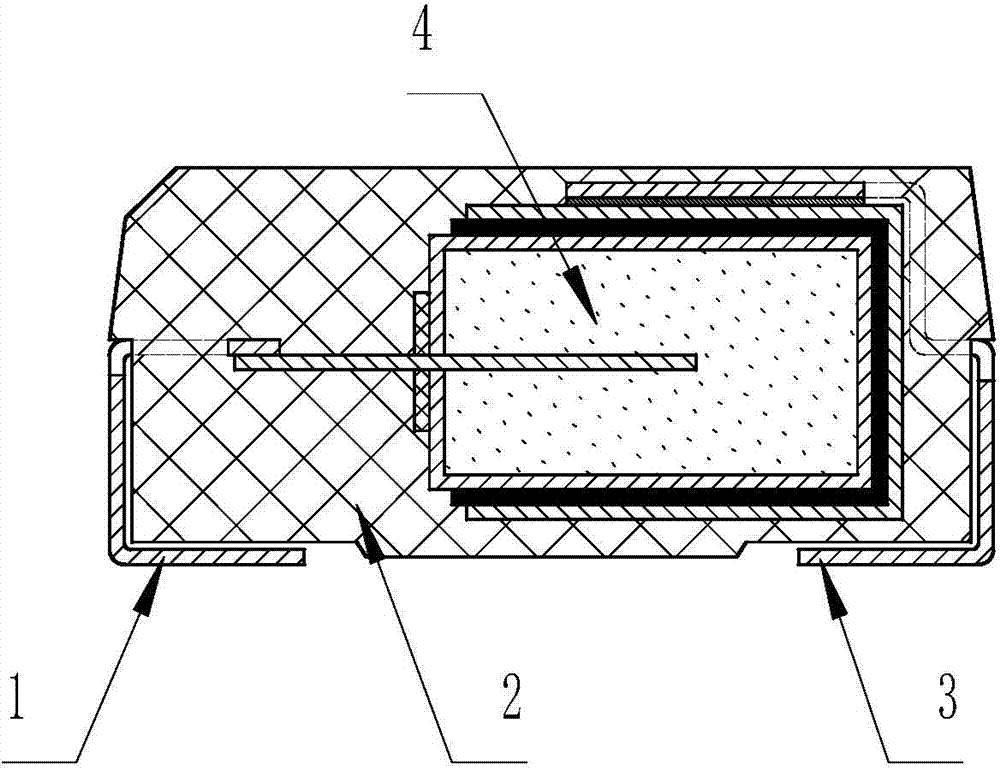

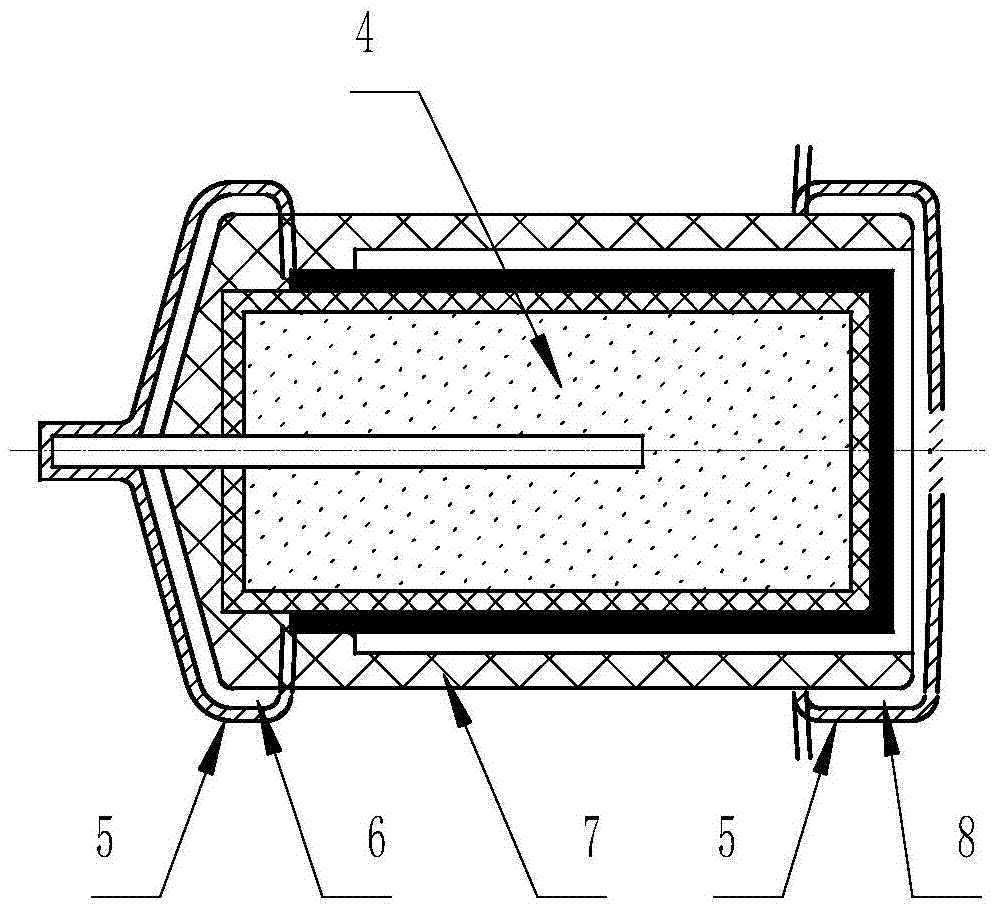

Leading-out process for anode and cathode of end cap-type tantalum capacitor

A technology of tantalum capacitors, positive and negative poles, which is applied in the lead-out process of the positive and negative poles of end-cap tantalum capacitors, which can solve the problems of wasting the anode space of tantalum capacitors and achieve the effect of increasing the design space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Taking the end-cap tantalum capacitor 25V47μF as an example, a leading-out process for the positive and negative electrodes of the end-cap tantalum capacitor includes the following steps:

[0026] (1) According to the existing process steps, molding, sintering, spot welding, forming, coating, and graphite silver paste are completed to obtain the prototype of the tantalum core with positive and negative electrodes;

[0027] (2) Attach the high-temperature tape with the same width as the prototype of the tantalum core to the bottom of the tantalum core, and then preheat the tantalum core to make the temperature reach 160°C;

[0028] (3) Embed the preheated tantalum core in epoxy resin powder for 2 seconds, and then tear off the high-temperature tape on the bottom of the tantalum core;

[0029] (4) Put the tantalum core with epoxy resin powder on the surface into an oven at 120°C for 120 minutes to cure the epoxy resin;

[0030] (5) Immerse 1 / 4 of the lower part of the ta...

Embodiment 2

[0035] Taking the end-cap tantalum capacitor 6.3V330μF as an example, a leading-out process for the positive and negative electrodes of the end-cap tantalum capacitor includes the following steps:

[0036] (1) According to the existing process steps, molding, sintering, spot welding, forming, coating, and graphite silver paste are completed to obtain the prototype of the tantalum core with positive and negative electrodes;

[0037] (2) Attach the high-temperature tape with the same width as the prototype of the tantalum core to the bottom of the tantalum core, and then preheat the tantalum core to make the temperature reach 120°C;

[0038] (3) Embed the preheated tantalum core in epoxy resin powder for 4 seconds, and then tear off the high-temperature tape on the bottom of the tantalum core;

[0039] (4) Put the tantalum core with epoxy resin powder on the surface into an oven at 90°C for 150 minutes to cure the epoxy resin;

[0040] (5) Immerse the lower part of 1 / 3 of the t...

Embodiment 3

[0045] A process for drawing out the positive and negative poles of an end-cap type tantalum capacitor comprises the following steps:

[0046] (1) According to the existing process steps, molding, sintering, spot welding, forming, coating, and graphite silver paste are completed to obtain the prototype of the tantalum core with positive and negative electrodes;

[0047] (2) Attach the high-temperature tape with the same width as the prototype of the tantalum core to the bottom of the tantalum core, and then preheat the tantalum core to make the temperature reach 200°C;

[0048] (3) Embed the preheated tantalum core in epoxy resin powder for 3 seconds, and then tear off the high-temperature tape on the bottom of the tantalum core;

[0049] (4) Put the tantalum core with epoxy resin powder on the surface into an oven at 150°C for 60 minutes to cure the epoxy resin;

[0050] (5) Immerse 1 / 5 of the lower part of the tantalum core obtained in step (4) with silver paste, and put it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com