Burn-in method of high-temperature-resistant tantalum capacitor

A tantalum capacitor, high temperature resistant technology, used in the field of tantalum electrolytic capacitor aging, can solve the problems of instrument output waveform distortion, high downtime cost, circuit can not work normally, etc., to ensure reliability and life, improve service life, shorten Effects of aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

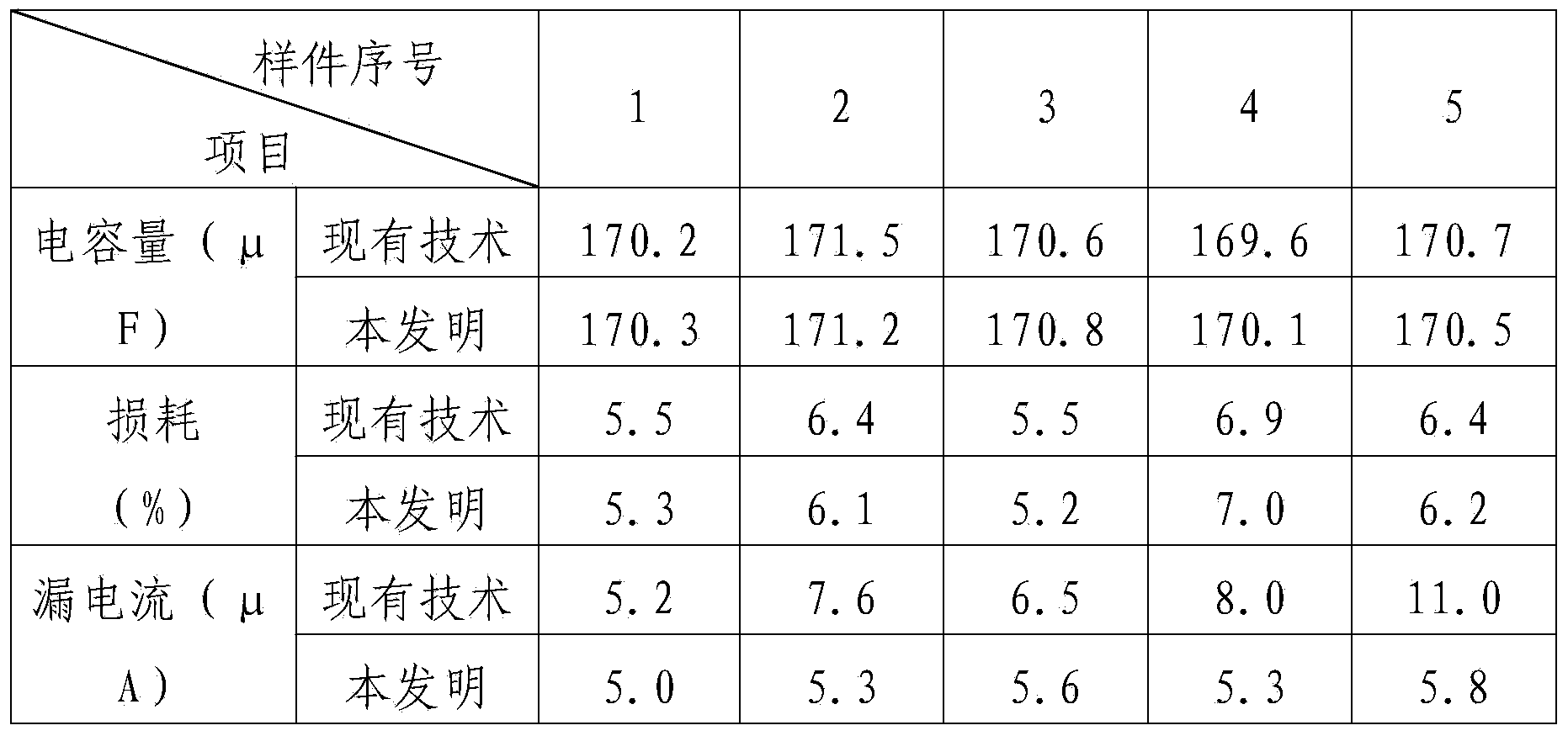

Embodiment 1

[0019] An aging method for high temperature resistant tantalum capacitors, taking CAXH type 50V160μF as an example, it includes the following steps:

[0020] (1) Apply a constant voltage of 3V to the packaged tantalum capacitor for 1.5h at room temperature;

[0021] (2) Stage of temperature rise and pressure application: Apply a DC voltage to both ends of the encapsulated tantalum capacitor at a temperature of 85°C, power on for 12 hours, and the applied voltage is 1U R , where U R The rated voltage of the tantalum capacitor is 50V;

[0022] (3), temperature rise and pressure stage II: Apply a DC voltage to both ends of the tantalum capacitor at a temperature of 125°C, power on for 1h, and the applied voltage is 0.63U R ;

[0023] (4) Temperature rise and pressure stage Ⅲ: Apply a DC voltage to both ends of the tantalum capacitor at a temperature of 200°C, power on for 2.5h, and the applied voltage is 0.58U R ;

[0024] (5) Stage IV of temperature rise and pressure applic...

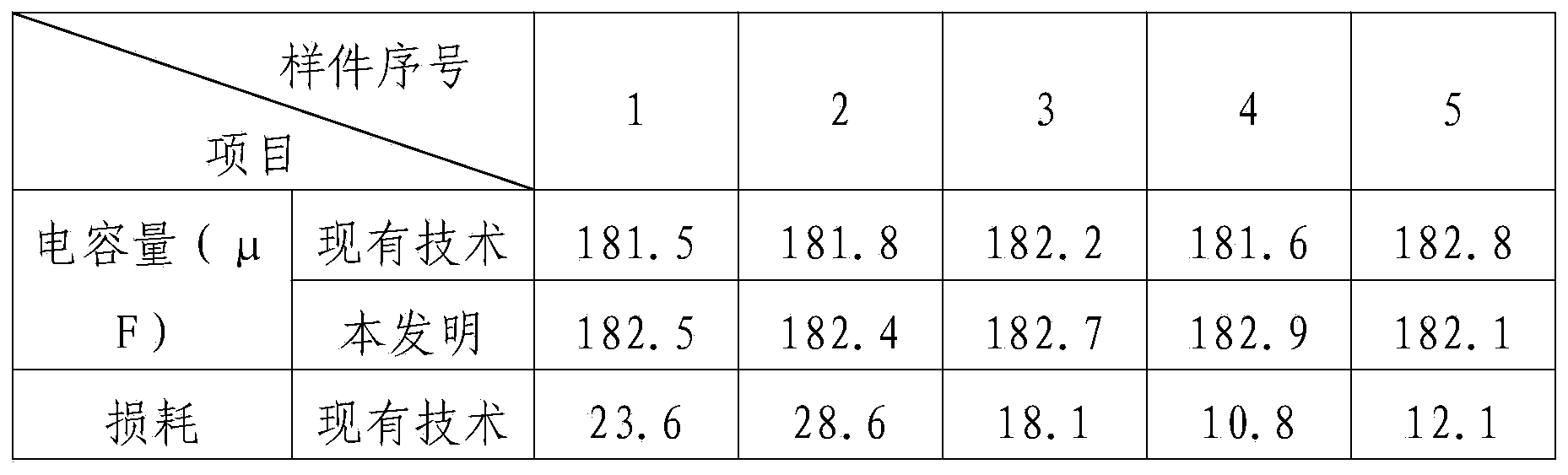

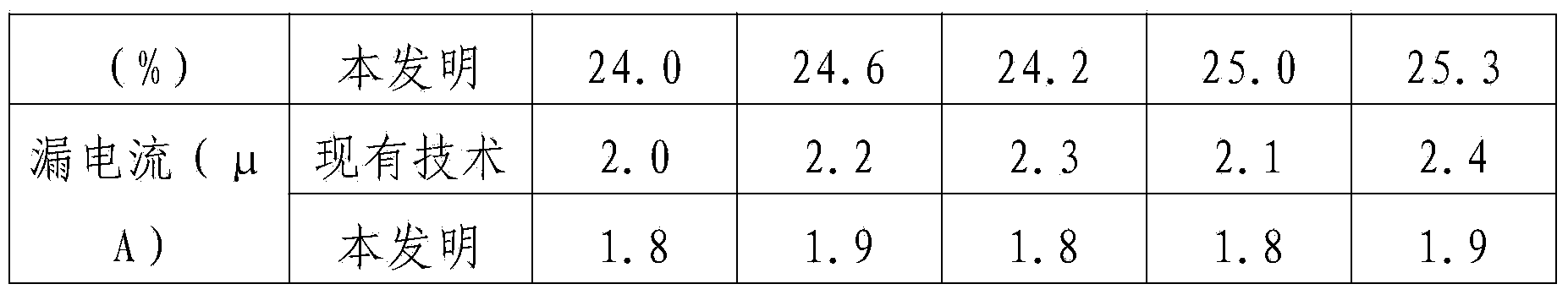

Embodiment 2

[0028] A aging method for high temperature resistant tantalum capacitors, CAXH type 75V180μF, it includes the following steps:

[0029] (1) Apply a constant voltage of 5V to the packaged tantalum capacitor for 1.5h at room temperature;

[0030] (2), temperature rise and pressure stage Ⅰ: Apply a DC voltage to both ends of the packaged tantalum capacitor at a temperature of 85°C, power on for 12 hours, and the applied voltage is U R , where U R The rated voltage of the tantalum capacitor is 75V;

[0031] (3) Phase II of temperature rise and pressure application: Apply a DC voltage to both ends of the tantalum capacitor at a temperature of 125°C, power on for 1.5h, and the applied voltage is 0.63U R ;

[0032] (4) Temperature rise and pressure stage Ⅲ: Apply a DC voltage to both ends of the tantalum capacitor at a temperature of 200°C, power on for 2 hours, and the applied voltage is 0.58U R ;

[0033] (5) Stage IV of temperature rise and pressure application: Apply a DC vo...

Embodiment 3

[0037] A method for aging a high-temperature-resistant tantalum capacitor, which comprises the following steps:

[0038] (1) Apply a constant voltage of 4V to the packaged tantalum capacitor for 1.5h at room temperature;

[0039] (2), temperature rise and pressure stage Ⅰ: Apply a DC voltage to both ends of the encapsulated tantalum capacitor at a temperature of 80°C, power on for 24 hours, and the applied voltage is 1U R , where U R is the rated voltage of the tantalum capacitor;

[0040] (3) Phase II of temperature rise and pressure application: Apply a DC voltage to both ends of the tantalum capacitor at a temperature of 120°C, power on for 3 hours, and the applied voltage is 0.65U R ;

[0041] (4), temperature rise and pressure stage III: Apply a DC voltage to both ends of the tantalum capacitor at a temperature of 190°C, power on for 1.5h, and the applied voltage is 0.55U R ;

[0042] (5) Stage IV of temperature rise and pressure application: Apply a DC voltage to bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com