Foam copper-supported porous copper oxide nanowire composite material and preparation method and application thereof

A technology of copper oxide nanowires and composite materials, which is applied in the direction of copper oxide/copper hydroxide, etc., can solve the problems of reduced reaction adequacy, long process time, battery performance attenuation, etc., to improve activity and space, and high ion transmission rate , The effect of improving the performance retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

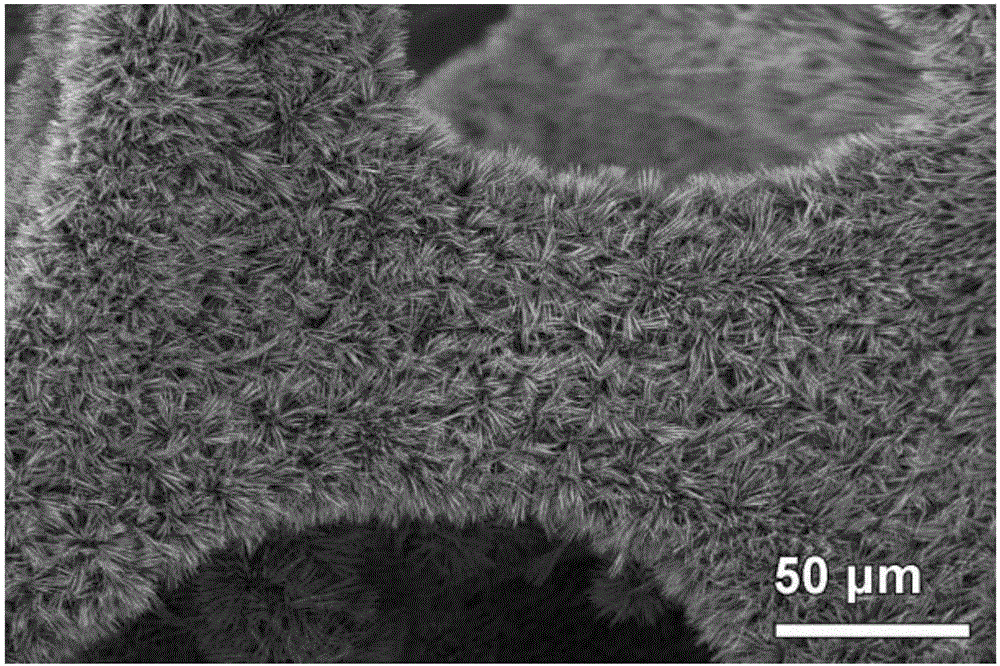

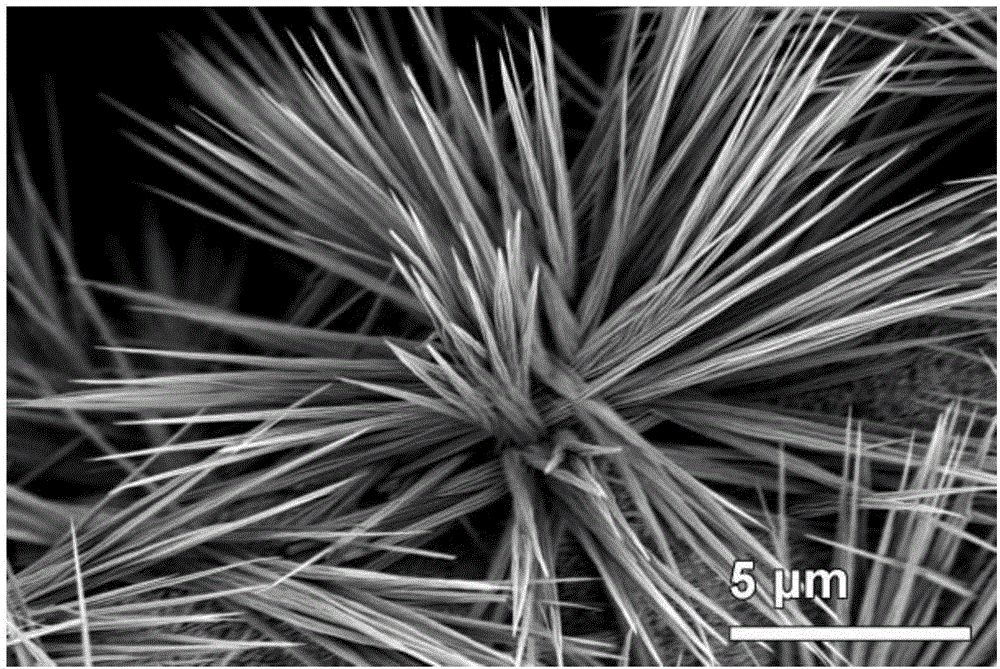

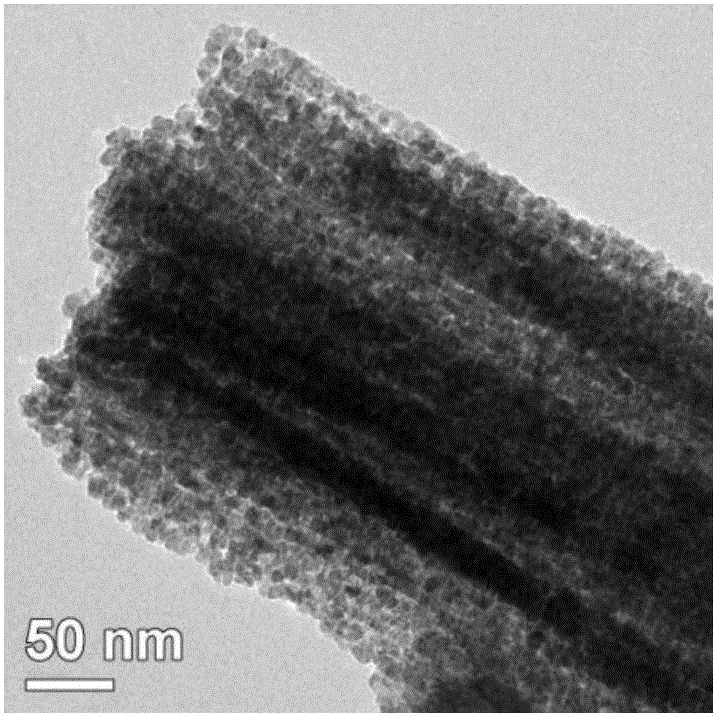

[0031] The first step, anodic oxidation method to synthesize copper hydroxide nanowires

[0032] Cut the foamed copper material (purchased from Kunshan Jiayisheng Electronics Co., Ltd., material thickness 1.0mm, ligament width 80μm, pore diameter 200μm, purity 99.95wt.%, porosity 80%) into 3cm long and 1.5cm wide samples, followed by Wash with acetone, absolute ethanol and ultrapure water, take two samples after air drying and connect them to the positive and negative poles of the DC power supply respectively, and immerse the samples in 1.0M potassium hydroxide solution for anodic oxidation, where the solution temperature is set At 20°C, at 8.5mA / cm 2 Anodize at a current density of 10 min, and then the substrate connected to the positive electrode is repeatedly washed twice with absolute ethanol and ultrapure water, and then air-dried to obtain a copper hydroxide nanowire composite material supported by foamed copper;

[0033] The second step, calcining porous copper oxide n...

Embodiment 2

[0041] The first step, anodic oxidation method to synthesize copper hydroxide nanowires

[0042] Copper foam material (purchased from Kunshan Jiayisheng Electronics Co., Ltd., material thickness 0.9mm, ligament width 70μm, pore diameter 150μm, purity 99.95wt.%, porosity 82%) was cut into 3cm long, 1.5cm wide samples, followed by Wash with acetone, absolute ethanol and ultrapure water, take two samples after air drying and connect them to the positive and negative poles of the DC power supply respectively, and immerse the samples in 1.2M potassium hydroxide solution for anodic oxidation, where the solution temperature is set At 18°C, at 8mA / cm 2 Anodizing at a current density of 8 min, and then the substrate connected to the positive electrode was repeatedly washed twice with absolute ethanol and ultrapure water, and then air-dried to obtain a copper hydroxide nanowire composite material supported by foamed copper;

[0043] The second step, calcining porous copper oxide nanowi...

Embodiment 3

[0050] The first step, anodic oxidation method to synthesize copper hydroxide nanowires

[0051] Copper foam material (purchased from Kunshan Jiayisheng Electronics Co., Ltd., material thickness 0.95mm, ligament width 100μm, pore diameter 250μm, purity 99.95wt.%, porosity 78%) was cut into 3cm long and 1.5cm wide samples, followed by Wash with acetone, absolute ethanol and ultrapure water, take two samples after air drying and connect them to the positive and negative poles of the DC power supply respectively, and immerse the samples in 0.8M potassium hydroxide solution for anodic oxidation, where the solution temperature is set At 23°C, at 9mA / cm 2 Anodized at a current density of 12 min, and then the matrix connected to the positive electrode was repeatedly washed twice with absolute ethanol and ultrapure water, and then air-dried to obtain a copper hydroxide nanowire composite material supported by foamed copper;

[0052] The second step, calcining porous copper oxide nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com