Metallic packaging structurized chip-type tantalum capacitor and packaging method thereof

A technology of metal encapsulation and tantalum capacitors, applied in the direction of capacitor shell/package, capacitors, electrolytic capacitors, etc., to ensure the effect of welding sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

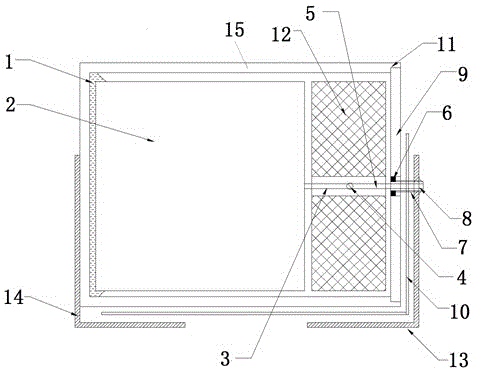

[0032] by attaching figure 1 It can be seen that the present invention relates to a chip tantalum capacitor with a metal package structure, which adopts a metal package structure, wraps a layer of bonding conductive adhesive 1 on the outside of the tantalum chip 2, and then wraps a layer of metal shell 11 on the outside of the bonding conductive adhesive 1 At the same time, a tantalum wire 3 is connected to one end of the tantalum chip 2, and the tantalum wire 3 is led out of the metal shell 11 through the tantalum wire lead-out wire 5, forming a chip tantalum capacitor with a metal package structure.

[0033] The tantalum wire 3 and the tantalum wire lead-out wire 5 are connected by welding, and the welding point 4 of the tantalum wire 3 and the tantalum wire lead-out wire 5 is located on the inner surface of the metal shell 11, and the tantalum wire 3 and the tantalum wire lead-out wire 5 The welding point 4 is covered with an insulating block 12, between the insulating blo...

Embodiment 2

[0038] The structure of the second embodiment is basically the same as that of the first embodiment, except that an "L"-shaped positive pole pin 13 and an "L"-shaped negative pole pin 14 are respectively connected to the cylinder body and the cover plate of the metal casing; wherein, The "L"-shaped positive pin 13 is connected to the tantalum wire lead-out line protruding from the cover plate, and the "L"-shaped negative pin 14 is connected to the bottom of the cylinder of the metal casing, and the positive pin and the negative pin The two toes are arranged opposite to each other, which is convenient for connection with the outside.

Embodiment 3

[0040] The structure of the third embodiment is basically the same as that of the second embodiment, except that an "L"-shaped insulating sheet 10 is set on the tantalum wire lead-out line between the positive pin and the cover plate, and the insulating sheet 10 is "L"-shaped. The top of the folded edge extends between the negative pin and the barrel of the metal casing to prevent short-circuiting of the positive and negative poles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com