Additive for lubricant for improving the tribologic properties, a method for its production and application

A technology of lubricants and additives, applied in the directions of additives, lubricating compositions, petroleum industry, etc., can solve the problem of not ensuring real and continuous action and anti-wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0067] 90% of spherical SiO with a particle size of 100nm 2 The nanoparticles were stirred with 10% pure DITA (diisotridecyl adipate) or 10% pure rapeseed oil as base oil to give a paste. In the paste the nanoparticles have not been separated, which is evident from the fact that the paste is opaque. Once the paste has passed through the rolling mill with the narrowest roll gap, a transparent or at least translucent gel is obtained, which clearly demonstrates that the nanoparticles are completely dispersed.

[0068] These concentrates with pure DITA or rapeseed oil are then used to prepare a lubricating oil or grease from there.

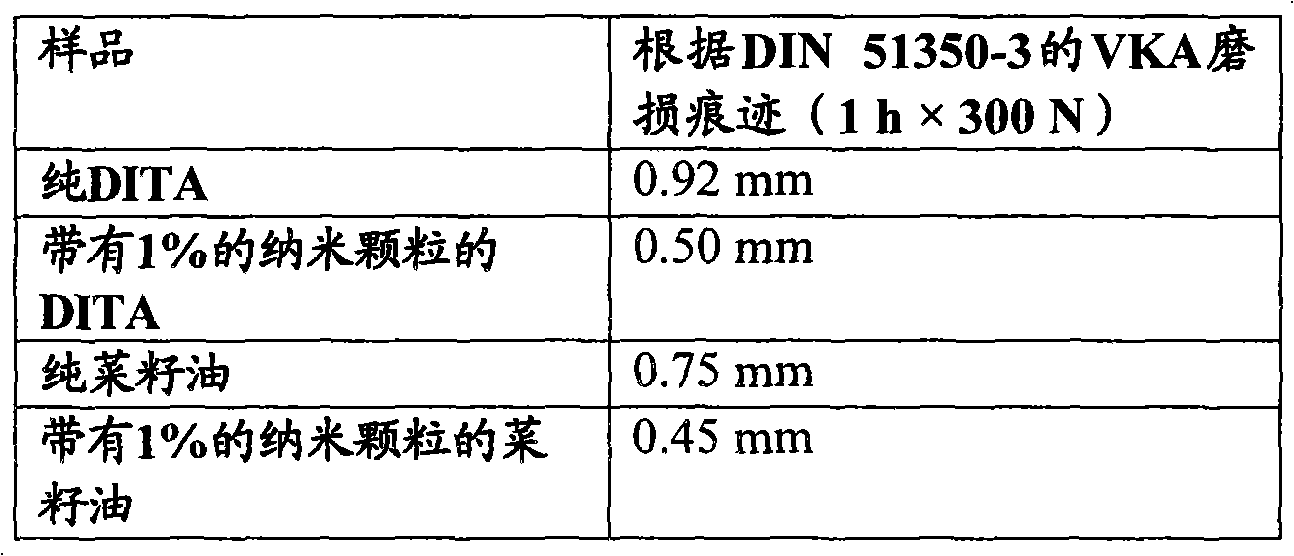

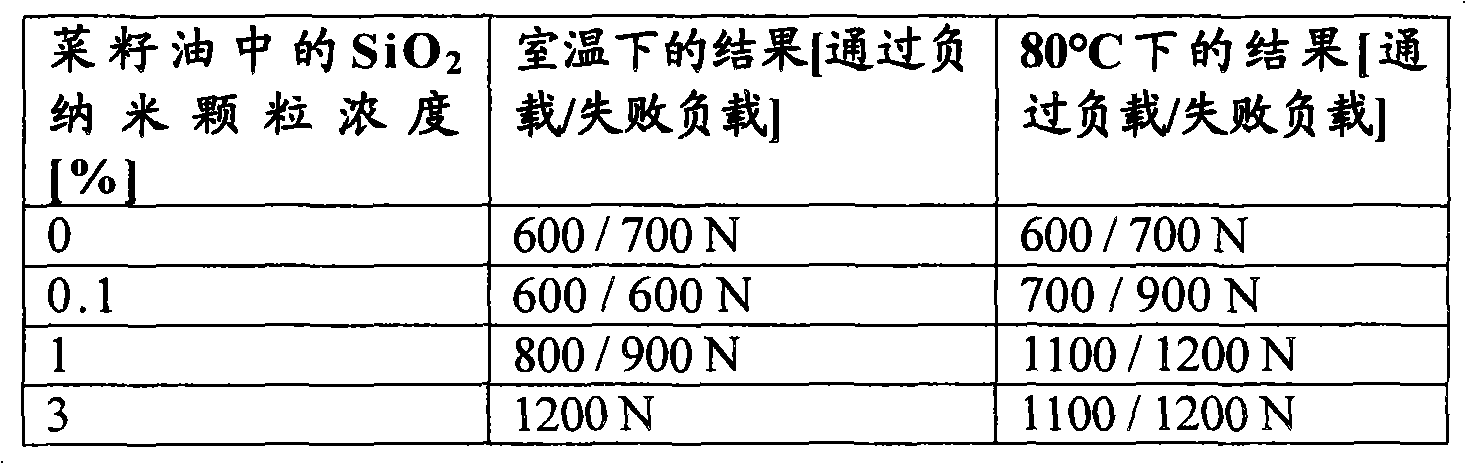

[0069]As evident from Table 1, a nanoparticle concentration of 1% was achieved in these respective base oils. The anti-wear (AW) properties of the oil without additives were tested by means of multiple test runs according to DIN 51350 on a four-ball arrangement and on a reciprocating friction tester (SRV tester). The results are shown below.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com