Vanadium pentoxide/graphene composite material and preparation method and application thereof

A technology of vanadium pentoxide and composite material, applied in the field of vanadium pentoxide/graphene composite material and its preparation, can solve the problems such as the preparation of composite positive electrode that cannot be directly transferred to zinc ion battery, and achieves the improvement of atom utilization rate, Less time consuming and less expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 Preparation of a vanadium pentoxide-graphene composite material

[0046] Proceed as follows:

[0047] (1) Mix 500g of vanadium pentoxide and 100g of graphene oxide (the mass ratio of the two is 5:1), disperse it in 2100g of water, then seal it in a hydrothermal kettle, and react for about 12 hours at 180±5°C ;

[0048] (2) Freeze-drying to obtain a solid product, which is a vanadium pentoxide-graphene composite material.

[0049] Effect verification:

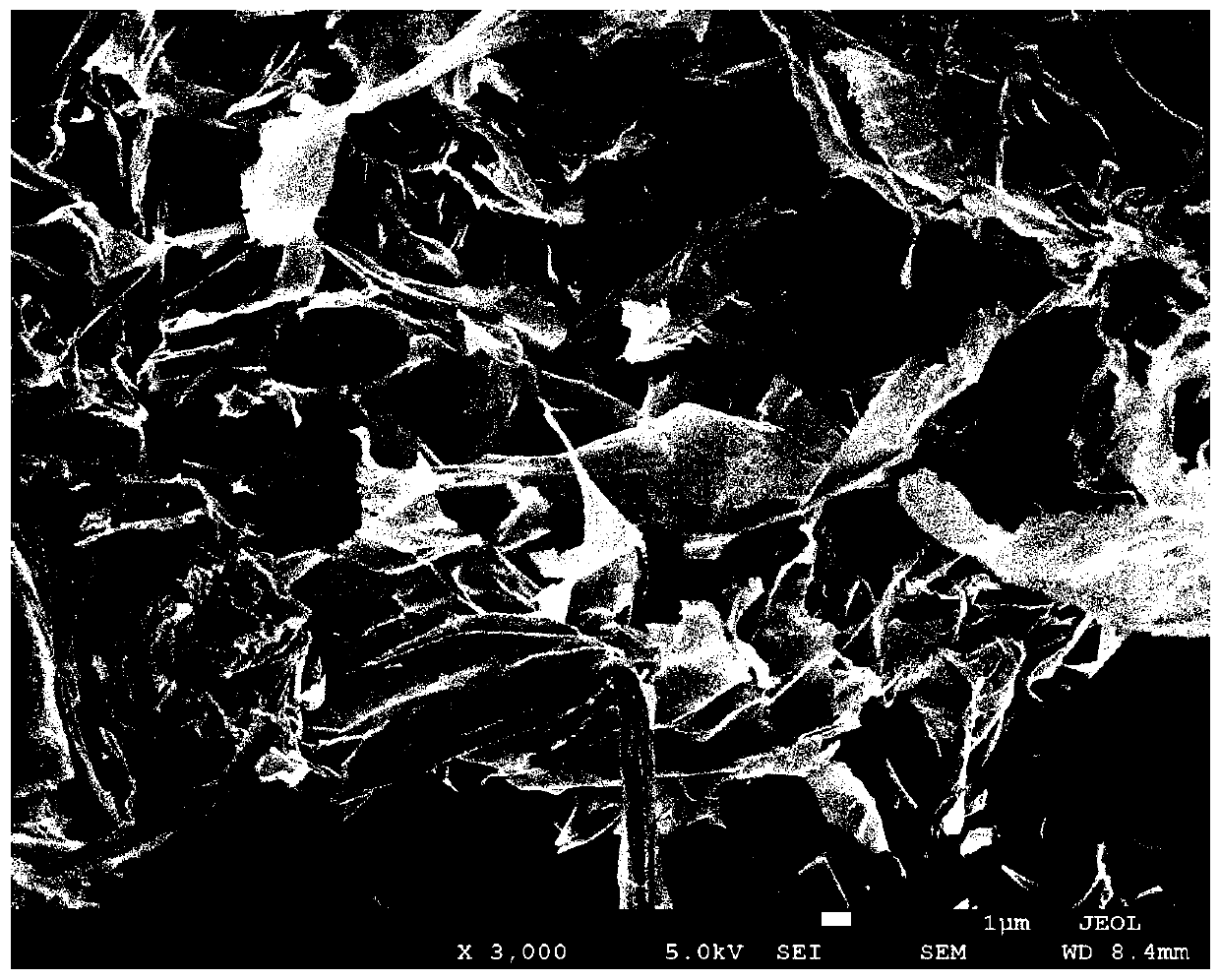

[0050] 1. Characterize the morphology of the obtained vanadium pentoxide-graphene composite material. For the results, see figure 1 . The vanadium pentoxide-graphene composite material is composed of graphene with an average length of 5 μm and spherical non-hydrated vanadium pentoxide. The size of the vanadium pentoxide is 200 nanometers. The vanadium pentoxide accounts for 50-99% of the total mass of the composite material.

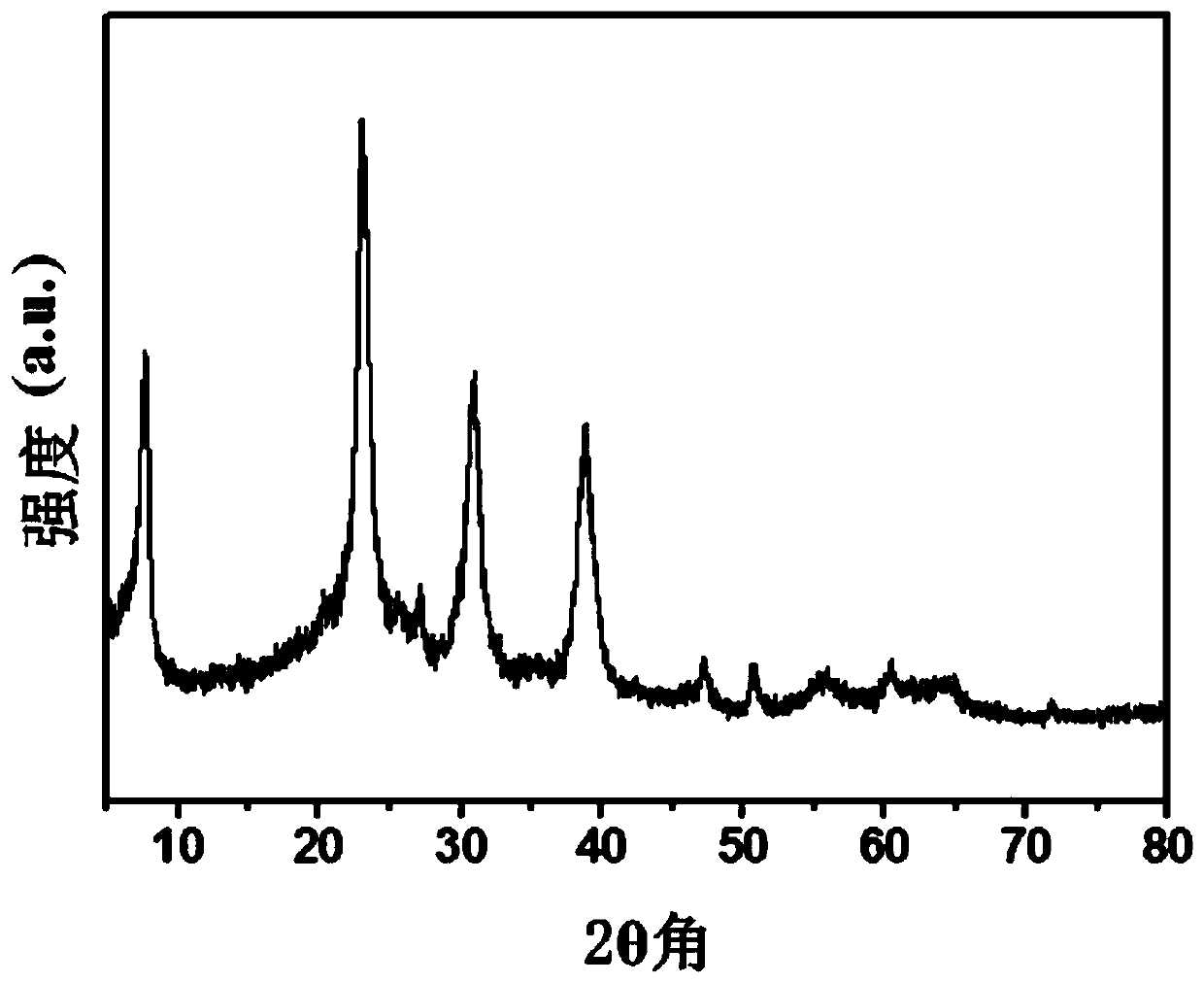

[0051] 2. For the structural characterization of the obtained vanadium pento...

Embodiment 2

[0056] Embodiment 2 Preparation of a vanadium pentoxide-graphene composite material

[0057] Embodiment 2 provides a vanadium pentoxide-graphene composite material, the preparation method of which is basically the same as that of embodiment 1, the difference being that the mass ratio of the raw material vanadium pentoxide to graphene oxide is 10:1.

[0058] Effect verification:

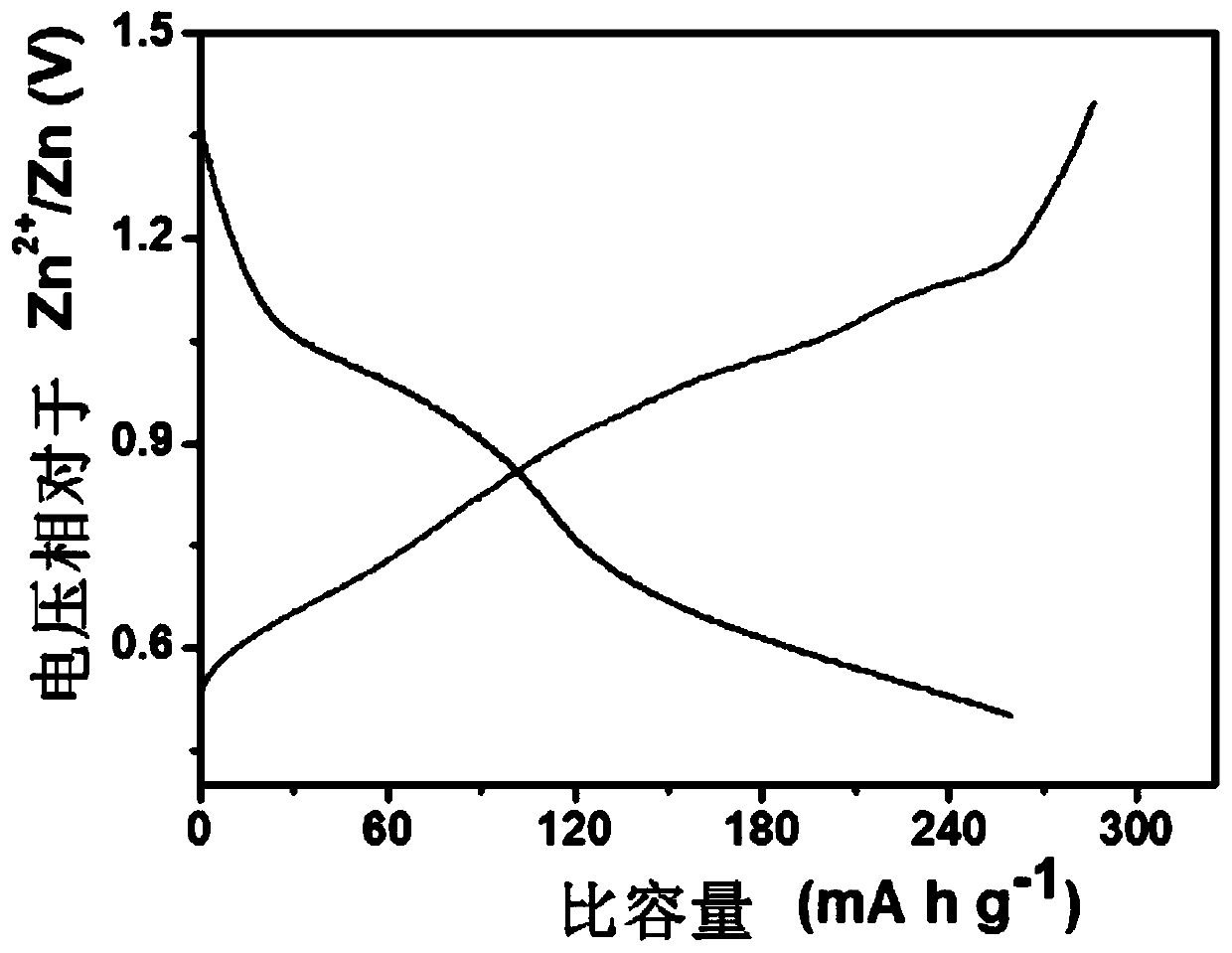

[0059] The vanadium pentoxide-graphene composite material is made into a working electrode according to the above method, and the corresponding electrical performance test is carried out. The results are as follows: when charging and discharging at 1C, the first discharge specific capacity is 281mAh / g; when charging and discharging at the above rate , the capacity can maintain more than 78% of the initial capacity after 1000 repeated charge and discharge.

Embodiment 3

[0060] Embodiment 3 Preparation of a vanadium pentoxide-graphene composite material

[0061] This embodiment provides a vanadium pentoxide-graphene composite material, the preparation method of which is basically the same as that of Example 1, the difference is that the mass ratio of the raw material vanadium pentoxide to graphene oxide is 0.5:1.

[0062] Effect verification:

[0063] The vanadium pentoxide-graphene composite material was made into a working electrode according to the method provided above and the corresponding electrical properties were tested. The results are as follows: when charging and discharging at 1C, the first discharge specific capacity is 268mAh / g; When discharging, the capacity can maintain more than 76% of the initial capacity after 1000 times of repeated charge and discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com