High-voltage sleeve with uniform electric field function, and cable terminal

A high-voltage bushing and uniform electric field technology, applied in the field of electric power, can solve the problems of easy generation of burrs in the mesh, easy residue of debris, easy penetration of debris, etc., to achieve good effect, reduce the effect of electric field, and reduce the voltage gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

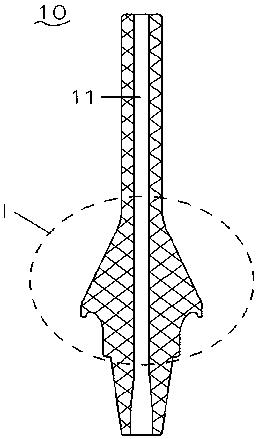

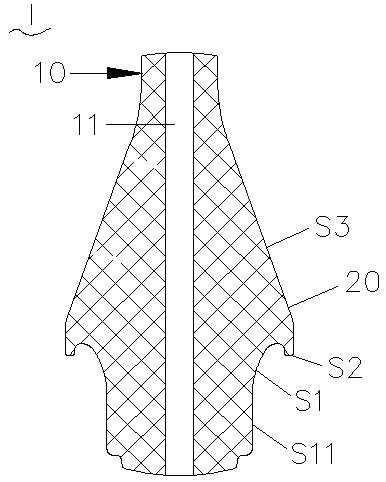

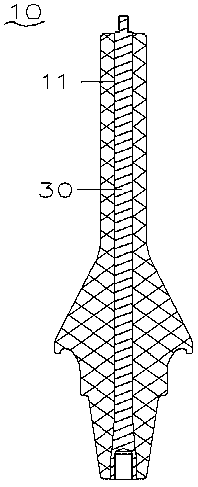

[0019] see figure 1 and figure 2 , which discloses Embodiment 1 of the high voltage bushing 10 with a uniform electric field function of the present invention. The high voltage bushing 10 has a tube hole 11 extending from bottom to top, and the outer edge of the longitudinal section of the high voltage bushing 10 includes a first curve S1 , a second curve S2 and a third straight line S3 which are sequentially and smoothly connected.

[0020] The outer edge of the high voltage bushing 10 gradually extends outward from bottom to top to form a smooth and continuous first curve S1. The end of the first curve S1 extends downwards, bends outwards and then extends upwards to form a smooth and continuous downward convex second curve S2. The end of the second curve S2 gradually extends inward along the upward direction to form a smooth and continuous third straight line S3.

[0021] The high-voltage bushing 10 is a bushing made of a solid insulating medium formed by surrounding the...

Embodiment 2

[0026] see Figure 4 , which discloses Embodiment 2 of the high-voltage bushing 10' with a uniform electric field function in the present invention. This embodiment is similar to Embodiment 1, the difference being that the third straight line in Embodiment 1 is replaced by the third curve in this embodiment S3'.

[0027] A connecting straight line S31 may also be connected between the second curve S2 and the third curve S3', the lower end of the connecting straight line S31 is smoothly transitioned to the end of the second curve S2, and the upper end of the connecting straight line S31 is smooth with the lower end of the third curve S3' Transition connection, the connecting straight line S31 together with the first curve S1 , the second curve S2 and the third curve S3 ′ form the outer edge of the high voltage bushing 10 ′.

Embodiment 3

[0029] see Figure 5 , which discloses Embodiment 3 of the high-voltage bushing 10'' with a uniform electric field function in the present invention. This embodiment is similar to Embodiment 2, the difference being that an umbrella or edge S32 is formed on the third curve S3''.

[0030] The above embodiments only enumerate some cases of the first curve, the second curve and the third curve or straight lines, because it is impossible to enumerate all the structural cases of the curves one by one, but all other different straight lines and / or curve segment combinations with similar effects The continuous curves produced also belong to the scope of the first curve, and all the continuous curves formed by other different straight lines and / or curve segments with similar effects also belong to the scope of the second curve, and all continuous curves or straight lines with approximately along a certain inclination angle It also belongs to the scope of the third curve or straight lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com