Back-end production detection process and production line of tantalum capacitors

A technology for production testing and tantalum capacitors, applied in capacitance measurement, dielectric performance measurement, measurement of electricity, etc., can solve the problems of poor connection and flow coordination, low production efficiency, and a lot of labor, so as to save manual labor intervention. , The effect of improving production efficiency and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

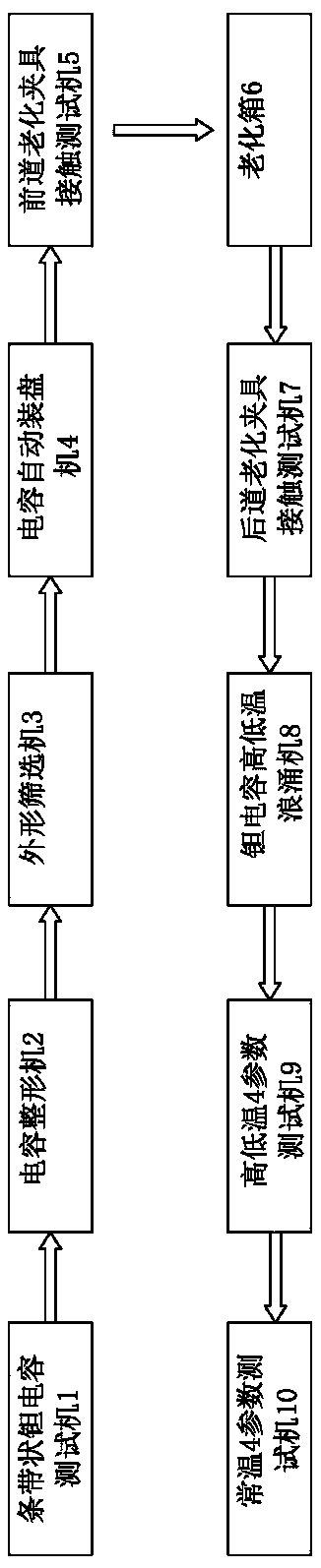

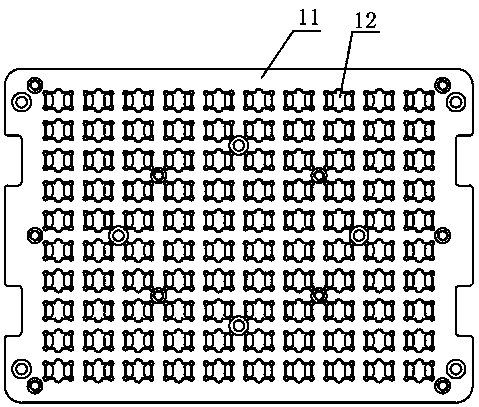

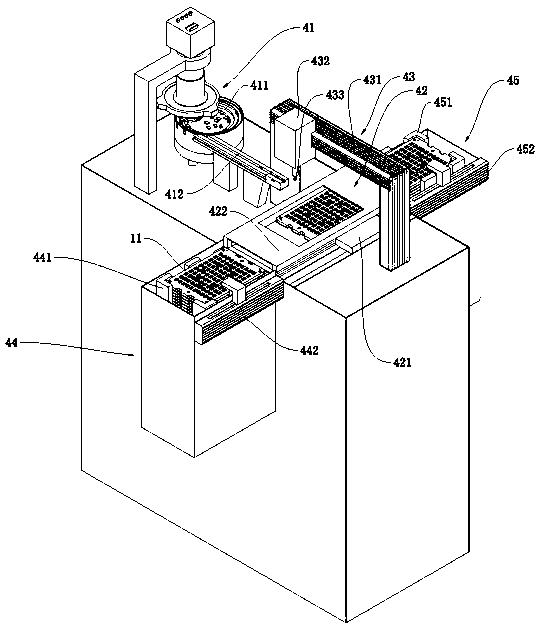

[0032] The post-production detection process of the tantalum capacitor of the present invention divides the semi-finished tantalum capacitors that are connected together in strips from the previous production process into individual tantalum capacitors, and uses a transfer plate capable of loading a single tantalum capacitor to load the tantalum capacitors. Capacitors, transfer tantalum capacitors between various production and testing equipment through the transfer plate, and a single tantalum capacitor can expose its own electrodes in the transfer plate for testing. After the transfer plate is loaded with tantalum capacitors, it can be used in each production and testing equipment. In the test, the following steps are specifically included:

[0033] Step 1, strip-shaped tantalum capacitor test: carry out capacitance, loss, leakage current, and ESR tests on the tantalum capacitors connected together in strips that are semi-finished products produced in the previous production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com