Technique method of preparing cathode of panseal non-solid electrolytes whole tantalum capacitor

A tantalum capacitor and its preparation technology are applied in the field of cathode preparation technology of all-tantalum electrolytic capacitors with hermetically sealed non-solid electrolyte, which can solve the problem of low volume energy density and volume specific capacity of capacitors, inability to withstand reverse voltage, and inability to withstand reverse voltage. Voltage and other issues, to achieve the effect of small loss, improved performance, and large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

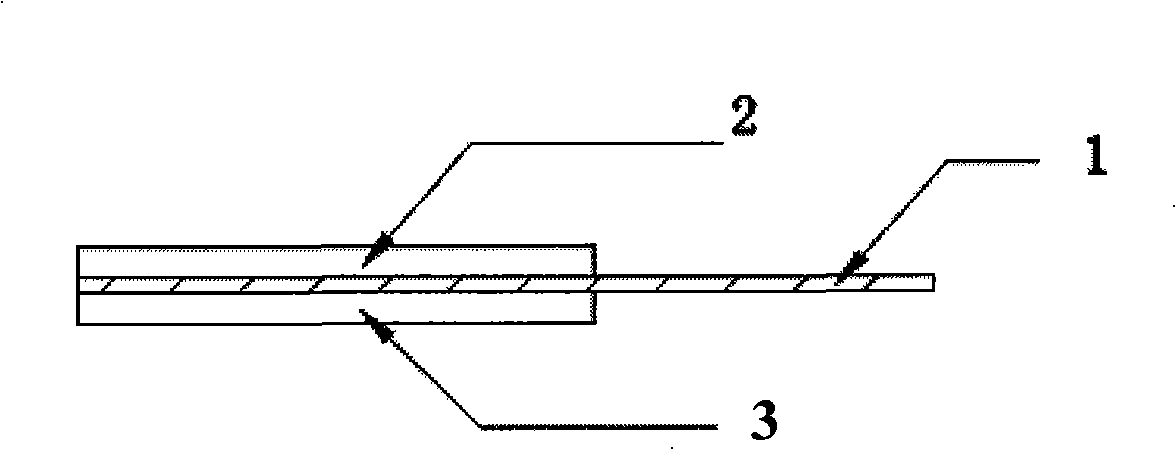

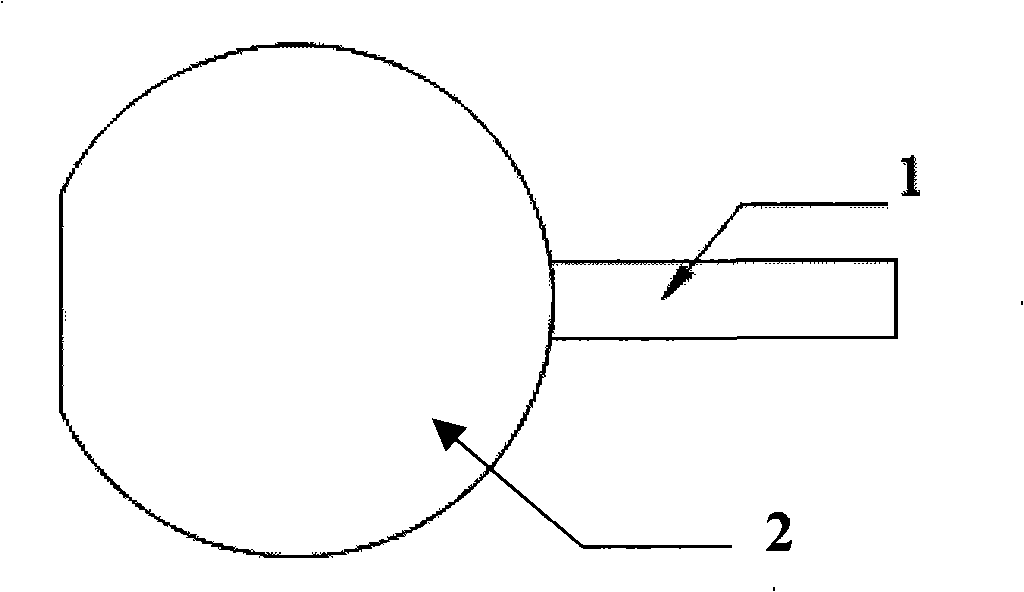

[0016] figure 1 and figure 2 Provided a specific embodiment of the present invention, from the appended figure 1 and 2 It can be seen that what the present invention relates to is a fully sealed non-solid electrolyte tantalum capacitor cathode; the tantalum capacitor cathode includes a tantalum sheet 1, and an upper layer of tantalum powder 2 and a lower layer of tantalum powder are respectively pasted on both sides of the tantalum sheet 1 3. It is characterized in that: the cathode of the tantalum capacitor is obtained through treatment including current collector, forming and sintering of the cathode, and electrochemical oxidation of the tantalum cathode. The manufacturing process adopted at least includes the following manufacturing process steps:

[0017] ①Cut the tantalum sheet into figure 2 The shape, first degrease with ethanol, acetone and other solvents, then put it into a certain concentration of sulfuric acid, nitric acid or hydrofluoric acid and other inorgan...

Embodiment 2

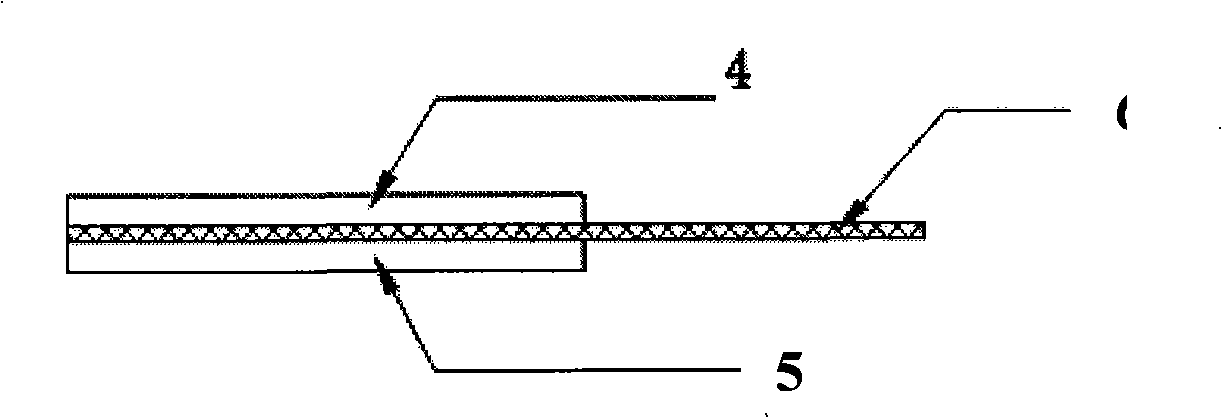

[0021] figure 1 and figure 2 Provided a specific embodiment of the present invention, from the appended figure 1 and 2 It can be seen that what the present invention relates to is a fully sealed non-solid electrolyte tantalum capacitor cathode; the tantalum capacitor cathode includes a tantalum felt or tantalum mesh 6, and the two sides of the tantalum felt or tantalum mesh 6 are respectively pasted with An upper layer of tantalum powder 4 and a lower layer of tantalum powder 5; the characteristic lies in that the cathode of the tantalum capacitor is made through a process including current collector treatment, forming and sintering of the cathode, and electrochemical oxidation of the tantalum cathode. The manufacturing process adopted at least includes the following manufacturing process steps:

[0022] ①Tantalum felt or tantalum mesh is cut into such Figure 4 The shape, first degrease with ethanol, acetone and other solvents, then put it into a certain concentration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com