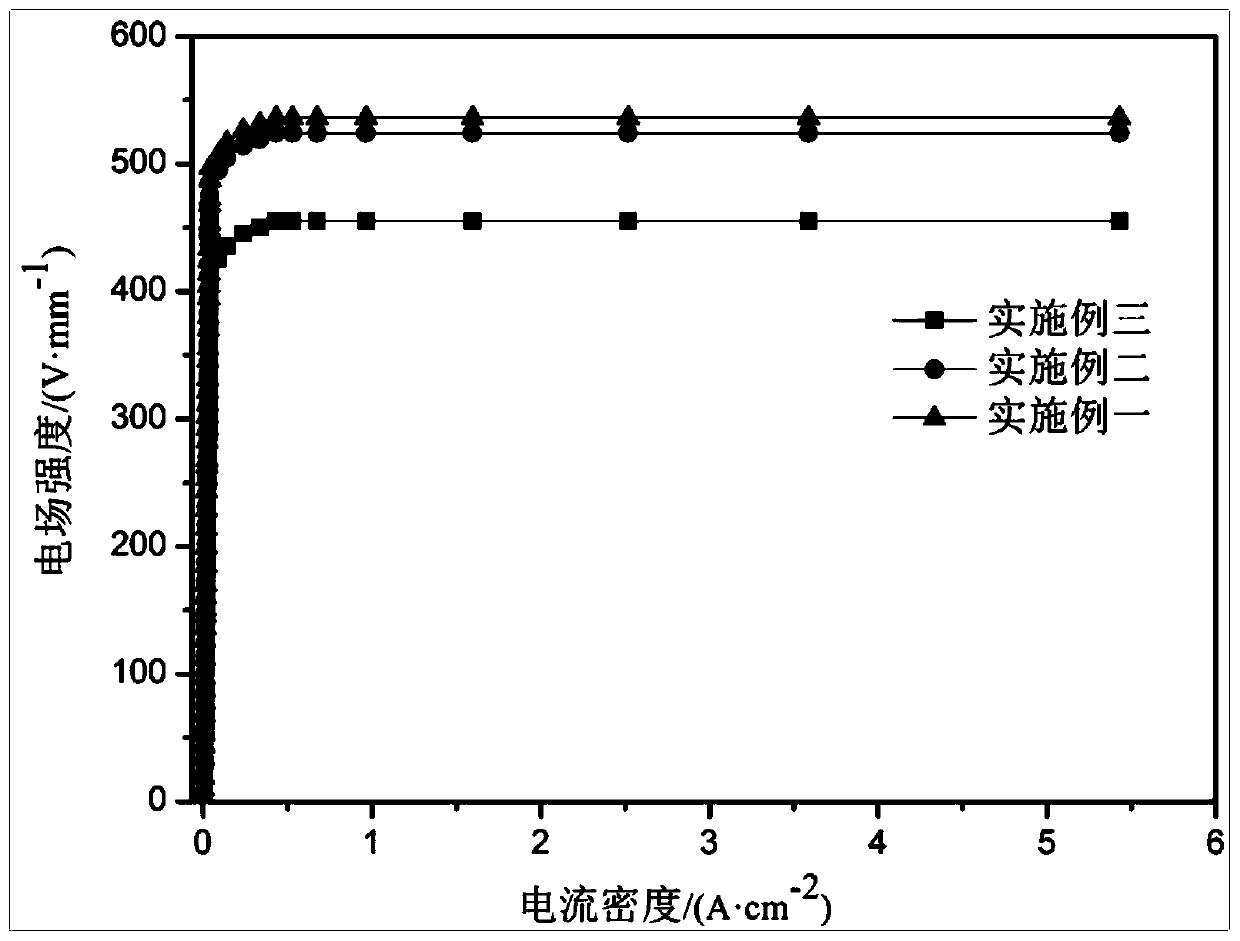

SnO2 metal oxide varistor and preparation method thereof

A varistor, ho2o3 technology, applied in the direction of varistor, varistor core, resistance manufacturing, etc., can solve the problem of high voltage gradient, low leakage current density, excessive leakage current varistor development, varistor The leakage current is too large to achieve the effects of low leakage current density, suppression of electron transmission, and increased voltage gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also proposes a kind of above-mentioned SnO 2 The preparation method of varistor, this method specifically comprises the following steps:

[0037] 1) Preparation and mixing of powder raw materials

[0038] Weigh the powder raw materials according to the mass percentage of the following components:

[0039]

[0040] Add acid radical solution and deionized water to the powder configured above, and stir evenly to obtain the first mixed solution;

[0041] 2) Add binder

[0042] Adding 35-45mol% binder to the first mixed solution prepared in step 1) and stirring, so that the added binder is evenly distributed in the mixed solution to obtain a second mixed solution;

[0043] 3) Slurry vibration and drying

[0044] Vibrating the second mixed solution prepared in step 2) at a high frequency so that the powder particles in the second mixed solution reach 2-7 μm, and then drying at a constant temperature to obtain a dry material;

[0045] 4) Calcinat...

Embodiment 1

[0057] The SnO of this embodiment 2 The varistor preparation process is as follows:

[0058] 1) Preparation and mixing of powder raw materials

[0059] The SnO 2 Varistor ceramic material in the following ratio SnO 2 : 94.498%, MnCO 3 : 3%, Cr 2 o 3 : 1%, V 2 o 5 : 1.5%, Ho 2 o 3 : 0.002% configured powder raw material; put the configured powder raw material in a polyethylene tank, add 67mol% acid radical solution and 900g deionized water, stir for 45min until all the powder material and acid radical solution are mixed evenly, and prepare Get the first mixture.

[0060] 2) Add binder

[0061] Add 35mol% binder (PVA) to the first mixed solution obtained in the above step 1), and stir for 55 minutes, so that the added binder is evenly distributed among the first mixed solution, and the second mixed solution is prepared .

[0062] 3) Slurry vibration and drying

[0063] Tighten the lid of the polyethylene tank with the second mixed solution obtained in the above ste...

Embodiment 2

[0092] The SnO of this embodiment 2 The varistor preparation process is as follows:

[0093] 1) Preparation and mixing of powder raw materials:

[0094] The SnO 2 Varistor ceramic material in the following ratio SnO 2 : 92.229%, MnCO 3 : 3.75%, Cr 2 o 3 : 1.75%, V 2 o 5 : 2.25%, Ho 2 o 3: 0.021% to configure the initial slurry; put the configured powder raw materials into a polyethylene tank, add 77mol% acid radical solution and 1.15kg deionized water, and stir for 51.5min until all the powder and acid radical solution are mixed evenly , to obtain the first mixed solution.

[0095] 2) Add binder

[0096] Add 40 mol% binder (PVA) to the first mixed solution obtained in the above step 1), and stir for 61 minutes, so that the added binder is evenly distributed in the mixed solution, and the second mixed solution is obtained.

[0097] 3) Slurry vibration and drying

[0098] The polyethylene tank that the second mixed solution obtained in above-mentioned steps 2) is ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com