Large-scale preparation and lithium battery application of vanadium pentoxide and carbon nano composite thereof

A technology of vanadium pentoxide and composite carbon, which is applied in the direction of secondary batteries, nanotechnology, battery electrodes, etc., can solve the problems of high energy consumption, high cost, complex production process, etc., and achieve low energy consumption, short time consumption, and source wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

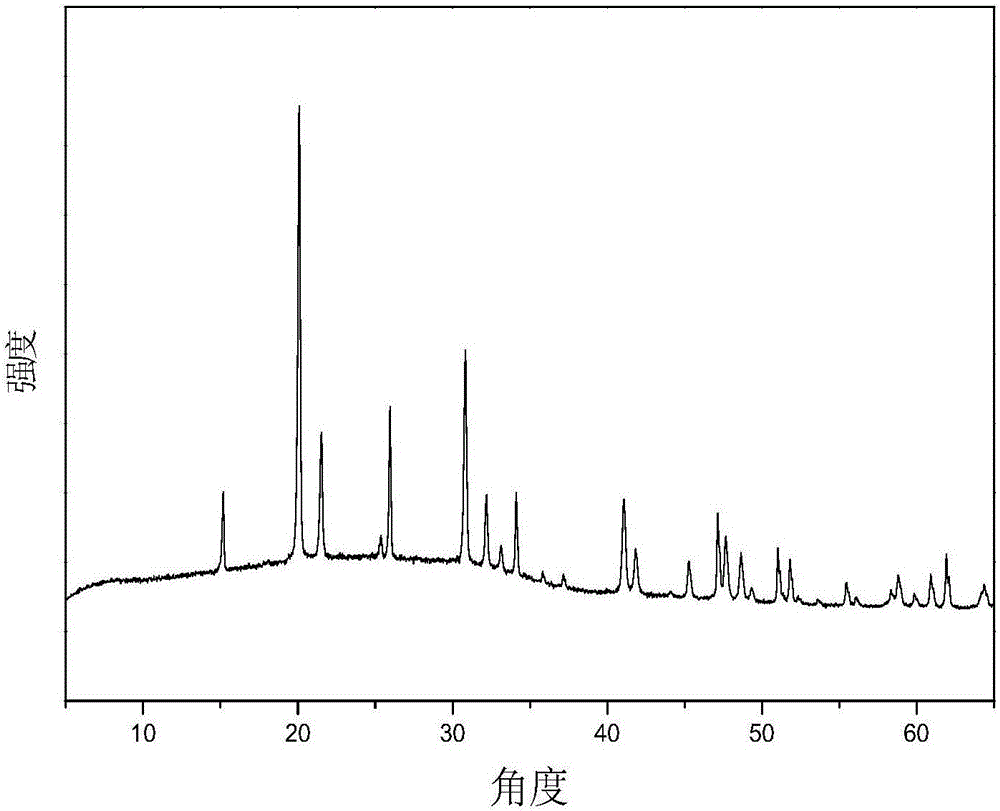

[0034] Dissolve 0.364g of vanadium pentoxide solid powder in 25ml of pure water, add 5ml of hydrogen peroxide solution with a mass fraction of 30%, and place it at room temperature for 1 hour to obtain a dark red solution. The solution was placed in a thermostat at 50° C. for 24 hours, and the solution became a sol. The sol was frozen in liquid nitrogen for 10 min, and then immediately put into a lyophilizer for vacuum drying, and a fluffy solid was obtained after 48 h. Take part of the solid and calcinate it under a nitrogen atmosphere, raise the temperature to 400°C for 0.5h, and the heating rate is 10°C / min to obtain vanadium pentoxide nanomaterials. figure 1Shown is the XRD spectrum of vanadium pentoxide after calcination in Example 1, which is consistent with the standard card JCPDS card no: 41-1426, and belongs to the orthorhombic crystal system and the space group Pmmn.

Embodiment 2

[0036] Dissolve 1.092g of vanadium pentoxide solid powder in 25ml of pure water, add 5ml of hydrogen peroxide solution with a mass fraction of 30%, and place it at room temperature for 1 hour to obtain a dark red solution. The solution was placed in a thermostat at 50° C. for 24 hours, and the solution became a sol. The sol was frozen in liquid nitrogen for 10 min, and then immediately put into a lyophilizer for vacuum drying, and a fluffy solid was obtained after 48 h. Take part of the solid and calcinate it under a nitrogen atmosphere, raise the temperature to 400°C for 0.5h, and the heating rate is 10°C / min to obtain vanadium pentoxide nanomaterials.

Embodiment 3

[0038] Dissolve 1.82g of vanadium pentoxide solid powder in 25ml of pure water, add 5ml of hydrogen peroxide solution with a mass fraction of 30%, and leave it at room temperature for 1 hour to obtain a dark red solution. The solution was placed in a thermostat at 50° C. for 24 hours, and the solution became a sol. The sol was frozen in liquid nitrogen for 10 min, and then immediately put into a lyophilizer for vacuum drying, and a fluffy solid was obtained after 48 h. Take part of the solid and calcinate it under a nitrogen atmosphere, raise the temperature to 400°C for 0.5h, and the heating rate is 10°C / min to obtain vanadium pentoxide nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com