Composite coating electrode and preparing method thereof and electrolytic cell

A composite coating and electrode technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of short coating oxidation life, low current efficiency, and many cracks on the coating surface, achieve good application prospects, improve current Efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

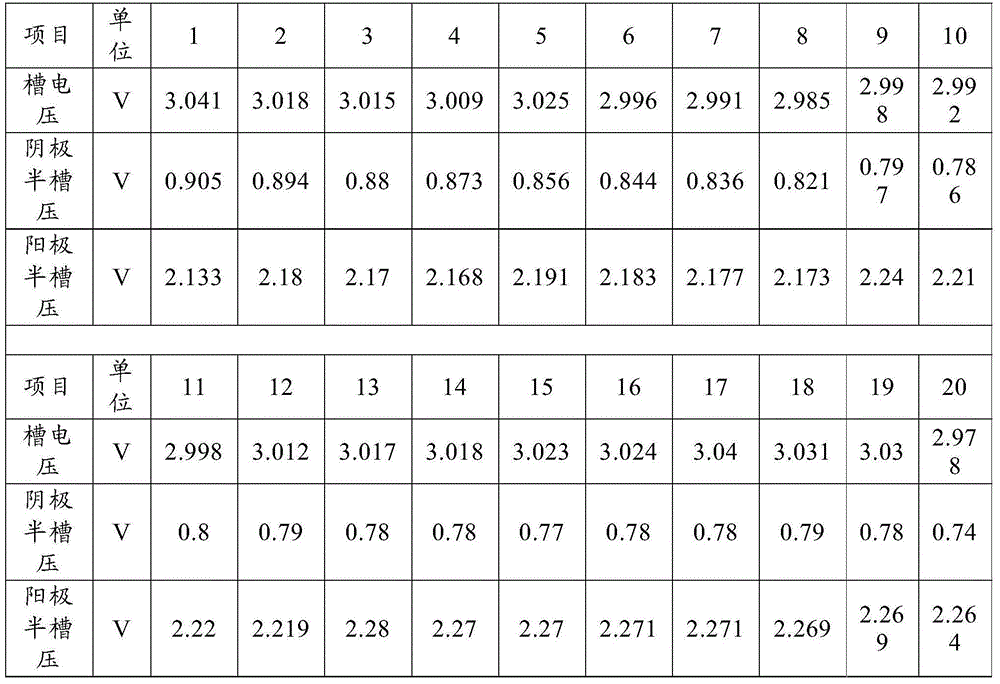

Embodiment 1

[0027] 1) Use the mixture prepared by mixing sodium phosphate, 40g / L sodium carbonate, and 15g / L sodium hydroxide with a concentration of 30g / L, respectively, to TA1 cold-rolled pure titanium with a specification of 595mm×402mm×2mm after sandblasting. The board is chemically degreased, then etched with 10% Wt hot oxalic acid solution for 2 hours, and finally rinsed with distilled water, and put into ethanol for later use. Good pretreatment can increase the geometric area of the titanium substrate, which can not only improve the bonding force with the coating, but also increase the electrocatalytic active surface area of the anode.

[0028] 2) Weigh ruthenium trichloride and tetra-n-butyl titanate at a molar ratio of 1:5, carry out batching, dissolve in absolute ethanol, and mix to prepare coating liquid I.

[0029] 3) Dissolve chloroiridic acid and tantalum pentachloride in n-butanol at a molar ratio of 5:1 in absolute ethanol to prepare coating solution II.

[0030] 4) T...

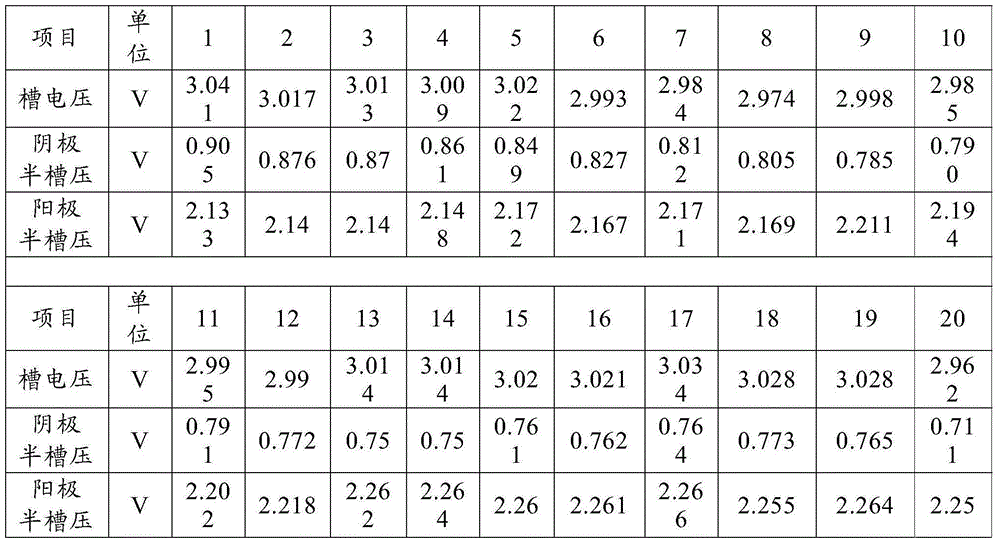

Embodiment 2

[0035] 1) Use the mixture prepared by mixing sodium phosphate, 40g / L sodium carbonate, and 15g / L sodium hydroxide with a concentration of 30g / L, respectively, to TA1 cold-rolled pure titanium with a specification of 595mm×402mm×2mm after sandblasting. The board is chemically degreased, then etched with 10% Wt hot oxalic acid solution for 2 hours, and finally rinsed with distilled water, and put into ethanol for later use. Good pretreatment can increase the geometric area of the titanium substrate, which can not only improve the bonding force with the coating, but also increase the electrocatalytic active surface area of the anode.

[0036] 2) Weigh ruthenium trichloride and tetra-n-butyl titanate in a molar ratio of 3:7, carry out batching, dissolve in absolute ethanol, and mix to prepare coating liquid I.

[0037] 3) Dissolve chloroiridic acid and tantalum pentachloride in n-butanol at a molar ratio of 7:3 in absolute ethanol to obtain coating solution II.

[0038] 4) Th...

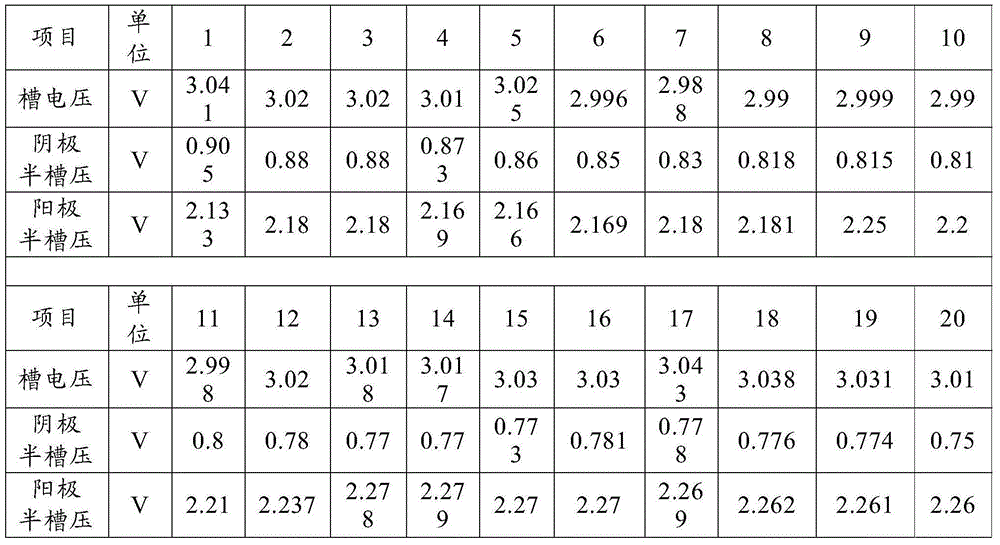

Embodiment 3

[0044] 1) Use the mixture prepared by mixing sodium phosphate, 40g / L sodium carbonate, and 15g / L sodium hydroxide with a concentration of 30g / L, respectively, to TA1 cold-rolled pure titanium with a specification of 595mm×402mm×2mm after sandblasting. The board is chemically degreased, then etched with 10% Wt hot oxalic acid solution for 2 hours, and finally rinsed with distilled water, and put into ethanol for later use. Good pretreatment can increase the geometric area of the titanium substrate, which can not only improve the bonding force with the coating, but also increase the electrocatalytic active surface area of the anode.

[0045] 2) Weigh ruthenium trichloride and tetra-n-butyl titanate in a molar ratio of 5:10, carry out batching, dissolve in absolute ethanol, and mix to prepare coating solution I.

[0046] 3) Dissolve chloroiridic acid and tantalum pentachloride in n-butanol at a molar ratio of 10:5 in absolute ethanol to prepare coating solution II.

[0047]4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com