Cobalt oxide nanosheet coated with nitrogen-doped carbon layer and preparation method and energy storage application of cobalt oxide nanosheet

A nitrogen-doped carbon and cobalt oxide technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problem of material specific capacity and rate performance deterioration, poor electrical conductivity and ionic conductivity, The material is prone to polarization and other problems, achieving the effects of excellent specific capacity and rate performance, easy process control and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example uses solvothermal synthesis of cobalt oxide nanosheet precursors:

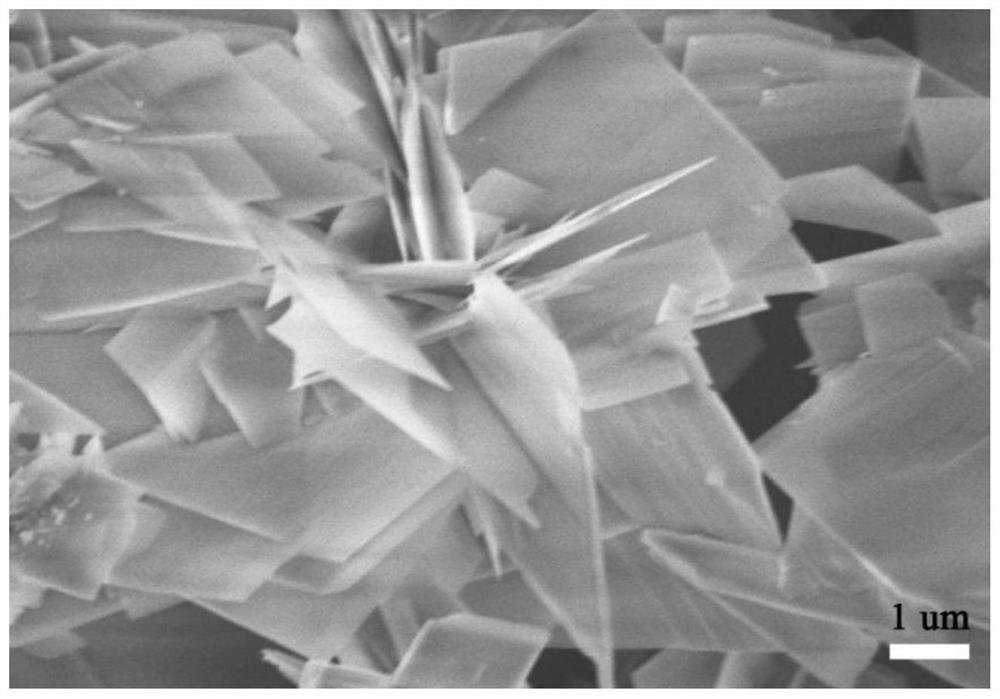

[0030] Weigh 0.873g Co(NO 3 ) 2 ·6H 2 Add O to 30 mL of deionized water, stir for 30 min, add 0.54 g of urea, and stir until a solution free of solid precipitates is formed. Then the solution was added into a reaction kettle with a volume of 50 mL, and kept in an electric heating constant temperature blast drying oven at a temperature of 160° C. for 16 hours. Cool naturally to room temperature to form a pink precipitate in the reaction kettle, alternately centrifuge with ethanol and deionized water, and dry in an oven to obtain a cobalt oxide nanosheet precursor. Its FESEM photo as figure 1 shown.

Embodiment 2

[0032] This embodiment prepares cobalt oxide nanosheets according to the following steps

[0033] (1) Solvothermal synthesis of cobalt oxide nanosheet precursors:

[0034] Weigh 0.873g Co(NO 3 ) 2 ·6H 2 Add O to 30 mL of deionized water, stir for 30 min, add 0.54 g of urea, and stir until a solution free of solid precipitates is formed. Then the solution was added into a reaction kettle with a volume of 50 mL, and kept at a temperature of 160° C. in an electric thermostat blast drying oven for 16 hours. Cool naturally to room temperature to form a pink precipitate in the reaction kettle, alternately centrifuge with ethanol and deionized water, and dry in an oven to obtain a cobalt oxide nanosheet precursor.

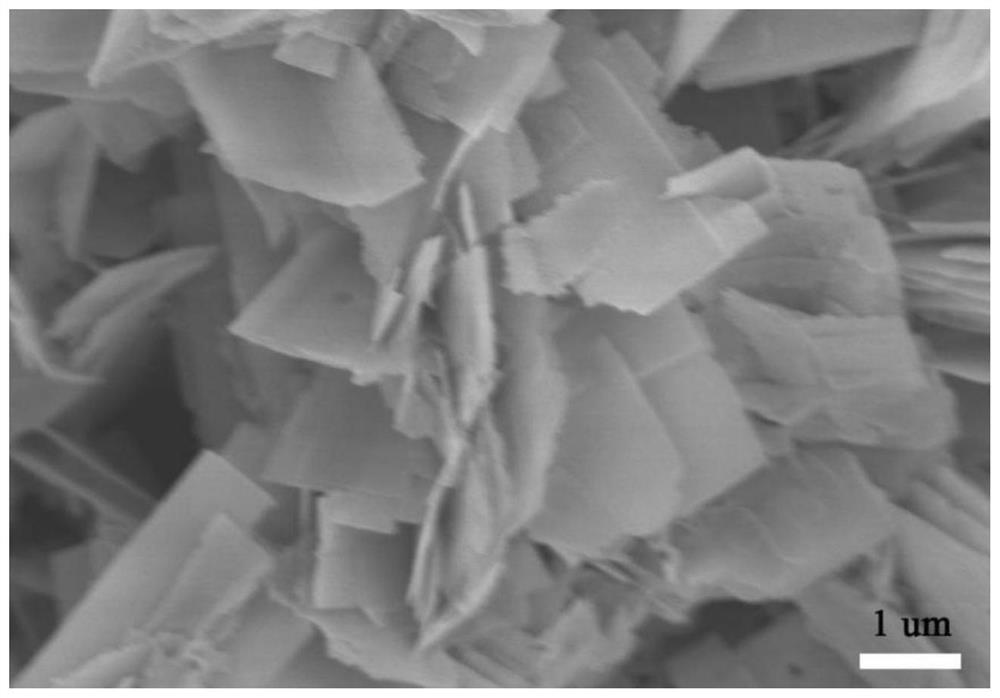

[0035] (2) Synthesis of cobalt oxide nanosheets by argon annealing

[0036] Place the cobalt oxide nanosheet precursor in a burning boat, and then raise the temperature in the tube furnace to 400°C under an argon atmosphere, with a heating rate of 5°C min -1 , heat-...

Embodiment 3

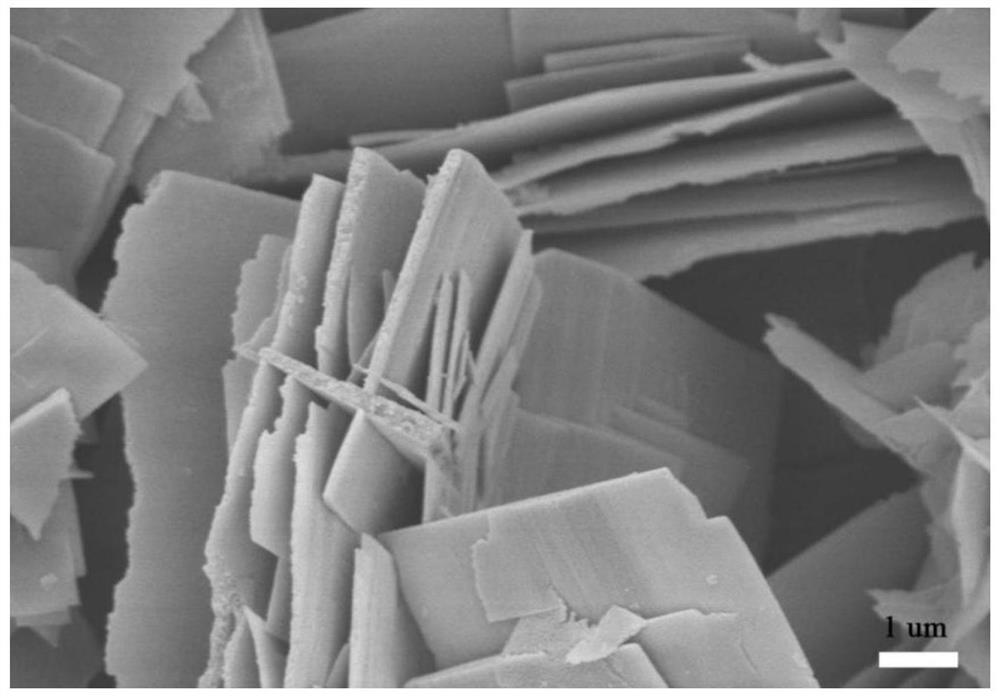

[0038] In this example, cobalt oxide nanosheet precursor@polyvinylpyrrolidone layer is prepared according to the following steps:

[0039] (1) Solvothermal synthesis of cobalt oxide nanosheet precursors

[0040] Weigh 0.873g Co(NO 3 ) 2 ·6H 2Add O to 30 mL of deionized water, stir for 30 min, add 0.54 g of urea, and stir until a solution free of solid precipitates is formed. Then the solution was added into a reaction kettle with a volume of 50 mL, and kept at a temperature of 160° C. in an electric thermostat blast drying oven for 16 hours. Cool naturally to room temperature to form a pink precipitate in the reaction kettle, alternately centrifuge with ethanol and deionized water, and dry in an oven to obtain a cobalt oxide nanosheet precursor.

[0041] (2) Obtain cobalt oxide nanosheet precursor@polyvinylpyrrolidone layer in water bath

[0042] First prepare the mixed solution that deionized water and ethylene glycol volume ratio are 1:5, then add 0.5g polyvinylpyrrolid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com