Silver paste for gluing tantalum capacitor and preparation method thereof

A technology of tantalum capacitors and silver paste, which is applied in the field of bonding silver paste for tantalum capacitors and its preparation, can solve the problems of unstable quality and low bonding strength, and achieve good anti-sinking, good bonding strength, and stable storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

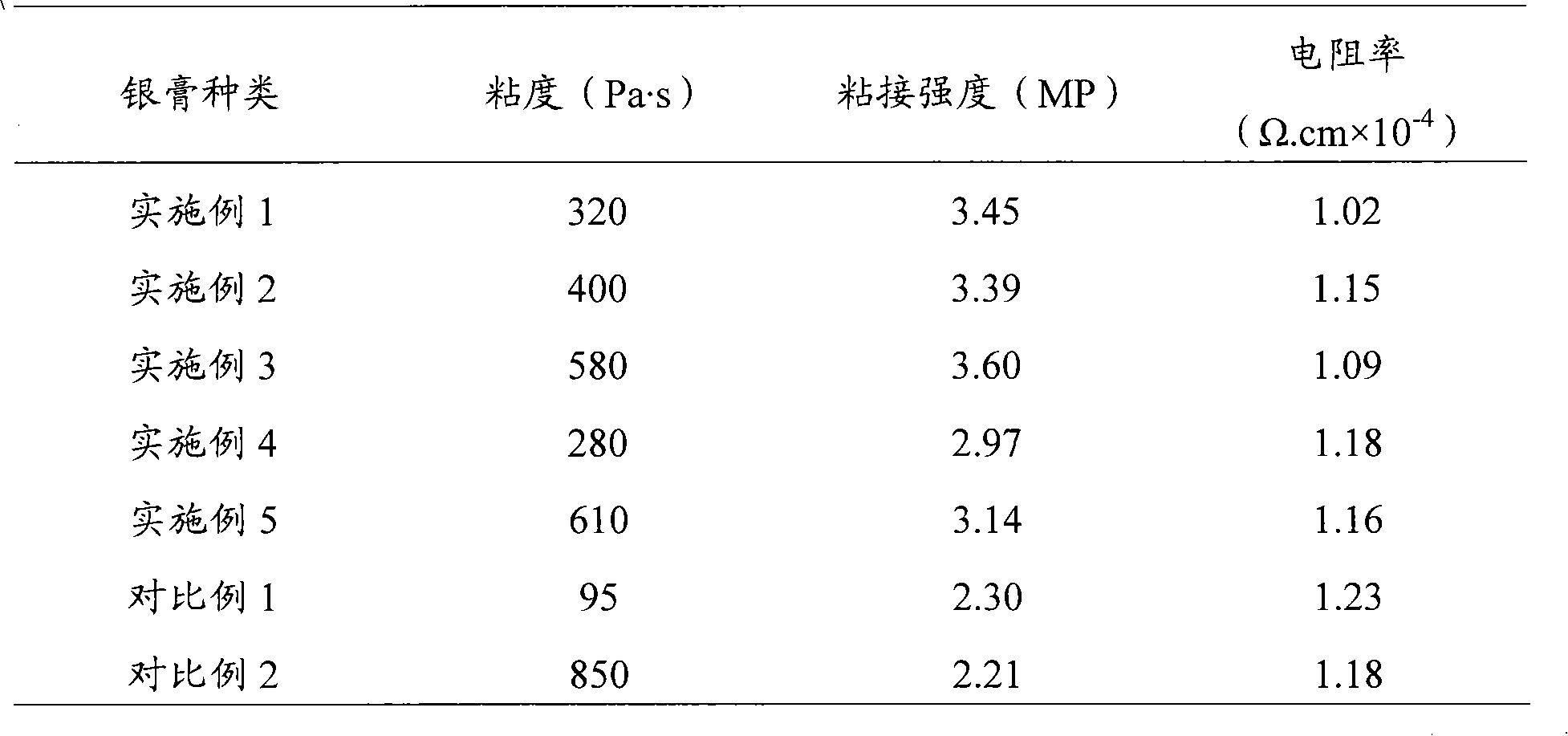

Examples

preparation example Construction

[0051] The preparation steps of bonding silver paste of the present invention:

[0052] 1) Fully mix epoxy resin, curing agent, accelerator, anti-settling agent, solvent and silver powder in proportion. As preferably, the present invention first mixes epoxy resin, curing agent, accelerator, anti-sedimentation agent and solvent in proportion, puts into high-speed disperser and stirs, then adds required proportion of silver powder to the above-mentioned mixture, and continues to stir.

[0053] 2) Rolling the uniformly mixed silver paste to grind the silver paste particles into a micron size and disperse them more uniformly. The rolling method is well known to those skilled in the art. The present invention preferably uses a three-roll mill for rolling.

[0054] After the silver paste is rolled, its viscosity value can be detected with a rotational viscometer. The viscosity range of the silver paste with good dot paste molding is preferably controlled at 100Pa·s-800Pa·s, more p...

Embodiment 1

[0057] The method for preparing the bonding silver paste for tantalum capacitors in this embodiment comprises steps:

[0058] 1) Take epoxy resin E-51 according to the amount of 15% in the silver paste, and the epoxy resin E-51 is a product of Shanghai Kaiping Resin Co., Ltd.;

[0059] 2) Weigh the tertiary amine curing agent DMP-30 according to the content of 6% in the silver paste, and the DMP-30 is a product of Wuxi Huili Synthetic Materials Co., Ltd.;

[0060] 3) Take tetraethylammonium bromide according to the content of 2% in the silver paste, and the tetraethylammonium bromide is a product of Wuxi Huilong Electronic Materials Co., Ltd.;

[0061] 4) Weigh fumed silica according to the content of 3% in the silver paste, and said fumed silica is a product of Guangzhou Hualisen Trading Co., Ltd.;

[0062] 5) Take by weighing the mixed solution of butyl acetate and isoamyl acetate according to the amount of 9% content in the silver paste, the ratio of the content of butyl a...

Embodiment 2

[0067] Same as the preparation method of Example 1, the percentage by weight of each component is selected as: epoxy resin E-51 of Shanghai Kaiping Resin Co., Ltd.: 12%; phthalic anhydride PA 50-65 of Jiangyin Zhongrun Chemical Co., Ltd. : 9%; 1,2-dimethylimidazole from Wuxi Huilong Electronic Materials Co., Ltd.: 1%; hydrogenated castor oil from Tongliao Weining Chemical Co., Ltd.: 1%; acetic acid from Zhejiang Jiande Jianye Organic Chemical Co., Ltd. 1:1 mixture of butyl ester and isoamyl acetate from Shanghai Maochang Chemical Co., Ltd.: 7%; 1 μm-20 μm flake silver powder: 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com