Group VB doping CaCu3Ti4O12 based pressure sensitive material and preparation method

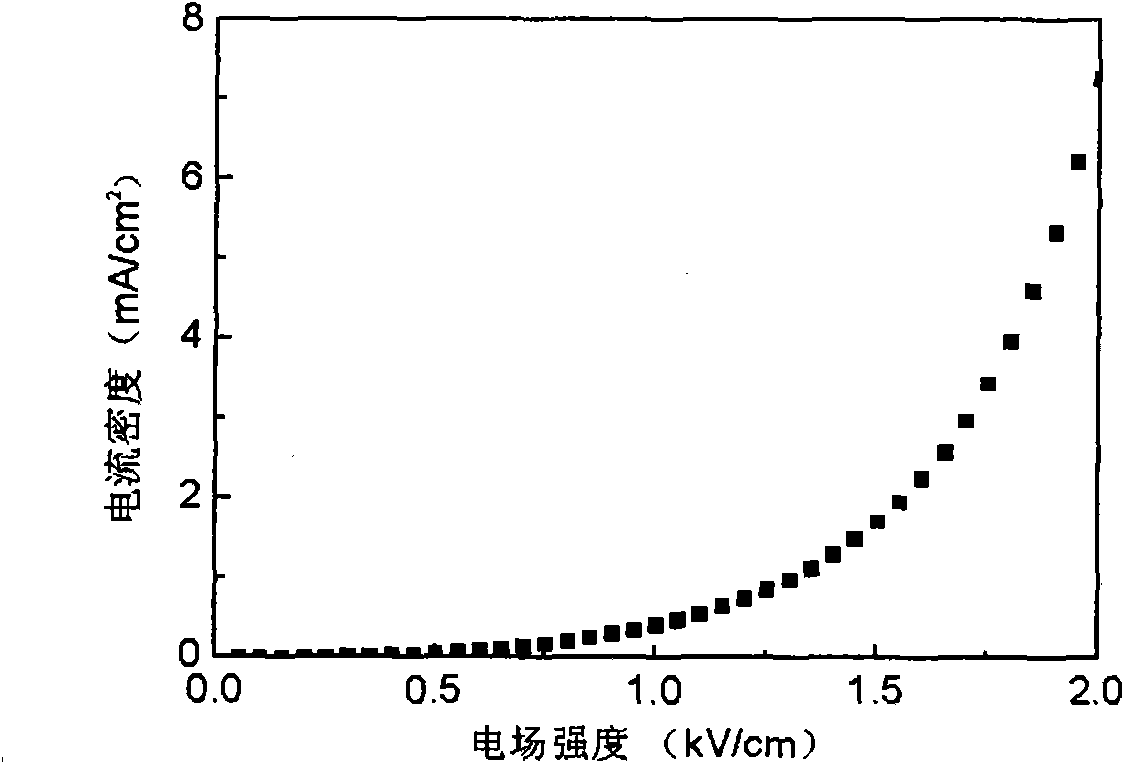

A cacu3ti4-xbxo12, group element technology, applied in the field of VB group element-doped CaCu3Ti4O12-based varistor materials and preparation, can solve the problems of low voltage gradient, large leakage current, etc. Effect of leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

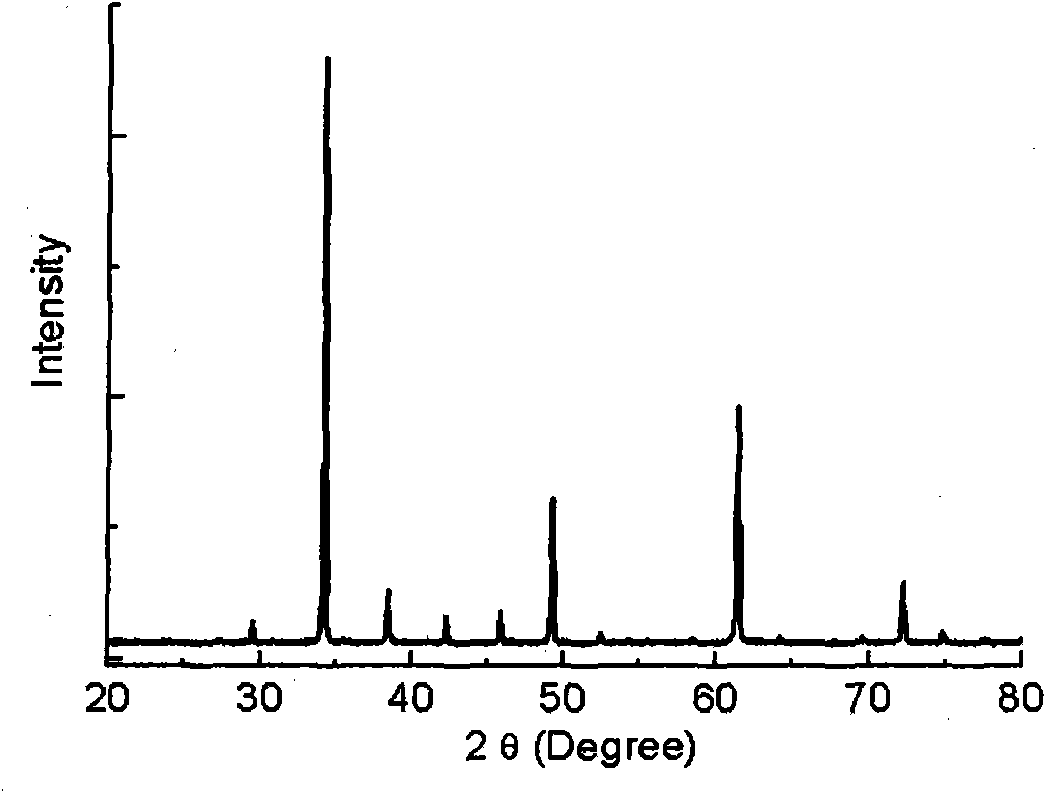

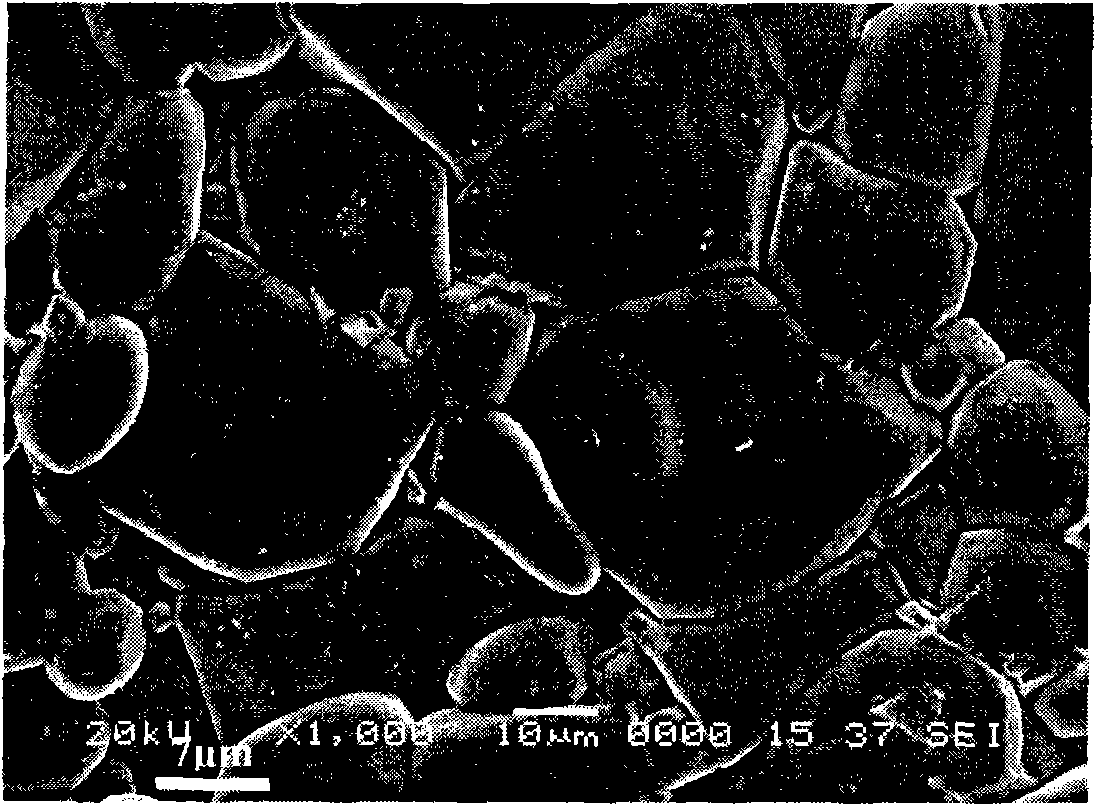

[0018] Analytical grades of calcium carbonate, copper oxide, titanium dioxide and niobium pentoxide, stoichiometrically CaCu 3 Ti 3.8 Nb 0.2 o 12 ingredients. The prepared materials are put into a ball mill and mixed according to the ratio of zirconia balls:materials at 10:1, and no other medium is added during the mixing process. The ball milling time is 7 hours, the rotating speed is 400 rpm, and the mixed material briquettes are pre-fired at 900° C. for 2 hours. Take out the calcined material and grind it, then ball mill it for 7 hours and pass through a 40-mesh sieve, the ball milling speed is 400 rpm; add the powder to the deionized water with a mass ratio of 32%, polyacrylic acid ammonia dispersant with a mass ratio of 1.2% and A polyvinyl alcohol binder with a mass ratio of 8%, is mixed uniformly by ball milling for 2 hours to form a slurry, the ball milling speed is 100 rpm, and air spray is used to granulate; the powder particles are put into a press, Obtain a di...

Embodiment 2

[0020] Analytical grades of calcium carbonate, copper oxide, titanium dioxide and vanadium pentoxide, stoichiometrically CaCu 3 Ti 3.6 V 0.4 o 12 ingredients. The prepared materials are put into a ball mill and mixed according to the ratio of agate balls:materials at 15:1, and no other medium is added during the mixing process. The ball milling time is 10 hours, the rotating speed is 400 rpm, and the mixed material briquette is pre-fired at 950° C. for 2 hours. Take out the calcined material and grind it, and pass through a 40-mesh sieve after ball milling for 10 hours. The ball milling speed is 400 rpm; the powder is added with 20% by mass ratio of deionized water, 1.8% by mass ratio of polyacrylic acid ammonia dispersant and A polyvinyl alcohol binder with a mass ratio of 8%, is mixed uniformly by ball milling for 2 hours to form a slurry, the ball milling speed is 150 rpm, and air spray is used to granulate; the powder particles are put into a press, Obtain a disc with...

Embodiment 3

[0022] Using analytically pure grades of calcium carbonate, copper oxide, titanium dioxide, niobium pentoxide and vanadium pentoxide, the stoichiometric ratio is CaCu 3 Ti 3.4 Nb 0.3 V 0.3 o 12ingredients. The prepared materials are put into a ball mill and mixed according to the ratio of alumina ball:material is 18:1, and no other medium is added during the mixing process. The ball milling time is 12 hours, the rotating speed is 450 rpm, and the mixed material briquettes are pre-fired at 900° C. for 2 hours. Take out the calcined material and grind it, and pass through a 40-mesh sieve after ball milling for 12 hours. The ball milling speed is 450 rpm; the powder is added with 40% by mass ratio of deionized water, 1.8% by mass ratio of polyacrylic acid ammonia dispersant and A polyvinyl alcohol binder with a mass ratio of 7%, is mixed uniformly by ball milling for 2 hours to form a slurry, the ball milling speed is 200 rpm, and air spray is used to granulate; the powder p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com