Hermetically-sealed solid electrolyte tantalum capacitor packaged through ceramic

A technology of solid electrolyte and ceramic packaging, applied in the direction of electrolytic capacitors, capacitors, capacitor parts, etc., can solve the problem that capacitors cannot meet the high temperature working environment, and achieve the effect of improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

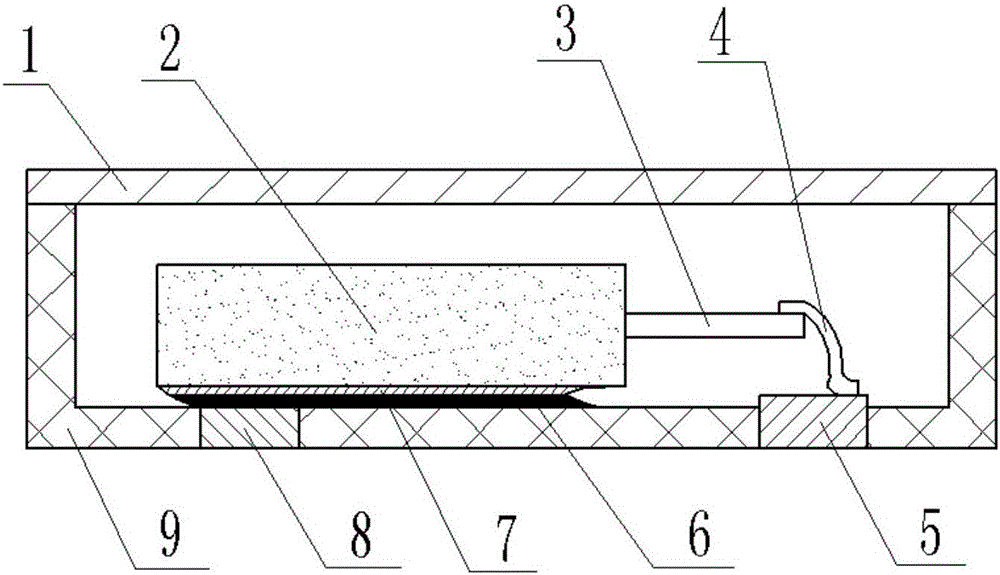

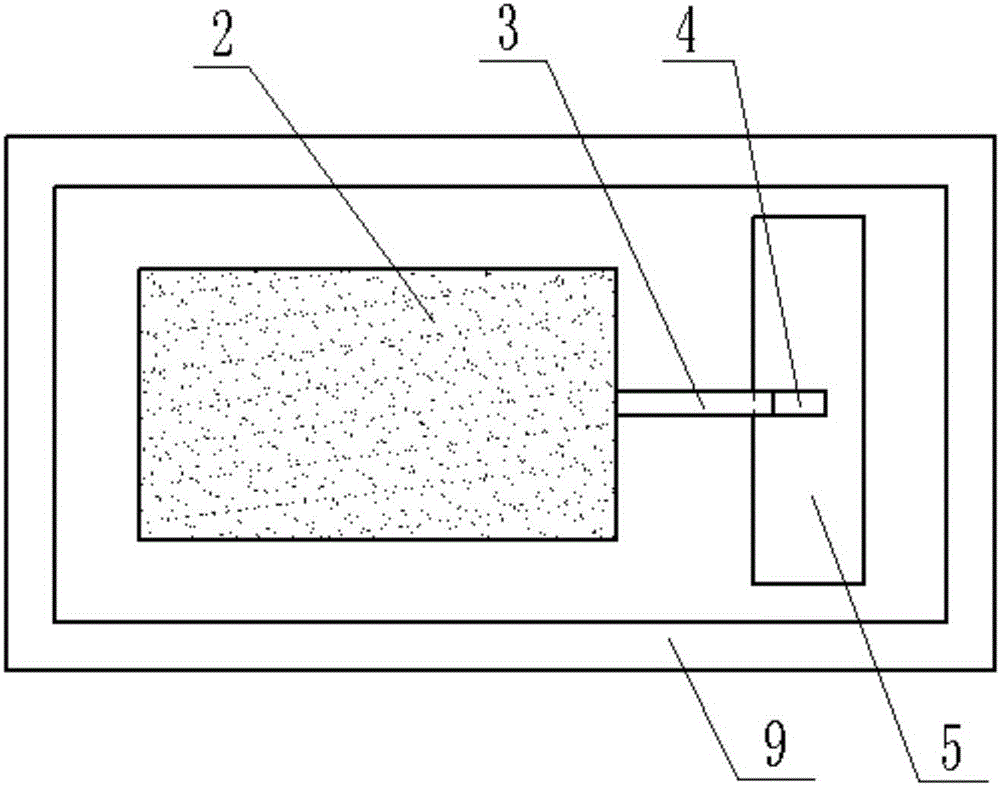

[0017] Such as figure 1 and figure 2 A fully sealed solid electrolyte tantalum capacitor with ceramic package as shown, including cover plate 1, anode tantalum core 2, anode tantalum wire 3, connecting lead 4, anode lead-out 5, bonding silver paste 6, nickel strip 7, cathode The lead end 8 and the ceramic shell 9; the lower side of the anode tantalum core 2 is welded and fixed with the nickel strip 7, and then bonded in the ceramic shell 9 by bonding the silver paste 6, and fixedly arranged on the ceramic shell 9 The cathode lead-out end 8 of the anode tantalum core 2 is connected; the anode tantalum wire 3 on the anode tantalum core 2 communicates with the anode lead-out end 5 fixedly arranged on the ceramic shell 9 through the connection lead 4; the cover plate 1 is sealed on the ceramic shell 9, and is sealed and fixedly conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com