Non solid electrolyte all tantalum capacitor and preparation thereof

A tantalum capacitor and electrolyte technology, applied in the field of electronic components, can solve the problems of low reliability, insufficient capacity of tantalum capacitors, poor back pressure resistance, etc., and achieve high reliability, strong back pressure resistance, and back pressure ability. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

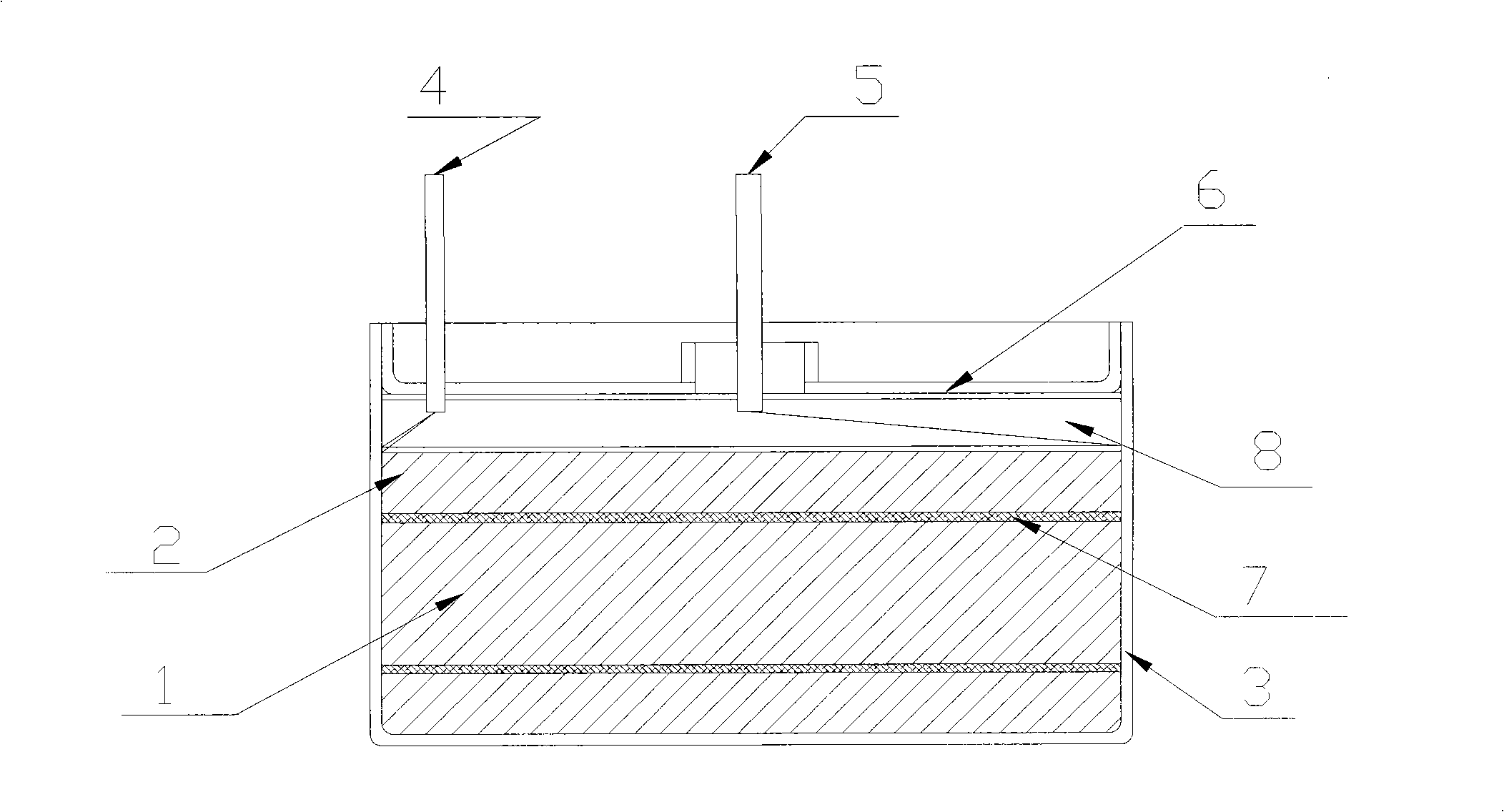

[0021] attached figure 1 A schematic diagram of the basic structure of the present invention is given. It can be seen from the accompanying drawings that the present invention is a non-solid electrolyte all-tantalum capacitor, which adopts a new non-solid electrolyte all-tantalum capacitor structure and its manufacturing process. A bidirectional energization method is adopted, and a layer of anti-back pressure TaO is attached to both sides of the anode sheet 1 and / or cathode sheet 2. 5 Metal oxide film medium, and adopts the sandwich structure of two layers of cathode sheet and one layer of anode sheet, the anode sheet 1 and the cathode sheet 2 are composed of porous tantalum core, around the anode sheet 1 and cathode sheet 2 in the capacitor shell 3, And the holes of the porous tantalum core of the anode sheet 1 and the cathode sheet 2 are all filled with non-solid electrolyte, through the back pressure TaO on the anode sheet 1 and / or cathode sheet 2 5 The metal oxide film g...

Embodiment 2

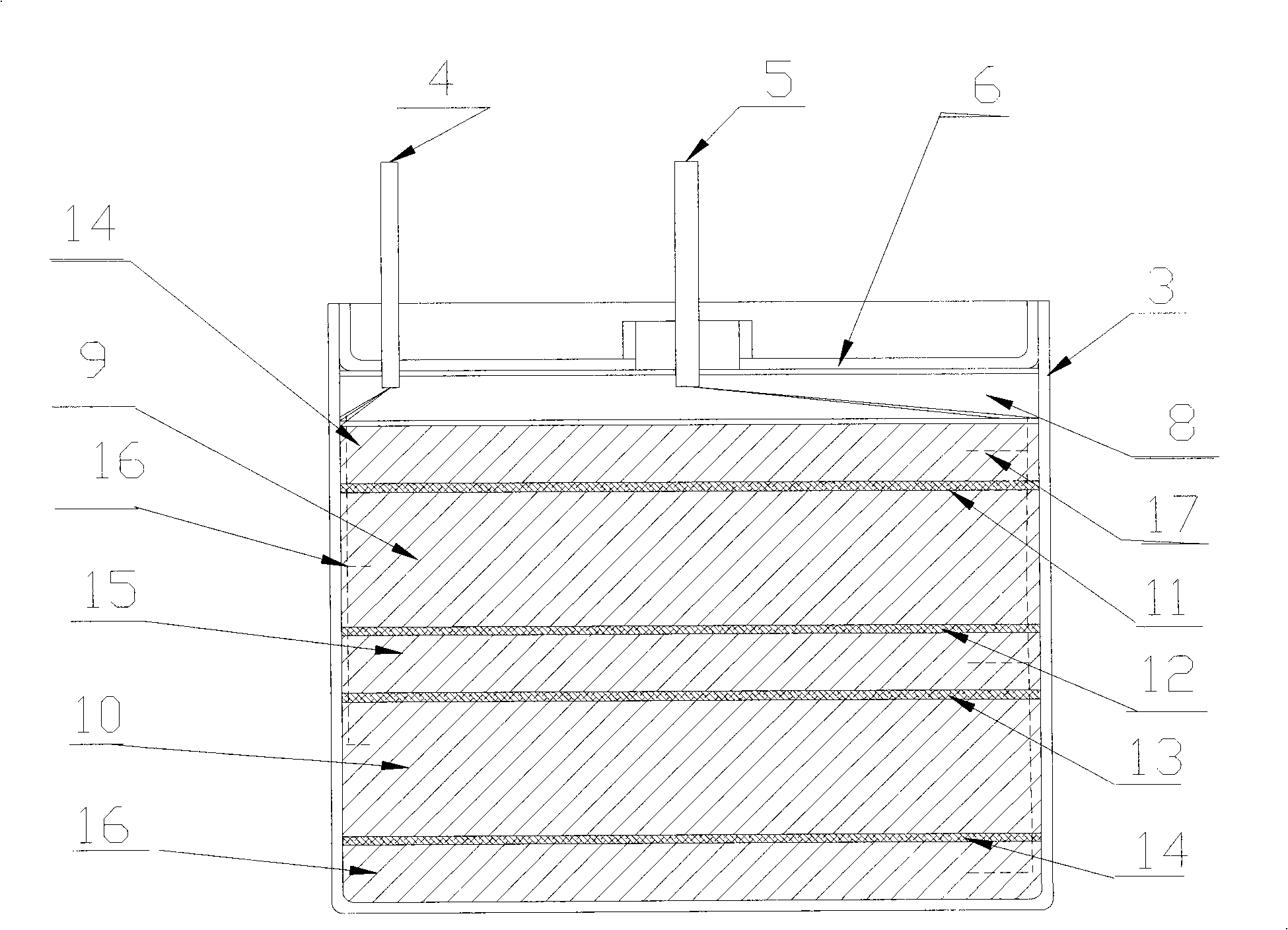

[0031] attached figure 2 A schematic diagram of another structure of the present invention is given. It can be seen from the accompanying drawings that the structural principle of the second embodiment is the same as that of the first embodiment, except that this embodiment adopts a double-layer anode sheet structure. figure 2Among them, the first layer of anode sheets 9 and the second layer of anode sheets 10 are alternately separated from the first cathode sheets 14, the second cathode sheets 15 and the third cathode sheets 16, and each layer of anode sheets is in contact with the cathode sheet. The first insulating layer 11, the first insulating layer 12, the third insulating layer 13, and the fourth insulating layer 14 are arranged between the surfaces; the first layer of anode sheet 9 and the second layer of anode sheet 10 are connected in series by a lead wire 15 and passed through the anode The lead wire 16 leads out, and the first cathode sheet 14 , the second cathod...

Embodiment 3

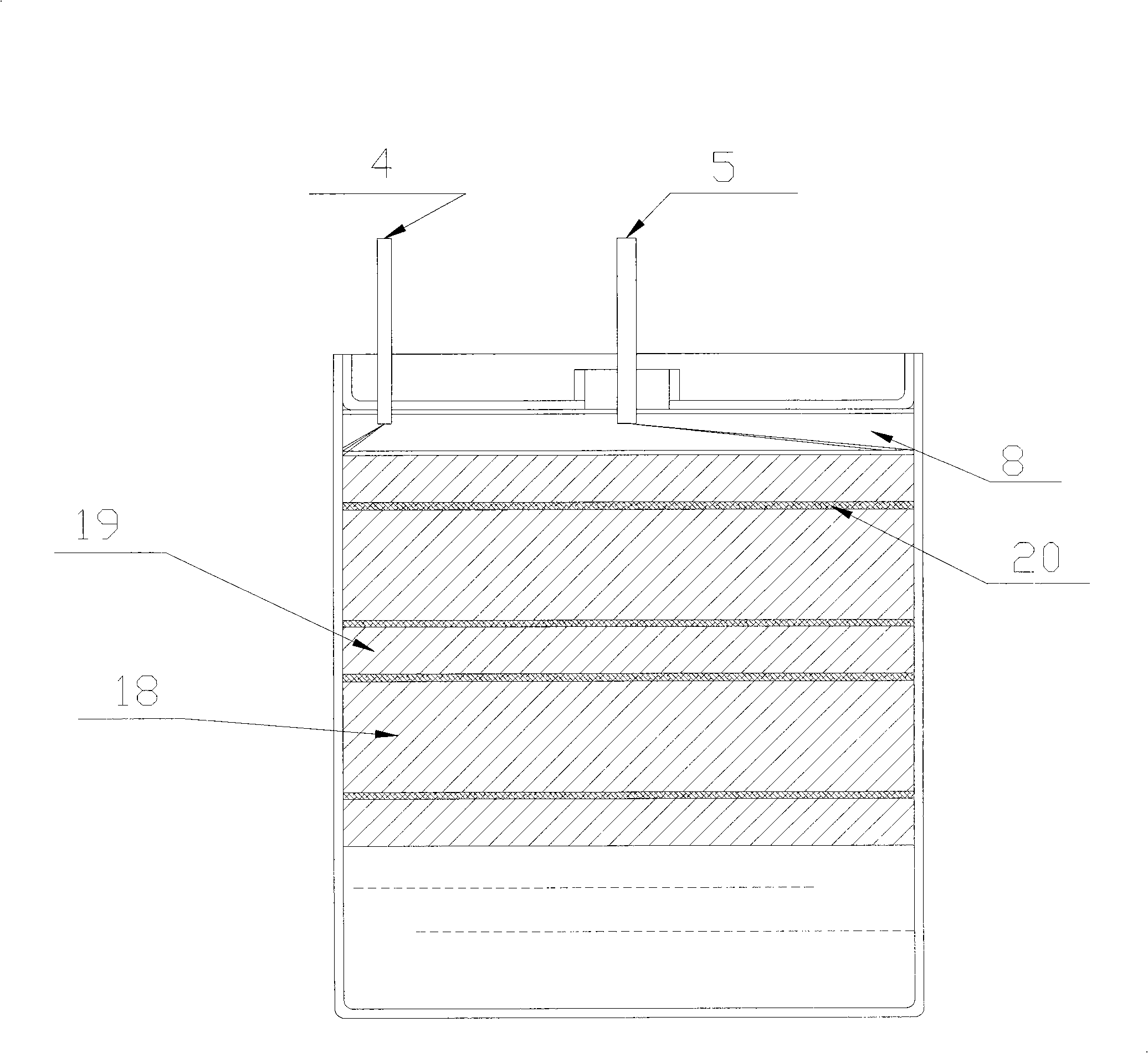

[0033] attached image 3 A schematic diagram of another structure of the present invention is given. It can be seen from the accompanying drawings that the structural principle of the third embodiment is the same as that of the first embodiment. image 3 Among them, the anode sheet 18 is an N-layer anode sheet with more than two layers, the cathode sheet 19 is an N+1 layer cathode sheet with more than three layers, and the insulating layer 20 is an N+2 layer insulating layer with more than four layers; the anode sheet 18 and the cathode The sheets 19 are staggered and separated to form a structure in which two cathode sheets clamp an anode sheet; all the anode sheets 18 are connected in series with lead wires and lead out through the anode lead wire 4, and all the cathode sheets 19 are connected in series with lead wires and then lead out through the cathode lead wire 5. All anode sheets are composed of porous tantalum cores, and a layer of metal oxide film media is attached t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com