Photoelectric glass maintenance device and method

A technology of photoelectric glass and current detection device, which is applied in the direction of measuring devices, optical testing of defects/defects, and material analysis through optical means, which can solve the problem of low repair accuracy, false welding of lamp beads and lines, and affect the maintenance of photoelectric glass effect and other issues, to achieve the effect of improving accuracy and avoiding vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

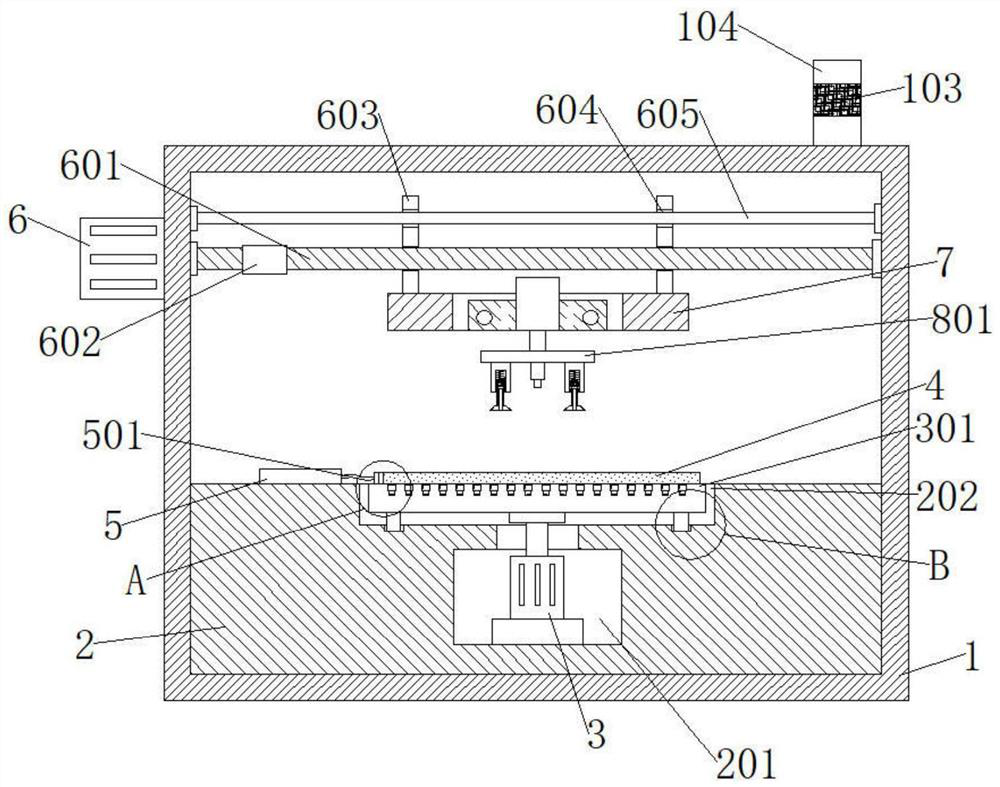

[0061] see Figure 1-13 middle,

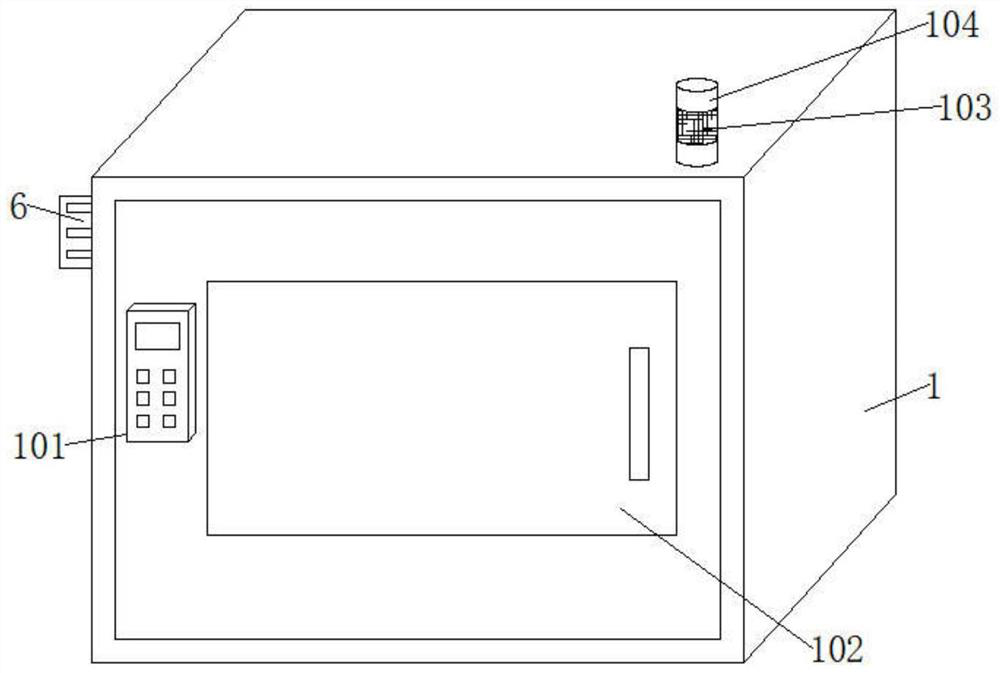

[0062] A maintenance device for photoelectric glass provided in this embodiment is fixedly installed on a body 1, and

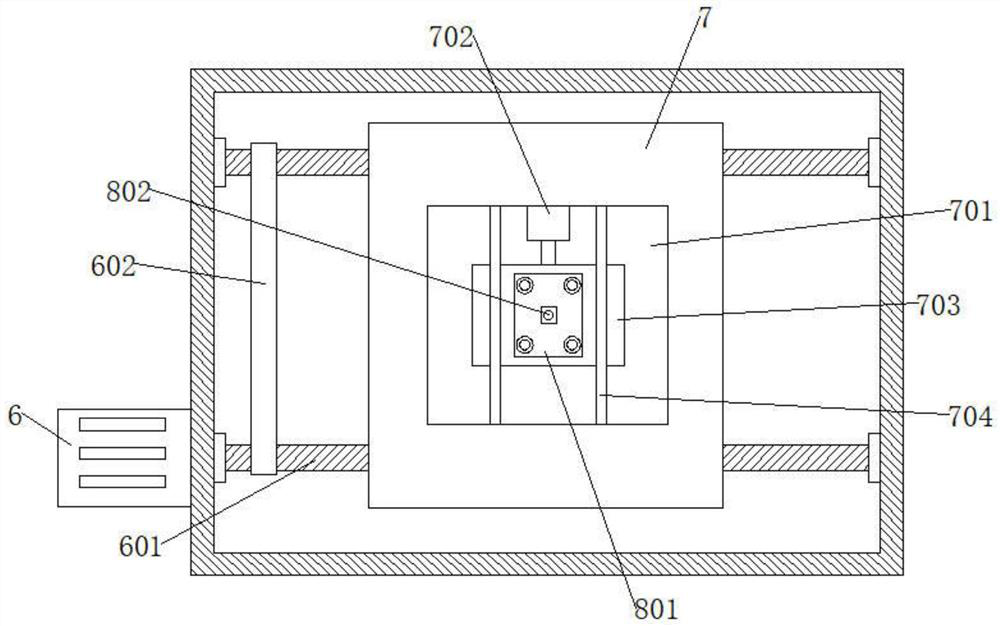

[0063] The workbench 2 fixedly installed inside the body 1, the top of the workbench 2 is provided with a lifting plate 801, the top of the workbench 2 is provided with a placement groove 202, and the inside of the placement groove 202 is provided with a detection platform 301 for matching use;

[0064] The photoelectric glass 4 placed on the top of the detection platform 301, the front of the body 1 is fixedly installed with the control panel 101, and the top of the lifting plate 801 is provided with a longitudinal moving plate 703;

[0065] The second electric push rod 8 fixedly installed on the top of the longitudinal moving plate 703, and the laser head 802 is fixedly installed at the bottom of the lifting plate 801;

[0066] A positioning component fixedly installed between the detection table 301 and the photoelectric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com