Preparation method of moisture-proof and efficient ozone decomposition agent

A high-efficiency technology for ozone decomposition, applied in the direction of separation methods, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of not being practically applicable, relying on imports, etc., and achieve superior catalytic performance, low cost, and porosity rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

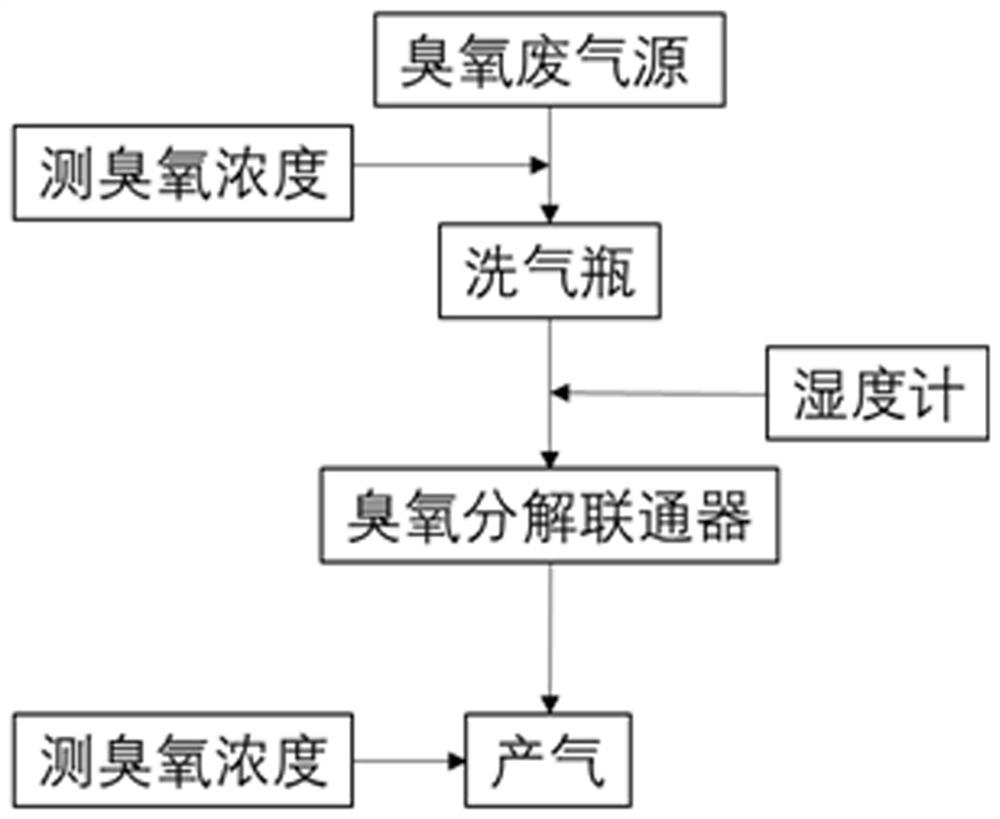

Image

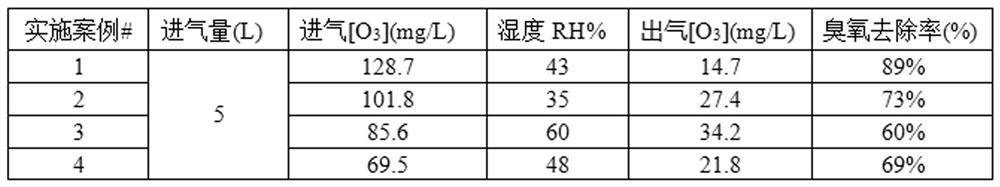

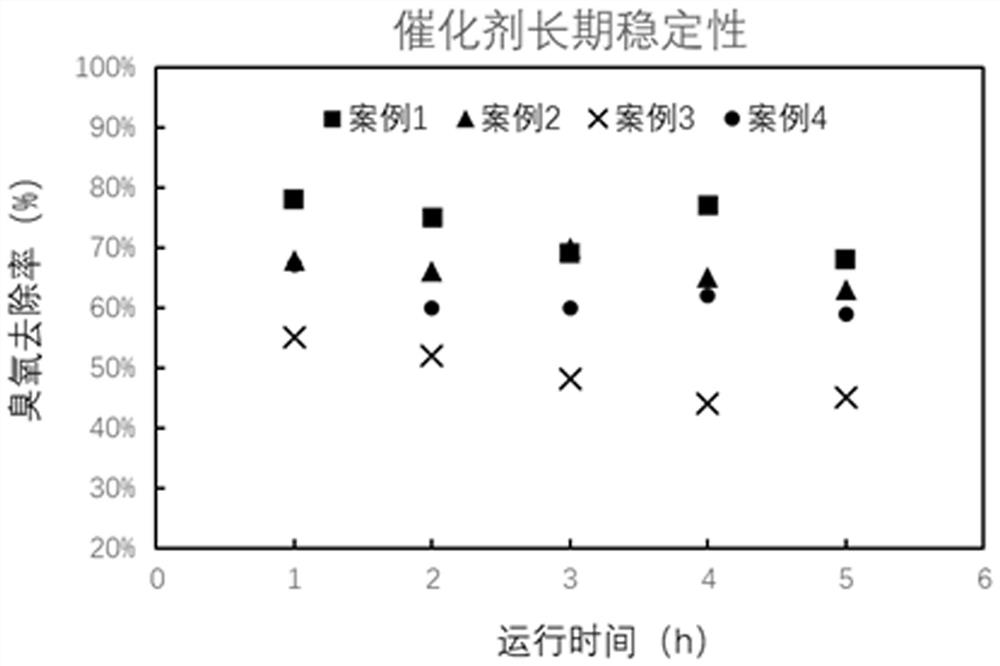

Examples

Embodiment 1

[0041] In order to make the invention, the present invention is further illustrated in the following description of the invention, and the specific embodiments described herein are intended to be used herein, and is not intended to limit the invention.

[0042] The present invention adds a structural template material to the process of synthesizing manganese dioxide in the process of hydrothermal, first obtains a low particle size and a high-specific surface area of mesoporous manganese dioxide material, and then the reaction is reacted by one step, and the high-specific surface area is obtained. The pore manganese dioxide substrate is doped with transition metal ions while transitioning the γ or δ phase manganese dioxide of low catalytically active crystal phase into high active crystal phase, and achieves transition metal ion helping catalyst doping and The low-catalytic activated crystal phase transitions to high-catalytic activated crystal phase manganese dioxide, and the re...

Embodiment 2

[0059] The prepared steps are the same as in Example 1, and its parameters are specifically as follows:

[0060] Precraft manufacturing: 5 ~ 10 wt% potassium permanganate, 2.5 wt% polyethylene glycol; solvent is water, and the mixture is stirred at 50 ° C for 2 h, and the aging 12h; 60 ° C drying 12h.

[0061] Doped powder: 20 wt% of the above precursor, 2.5 wt% copper sulfate, 1.5 wt% cobalt sulfate, 0.4 wt% graphite powder, dispersion of water, reaction 12h at 150 ° C, filtrate and dried at 80 ° C for 12h, Grinding into 400 mesh powder.

[0062] Granulation step: 75% of the above-described doped powder, 10 wt% mesh silica, 15 wt% concave ceiling, adding an appropriate amount of water uniformly mixed, using extrusion granulation machine into 5 * 10 mm size particles, 2 mol / L nitric acid solution Acidification treatment of 3 h, baked at 350 ° C for 2 h, resulting in a finished product.

Embodiment 3

[0064] The prepared steps are the same as in Example 1, and its parameters are specifically as follows:

[0065] Precraft manufacturing: 5 to 10 wt% permanganate, 2 wt% citric acid; solvent is water, heat and stirred at 70 ° C for 2 h, and agonized 6 h; at 80 ° C for 12 h.

[0066] Doped powder: 30 wt% of the precursor, 5 wt% copper sulfate, 0.4 wt% carbon nanotubes, dispersion liquid, 15H, 150 ° C, taking filtration and dried at 80 ° C for 12 h, ground into 400 mesh powder.

[0067] Glym step: 60% of the above-described doped powder, 10 wt% mesh silica, 10 wt% magnesium oxide, 20 wt% irich soil, use rolling granulator sphere, add appropriate amount of water, a circle of diameter 2 to 4 mm size The ball was acidified with 1 mol / L nitric acid solution for 3 hours, and 3 hours were taken at 350 ° C to obtain a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com