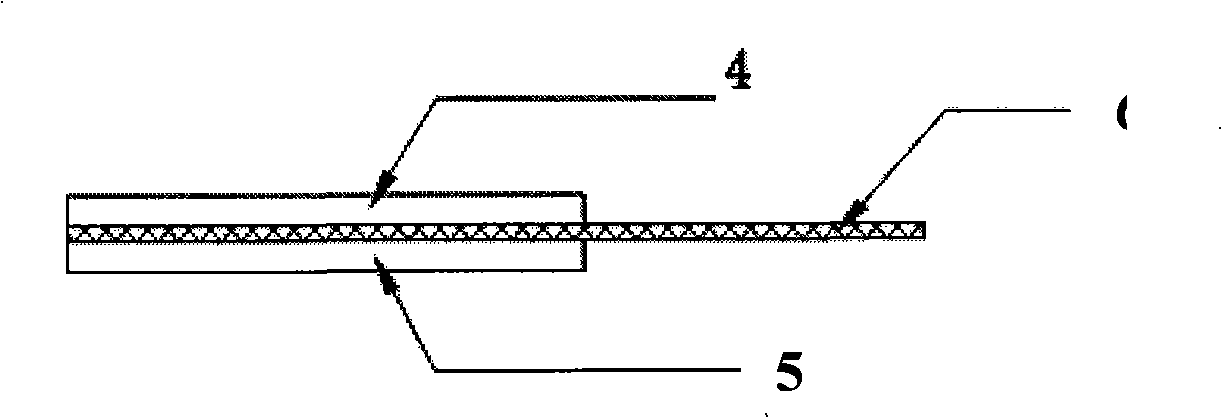

Leading-out process for anode and cathode of end cap-type tantalum capacitor

ActiveCN103700501AImproved positive and negative lead-out processLarge design spaceCapacitor housing/encapsulationEpoxySilver paste

The invention discloses a leading-out process for an anode and a cathode of an end cap-type tantalum capacitor. The leading-out process comprises the following steps: (1) getting a tantalum core preform with the anode and the cathode; (2) enabling a high-temperature adhesive tape of which the width is equal to that of the tantalum core preform to cling to the bottom part of a tantalum core, and then, preheating the tantalum core; (3) burying the preheated tantalum core in epoxy resin powder for 2s-5s, and then, tearing off the high-temperature adhesive tape at the bottom part of the tantalum core; (4) solidifying epoxy resin; (5) solidifying cathode silver paste; (6) solidifying anode silver paste; (7) separating the tantalum core to become a whole individual with specified dimensions; (8) electroplating the tantalum core obtained in the step (7). The leading-out process disclosed by the invention has the beneficial effects that an anode and cathode leading-out process for a traditional tantalum capacitor is improved; without an anode and cathode soldering lug or a leading-out wire, the middle part of the tantalum capacitor is insulated by utilizing the epoxy resin; the anode and the cathode of the capacitor are directly led out by the silver paste at both ends, so that the design space of the tantalum capacitor is enlarged.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

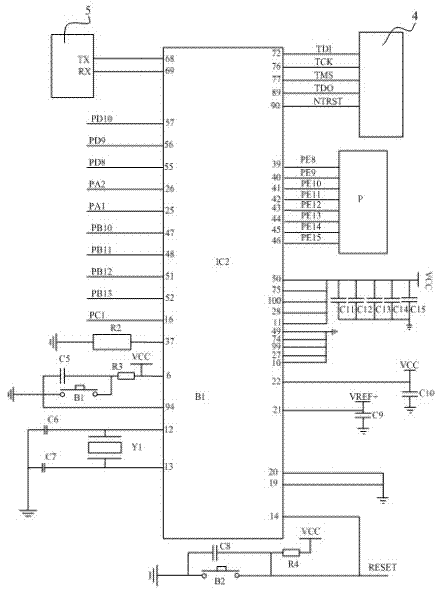

Serial port to Ethernet control device based on STM32

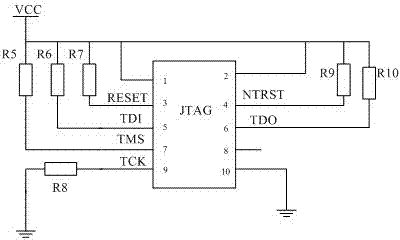

InactiveCN102387054AIntegrity guaranteedGuaranteed reliabilityEnergy efficient ICTData switching by path configurationCapacitanceInterconnectivity

The invention relates to a serial port to Ethernet control device based on STM32. The control device comprises: a power supply circuit, a micro-control unit circuit, a JTAG debugging interface circuit, a serial port communication interface circuit and an Ethernet physics interface transceiver control circuit. The power supply circuit comprises: a power supply voltage stabilization chip, a double pin power supply connector, a rectifier diode, a light emitting diode, an inductor, a chip resistor, two tantalum capacitors and four ceramic capacitors. The micro-control unit circuit comprises: a STM32 interconnectivity processor, an expansion pin, a crystal oscillator, two buttons, the three chip resistors and the eleven ceramic capacitors. The Ethernet physics interface transceiver control circuit comprises: an Ethernet physics interface transceiver control chip, an RJ45 interface, an active crystal oscillator, the tantalum capacitor, the sixteen chip resistors and nine ceramic capacitors. The control device has advantages of a small volume, low costs and low power consumption. And telnet can be achieved so as to perform real time operation and monitoring.

Owner:杭州先驱海洋科技开发有限公司

High capacitance tantalum flakes and methods of producing the same

InactiveCN101010160ACapacitive maximizationGood capacitance characteristicsElectrolytic capacitorsTransportation and packagingCapacitanceTantalum capacitor

Owner:CABOT CORP

Burn-in method of high-temperature-resistant tantalum capacitor

ActiveCN103854860AStable jobExtended service lifeElectrolytic capacitorsTantalum capacitorRoom temperature

The invention discloses a burn-in method of a high-temperature-resistant tantalum capacitor. The method comprises the following steps that (1), constant voltage being 2-5 V is exerted on the capacitor at the room temperature; (2), the capacitor is electrified with voltage 1UR at the temperature being 80-90 DEG C; (3), the capacitor is electrified with voltage 0.62-0.65 UR at the temperature being 120-130 DEG C; (4), the capacitor is electrified with voltage 0.55-0.6 UR at the temperature being 190-205 DEG C; (5), the capacitor is electrified with voltage 0.45-0.52 UR at the temperature being 225-230 DEG C; (6), the capacitor is naturally cooled; (7), the cooled capacitor is heated with voltage. The method has the advantages that burn-in is carried out by application of different voltages through high-temperature sections, the burn-in time in the prior art is shortened greatly, the burn-in purpose is achieved, the reliability and the service life are ensured, the tantalum capacitor can stably work for a long time at the high temperature being 230 DEG C, the service life of the capacitor is prolonged, and the blank of the tantalum capacitor burn-in technology above the 200 DEG C is filled.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

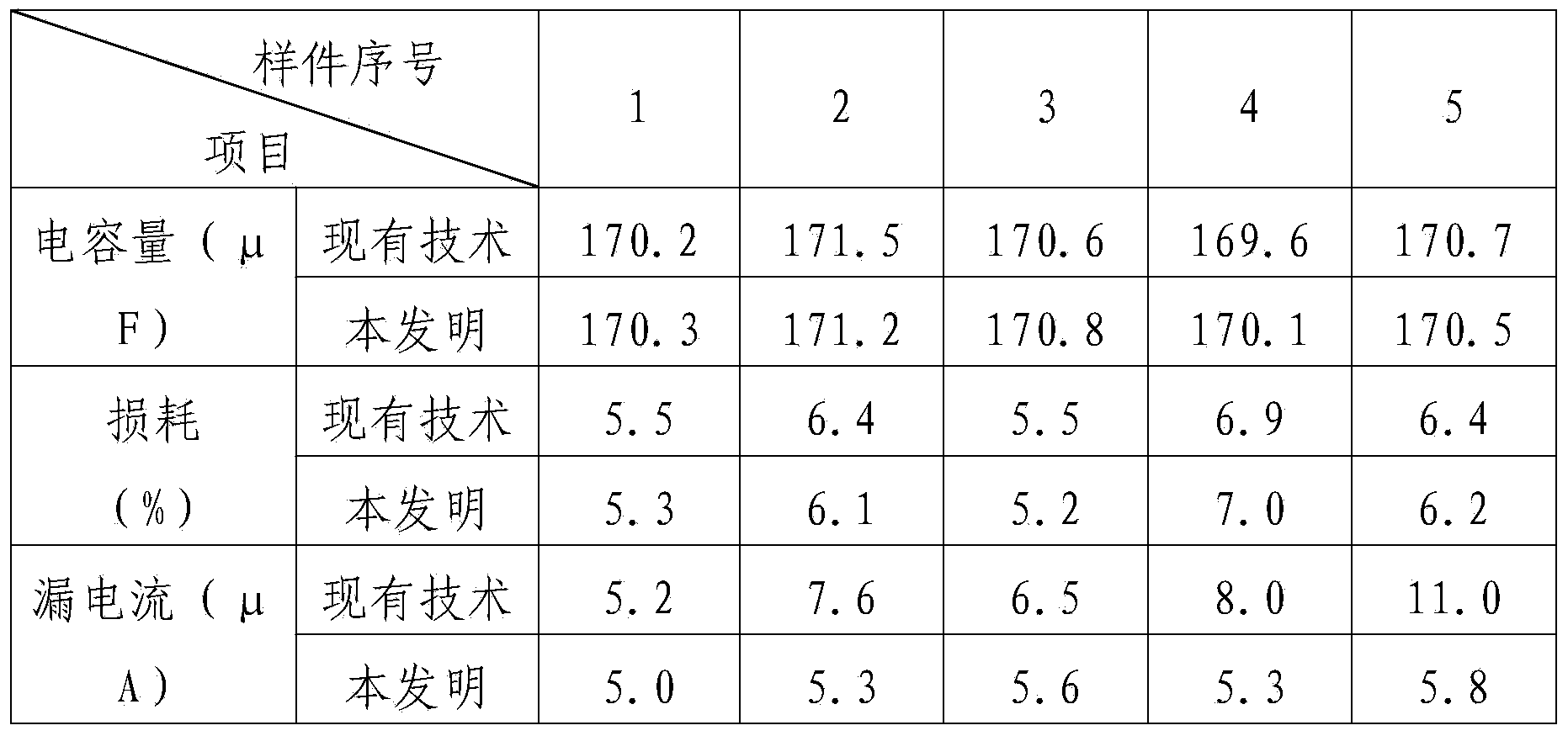

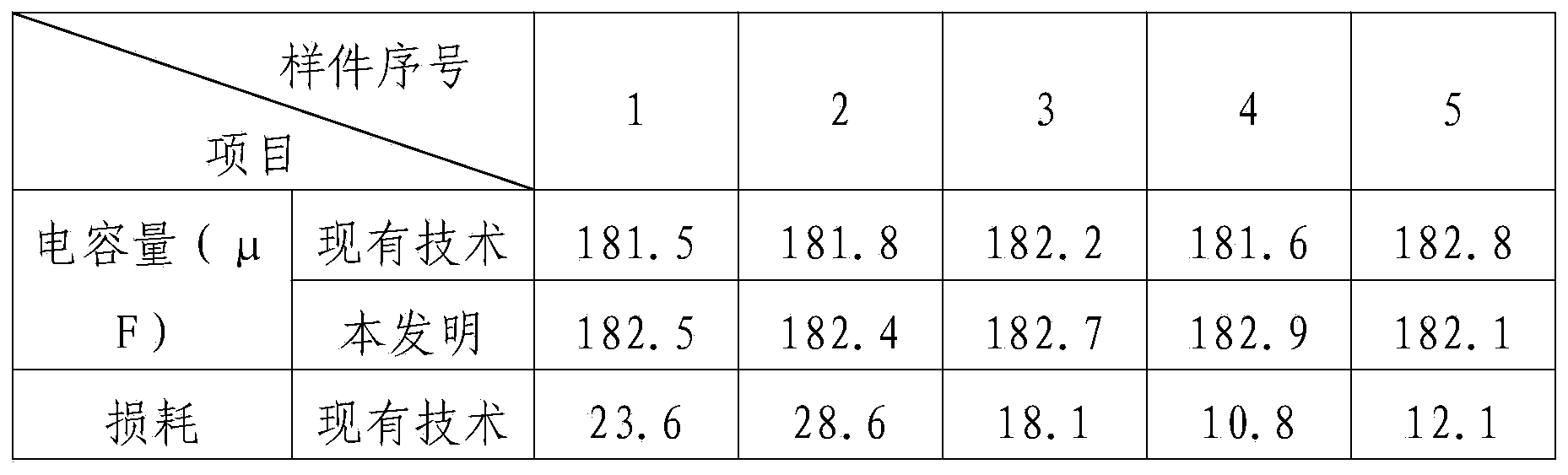

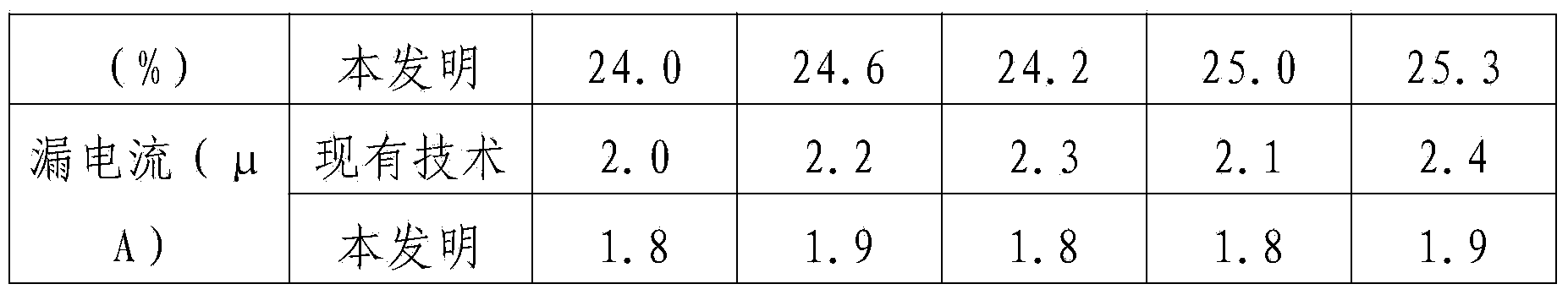

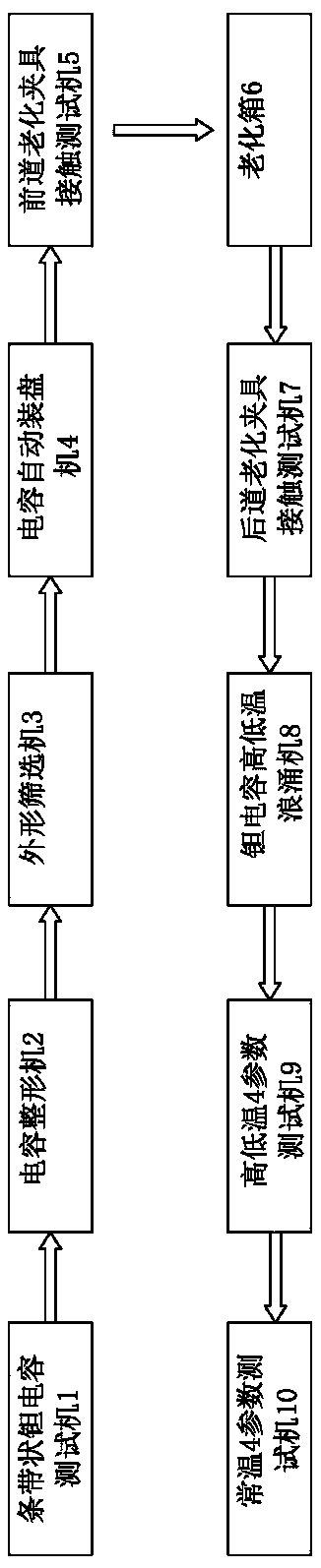

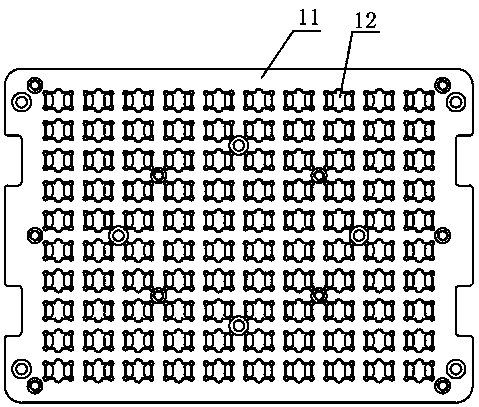

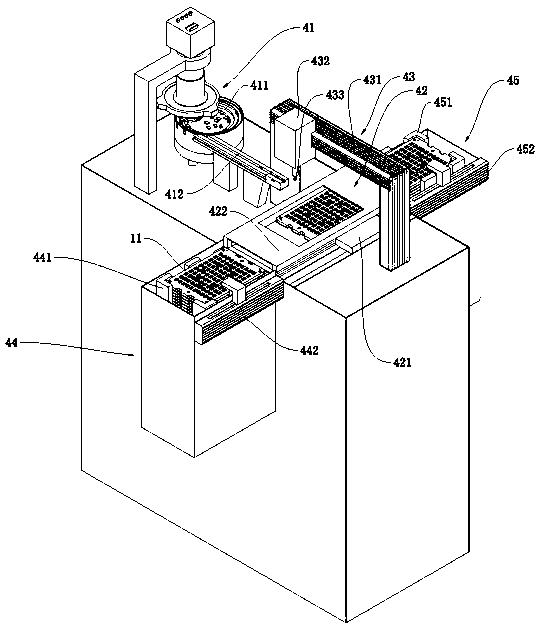

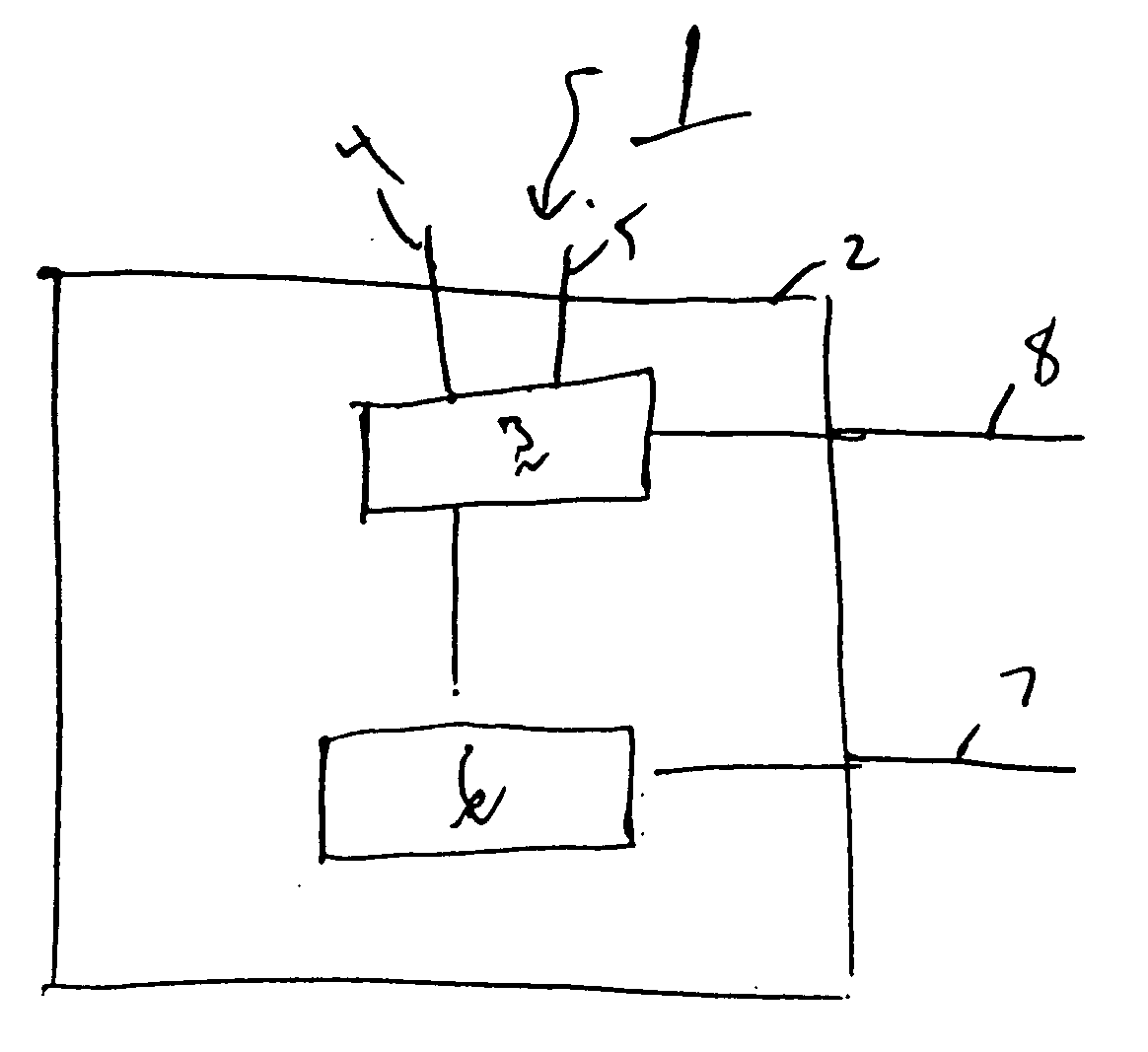

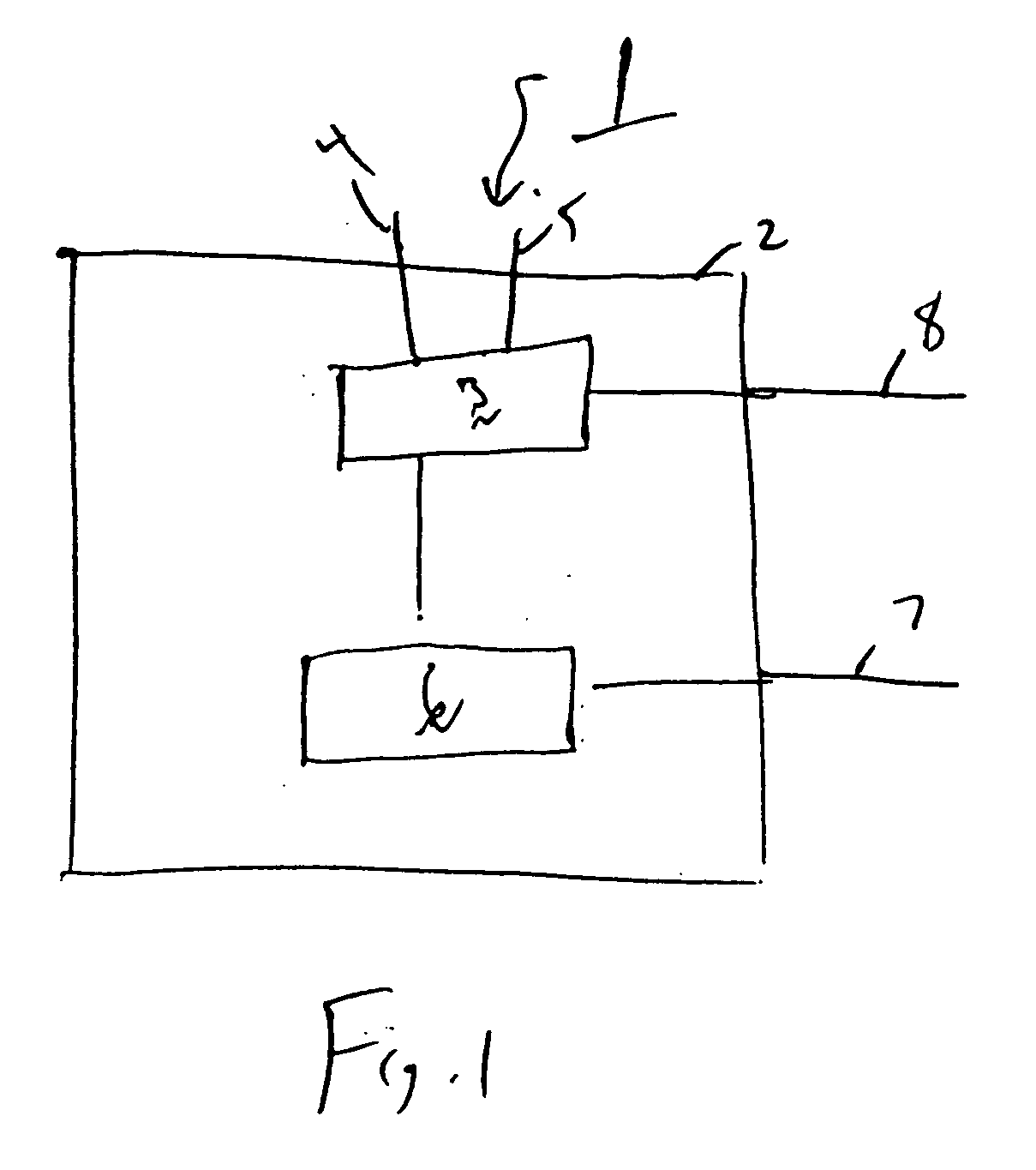

Back-end production detection process and production line of tantalum capacitors

PendingCN108761211AReduce the process of reloading tantalum capacitorsIncrease productivityDielectric property measurementsCapacitance measurementsContact testProduction line

The invention provides a back-end production detection process and a production line of tantalum capacitors, which can realize the circulation of tantalum capacitors between different test devices, and can achieve convenient and quick circulation, improve the production efficiency, and reduce the labor cost. The production line includes a strip-shaped tantalum capacitor tester, a capacitor shaper,a shape screening machine, and a capacitor auto-loader which are sequentially arranged; the auto-loader includes a circulation plate; capacitor fixing grooves capable of accommodating the capacitorsare distributed on the circulation plate; a single tantalum capacitor screened by the shape screening machine is mounted in the capacitor fixing groove of the circulation plate; the circulation platecirculates among a front-end aging fixture contact test machine, an aging box, a back-end aging fixture contact test machine, a tantalum capacitor high-low temperature surge machine, a high-low temperature 4 parameter test machine, and a normal temperature 4 parameter test machine.

Owner:江苏伊施德创新科技有限公司

Wet tantalum capacitor usable without reformation and medical devices for use therewith

ActiveUS20060187616A1Extend battery lifeSmall sizeAnodisationHeart defibrillatorsO-Phosphoric AcidElectrolysis

A therapeutic medical device system comprising an electrolytic capacitor including an anode, cathode and an electrolyte. The anode is anodized in an electrolyte comprises an aqueous solution of alkanol amine, phosphoric acid and an organic solvent preferably defined by formula 1: CH3—(OCH2CH2)m—OCH3 Formula 1 wherein m is an integer from 3 to 10.

Owner:MEDTRONIC INC

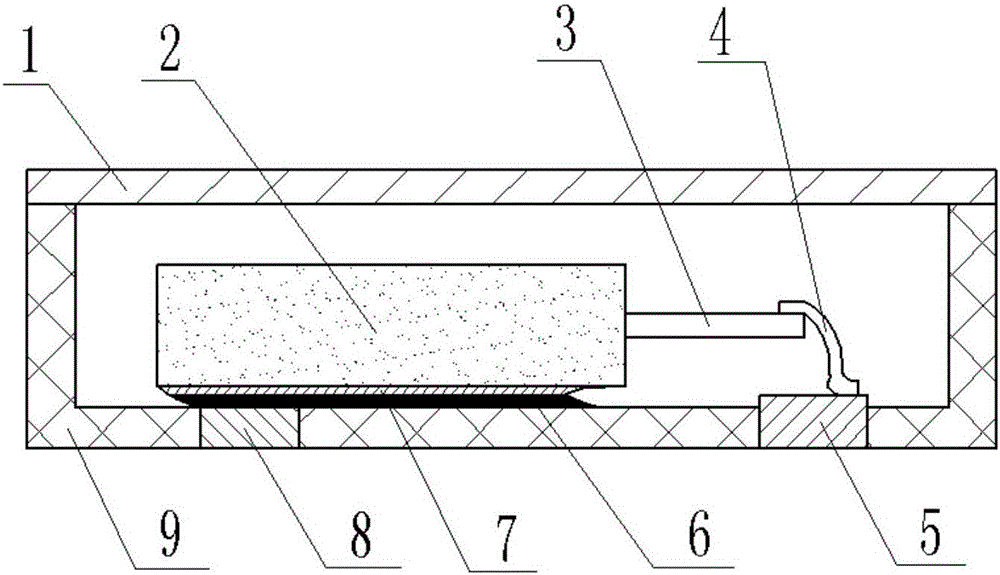

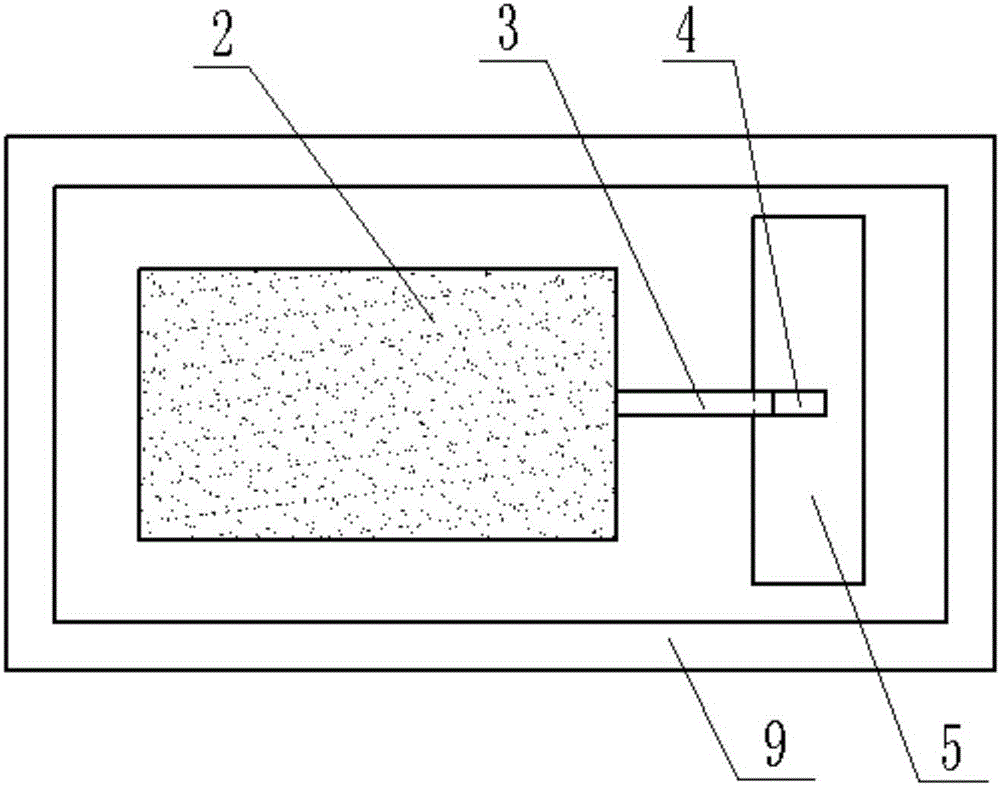

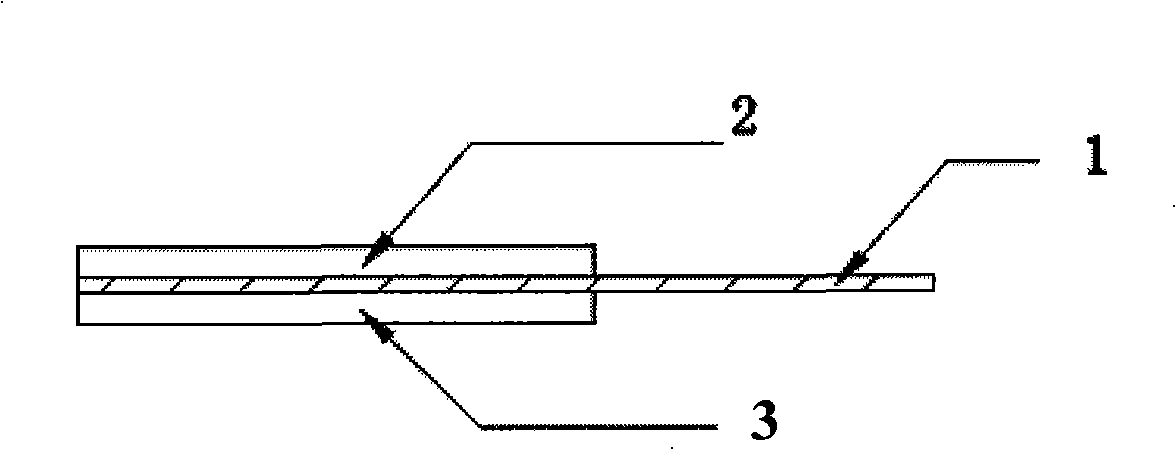

Metallic packaging structurized chip-type tantalum capacitor and packaging method thereof

ActiveCN105097288AEasy fusion weldingAvoid contact collisionSolid electrolytic capacitorsCapacitor housing/encapsulationMetallic enclosureTantalum capacitor

The invention relates to a metallic packaging structurized chip-type tantalum capacitor and a packaging method thereof. With the adoption of a metallic packaging structure, a layer of bonding conductive glue wraps outside a tantalum chip, and then a layer of metal shell wraps outside the bonding conductive glue; and meanwhile, one head of the tantalum chip is connected with a tantalum filament, and the tantalum filament is led out of the metal shell through a tantalum filament leading-out line to form the metallic packaging structurized chip-type tantalum capacitor. The tantalum filament and the tantalum filament leading-out line are connected together by welding, a welding point of the tantalum filament and the tantalum filament leading-out line is arranged on the inner surface of the metal shell, an insulation block sleeves outside the welding point of the tantalum filament and the tantalum filament leading-out line, the bonding conductive glue wraps between the insulation block and the tantalum chip and also wraps outside the insulation block, and thus, the spaces among the tantalum chip, the tantalum filament, the tantalum filament leading-out line and the shell are relatively fixed.

Owner:ZHUZHOU HONGDA ELECTRONICS

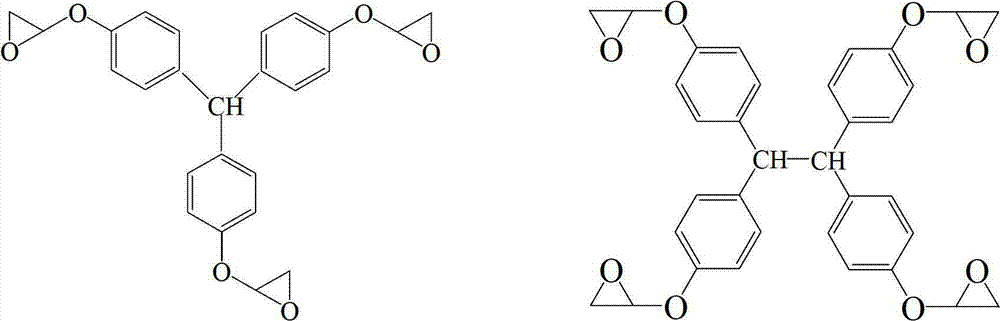

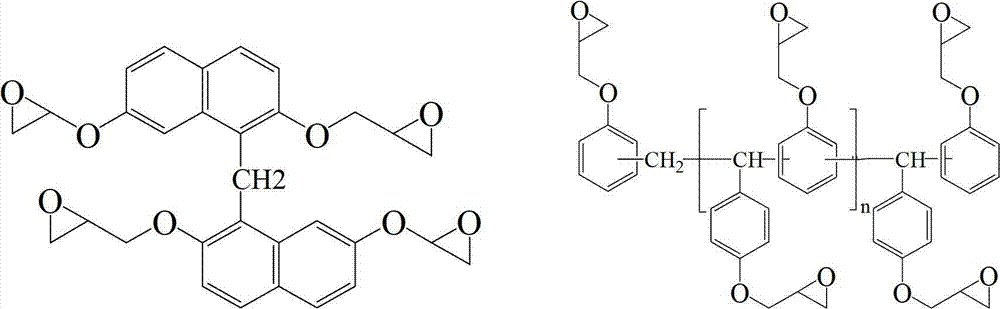

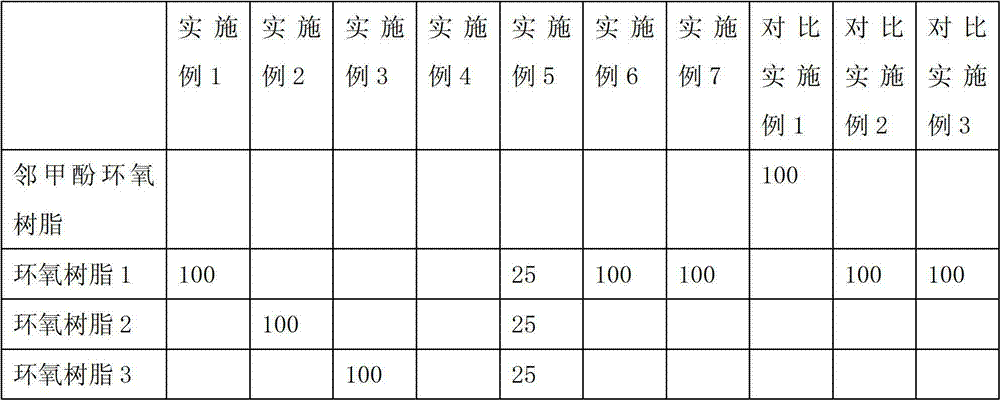

Epoxy molding compound for packaging tantalum capacitor and manufacturing method for epoxy molding compound

ActiveCN102898786AReduce melt viscosityImprove liquidityCapacitor housing/encapsulationTantalum capacitorTa element

The invention relates to an epoxy molding compound for packaging a tantalum capacitor and a manufacturing method for the epoxy molding compound, and belongs to the technical field of epoxy molding compounds. The epoxy molding compound for packaging the tantalum capacitor is characterized by comprising the following components in percentage by mass: 3 to 10 percent of multifunctional epoxy resin, 1 to 5 percent of multifunctional phenolic resin, 0.5 to 3 percent of reactive diluent, 0.5 to 2 percent of stress-releasing agent, 0.1 to 1 percent of accelerant and 70 to 90 percent of mineral filler. The manufacturing method comprises the following steps of: adding the components of the epoxy molding compound into a mixer, mixing the components uniformly, extruding the mixture by using a twin-screw extruder at the temperature of between 100 and 150 DEG C, cooling, crushing and performing pre-press molding to obtain the epoxy molding compound for packaging the tantalum capacitor. The epoxy molding compound for packaging the tantalum capacitor is halogen-free and antimony-free, can package tantalum capacitors at low temperature and under low pressure, and is low in stress, and high in moldability, relux resistance, wet resistance and reliability; the manufacturing method is convenient to operate, high in production efficiency, safe and reliable, and product quality is stable; and the epoxy molding compound is particularly suitable for packaging a polymer solid chip tantalum capacitor.

Owner:天津凯华绝缘材料股份有限公司

Method for sintering anode block of tantalum capacitor

ActiveCN102513538AHigh purityGuaranteed purityFixed capacitor electrodesElectrolytic capacitorsCapacitancePorosity

A method for sintering an anode block of a tantalum capacitor is characterized by including: placing tantalum anode block pressed by tantalum powder mixed with adhesive in a drying furnace filled with degreased solvent, performing airtight low-temperature solvent catalysis wet dewaxing, drying in vacuum and then performing vacuum sintering. The tantalum anode block obtained through the method maintains high specific surface area and high porosity, so that the tantalum anode block is high in specific capacity and low in leakage current, carbon content and oxygen content of the anode block can respectively drop to 0.005%-0.010% and 0.18% to 0.65%.

Owner:TAIKE TECH SUZHOU

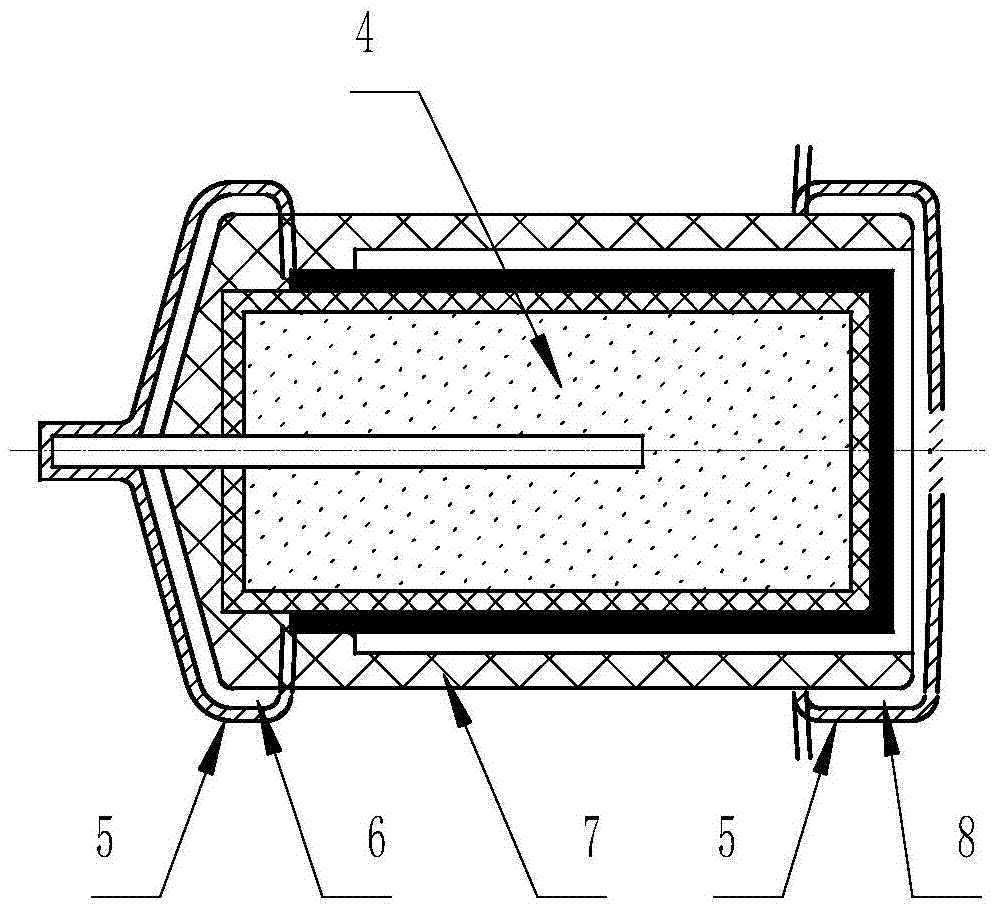

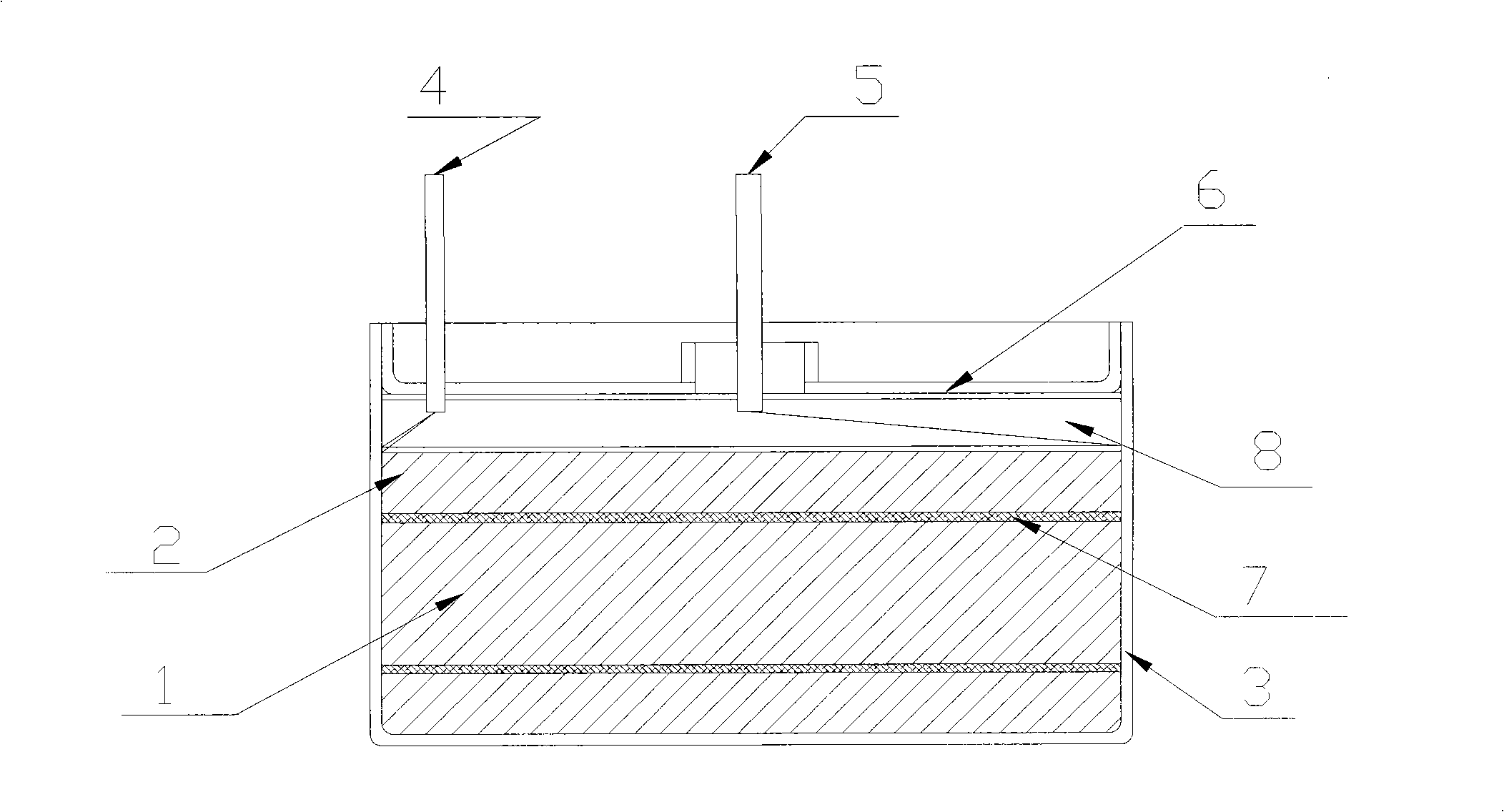

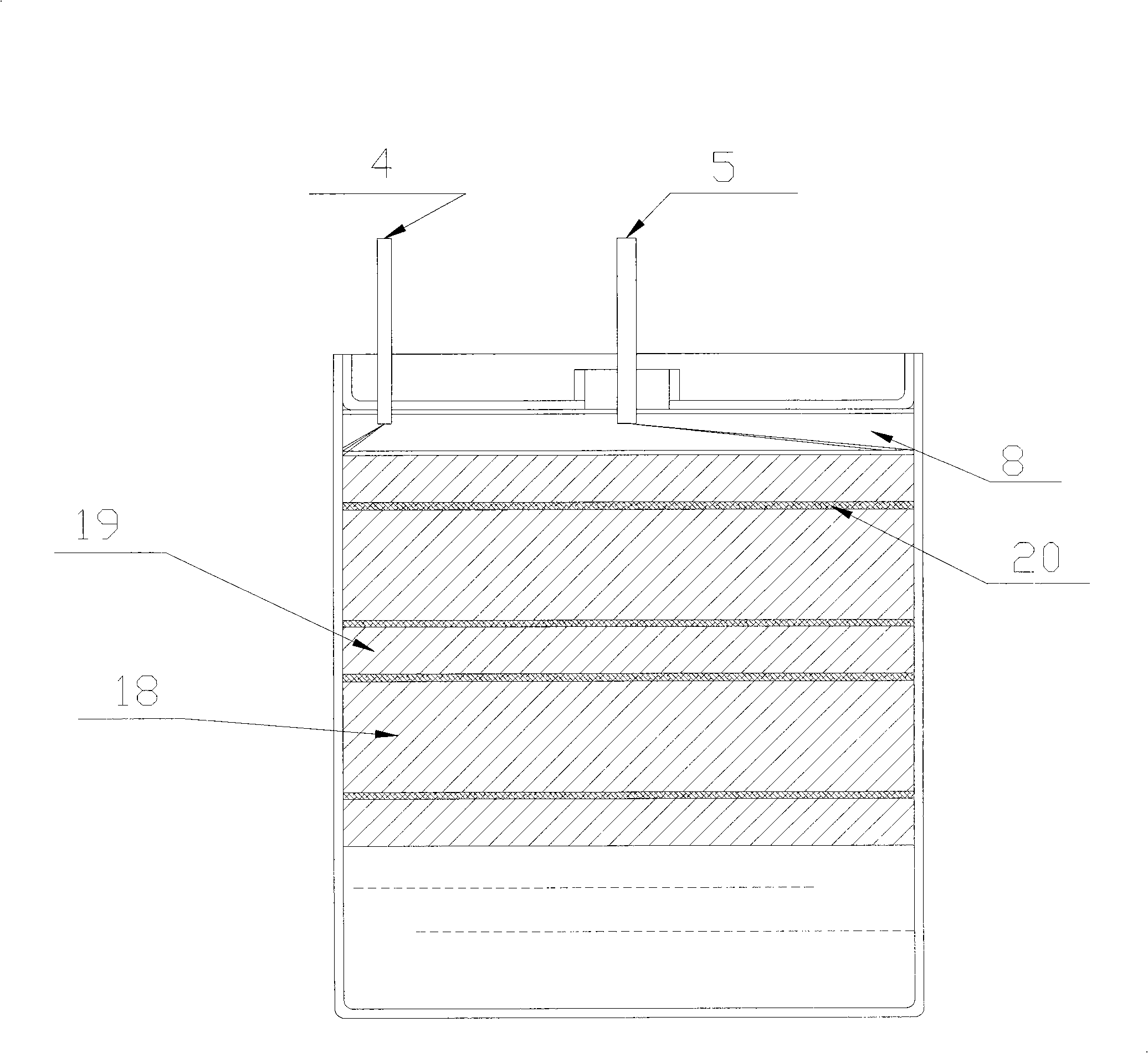

Non solid electrolyte all tantalum capacitor and preparation thereof

ActiveCN101339849AImproved back pressure capabilityIncrease capacityCapacitor electrolytes/absorbentsCapacitor housing/encapsulationTantalum capacitorPorous tantalum

The invention discloses a non-solid electrolyte all-tantalum capacitor and a preparation method thereof. The non-solid electrolyte all-tantalum capacitor comprises an enclosure, a cathode strip, an anode strip, a cathode lead, an anode lead and a gland, wherein, the cathode strip and the anode strip are arranged inside the enclosure; the cathode lead is connected with the cathode strip by penetrating the gland; the anode lead is connected with the anode strip by penetrating the gland; a porous tantalum core cathode strip produced by the pressing and sintering of tantalum metal powder is adopted, the two sides of the anode strip and / or the cathode strip are attached with a metal oxide film medium TaO5 for insulation and back pressure resistance; the cathode strip and the anode strip are of sandwich structure in which two layers of cathode strips clamp one layer of anode strip, an isolating and insulating layer is arranged between the anode strip and the cathode strip; the cathode strip consists of porous tantalum cores and the metal oxide film medium as the insulating layer can also be attached to the cathode strip; and the structures of the enclosure, the gland and the like of the capacitor are composed of tantalum material; The non-solid electrolyte is filled around the anode strip and the cathode strip as well as in the porous tantalum core pores of the anode strip and the cathode strip, thus the non-solid electrolyte all-tantalum capacitor is formed.

Owner:ZHUZHOU HONGDA ELECTRONICS

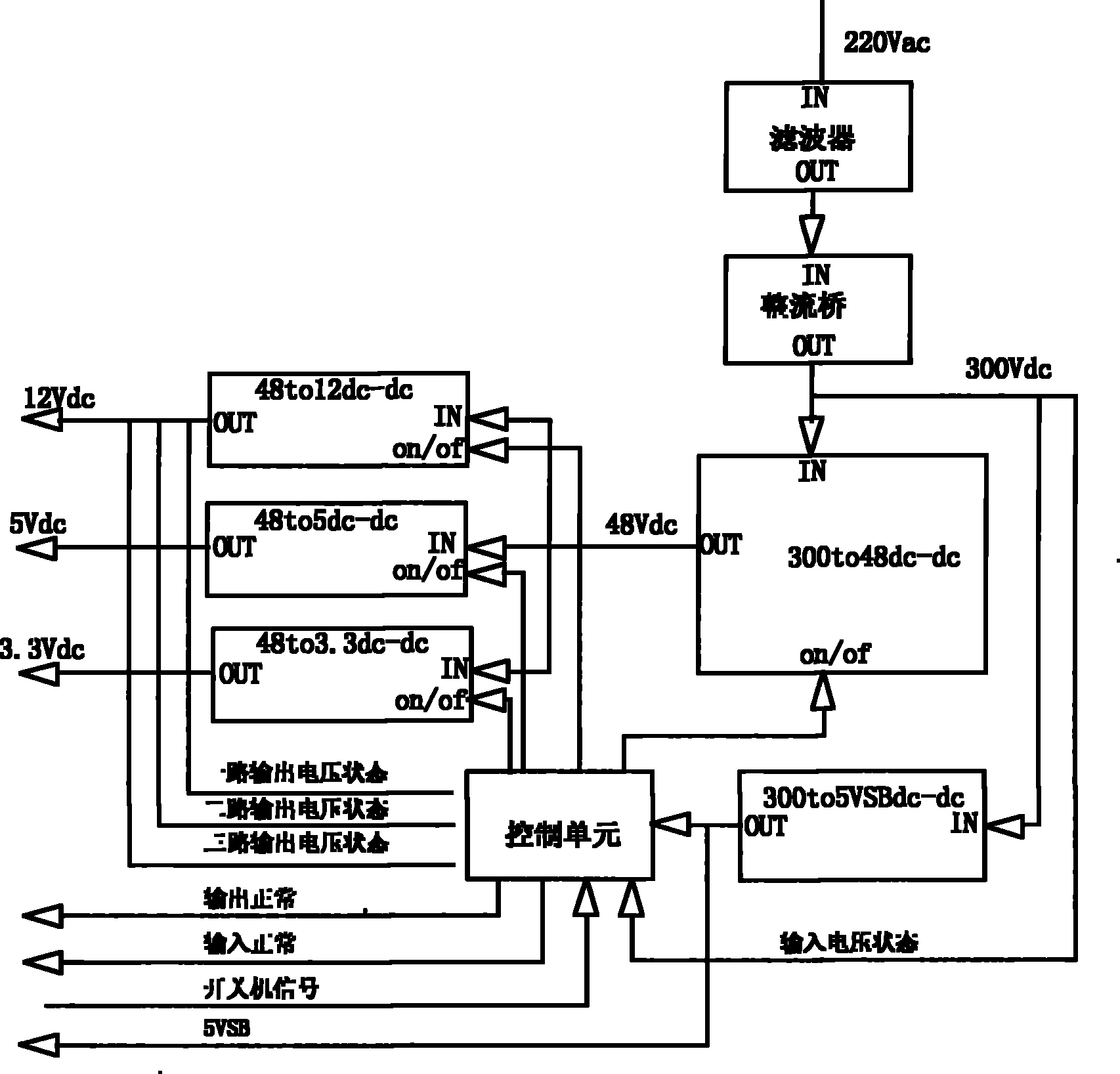

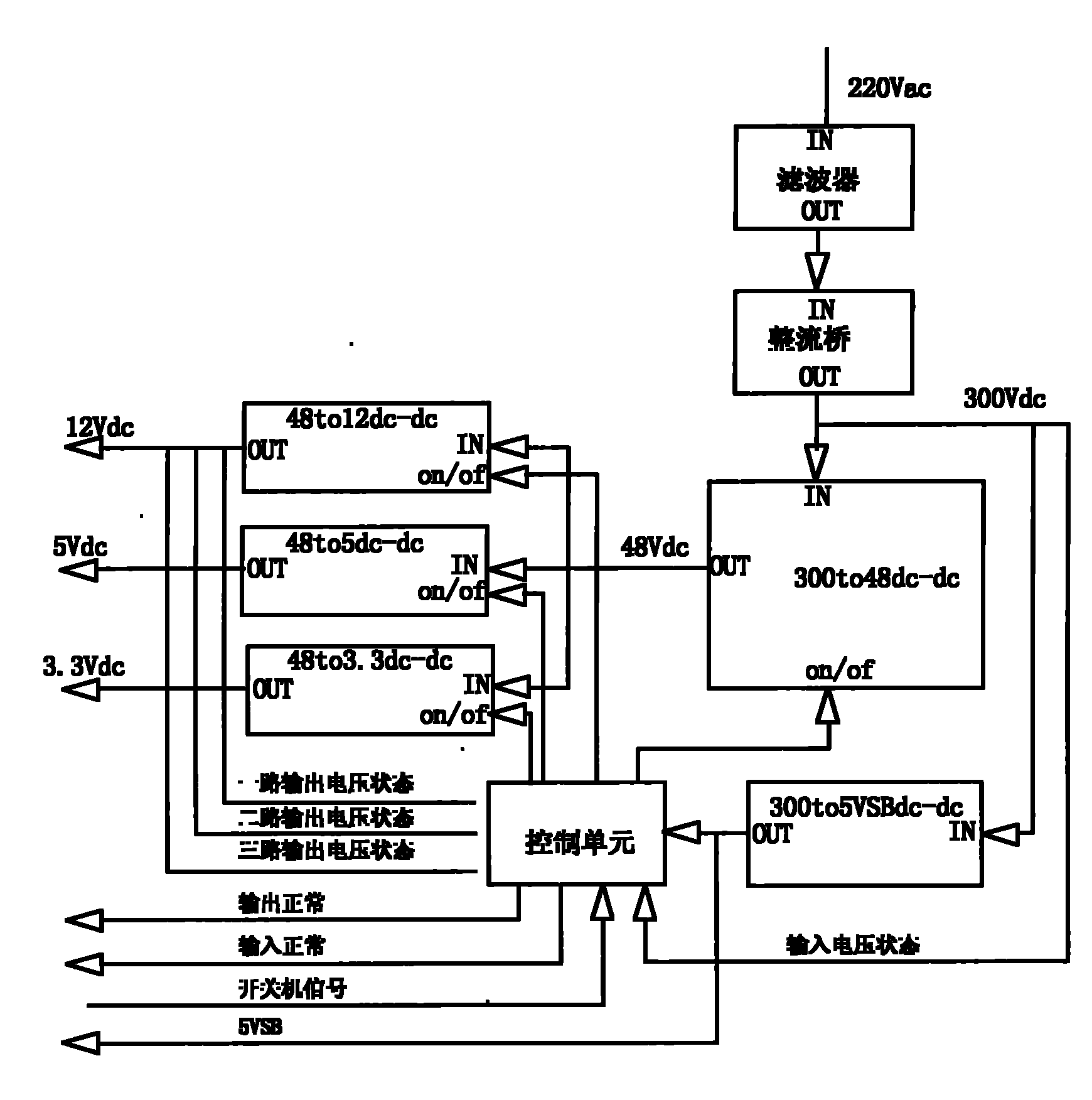

Method for designing high-power and high-reliability server power supply by using modular power supply

InactiveCN101895191AWide temperature rangeGuaranteed to workApparatus without intermediate ac conversionCooling/ventilation/heating modificationsCapacitanceCeramic capacitor

The invention provides a method for designing a high-power and high-reliability server power supply by using a modular power supply. The method comprises the following steps of: 1) replacing a conventional printed circuit board (PCB) by a metal substrate in a brick-type DC-DC modular power supply, dissipating heat in a thermal conduction mode by using the metal substrate to save a fan and eliminate noises; 2) using surface mounting technology (SMT) capacitors including a multilayer ceramic capacitor and a tantalum capacitor in the brick-type DC-DC modular power supply to save an electrolytic capacitor, enhance reliability, reduce size and ensure that the brick-type DC-DC modular power supply runs at the temperature of between 55 DEG C below zero and 85 DEG C due to the saving of the electrolytic capacitor; and 3) filtering alternating current of 220V by using a filter, converting the filtered alternating current into high-voltage direct current by using a rectifier bridge, converting the brick-type DC-DC modular power supply input by the high-voltage direct current into intermediate direct current bus voltage of 48V and Standby voltage, converting the input brick-type DC-DC modular power supply of 48V into various voltages needed by a system, setting a control unit, controlling the time sequence of each path of output and providing various monitoring signals.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Technique method of preparing cathode of panseal non-solid electrolytes whole tantalum capacitor

ActiveCN101494120AImprove performanceLarge capacityCapacitor electrodesFurnace temperaturePhosphoric acid

The invention discloses a method for preparing a cathode of a full-sealing non-solid-electrolyte full tantalum capacitor; the method comprises the processing of a current collector, the molding and sintering of the cathode and the electrochemical oxidation of a tantalum cathode; the method at least comprises the following technical steps: (1) tantalum chips or tantalum meshes or tantalum felts are taken as the current collector which then is processed; the tantalum chips or tantalum meshes are put in a solution containing inorganic acids including sulfuric acid, nitric acid or hydrofluoric acid and the like for surface treatment, heated and boiled, washed with clean water and finally dried to obtain the processed current collector; (2) the processed current collector is put in a molding-machine die, loaded with high specific-volume tantalum powder, compressed and molded by the molding machine, put into a vacuum sintering furnace for vacuum sintering, sintered at the temperature of 1,200 DEG C to 1,600 DEG C for 20 minutes to 60 minutes, and the cathode is taken out of after the furnace temperature is reduced; and (3) the molded and sintered tantalum cathode is put in the phosphoric acid solution for the electrochemical oxidation and is applied with certain direct current and voltage so that a layer of tantalum pentoxide film is produced on the surface of the tantalum cathode.

Owner:ZHUZHOU HONGDA ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com