Tantalum-modified high-nickel cathode material and preparation method and application thereof

A positive electrode material, high nickel technology, applied in the direction of positive electrode, active material electrode, battery electrode, etc., can solve the problems of poor thermal stability and structural stability of materials, decreased electrochemical performance of materials, mixed lithium and nickel, etc. Achieve the effect of improving cycle performance, improving electrochemical performance, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Lithium hydroxide (LiOH·H 2 0) put into the mortar, then add ethanol for wet milling, grind the granular lithium hydroxide to powder, then add the precursor of 1g high-nickel positive electrode material and 0.003g tantalum pentoxide and grind until the alcohol is evaporated to dryness, A solid powder was obtained. The solid powder is calcined in an oxygen atmosphere. First, it is pre-calcined at 500°C for 5 hours, and then it is heated to 720°C for 15 hours. min. A Ta-modified high-nickel positive electrode material is obtained. Among them, LiOH·H 2 The molar ratio of O to high-nickel precursor powder was 1.02:1.

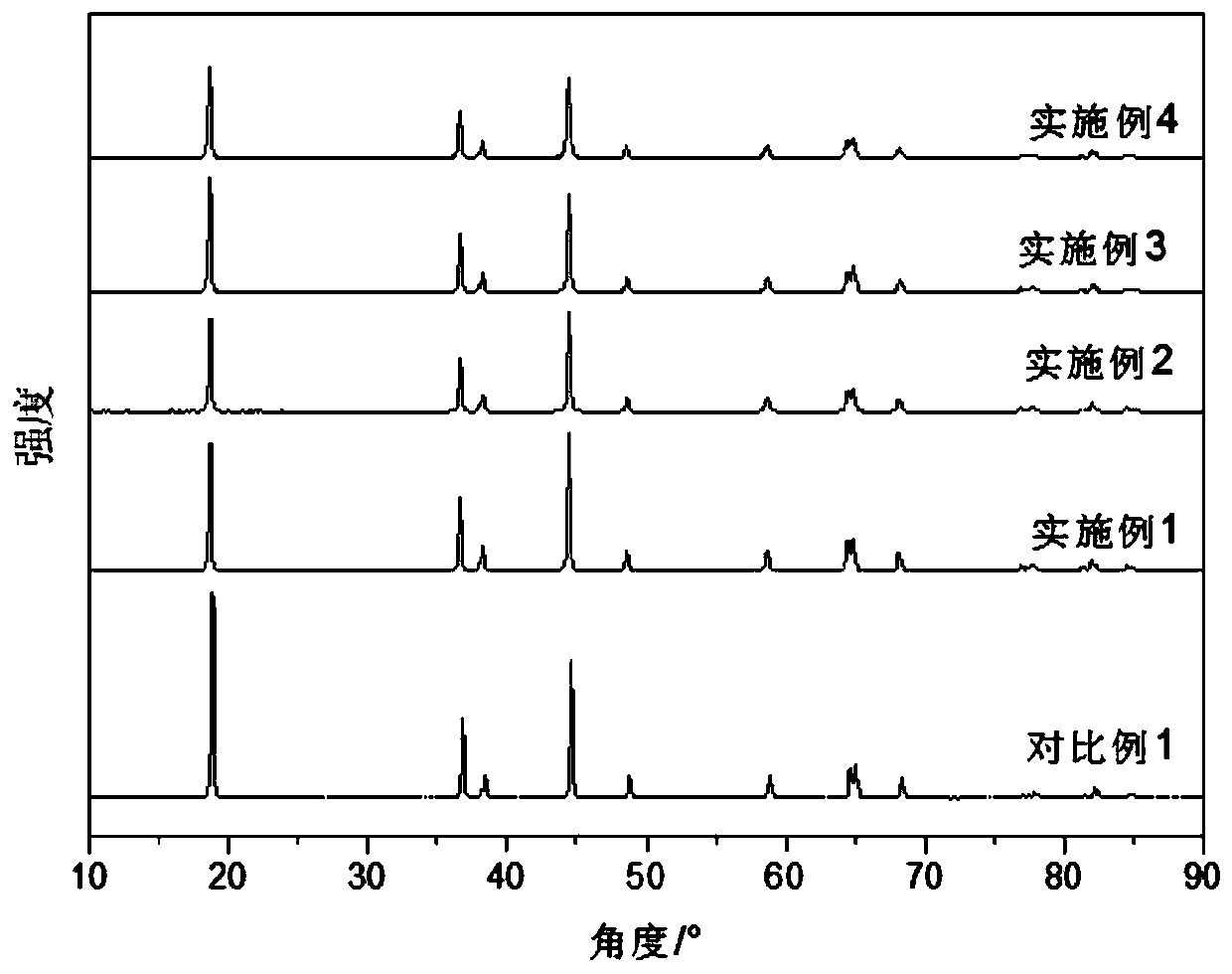

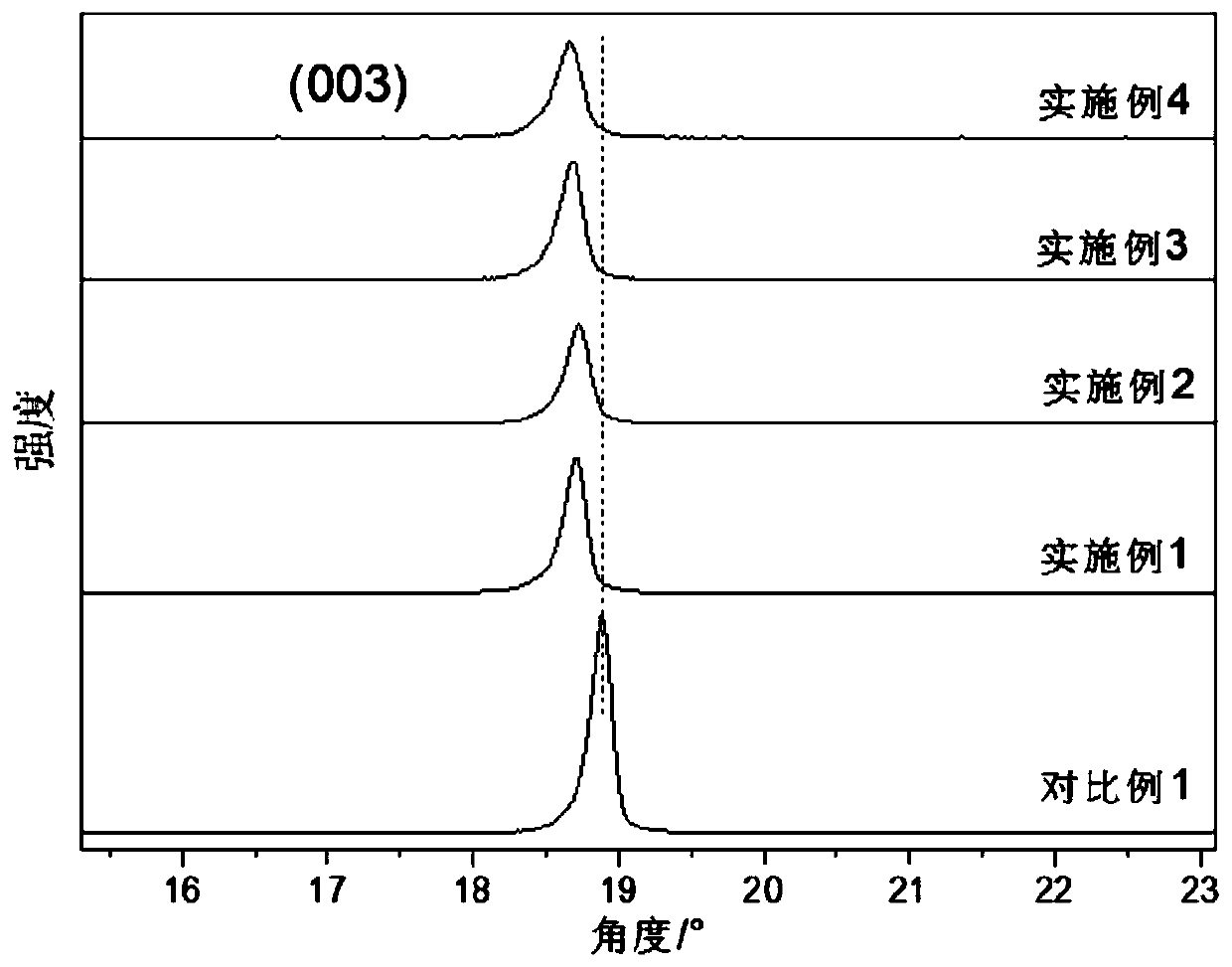

[0048] figure 1 In order to use X-ray diffractometer to test and analyze the crystal structure of the high-nickel cathode material prepared in Example 1, it can be seen that the ternary cathode material prepared in Example 1 does not change the original high-nickel cathode material (Comparative Example 1). The host crystal structure, both of which are t...

Embodiment 2

[0050] Lithium hydroxide (LiOH·H 2 0) put into the mortar, then add ethanol for wet milling, grind the granular lithium hydroxide to powder, then add the precursor of 1g high-nickel positive electrode material and 0.007g tantalum pentoxide and grind until the alcohol is evaporated to dryness, A solid powder was obtained. The solid powder is calcined in an oxygen atmosphere. First, it is pre-calcined at 500°C for 5 hours, and then it is heated to 720°C for 15 hours. min. A Ta-modified high-nickel positive electrode material is obtained. Among them, the molar ratio of LiOH·H2O to high-nickel precursor powder is 1.02:1.

[0051] figure 1 The XRD pattern in shows that the ternary positive electrode material prepared in Example 2 does not change the main crystal structure of the original high-nickel positive electrode material, both of which are typical α-NaFeO2 structures, belonging to space group. figure 2 It can be seen from the partially enlarged XRD pattern of 15°-30° ...

Embodiment 3

[0053] Lithium hydroxide (LiOH·H 2 0) Putting it into a mortar, adding ethanol for wet milling, grinding the granular lithium hydroxide to powder, then adding 1 g of the precursor of the high-nickel positive electrode material and 0.01 tantalum pentoxide for grinding until the alcohol evaporated to dryness, to obtain solid powder. The solid powder is calcined in an oxygen atmosphere. First, it is pre-calcined at 500°C for 5 hours, and then it is heated to 720°C for 15 hours. min. A Ta-modified high-nickel positive electrode material is obtained. Among them, LiOH·H 2 The molar ratio of O to high-nickel precursor powder was 1.02:1.

[0054] figure 1 The XRD pattern in shows that the high-nickel cathode material prepared in Example 3 does not change the main crystal structure of the original material, both of which are typical α-NaFeO2 structures and belong to the R-3m space group. figure 2 It can be seen from the partially enlarged XRD pattern of 15°-30° in the middle tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com