Connection and joint piece for well tubes

A technology of corrugated pipes and connectors, applied in the direction of pipes/pipe joints/pipe fittings, couplings, passing elements, etc., can solve the problems of reducing sealing performance, failure, damage, etc., and achieve reliable sealing performance, prevention of sealing effect, high Effect on pull-out strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

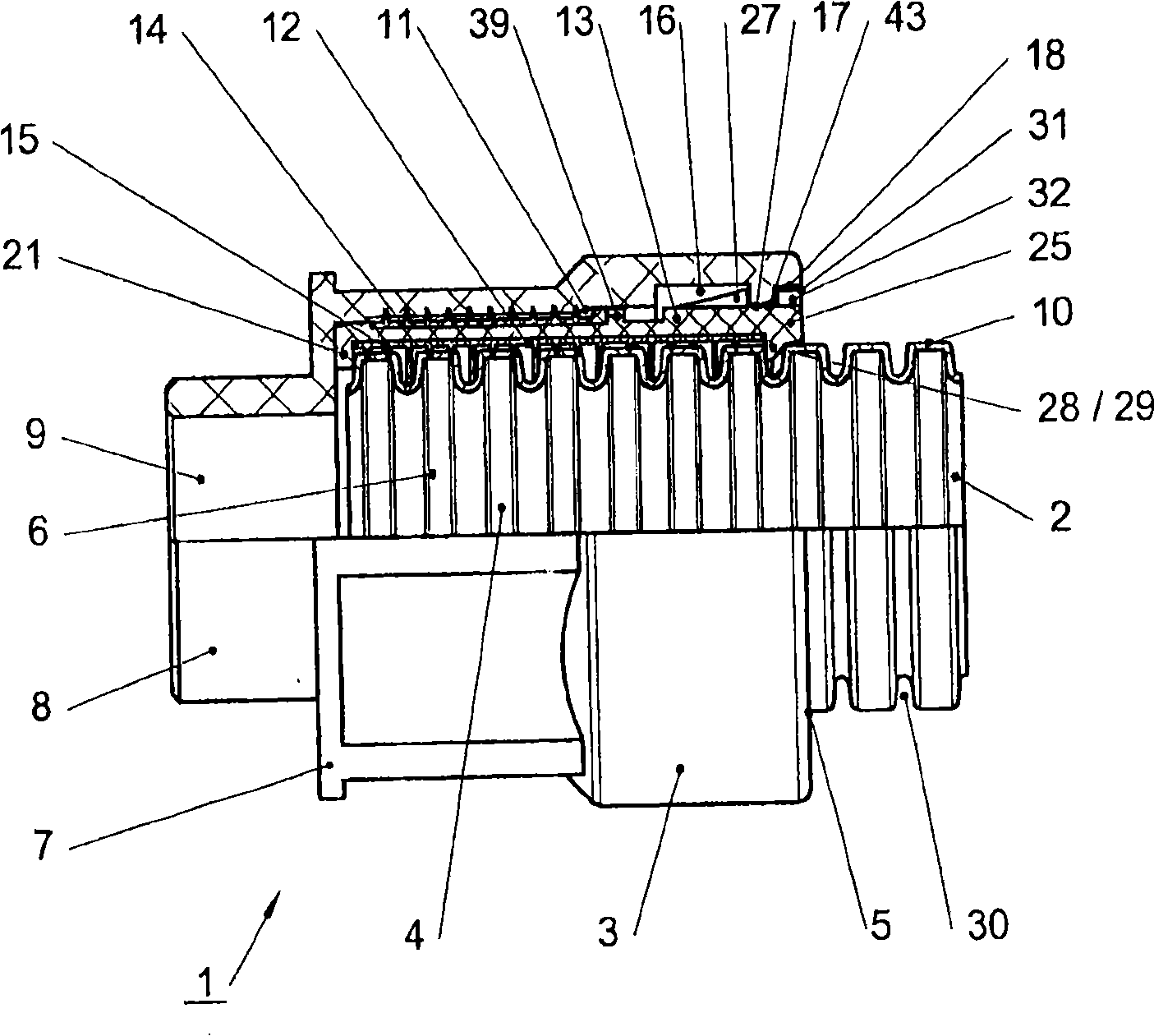

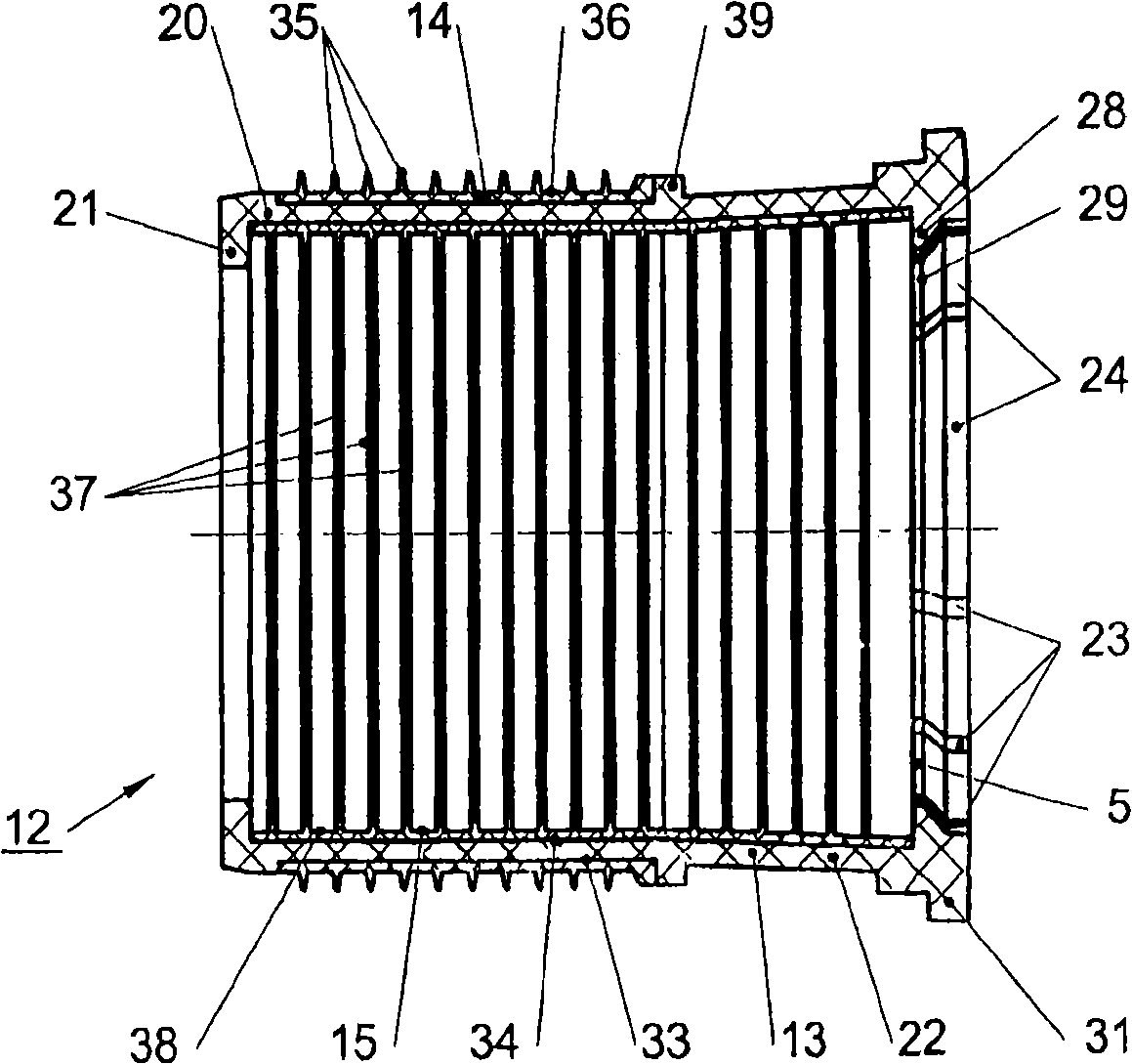

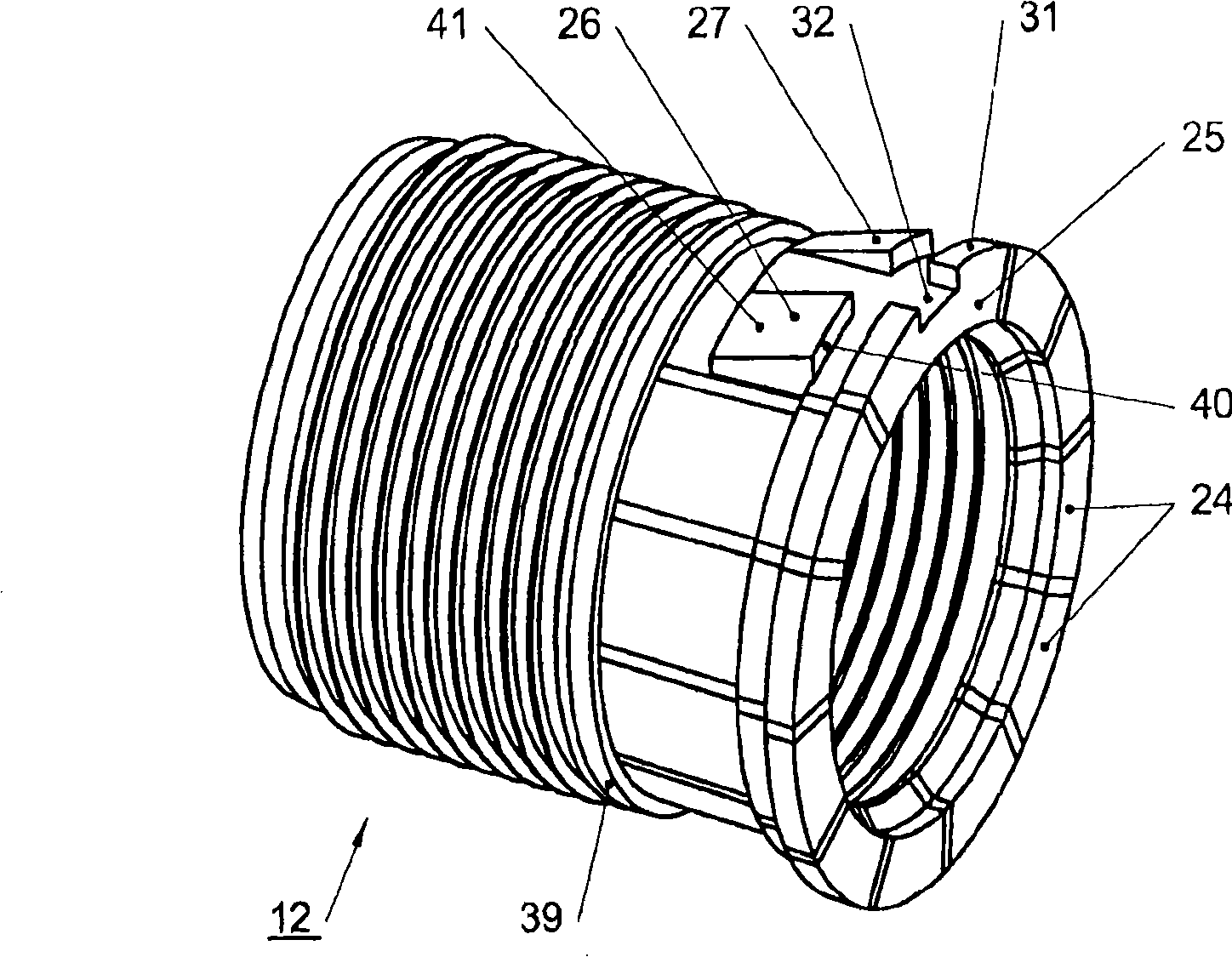

[0020] figure 1 The coupling piece 1 is shown together with the inserted end 6 of the bellows 2 . The upper half of the figure is shown here as a section. The coupling part 1 comprises a housing 3 with a core cavity 4 . The housing 3 has an insertion opening 5 at one end, toward which the core cavity 4 is also open. At the opposite end of the housing 3 there is provided a connecting piece 8 with a passage opening 9 and a connecting flange 7 . In the exemplary embodiment shown, the connecting piece 8 is designed as a screw connection. However, it can also have another shape known for the coupling part described, for example it can also be a coupling element for the connection to the second bellows. In the core cavity 4 of the housing 3 there is a sleeve 12 which surrounds the end 6 of the bellows 2 . The housing 3 has a completely closed sheath without radial breaks. In the exemplary embodiment shown, both the housing 3 and the sleeve 2 are injection-molded parts made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com