Patents

Literature

379 results about "Tantalum pentoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tantalum pentoxide, also known as tantalum(V) oxide, is the inorganic compound with the formula Ta₂O₅. It is a white solid that is insoluble in all solvents but is attacked by strong bases and hydrofluoric acid. Ta₂O₅ is an inert material with a high refractive index and low absorption (i.e. colourless), which makes it useful for coatings. It is also extensively used in the production of capacitors, due to its high dielectric constant.

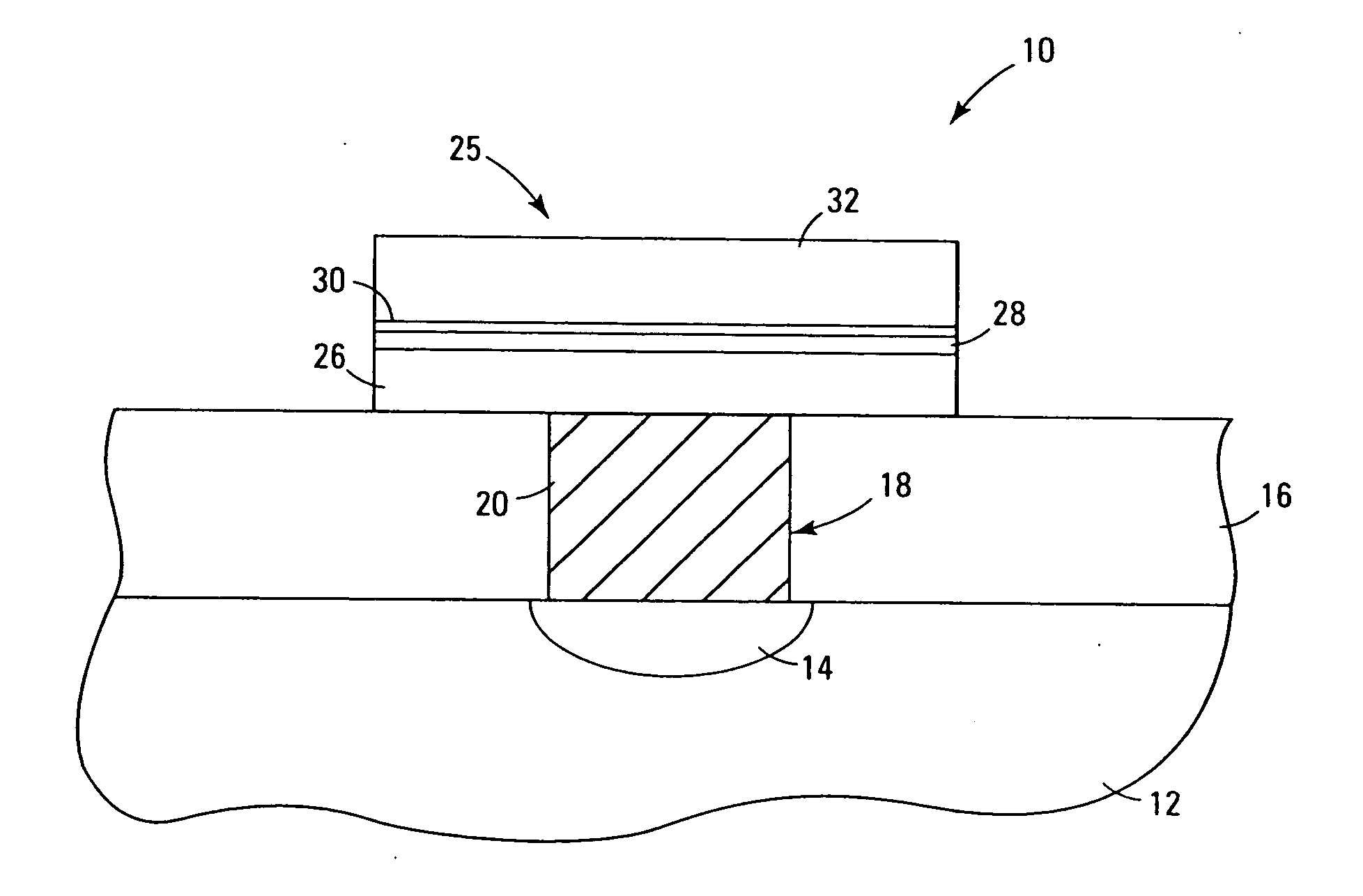

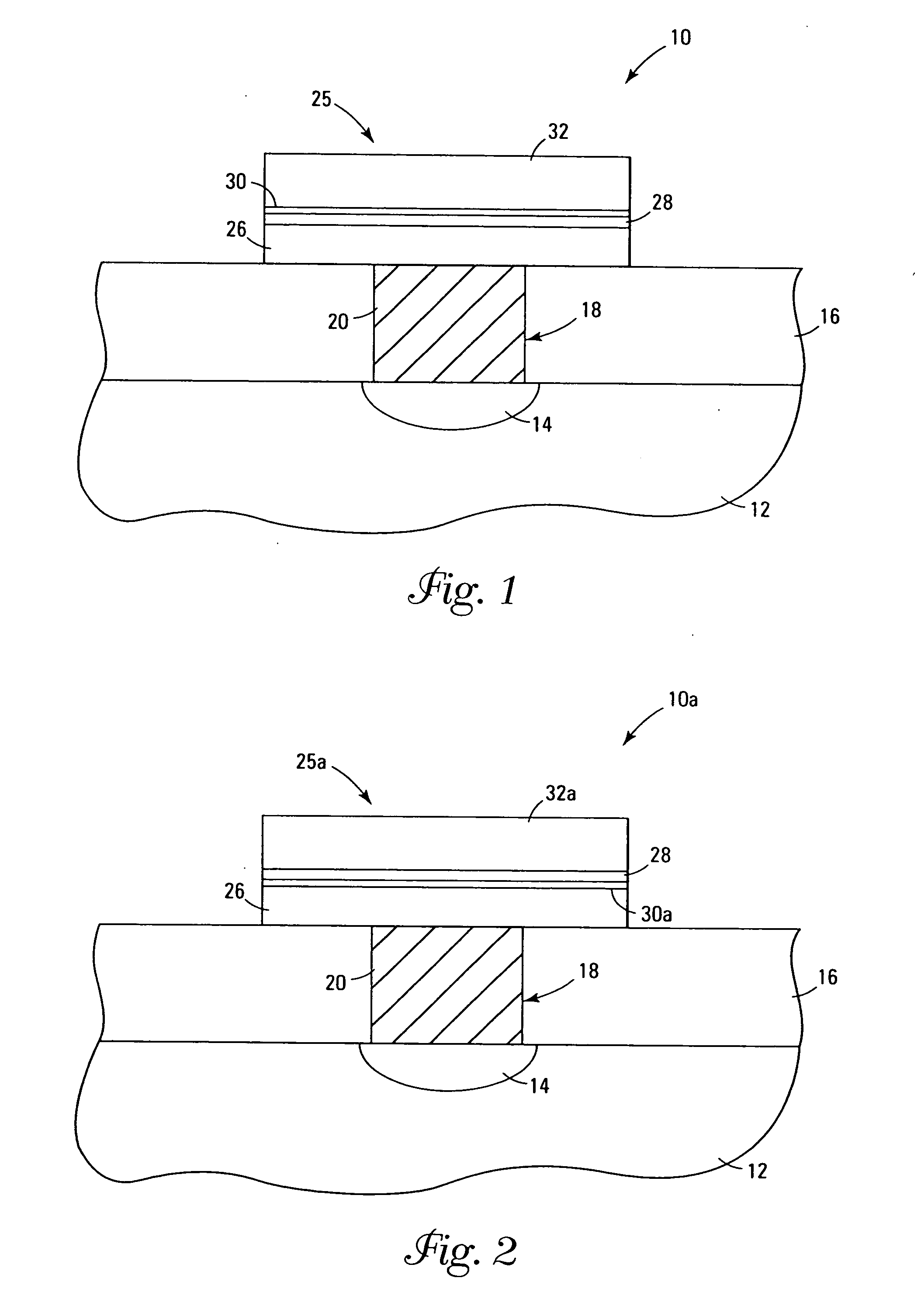

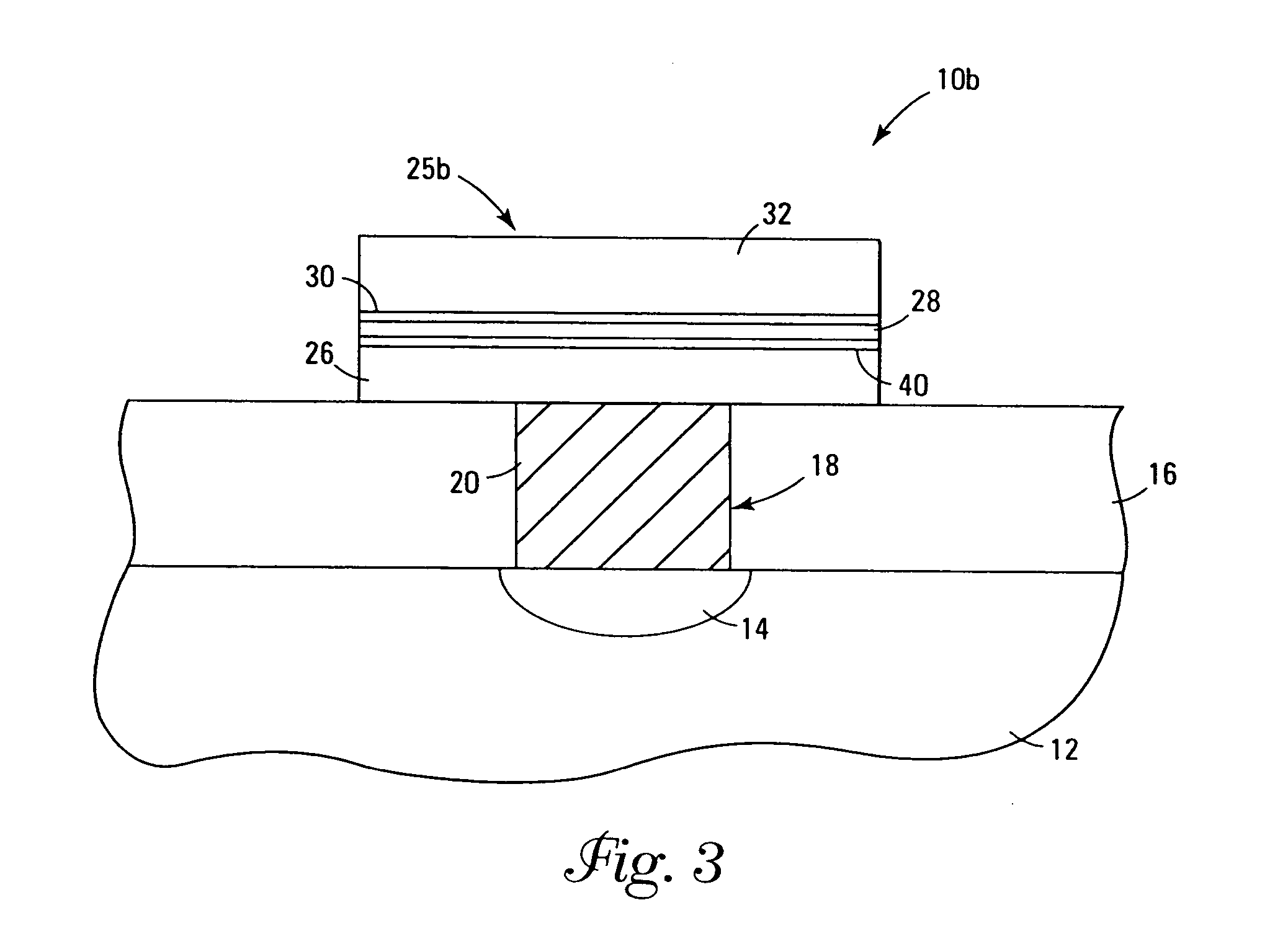

Systems and methods for forming refractory metal oxide layers

InactiveUS20050009266A1Easy to controlMinimizing detrimental gas phase reactionSemiconductor/solid-state device manufacturingCapacitorsGas phaseEther

A method of forming (and apparatus for forming) refractory metal oxide layers, such as tantalum pentoxide layers, on substrates by using vapor deposition processes with refractory metal precursor compounds and ethers.

Owner:MICRON TECH INC

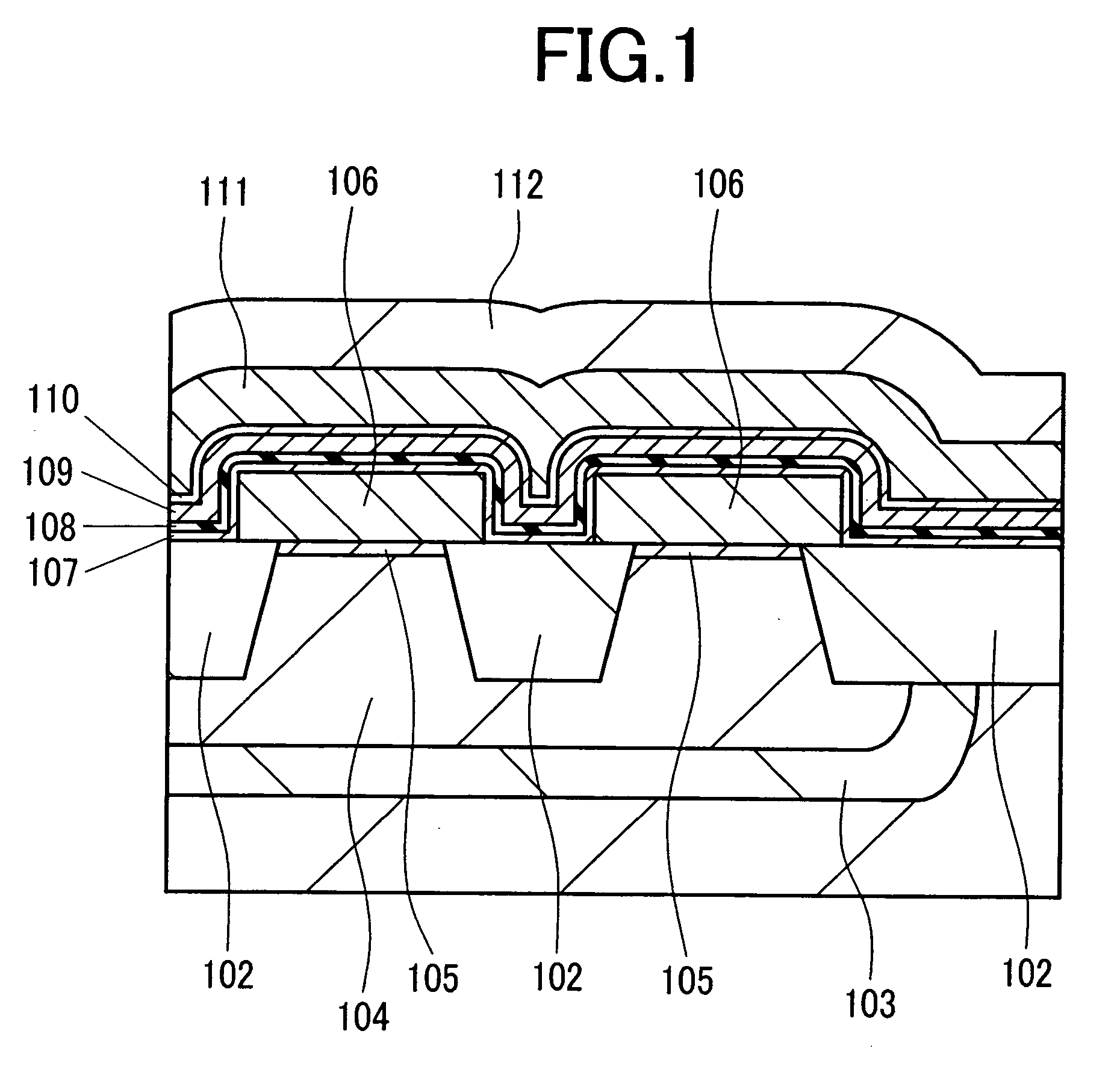

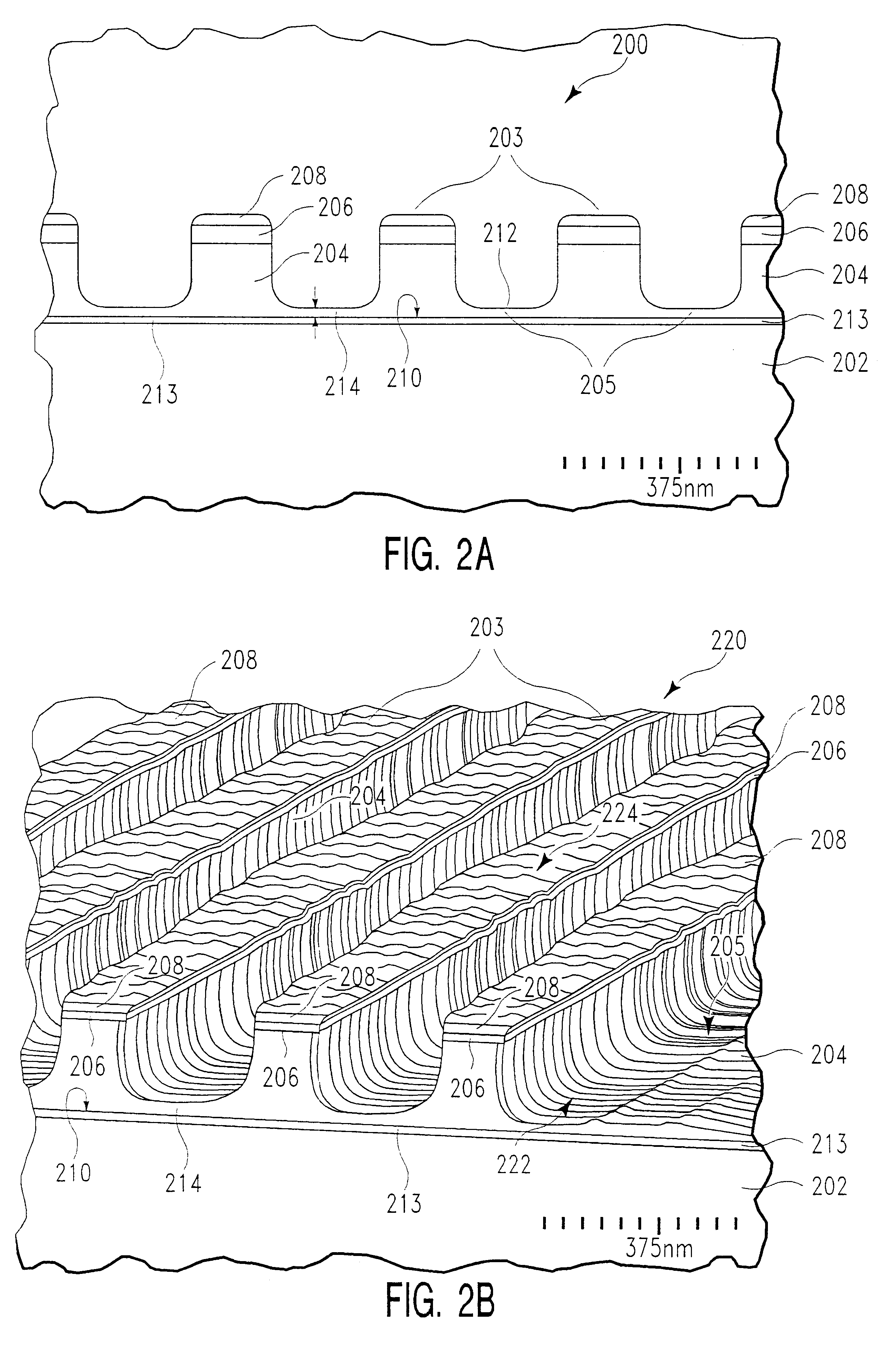

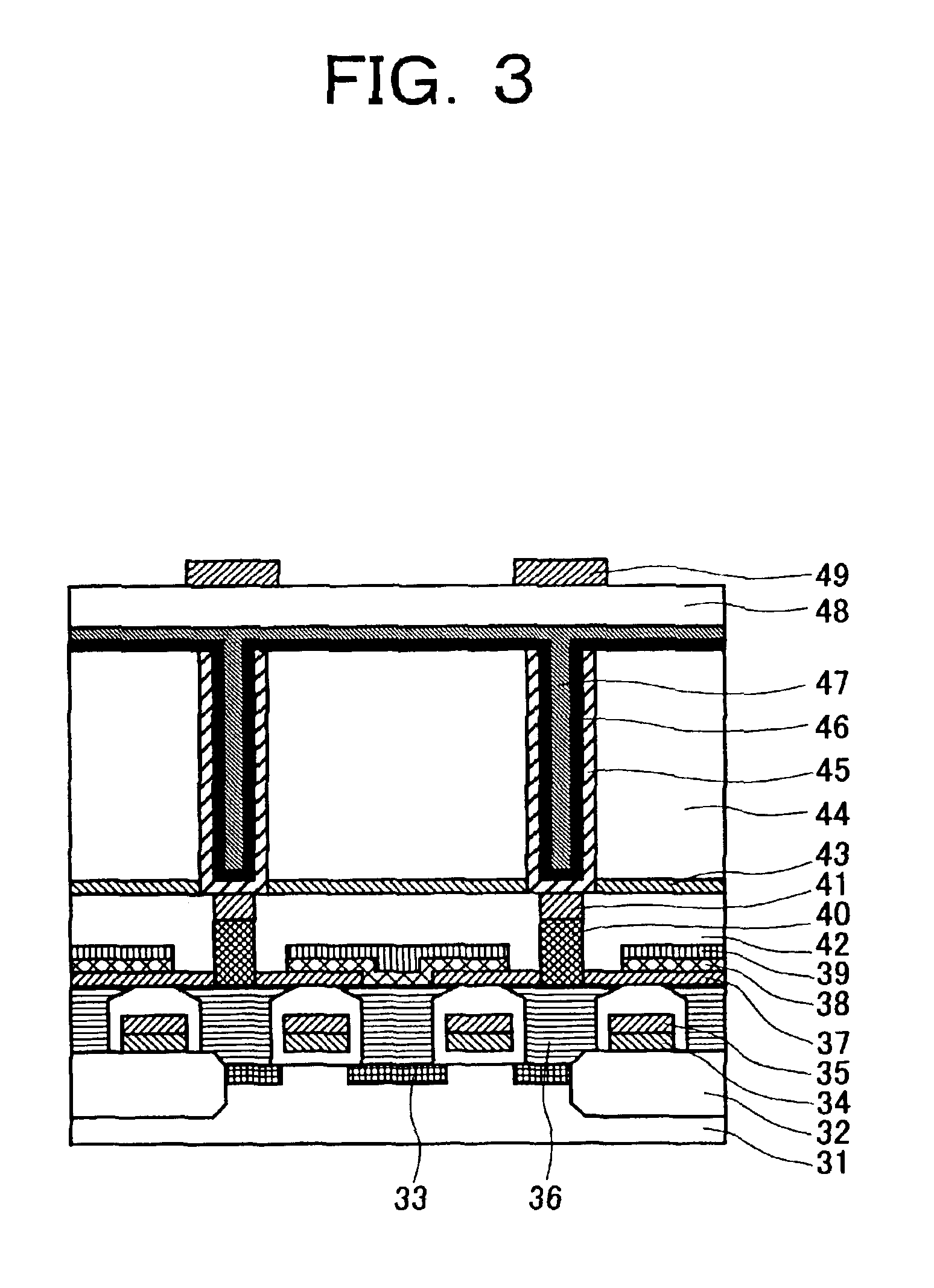

Nonvolatile semiconductor storage and its manufacturing method

InactiveUS20050079662A1Complicated processEasy to integrateTransistorSolid-state devicesSilicon dioxideSemiconductor

To achieve a higher operating speed, higher reliability, and lower power consumption by reducing the thickness of an inter-poly silicon insulator film between a floating gate and a control gate of a flash memory, a silicon dioxide film, a silicon nitride film, tantalum pentoxide, and a silicon dioxide film are formed in a multilayer structure to serve as the inter-poly insulator film between a floating gate and a control gate. With this configuration, tantalum pentoxide formed on the silicon nitride film has a dielectric constant of 50 or more, which is higher than that of the silicon dioxide film, and the thickness of the inter-poly silicon insulator film can be reduced.

Owner:RENESAS ELECTRONICS CORP

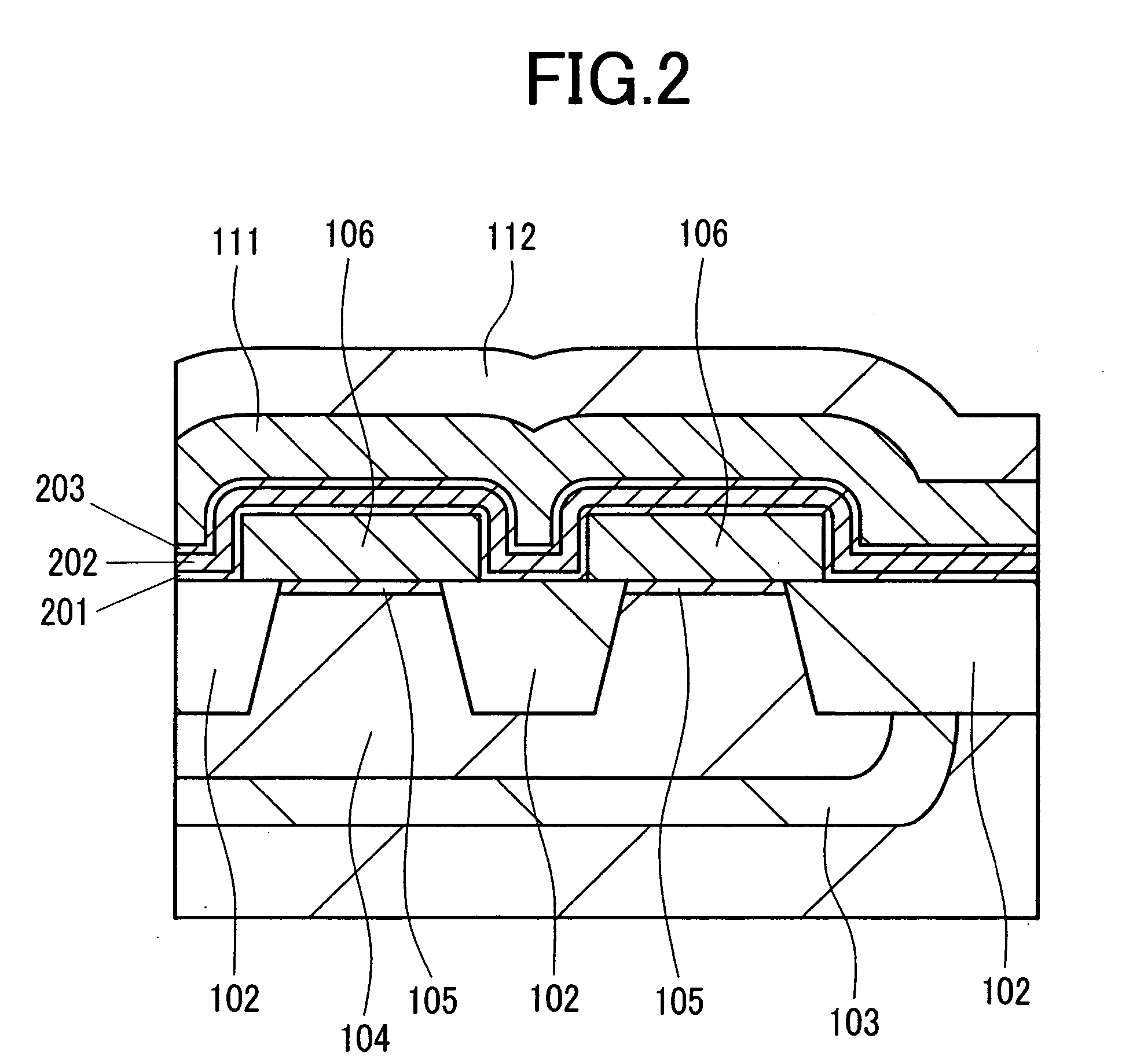

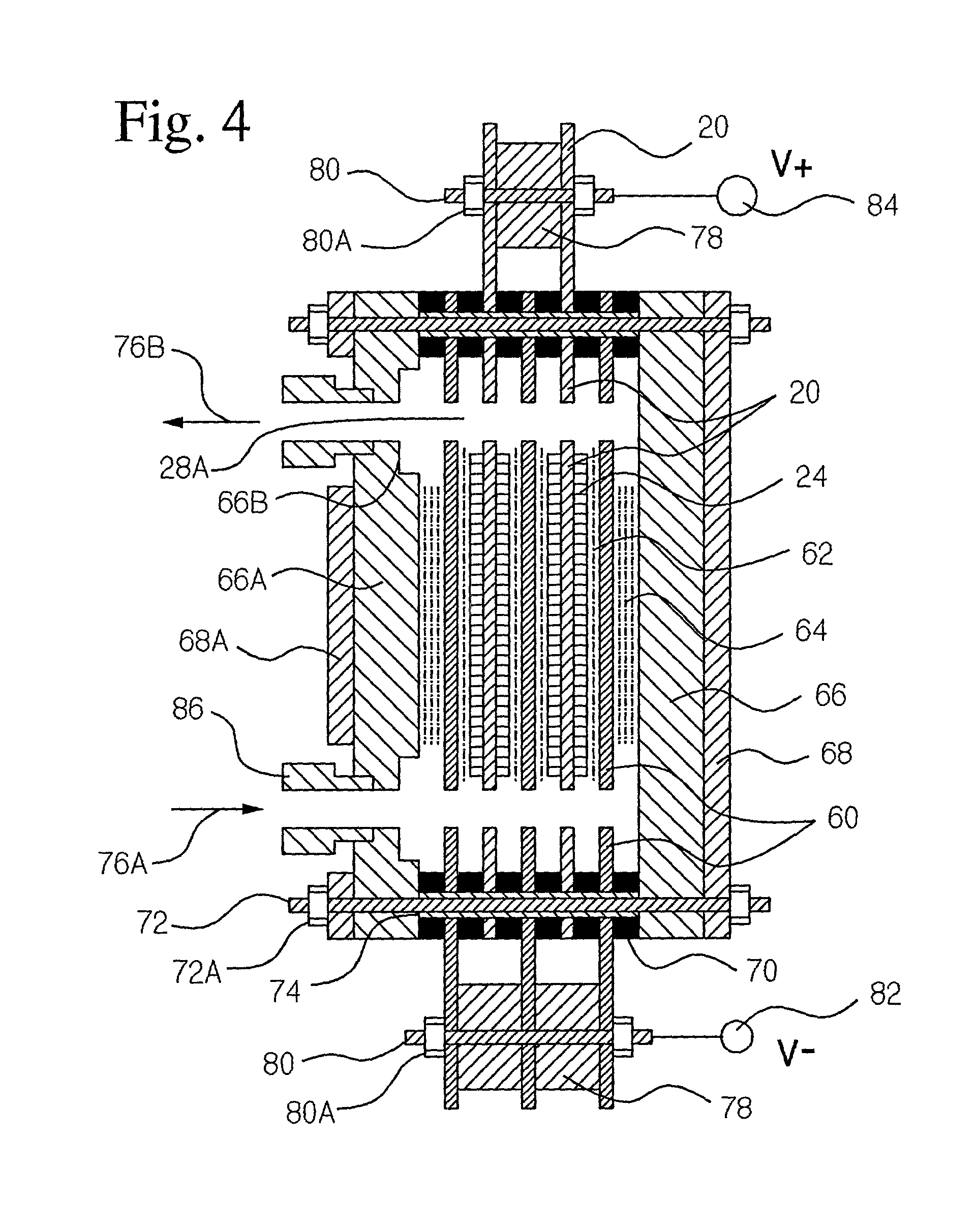

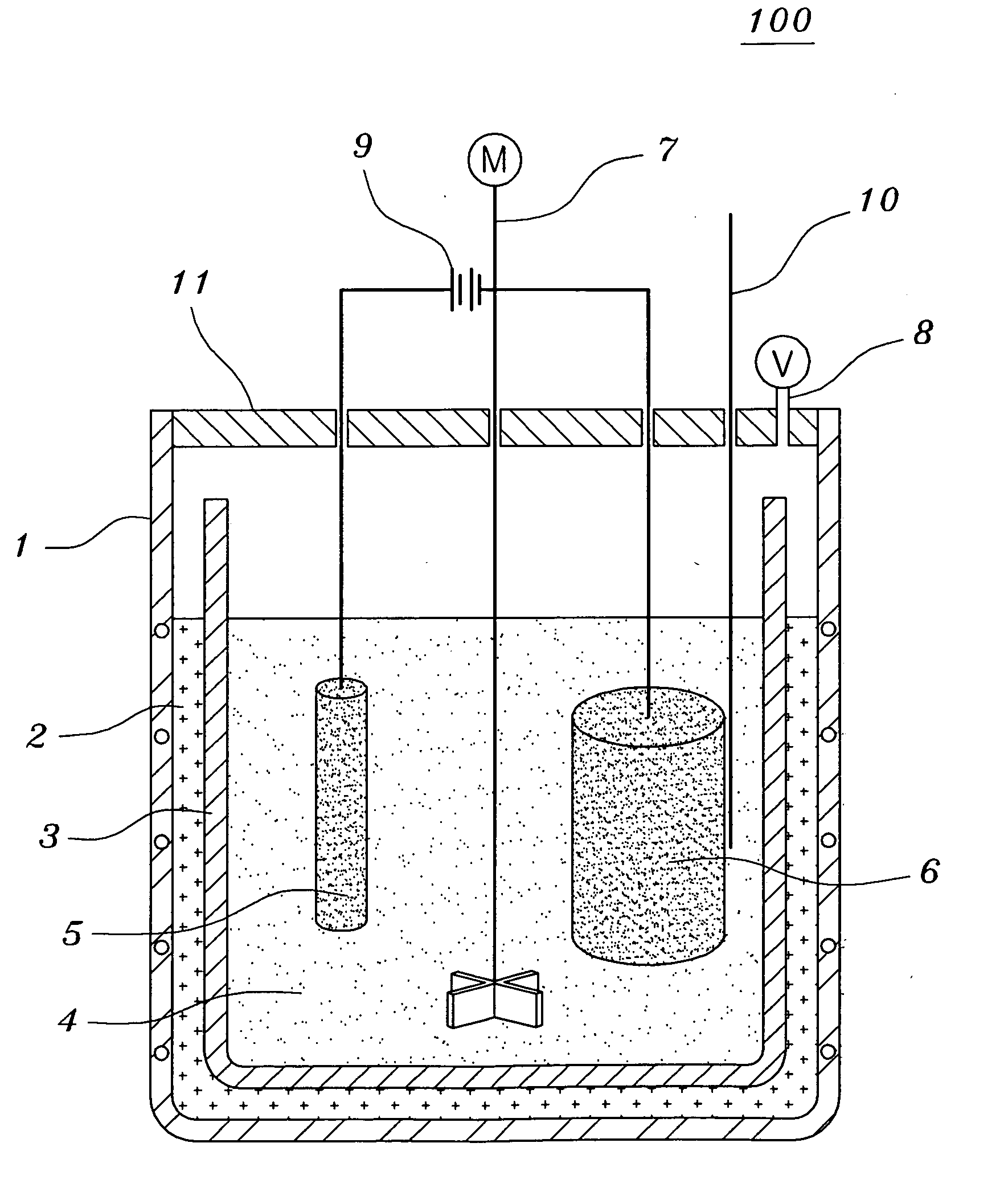

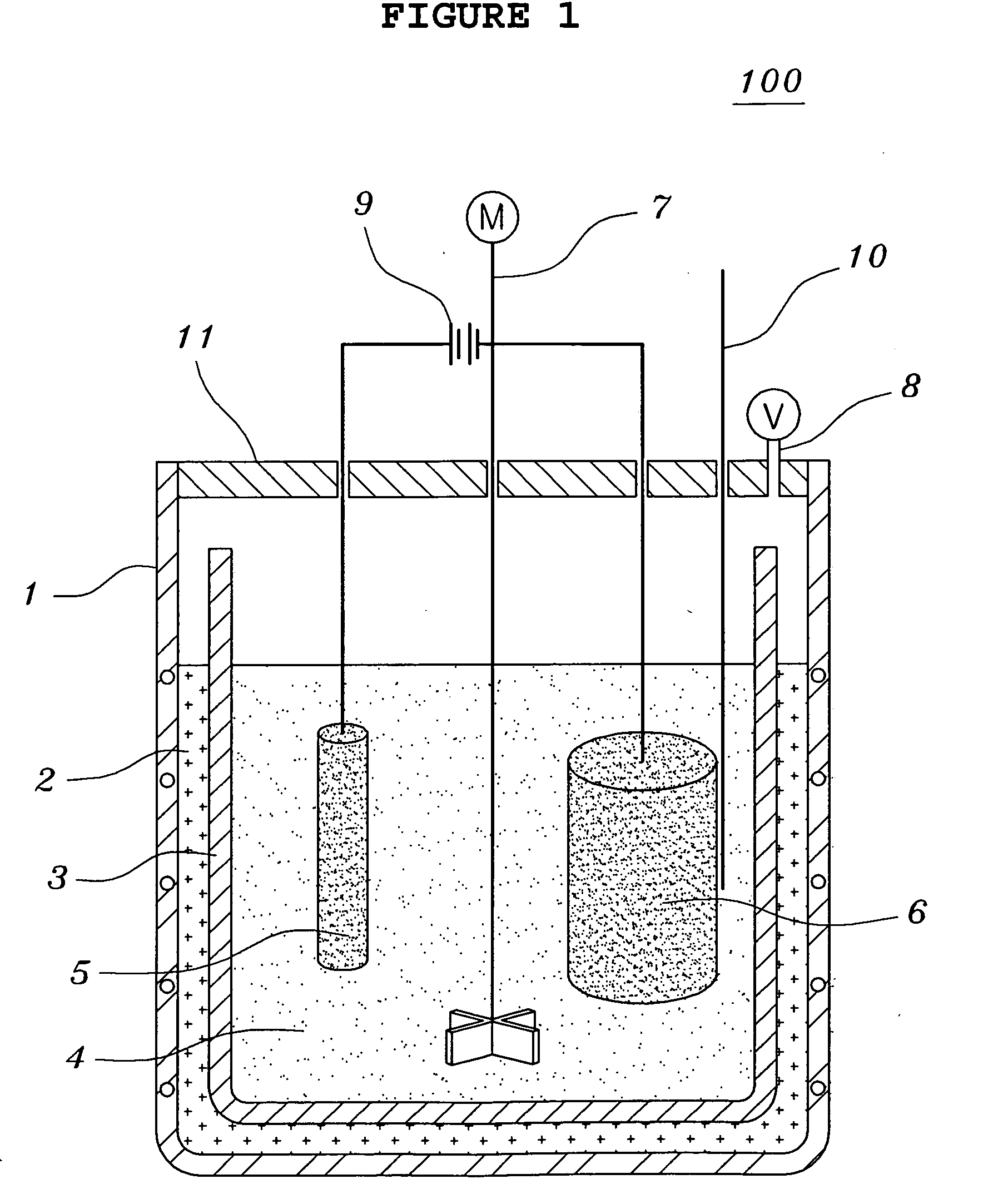

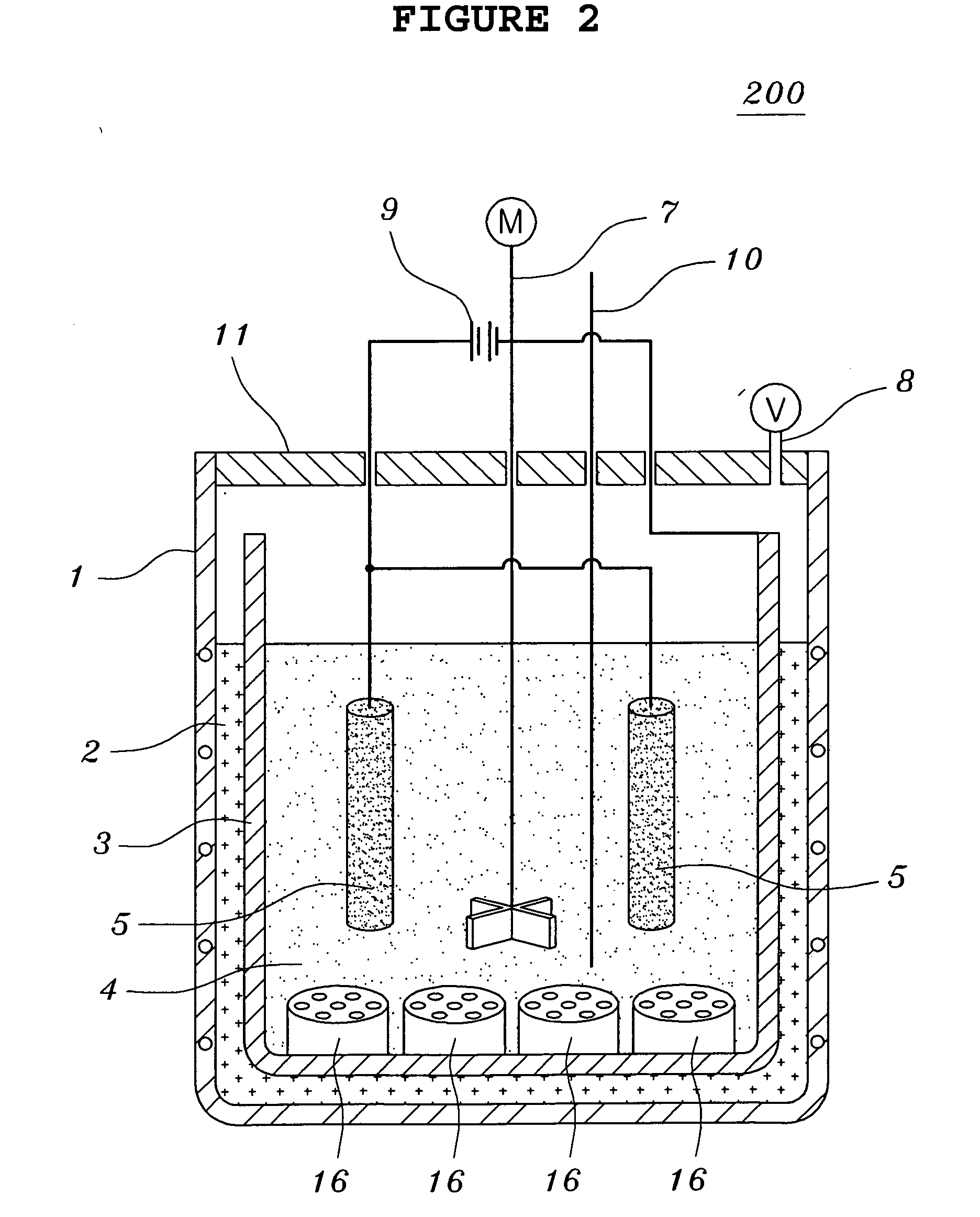

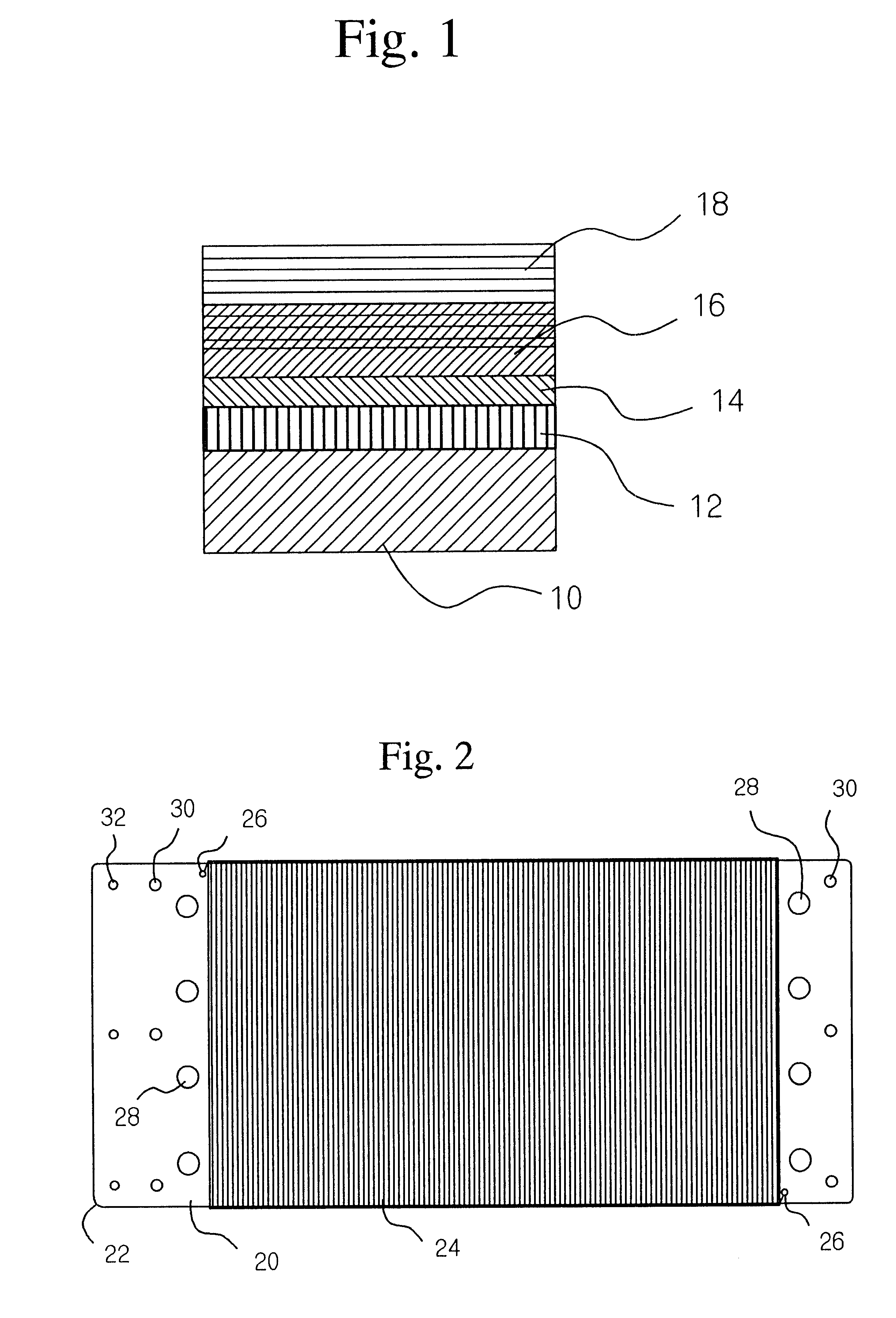

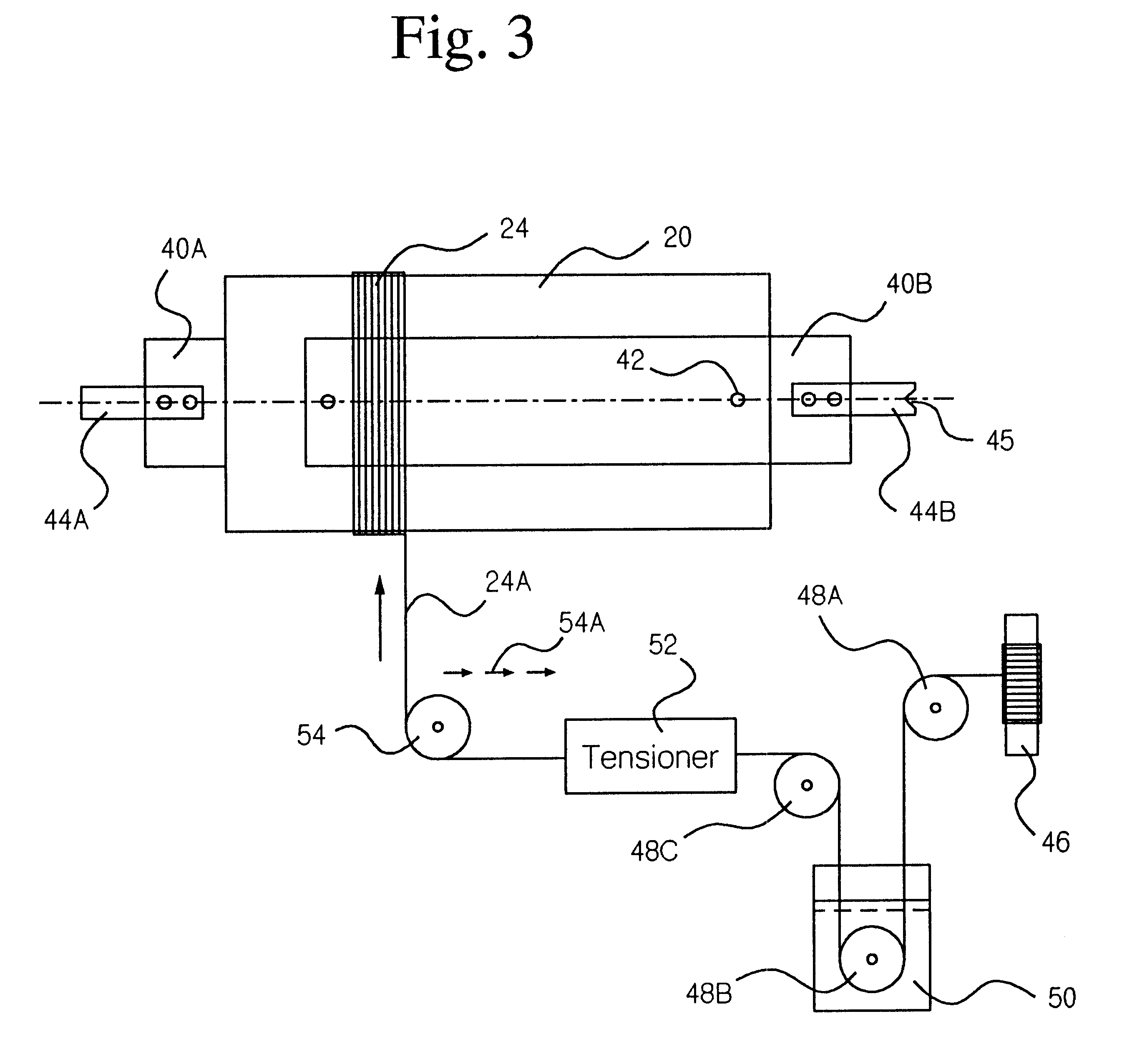

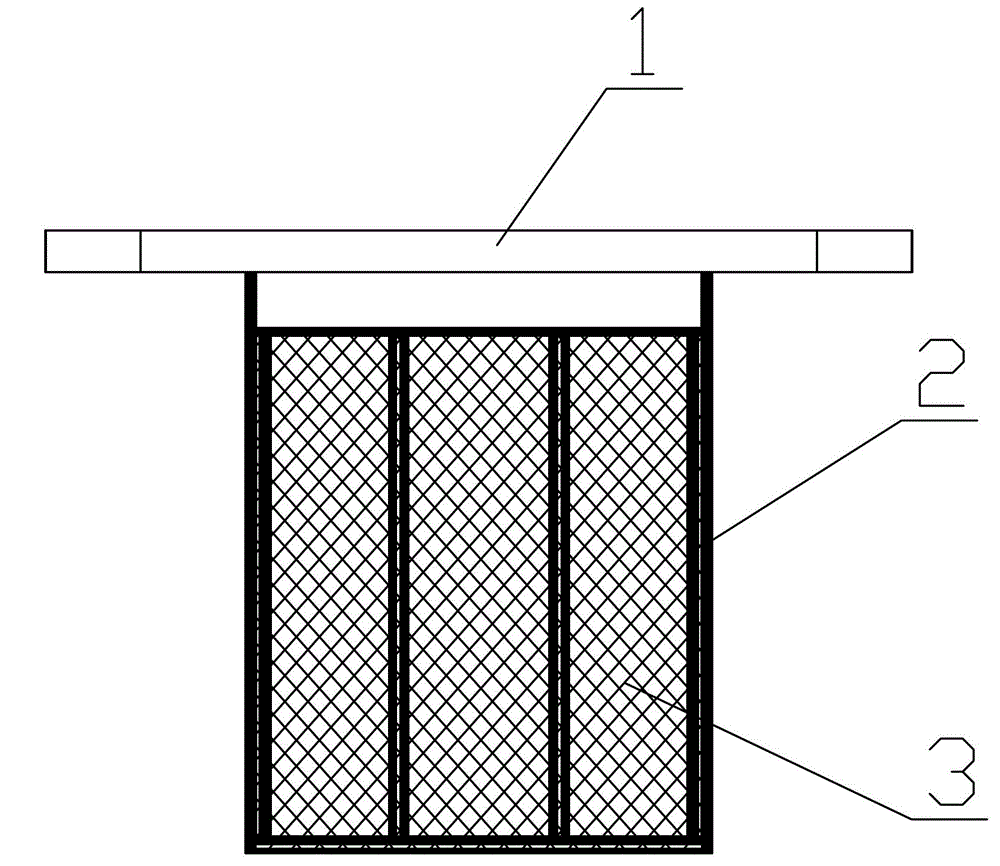

Electrode and electrochemical cell for water purification

An electrode with large active surface area is made by winding a Ti-fiber tow around a rectangular Ti-plate, and an electrocatalytic coating of three layers is applied. A precoat comprising a mixture of iridium dioxide and tantalum pentoxide is applied first, using a solution of the corresponding chloride salts in hydrochloric acid with some nitric acid added to inhibit corrosion of the metal. A sealing coat is then applied, comprising tin dioxide doped with antimony, in order to improve adhesion of the final oxide coat to the precoat. The third and final coat comprises particles of titanium dioxide doped with niobium in the +4 oxidation cemented with titanium dioxide that is doped with antimony. Anodes of this description are preferably assembled together with corrosion resistant cathodes in an alternating sequence, with a plastic coated fiber glass mesh placed between the anodes and cathodes to prevent short circuiting. When a sufficiently large voltage is applied across the cell, organic substances dissolved in the electrolyte will be oxidized.

Owner:WERES OLEH

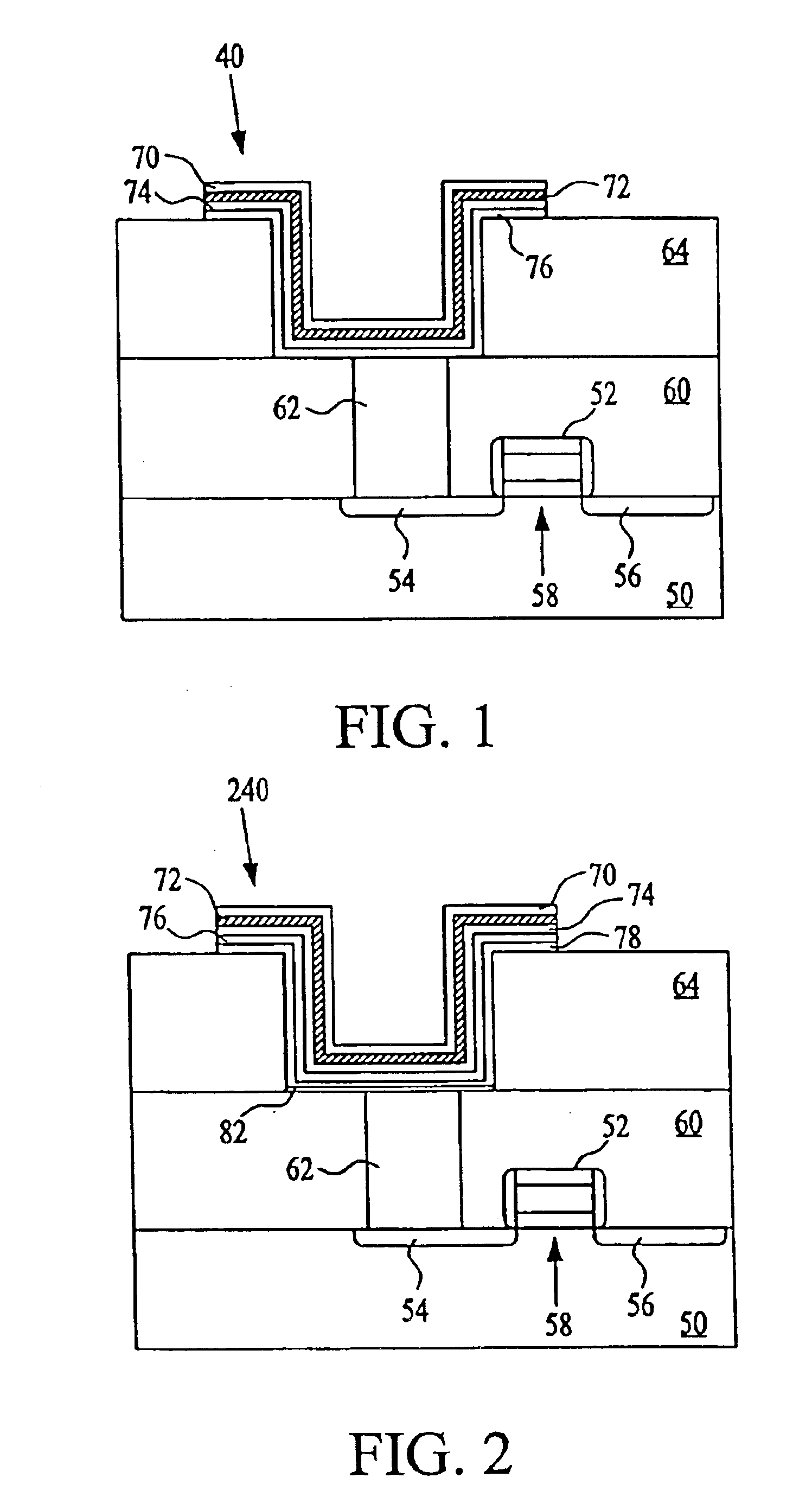

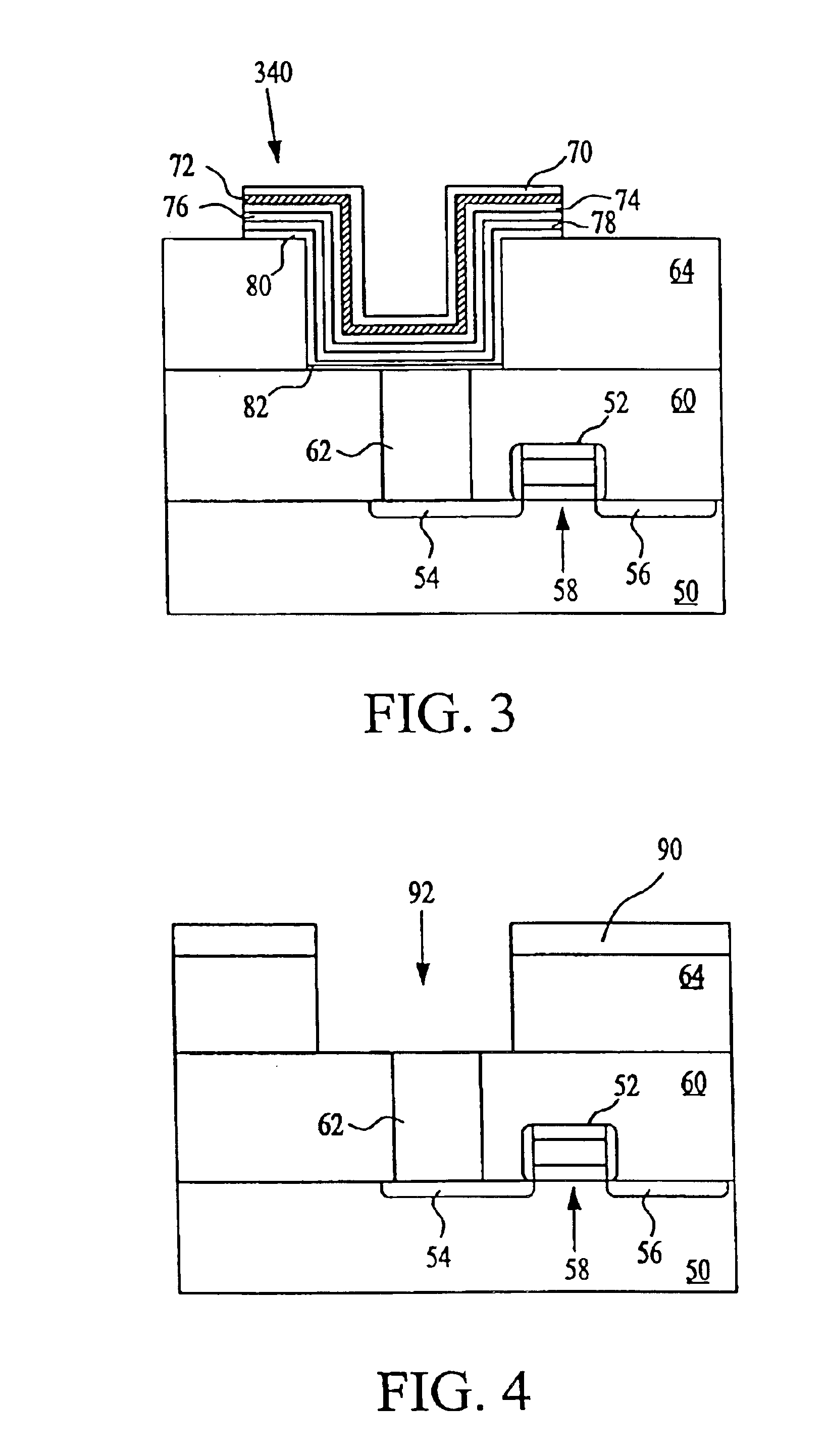

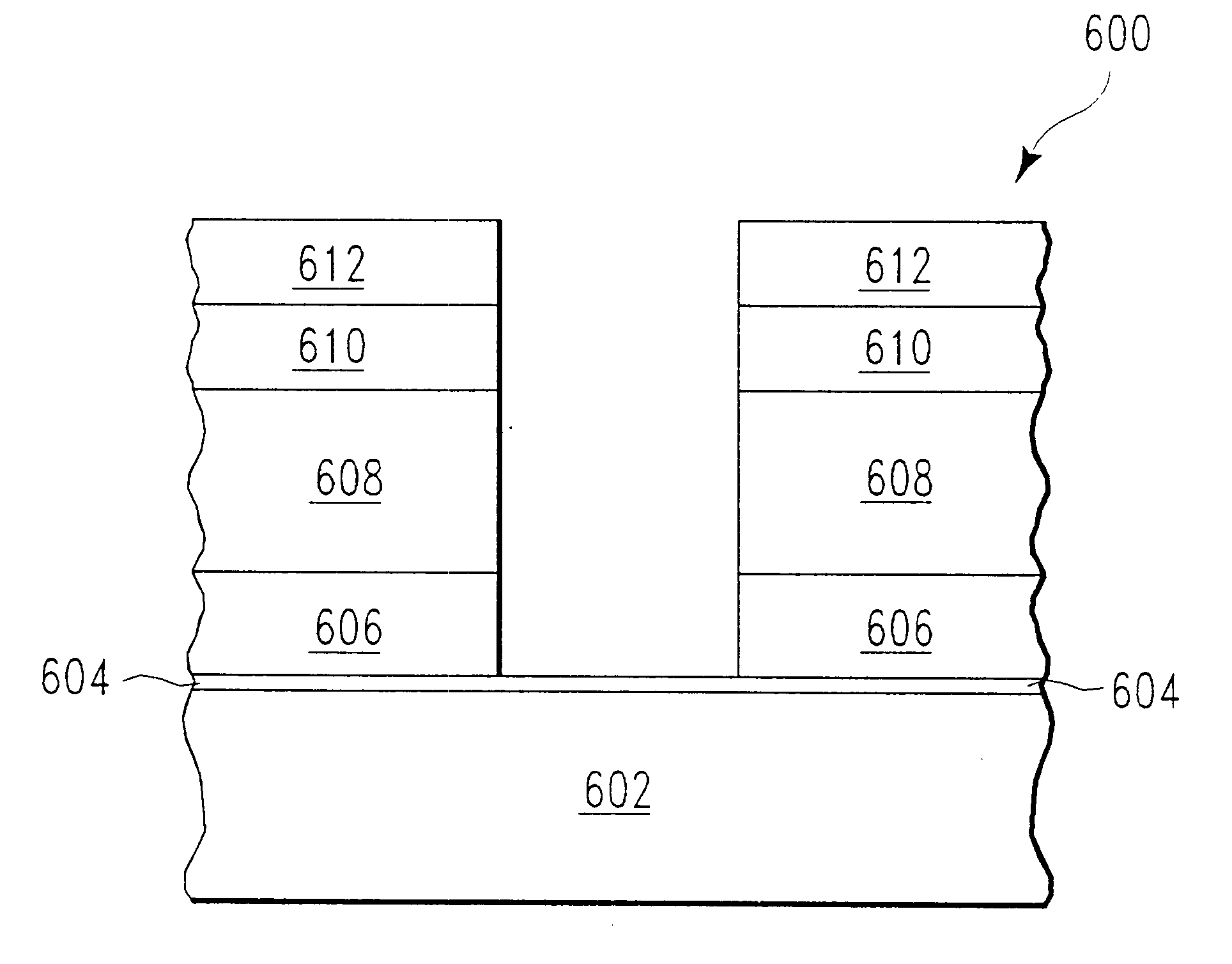

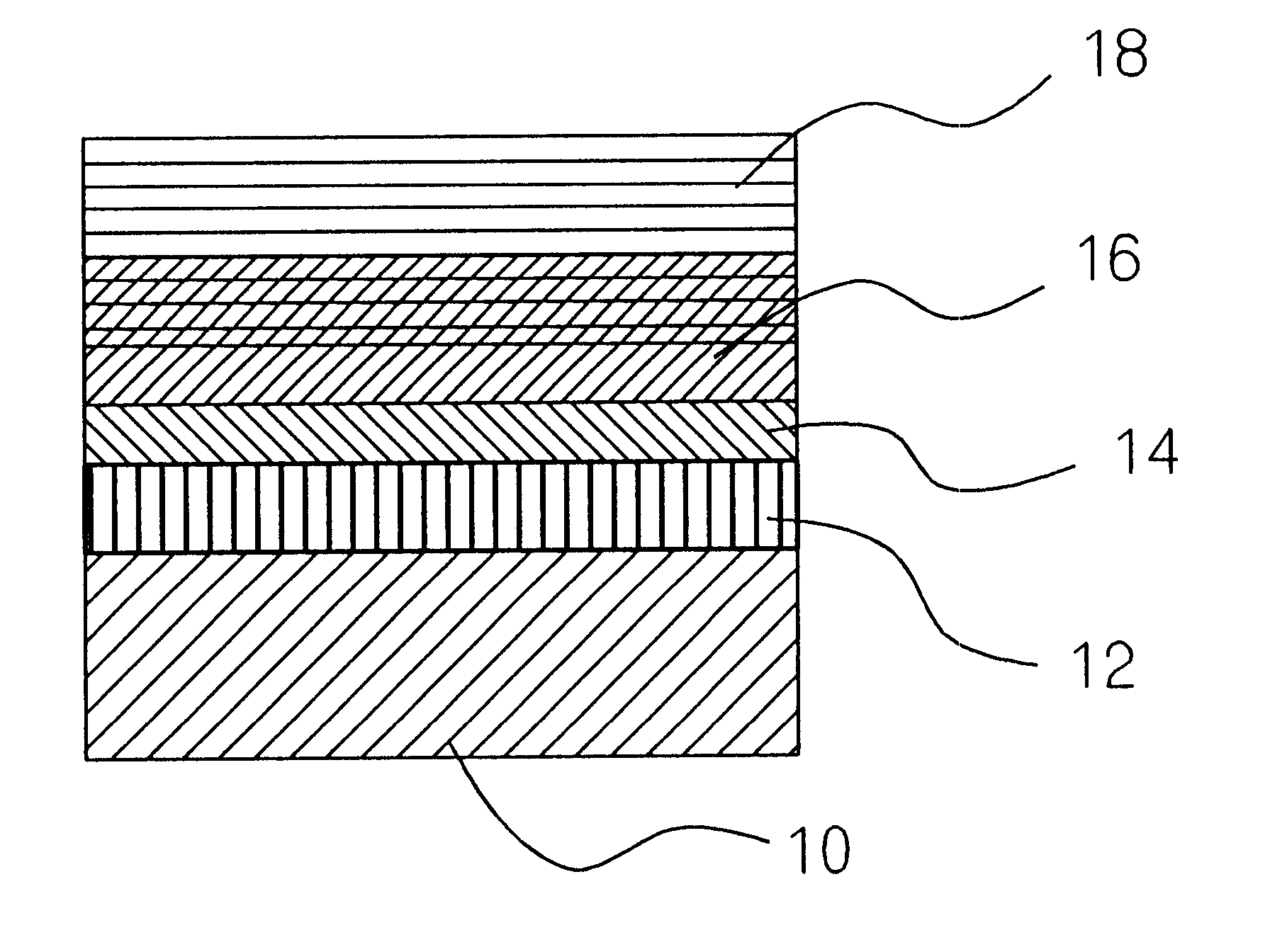

Integrated circuit with a capacitor comprising an electrode

InactiveUS6900497B2Improve capacitor performanceImprove performanceTransistorThin/thick film capacitorPlatinumRandom access memory

A ferroelectric or high dielectric constant capacitor having a multilayer lower electrode comprising at least two layers—a platinum layer and a platinum-rhodium layer—for use in a random access memory (RAM) cell. The platinum layer of the lower electrode adjoins the capacitor dielectric, which is a ferroelectric or high dielectric constant dielectric such as BST, PZT, SBT or tantalum pentoxide. The platinum-rhodium layer serves as an oxidation barrier and may also act as an adhesion layer for preventing separation of the lower electrode from the substrate, thereby improving capacitor performance. The multilayer electrode may have titanium and / or titanium nitride layers under the platinum-rhodium layer for certain applications. The capacitor has an upper electrode which may be a conventional electrode or which may have a multilayer structure similar to that of the lower electrode. Processes for manufacturing the multilayer lower electrode and the capacitor are also disclosed.

Owner:MICRON TECH INC

Additive for lubricant for improving the tribologic properties, a method for its production and application

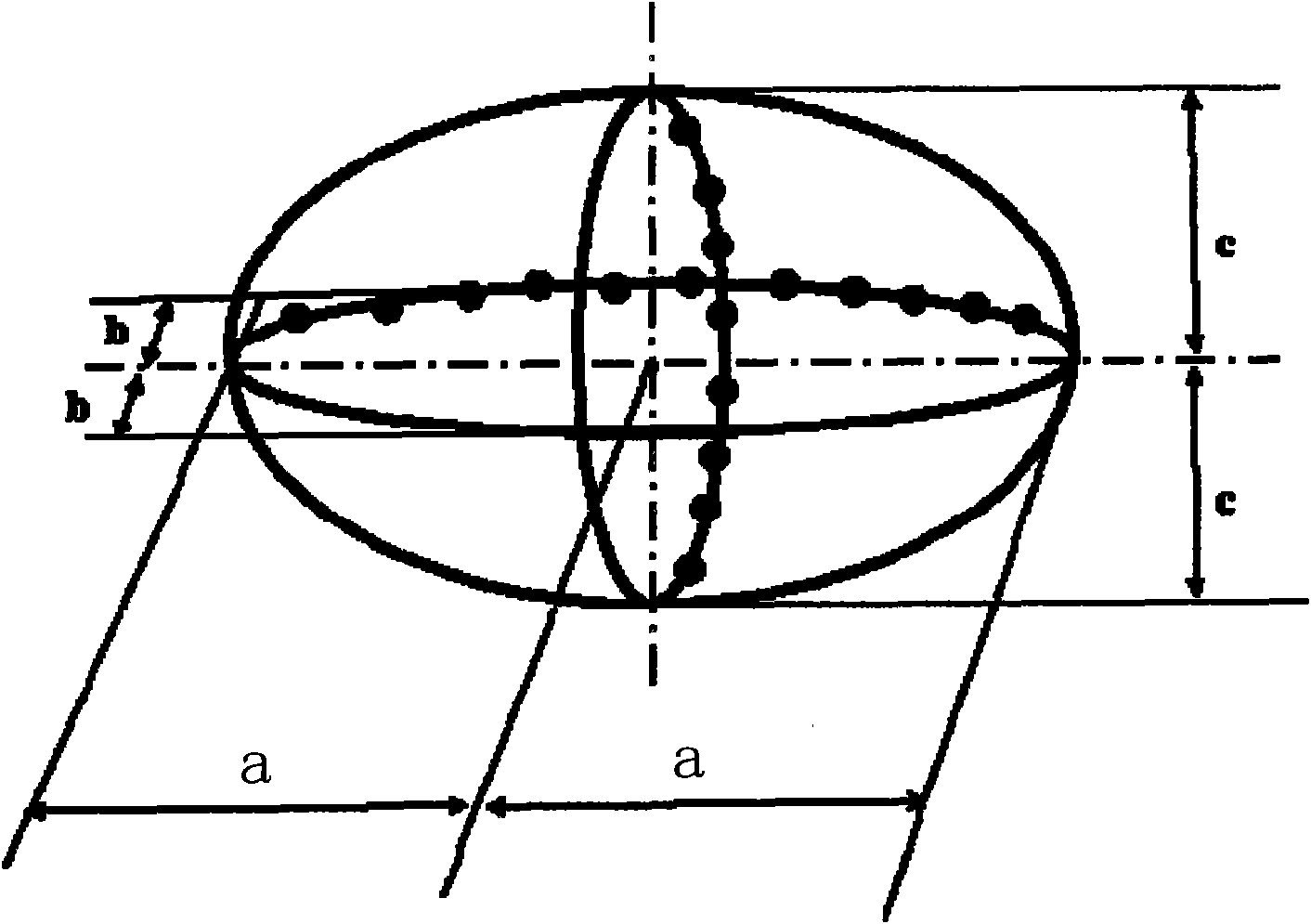

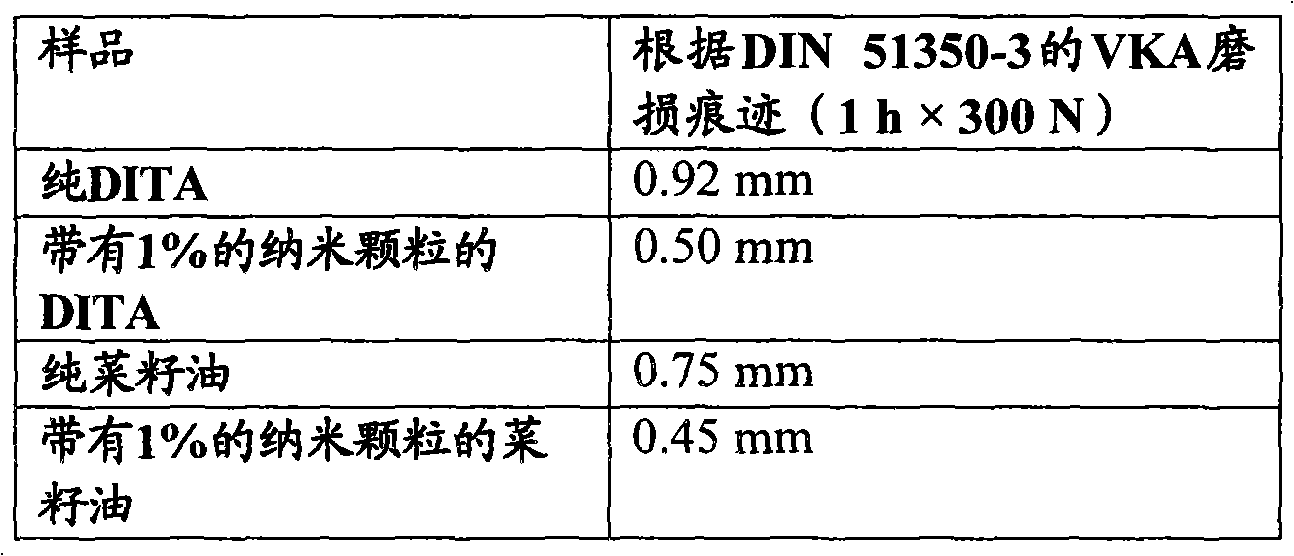

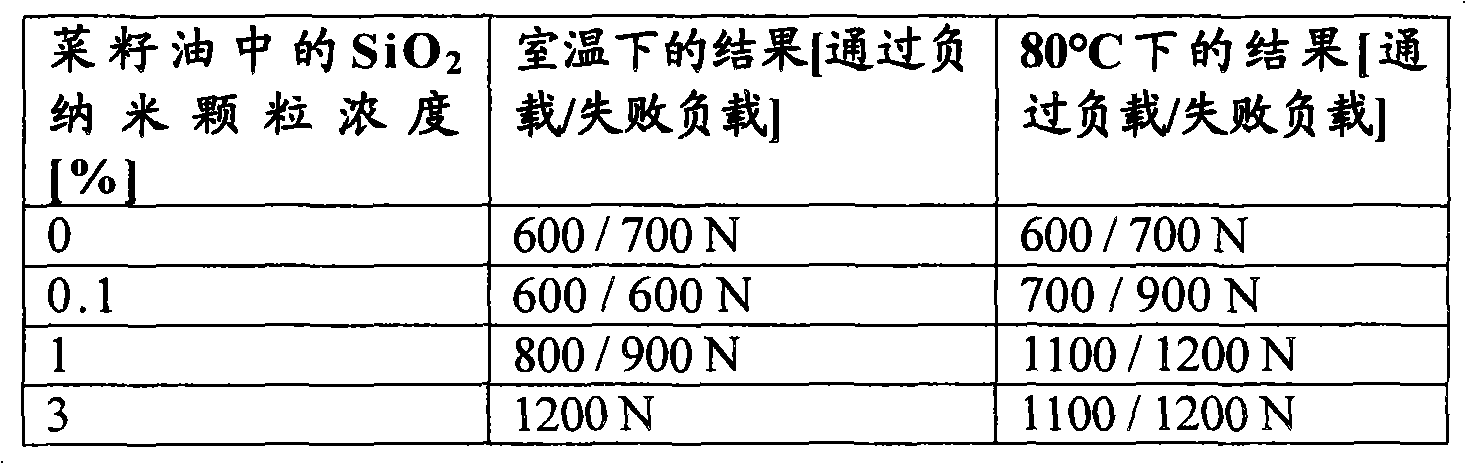

The present invention relates to novel lubricant additives for improving the tribological properties, novel lubricants containing these additives, processes for the preparation thereof and the use thereof. Lubricant comprises ceramic nanoparticles as additives comprising aluminum oxide, aluminum nitride, silicon dioxide, titanium dioxide, zirconium oxide, yttrium oxide, tungsten oxide, tantalum pentoxide, vanadium pentoxide, niobium pentoxide, cerium dioxide, boron carbide, aluminum titanate, boron nitride, molybdenum disilicide, silicon carbide, silicon nitride, titanium carbide, titanium nitride, zirconium diboride and / or clay minerals, and thermally stable carbonates and / or sulfates. The nanoparticles represent an ellipsoid with three semi-axes a, b and c, which are not equal to each other, or equal to each other. The ratio of a and b is 1-100, a and c is 1-1000, and b and c is 1:100.

Owner:แลนด์เซสส์ ดอยช์แลนด์ จีเอ็มบีเอช

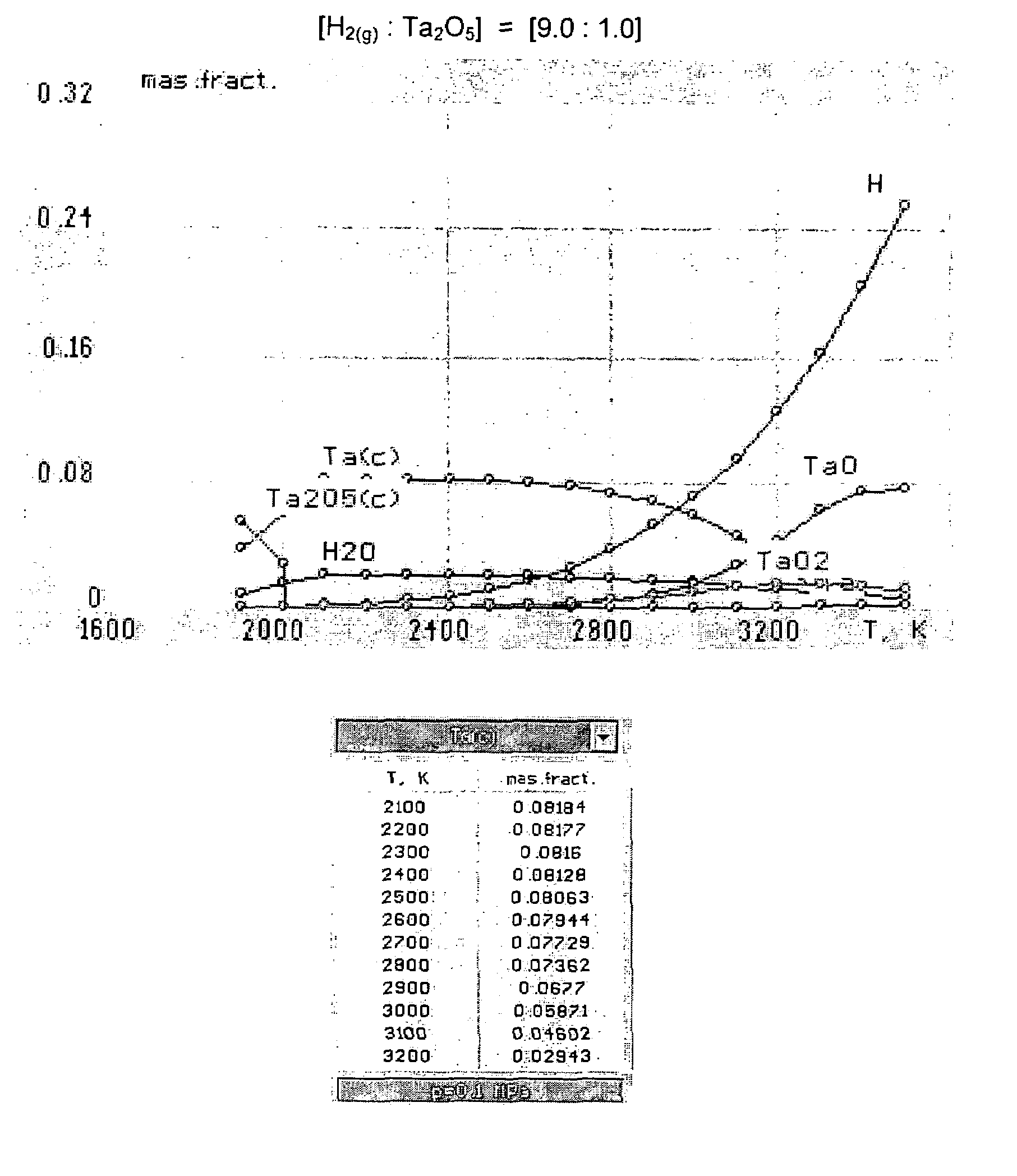

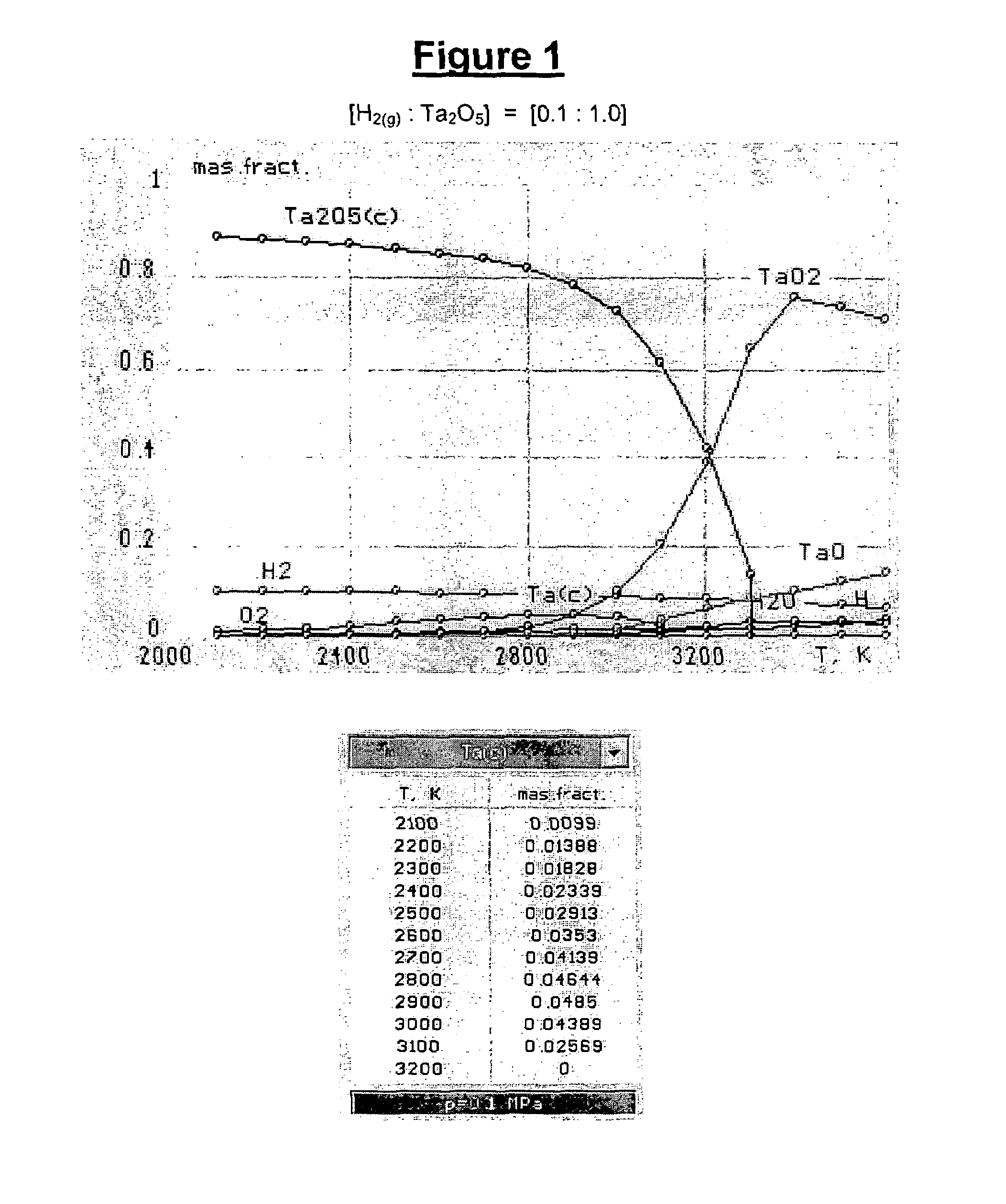

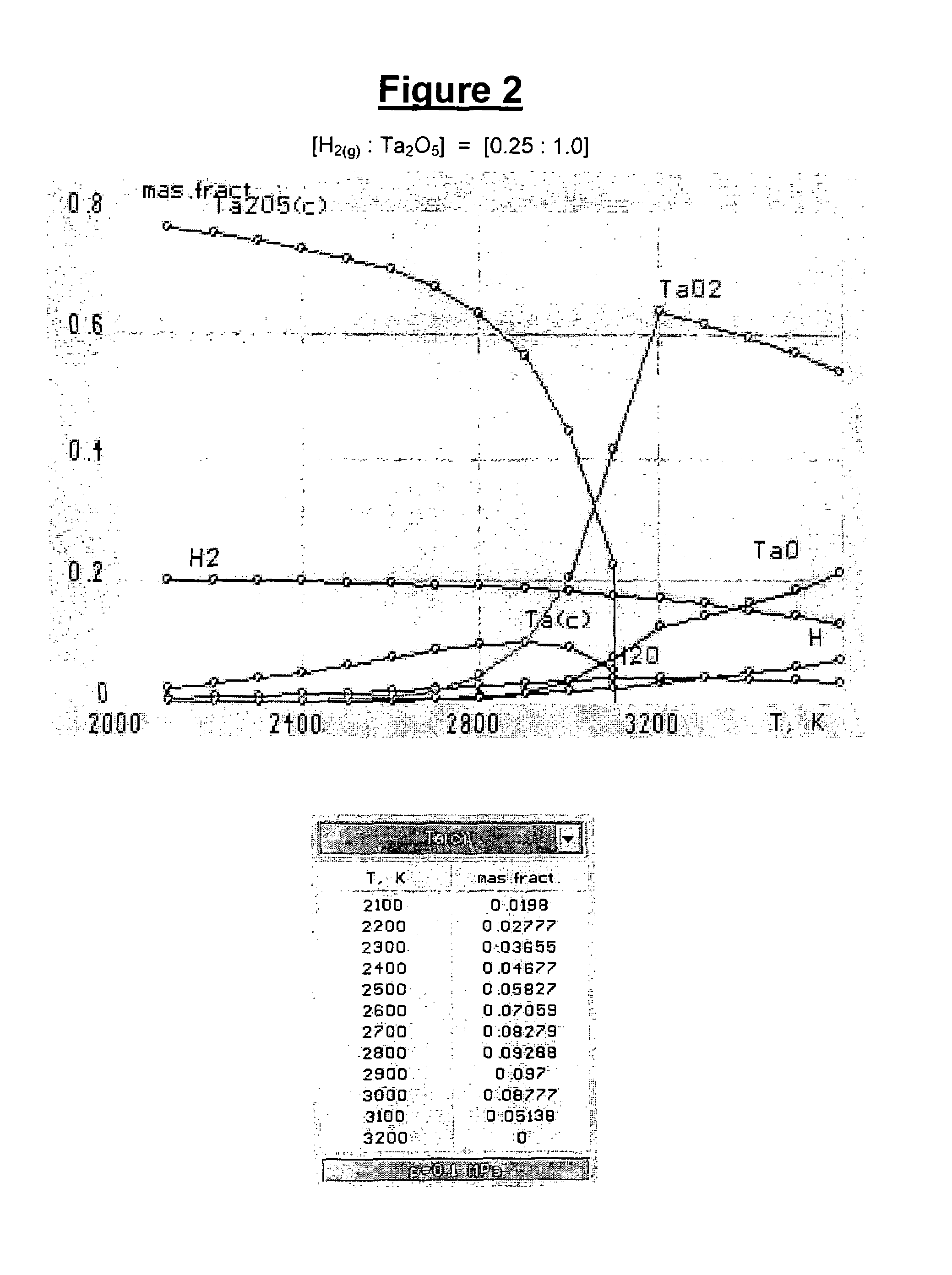

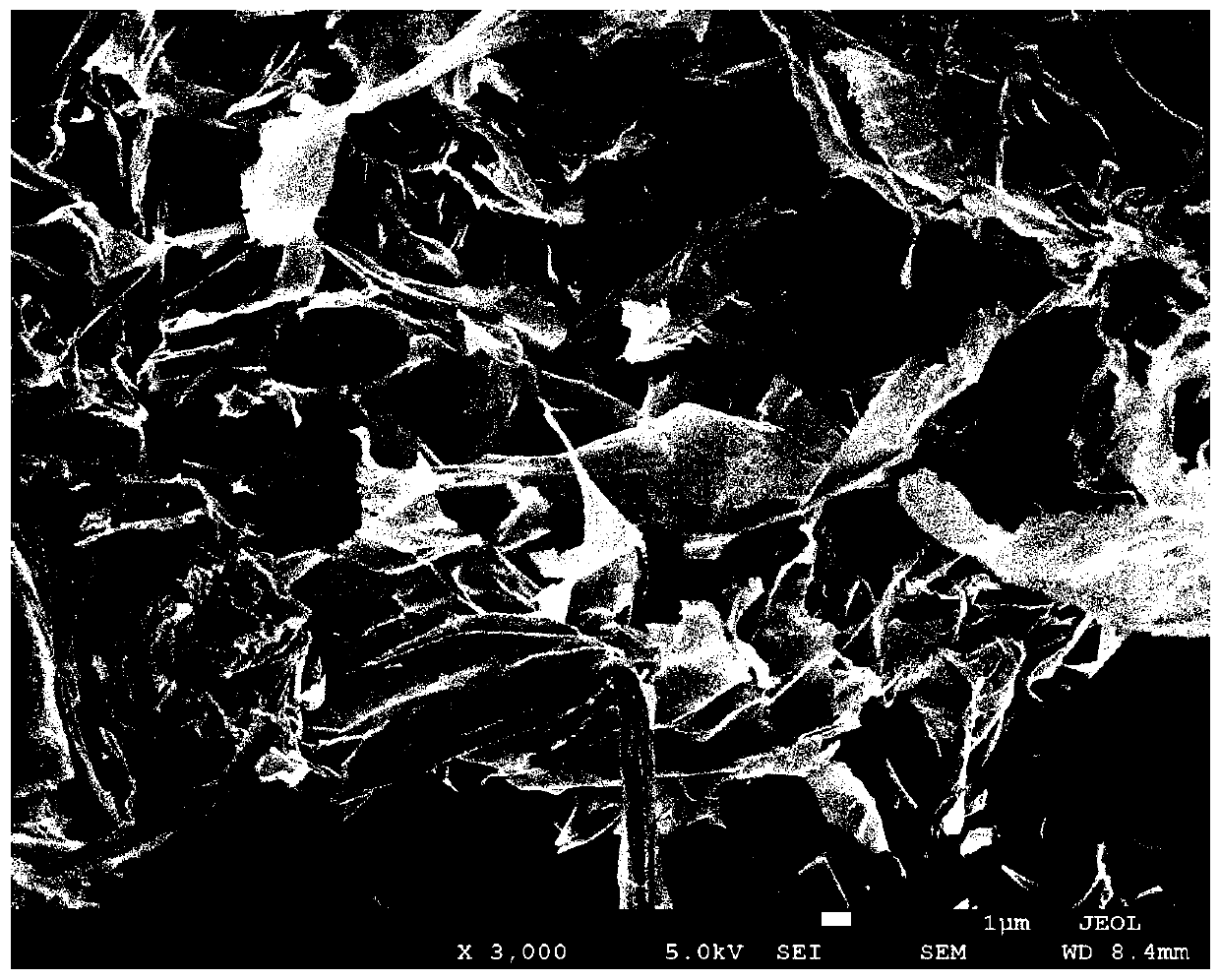

Method of preparing primary refractory metal

A method of preparing primary refractory metals (e.g., primary tantalum metal) by contacting a particulate refractory metal oxide (e.g., tantalum pentoxide) with a heated gas (e.g., a plasma), is described. The heated gas comprises hydrogen gas. The temperature range of the heated gas and the mass ratio of hydrogen gas to refractory metal oxide are each selected such that: (i) the heated gas comprises atomic hydrogen; (ii) the refractory metal oxide feed material is substantially thermodynamically stabilized (i.e., the concurrent formation of suboxides that are not reduced by atomic hydrogen is minimized); and (iii) the refractory metal oxide is reduced by contact with the heated gas, thereby forming primary refractory metal (e.g., primary tantalum metal and / or primary niobium metal).

Owner:TANIOBIS GMBH

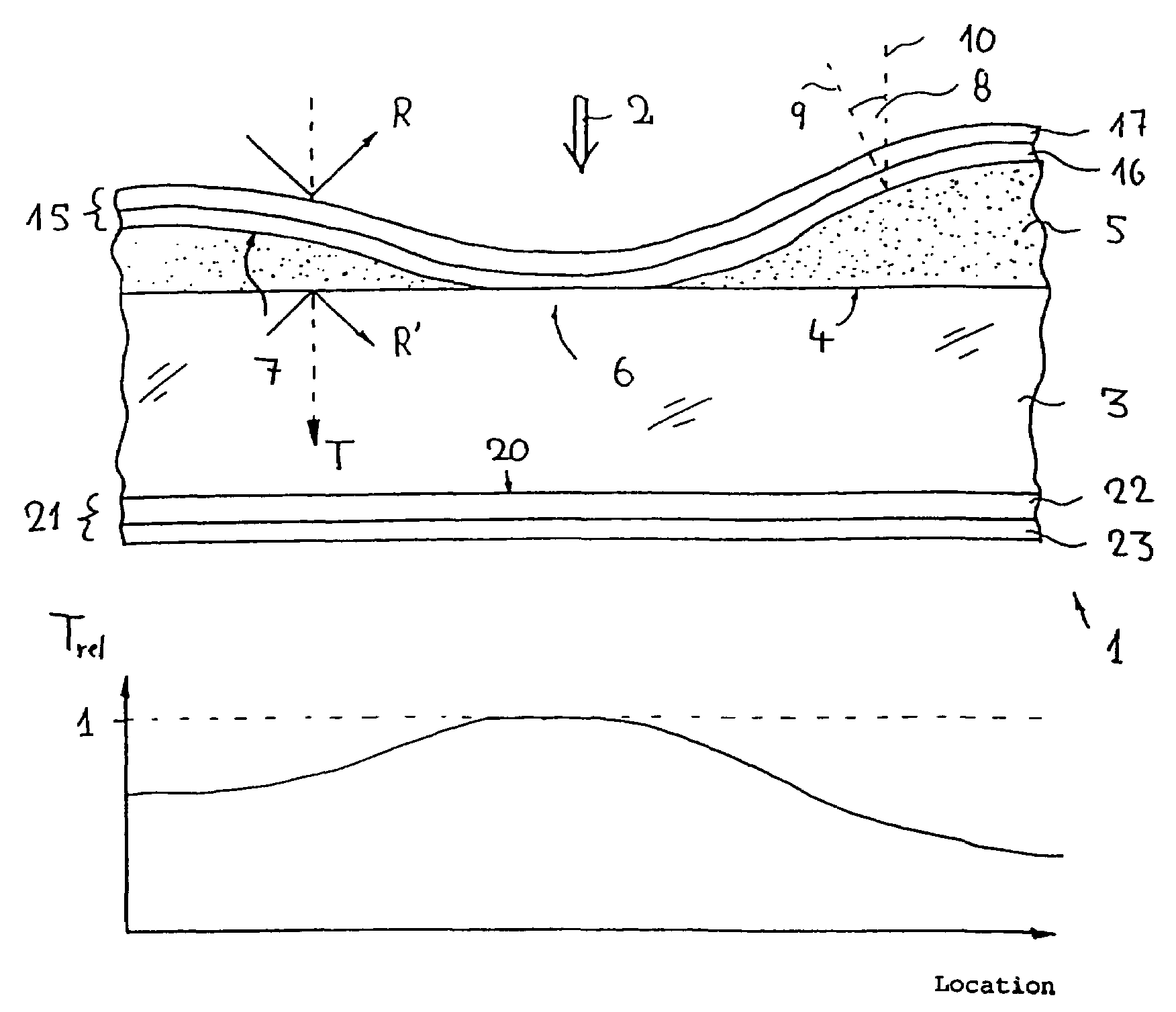

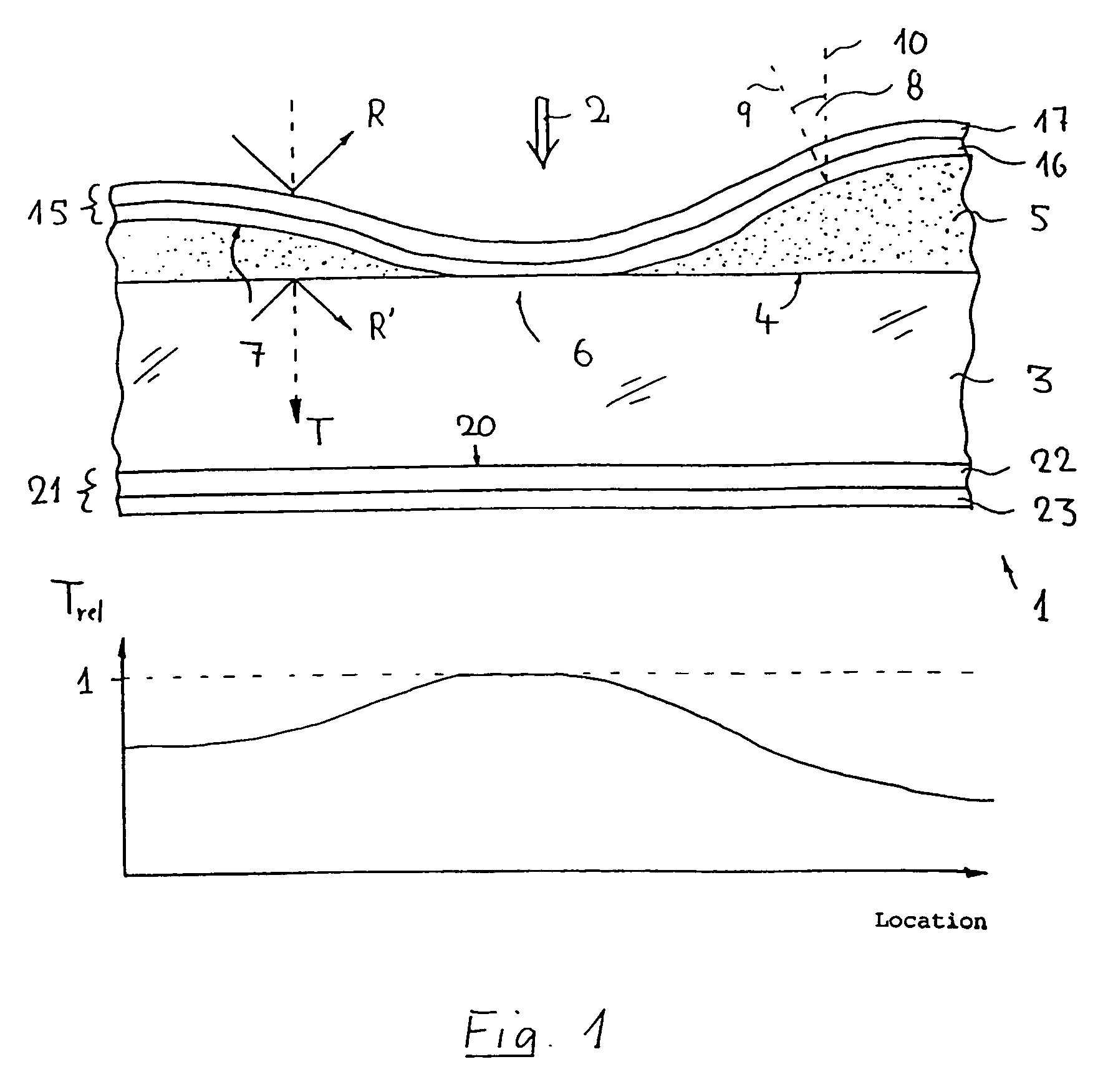

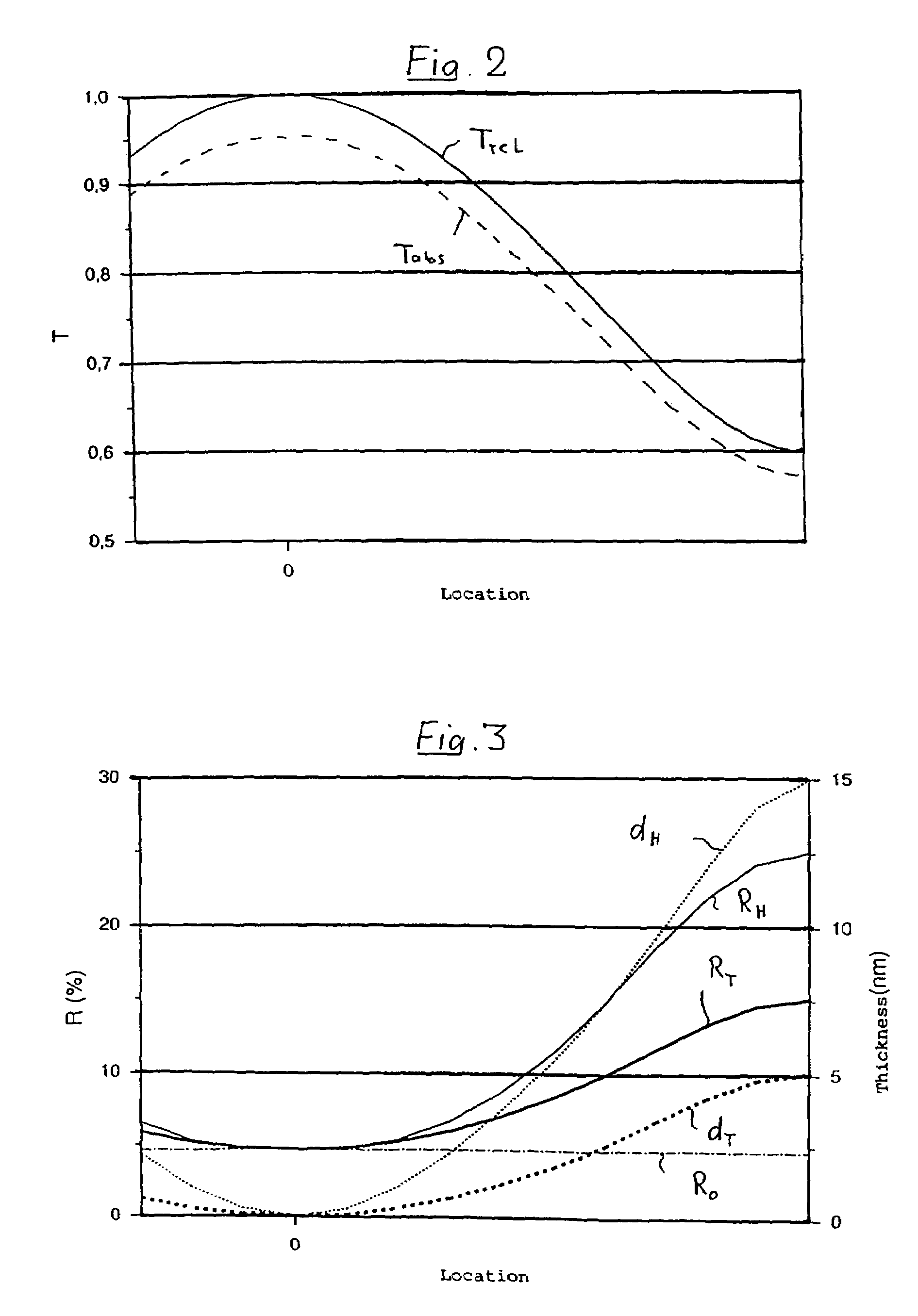

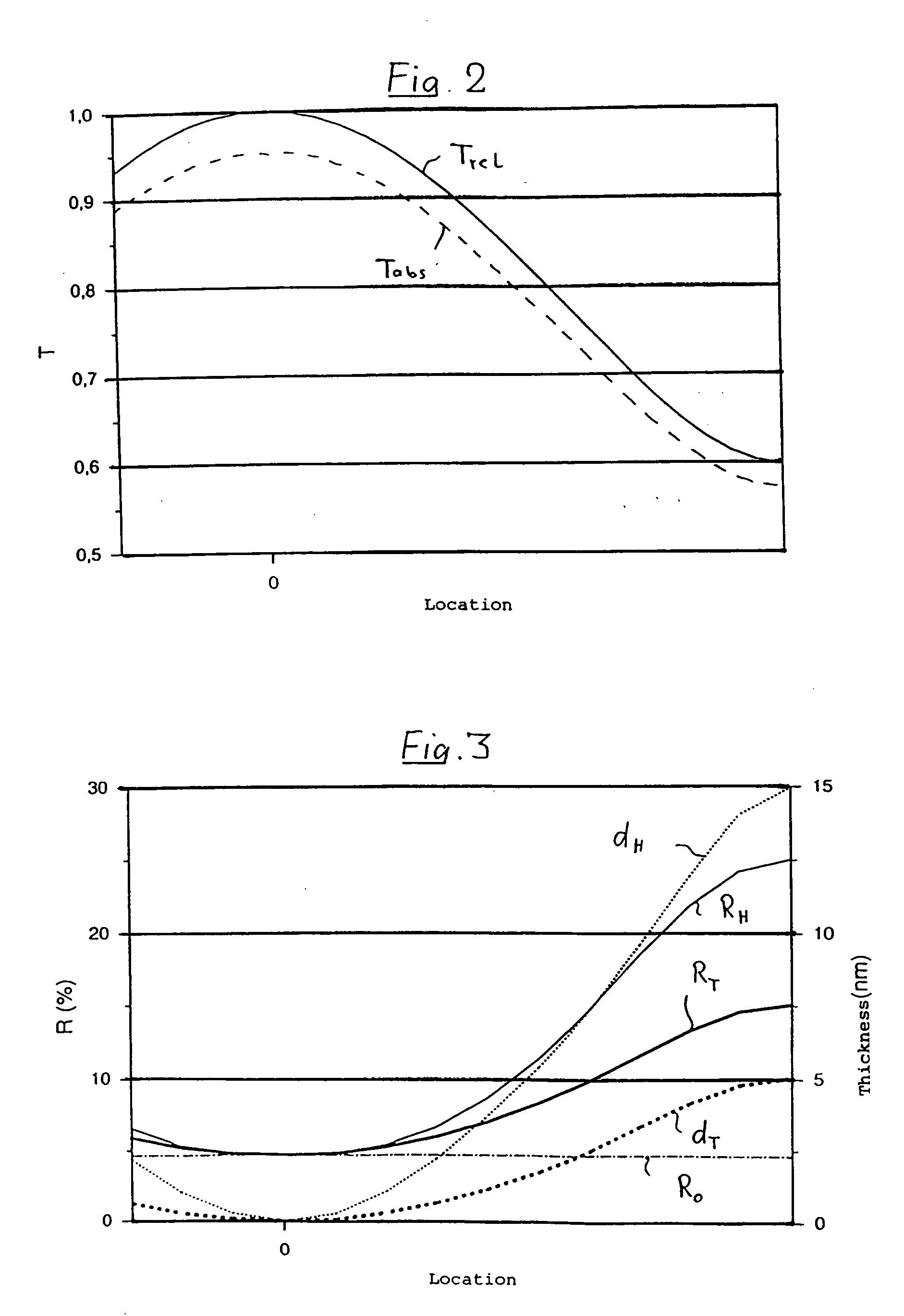

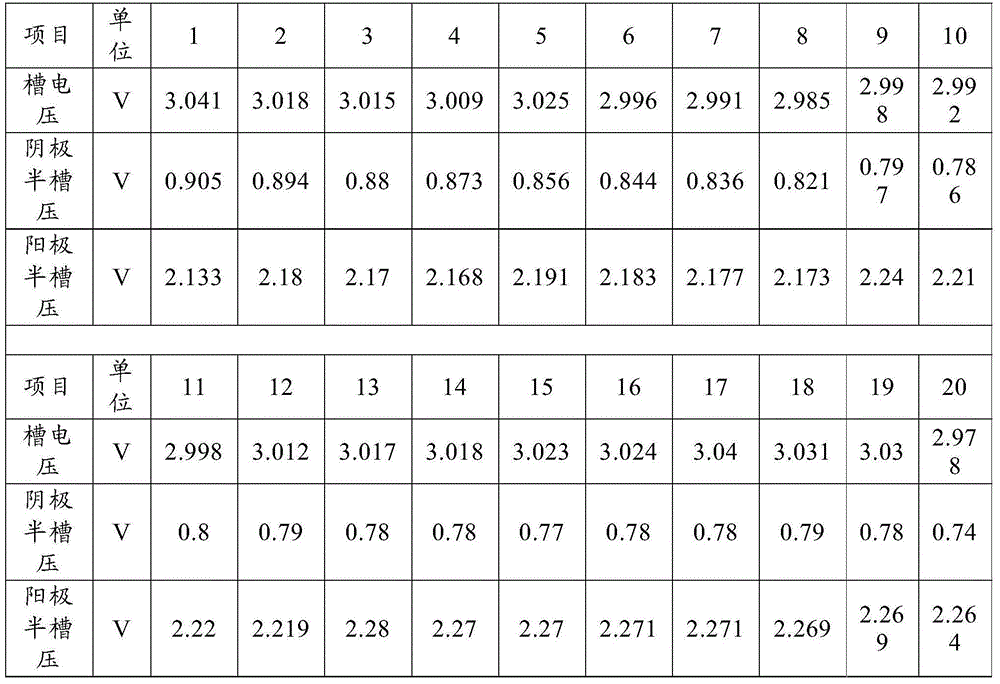

Attenuating filter for ultraviolet light

InactiveUS7196842B2Simple and inexpensive to fabricateVariation of the transmittance of the filter coatingMirrorsOptical filtersSpectral transmittanceUltraviolet lights

Owner:CARL ZEISS SMT GMBH

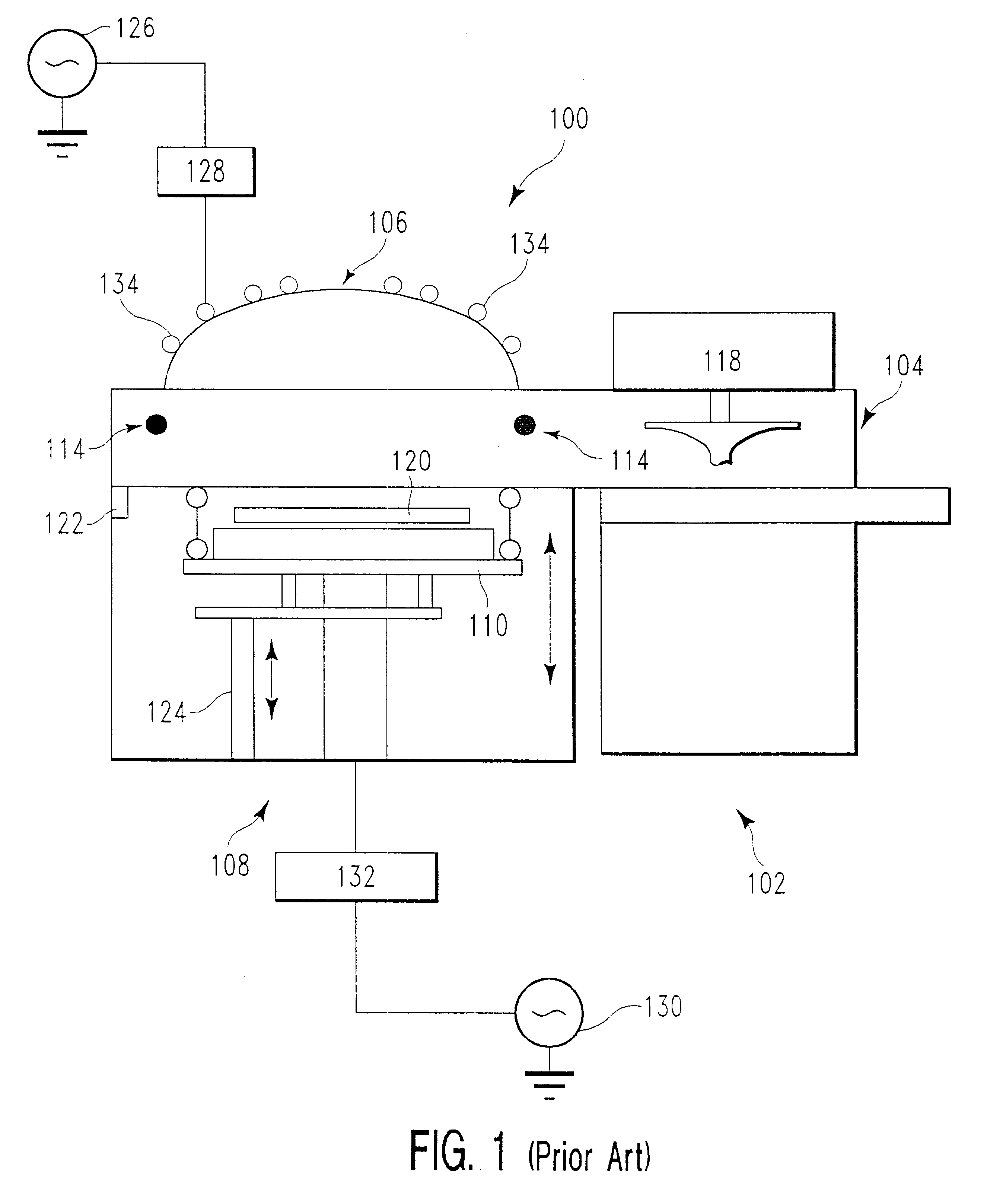

Method of etching tungsten or tungsten nitride electrode gates in semiconductor structures

InactiveUS6440870B1Decorative surface effectsSemiconductor/solid-state device detailsEtchingSulfur hexafluoride

The present invention relates to a method of etching tungsten or tungsten nitride in semiconductor structures, and particularly to the etching of gate electrodes which require precise control over the etching process. We have discovered a method of etching tungsten or tungsten nitride which permits precise etch profile control while providing excellent selectivity, of at least 175:1, for example, in favor of etching tungsten or tungsten nitride rather than an adjacent oxide layer. Typically, the oxide is selected from silicon oxide, silicon oxynitride, tantalum pentoxide, zirconium oxide, and combinations thereof. The method appears to be applicable to tungsten or tungsten nitride, whether deposited by physical vapor deposition (PVD) or chemical vapor deposition (CVD). In particular, an initial etch chemistry, used during the majority of the tungsten or tungsten nitride etching process (the main etch), employs the use of a plasma source gas where the chemically functional etchant species are generated from a combination of sulfur hexafluoride (SF6) and nitrogen (N2), or in the alternative, from a combination of nitrogen trifluoride (NF3), chlorine (Cl2), and carbon tetrafluoride (CF4). Toward the end of the main etching process, a second chemistry is used in which the chemically functional etchant species are generated from Cl2 and O2. This final portion of the etch process may be referred to as an "overetch" process, since etching is carried out to at least the surface underlying the tungsten or tungsten nitride. However, this second etch chemistry may optionally be divided into two steps, where the plasma source gas oxygen content and plasma source power are increased in the second step.

Owner:APPLIED MATERIALS INC

Method for preparing tantalum or niobium powders used for manufacturing capacitors

Disclosed relates to a method for preparing tantalum or niobium powders used for manufacturing capacitors in an electrolytic reducing reactor including an anode, a cathode and a molten salt, the method comprising: obtaining a tantalum or niobium oxide, expressed by Ta2O(5-y) or Nb2O(5-y) where y=2.5 to 4.5, from a tantalum pentoxide Ta2O5 or a niobium pentoxide Nb2O5 generated partially by an alkaline metal electrolytically reduced via a first electrolytic reducing reaction that reduces an alkaline metal oxide from a molten salt comprising at least one metal halogen compound, selected from the group consisting of alkaline metal and alkaline earth metal, and an alkaline metal oxide on the cathode; and preparing a tantalum or niobium powder by a first electrolytic reducing reaction that reduces at least one metal halogen compound selected from the group consisting of the alkaline metal oxide and the alkaline earth metal on the cathode and by a second reducing reaction with the tantalum or niobium oxide, represented by Ta2O(5-y) or Nb2O(5-y) where y=2.5 to 4.5.

Owner:KOREA ATOMIC ENERGY RES INST +1

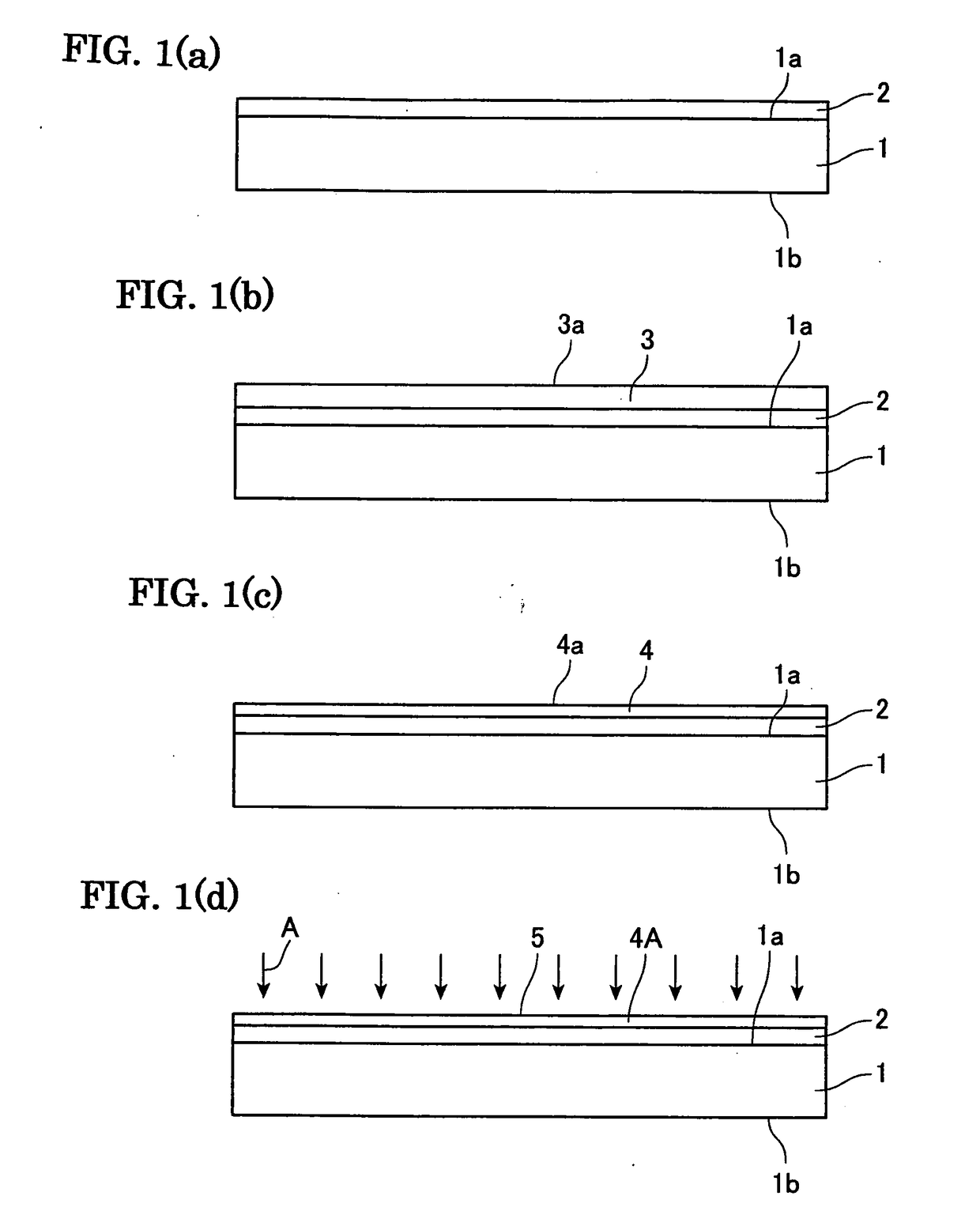

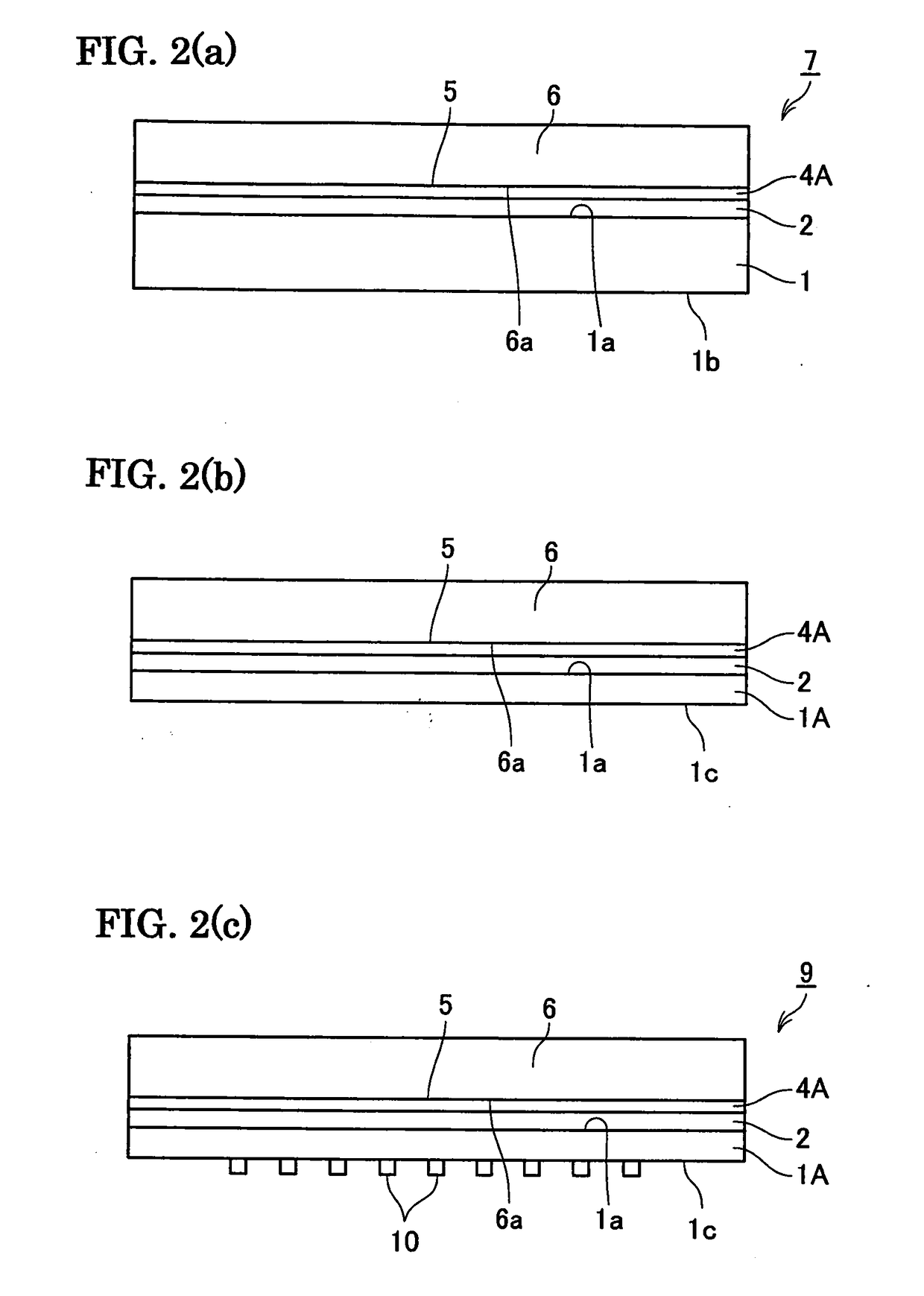

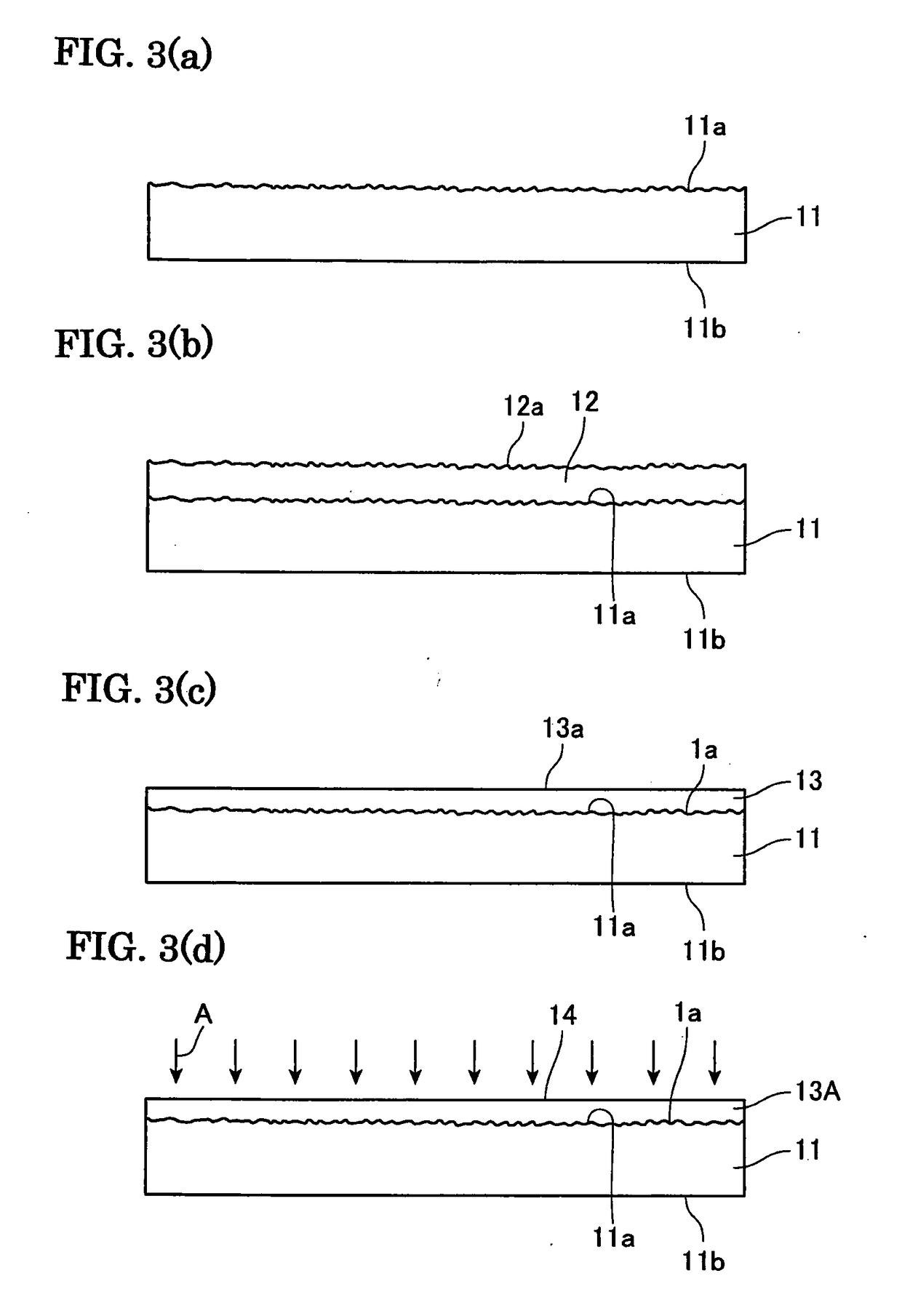

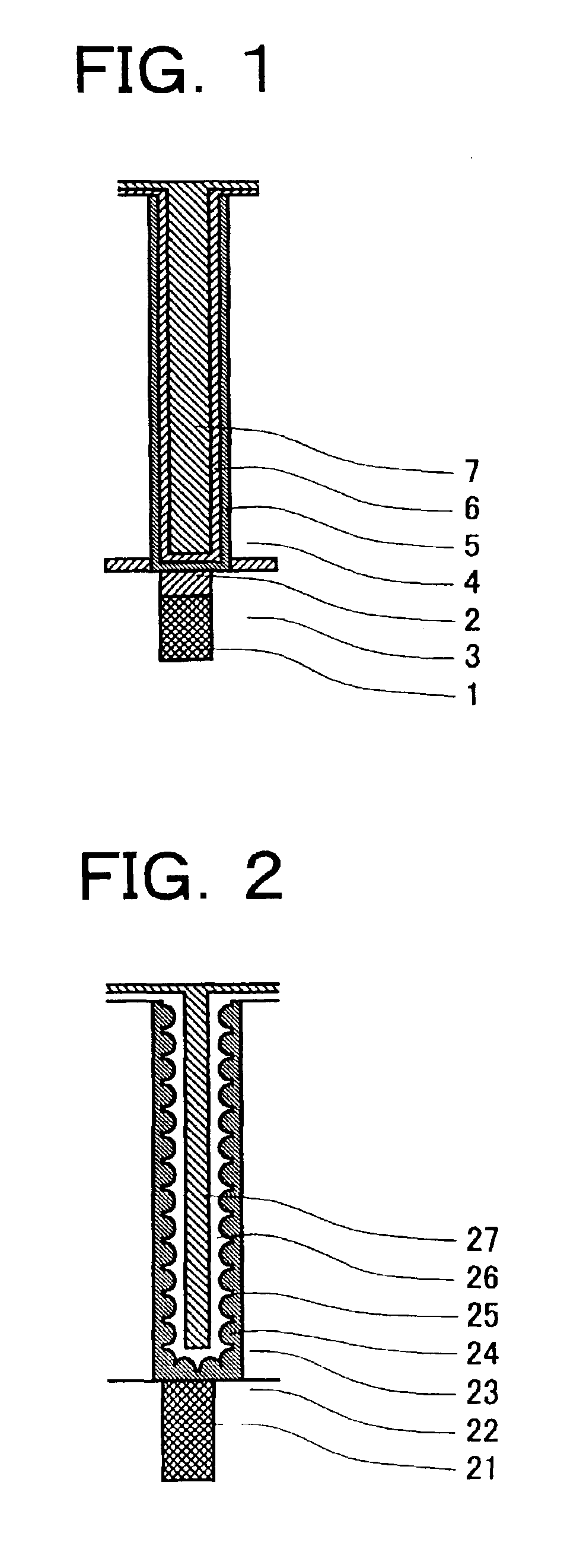

Bonding method

ActiveUS20190036009A1High bonding strengthReduce intensityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksMulliteNitride

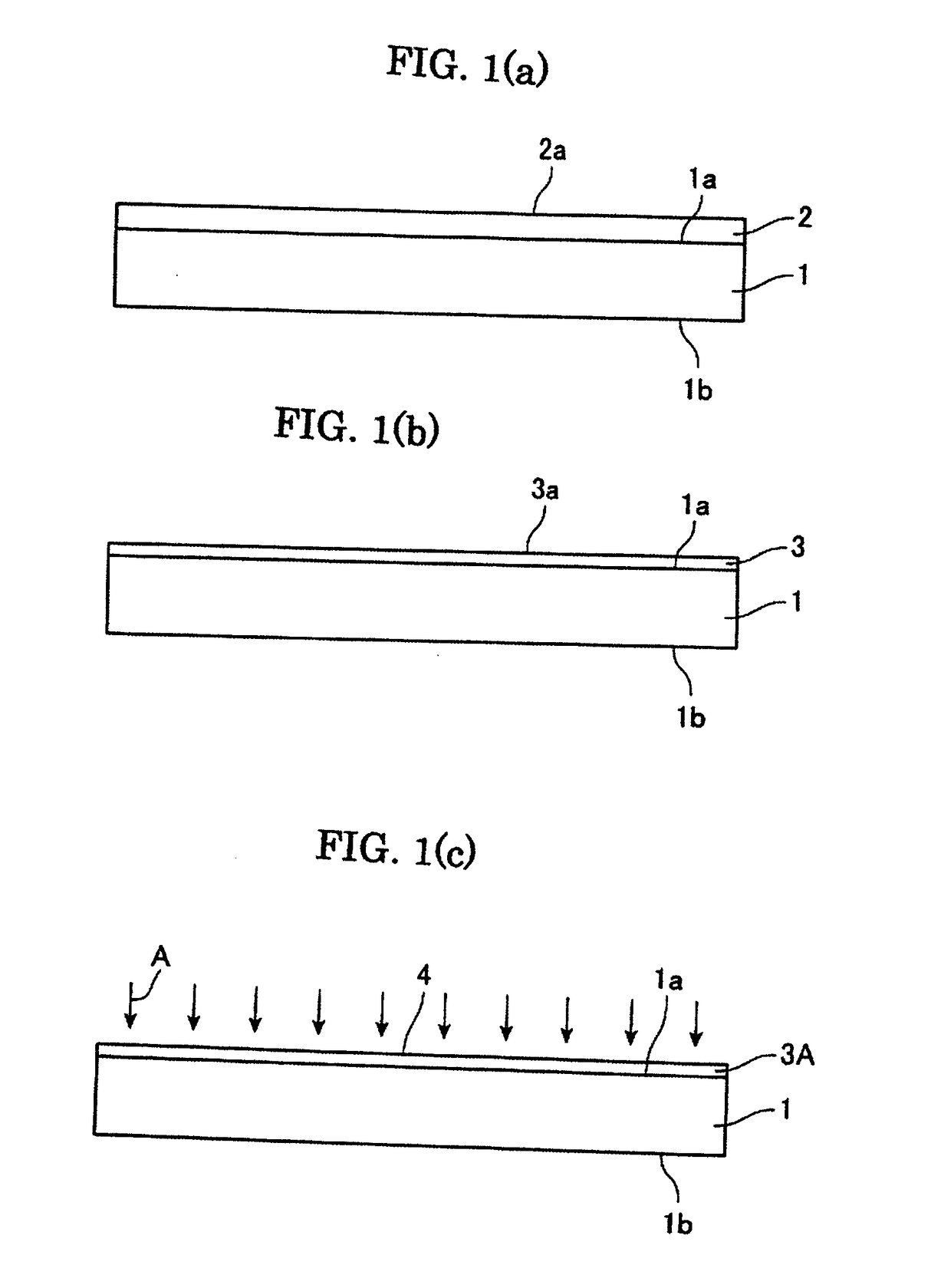

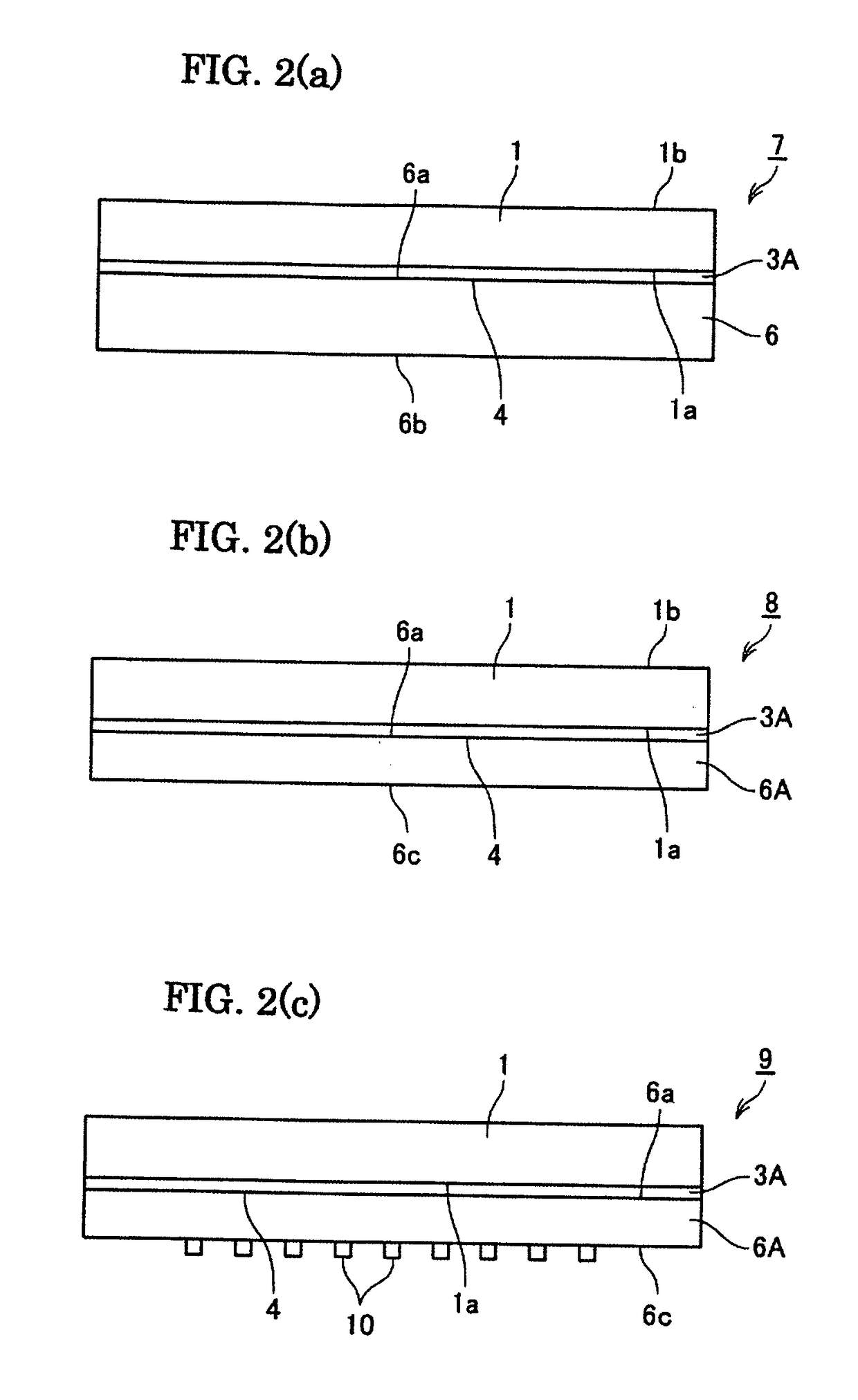

A bonding layer 3 is formed over a piezoelectric material substrate, and the bonding layer 3 is made of or more material selected from the group consisting of silicon nitride, aluminum nitride, alumina, tantalum pentoxide, mullite, niobium pentoxide and titanium oxide. Neutralized beam A is irradiated onto a surface 4 of the bonding layer and a surface of a supporting body to activate the surface of the bonding layer and the surface of the supporting body. The surface of the bonding layer and the surface of the supporting body are bonded by direct bonding.

Owner:NGK INSULATORS LTD

Rare earth high-magnetic-permeability soft magnetic ferrite and preparation method thereof

The present invention discloses a rare earth high-magnetic-permeability soft magnetic ferrite and a preparation method thereof, wherein the rare earth high-magnetic-permeability soft magnetic ferrite is prepared from the following raw materials by weight: 55-65 parts of ferroferric oxide, 1-13 parts of zinc oxide, 15-18 parts of manganese oxide, 4-8 parts of copper oxide, 0.4-0.6 part of lanthanum oxide, 0.2-0.6 part of tantalum pentoxide, 0.3-0.4 part of carbonyl iron powder, 6-10 parts of chlorinated polyethylene, 0.4-1 part of carbon powder, 1-2 parts of sodium lignin sulfonate, 6-9 parts of an organosilicon resin, and a proper amount of deionized water. The rare earth high-magnetic-permeability soft magnetic ferrite of the present invention has characteristics of high magnetic-permeability, low loss, easy operation, low environmental pollution, cost reducing, high qualification rate, and stable quality.

Owner:MAANSHAN KEXIN CONSULTING

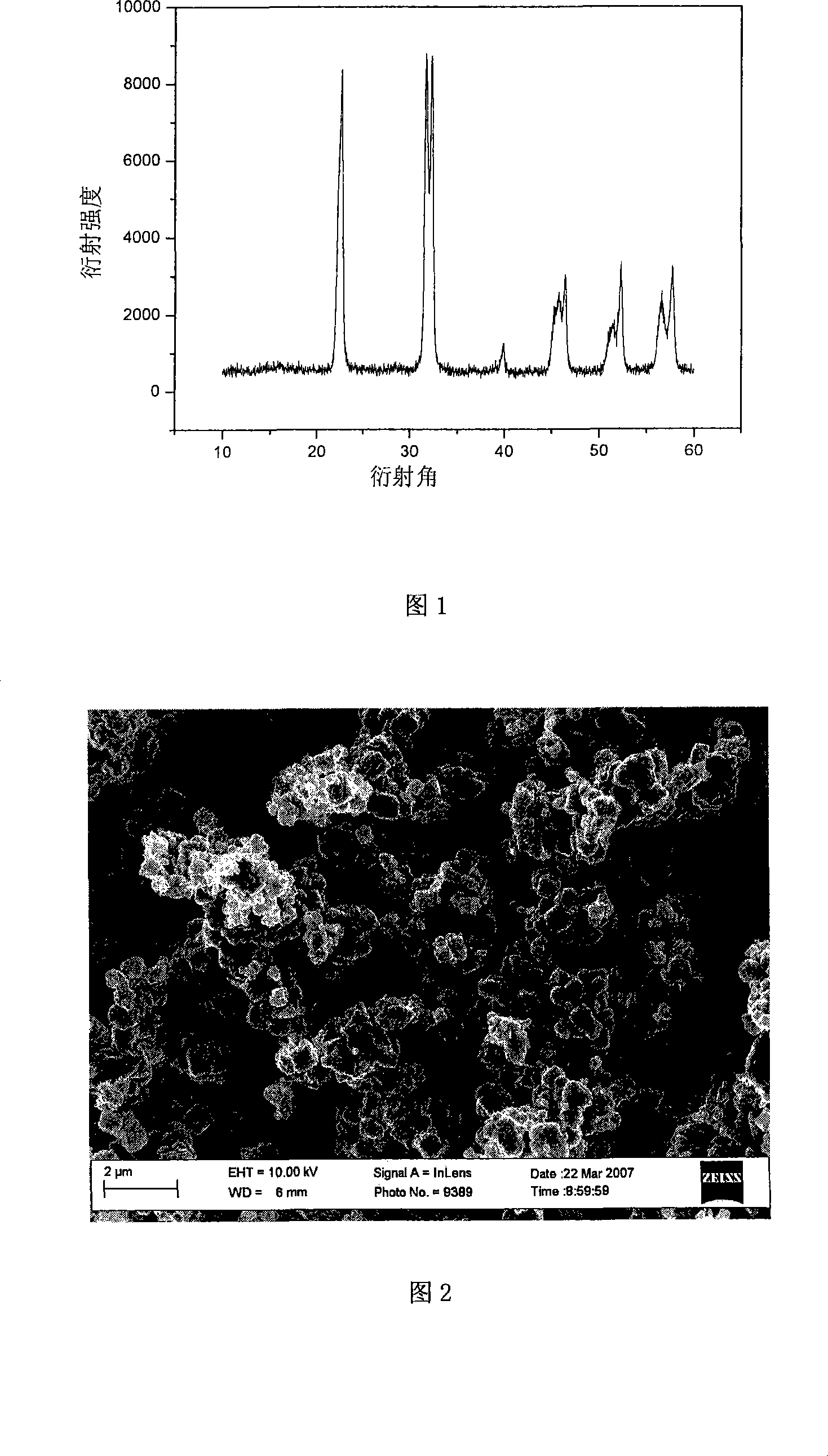

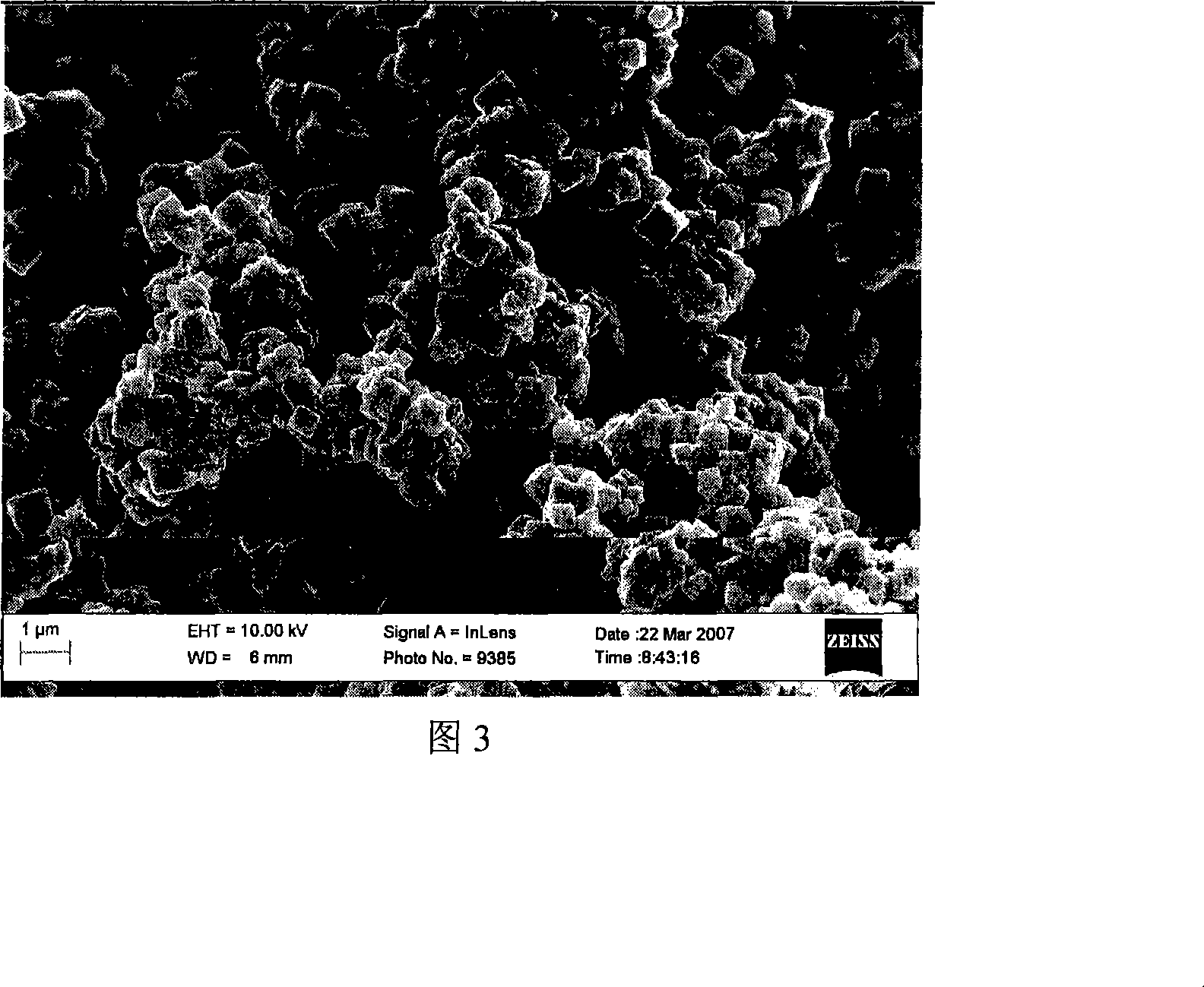

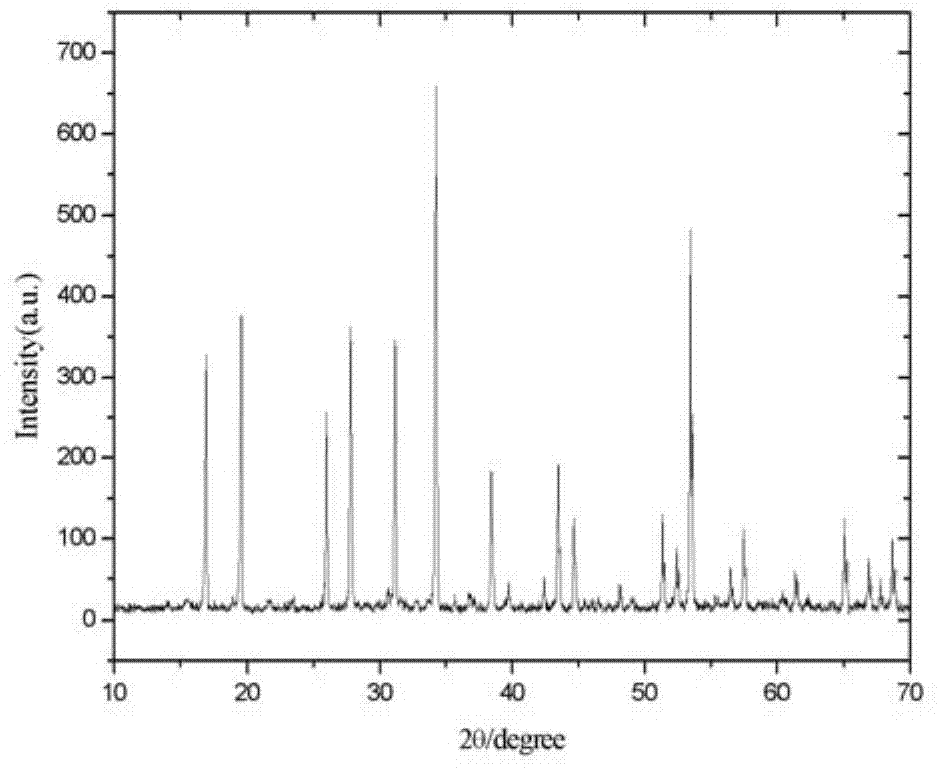

Hydro-thermal synthesis method for tantalum adulterated potassium sodium niobate leadless piezoelectric ceramic powder

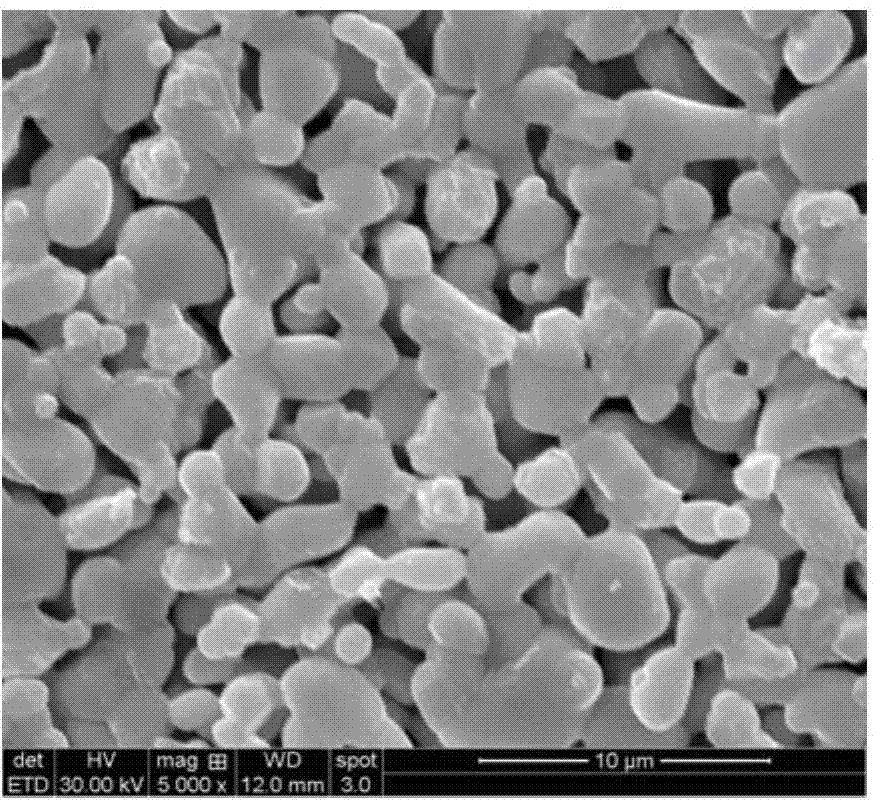

InactiveCN101186338APiezoelectric/electrostrictive/magnetostrictive devicesNiobium compoundsCeramic sinteringSynthesis methods

The invention relates to a hydrothermal synthesis method for preparation of sodium-potassium niobate lead-free piezoelectric ceramic powder intermingled with tantalum, which belongs to the functional ceramic material field. The invention is characterized in that sodium hydroxide, potassium hydroxide, niobium pentaoxide and tantalum pentoxide are used as raw materials at the temperature ranging from 200 to 250 DEG C, and K0.5Na0.5NbO3 piezoelectric ceramic powder intermingled with Ta can be achieved by hydrothermal synthesis while preserving the heat for 20 to 36 hours; the molar ratio of the total added amount of niobium pentaoxide and tantalum pentoxide to alkali solution is 1:10 to 1:25, and the molar ratio of the added niobium pentaoxide to tantalum pentoxide is 1:9 to 4:6; the solution mixture ratio of sodium hydroxide to potassium hydroxide is 1:4 to 1:6, and the concentration of alkali solution is 4-10mol / L. The synthesis temperature is low and the powder grain is fine and average with a diameter about hundreds of nanometers in the invention. And the surface activity is great, which is favorable to the ceramic sintering at the latter stage.

Owner:UNIV OF SCI & TECH BEIJING

Method for manufacturing solid polymer electrolytic condenser

InactiveCN103474247AHigh bonding strengthImprove electrical performanceSolid electrolytic capacitorsCapacitor electrolytes/absorbentsPolymer scienceElectrolysis

The invention provides a method for manufacturing a solid polymer electrolytic condenser and belongs to the technical field of electronic elements. The method is characterized in that a first conducting polymer layer is prepared on the surface of tantalum pentoxide electrolyte, a second conduction polymer layer is prepared on the surface of the first conducting polymer layer, intrinsic conductive polymer is prepared on the first conducting polymer layer through the in-situ chemical oxidative polymerization method, the second conducting polymer layer is prepared through conducting polymer suspension liquid, and a middle adhesion layer is prepared between the first conducting polymer layer and the second conducting polymer layer through silane. The electrolytic condenser manufactured through the method is stable in electrical property like capacitance, leak currents, ESR and loss under various complex environments, and has high high-temperature resistance, high-humidity resistance and high-voltage resistance abilities.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

Multilayer oxide coated valve metal electrode for water purification

An electrode with large active surface area is made by winding a Ti-fiber tow around a rectangular Ti-plate, and an electrocatalytic coating of three layers is applied. A precoat comprising a mixture of iridium dioxide and tantalum pentoxide is applied first, using a solution of the corresponding chloride salts in hydrochloric acid with some nitric acid added to inhibit corrosion of the metal. A sealing coat is then applied, comprising tin dioxide doped with antimony, in order to improve adhesion of the final oxide coat to the precoat. The third and final coat comprises particles of titanium dioxide doped with niobium in the +4 oxidation cemented with titanium dioxide that is doped with antimony. Anodes of this description are preferably assembled together with corrosion resistant cathodes in an alternating sequence, with a plastic coated fiber glass mesh placed between the anodes and cathodes to prevent short circuiting. When a sufficiently large voltage is applied across the cell, organic substances dissolved in the electrolyte will be oxidized.

Owner:WERES OLEH

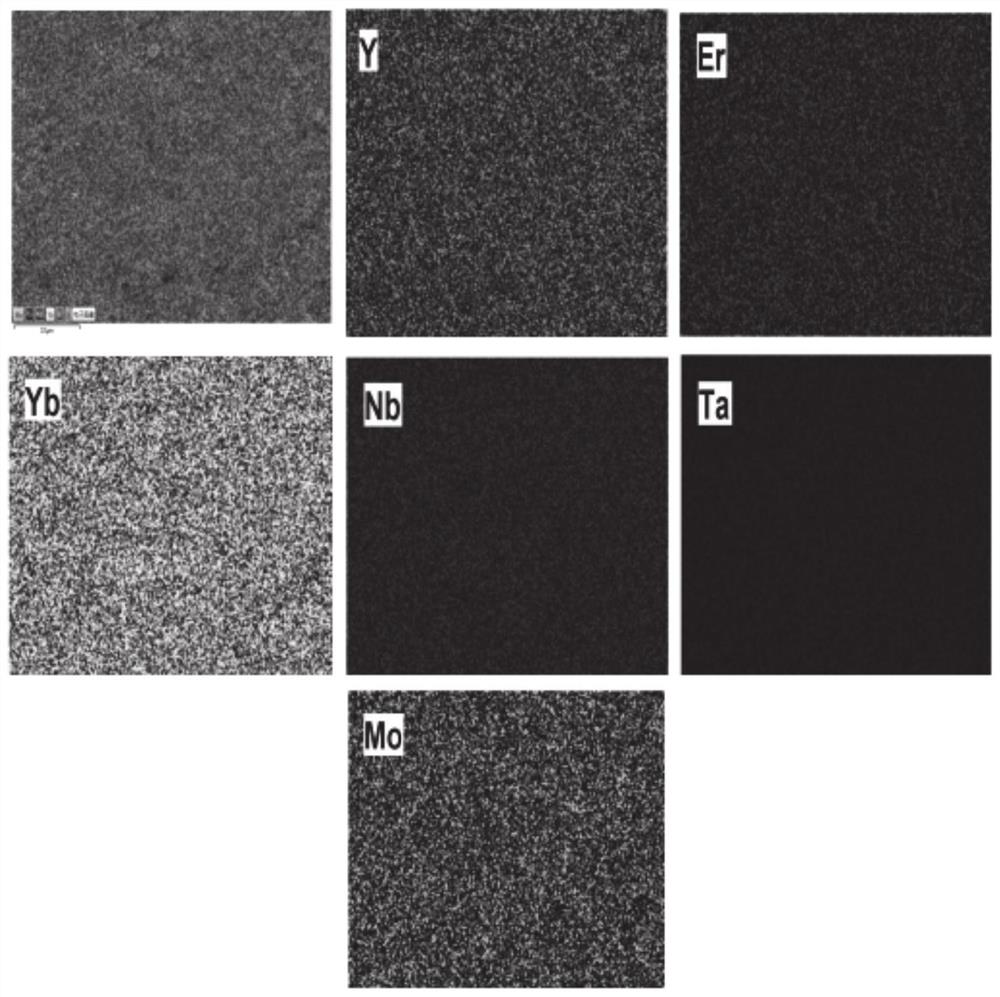

High-entropy rare earth niobium/tantalum/molybdate ceramic and preparation method thereof

The invention relates to the technical field of high-entropy ceramic materials, and particularly provides high-entropy rare earth niobium / tantalum / molybdate ceramic and a preparation method thereof. The chemical formula of the high-entropy rare earth niobium / tantalum / molybdate ceramic is RE3(Nb1 / 3Ta1 / 3Mo1 / 3)O7, RE is any 3-7 different elements of Y, Nd, Sm, Eu, Gd, Dy, Ho, Er, Yb and Lu. The preparation method comprises the following steps of (1) weighing rare earth oxide, niobium pentoxide, tantalum pentoxide, molybdenum trioxide and molybdenum dioxide according to a stoichiometric ratio, (2) adding a solvent and a ball-milling medium, ball-milling and mixing the raw materials by adopting a wet method, and carrying out vacuum drying and sieving to obtain uniformly mixed powder, (3) placing the uniformly mixed powder in a stainless steel mold for hydraulic compaction, and then carrying out cold isostatic pressing to obtain a densified green body, and (4) putting the green body into an alumina crucible, putting the alumina crucible into a high-temperature sintering furnace, and sintering in an air atmosphere. The prepared high-entropy ceramic is low in heat conductivity, the adopted preparation method has the advantages of being simple and rapid in process, low in equipment requirement, low in energy consumption, high in controllability and the like, and large-scale production is easy to achieve.

Owner:SHANDONG UNIV

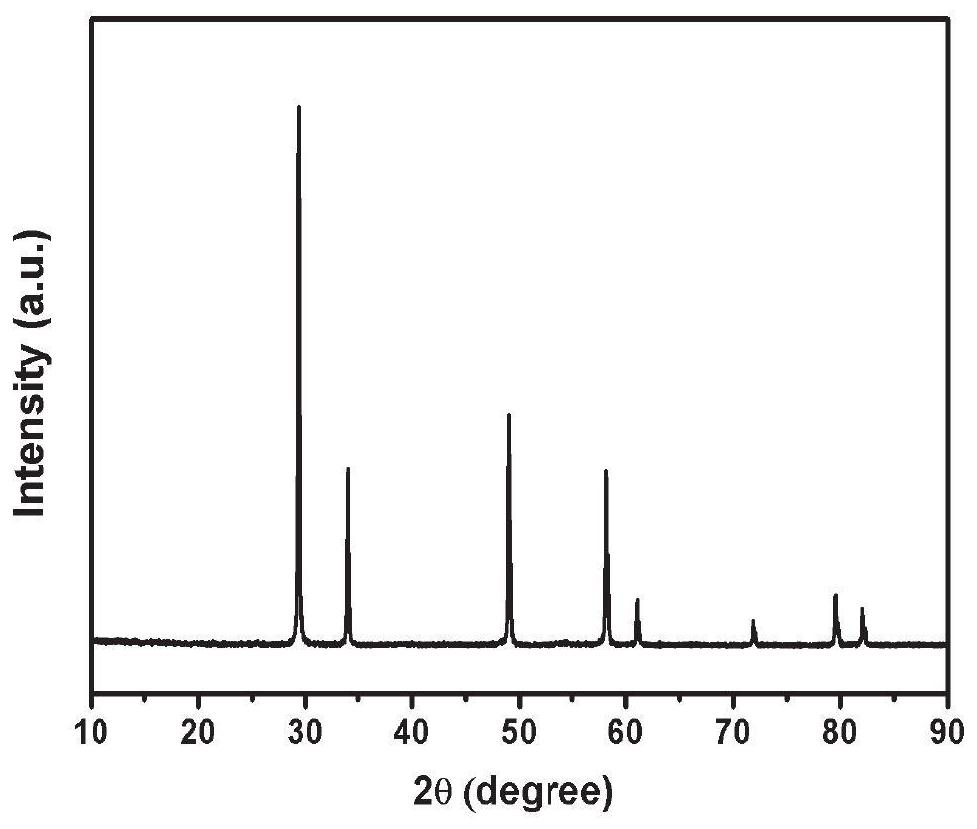

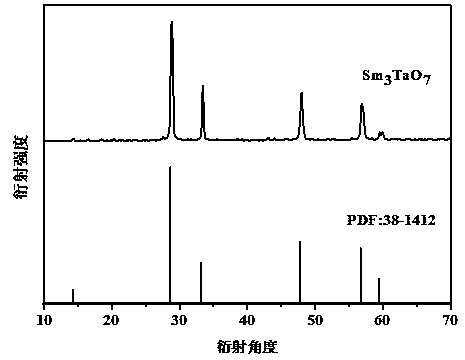

Preparation method of dense rare earth tantalate high temperature ceramic

ActiveCN107602120AEffective control of crystal structureLow thermal diffusivityRare earthCopper oxide

The invention relates to a preparation method of dense rare earth tantalate high temperature ceramic and belongs to the technical field of high temperature materials. The preparation method comprisesweighing rare earth oxide RE2O3 and tantalum pentoxide according to the stoichiometric ratio of rare earth tantalate RE3TaO7, carrying out ball milling mixing on the rare earth oxide RE2O3, tantalum pentoxide, titanium oxide and copper oxide to obtain uniform mixed powder A, screening the mixed powder A, putting the mixed powder A into a mold, carrying out compaction, carrying out carbon sprayingtreatment and carrying out pressure-keeping sintering to obtain the dense rare earth tantalate high temperature ceramic. The dense rare earth tantalate high temperature ceramic has the characteristicsof high process purity, less impurity content, high compactness and uniform crystal grain size.

Owner:陕西天璇涂层科技有限公司

Titanium mesh anode for electrodeposited nickel and preparing method thereof

InactiveCN102719859AHigh strengthIncrease the areaPhotography auxillary processesElectrodesAlloyOxide coating

The invention discloses a titanium mesh anode for an electrodeposited nickel, which consists of a titanium coated copper conducting bar, a titanium plate support welded below the titanium coated copper conducting bar, and two titanium meshes welded onto the two sides of the titanium plate support, wherein the surfaces of both the titanium meshes are covered with metallic oxide coatings; the metallic oxide coating consists of platinum group metallic oxide and valve metallic oxide; the molar ratio of the platinum group metal and the valve metal is 1 to 2:1 to 3; 10 to 50g platinum group metal is contained in the titanium mesh per square meter; the platinum group metallic oxide is iridium oxide and / or ruthenium dioxide; and the valve metallic oxide is or several of titanium dioxide, tantalum pentoxide and zirconium dioxide. The invention also provides a preparing method for the titanium mesh anode. Compared with the conventional lead-base alloy anode, the titanium mesh anode has light weight, low oxygen evolution potential and long service life, can prevent the titanium meshes from being dissolved, and can improve the quality of the cathode products.

Owner:XIAN TAIJIN NEW ENERGY & MATERIALS SCI TECH CO LTD

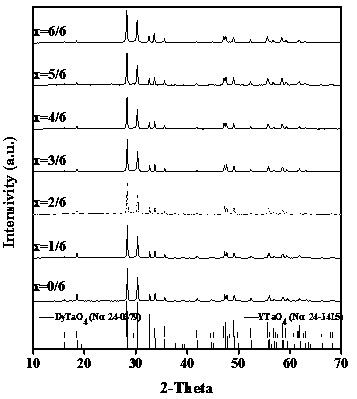

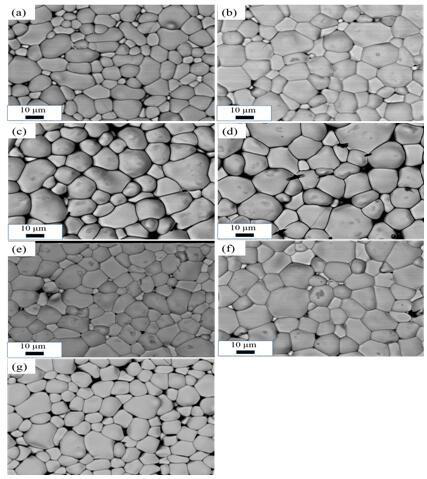

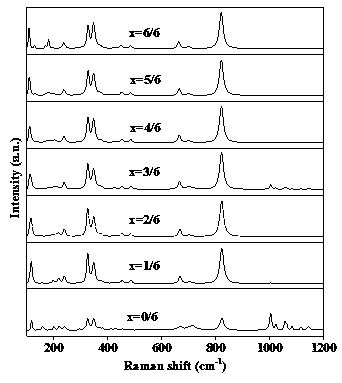

Compact ferroelastic dual rare earth tantalate solid solution high-temperature ceramic and preparation method thereof

The invention discloses compact ferroelastic dual rare earth tantalate solid solution high-temperature ceramic and a preparation method thereof, and belongs to the technical field of high temperatureresistant material of thermal barrier ceramic coating. The structural formula is (Y1-xDyx)TaO4 (x=0.1-0.9). Previously dried rare earth oxides (Y2O3, Dy2O3) and tantalum pentoxide (Ta2O5) are weighedaccording to the stoichiometric ratio required. Then, the materials are ball milled with ethanol as a solvent to obtain mixed powder A; the mixed powder A is sieved and compacted in a mold, and then ablank undergoes isostatic cool pressing to prepare a compact blank; and finally, the compact blank undergoes pressureless sintering to obtain the compact dual rare earth tantalate solid solution high-temperature ceramic. The dual rare earth tantalate solid solution high-temperature ceramic prepared by the method has characteristics of high process purity, low impurity content, high compactness, uniform grain size, low heat conductivity, large coefficient of thermal expansion, good toughness and the like.

Owner:KUNMING UNIV OF SCI & TECH

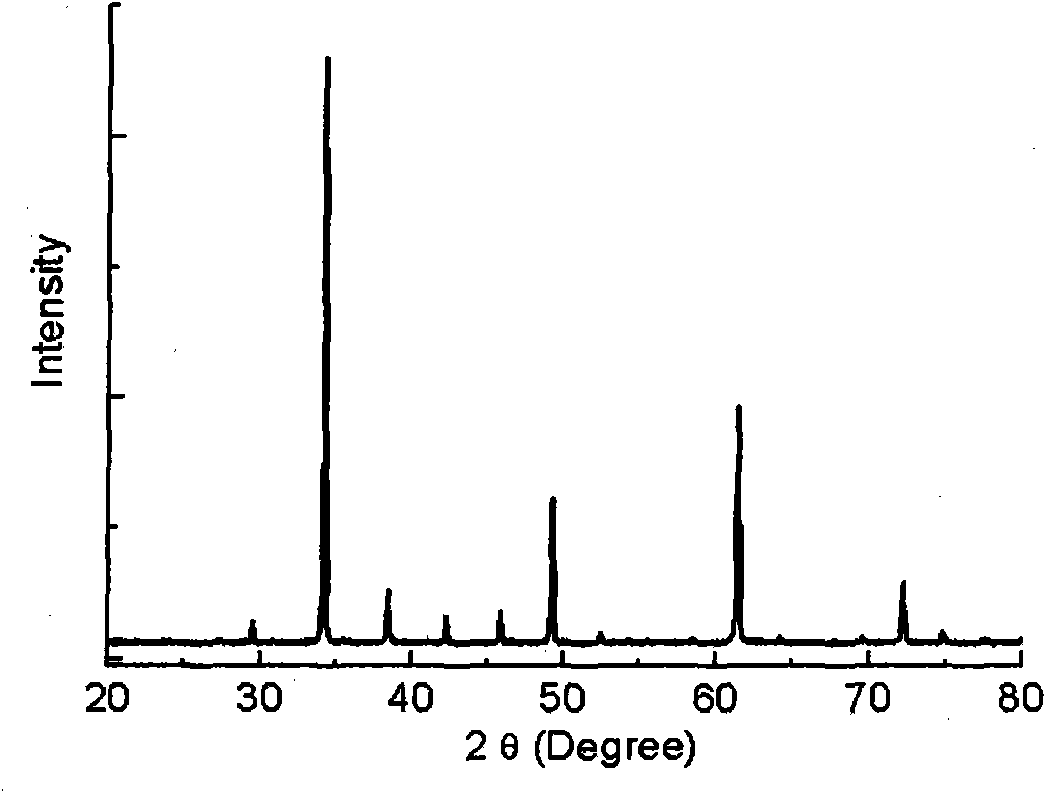

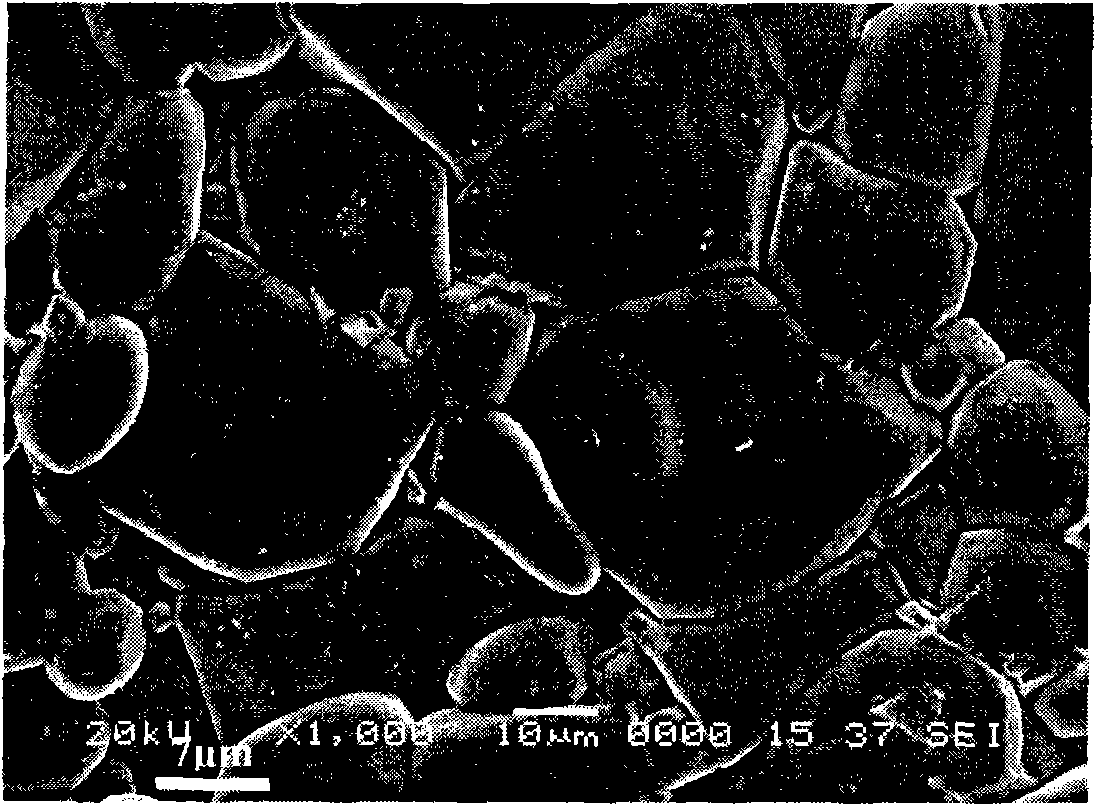

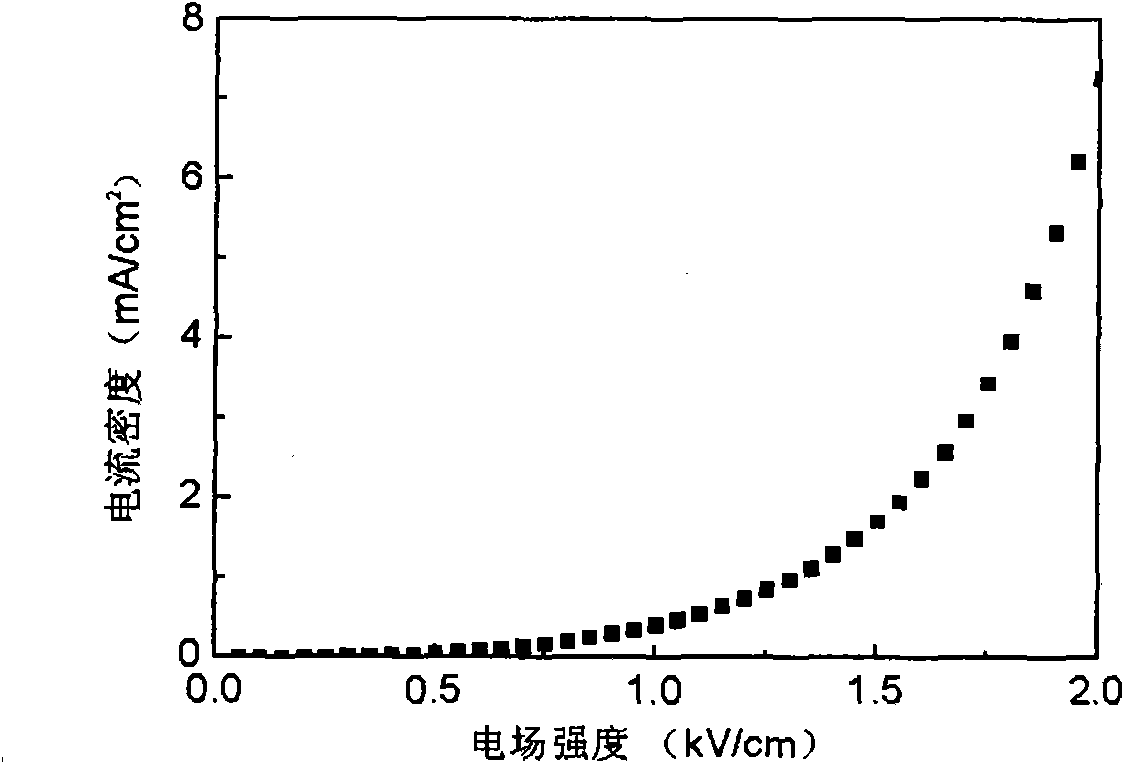

Group VB doping CaCu3Ti4O12 based pressure sensitive material and preparation method

InactiveCN101880159AIncrease intrinsic conductanceReduce the voltage gradientLow voltageChemical element

The invention discloses a group VB doping CaCu3Ti4O12 based pressure sensitive material and a preparation method. The general chemical composition formula of the group VB doping CaCu3Ti4O12 based pressure sensitive materia is CaCu3Ti4-xBxO12, wherein B represents one or combination of group VB elements in the periodic table of chemical elements, and x=0.001-1. The preparation method comprises thefollowing steps of compounding calcium carbonate, copper oxide, vanadium pentoxide, niobium pentaoxide and tantalum pentoxide in accordance with the stoichiometric ratio of CaCu3Ti4-xBxO12 (x=0.001-1, and B represents one or combination of group VB elements in the periodic table of chemical elements), ball milling, calcining, secondary ball milling, pelleting, forming, binder removing, high temperature sintering and the like so that Ca, Cu, Ti-O based ceramics with high permittivity and high pressure sensitive feature can be finally prepared. The invention compensates valence changes of copper ions and titanium ions in the sintering process, which can cause low voltage gradient and large leakage current, by partially replacing a +4 Ti element with a +5 element, thereby reducing the intrinsic conductivity of materials and improving the voltage gradient of the materials.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

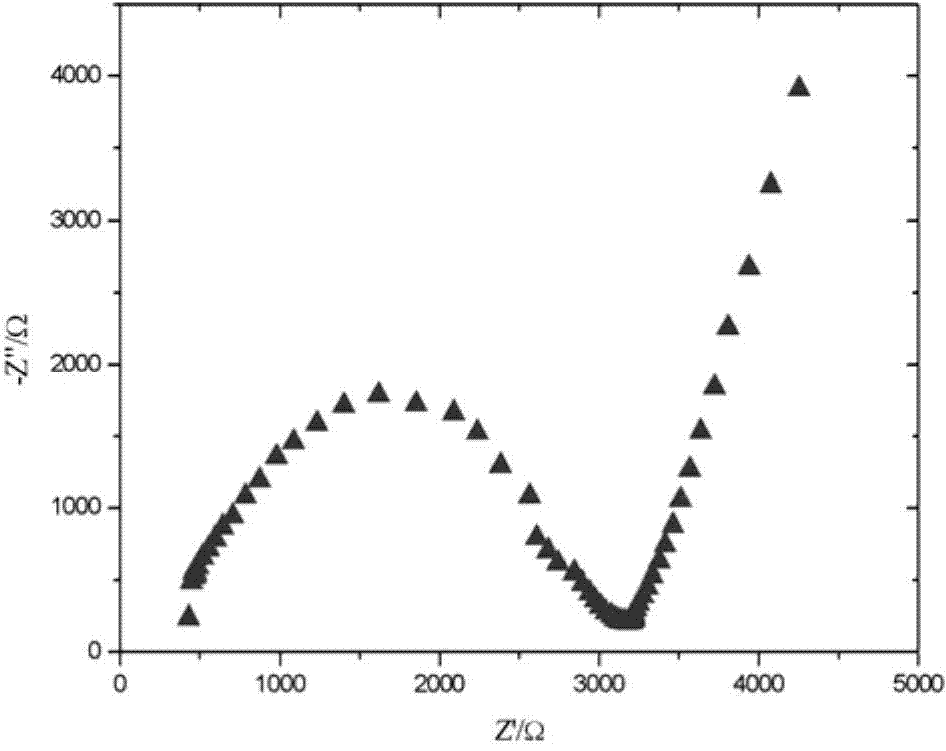

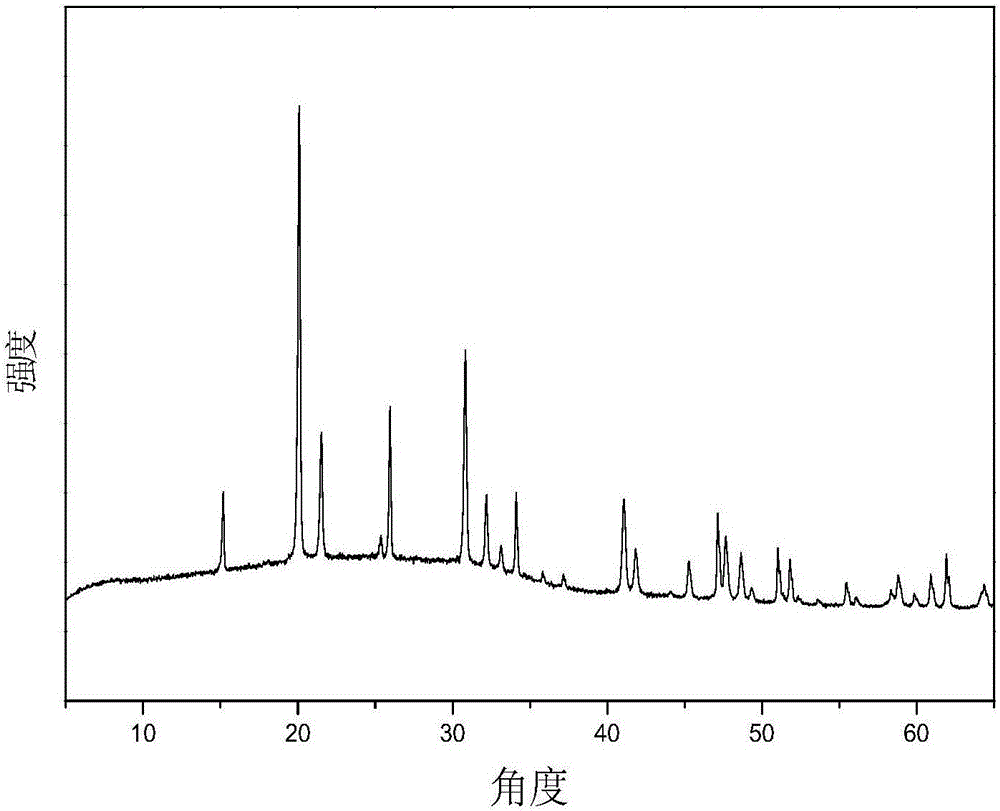

Garnet-structure lithium lanthanum tantalate-based solid electrolyte material and preparation method thereof

InactiveCN103594726AWill not cause churnImprove electrochemical performanceFinal product manufactureElectrolyte accumulators manufactureLanthanumElectrochemistry

The invention discloses a garnet-structure lithium lanthanum tantalate-based solid electrolyte material and a preparation method thereof. The lithium lanthanum tantalate-based solid electrolyte material is a compound of Li5La3Ta2O12 doped at the lanthanum site and / or tantalum site; and the preparation method comprises the following steps: dissolving tantalum pentoxide in a H2C2O4 solution; adding lithium salt and lanthanum slat and the salt of a lanthanum site-doped compound and / or the salt of a tantalum site-doped compound, and mixing to obtain a solution; adding EDTA into the obtained mixed solution for reaction until transparent and clear sol appears; adding a water-soluble high-molecular polymer and continuously reacting until gel appears; drying the obtained gel and calcining; performing mould pressing of the calcined particles to obtain a blank; and further calcining the blank to obtain the solid electrolyte material. The preparation method is mild in conditions, simple in process and simple to operate, and can realize industrial production; the prepared solid electrolyte material has good electrochemical stability and relatively high electrical conductivity, and can be used for preparing an all-solid-state lithium ion battery.

Owner:CENT SOUTH UNIV

Producing method of low-fluorine high-purity tantalic oxide

The invention provides a preparation method of low-fluorine high-purity tantalic oxide, which comprises the following steps: preparing high-purity tantalic liquid from impure tantalic liquid materials by adopting a liquid-liquid extraction method; neutralizing the high-purity tantalic liquid by purified ammonia to obtain high-purity tantalum hydroxide which is then washed, filtered, dried; sectionally calcining the high-purity tantalum hydroxide according to the following steps: heating to 180-230 DEG C, and carrying out heat preservation for 2-3 hours; heating to 480-530 DEG C, and carrying out heat preservation for 4-6 hours; heating to 620-680 DEG C, and carrying out heat preservation for 2-3 hours; heating to 790-840 DEG C, and carrying out heat preservation for 3-5 hours; reducing temperature to 180-230 DEG C, and then discharging the high-purity tantalum hydroxide from a furnace and screening to obtain the high-purity tantalic oxide. The invention has the advantages that the prepared high-purity tantalic oxide product has good consistency and evenness, low fluorine content, less ignition loss and protection function to a furnace hearth, and the service life of a roasting hearth can be prolonged.

Owner:ZHAOQING DUOLUSN RARE METAL

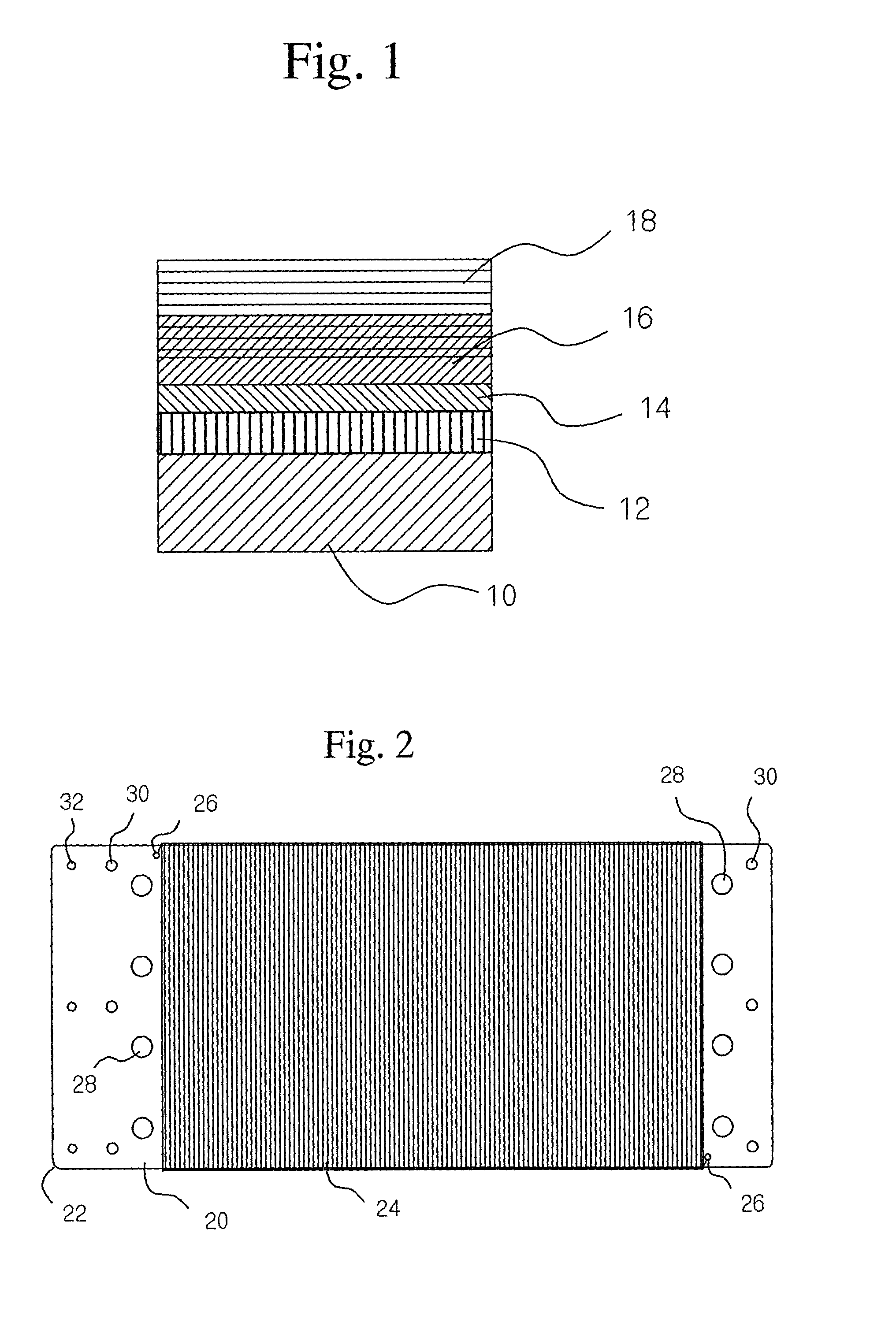

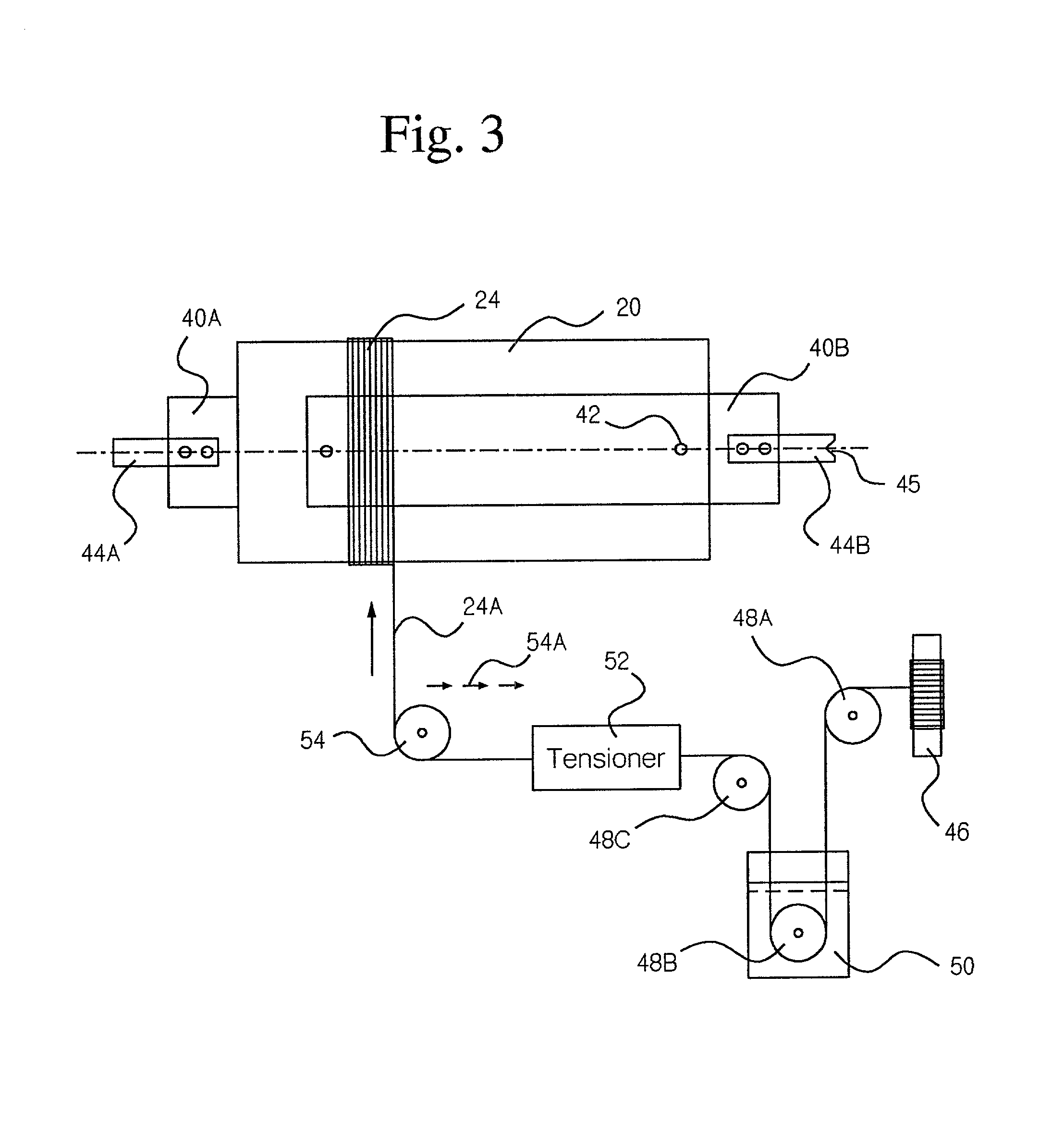

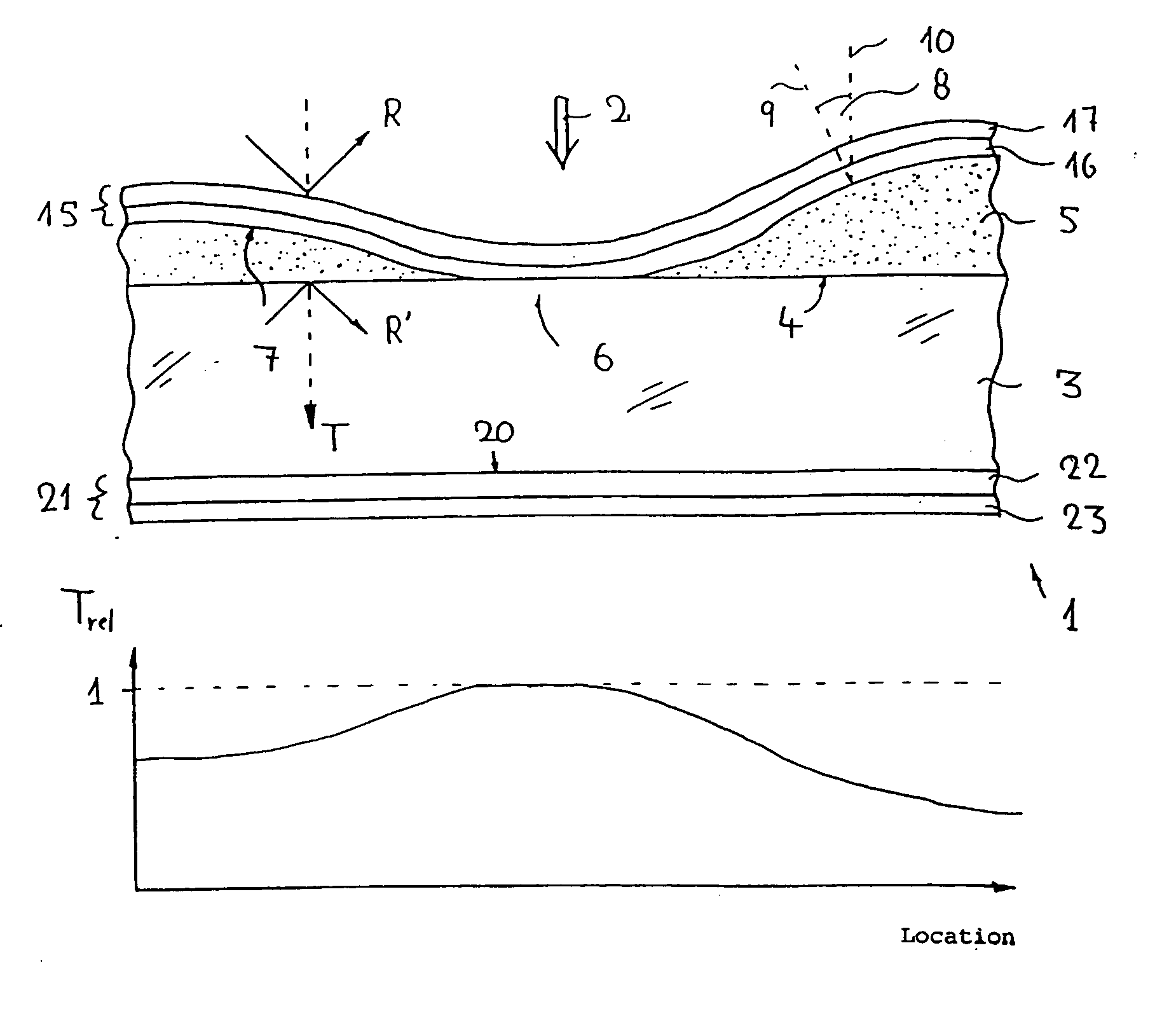

Attenuating filter for ultraviolet light

InactiveUS20050179996A1Simple and inexpensive to fabricateVariation of the transmittance of the filter coatingMirrorsOptical filtersUltraviolet lightsSpectral transmittance

An attenuating filter provides a prescribed attenuation of the intensity of transmitted, short-wavelength, ultraviolet light, in particular, at wavelengths below 200 nm, that is governed by a predefinable spatial distribution of its spectral transmittance. The filter has a transparent substrate (3), e.g. fabricated from crystalline calcium fluoride. A filter coating (5) fabricated from a dielectric material that absorbs over a predefined wavelength range is applied to at least one surface (4) of the substrate. In the case of operating wavelengths of about 193 nm, the filter coating consists largely of tantalum pentoxide. Filters of the type, which may be inexpensively fabricated with high yields, are noted for their high abilities to withstand laser radiation and may be effectively antireflection coated employing simply designed antireflection coatings.

Owner:CARL ZEISS SMT GMBH

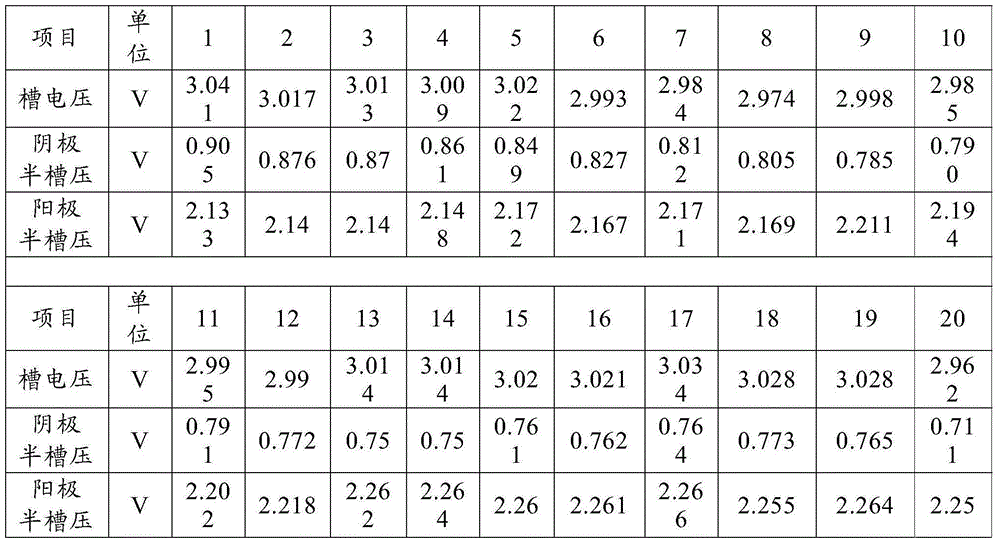

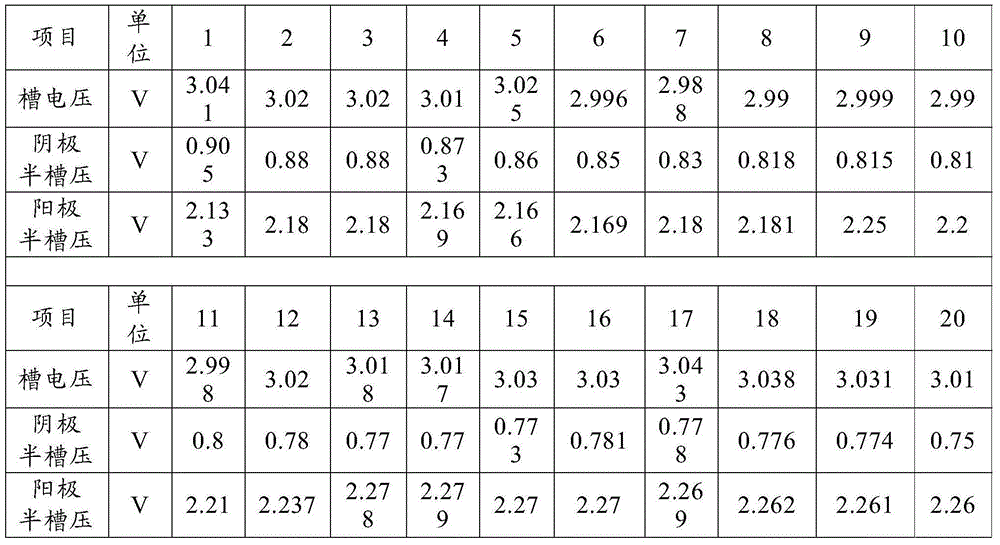

Composite coating electrode and preparing method thereof and electrolytic cell

The invention discloses a composite coating electrode and a preparing method thereof and an electrolytic cell. The composite coating electrode comprises a conductive matrix and an electro-catalysis coating. The electro-catalysis coating is composed of ruthenium oxide, iridium oxide, tantalum pentoxide and titanium oxide. The electrolytic cell comprises an electrolyte, an anode, a cathode and a power source. The anode is coated with the electro-catalysis coating composed of the ruthenium oxide, the iridium oxide, the tantalum pentoxide and the titanium oxide. The preparing method of the composite coating electrode comprises the following steps that the pretreated electrode is coated with three kinds of coating liquid in sequence, and heat treatment is carried out every time coating is conducted. The composite coating electrode is long in service life, the voltage of the electrolytic cell is effectively reduced and the current efficiency is effectively improved through the electro-catalysis coating used in the composite coating electrode, and the oxygen content of generated hydrogen which is an electrolysis side product is low; meanwhile, the hydrogen can be recycled, and good application prospects are achieved.

Owner:HAINAN JINHAI PULP & PAPER

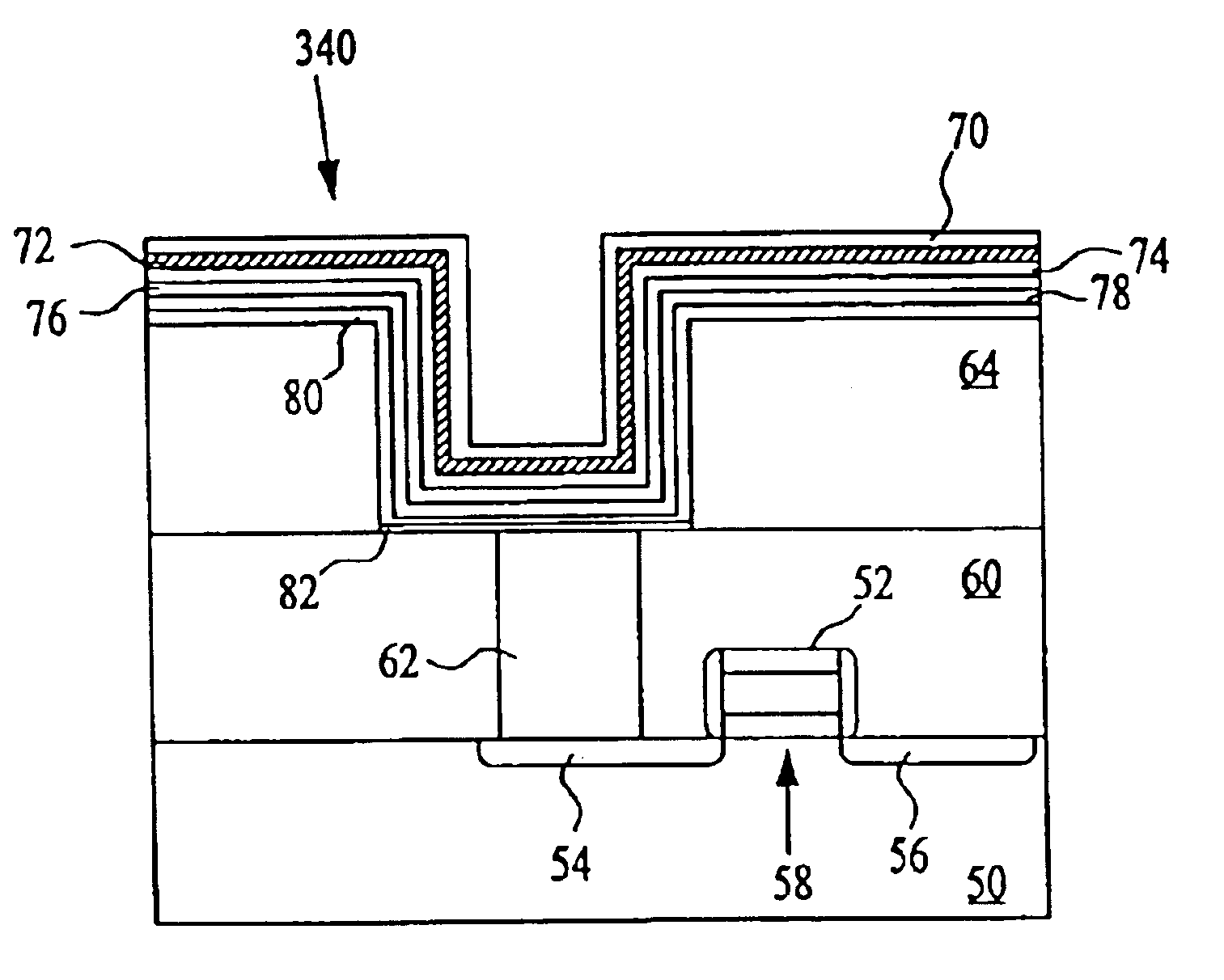

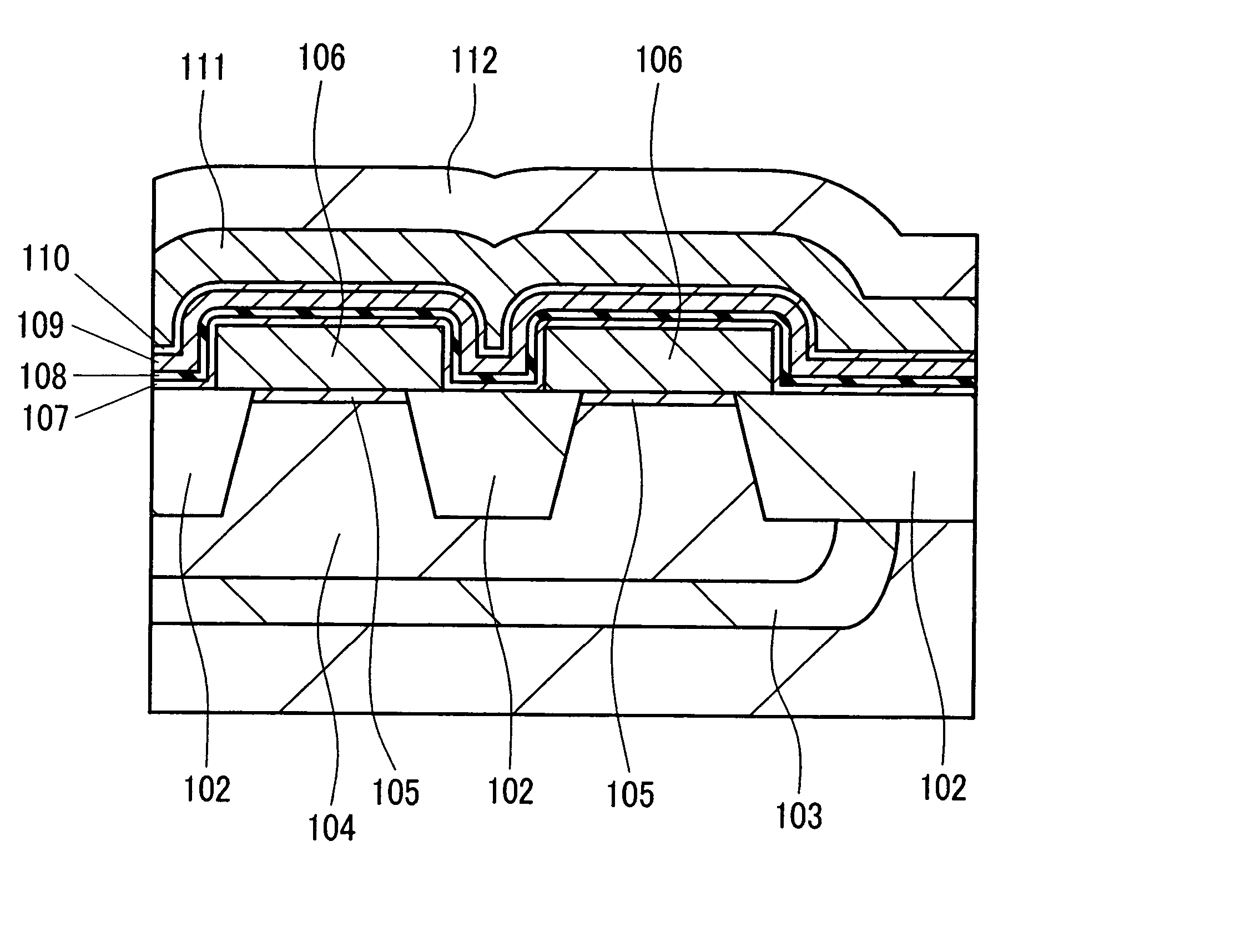

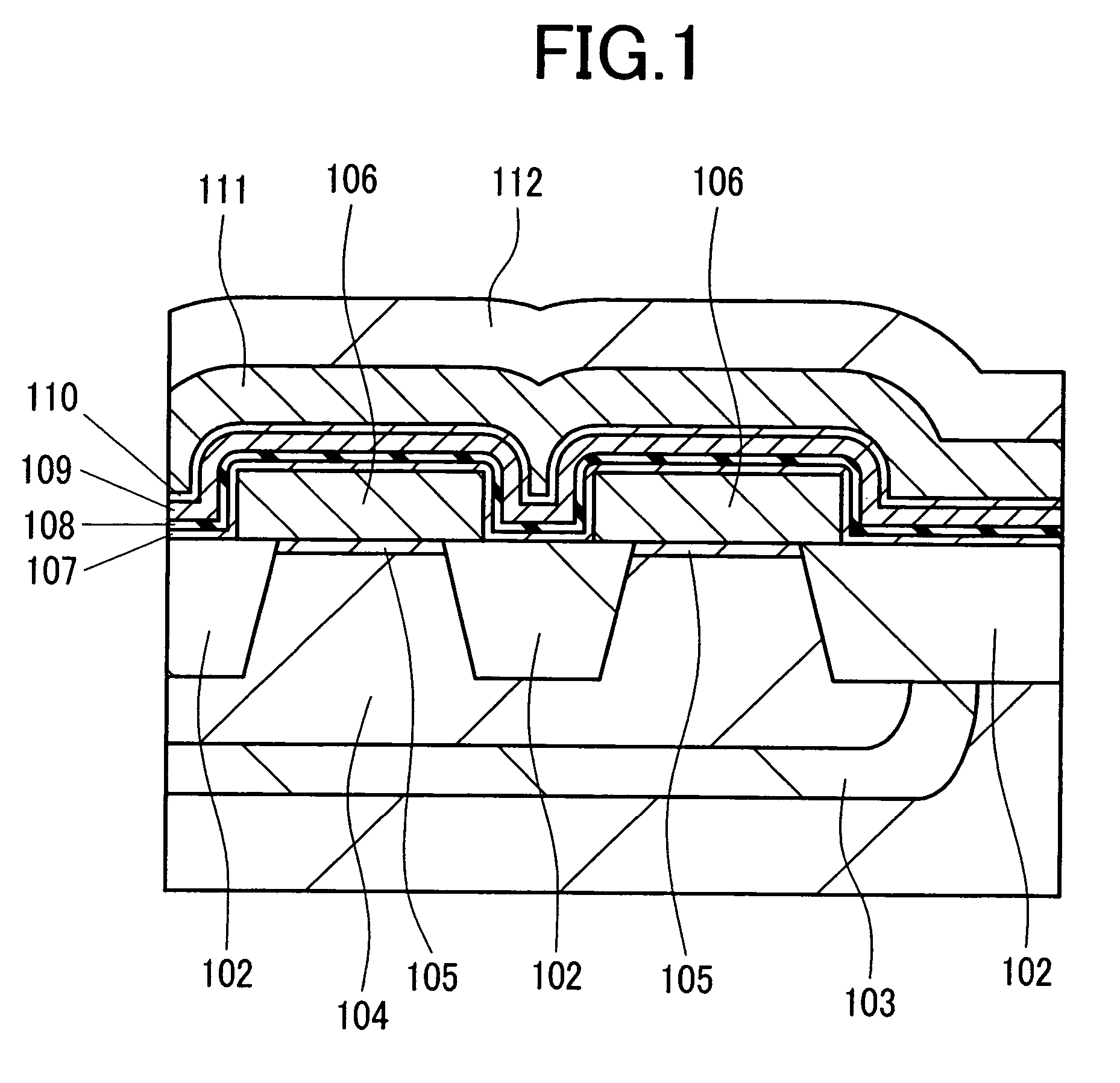

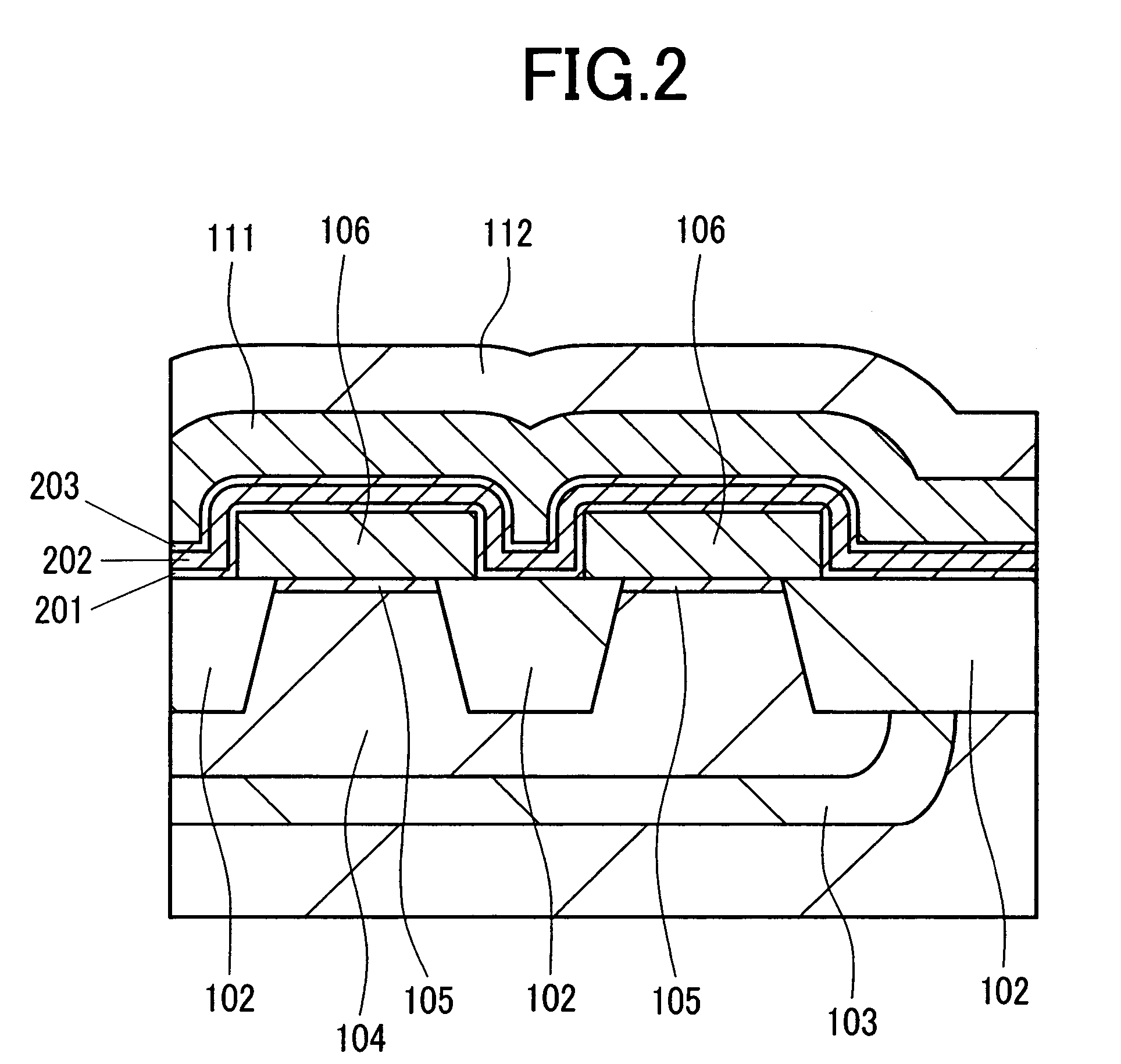

Semiconductor device and method of manufacturing thereof

By using a solid solution of tantalum pentoxide and niobium pentoxide as a dielectric film installed between upper electrode and lower electrode in a capacitor which is used in a semiconductor device, the capacitor structure can be simplified to improve reliability of the semiconductor device while reducing the production cost thereof.

Owner:HITACHI LTD

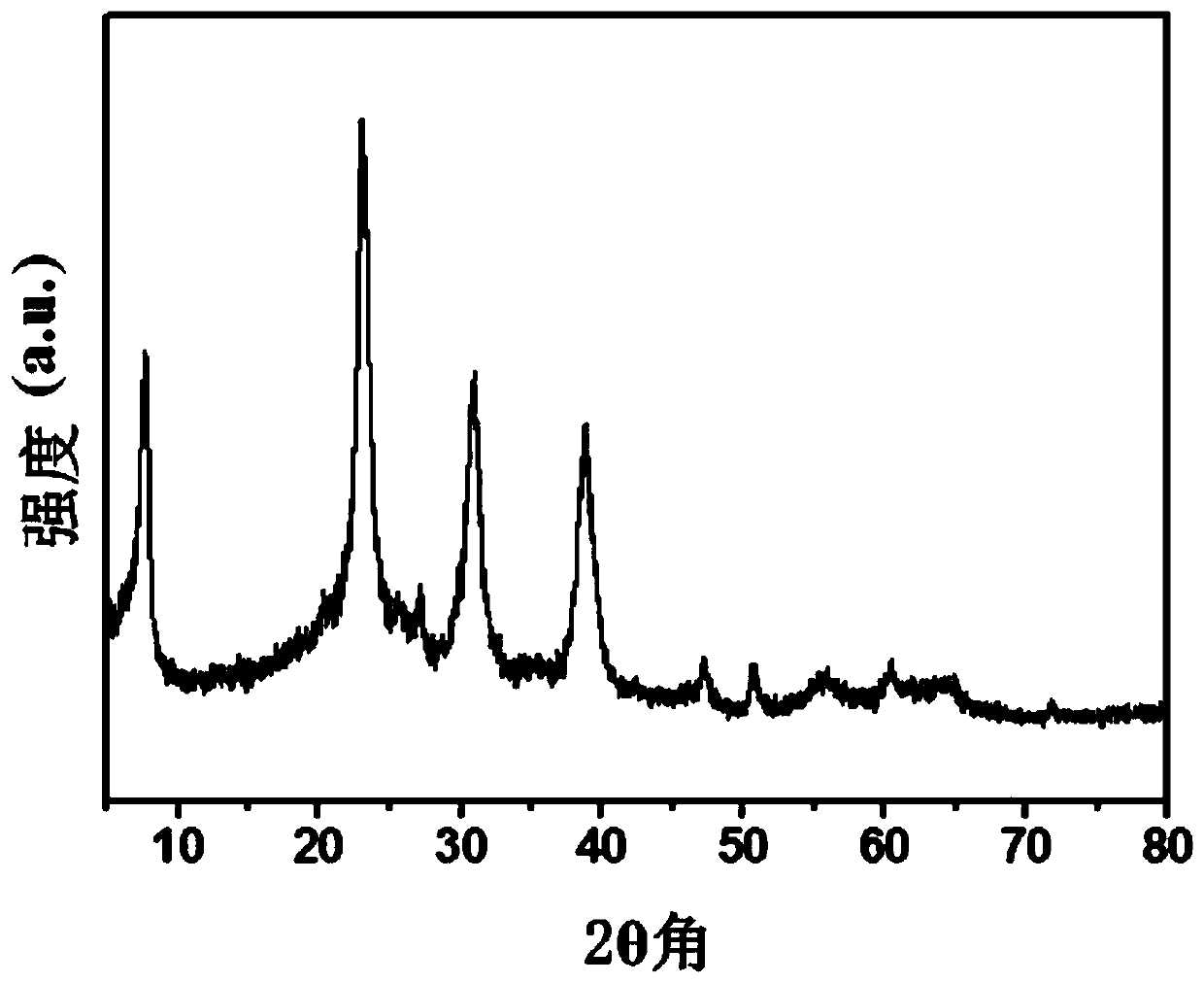

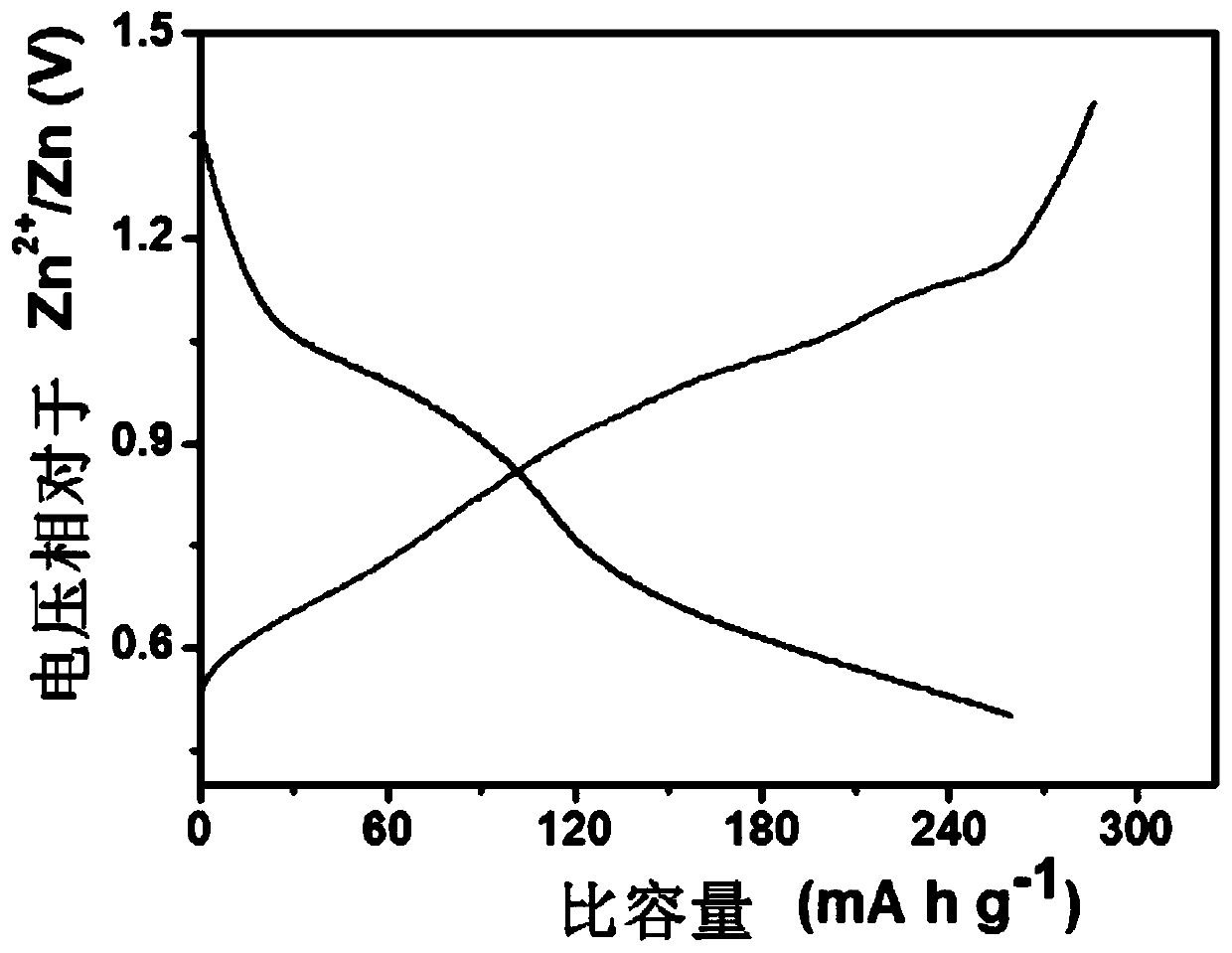

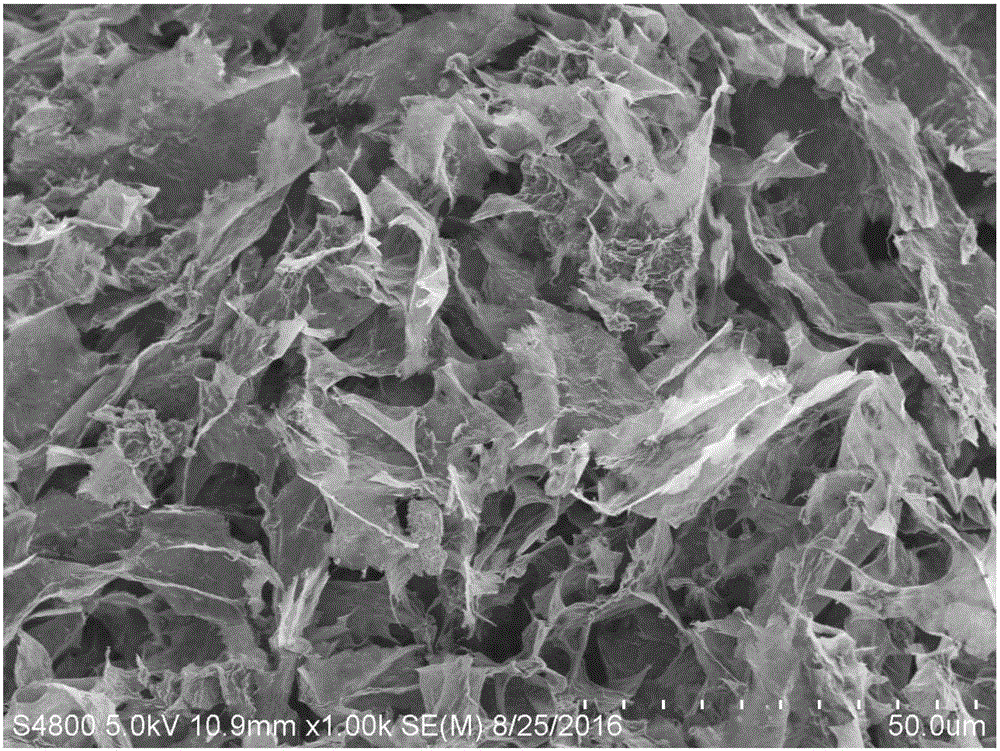

Vanadium pentoxide/graphene composite material and preparation method and application thereof

InactiveCN109980205AHigh specific capacityIncrease profitSecondary cellsPositive electrodesZinc ionCvd graphene

The invention relates to a vanadium pentoxide / graphene composite material and a preparation method and an application thereof. The vanadium pentoxide-graphene composite material comprises graphene with three-dimensional conductive network configuration and vanadium pentoxide loaded on the surface and internal part of graphene. The specific capacity is higher than 200mAh / g (high utilization rate) when the composite material is used as a positive electrode material of zinc-ion batteries, and the composite material has good cycling performance. In addition, the composite material further has thecharacteristics of low raw material cost, high repeatability, simple preparation process and less time consumption, and is suitable for industrial production.

Owner:BEIHANG UNIV

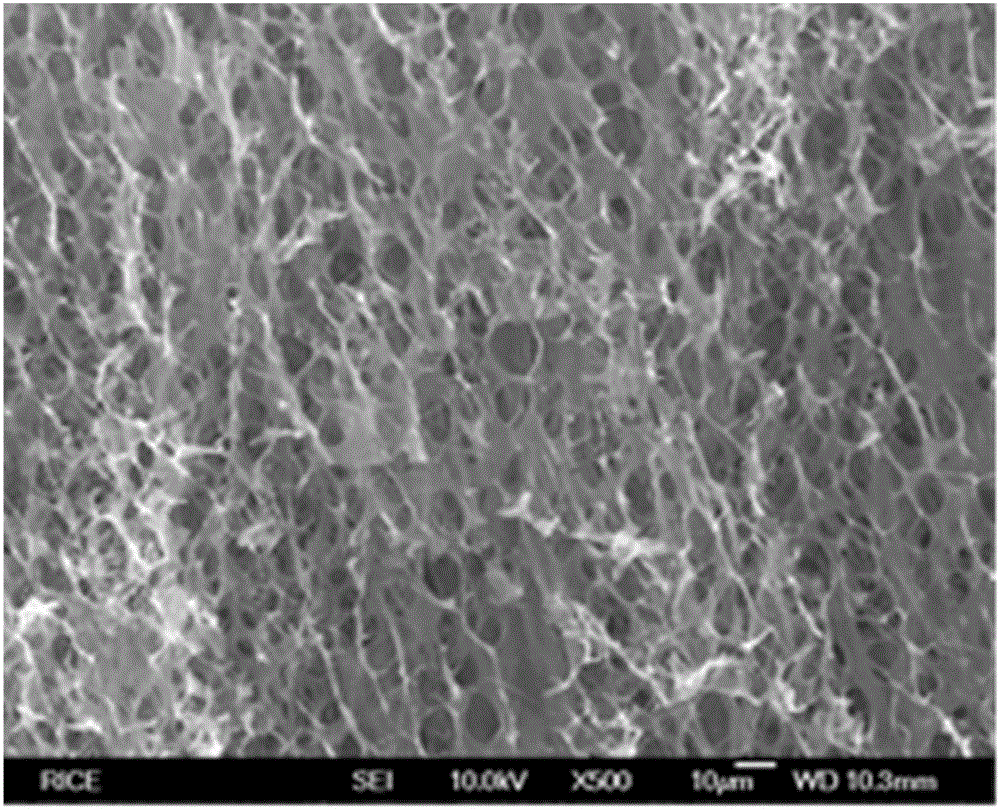

Large-scale preparation and lithium battery application of vanadium pentoxide and carbon nano composite thereof

InactiveCN106654186AWide variety of sourcesEasy accessFinal product manufactureCell electrodesFreeze-dryingCarbon nanotube

The invention discloses large-scale preparation and lithium battery application of vanadium pentoxide and carbon nano composite thereof, and belongs to the technical field of functional nano material preparation. The preparation method comprises the following steps: dissolving vanadium pentoxide solid powder in pure water, mixing with hydrogen peroxide, obtaining a scarlet solution, and preserving the temperature of the solution for a period of time to become a colloidal sol; carrying out freeze drying treatment on the colloidal sol to obtain a three-dimensional self-supporting solid; and taking partial solid to be calcinated under nitrogen atmosphere so as to obtain a vanadium pentoxide nano material. The corresponding solid is added into composite carbon nano tube and graphene as long as the scarlet solution is obtained, and the mixture is dispersed uniformly without changing remaining operation. The lithium battery positive electrode material prepared in the method is long in service life, high in capacity and stable in cycle performance. The whole technological process is simple, the price of raw materials is low, no toxic product is generated, the energy consumption is low, and the material is green and environmentally-friendly, so that the disadvantage that existing lithium battery materials are high in production cost, complex in process and great in byproduct toxicity is overcome, and the material is applicable to industrial large-scale production.

Owner:NANJING UNIV OF TECH

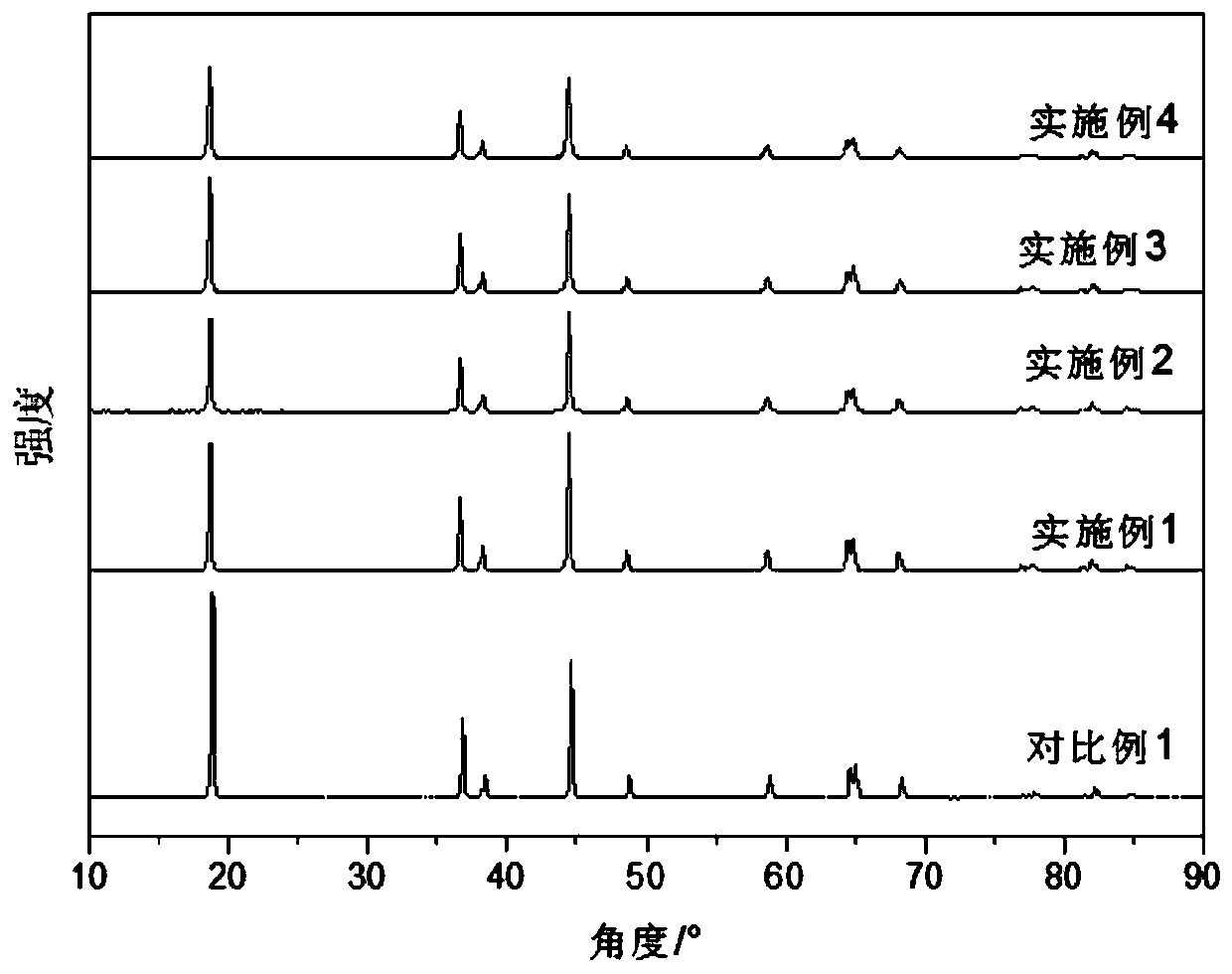

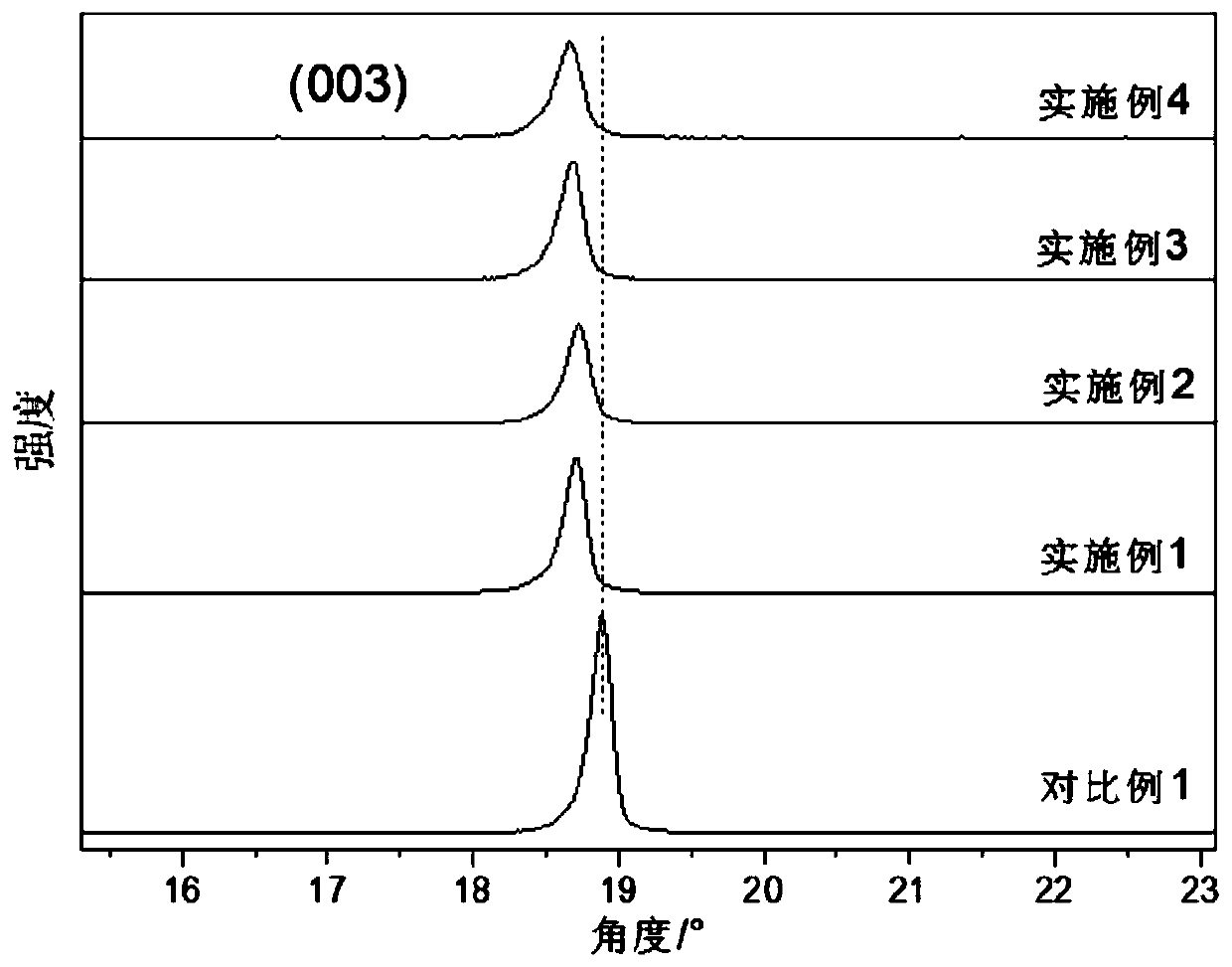

Tantalum-modified high-nickel cathode material and preparation method and application thereof

ActiveCN110993903ADoping achievedImprove electrochemical performanceSecondary cellsPositive electrodesLithium hydroxidePhysical chemistry

The invention discloses a tantalum-modified high-nickel cathode material and a preparation method and application thereof. In the material, the tantalum element is doped on the surface of the high-nickel cathode material, and the doping mass of the tantalum element is 0.1-2%. The preparation method comprises the following steps: mixing tantalum pentoxide, the precursor of the high-nickel cathode material and lithium hydroxide, and carrying out high-temperature calcination to obtain the tantalum-modified high-nickel cathode material. According to the invention, Ta doping can stabilize the layered structure of the body material, widen the lithium ion transmission channel, and further improve the electrochemical performance of the high-nickel material.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

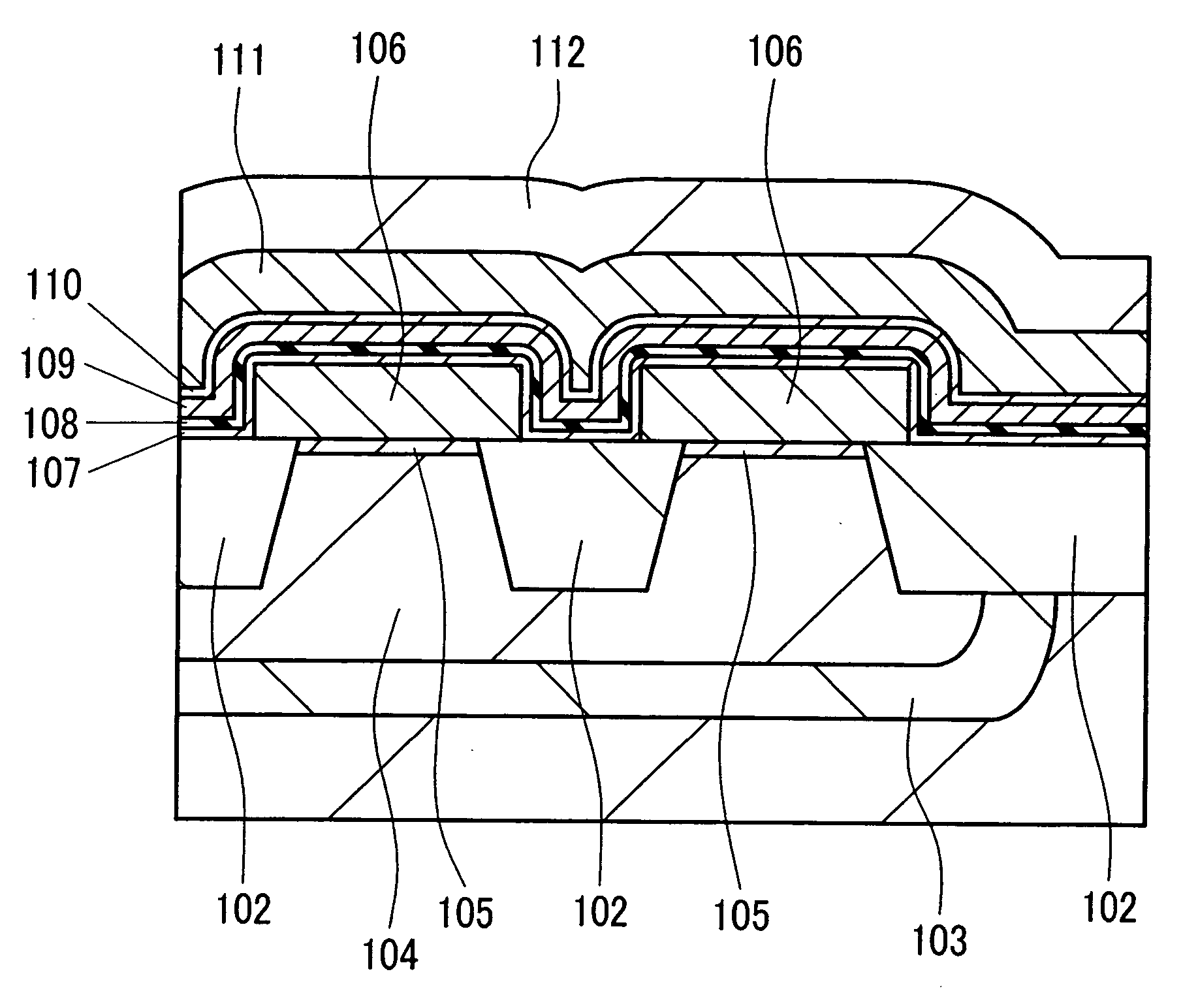

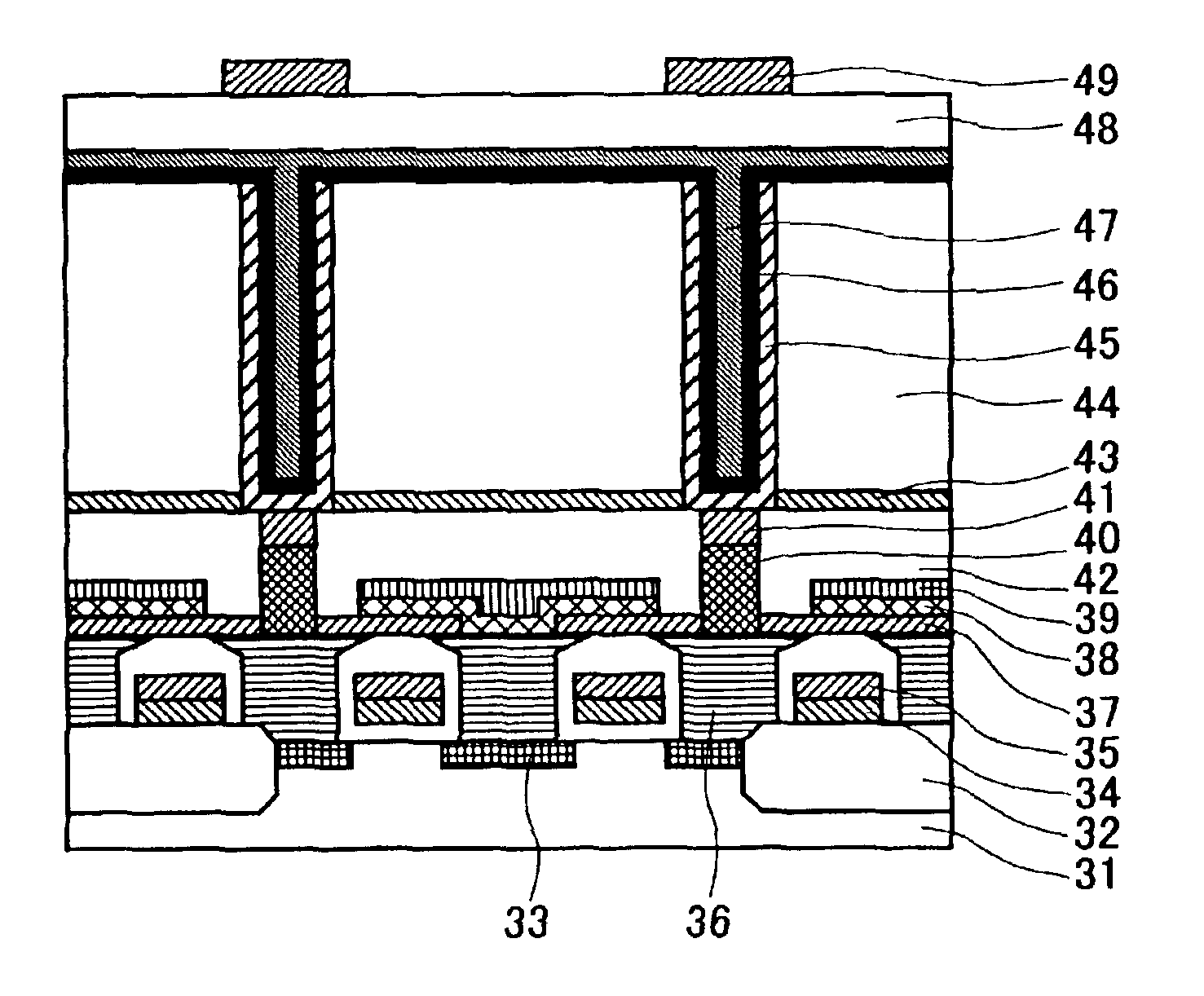

Nonvolatile semiconductor storage and its manufacturing method

InactiveUS7034355B2Easy to integrateReduce power consumptionTransistorSolid-state devicesSilicon dioxideMaterials science

To achieve a higher operating speed, higher reliability, and lower power consumption by reducing the thickness of an inter-poly silicon insulator film between a floating gate and a control gate of a flash memory, a silicon dioxide film, a silicon nitride film, tantalum pentoxide, and a silicon dioxide film are formed in a multilayer structure to serve as the inter-poly insulator film between a floating gate and a control gate. With this configuration, tantalum pentoxide formed on the silicon nitride film has a dielectric constant of 50 or more, which is higher than that of the silicon dioxide film, and the thickness of the inter-poly silicon insulator film can be reduced.

Owner:RENESAS ELECTRONICS CORP

Nano functional ceramic material and preparation method thereof

The invention provides a nano functional ceramic material, and in particular relates to a nano functional ceramic material with an ABO3 perovskite structure and a method for preparing the material. The method comprises the following steps: preparing an organic solvent solution of alkali metal hydroxide; adding the weighed organic solvent solution in a polytetrafluoroethylene lining of a reaction kettle, and stirring; adding weighed niobium pentaoxide powder and tantalum pentoxide powder in the polytetrafluoroethylene lining according to the chemical dose proportion of a ceramic material molecular formula and the concentration and volume of an organic solvent, and then continuing to stir; putting the polytetrafluoroethylene lining in a stainless steel hydro-thermal reaction kettle for a solvent heat reaction so as to obtain a precipitate; and processing the obtained precipitate so as to obtain A(NbxTa1-x)O3 nano powder. In the method, the characteristics of the organic solvent are fully utilized, the ceramic powder is synthesized under the milder conditions; the powder has the advantages of good dispersibility and uniformly distributed crystallite dimension; the steps are simple and easy to operate and achieve; and the synthesis conditions are mild, thus being convenient for industrial production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Bonded body and elastic wave element

ActiveUS20190036509A1Enhance layeringHigh strengthImpedence networksSolid-state devicesMulti materialMullite

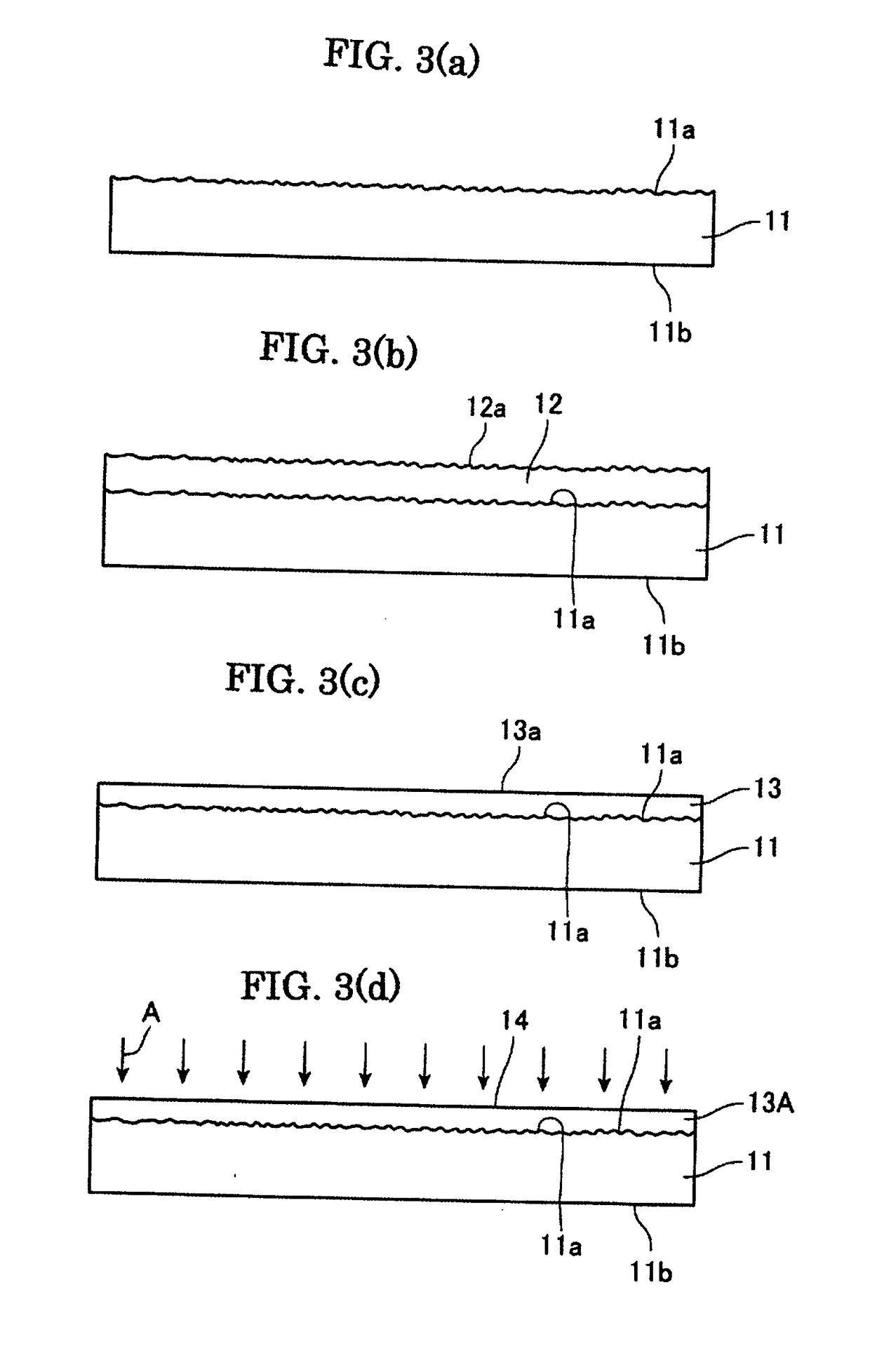

A bonded body includes a supporting body composed of a ceramic, a bonding layer provided over a surface of the supporting body and composed of one or more material selected from the group consisting of mullite, alumina, tantalum pentoxide, titanium oxide and niobium pentoxide, and a piezoelectric single crystal substrate bonded with the bonding layer. The surface of the supporting body has an arithmetic average roughness Ra of 0.5 nm or larger and 5.0 nm or smaller.

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com